TPS929120-Q1

TPS929120-Q1

SLVSE03B – APRIL 2019 – REVISED

FEBRUARY 2021

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

www.ti.com

TPS929120-Q1 12-Channel Automotive 40-V High-Side LED Driver with FlexWire

1 Features

2 Applications

•

•

•

•

•

•

•

•

•

AEC-Q100-qualified for automotive applications:

– Temperature grade 1: –40°C to +125°C, TA

Functional Safety-Capable

– Documentation available to aid functional safety

system design

12-Channel precision high-side current output:

– Supply voltage 4.5 V to 40 V

– Up to 75 mA channel current set by resistor

– 2-Bit global, 6-bit independent current setting

– High current accuracy < ±5% at 5 mA to 75 mA

– High current accuracy < ±10% at 1 mA

– Low voltage drop 500 mV at 50 mA

– 12-Bit independent PWM dimming

– Programmable PWM frequency up to 20 kHz

– Linear and exponential dimming method

FlexWire control interface

– Up to 1-MHz clock frequency

– Maximum 16 devices on one FlexWire bus

– Up to 8 bytes data transaction in one frame

– 5-V LDO output to supply CAN transceiver

Diagnostic and protection:

– Programmable fail-safe state

– LED open-circuit detection

– LED short-circuit detection

– Single-LED short-circuit diagnostic

– Programmable low-supply detection

– Open-drain ERR for fault indication

– Watchdog and CRC for FlexWire interface

– 8-Bit ADC for pin voltage measurement

– Overtemperature protection

RX

CANH

CANL

CAN

Transceiver

(optional)

TX

RX

TPS929120-Q1

Automotive exterior rear light

Automotive exterior headlight

Automotive interior ambient light

Automotive cluster display

3 Description

With increasing demand for animation in automotive

lighting, LEDs must be controlled independently.

Therefore, LED drivers with digital interfaces are

essential to effectively drive pixel-controlled lighting

applications. In exterior lighting, multiple lamp

functions are typically located on different PCB boards

with off-board wires connected to each other. It is

difficult for a traditional single-ended interface to meet

the strict EMC requirements. By using an industrialstandard CAN physical layer, the UART-based

FlexWire interface of the TPS929120-Q1 easily

accomplishes long distance off-board communication

without impacting EMC.

The TPS929120-Q1 is a 12-channel, 40-V high-side

LED driver that controls the 8-bit output current and

12-bit PWM duty cycles. The device meets multiple

regulation requirements with LED open-circuit, shortto-ground, and single LED short-circuit diagnostics. A

configurable watchdog also automatically sets failsafe states when the MCU connection is lost, and,

with programmable EEPROM, TPS929120-Q1 can

flexibly be set for different application scenarios.

Device Information (1)

PART NUMBER

TPS929120-Q1

(1)

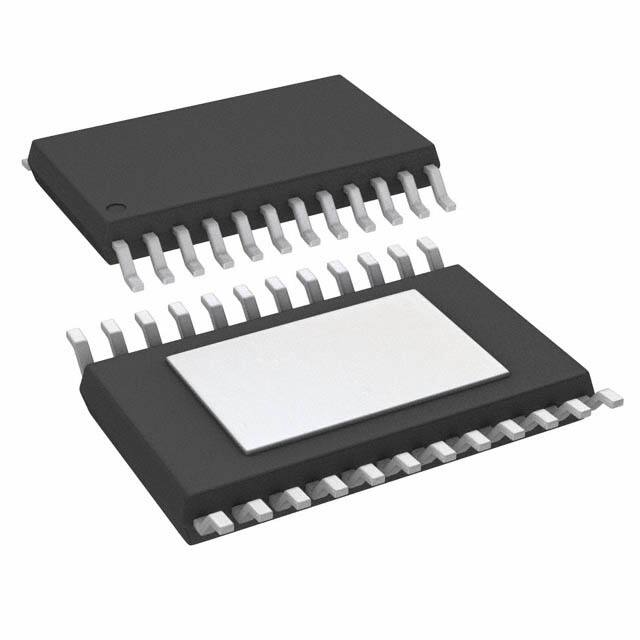

HTSSOP (24)

BODY SIZE (NOM)

7.80 mm × 4.40 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

OUT11

VLDO

OUT10

GND

OUT9

TX

OUT8

ERR

OUT7

SUPPLY

OUT6

SUPPLY

OUT5

FS

PACKAGE

OUT4

ADDR2/CLK

OUT3

ADDR1/PWM1

OUT2

ADDR0/PWM0

OUT1

REF

OUT0

GND

GND

Typical Application Diagram

An©IMPORTANT

NOTICEIncorporated

at the end of this data sheet addresses availability, warranty, changes, use in

safety-critical

applications,

Copyright

2021 Texas Instruments

Submit

Document

Feedback

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Product Folder Links: TPS929120-Q1

1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................4

6 Specifications.................................................................. 5

6.1 Absolute Maximum Ratings ....................................... 5

6.2 ESD Ratings .............................................................. 5

6.3 Recommended Operating Conditions ........................5

6.4 Thermal Information ...................................................6

6.5 Electrical Characteristics ............................................6

6.6 Timing Requirements ................................................. 8

6.7 Typical Characteristics................................................ 9

7 Detailed Description......................................................14

7.1 Overview................................................................... 14

7.2 Functional Block Diagram......................................... 15

7.3 Feature Description...................................................15

7.4 Device Functional Modes..........................................33

7.5 Programming............................................................ 37

7.6 Register Maps...........................................................45

8 Application and Implementation................................ 154

8.1 Application Information........................................... 154

8.2 Typical Application.................................................. 154

9 Power Supply Recommendations..............................158

10 Layout.........................................................................158

10.1 Layout Guidelines................................................. 158

10.2 Layout Example.................................................... 158

11 Device and Documentation Support........................159

11.1 Receiving Notification of Documentation Updates 159

11.2 Support Resources............................................... 159

11.3 Trademarks........................................................... 159

11.4 Electrostatic Discharge Caution............................ 159

11.5 Glossary................................................................ 159

12 Mechanical, Packaging, and Orderable

Information.................................................................. 159

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (February 2020) to Revision B (February 2021)

Page

• Updated the numbering format for tables, figures and cross-references throughout the document...................1

• Changed the bullet "Functional safety capable" to "Functional Safety-Capable" in the Features list ................ 1

• Change to “CONF_ODPW=0h” from “CONF_ODPW=4h” in Timing Requirements table................................. 5

• Change to "80-mA" from "50-mA".....................................................................................................................15

• Add "LSB first" to CRC Algorithm Diagram.......................................................................................................27

• Change "Supply UVLO" row to "Constant pulled down" from "No action"........................................................ 28

• Change "Supply UVLO" row to "Constant pulled down" from "No action"........................................................ 32

• Add description for TPS929120A version.........................................................................................................38

• Add "All EEPROM shadow registers need to be written to target value before burning."................................ 42

• Change default value of register FLAG7 to "B3h" from "EFh".......................................................................... 45

• Add note for default value of register FLAG7 for TPS929120A version........................................................... 45

• Change default value of register EEPM7 to "A7h" from "07h".......................................................................... 45

• Add note for default value of EEPROM register EEPM6 for TPS929120A version..........................................45

• Add note for default value of EEPROM register EEPM15 for TPS929120A version........................................45

• Change reset value for CONF_AUTOSS to "0h" from "X"................................................................................50

• Change to "FlexWire" from "FlexLED" in CONF_MISC2 register description...................................................50

• Change to "19 V" from "20 V" in CONF_MISC2 register description ...............................................................50

• Add "Fh = 20 V" in CONF_MISC2 register description.....................................................................................50

• Add "automatically reset to 0" in CONF_FORCEERR register description...................................................... 50

• Change to "Configuration" from "Miscellanous" in CONF_LOCK register description......................................50

• Change to "B3h" from "EFh" for FLAG7 register reset value............................................................................50

• Add "Reset value is 09h for TPS929120A version" in FLAG7 register description.......................................... 50

• Change to "CONFx" from "EEPROM" for FLAG8 register description............................................................. 50

• Add "Reset value is 8h for TPS929120A version" in EEPM6 register description............................................50

• Change to "19 V" from "20 V" in EEPM8 register description ..........................................................................50

• Add "Fh = 20 V" in EEPM8 register description................................................................................................50

• Change to "B3h" from "23h" for EEPM15 register reset value..........................................................................50

2

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

•

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

Add 09h for EEPM15 manufacture default value for TPS929120A version..................................................... 50

Changes from Revision Original (April 2019) to Revision A (February 2020)

Page

• Change from Advance Information to Production Data ..................................................................................... 1

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

3

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

5 Pin Configuration and Functions

RX

1

24

OUT11

VLDO

2

23

OUT10

GND

3

22

OUT9

TX

4

21

OUT8

ERR

5

20

OUT7

SUPPLY

6

19

OUT6

SUPPLY

7

18

OUT5

FS

8

17

OUT4

ADDR2/CLK

Thermal

Pad

9

16

OUT3

ADDR1/PWM1

10

15

OUT2

ADDR0/PWM0

11

14

OUT1

REF

12

13

OUT0

Not to scale

Figure 5-1. PWP Package 24- Pin HTSSOP With PowerPAD™ Top View

Table 5-1. Pin Functions

PIN

NO.

