Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

Reference

Design

UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

UCC28250 Advanced PWM Controller With Prebias Operation

1 Features

3 Description

•

•

The UCC28250 PWM controller is designed for high

power density applications that may have stringent

prebiased start-up requirements. The integrated

synchronous rectifier control outputs target highefficiency and high-performance topologies such as

half-bridge, full-bridge, interleaved forward, and pushpull. The UCC27200 half-bridge drivers and

UCC2732X MOSFET drivers used in conjunction with

the UCC28250 provide a complete power converter

solution.

1

•

•

•

•

•

•

•

Prebiased Start-up

Synchronous Rectifier Control Outputs With

Programmable Delays (Including Zero Delay

Support)

Voltage Mode Control With Input Voltage FeedForward or Current Mode Control

Primary or Secondary-Side Control

3.3-V, 1.5% Accurate Reference Output

1-MHz Capable Switching Frequency

1% Accurate Cycle-by-Cycle Overcurrent

Protection with Matched Duty Cycle Outputs

Programmable Soft-Start and Hiccup Restart

Timer

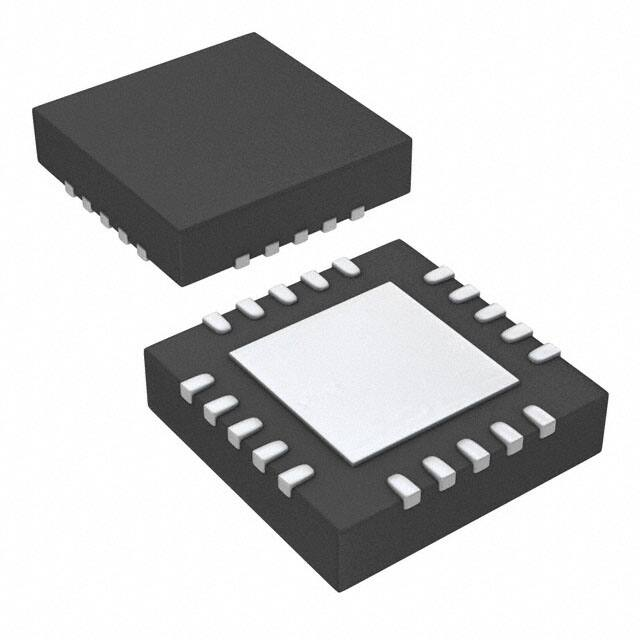

Thermally Enhanced 4-mm × 4-mm QFN-20

Package and 20-pin TSSOP Package

Externally

programmable

soft-start,

used

in

conjunction with an internal prebiased start-up circuit,

allows the controller to gradually reach a steady-state

operating point under all output conditions. The

UCC28250 can be configured for primary or

secondary-side control and either voltage or current

mode control can be implemented.

The oscillator operates at frequencies up to 2 MHz,

and can be synchronized to an external clock. Input

voltage feedforward, cycle-by-cycle current limit, and

a programmable hiccup timer allow the system to

stay within a safe operation range. Input voltage,

output voltage and temperature protection can be

implemented. Dead time between primary-side switch

and secondary-side synchronous rectifiers can be

independently programmed.

2 Applications

•

•

•

•

•

Half-Bridge, Full-Bridge, Interleaved Forward, and

Push-Pull Isolated Converters

Telecom and Data-com Power

Wireless Base Station Power

Server Power

Industrial Power Systems

Device Information(1)

PART NUMBER

UCC28250

PACKAGE

BODY SIZE (NOM)

TSSOP (20)

6.50 mm × 4.40 mm

VQFN (20)

4.00 mm × 3.50 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Simplified Application Diagram

VIN (36 V ~ 75 V)

VIN (36 V ~ 75 V)

UCC28250

UCC27200

OVP

OUTA

HI

HI

RAMP

OUTB

LO

LO

RT

SRA

SS

SRB

Isolation

COMP

VOUT

UCC2732x

Feedback and Isolation

GND

Not Shown: PS, SP, HICC, VDD, EA+, EA-, VREF, EN, ILIM, AND VSENSE

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

4

5

7

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description ............................................ 11

7.1 Overview ................................................................. 11

7.2 Functional Block Diagram ....................................... 12

7.3 Feature Description................................................. 12

7.4 Device Functional Modes........................................ 28

8

Applications and Implementation ...................... 29

8.1 Application Information............................................ 29

8.2 Typical Applications ................................................ 36

9 Power Supply Recommendations...................... 45

10 Layout................................................................... 45

10.1 Layout Guidelines ................................................. 45

10.2 Layout Example .................................................... 46

10.3 Thermal Protection................................................ 46

11 Device and Documentation Support ................. 47

11.1

11.2

11.3

11.4

11.5

Documentation Support ........................................

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

47

47

47

47

47

12 Mechanical, Packaging, and Orderable

Information ........................................................... 47

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision C (July 2011) to Revision D

•

Page

Added ESD Ratings table, Feature Description section, Device Functional Modes, Application and Implementation

section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and

Mechanical, Packaging, and Orderable Information section ................................................................................................. 1

Changes from Revision B (October 2010) to Revision C

Page

•

Changed Operating junction temperature range from (-40 to 125) to (125 to 150). .............................................................. 4

•

Changed Functional Block Diagram ..................................................................................................................................... 12

Changes from Revision A (April, 2010) to Revision B

•

2

Page

Added note, "The minimum value for RPS/RSP is 5 kΩ and the maximum value is 250 kΩ." in two places. ........................ 17

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

5 Pin Configuration and Functions

RGB Package

20-Pin VQFN

Top View

PW Package

20-Pin TSSOP

Top View

RT

VSENSE

SS

SP

PS

15

14

13

12

11

RAMP/CS 16

VSENSE

1

20 SS

RT

2

19 SP

RAMP/CS

3

18 PS

ILIM

4

17 HICC

EN

5

16 OUTA

OVP/OTP

6

15 OUTB

VREF

7

14 SRA

REF/EA+

8

13 SRB

FB/EA-

9

12 VDD

COMP 10

11 GND

10 HICC

ILIM 17

9

OUTA

EN 18

8

OUTB

OVP/OTP 19

7

SRA

VREF 20

6

SRB

1

2

3

REF/EA+ FB/EA- COMP

4

5

GND

VDD

Pin Functions

PIN

I/O

DESCRIPTION

NAME

QFN

PW

COMP

3

10

I/O

EN

18

5

I

Device enable and disable

FB/EA-

2

9

I

Error amplifier inverting input

GND

4

11

I

Ground

HICC

10

17

I

Cycle-by-cycle current limit time delay and Hiccup time setting

ILIM

17

4

I

Current sense for cycle-by-cycle overcurrent protection

OUTA

9

16

O

0.2-A sink/source primary switching output

OUTB

8

15

O

0.2-A sink/source primary switching output

OVP/OTP

19

6

I

Overvoltage and overtemperature protection pin

PS

11

18

I

Primary off to synchronous rectifier on dead-time set

RAMP/CS

16

3

I

PWM ramp input (for voltage mode control) or current sense input (for current

mode control)

REF/EA+

1

8

I

Error amplifier noninverting input

RT

15

2

I

Oscillator frequency set or synchronous clock input

SP

12

19

I

Synchronous rectifier off to primary on dead-time set

SRA

7

14

O

0.2-A sink/source synchronous rectifier output

SRB

6

13

O

0.2-A sink/source synchronous rectifier output

SS

13

20

I/O

Soft-start programming

VDD

5

12

I

Bias supply input

VREF

20

7

O

3.3-V reference output

VSENSE

14

1

I

Output voltage sensing for prebias control

Error amplifier output

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

3

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (1) (2) (unless otherwise noted)

VDD (3)

Tstg

(1)

(2)

(3)

MIN

MAX

UNIT

Input supply voltage

–0.3

20

V

OUTA, OUTB, SRA and SRB

–0.3

VDD + 0.3

V

COMP

–0.3

VREF + 0.3

V

Input voltages on SS and EN

–0.3

5.5

V

Input voltages on RT, PS, SP, ILIM, OVP, HICC, VSENSE, EA+ and EA-

–0.3

3.6

V

Input voltage on RAMP/CS

–0.3

4.3

V

Output voltage on VREF

–0.3

3.6

V

Lead temperature (soldering 10 sec) PW package

300

Storage temperature

–65

°C

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

These devices are sensitive to electrostatic discharge; follow proper device handling procedures.