I/O

DESCRIPTION

1

RX

I

2

VLDO

Power

3

GND

GND

4

TX

O

FlexWire TX

5

ERR

I/O

Open-drain error output

SUPPLY

Power

8

FS

I

Fail-safe state selection. 0: Fail-safe state 0 ; 1: Fail-safe state 1

9

ADDR2/CLK

I

Function as device address 2 in external address mode; Function as PWM clock input internal address

mode when CONF_EXTCLK is 1.

10

ADDR1/ PWM1

I

Function as device address 1 in external address mode; Function as PWM input channel for OUT6-11 in

internal address mode.

11

ADDR0/ PWM0

I

Function as device address 0 in external address mode; Function as PWM input channel for OUT0-5 in

internal address mode.

12

REF

I/O

Device reference current setting, EEPROM programming chip-selection input

13

OUT0

O

Output channel 0

14

OUT1

O

Output channel 1

15

OUT2

O

Output channel 2

16

OUT3

O

Output channel 3

17

OUT4

O

Output channel 4

18

OUT5

O

Output channel 5

19

OUT6

O

Output channel 6

20

OUT7

O

Output channel 7

21

OUT8

O

Output channel 8

22

OUT9

O

Output channel 9

23

OUT10

O

Output channel 10

24

OUT11

O

Output channel 11

6, 7

4

NAME

FlexWire RX

5-V regulator output

Device ground

Power supply

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)(1)

MIN

MAX

UNIT

SUPPLY

Device supply voltage

–0.3

45

V

FS

High-voltage input

–0.3

V(SUPPLY) + 0.3

V

OUT0 - 11

High-voltage outputs

–0.3

V(SUPPLY) + 0.3

V

ERR

High-voltage output

–0.3

22

V

ADDR2/CLK,

ADDR1/PWM1,

Low-voltage input

ADDR0/PWM0,

REF, RX

–0.3

5.5

V

VLDO, TX

Low-voltage output

–0.3

5.5

V

TJ

Junction temperature

–40

150

°C

Tstg

Storage temperature

–65

150

°C

(1)

Stresses beyond those listed under Absolute Maximum Rating may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Condition. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

6.2 ESD Ratings

VALUE

Human body model (HBM), per AEC

V(ESD)

(1)

Electrostatic discharge

Charged device model (CDM), per

AEC Q100-011

Q100-002(1)

±2000

Corner pins (RX, REF, OUT0,

OUT11)

±750

Other pins

±500

UNIT

V

AEC Q100-002 indicates that HBM stressing shall be in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

NOM

MAX

UNIT

SUPPLY

Device supply voltage

4.5

36

V

IOUT0-IOUT11

Channel output current

FS

External fail-safe selection input

0.5

75

mA

0

V(SUPPLY)

V

TX

RX

FlexWire TX output

0

5

V

FlexWire RX input

0

5

V

VLDO

Internal 5V LDO output

0

5

V

I(VLDO)

LDO external current load

0

80

mA

ADDR2/CLK, ADDR1/

PWM1, ADDR0/

Device address selection and external CLK/PWM inputs

PWM0

0

5

V

REF

Current reference setting

0

5

V

ERR

Error feedback open-drain output

0

20

V

t(r_RX)

RX risetime

5%/fCLK

t(f_RX)

RX falltime

fCLK

FlexWire frequency

5%/fCLK

DSYNC

Synchronization pulse dutycycle

TA

Ambient temperature

10

45

–40

1000

50

kHz

55

%

125

°C

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

5

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6.3 Recommended Operating Conditions (continued)

over operating free-air temperature range (unless otherwise noted)

MIN

TJ

Junction temperature

NOM

–40

MAX

UNIT

150

°C

6.4 Thermal Information

TPS929120-Q1

THERMAL METRIC(1)

HTSSOP (PWP)

UNIT

24 PINS

RθJA

Junction-to-ambient thermal resistance

35

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

26.1

°C/W

RθJB

Junction-to-board thermal resistance

13.7

°C/W

ΨJT

Junction-to-top characterization parameter

0.4

°C/W

ΨJB

Junction-to-board characterization parameter

13.6

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

2.4

°C/W

(1)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

6.5 Electrical Characteristics

TJ = –40°C to 150°C, V(SUPPLY) = 5-40 V, For digital outputs, C(LOAD) = 20 pF, (unless otherwise noted).

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

4.5

12

UNIT

BIAS

V(SUPPLY)

Operating input voltage

IQ(ON)

Quiescent current, all-channels-on

V(SUPPLY) = 12 V, R(REF) =31.6 kΩ, alloutput ON

IQ(OFF)

Quiescent current, all-channels-off

V(SUPPLY) = 12 V, R(REF) = 31.6 kΩ, alloutput OFF

I(FAULT)

Quiescent current, fail-safe state fault

mode

V(SUPPLY) = 12 V, fail-safe state, alloutput OFF, ERR = LOW

2.5

40

V

10

mA

3.5

mA

2.85

mA

V(POR_rising)

Power-on-reset rising threshold

4

4.2

4.4

V

V(POR_falling)

Power-on-reset falling threshold

3.8

4

4.2

V

V(SUPPLY) > 5.6 V, I(LDO) = 40 mA,

CONF_LDO = 0b

4.75

5

5.25

V

V(SUPPLY) > 5.6 V, I(LDO) = 40 mA,

CONF_LDO = 1b

4.18

4.4

4.62

V

V(LDO)

LDO output voltage

I(LDO)

LDO output current capability

I(LDO_LIMIT)

LDO output current limit

80

V(LDO_DROP)

LDO maximum dropout voltage

I(LDO) = 80 mA

0.5

0.9

V

V(LDO_DROP)

LDO maximum dropout voltage

I(LDO) = 50 mA

0.3

0.6

V

100

mA

mA

V(LDO_POR_rising)

LDO power-on-reset rising threshold

2.75

3

3.25

V

V(LDO_POR_falling)

LDO power-on-reset falling threshold

2.5

2.75

3

V

C(LDO)

Supported LDO loading capacitance

range

1

10

µF

f(OSC)

Internal oscillator frequency

-2.5%

32.15

+2.5%

MHz

ERR

VIL(ERR)

6

Input logic low voltage, ERR

0.7

VIH(ERR)

Input logic high voltage, ERR

I(pd_ERR)

ERR pull-down current capability

2

V(ERR) = 0.4 V

Submit Document Feedback

3

V

V

6

9

mA

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6.5 Electrical Characteristics (continued)

TJ = –40°C to 150°C, V(SUPPLY) = 5-40 V, For digital outputs, C(LOAD) = 20 pF, (unless otherwise noted).

PARAMETER

Ilkg(ERR)

TEST CONDITIONS

MIN

TYP

ERR leakage current

MAX

UNIT

1

µA

0.7

V

FLEXWIRE INTERFACE

VIL(RX)

Input logic low voltage, RX

VIH(RX)

Input logic high voltage, RX

VOL(TX)

Low-level output voltage TX,

Isink = 5 mA,

2

VOH(TX)

High-level output voltage TX,

Isource = 5 mA, Vpull-up = 5 V

Ilkg

TX, RX

V

0

0.3

V

4.7

5

V

–1

1

µA

0.7

V

ADDRESS, FS

VIL(IO)

Input logic low voltage, ADDR2/CLK,

ADDR1/PWM1, ADDR0/PWM0, FS

VIH(IO)

Input logic high voltage, ADDR2/CLK,

ADDR1/PWM1, ADDR0/PWM0, FS

R(PD_ADDR)

Internal pull down resistance, ADDR2/

CLK, ADDR1/PWM1, ADDR0/PWM0

100

kΩ

R(PD_FS)

Internal pull down resistance, FS

100

kΩ

2

V

ADC

DNL

Differential nonlinearity

–1(1)

1(1)

LSB

INL

Integral nonlinearity

–2(1)

2(1)

LSB

OUTPUT DRIVERS

f(PWM_200)

200-Hz selection

f(PWM_1000)

1-kHz selection

ΔI(OUT_d2d)

ΔI(OUT_c2c)

Device-to-device accuracy ΔI(OUT_d2d)

= 1- Iavg(OUT) / Iideal(OUT)

Channel-to-channel accuracy

ΔI(OUT_c2c) = 1- I(OUTx) / Iavg(OUT)

200

Hz

1000

Hz

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 11b, DC=63

–5

0

5

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 10b, DC=63

–5

0

5

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 01b, DC=63

–5

0

5

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 00b, DC=63

–5

0

5

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 11b, DC=63

–3

0

3

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 10b, DC=31

–3

0

3

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 01b, DC=15

–5

0

5

R(REF) = 31.6 kOhm,

CONF_REFRANGE = 01b, DC=12

–7

0

7

%

%

I(OUT_75mA)

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 11b, DC=63

75

mA

I(OUT_50mA)

R(REF) = 12.7 kOhm,

CONF_REFRANGE = 11b, DC=63

50

mA

I(OUT_20mA)

R(REF) = 31.6 kOhm,

CONF_REFRANGE = 11b, DC=63

20

mA

I(OUT_1mA)

R(REF) = 31.6 kOhm,

CONF_REFRANGE = 01b, DC = 12

1

mA

V(OUT_drop)

output dropout voltage

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 11b, DC=38,

I(OUTx) = 45 mA

400

700

mV

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

7

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6.5 Electrical Characteristics (continued)

TJ = –40°C to 150°C, V(SUPPLY) = 5-40 V, For digital outputs, C(LOAD) = 20 pF, (unless otherwise noted).

PARAMETER

V(OUT_drop)

TEST CONDITIONS

MIN

R(REF) = 8.45 kOhm,

CONF_REFRANGE = 11b, DC=63,

I(OUTx) = 75 mA

output dropout voltage

TYP

MAX

UNIT

600

1000

mV

R(REF)

1

50

kΩ

C(REF)

0

4.7

nF

V(REF)

1.235

K(REF_11)

CONF_REFRANGE = 11b

512

K(REF_10)

CONF_REFRANGE = 10b

256

K(REF_01)

CONF_REFRANGE = 01b

128

K(REF_00)

CONF_REFRANGE = 00b

64

V

I(REF_OPEN_th)

10

µA

V(REF_SHORT_th)

0.6

V

DIAGNOSTICS

V(OPEN_th_rising)

LED open rising threshold

V(SUPPLY) - V(OUTx)

200

400

600

mV

V(OPEN_th_falling)

LED open falling threshold

V(SUPPLY) - V(OUTx)

300

500

700

mV

V(OPEN_th_hyst)

100

mV

V(SG_th_rising)

Short-to-ground

rising threshold

0.8

0.9

1

V

V(SG_th_falling)

Short-to-ground

falling threshold

1.1

1.2

1.3

V

V(SG_th_hyst)

Short-to-ground

hysteresis

0.3

V

135

oC

5

oC

EEPROM

N(EEP)

Number of programming cycles.

V(SUPPLY) = 12 V

1000

MISC

T(PRETSD)

Pre-thermal warning threshold

T(PRETSD_HYS)

Pre-thermal warning hysteresis

T(TSD)

Over-temperature

protection threshold

T(TSD_HYS)

Over-temperature

protection hysteresis

(1)

160

175

190

oC

oC

15

Guaranteed by design only

6.6 Timing Requirements

MIN

8

NOM

MAX

UNIT

t(ODPW)

Diagnostics pulse-width, CONF_ODPW = 0h

100

µs

t(CONV)

time needed to complete one AD conversion

57

µs

t(OPEN_deg)

Open-circuit deglitch timer

5

µs

t(SHORT_deg)

Short-circuit deglitch timer

5

µs

t(retry)

Fault retry timer

10

ms

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6.7 Typical Characteristics

4

7.2

Supply Standby Current (mA)

3.5

Fault Current (mA)

7.4

TA = 25 oC

TA = 125 oC

TA = 40 oC

3

2.5

2

1.5

7

6.8

6.6

6.4

6.2

6

5.8

5.6

1

0

5

10

15

20

25

Supply Voltage (V)

30

35

0

40

10

20

30

D001

40

50

60

70

REF Resistor (k:)

80

90

100

D002

R(REF) = 8.35 kΩ

CONF_REFRANGE[1:0] = 3h

CONF_REFRANGE[1:0] = 3h

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

Figure 6-2. Standby Current vs REF Resistor

105

TA = 25 oC

TA = 125 oC

TA = 40 oC

I(OUT) = 5 mA

I(OUT) = 50 mA

I(OUT) = 75 mA

90

Output Current (mA)

Output Current (mA)

Figure 6-1. Fault Current vs Supply Voltage

75

60

45

30

15

0

0

10

20

30

40

50

60

70

REF Resistor (k:)

80

90

100

0

0.5

1

D003

1.5

2

2.5

Dropout Voltage (V)

3

3.5

4

D004

CONF_IOUTx[5:0] = 3Fh

CONF_REFRANGE[1:0] = 3h

CONF_REFRANGE[1:0] = 3h

Figure 6-3. Output Full-range Current vs REF Resistor

80

105

TA = 25 oC

TA = 125 oC

TA = 40 oC

70

I(OUT) = 5 mA

I(OUT) = 50 mA

I(OUT) = 75 mA

90

60

Output Current (mA)

Output Current (mA)

Figure 6-4. Output Current vs Dropout Voltage

50

40

30

20

75

60

45

30

15

10

0

0

0

0.5

1

1.5

2

2.5

Dropout Voltage (V)

3

3.5

4

0

D005

5

10

15

20

25

Supply Voltage (V)

30

35

40

D006

R(REF) = 12.6 kΩ

CONF_IOUTx[5:0] = 3Fh

CONF_REFRANGE[1:0] = 3h

Figure 6-5. Output Current vs Dropout Voltage

Figure 6-6. Output Current vs Supply Voltage

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

9

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6.7 Typical Characteristics

100

70

I(OUT) = 75 mA TA = 25 oC

I(OUT) = 50 mA TA = 25 oC

I(OUT) = 75 mA TA = 125 oC

I(OUT) = 50 mA TA = 125 oC

I(OUT) = 75 mA TA = 40 oC

I(OUT) = 50 mA TA = 40 oC

90

60

80

Output Current (mA)

Output Average Current (mA)

I(OUT) = 50 mA

50

40

30

20

70

60

50

40

30

20

10

10

0

0

32

64

96

128

160

PWMOUT[7:0]

192

224

0

256

0

8

16

24

D007

R(REF) = 12.6 kΩ

R(REF) = 8.35 kΩ & 12.6 kΩ

CONF_IOUTx[5:0] = 3Fh

CONF_REFRANGE[1:0] = 3h

Figure 6-7. Average Current vs PWMOUT[7:0]

6

64

D008

5.08

5.4

5.2

5

4.8

4.6

5.06

5.04

5.02

5

4.98

4.96

4.4

4.94

4.2

4.92

4

4.9

0

5

10

15

20

25

Supply Voltage (V)

30

35

40

Ch1 = V(SUPPLY)

Ch3 = V(OUT0)

0

10

D009

Figure 6-9. LDO Output Line Regulation

Ch6 = I(OUT0)

Figure 6-11. PWM Dimming at 200 Hz

10

56

5.1

LDO Output Voltage (V)

LDO Output Voltage (V)

5.6

48

Figure 6-8. Output DC Current vs IOUT[5:0]

TA = 25 oC

TA = 125 oC

TA = 40 oC

5.8

32

40

IOUT[5:0]

20

30

40

50

60

LDO Output Current (mA)

70

80

D010

Figure 6-10. LDO Output Load Regulation

Ch1 = V(SUPPLY)

Ch3 = V(OUT0)