All voltages are with respect to GND unless otherwise noted. Currents are positive into, negative out of the specified terminal. See

Mechanical, Packaging, and Orderable Information of the data sheet for thermal limitations and considerations of packages.

6.2 ESD Ratings

VALUE

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

V(ESD)

(1)

(2)

Electrostatic discharge

(1)

UNIT

±3000

Charged-device model (CDM), per JEDEC specification JESD22C101 (2)

V

±2000

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

NOM

MAX

4.7

12

17

Supply voltage, VDD

Supply bypass capacitor, CVDD

1

VREF bypass capacitor

Error amplifier input common-mode (REF/EA+, FB/EA-)

VSENSE input voltage

RT resistor

UNIT

V

µF

0.5

2

µF

0

3

V

0

3.3

V

12.5

200

kΩ

5

250

kΩ

PS, SP resistor

RAMP/CS voltage

Operating junction temperature

0

2.7

V

–40

150

°C

6.4 Thermal Information

UCC28250

THERMAL METRIC

RθJA

Junction-to-ambient thermal resistance

RθJC(top)

Junction-to-case(top) thermal resistance

RθJB

Junction-to-board thermal resistance

RθJC(bot)

Junction-to-case(bottom) thermal resistance

4

RGB (VQFN)

PW (TSSOP)

20 PINS

20 PINS

126 with hot spot,

104 without hot spot

60.3 with hot spot,

39.3 without hot spot

°C/W

31.5

°C/W

55.8

°C/W

Submit Documentation Feedback

0.8

UNIT

°C/W

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

6.5 Electrical Characteristics

VDD = 12 V, 1-µF capacitor from VDD and VREF to GND, TA = TJ = –40°C to 125°C, RT = 75 kΩ connected to ground to set

FSW = 200 kHz (unless otherwise noted). (1)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

SUPPLY CURRENTS

IDD(off)

Start-up current

VDD = 3.6 V

IDD

Operating supply current

100-pF capacitor on OUTA, OUTB, SRA and SRB

IDD(dis)

Standby current

EN = 0 V

150

275

µA

2

2.7

3.4

mA

250

425

600

µA

4

4.3

4.6

V

3.8

4.1

4.4

V

0.15

0.2

0.25

V

25

27

29

µA

3.3

3.6

4

V

2.25

V

UNDERVOLTAGE LOCKOUT

VUVLOR

Start threshold

VUVLOF

Minimum operating voltage

after start

Hysteresis

SOFT START

ISS

Soft-start charge current

VSS(max)

Clamp voltage

VSS = 0 V

ENABLE (2)

Trigger threshold

Minimum pulse width for

pulse enable

3

µs

ERROR AMPLIFIER

High-level COMP voltage

2.8

Low-level COMP voltage

3

0.3

Input offset

-12

Open loop gain

V

0.4

V

12

mV

70

100

ICOMP(snk)

COMP sink current

3

6.5

9

mA

dB

ICOMP(src)

COMP source current

2

4.5

8

mA

185

200

215

kHz

OSCILLATOR

FSW(nom)

Nominal switching frequency

at OUTA or OUTB set by RT

resistor

FSW(min_sync)

Minimum switching frequency

at OUTA or OUTB set by

fRT/SYNC = 100 kHz

external sync frequency

FSW(max_sync)

Maximum switching

frequency at OUTA or OUTB

set by external sync

frequency

RT/SYNC = 75 kΩ, RSP = 20 kΩ

fRT/SYNC = 2.5 MHz

External synchronization

signal high

85

kHz

1.15

MHz

1

V

External synchronization

signal low

0.2

V

VOLTAGE REFERENCE

VVREF

Output voltage

Short circuit current

(1)

(2)

VDD = from 7 V to 17 V, IVREF = 2 mA

3.22

3.3

3.38

0 < IREF < 10 mA

3.22

3.3

3.38

12

25

40

VREF = 3 V, TJ = 25°C

V

mA

Typical values for TA = 25°C.

Refer to EN pin description in .

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

5

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Electrical Characteristics (continued)

VDD = 12 V, 1-µF capacitor from VDD and VREF to GND, TA = TJ = –40°C to 125°C, RT = 75 kΩ connected to ground to set

FSW = 200 kHz (unless otherwise noted). (1)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

0.495

0.502

0.509

V

15

25

36

ns

40

60

90

ns

CURRENT SENSE, CYCLE-BY-CYCLE CURRENT LIMIT WITH HICCUP

VILIM

ILIM cycle-by-cycle threshold

TPDILIM

Propagation delay from ILIM

to OUTA and OUTB outputs

TBLANK

leading edge blanking

Current limit shutdown delay

timing program current

Measured at HICC pin

55

75

95

µA

Hiccup timing program

current

Measured at HICC pin

2

2.7

3.5

µA

0.55

0.6

0.65

V

2.3

2.4

2.5

V

0.25

0.3

0.35

V

3.5

4

4.5

V

0.66

0.7

0.74

V

8.5

11

13.5

µA

VHICC_SD

Current limit shutdown delay

timer threshold at HICC

VHICC_PU

HICC pullup threshold

VHICC_RST

Hiccup restart threshold

VCS(max)

Exclude leading edge blanking

RAMP/CS clamp voltage

10-V ramp charging voltage source with 40-kΩ

current limiting resistor

OVP/OTP COMPARATOR

VOVP

Internal reference

IOVP

Internal current

PRIMARY OUTPUTS

Rise/fall time

CLOAD = 100 pF

RSRC

Output source resistance

IOUT = 20 mA

12

20

8

35

ns

Ω

RSNK

Output sink resistance

IOUT = 20 mA

4

12

30

Ω

IOUT = 20 mA, VDD = 12 V

12

20

35

IOUT = 20 mA, VDD = 5 V

15

25

45

SYNCHRONOUS RECTIFIER OUTPUTS

Rise/fall time

RSRC

Output source resistance

RSNK

Output sink resistance

TDPS

TDSP

6

Primary off to secondary on

dead time

Secondary off to primary on

dead time

CLOAD = 100 pF

IOUT = 20 mA, VDD = 12 V

8

ns

4

12

30

PS = VREF

-5

0

7.5

PS = 27 kΩ

27

40

50

PS = 27 kΩ, 25°C

37

40

43

SP = VREF

-5

0

7.5

SP = 20 kΩ

30

40

50

SP = 20 kΩ, 25°C

37

40

43

Submit Documentation Feedback

Ω

Ω

ns

ns

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

6.6 Typical Characteristics

240

465

VDD = 3.6 V

VDD = 12 V

450

IDD(dis) - Stand-by Current - mA

IDD(off) - Start-Up Current - mA

220

200

180

160

140

420

405

390

120

100

375

-45

-15

15

45

75

135

105

-45

-15

15

45

75

105

135

TJ - Temperature - °C

TJ - Temperature - °C

Figure 1. Start-up Current vs

Temperature

Figure 2. Stand-by Current vs Temperature

4.41

UVLO - Under Voltage Lockout Hysteresis - V

0.225

4.33

Turn On

UVLO Thresholds - V

435

4.25

4.17

Turn Off

4.09

4.01

3.93

0.220

0.215

0.210

0.205

0.200

0.195

0.190

-45

-15

15

45

75

105

135

-45

-15

TJ - Temperature - °C

15

45

75

105

135

TJ - Temperature - °C

Figure 3. UVLO Thresholds vs

Temperature

Figure 4. UVLO Voltage Lockout Hysteresis

2.85

27.4

27.3

2.80

ISS - Soft-Start Current - mA

IDD - Operating Supply Current - mA

FSW = 200 kHz

2.75

2.70

2.65

27.2

27.1

27.0

26.9

2.60

26.8

-45

-15

15

45

75

105

135

-45

TJ - Temperature - °C

-15

15

45

75

105

135

TJ - Temperature - °C

Figure 5. Operating Supply Current vs

Temperature

Figure 6. Soft-start Current vs Temperature

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

7

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Typical Characteristics (continued)