Ch6 = I(OUT0)

Figure 6-12. PWM Dimming at 2000 Hz

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6.7 Typical Characteristics (continued)

Ch1 = V(SUPPLY)

Ch3 = V(OUT0)

Ch6 = I(OUT0)

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch3 = V(OUT0)

Ch6 = I(OUT0)

Figure 6-13. Supply Dimming In Fail-Safe Mode

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch3 = V(OUT0)

Ch6 = I(OUT0)

Figure 6-14. Transient Undervoltage

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch3 = V(OUT0)

Ch6 = I(OUT0)

Figure 6-15. Transient Overvoltage

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch3 = V(OUT0)

Ch6 = I(OUT0)

Figure 6-16. Jump Start

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch3 = V(OUT0)

Ch6 = I(OUT0)

Figure 6-17. Superimposed Alternating Voltage 15 Hz

Figure 6-18. Superimposed Alternating Voltage 1 kHz

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

11

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6.7 Typical Characteristics (continued)

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch4 = V(LDO)

Ch6 = I(OUT0)

Ch3 = V(OUT0)

Figure 6-19. Slow Decrease and Quick Increase of Supply

Voltage

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch6 = I(LDO)

Ch4 = V(LDO)

0 to 80 mA

Figure 6-21. LDO Output Load Transient

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch6 = I(OUT0)

T(ODPW) = 100 µs

Ch3 = V(OUT0)

F(PWM) = 2 kHz

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch4 = V(LDO)

Ch6 = I(OUT0)

Ch3 = V(OUT0)

Figure 6-20. Slow Decrease and Slow Increase of Supply

Voltage

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch6 = I(OUT0)

T(ODPW) = 100 µs

Ch3 = V(OUT0)

F(PWM) = 2 kHz

Figure 6-22. LED Open-Circuit Detection In Normal Mode

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch6 = I(OUT5)

T(ODPW) = 100 µs

Ch3 = V(OUT5)

F(PWM) = 2 kHz

V(ADCSHORTTH) = 4 V

Figure 6-23. LED Short-Circuit Detection In Normal Mode

12

Figure 6-24. Single-LED Short-Circuit Detection In Normal Mode

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

6.7 Typical Characteristics (continued)

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch6 = I(OUT0)

T(ODPW) = 100 µs

Ch3 = V(OUT5)

F(PWM) = 2 kHz

Figure 6-25. LED Open-Circuit Detection In FS Mode

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch6 = I(OUT0)

T(ODPW) = 100 µs

Ch3 = V(OUT5)

F(PWM) = 2 kHz

Figure 6-27. LED Short-Circuit Detection In Fail-Safe Mode

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch3 = V(OUT5)

Ch6 = I(OUT0)

T(ODPW) = 100 µs

F(PWM) = 2 kHz

Figure 6-26. LED Open-Circuit Recovery In FS Mode

Ch1 = V(SUPPLY)

Ch2 = ERR

Ch6 = I(OUT0)

T(ODPW) = 100 µs

Ch3 = V(OUT5)

F(PWM) = 2 kHz

Figure 6-28. LED Short-Circuit Recovery In Fail-Safe Mode

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

13

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

7 Detailed Description

7.1 Overview

TPS929120-Q1 is an automotive 12-channel LED driver with FlexWire interface to address increasing

requirements for individual control of each LED string. Each of its channel can support both analog dimming and

pulse-width-modulation (PWM) dimming, configured through its FlexWire serial interface. The internal electrically

erasable programmable read-only memory (EEPROM) allows users to configure device in the scenario of

communication loss to fulfill system level safety requirements.

The FlexWire interface is a robust address-based master-slave interface with flexible baud rate. The interface is

based on multi-frame universal asynchronous receiver-transmitter (UART) protocol. The unique synchronization

frame of FlexWire reduces system cost by saving external crystal oscillators. It also supports various physical

layer with the help of external physical layer transceiver such as CAN or LIN transceivers. The embedded CRC

correction is able to ensure robust communication in automotive environments. The FlexWire interface is easily

supported by most MCUs in the markets.

Each output is a constant current source with individually programmable current output and PWM duty cycle.

Each channel features various diagnostics including LED open-circuit, short-circuit and single-LED short-circuit

detection. The on-chip analog-digital convertor (ADC) allows controller to real-time monitor loading conditions.

To further increase robustness, the unique fail-safe of the device state machine allows automatic switching to

fail-safe states in the case of communication loss, for example, MCU failure. The device supports programming

fail-safe settings with user-programmable EEPROM. In fail-safe states, the device supports different

configurations if output fails, such as one-fails-all-fail or one-fails-others-on. Each channel can be independently

programmed as on or off in fail-safe states. The fail-safe state machine also allows the system to function with

pre-programmed EEPROM settings without presence of any controller in the system, also known as stand-alone

operation.

The microcontroller can access each of the device through the FlexWire interface. By setting and reading back

the registers, the master, which is the microcontroller, has full control over the device and LEDs. All EEPROMs

are pre-programmed to default values. TI recommends that users program the EEPROM at the end-of-line for

application-specific settings and fail-safe configurations.

14

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

7.2 Functional Block Diagram

TPS929120-Q1

SUPPLY

FS

REF

Bias

12-Ch Output

VLDO

ERR

OUT 11 - 0

Error Feedback

Diagnostics

TX

Digital Core

FlexWire

Interface

RX

ADC

ADDR2 / CLK

GND

EEPROM

ADDR1 / PWM1

Device Address

ADDR0 / PWM0

Fail-Safe Statemachine

7.3 Feature Description

7.3.1 Device Bias and Power

7.3.1.1 Power Supply (SUPPLY)

The TPS929120-Q1 is AECQ-100 qualified for automotive applications. The power input to the device through

SUPPLY pin can be low to 4.5 V and up to 40 V for automotive battery directly powered systems.

7.3.1.2 5-V Low-Drop-Out Linear Regulator (VLDO)

The TPS929120-Q1 has an integrated low-drop-out linear regulator to provide power supply to external CAN

transceivers, such as TCAN1042. The internal LDO powered by supply voltage V(SUPPLY) provides a stable 5-V

output with up to 80-mA constant current capability. TI recommends a ceramic capacitor from 1 µF to 10 µF on

the VLDO pin. The LDO has an internal current limit I(LDO_LIMIT) for protection and soft start. The capacitor

charging time must be considered to total start-up time period, because the device is held in POR state if the

capacitor voltage is not charged to above UVLO threshold.

7.3.1.3 Undervoltage Lockout (UVLO) and Power-On-Reset (POR)

In order to ensure clean start-up, the TPS929120 uses UVLO and POR circuitry to clear its internal registers

upon power-up and to reset registers with its default values.

The TPS929120-Q1 has internal UVLO circuits so that when either power supply voltage V(SUPPLY) or LDO

output voltage V(LDO) is lower than its UVLO threshold, POR is triggered. In POR state, the device resets digital

core and all registers to default value. FLAG_POR register is set to 1 for each POR cycle to indicate the POR

history.

Before both powers are above UVLO thresholds, the TPS929120-Q1 stays in POR state with all outputs off and

ERR pulled down. Once both power supplies are above UVLO threshold, the device enters INIT mode for

initialization releasing ERR pulldown. A programmable timer starts counting in INIT state, the timer length can be

set by EEPROM register EEP_INITTIMER. When the timer is completed, the device switches to normal state. In

INIT state, setting CLR_POR to 1 clears FLAG_POR, disables the timer, and sets the device to normal state.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

15

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

Upon powering up, the TPS929120-Q1 automatically loads all settings stored in EEPROM to correlated registers

and sets the other registers to default value which don't have correlated EEPROM. All channels are powered up

in off-state by default to avoid unwanted blinking.

Writing 1 to CLR_REG manually loads EEPROM setting to the correlated registers and set the other registers to

default value. After CLR_REG is set, the FLAG_POR is set 1 to indicate registers clear to default values. Writing

1 to CLR_POR resets the FLAG_POR register to 0. TI recommends settting CLR_REG to 1 to clear the internal

registers every time after POR. The CLR_REG automatically resets to 0.