5.0

500.4

500.2

500.0

499.8

499.6

499.4

-45

-15

15

75

45

105

135

VHICC_PU / VCS(max) - RAMP/CS Clamp Voltage and Hiccup

Pull-Up Threshold - V

IILIM - Cycle-by-Cycle Current Limit Threshold - mV

500.6

4.5

4.0

VCS(max)

3.5

3.0

2.5

VHICC_PU

2.0

1.5

-45

-15

TBLANK

50

TPD_ILIM

10

-45

-15

15

75

45

105

135

105

135

Figure 8. RAMP/CS Clamp Voltage and Hiccup Pullup

Threshold vs Temperature

VHICC_SD / VHICC_RST - Current Limit Shutdown Delay Timer

and Hiccup Restart - V

TPD_ILIM / TBLANK - Propagation Delay from ILIM to Outputs

and Leading Edge Blanking - ns

90

30

75

TJ - Temperature - °C

Figure 7. Cycle-by-Cycle Current Limit vs Temperature

70

45

15

TJ - Temperature - °C

0.7

0.6

VHICC_SD

0.5

0.4

VHICC_RST

0.3

0.2

-15

-45

45

15

TJ - Temperature - °C

75

105

135

TJ - Temperature - °C

Figure 9. Propagation Delay and Leading Edge Blanking vs

Temperature

Figure 10. Current Limit Shutdown Delay Timer and Hiccup

Restart vs Temperature

3.306

VDD = 12 V

ILOAD = 1 mA

3.305

3.295

3.302

VREF - Reference Voltage - V

VREF - Reference Voltage - V

ILOAD = 10 mA

ILOAD = 1 mA

ILOAD = 10 mA

3.285

3.275

VDD = 7 V

3.298

VDD = 17 V

3.290

-55

-35

-15

5

25

45

65

85

105

125

-55

TJ - Temperature - °C

-35

-15

5

25

45

65

85

105

125

TJ - Temperature - °C

Figure 11. Reference Voltage vs Temperature

8

VDD = 12 V

3.294

Figure 12. Reference Voltage vs Temperature

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Typical Characteristics (continued)

11.20

0.7015

11.15

IOVP - OVP Internal Currente - mA

VOVP - OVP Internal Reference - V

0.7010

0.7005

0.7000

0.6995

0.6990

11.10

11.05

11.00

10.95

10.90

10.85

-45

-15

15

45

75

105

135

-45

-15

TJ - Temperature - °C

Figure 13. OVP Internal Reference vs Temperature

75

105

135

1.153

85.2

85.0

84.8

84.6

84.4

84.2

84.0

-45

-15

15

45

75

105

135

FSYN(max) - Maximum Synchronization Frequency - MHz

FSYN(min) - Minimum Synchronization - kHz

45

Figure 14. OVP Internal Current vs Temperature

85.4

1.151

1.149

1.147

1.145

1.143

-45

-15

TJ - Temperature - °C

15

45

75

105

135

TJ - Temperature - °C

Figure 15. Minimum Synchronization Frequency vs

Temperature

Figure 16. Maximum Synchronization Frequency vs

Temperature

201.0

42.5

42.0

200.6

TDPS at RPS = 27 kW

41.5

TDSP/TDPS - Dead Time- ns

FSW(nom) - Nominal Switching Frequency - kHz

15

TJ - Temperature - °C

200.2

199.8

199.4

41.0

40.5

40.0

TDSP at RSP = 20 kW

39.5

39.0

38.5

199.0

38.0

-45

-15

15

45

75

105

135

TJ - Temperature - °C

-45

-15

15

45

75

105

135

TJ - Temperature - °C

Figure 17. Nominal Switching Frequency vs Temperature

Figure 18. Dead Time vs Temperature

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

9

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

12

VDD = 12 V

TR / TF - Output Rise/Fall Time - ns

11

TR

10

9

TF

8

7

6

-45

-15

15

45

75

105

135

RSRC / RSNK - Output Source Resistance/Sink Resistance - W

Typical Characteristics (continued)

TJ - Temperature - °C

30

RSRC

25

RSNK

20

15

10

-45

-15

15

45

75

105

135

TJ - Temperature - °C

Figure 19. Output Rise/Fall Time vs Temperature

10

35

Figure 20. Output Source Resistance/Sink Resistance vs

Temperature

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

7 Detailed Description

7.1 Overview

The UCC28250 is a high-performance PWM controller with advanced synchronous rectifier outputs and is ideally

suited for regulated half-bridge, full-bridge and push-pull converters. A dedicated internal prebiased start-up

control loop working in conjunction with a primary-side voltage loop achieves prebiased start-up for either

primary-side or secondary-side control applications. The UCC28250 architecture allows either voltage mode or

current mode control.

Input voltage feedforward can be implemented, allowing PWM ramp generator to improve the converter line

transient response. Advanced cycle-by-cycle current limit achieves volt-second balancing even during fault

conditions. The hiccup timer helps the system to stay within a safe operation range under over load conditions.

With a multifunction OVP/OTP pin, combinations of input voltage protection, output voltage protection and

overtemperature protection can be implemented. The UCC28250 allows individual programming of dead time

between primary-side switch and secondary-side SRs, to allow optimal power stage design. Dead time can also

be reduced to zero, and this allows optimal system configuration considering the delays on the gate driver stage.

The UCC28250 also provides complete system level protection functions, including UVLO, thermal shut down

and overvoltage, overcurrent protection.

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

11

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Over

temperature

OUTB

SRA

SRB

9

8

7

6

OTP

+

4.1V/4.3V

OUTA

7.2 Functional Block Diagram

UVLO

VDD 5

Vref OK

COMP

2

FB/EA-

1

REF/EA+

13

SS

16

RAMP/CS

14

VSENSE

4

GND

EN_INT

Switching Logic

LDO

OP

+

+

OCP

VREF 20

3

Vref ready

+

Enable detection

Level&pulse

EN 18

+

Cycle by cycle

current limit

& duty cycle match

+

0.5V

BLANK

SR_RAMP

ILIM 17

Enable

OCP delay

timer

550mV

HICC 10

SR_RAMP

generator

gm

+

+

11uA

Hiccup

timer

OVP/OTP 19

+

0.7V

OVP

RT 15

CLK

Oscillator

SP 12

PS 11

70ns

leading edge blanking

BLANK

Deadtime

NOTE: Pin numbers are used for RGP package. PW package has different pin numbers.

7.3 Feature Description

7.3.1 VDD (5/12)

The UCC28250 can be powered up by a wide supply range from 4.3 V (UVLO rising typical) to 20 V (absolute

maximum), making it suitable for primary-side control or secondary-side control. When the voltage at the VDD

pin is lower than 4.1 V (typical), the controller is in stand-by mode and consumes 150 µA (typical) at 3.6 V VDD.