7.3.1.4 Programmable Low Supply Warning

The TPS929120-Q1 uses its internal ADC to monitor supply voltage V(SUPPLY). If the supply is below allowable

working threshold, the output voltage may not be sufficient to keep the LED operating with desired brightness

output as expected. The ADC output is automatically compared with threshold set by register

CONF_ADCLOWSUPTH as described in Register Maps. When the supply voltage is below threshold, the device

sets warning flag register FLAG_ADCLOWSUP to 1 in the status register. CLR_FAULT is able to clear the

FLAG_ADCLOWSUP as well as other fault registers. In addition, the LED open-circuit and single LED shortcircuit detection is disabled if the supply voltage is below threshold to avoid LED open circuit and to prevent the

single LED short-circuit fault from being mis-triggered. The 4-bit register CONF_ADCLOWSUPTH has total 15

options covering from 5 V to 20 V.

7.3.2 Constant Current Output

7.3.2.1 Reference Current With External Resistor (REF)

The TPS929120-Q1 must have an external resistor R(REF) to set the internal current reference I(REF) as shown in

Figure 7-1.

CONF_REFRANGE[1:0]

2-bit range selection

K(REF)

CONF_IOUT0[5:0]

I(FULL_RANGE)

×512

OUT0

6-bit DAC

CH0

CONF_IOUT1[5:0]

×256

×128

OUT1

6-bit DAC

×64

CH1

Optional

CREF

REF

V(REF)

1.235V

Vbg

1.235V

CONF_IOUT11[5:0]

OUT11

6-bit DAC

RREF

CH11

Figure 7-1. Output Current Setting

The internal current reference I(FULL_RANGE) is generated based on the I(REF) multiplied by factor K(REF) to provide

the full range current reference for each OUTx channel. The K(REF) is programmable by 2-bit register

CONF_REFRANGE with 4 different options. The I(FULL_RANGE) can be calculated with Equation 1.

I(FULL _ RANGE)

V(REF)

R(REF)

u K(REF)

(1)

where

•

•

16

V(REF) = 1.235 V typically

K(REF) = 64, 128, 256, or 512 (default)

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

The recommended resistor values of R(REF) and amplifier ratios of K(REF) are listed in Table 7-1.

Table 7-1. Reference Current Range Setting

CONF_REFRA

NGE

K(REF)

11b

512

FULL RANGE CURRENT (mA)

R(REF) = 8.45 kΩ

R(REF) = 12.7 kΩ

R(REF) = 31.6 kΩ

75

50

20

10b

256

37.5

25

10

01b

128

18.75

12.5

5

00b

64

9.375

6.25

2.5

Place the R (REF) resistor as close as possible to the REF pin with an up to 2.2-nF ceramic capacitor in parallel to

improve the noise immunity. The off-board R(REF) setup is not allowed due to the concern of instability reference

current. TI recommends a 1-nF ceramic capacitor in parallel with R(REF).

7.3.2.2 64-Step Programmable High-Side Constant-Current Output

TPS929120-Q1 has 12 channels of high-side current sources. Each channel has its own enable configuration

register CONF_ENCHx. Setting CONF_ENCHx to 1 enables the channel output; clearing the register to 0

disables the channel output. To completely turn off the channel current, user can clear channel enable bit

CONF_ENCHx to 0. Upon power up, CONF_ENCHx is automatically reset to 0 to avoid unwanted blinking.

Each OUTx channel supports individual 64-step programmable current setting, also known as dot correction

(DC). The DC feature can be used to set binning values for output LEDs or to calibrate the LEDs to achieve high

brightness homogeneity based on external visual system to further save binning cost. The 6-bit register

CONF_IOUTx sets the current independently, where x is the channel number from 0 to 11. The OUTx current

can be calculated with Equation 2

I(OUTx)

(CONF _IOUTx 1)

u I(FULL _ RANGE)

64

(2)

where

•

•

•

CONF_IOUTx is programmable from 0 to 63

x is from 0 to 11 for different output channel

I(FULL_RANGE) can be calculated with Equation 1

7.3.3 PWM Dimming

TPS929120-Q1 integrates independent 12-bit PWM generators for each OUTx channel. The current output for

each OUTx channel is turned on and off controlled by the integrated PWM generator. The average current of

each OUTx can be adjusted by PWM duty cycle independently, therefore, to control the brightness for LEDs in

each channel.

7.3.3.1 PWM Dimming Frequency

The frequency for PWM dimming is programmable by 4-bit register CONF_PWMFREQ with 16 options covering

from 200 Hz to 20.8 kHz. Select the frequency for PWM dimming based on the minimum brightness requirement

in application. TPS929120-Q1 supports down to 1-µs minimum pulse current for all 12 channel outputs.

7.3.3.2 PWM Generator

The 12-bit PWM generator constructs the cyclical PWM output based on a 12-bit digital binary input to control

the output current ON and OFF. Basically the PWM generator counts 256 pulses at base high frequency for

PWM output cycle period and counts number of pulses determined by MSB 8 bits of 12-bit binary input at the

same frequency for PWM ON period. The LSB 4 bits of 12-bit binary input is used to set up the dithering to

realize total 12-bit resolution. The base high frequency is generated by internal oscillator, which is 256 times of

the frequency programmable by CONF_PWMFREQ. Figure 7-2 is the signal path diagram for PWM generator.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

17

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

ADDR0/PWM0

CH5-CH0

NAND

6

EEP_INTADDR

1: INT ADDR

0: EXT ADDR

ADDR1/PWM1

12

CH11-CH6

NAND

6

CONF_EXPEN

1: LUT EN

0: LUT DIS

Exponential

Look-Up Table

CONF_PWMOUTx[7:0]

8

1

8

12

MUX

8

12

Linear

12

CONF_PWMLOWOUTx[3:0]

PWMOUT

12-bit PWM

Generator

0

CONF_EXTCLK EEP_INTADDR

1: EXT CLK

1: INT ADDR

0: INT CLK

0: EXT ADDR

AND

12

12

12

CONF_ENCHx

x: 0~11

ADDR2/CLK

1

0h: 200Hz

1h: 250Hz

2h: 300Hz

3h: 350Hz

4h: 400Hz

5h: 500Hz

6h: 600Hz

7h: 800Hz

8h: 1000Hz

9h: 1200Hz

Ah: 2000Hz

Bh: 4000Hz

Ch: 5900Hz

Dh: 7800Hz

Eh: 9600Hz

Fh: 20800Hz

CONF_PWMFREQ[3:0]

MUX

Internal Oscillator

0

Figure 7-2. PWM Generator Path Diagram

7.3.3.3 Linear Brightness Control

When register CONF_EXPEN is set to 0, the MSB 8 bits of 12-bit binary input to PWM generator is directly

copied from 8-bit register CONF_PWMOUTx, and the LSB 4 bits is directly copied from 4-bit register

CONF_PWMLOWOUTx. The PWM output duty cycle can be calculated with Equation 3. Because the 4 LSB bits

inputs are used to control the dithering, setting CONF_PWMLOWOUTx to Fh disables the dithering if it is not

needed. The PWM output duty cycle is linearly controlled by the register CONF_PWMOUTx and

CONFPWMLOWOUTx, which provides the linearly brightness control to each channel output.

D(OUTx)

(16 u CONF_PWMOUTx+CONF_PWMLOWOUTx+1)

u 100%

4096

(3)

where

•

•

•

CONF_PWWOUTx is decimal number from 0 to 255.

CONF_PWMLOWOUTx is decimal number from 0 to 15.

x is from 0 to 11 for different output channel

If using the dithering feature to realize the 12-bit dimming resolution, set the PWM frequency higher than 2 kHz

through setting register CONF_PWMFREQ to avoid visible brightness flicker when the value of

CONF_PWMLOWOUTx is less than Fh. Higher PWM frequency can also prevent the visible LED flash in video

display due to the low beat frequency between digital camera shutter frequency and PWM frequency for LED

dimming.

Because the 12-bit PWM duty cycles require 2 bytes of write operation to update the completed data, the output

PWM duty cycle is not changed in between of the two bytes data transmission. TPS929120-Q1 only updates

PWM duty cycle of any output when its high 8-bit CONF_PWMOUTx is written. When very fast brightness

change is needed, for example, fade-in and fade-out effects, simultaneous PWM duty cycle change of all

18

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

channels is required. Setting CONF_SHAREPWM to 1 enables all channels using the PWM dutycycle setting of

channel 0 to save communication latency.