In stand-by mode, VREF continues to be regulated to 3.3 V or follows VDD if VDD is lower than 3.3 V. Refer to

the VREF description VREF (Reference Generator) (20/7) for more detailed information. A minimum 1-µF bypass

capacitor is required from VDD to ground. Keep the bypass capacitor as close to the device as possible.

7.3.2 VREF (Reference Generator) (20/7)

The VREF pin is regulated at 3.3 V. An external ceramic capacitor must be placed as close as possible to the

VREF and GND pins for noise filtering and to provide compensation to the regulator. The capacitance range

must be limited from 0.5 µF to 2 µF for stability. This reference is used to power the controller’s internal circuits,

and can also be used to bias an opto-coupler transistor, an external house-keeping microcontroller, or other

peripheral circuits. This reference can also be used to generate the reference for an external error amplifier. This

regulator output is internally current limited to 25 mA (typical).

12

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Feature Description (continued)

7.3.3 EN (Enable Pin) (18/5)

The following conditions must be met before the controller allows start-up:

1. VDD voltage is above the rising UVLO threshold 4.3 V (typical).

2. The 3.3-V reference voltage output at the VREF pin is available and above 2.4 V (typical).

3. Junction temperature is below the thermal shutdown threshold 130°C (minimum).

4. The voltage at OVP is below 0.7 V (typical).

If all these conditions are met, the signal driving the EN pin is able to initiate the soft start process. When the

device is enabled, the 27-µA internal charging current at the SS pin is turned on and begins to charge the softstart capacitor. The EN pin can accept both level-enable and pulse-enable signals.

For level-enable, the voltage level on the EN pin must be continuously higher than 2.25 V to allow continuous

operation. When the EN pin falls below 2.25 V, the device is disabled (see Figure 21).

UVLO

EN

0.3V

SS

CLK

Figure 21. Level Enable at EN pin

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

13

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

A pulse signal may also be applied to the EN pin. Pulse-enable operation is shown on Figure 22. As long as the

EN falling edge happens before the SS voltage reaches 0.3 V, the enable signal at EN pin is considered as a

pulse. In this case, the next rising edge at EN pin disables the controller. As long as the falling edge of the first

pulse at EN pin happens after SS rises to 0.3 V, the UCC28250 interprets the pulse enable as a level enable,

and an external solution as shown on Figure 23 (a) can be used to reduce the pulse width. In this circuit, R2 is

used to limit the current (especially the negative current) through the internal ESD cell. Figure 23 (b) illustrates

the waveforms based on this solution. To prevent false trigger by noises, the pulse at the EN pin must be at least

2.25 V (minimum) high and 3 µs wide to be considered valid.

Choose the R1, R2, and C values based on the following equations:

Choose R2 based on the current limit requirement from the device.

R2 > 10kW

(1)

Choose R1 arbitrarily but much smaller than R2 and choose C1 according to the time constant requirement to

generate longer than 3-µs pulse.

C1 =

6 ms

R1

(2)

In the case that the UCC28250 is enabled with a level EN signal and the SS is discharged internally when the

OCP is triggered, pulling the EN pin down before SS rises to 0.3 V cannot disable the part because the controller

interprets it to be a pulse enable. In this case, the next rising edge at the EN pin disables the controller. If the

designer wants to disable UCC28250 with a level signal during an over current condition, the recommended

solution is to pull down the SS pin rather than the EN pin. If the enable function is not used, pull the EN pin to the

VREF pin.

UVLO

EN

SS

0.3V

CLK

Figure 22. Pulse Enable at EN Pin

(a)

(b)

UCC28250

Enable

Signal

C1

R2

EN

Enable

Signal

R1

EN

Figure 23. An External Solution to Generate Enable Pulses for Pulse Enable

14

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Feature Description (continued)

7.3.4 RT (Oscillator Frequency Set and Synchronization) (15/2)

The UCC28250 oscillator frequency is set by an external resistor connected between the RT pin and ground.

Switching frequency selection is a trade-off between efficiency and component size. Based on the selected

switching frequency, the programming resistor value can be calculated as:

1

- Td(SP )

2 ´ fSW

RT =

33.2pF

(3)

In this equation, fSW is the switching frequency and TD(sp) is the dead time between synchronous rectifier turnoff

to primary switch turnon. TD(sp) is set by an external resistor between the SP pin and ground (refer to SP

(Synchronous Rectifier Turnoff to Primary Output Turnon Dead Time Programming) (13/19)).

Each output (OUTA, OUTB, SRA, SRB) switches at half the oscillator frequency (fSW = ½ x fOSC). Figure 24

shows the relationship between RT and fOSC at certain TD(sp) and can be used to program oscillator frequency

accordingly.

OSCILLATOR FREQUENCY

vs

RT RESISTOR

2000

TD(ps) = 40 ns

1800

FOSC - Oscillator Frequency - kHz

1600

1400

1200

1000

800

600

400

TD(ps) = 100 ns

200

0

0

20

40

60

80

100 120 140 160 180 200

RT Resistor - kW

Figure 24. Oscillator Frequency FOSC vs External Resistance of RT at TD(ps) = 40 ns and 100 ns

The UCC28250 can be synchronized to an external clock by applying an external clock source to the RT pin.

Synchronization helps with parallel operation and/or preventing beat frequency noise. The UCC28250

synchronizes its internal oscillator to an external frequency source ranging from 170 kHz to 2.3 MHz, which is

equivalent to an 85-kHz to 1.15-MHz switching frequency. The internal oscillator frequency is clamped to 170

kHz during synchronization if the external source frequency drops below 170 kHz.

The UCC28250 aligns the turnon of primary outputs OUTA and OUTB to the falling edge of the synchronizing

signal, as shown in Figure 25. If the frequency source is from the gate outputs of another half bridge controller,

interleaving can be achieved. The interleaving angle is determined by the frequency source’s duty cycle. When a

50% duty cycle is applied, optimal interleaving is achieved, and EMI filters can be minimized.

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

15

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

Frequency

Source

OUTA

OUTB

Figure 25. Timing Diagram for Synchronization

CLK

OUTA

SRA

Td(SP)

Td(PS)

OUTB

SRB

Td(SP)

Td(PS)

Figure 26. UCC28250 Outputs Timing Waveforms

16

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Feature Description (continued)

7.3.5 SP (Synchronous Rectifier Turnoff to Primary Output Turnon Dead Time Programming) (13/19)

The dead time TD(sp) between synchronous rectifier turnoff to primary output turnon is programmed by an

external resistor, RSP, connected between the SP pin and ground. The value of RSP can be determined by

Figure 27. Zero dead time can be achieved by tying the SP pin to VREF. The falling edge of synchronous

rectifier SRA/SRB is aligned with the raising edge of the primary output OUTA/OUTB.

NOTE

The minimum value for RPS/RSP is 5 kΩ and the maximum value is 250 kΩ.

SP DEAD TIME

vs

SP RESISTOR

400

350

DSP - SP Dead Time - ns

300

250

200

150

100

50

0

0

20 40 60 80 100 120 140 160 180 200 220 240

RSP - SP Resistor - kW

Figure 27. Dead Time TD(sp) vs. External Resistor RSP at SP Pin

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

17

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

7.3.6 PS (Primary Output Turnoff to Synchronous Rectifier Turnon Dead Time Programming) (11/18)

The dead time TD(ps) between primary output turnoff to synchronous rectifier turnon is set by external resistor,

RPS, connected between PS pin and ground. The value of is RPS is defined by Figure 28. Zero dead time can be

achieved by tying the SP pin to VREF.

NOTE

The minimum value for RPS/RSP is 5 kΩ and the maximum value is 250 kΩ.

PS DEAD TIME

vs

PS RESISTOR

400

350

DPS - PS Dead Time - ns

300

250

200

150

100

50

0

0

20 40 60 80 100 120 140 160 180 200 220 240

RPS - PS Resistor - kW

Figure 28. Dead Time TD(ps) vs. External Resistor RPS at PS Pin

18

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Feature Description (continued)

7.3.7 RAMP/CS (PWM Ramp Input or Current Sense Input) (16/3)

The UCC28250 can be controlled using either voltage mode or current mode. RAMP/CS is a multi-function pin

used either to generate the ramp signal for voltage mode control or to sense current for current mode control.The

following sections describe the RAMP/CS functionality for voltage mode and current mode control.

7.3.7.1 RAMP: Voltage Mode Control With Feed-Forward Operation

For voltage mode control, a resistor RCS and a capacitor CCS must be connected to the RAMP/CS pin as shown

in Figure 29. The internal pulldown switch has approximately 40-Ω on-resistance. The RAMP/CS pin is clamped

internally to 4 V for internal device protection. The CCS value must be small enough to discharge the RAMP/CS

pin from its peak voltage to ground within the pulse width of the BLANK signal (TD(sp) + 70 ns). The following

formula derives a CCS value.

æ 4 V / 2 ö Td(SP) + 70ns

CCS < ç

÷´

4V

è 40 W ø

(4)

A CCS value less than 650 pF works for most applications. To minimize the impacts of parasitic capacitance

caused by the PCB layout and routing, a minimum of 100 pF is recommended for CCS. Once CCS is determined,

RCS can be calculated according to the desired ramp peak amplitude.

RCS =

1

æ VCHARGE

ö

2 ´ ln ç

÷ ´ CCS ´ fSW

è VCHARGE - VPK ø

(5)

In this equation, the VCHARGE is the voltage used to generate the ramp, VPK is the desired ramp amplitude and

the fSW is the switching frequency.

Choose the ramp amplitude to accommodate the voltage range of the COMP pin and the maximum duty cycle

required by the power stage. Use the following equation to select VPK, in the equation, DMAX is the maximum duty

cycle for primary outputs.

VPK =

1.4 V

DMAX

(6)

UCC28250

UCC28250

VIN 36 V to 75 V

VREF

RCS

RCS

RAMP/CS

CCS

RAMP/CS

BLANK

CCS

GND

BLANK

GND

Figure 29. Fixed Ramp Generation/Ramp Generation With Input Voltage Feedforward

Voltage feed-forward can be achieved by driving RCS from line input VIN. The peak of RAMP/CS is proportional

to VIN and output has have much faster line transient response. When the UCC28250 is used for the primaryside control, RAMP parameters are critical for the optimal prebiased start-up performance. Refer to the RAMP:

Voltage Mode Control With Feed-Forward Operation for a detailed design procedure of choosing RCS.

If the line input cannot be easily accessed due to limited board area or other limitation, a RAMP signal with fixed

peak voltage can be implemented by simply driving RCS from 3.3-V VREF (Figure 29).

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

19

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

7.3.7.2 CS: Current Mode Control

For current mode control, the RAMP/CS pin is driven by a signal representative of the transformer primary-side

current. The current signal must have compatible input range of the COMP pin. As shown in Figure 30, the

COMP pin voltage is used as the reference for peak current. The primary-side signals OUTA and OUTB are

turned on by the internal clock signal and turned off when sensed peak current reaches the COMP pin voltage.

Choose the current sense transformer turns ratio (1:n) and the burden resistor value (RB) based on the peak

current at maximum load IMAX.

RB =

3V

IMAX / n

(7)

COMP

CS

OUTA

OUTB

Figure 30. Peak Current Mode Control and PWM Generation

7.3.8 REF/EA+ (1/8)

REF/EA+ is the noninverting input of the UCC28250’s internal error amplifier.

When the UCC28250 is configured for secondary-side control, the internal error amplifier is used as the control

loop error amplifier. Connect REF/EA+ directly to the VREF pin to provide the reference voltage for the feedback

loop.

When the UCC28250 is configured for primary-side control, the error amplifier is connected as a voltage follower.

Connect REF/EA+ to the opto-coupler output.

The voltage range on REF/EA+ pin is 0 V to 3.7 V.

20

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Feature Description (continued)

7.3.9 FB/EA- (2/9)

FB/EA- is the inverting input of the UCC28250’s internal error amplifier.

When the UCC28250 is configured for secondary-side control, connect the output voltage sensing divider to this

pin. The voltage divider can be selected according to the voltage on REF/EA+ pin. Referring to Figure 32, pick

the lower resistor RO1 value arbitrarily, and choose the upper resistor RO2 value as:

æ VO

ö

RO2 = ç

- 1÷ ´ RO1

è VREF / EA +

ø

(8)

Because the control loop gain is affected by voltage divider resistor values, choose an appropriate RO1 value so

that the voltage loop DC gain is larger than 40 dB to prevent interference between the primary-side control loop

and the SR control loop during start-up.

When the UCC28250 is sitting on the primary side, the error amplifier is connected as a voltage follower.

Connect FB/EA- directly with COMP pin.

The maximum voltage allowed on FB/EA- pin is 3.7 V.

7.3.10 COMP (3/10)

The COMP pin is the internal error amplifier’s output and also the input signal for PWM comparator. The

maximum input common voltage of the PWM comparator is 2.8 V. It is suggested to program the peak value of

RAMP to be lower than 2.3 V. Otherwise, the voltage of COMP pin should be clamped to be lower than 2.8 V by

external circuit to make the internal PWM comparator work properly. Figure 31 shows tan external circuit that is

recommended for voltage clamp function. Both the primary-side switches’ duty cycle and secondary-side SRs’

duty cycle is controlled by the COMP pin voltage. At steady state, a higher COMP pin voltage results in a larger

duty cycle for the primary-side switches and a smaller duty cycle on the SRs.

When the UCC28250 controller is set up for secondary-side control, connect the compensation network from the

FB/EA- pin to the COMP pin.

For primary-side control, the error amplifier is connected as a voltage follower. Directly connect the COMP pin to

the FB/EA- pin.

UCC28250

REF

R CS

COMP

C CS

GND

Figure 31. Comp Clamp Circuit

7.3.11 VSENSE (14/1)

The VSENSE pin is used to directly sense the output voltage and to feed it into a transconductance error

amplifier. The measured voltage allows the UCC28250 to achieve optimal prebiased start-up performance.

When configured as a secondary-side controller, the output voltage is sensed and fed into the FB/EA- pin. The

UCC28250 uses a conventional error amplifier approach to allow type III compensation. Therefore, the FB/EApin voltage always follows the REF/EA+ voltage. The FB/EA- pin does not reflect the true output voltage and

therefore this dedicated VSENSE pin is required. The voltage divider connected to VSENSE is discussed in the

Prebiased Start-Up Section.

When UCC28250 is set up as primary-side control, connect VSENSE pin to VREF.

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

21

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

7.3.12 SS (Soft Start Programming Pin) (13/20)

The soft-start circuit gradually increases the converter’s output voltage until steady state operation is reached.

This reduces start-up stresses and current surge.

When the UCC28250 reaches its valid operating threshold, the SS pin capacitor is charged with a 27-µA current

source. The UCC28250’s internal error amplifier noninverting terminal follows the SS pin voltage on REF/EA+ pin

voltage depending on which one is lower. Hence, during soft start, the SS pin voltage is lower than REF/EA+.