7.3.3.4 Exponential Brightness Control

The TPS929120-Q1 can also generate PWM duty-cycle output following exponential curve. The integrated lookup table provides a one-to-one conversion from 8-bit register CONF_PWMOUTx to 12-bit binary code following

exponential increment when register CONF_EXPEN is set to 1 as Figure 7-3 illustrated. When exponential

control path is selected, the CONF_PWMLOWOUTx data is neglected. By using the exponential brightness

control, LED brightness change by one LSB is invisible to human eyes especially at low brightness range.

4096

12-Bit Lookup Table Output

3584

3072

2560

2048

1536

1024

512

0

0

32

64

96

128

160

8-Bit CONF_PWMOUTx[7:0]

192

224

256

D100

Figure 7-3. PWM Duty Cycle vs 8-bit Code for Exponential Dimming

CONF_EXPEN bit selects the dimming method between linear or exponential. Setting the bit CONF_EXPEN to 1

enables the look-up table for exponential dimming curve. In exponential PWM dimming mode, 8-bit register

CONF_PWMOUTx is converted to 12-bit PWM dutycycle by look-up table automatically. Clear the bit

CONF_EXPEN to 0 disables the look-up table. In this case, users must provide 12-bit PWM duty cycle.

CONF_PWMOUTx stores the high 8-bit of 12-bit PWM duty-cycle information. CONF_PWMLOWOUTx stores

the low 4-bit.

To avoid visible brightness flicker for exponential dimming, choose PWM frequency higher than 2 kHz through

setting register CONF_PWMFREQ. Higher PWM frequency can also avoid the visible LED flash in video display

due to the low beat frequency between digital camera shutter frequency and PWM frequency for LED dimming.

During power-up or in fail-safe state, the registers CONF_EXPEN, CONF_PWMOUTx, CONF_PWMFREQ are

automatically reset to their default values stored in EEPROM register EEP_EXPEN, EEP_PWMOUTx,

EEP_PWMFREQ. CONF_PWMLOWOUTx is reset to Fh as default value.

In fail-safe state, PWM generator only uses 8-bit EEPROM data from EEP_PWMOUTx to build PWM dutycycle

output and ignores the low 4-bit. The PWM duty-cycle calculation is as shown in Equation 4.

D(OUTx)

(EEP_PWMOUTx+1)

u 100%

256

(4)

where

•

•

EEP_PWMOUTx is decimal number from 0 to 255.

x is from 0 to 11 for different output channel

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

19

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

7.3.3.5 External Clock Input for PWM Generator (CLK)

The TPS929120-Q1 has internal precision oscillator for PWM generators. In addition, the device also supports

an external clock for the PWM generator source with ADDR2/CLK input considering the synchronization

requirement.

Then external clock inputs through ADDR2/CLK pin is a multi-function pin not only for external clock input but

also for device slave address selection. The device slave address stored in EEPROM must be enabled by

burning EEP_INTADDR to 1 to release ADDR2/CLK pin for external clock input. In addition, register

CONF_EXTCLK can be used to choose the PWM generator between external input or an internal oscillator.

Writing CONF_EXTCLK to 1 enables the external clock source. The external clock frequency must be 256 times

of desired PWM dimming frequency. The external clock source is only used in PWM generation. TI recommends

that the external clock frequency be less than 1 MHz. The internal clock is recommended when high dimming

frequency is required.

7.3.3.6 External PWM Input ( PWM0 and PWM1)

The TPS929120-Q1 has two PWM inputs that can be used to directly control OUT0-11. The both ADDR1/

PWM1 and ADDR0/ PWM0 pins are multi-function pins for not only external PWM input signal but also device

slave address selection pins. The register EEP_INTADDR must be written to 1 to release both twos for external

PWM input. When the EEP_INTADDR is 1, the ADDR0/ PWM0 is functional as external active low PWM control

input for OUT0-5 and the ADDR1/ PWM1 is functional as external active low PWM control input for OUT6-11, as

shown in Figure 7-2. Setting the register CONF_PWMOUTx to 0xFF and the register CONF_PWMLOWOUTx to

0xF is recommended when external PWM input is used. In case external PWM is not used, ADDR0/ PWM0 and

ADDR1/ PWM1 must be tied to GND when EEP_INTADDR is set to 1.

7.3.4 On-chip 8-bit Analog-to-Digital Converter (ADC)

The TPS929120-Q1 has integrated a successive-approximation-register (SAR) ADC for diagnostics. It routinely

monitors supply voltage if the ADC is idle and stores SUPPLY conversion results into ADC_SUPPLY.

To manually read the voltage of an ADC channel as listed in Table 7-2, user must write the 5-bit register

CONF_ADCCH to select channel. Once CONF_ADCCH register is written, the one time ADC conversion starts

and clears FLAG_ADCDONE register. As long as the ADC conversion is completed, the ADC result is available

in 8-bit register ADC_OUT and sets FLAG_ADCDONE to 1. Reading the ADC_OUT register also clears

FLAG_ADCDONE, and the FLAG_ADCDONE is set to 0 after reading completion.

Because the TPS929120-Q1 supports PWM control for adjusting LED brightness, the voltage on OUT0 to

OUT11 is like a pulse waveform. When the current output is enabled by setting CONF_ENCHx to 1, the ADC

measures the voltage on assigned OUTx after the channel is turned on with t(diag_pulse) delay time, which is

programmable by 4-bit register CONF_ODPW. When the channel is disabled by setting CONF_ENCHx to 0, the

ADC samples the voltage on assigned OUTx at off state.

The analog value can be calculated based on the read back binary code with Equation 5 and Table 7-2.

AnalogValue

a k u ADC _ OUT

(5)

where

•

20

ADC_OUT is decimal number from 0 to 255.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

Table 7-2. ADC Channel

CHANNEL

NO.

CONF_ADCCH

NAME

ADC

ADC

CALCULATION CALCULATION

PARAMETER

PARAMETER

(a)

(k)

COMMENT

0

00h

REF

0.007 V

0.0101 V/LSB

Reference voltage

1

01h

SUPPLY

0.0673 V

0.0804 V/LSB

Supply voltage

2

02h

VLDO

0.0465 V

0.022 V/LSB

5V LDO output voltage

3

03h

TEMPSNS

–242.35°C

2.152°C/LSB

Internal temperature sensor

4

04h

IREF

0.7592 µA

0.7461 µA/LSB

Reference current

5

05h

MAXOUT

0.0673 V

0.0804 V/LSB

Maximum channel output voltage

6-15

06h - 0Fh

RESERVED

RESERVED

RESERVED

RESERVED

16

10h

OUT0

Output voltage channel 0

17

11h

OUT1

Output voltage channel 1

18

12h

OUT2

Output voltage channel 2

19

13h

OUT3

Output voltage channel 3

20

14h

OUT4

Output voltage channel 4

21

15h

OUT5

22

16h

OUT6

23

17h

OUT7

Output voltage channel 7

24

18h

OUT8

Output voltage channel 8

25

19h

OUT9

Output voltage channel 9

26

1Ah

OUT10

Output voltage channel 10

27

1Bh

OUT11

Output voltage channel 11

28

1Ch

RESERVED

RESERVED

RESERVED

RESERVED

29

1Dh

RESERVED

RESERVED

RESERVED

RESERVED

30

1Eh

RESERVED

RESERVED

RESERVED

RESERVED

31

1Fh

RESERVED

RESERVED

RESERVED

RESERVED

0.0673 V

0.0804 V/LSB

Output voltage channel 5

Output voltage channel 6

The TPS929120-Q1 also provides ADC auto-scan mode for single-led short-circuit diagnostics. The detail

description for auto-scan mode can be found in On-Demand Off-State Single-LED Short-Circuit (SS)

Diagnostics.

In ADC auto-scan mode, If MAXOUT channel is selected by writing 05h to CONF_ADCCH, the maximum

voltage of OUT0 to OUT11 is recorded into ADC_OUT register. The maximum channel output voltage is

available after at least one output PWM cycle is completed. Based on the measured maximum output voltage

and supply voltage, microcontroller is able to regulate supply voltage from previous power stage to minimize the

power consumption on the TPS929120-Q1. Basically microcontroller needs to program the output voltage of

previous power stage to be just higher than the measured maximum channel output voltage plus the required

dropout voltage V(OUT_drop) of the TPS929120-Q1. In this way, the TPS929120-Q1 takes minimum power

consumption, and overall power efficiency is optimized.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

21

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

7.3.5 Diagnostic and Protection in Normal State

The TPS929120-Q1 has full-diagnostics coverage for supply voltage, current output, and junction temperature.

In normal state, the device detects all failures and reports the status out through the ERR or FLAG registers,

without any actions taken by the device except UVLO and overtemperature protection. The master controller

must handle all fault actions, for example, retry several times and shut down the outputs if the error still exists.

The fault behavior in normal state can be found in Table 7-3.

7.3.5.1 Fault Masking

The TPS929120-Q1 provides fault masking capability using masking registers. The device is capable of masking

faults by channels or by fault types. The fault masking does not disable diagnostics features but only prevents

fault reporting to FLAG_OUT register, FLAG_ERR register, and ERR output.

To disable diagnostics on a single channel, setting CONF_DIAGENCHx registers to 0 disables diagnostics of

channel x and thus no fault of this channel is reported to FLAG_OUT or FLAG_ERR registers, or to the ERR

output.

CONF_MASKREF prevents the reference fault being reported to FLAG_ERR and ERR output.

CONF_MASKOPEN prevents the output open-circuit fault being reported to FLAG_OUT, FLAG_ERR and ERR

output.

CONF_MASKSHORT prevents the output short-circuit fault being reported to FLAG_OUT, FLAG_ERR and ERR

output.

CONF_MASKTSD prevents the overtemperature shutdown fault being reported to FLAG_ERR and ERR output.

CONF_MASKCRC prevents the CRC fault being reported to FLAG_ERR and ERR output.

7.3.5.2 Supply Undervoltage Lockout Diagnostics in Normal State

When SUPPLY or VLDO voltage drops below its UVLO threshold, the device enters POR state. Upon voltage

recovery, the device automatically switches to INIT state with FLAG_POR and FLAG_ERR set to 1.

7.3.5.3 Low-Supply Warning Diagnostics in Normal State

The internal AD converter of TPS92910-Q1 continuously monitors the supply voltage and compares the results

with internal threshold V(ADCLOWSUPTH) set by CONF_ADCLOWSUPTH as described in Register Maps. If the

supply voltage is lower than threshold, the device pulls ERR pin down with one pulsed current sink for 50 µs to

report the fault and set flag registers including FLAG_ADCLOWSUP to 1. The master controller can write

register CLR_FAULT to 1 to reset this flag, and the CLR_FAULT bit automatically returns to 0. The internal ADC

monitors supply voltage and converters to 8-bit binary code in every conversion cycle T(CONV) when it is in idle.

After each AD conversion-cycle time on supply, the ADC_SUPPLY is automatically updated with the latest result.

The low-supply warning is also used to disable the LED open-circuit detection and single-LED short-circuit

detection. When the voltage applied on SUPPLY pin is higher than the threshold V(ADCLOWSUPTH), the

TPS929120-Q1 enables LED open-circuit and single-LED short-circuit diagnosis. When V(SUPPLY) is lower than

the threshold V(ADCLOWSUPTH), the device disables LED-open-circuit detection and single-LED short-circuit

diagnosis. Because when V(SUPPLY) drops below the maximum total LED forward voltage plus required

V(DROPOUT) at required current, the TPS929120-Q1 is not able to deliver sufficient current output to pull the

voltage of each output channel as close as possible to the V(SUPPLY). In this condition, the LED open-circuit fault

or single-LED short-circuit fault might be detected and reported by mistake. Setting the low-supply warning

threshold high enough can avoid the LED open-circuit and single LED short-circuit fault being detected when

V(SUPPLY) drops to low. The V(ADCLOWSUPTH) is programmable from 5 V to 20 V.

7.3.5.4 Reference Diagnostics in Normal State

The TPS929120-Q1 integrates diagnostics for REF resistor open/short fault. If the current output from REF pin

I(REF) is lower than I(REF_OPEN_th), the reference resistor open-circuit fault is reported. The reference resistor

short-circuit fault is reported if the voltage of REF pin V(REF) is lower than V(REF_SHORT_th). The device pulls the

22

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

ERR pin down with constant current sink and set flag registers including FLAG_REF and FLAG_ERR to 1. The

master controller must send CLR_FAULT to clear fault flag registers after fault removal.

In normal state, the device does not perform any actions automatically when reference resistor fault is detected.

However, the output may not work properly and the output current may be operating at high current level. It is

recommended for master controller to shut down the device outputs and report error to upper level control

system such as body control module (BCM).

The TPS929120-Q1 monitors the reference current I(REF) set by external resistor R(REF). The I(REF) can be

calculated with Equation 6.

I(REF)

V(REF)

R(REF)

(6)

where

•

V(REF) = 1.235 V typically

7.3.5.5 Pre-Thermal Warning and Overtemperature Protection in Normal State

The TPS929120-Q1 has pre-thermal warning at typical 135°C and overtemperature shutdown at typical 175°C .

When the junction temperature T(J) of TPS929120-Q1 rises above pre-thermal warning threshold, the device

reports pre-thermal warning, pull ERR pin with pulsed current sink for 50 µs and sets the flag registers including

FLAG_PRETSD to 1. The master controller must write 1 to CLR_FAULT register to clear FLAG_PRETSD.

When device junction temperature T(J) further rises above overtemperature protection threshold, the device

shuts down all output drivers, pulls the ERR pin low with constant current sink, and sets the flag registers

including FLAG_TSD and FLAG_ERR to 1. When junction temperature falls below T(TSD) – T(TSD_HYS), the

device resumes all outputs and releases ERR pin pulldown. The FLAG_TSD still must be cleared by writing

CLR_FAULT to 1.

If the T(J) rises too high above 180oC typically, the TPS929120-Q1 turns off the internal linear regulator to

shutdown all the analog and digital circuit. When the T(J) drops below T(TSD) - T(TSD_HYS), the TPS929120-Q1

restarts from POR state with all the registers cleared to default value.

When more accurate thermal measurement on LED unit is required, one current output channel can be

sacrificed to provide current bias to external thermal resistor such as PTC or NTC. The voltage of external

thermal resistor can be measured by integrated ADC to acquire the temperature information of thermal resistor

located area. The master controller can determine actions based on the acquired temperature information to turn

off or reduce current output.

7.3.5.6 Communication Loss Diagnostic in Normal State

The TPS929120-Q1 monitors the FlexWire interface for the communication with an internal watchdog timer. Any

successful non-broadcast communication with correct CRC and address matching target device automatically

resets the timer . If the watchdog timer overflows, device automatically switches to fail-safe state as indicated by

external FS input. If FS = 0, the device switches to fail-safe state 0, If FS = 1, the device switches to fail-safe

state 1.

The watchdog timer is programmable by 4-bit register CONF_WDTIMER. The TPS929120-Q1 can directly enter

fail-safe states from normal mode by burning EEP_WDTIMER to 0xFh. Disabling the watchdog timer by setting

CONF_WDTIMER to 0x0h prevents the device from getting into fail-safe state.

7.3.5.7 LED Open-Circuit Diagnostics in Normal State

The TPS929120-Q1 integrates LED open-circuit diagnostics to allow users to monitor LED status real time. The

device monitors voltage difference between SUPPLY and OUTx to judge if there is any open-circuit failure. The

SUPPLY voltage is also monitored by on-chip ADC with programmable threshold to determine if supply voltage

is high enough for open-circuit diagnostics.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

23

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

The open-circuit monitor is only enabled during PWM-ON state with programmable minimal pulse width greater

than T(ODPW) + T(OPEN_deg). The T(ODPW) is programmed by register CONF_ODPW. If PWM on-time is less than

T(ODPW) + T(OPEN_deg), the device does not report any open-circuit fault.

When the voltage difference V(SUPPLY) – V(OUTx) is below threshold V(OPEN_th_rising) with duration longer than

T(ODPW) + T(OPEN_deg), and the device supply voltage V(SUPPLY) is above the threshold V(ADCLOWSUPTH) set by

register CONF_ADCLOWSUPTH, the TPS929120-Q1 pulls the ERR pin down with one pulsed current sink for

50 µs to report fault and set flag registers including FLAG_OPENCHx, FLAG_OUT and FLAG_ERR to 1. If the

device supply voltage V(SUPPLY) is below the threshold V(ADCLOWSUPTH) set by register CONF_ADCLOWSUPTH,

open-circuit fault is not detected nor reported.