The internal error amplifier then uses the SS pin as its reference voltage, until the SS pin voltage rises above the

REF/EA+ level. Once the SS pin voltage is above REF/EA+ voltage, soft-start time is considered finished.

The soft-start implementation scheme and timing is different, depending on the location of the UCC28250 with

respect to the isolation barrier.

For secondary-side control, the internal error amplifier is used to achieve the voltage regulation. The REF/EA+ is

connected to an external reference voltage, FB/EA- is connected to the voltage sensing divider, and the error

amplifier’s output pin (COMP) is connected through a compensation filter back to the FB/EA- pin (Figure 32). In

this case, the primary output’s start-up is a closed loop soft start (soft-start input reference of error amplifier). The

output soft-start time is determined by the external capacitor connected at SS pin based on the internal 27-µA

charging current and the voltage set at REF/EA+ pin.

Based on the soft-start time TSS, choose soft start capacitor CSS value as:

CSS =

27 mA ´ TSS

VREF / EA +

(9)

VOUT

UCC28250

VSENSE

CP1

RO2

VREF

RZ3

RS2

RZ2

CZ2

COMP

CZ3

FB/EA-

REF/EA+

+

+

RS1

RO1

SS

CSS

Figure 32. Error Amplifier EAMP Connections for Secondary-Side Control

22

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Feature Description (continued)

For primary-side control, the internal error amplifier is connected as a buffer stage. In other words, the COMP pin

is shorted to the FB/EA- pin, and the output of an external error amplifier is connected to the REF/EA+ pin

through an optical coupler (Figure 33). In this case, the output start-up is an open loop soft start because the

COMP follows the soft-start voltage instead of the voltage loop output. The soft-start time is still determined by

external capacitor CSS and the 27-µA internal charge current. The voltage depends on the value of final COMP

voltage which corresponds to the regulated primary output duty cycle. According to the desired soft start time and

COMP pin voltage level at steady state, the SS pin capacitor can be calculated as:

CSS =

27 mA ´ TSS

VCOMP _ final

(10)

After soft start, the voltage at SS pin is eventually clamped at around 4 V. Under fault conditions (UVLO, internal

thermal shut down, OVP/OTP, hiccup mode), or when externally disabled, SS pin is pulled down to ground

quickly by an internal switch with 2 kΩ on resistance to prepare for re-start. Pulling SS pin to ground externally

shuts down the controller as well.

VOUT

UCC28250

RO2

CP1

VSENSE

RZ3

CZ2

RZ2

VREF

COMP

CZ3

FB/EA-

+

REF/EA+

+

+

RO1

SS

External

Reference

CSS

Figure 33. Error Amplifier EAMP Connections for Primary-Side Control

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

23

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

7.3.13 ILIM (Current Limit for Cycle-By-Cycle Overcurrent Protection) (17/4)

Cycle-by-cycle current limit is accomplished using the ILIM pin for current mode control or for voltage mode

control. The input to the ILIM pin represents the primary current information. If the voltage sensed at ILIM pin

exceeds 0.5 V, the current sense comparator terminates the pulse of output OUTA or OUTB. If the high current

condition persists, the controller operates in a cycle-by-cycle current limit mode with duty cycle determined by the

current sense comparator instead of the PWM comparator. ILIM pin is pulled down by an internal switch at the

rising edge of every clock cycle. This internal switch remains on for an additional 70 ns after OUTA or OUTB

goes high to blank leading edge transient noise in the current sensing loop. This reduces the filtering

requirements at the ILIM pin and improves the current sense response time.

Transformer Primary

Side Current

UCC28250

ILIM

CT

RS

HICC

CS

1:n

CHICC

Figure 34. Current Limit Circuit

Once the over current protection level IPK is selected, the current transformer turns ratio and the burden resistor

value can be decided as:

RS =

0.5 V ´ n

IPK

(11)

In this equation, current transformer turns ratio is 1:n and RS is the burden resistor value.

Some filtering capacitance is required to reduce the sensing noise. Choose the RC constant at about 100 ns,

and calculate the capacitor value as:

CS =

100ns

RS

(12)

The cycle-by-cycle current limit operation time before all four outputs shut down can be programmed by external

capacitor CHICC at HICC pin. (See HICC pin description)

24

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Feature Description (continued)

7.3.14 HICC (10/17)

The cycle-by-cycle current limit operation time before all four outputs shut down can be programmed by an

external capacitor CHICC from HICC pin to ground, as shown in Figure 34. Once all four outputs are shutdown,

controller goes into hiccup cycle which is about 100 times of the cycle-by-cycle current limit shut-down delay

time. A 1-mA internal current source charges HICC pin up to 2.4 V, then the HICC pin is discharged by a 2.7-µA

internal current source to generate long hiccup restart time until HICC reaches 0.3 V. Based on the system

requirement, once the cycle-by-cycle current limit delay time TOC(delay) is selected, the HICC pin capacitor CHICC

can be selected based on the equation

TOC(delay ) ´ 75 mA

CHICC =

0.6 V

(13)

TOCdealy

THICC

HICC

2.4V

0.6V

0.3V

t

SS

4V

t

OUTA

OUTB

Normal

OC

Normal

OC

Hiccup

Soft Start

Figure 35. Cycle-by-Cycle Current Limit Delay Timer and Hiccup Restart Timer

As shown in Figure 35, cycle-by-cycle current limiting shut-down delay time is:

TOC(delay ) = CHICC ´

0.6 V

75 mA

(14)

And hiccup-restart-time THICC is equal to:

THICC = CHICC ´

2.4 V - 0.3 V

2.7 mA

(15)

As soon as the outputs are shut-down, the SS pin is pulled to ground internally until the hiccup restart timer is

reset after time duration THICC.

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

25

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

7.3.15 OVP/OTP (19/6)

The OVP/OTP pin provides multiple fault protection functions. If the voltage on the OVP/OTP pin exceeds 0.7 V,

a fault shutdown occurs. All outputs stop switching and stay off (low) during the shutdown, and the SS pin is

pulled to ground internally. Once the fault condition is cleared (that is, OVP/OTP voltage drops below 0.7 V), the

UCC28250 enters hiccup mode. A soft-start cycle begins after the hiccup cycle is finished. An internal 11-µA

switched current source is used to create hysteresis.

If the external resistor divider runs from line voltage VIN, a line overvoltage protection is implemented.

If the external resistor divider runs from the output voltage, output overvoltage fault protection is achieved.

Figure 36 shows the overvoltage protection external configuration at the OVP/OTP pin.

According to the protection threshold VR and recovery threshold VF, choose an arbitrary R2 value. To ensure a

realistic solution, R2 must meet the following:

R2 <

0.7 V ´ (VR - VF )

11mA ´ (VR - 0.7 V )

(16)

The other two resistors, R1 and R3 can be calculated.

R1 =

R3 =

VR - 0.7 V

´ R2

0.7 V

0.7 V ´ (VR - VF ) - 11mA ´ R2 ´ (VR - 0.7 V )

(17)

11mA ´ VR

(18)

If the external resistor divider runs from 3.3-V VREF, and replaces R2 with a positive temperature coefficient

(PTC) thermistor, an overtemperature fault protection with programmable hysteresis is accomplished (Figure 37).

Choose an arbitrary PTC value, which has a resistance as RPTC1 at protection temperature and resistance as

RPTC2 at recovery temperature. Because of its positive temperature coefficient, RPTC1 is larger than RPTC2. To

ensure an available solution, RPTC1 and RPTC2 need to meet the criteria.