Once the open-circuit failure is removed, the master controller must write 1 to CLR_FAULT to reset fault flags.

7.3.5.8 LED Short-circuit Diagnostics in Normal State

The TPS929120-Q1 has internal analog comparators to monitor all channel outputs with respect to a fixed

threshold. If the device has detected channel voltage below threshold, it sets FLAG_SHORTCHx accordingly.

The FLAG_OUT and FLAG_ERR are set as well. Writing 1 to CLR_FAULT register is able to clear the fault flag

registers.

The short-circuit detection is only enabled during PWM-ON state with programmable minimal pulse width of

T(ODPW) + T(SHORT_deg). The T(ODPW) is programmable by register CONF_ODPW. If PWM on-time is less than

T(ODPW) + T(SHORT_deg), the device can not report any short-circuit fault. When the voltage V(OUTx) is below

threshold V(SG_th_rising) with duration longer than deglitch timer length of T(ODPW) + T(SHORT_deg), the device pulls

ERR pin down with pulsed current sink for 50 µs to report fault and set flag registers including

FLAG_SHORTCHx, FLAG_OUT and FLAG_ERR. In normal state, the device does not take any actions in

response the LED short-circuit fault and waits for the master controller to detect need for protection behavior.

The fault is latched in flag registers. The master controller must write 1 to register CLR_FAULT to reset fault

flags if the LED short-circuit fault is removed.

Possible user case:

1. Supply voltage dip below threshold, triggering false single led short-circuit fault.

2. LED short to ground and recover

3. LED single LED short and recover

4. Dutycycle too short to detect

5. Extra capacitance caused false short-circuit

7.3.5.9 On-Demand Off-State Invisible Diagnostics

It is commonly required to ensure there is no fault on each LED load before lighting them up, especially for LED

animation. Otherwise, the LED fault is detected in the middle of the admiration pattern, which results a random

and uncertain failure animation pattern. The TPS929120-Q1 provides a solution to diagnose the LED opencircuit or LED short-circuit fault without lighting up the LEDs. With this feature, the master controller can initiate

the on-demand invisible diagnostics before commencing the animation sequence. If one of the channel fails, the

device is able to detect it immediately instead of only when the fault channel is turned on in traditional

diagnostics mode. To initiate the on-demand invisible diagnostics, the master controller writes register

CONF_INVDIAGSTART to 1. The register CONF_INVDIAGSTART returns to 0 automatically in the next clock

cycle. Once the diagnostics started, the on-demand diagnostics ready flag FLAG_ODREADY is cleared to 0.

Once the diagnostics finished, the FLAG_ODREADY is set to 1. If any channel has output failures, its ondemand diagnostic flag FLAG_ODDIAGCHx is set 1.

To ensure the invisibility of the diagnostics, the TPS929120-Q1 outputs only a small DC current in short period to

each output channel and detects if there is any LED open-circuit or LED short-circuit failures. The output DC

current I(ODIOUT) can be adjusted to a proper value by setting the DC current CONF_ODIOUT and ignoring the

DC current setup by register CONF_IOUTx. The pulse-width T(ODPW) of output DC current can be programmable

by CONF_ODPW and neglecting duty cycle configuration by register CONF_PWMOUTx. At the end of the

current output pulse, if there is any LED open-circuit fault as Section 7.3.5.7 described, the TPS929120-Q1 pulls

24

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

the ERR pin down with one pulsed current sink for 50 µs to report fault and set flag registers including

FLAG_OPENCHx, FLAG_OUT and FLAG_ERR to 1. If there is any LED short-circuit fault as Section 7.3.5.8

described, the TPS929120-Q1 pulls the ERR pin down with one pulsed current sink for 50 µs to report fault and

set flag registers including FLAG_SHORTCHx, FLAG_OUT and FLAG_ERR to 1. The master controller must

write 1 to CLR_FAULT register to clear fault flags after the fault removal is verified by another on-demand offstate invisible diagnostics. TI recommends turning off all output channels by set CONF_ENCHx to 0 before

invisible diagnostics.

For invisible diagnostics mode, it is required to have a short-pulse and low output current to avoid lighting up

LEDs. However, the diagnostics are strongly affected by large loading capacitance. If the invisible diagnostics

pulse failed to charge output capacitance above short-circuit threshold, the device reports a false short-circuit

failure. If pulse failed to charge output above open-circuit threshold at maximum supply voltage, the device does

not report open-circuit fault correctly. Thus, the DC current and period of the detection pulse must be carefully

selected based on the capacitance value at output in real application.

Invisible

Diagnostics

OUT0

tT(ODPW)t

Programmable

pulse width

Programmable

diagnostic current

Normal

OUT1

Short-circuit

detected

Short-circuit

OUT11

Open-circuit

Open-circuit

detected

Figure 7-4. Programmable Invisible Diagnostics Timing Sequence

7.3.5.10 On-Demand Off-State Single-LED Short-Circuit (SS) Diagnostics

To provide single-LED short-circuit diagnostics, the TPS929120 uses internal ADC to compare the output

channel voltage with respect to pre-set threshold V(ADCSHORTTH).

Setting the register CONF_SSSTART to 1 starts the diagnostics immediately. The CONF_SSSTART returns to 0

in the next clock cycle. Once the diagnostics starts, the on-demand diagnostics ready flag FLAG_ODREADY are

cleared to 0. Once the diagnostics finished, the FLAG_ODREADY are set to 1.

In off-state single-LED short-circuit diagnostics, once the master controller initiates single-LED short-circuit

diagnostics by setting the register CONF_SSSTART, the device sequentially turns on all outputs starting from

OUT0 with DC current I(ODIOUT) programed by register CONF_ODIOUT and pulse width T(ODPW) programmable

by CONF_ODPW. At the end of pulse, the device initiates an AD conversion. As long as the completion of ADC

conversion, the result are compared with pre-set threshold V(ADCSHORTTH) and start the diagnostics for the next

channel. After all channels have been checked, the TPS929120-Q1 also checks if the supply voltage is over

V(ADCLOWSUPTH) to make sure the device is not in low-dropout conditions. If the supply voltage is truly lower than

V(ADCLOWSUPTH), the single-LED short-circuit fault cannot be detected and reported. If the supply voltage is high

enough, and any one channel output voltage is less than pre-set threshold V(ADCSHORTTH), the TPS92910-Q1

pulls the ERR pin down with pulsed current sink for 50 µs to report fault and set the flag register including

FLAG_ODDIAGCHx, FLAG_OUT and FLAG_ERR to 1. The master controller must write 1 to CLR_FAULT

register to clear the fault flags after fault removal is verified by another on-demand off-state single-LED shortcircuit diagnostic.

The configurable DC current I(ODIOUT) and pulse width T(ODPW) can be used to minimize the optical impact during

on-demand diagnostics. TI recommends using the normal current setting and short pulse-width to avoid visible

pulse; however, the parasitic capacitance impact at each output must taken care of to leave enough charging

time and avoid false alarm. Low DC current setting also reduces LED forward voltage, which also affects the

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: TPS929120-Q1

25

�TPS929120-Q1

www.ti.com

SLVSE03B – APRIL 2019 – REVISED FEBRUARY 2021

integrity of the detection. Thus the threshold set by CONF_ADCSHORTTH must be selected carefully. Setting

CONF_ODIOUT to 0xFh uses the channel current setting by register CONF_IOUTx as on-demand pulse current.

The V(ADCSHORTTH) can be calculated with Equation 7.

V(ADCSHORTTH)

a k u CONF _ ADCSHORTTH

(7)

where

•

•

•

a = 0.0673 V

k = 0.0804 V/LSB

CONF_ADCSHORTTH is decimal number from 0 to 255.

Single-LED Shortcircuit diagnostic

ADC

IDLE

OUT0

Conversion

IDLE

OUT1

Conversion

OUT11

Conversion

SUPPLY

Conversion

IDLE

Single-LED

short-circuit

detected

OUT0

T(ODPW)

OUT1

Single-LED

Short-circuit

OUT11

Figure 7-5. Single-LED Short-Circuit Off-state Timing Sequence

7.3.5.11 Automatic Single-LED Short-Circuit (AutoSS) Detection in Normal State

In order to check LED single-LED short-circuit issue during lighting up, the TPS929120-Q1 also provides

automatically single-LED short-circuit (AutoSS) diagnostic. Setting the register CONF_AUTOSS to 1 enables the