0.7 V ´ (RPTC1 - RPTC2 ) - 11mA ´ RPTC1 ´ RPTC2 ³ 0

(19)

And resistors R1 and R3 can be calculated as:

R1 = 3.7 ´ RPTC1

R3 =

(20)

2.6 V ´ ëé0.7 V ´ (RPTC1 - RPTC2 ) - 11mA ´ RPTC1 ´ RPTC2 ûù

11mA ´ (2.6 V ´ RPTC1 + 0.7 V ´ RPTC2 )

(21)

UCC28250

VREF

VIN or VOUT

11 mA

R1

R3

OVP

+

R2

0.7 V

Figure 36. Overvoltage Protection

26

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Feature Description (continued)

UCC28250

VREF

R1

11 mA

R3

OVP

+

0.7 V

PTC

Figure 37. Overtemperature Protection

Figure 38 shows an external configuration using the OVP/OTP pin to achieve both overvoltage and

overtemperature protection. Follow the same design procedure for the OVP setting to choose R1, R2, and R3.

Choose an NTC value at protection temperature much smaller than R1 and with the resistance at protection

temperature as RNTC1, and recover temperature as RNTC2. The R4 value can be calculated as:

R4 =

0.7 V

´ RNTC1

3.3 V - 0.7 V

(22)

Because of the interaction between the two voltage dividers, overtemperature protection thresholds move slightly

with the different input voltages.

UCC28250

VREF

VIN or VOUT

NTC

R1

11 mA

R3

OVP

+

R4

R2

0.7 V

Figure 38. Overvoltage and Overtemperature Protection With Single OVP Pin

7.3.16 OUTA (9/16) and OUTB (8/15)

OUTA and OUTB are the primary-side switch control signals. With the 0.2-A peak current capability, an external

gate driver is required.

7.3.17 SRA (7/14) and SRB (6/13)

SRA and SRB are the synchronous rectifier control signals. With the 0.2-A peak current capability, an external

gate driver is required.

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

27

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Feature Description (continued)

7.3.18 GND (4/11)

GND pin is the ground reference for the whole device. Tie all the signal returns to this pin.

7.4 Device Functional Modes

The UCC28250 can be controlled using either voltage mode or current mode. RAMP/CS is a multi-function pin

used either to generate the ramp signal for voltage mode control or to sense current for current mode control.

Refer to RAMP/CS (PWM Ramp Input or Current Sense Input) (16/3) for the details.

28

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

8 Applications and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The UCC28250 is a high-performance PWM controller with advanced synchronous rectifier outputs and is ideally

suited for regulated half-bridge, full-bridge and push-pull converters. A dedicated internal prebiased start-up

control loop working in conjunction with a primary-side voltage loop achieves monotonic prebiased start-up for

either primary-side or secondary-side control applications. The UCC28250 architecture allows either voltage

mode or current mode control.

Input voltage feedforward can be implemented, allowing PWM ramp generator to improve the converter line

transient response. Advanced cycle-by-cycle current limit achieves volt-second balancing even during fault

conditions. The hiccup timer helps the system to stay within a safe operation range under over load conditions.

With a multifunction OVP/OTP pin, combinations of input voltage protection, output voltage protection and

overtemperature protection can be implemented. The UCC28250 allows individual programming of dead time

between primary-side switch and secondary-side SRs, To allow optimal power stage design. Dead time can also

be reduced to zero, and this allows optimal system configuration considering the delays on the gate driver stage.

The UCC28250 also provides complete system level protection functions, including UVLO, thermal shut down

and overvoltage, overcurrent protection.

8.1.1 Error Amplifier and PWM Generation

The UCC28250 includes a high-performance internal error amplifier with low input offset, high source/sink current

capability and high gain bandwidth (typical 3.5 MHz). The reference of the error amplifier (REF/EA+ pin) is set

externally to support flexible trimming of the voltage loop, and to make the controller flexible for both primary

side, as well as secondary-side control. The extra positive input for the error amplifier is the SS pin which is used

to externally program the soft-start time of the converter’s output.

During steady state operation, the primary switch duty cycle, D, is generated based on the external ramp on

RAMP/CS pin and the COMP pin voltage. A higher COMP pin voltage results in a larger duty cycle. The

secondary-side SR duty cycle is SR_D = (1-D), complementary to the primary-side duty cycle, without

considering the dead time between primary-side switch and secondary-side SR. The primary outputs begin to

switch when COMP pin voltage is above the 350 mV internal offset. The synchronous rectifier outputs only switch

after COMP pin voltage is above 550 mV internal offset. According to the internal logic, the minimum pulse width

for the primary-side OUTA and OUTB is typically 100 ns.

During soft start, the primary-side switch duty cycle is generated based on the external ramp on RAMP/CS pin

and the COMP pin voltage. However, the duty cycle of secondary-side SR is generated based on an internal

ramp and the COMP pin voltage. When the converter is controlled on the primary side, an internal ramp is a

fixed ramp with 3-V peak voltage. When the converter is controlled on secondary side, an internal ramp is

generated based on the internal prebiased start-up loop. An internal prebiased start-up loop modifies the SR duty

cycle during soft start to achieve the optimal prebiased start-up performance.

After the SS pin reaches 2.9 V, the prebiased start-up control loop is disabled. The secondary-side SR

instantaneously changes into its steady state value as complementary to the primary-side duty cycle.

8.1.2 Prebiased Start-Up

With the internal error amplifier, UCC28250 supports both primary-side control and secondary-side control. For

different control methods, the controller is configured accordingly and so is the prebiased start-up control. During

soft start, both the primary-side switches’ duty cycle and secondary-side SRs’ duty cycle are increased. This

gradually increases the output voltage until steady state operation is reached, thereby reducing surge current.

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

29

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Application Information (continued)

8.1.2.1 Secondary-Side Control

For secondary-side control, the UCC28250 implements close-loop control of both the primary-side switches and

secondary-side synchronous rectifiers’ duty cycles. This makes it easy to achieve optimal start-up performance.

The internal error amplifier is set up as the control loop error amplifier. Connect REF/EA+, FB/EA-, COMP and

VSENSE as shown in Figure 39. To achieve optimal prebiased start-up performance, the output voltage must be

directly measured. The UCC28250 uses the VSENSE pin to directly sense this output voltage. Choose the

voltage dividers on VSENSE slightly different to the FB/EA- voltage divider so that the voltage on VSENSE pin is

roughly 10% to 15% more than FB/EA- pin voltages. Select RO1 equal to RS1, and RS2 about 10% to 15% smaller

than RO2.

VOUT

UCC28250

VSENSE

CP1

RO2

VREF

RZ3

RS2

RZ2

CZ2

COMP

CZ3

FB/EA-

REF/EA+

+

+

RS1

RO1

SS

CSS

Figure 39. Error Amplifier Set Up for Secondary-Side Control

The error amplifier uses the lower voltage between the SS pin and the REF/EA+ pin to be the reference voltage

for the feedback loop. In this method, the control loop is said to be ‘closed’ during the entire start-up process, as

it is always based on the true output voltage.

During soft start, the primary-side switch duty cycle is controlled by the COMP pin voltage and ramp voltage

generated on the RAMP/CS pin. A higher COMP pin voltage results in larger duty cycle. However, to improve

start-up performance, the secondary-side synchronous rectifier duty cycle is controlled by a separate, internal

ramp signal (generated by a dedicated prebiased start-up loop) and by the COMP pin voltage. This dedicated

prebiased loop is much faster than the regular voltage loop to avoid interaction between the two loops. The startup loop reads the output voltage through a transconductance error amplifier connected to the VSENSE pin.

When the output voltage is higher than the reference, the prebiased start-up loop increases the SR duty cycle to

reduce the output voltage. Conversely, when the output voltage is lower than the reference, the SR duty cycle is

decreased to help maintain higher output voltage. To speed up the start-up time, the minimum duty cycle of the

synchronous rectifier is 50%.

Once the soft start is finished, the prebiased loop is disabled and the duty cycle of the synchronous rectifiers

becomes the complimentary of primary switches’ duty cycle, with some dead time inserted in between.

30

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Application Information (continued)

8.1.2.2 Primary-Side Control

When the UCC28250 is sitting on the primary side, the internal error amplifier is connected as a voltage follower

and an extra error amplifier is needed on the secondary side for closed loop control. The error amplifier

implementation is shown in Figure 40.

VOUT

UCC28250

RO2

CP1

VSENSE

RZ3

CZ2

RZ2

VREF

COMP

CZ3

FB/EA-

+

REF/EA+

+

+

RO1

SS

External

Reference

CSS

Figure 40. Error Amplifier Setup for Primary-Side Control

In the above configuration, the UCC28250 can only see the control loop feedback voltage, and cannot directly

access the output voltage. The design of the soft-start time is critical to achieve optimal prebiased start-up

performance. Some trial and error approaches are needed to achieve optimal performance. It is also important to

choose the appropriate ramp amplitude. Refer to RAMP/CS (PWM Ramp Input or Current Sense Input) (16/3)

discussion on the detailed design procedure for choosing ramp generation components.

During soft start, regardless of the prebiased condition, the output voltage is always lower than the regulation

voltage, so that the feedback loop is always saturated. When the internal error amplifier is connected as a

voltage follower, the COMP voltage follows the lower of the voltage on the RER/EA+ pin and the SS pin.

Because the feedback loop is saturated, the COMP pin always follows the SS pin voltage, until the output

voltage becomes regulated and the feedback voltage takes over. In this control method, the output voltage

control loop is always saturated, and the controller soft starts the COMP pin voltage. Therefore, it is called open

loop soft start.

The primary-side switch duty cycle is controlled by the COMP pin voltage and by the RAMP/CS pin voltage.

During soft start, the COMP pin voltage follows the SS pin as it is rising, so the primary-side switch duty cycle

keeps increasing. When the output voltage becomes regulated, the feedback voltage becomes less than the SS

pin voltage and the primary-side switch comes controlled by the control loop.

For the primary-side control setup, because output voltage is not directly accessible, the internal prebiased startup loop is disabled by connecting VSENSE to VREF. Instead, the internal ramp used to generate the

synchronous rectifier duty cycle is fixed, with the peak voltage of 3 V. The duty cycle of the synchronous rectifier

increases as the SS pin voltage increases. When the SS pin voltage reaches 2.9 V, the soft start is considered

finished and the synchronous rectifier duty cycle becomes the complementary of the primary-side switch duty

cycle, minus the programmed dead time. Because of different COMP pin voltages at different line voltages, the

SR duty cycle generated by the internal ramp might be different than the complementary of the primary-side

switch duty cycle (1-D). If the duty cycle is too large, the internal logic is able to limit the duty cycle to (1-D).

However, if the duty cycle is too small, when the soft start is finished, the SR duty cycle has a sudden change,

which will cause output voltage disturbance. To optimize the prebiased start-up performance, TI recommends

that the duty cycle change at the end of soft start be as small as possible.

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

31

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Application Information (continued)

8.1.2.3 Voltage Mode Control and Input Voltage Feed-Forward

For voltage mode control, a resistor RCS and a capacitor CCS are connected externally at RAMP/CS pin as

shown in Figure 41. A ramp signal is generated on the RAMP/CS pin, at a rate of two times that of the switching

frequency. The generated ramp signal is used to control the duty cycle for both the primary-side switches and

secondary-side synchronous rectifiers. The ramp amplitude can be fixed or variable with the input voltage (input

voltage feedforward).

To realize a fixed amplitude ramp, connect RCS to the VREF pin, so that the ramp capacitor charging voltage is

fixed regardless of line and load condition. The RAMP/CS pin is clamped internally to 4 V for internal device

protection. Because the internal pulldown switch has about 40-Ω on-resistance, the CCS value must be small

enough to discharge RAMP/CS from the peak to ground within TD(sp) + 70 ns (that is, the pulse width of BLANK

signal).

To achieve the input voltage feedforward, the slope of the ramp must be proportional to the input voltage. Tie

RCS to the input line voltage. Because the ramp voltage is much lower than the input voltage, the ramp capacitor

charging current is considered to be proportional to the input voltage. With input voltage feedforward, the COMP

pin voltage should only move slightly even with large input voltage variation. This will provide much better line

transient response for the converter.

UCC28250

UCC28250

VIN 36 V to 75 V

VREF

RCS

RCS

RAMP/CS

CCS

RAMP/CS

BLANK

CCS

GND

BLANK

GND

Figure 41. External Configuration of RAMP/CS Pin With/Without Feed-Forward Operation

32

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

�UCC28250

www.ti.com

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

Application Information (continued)

The input voltage feedforward also helps on prebiased start-up. When doing primary-side control to prebiased

start-up, three conditions need to be considered:

8.1.2.3.1 Condition 1

At initial start-up, the primary side must provide enough energy to prevent output voltage dip;

8.1.2.3.2 Condition 2

At the end of soft start, it is required to keep the SR duty cycle change to be as small as possible. With input

voltage feedforward, the COMP pin voltage is virtually fixed for different input voltages. Therefore, before the end

of soft start, the duty cycle is the same for different input voltages. Choose the RCS and CCS following the

procedure.

Considering initial start-up, the RAMP peak voltage should be:

VRAMP

VIN

- VPRE -BIAS

= 2´n

´ VSR(ramp)

2 ´ VPRE -BIAS

(23)

In this equation, VIN is the input voltage because of the feedforward any input voltage should be fine; VPRE-BIAS is

the highest prebias start-up voltage required by the system; n is the tranformer primary to secondary turns ratio

and VSR(ramp) is the internal SR ramp peak voltage 3 V.

Another consideration is at the end of soft start, the SR duty cycle changes from controlled by the soft start, to

complimentary to the primary-side duty cycle. The design should keep the transition as smooth as possible.

Considering this, based on the output voltage and input voltage range, as well as the transformer turns ratio,

calculate the SR duty cycle at different line voltages.

Next, based on the maximum duty cycle on the SR_DMAX, and the internal fixed ramp amplitude 3 V, the COMP

voltage at regulation can be chosen as:

VCOMP( final) = (SR _ DMAX - 0.5 )´ 3 V ´ 2

(24)

8.1.2.3.3 Condition 3

Use the calculated COMP pin voltage to derive the external ramp amplitude

VRAMP =

VCOMP( final)

(1 - SR _ DMAX )´ 2

(25)

According to the calculated ramp voltage from Equation 23 and Equation 25 some trade off is required to pick up

the appropriate ramp voltage. Based on the selected ramp capacitor CCS value, choose the ramp resistor RCS

value:

RCS =

VIN(max) ´ 2

VRAMP ´ CCS ´ fsw

(26)

In this equation, VIN(max) is the maximum input voltage, fSW is the switching frequency.

Because these calculations ignore the dead time and the non-linearity of the ramp, slight modification is expected

to achieve the optimal design. When the input voltage feed forward is not used, refer to RAMP/CS (PWM Ramp

Input or Current Sense Input) (16/3) for RC calculation.

Submit Documentation Feedback

Copyright © 2010–2015, Texas Instruments Incorporated

Product Folder Links: UCC28250

33

�UCC28250

SLUSA29D – APRIL 2010 – REVISED AUGUST 2015

www.ti.com

Application Information (continued)

8.1.2.4 Peak Current Mode Control

For peak current mode control, RAMP/CS pin is connected directly with the current signal generated from a

current transformer. The current signal must be compatible with the input range of the COMP pin. External slope