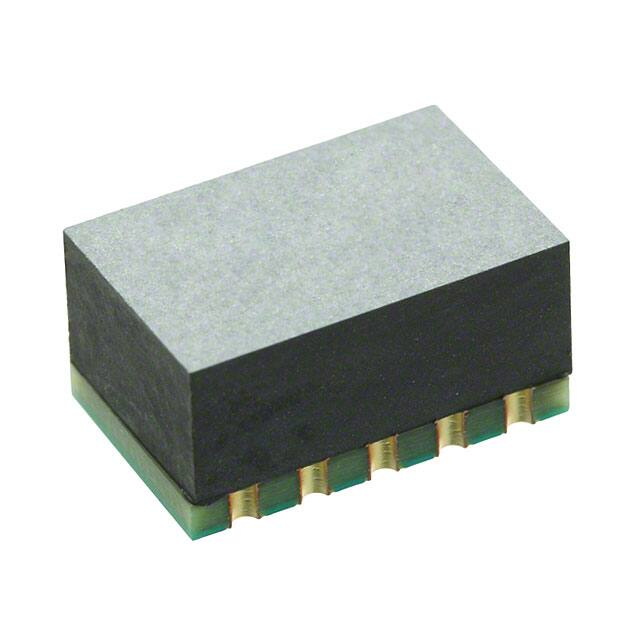

Surface Mount

Oven Stabilized Oscillator

DOCSC01-Series

OCXO or VCOCXO

2111 Comprehensive Drive

2111 Comprehensive Drive

Aurora, Illinois 60505

Aurora, Illinois 60505

Phone: 630- 851- 4722

Phone: 630- 851- 4722

Fax: 630- 851- 5040

Fax: 630- 851- 5040

www.conwin.com

www.conwin.com

US Headquarters:

630-851-4722

European Headquarters:

+353-61-472221

Description:

Features:

Connor-Winfield’s high stability

DOCSC Series is an exceptionally

precise frequency standard, excellent

for use in cellular base stations, test

equipment, Synchronous Ethernet

and VSAT applications.

Based on an SC-cut crystal,

the DOCSC Series offers low aging and tight

stability in a 9x14mm surface mount package.

• OCXO or VCOCXO

• 3.3 Vdc Operation

• SMT Package

• Frequency Stability ±10 ppb

• Temperature Ranges:

0 to 70°C, -20 to 75°C or -40 to 85°C

• Low Phase Noise

• LVCMOS Output

• RoHS Compliant / Lead Free

Suggested Pad Layout

Package Outline

DOCSC012F

Top

View

0.025

(0.64mm)

Side

View

4

Bottom

View

3

Top

5 View 2

0.260

(6.60mm)

0.100

(2.54mm)

DNC

0.085

(2.16mm)

0.060

(1.52mm)

0.100

(2.54mm)

0.040

(1.02mm)

0.375

(9.52mm)

0.085

(2.16mm)

DNC

0.275

(6.99mm)

1

0.555

(14.1mm)

0.060

(1.52mm)

0.330

(8.38mm)

1525

DOCSC022F

24.576MHz

0.358

(9.1mm)

0.040

(1.02mm)

6

1

DNC = Do Not Connect

Keep

Out

Area

Dimensional Tolerance: +/-0.005 (0.127mm)

Pad Connections

1: N/C or Voltage Control

2: Do Not Connect*

3: Ground

4: Output

5: Do Not Connect*

6: Supply Voltage (Vcc)

*DO NOT connect "DNC" pads to ground or supply rails.

Ordering Information

Bulletin

Page

Revision

Date

Cx270

1 of 4

02

06 May 2019

DOCSC

01

2

F

Oscillator

Type

Frequency

Stability

Temperature

Range

Voltage Control

Option

Output

Frequency

3.3 Vdc

LVCMOS Output

Surface Mount

OCXO

01 = ±10.0 ppb

0 = 0 to 70°C

1 = -20 to 75°C

2 = -40 to 85°C

F = OCXO

(Fixed Freq.)

V = VCOCXO

(Voltage Controlled)

Frequency Format

-xxx.xM Min *

-xxx.xxxxxxM Max *

-024.576M

Attention: System Designers please review Application Note AN2093:

System Design Information and Printed Circuit Board Layout Guidelines

for OCXO Oscillators. @ www.conwin.com/support.html

* Number

of allowable

digits after

the decimal

point.

M = MHz

�2111 Comprehensive Drive

Aurora, Illinois 60505

Phone: 630- 851- 4722

Fax: 630- 851- 5040

www.conwin.com

Absolute Maximum Ratings

Parameter

Minimum

Storage Temperature

Supply Voltage - 3.3 Vdc (Vcc)

Control Voltage (Vc)

Nominal

-55

-0.5

-0.5

-

-

-

Maximum

Units

Notes

125

4.5

Vcc+0.5

°C

Vdc

Vdc

Operating Specifications

Parameter

Center Frequency (Fo)

Frequency Stability vs. Change in Temperature

Option 01

Operating Temperature Range

Option 0

Option 2

Frequency Calibration

Frequency Stability vs Load

Frequency Stability vs Voltage

Aging: Daily

Aging: First Year

Total Frequency Tolerance (20 Years)

Supply Voltage (Vcc)

Power Consumption Vcc = Nominal Voltage

Commercial Temperature Range: 0 to 70 °C

Turn On

Steady State @ 25°C

Industrial Temperature Range: -40 to 85 °C

Turn On

Steady State @ 25°C

Phase Jitter: (BW: 12 KHz to 5MHz @ Fo=40.0MHz)

Allan Deviation (Tau=1s)

Start-Up Time

Warm Up Time (Within Specification @ 25°C)

Warm Up Time (Within Specification @ -40°C)

Minimum

Nominal

Maximum

Units

Notes

-10

-

10

ppb

1

0

-40

-1.0

-20

-20

-5.0

-0.3

-3.0

3.13

-

-

-

-

-

-

-

-

3.30

70

85

1.0

20

20

5.0

0.3

3.0

3.47

°C

°C

ppm

ppb

ppb

ppb/day

ppm

ppm

Vdc

-

-

-

-

2.5

1.1

W

W

-

-

-

-

-

-

-

-

-

0.25

3.0E-11

-

-

-

3.0

1.3

0.35

10

60

90

W

W

ps RMS

10

-

40

MHz

2

±5%

±5%

3

4

5

ms

s

s

CMOS Output Characteristics

Parameter

Load

Output Voltage

Output Voltage: High (Voh)

Low (Vol)

Output Current: High (Ioh)

Low (Iol)

Duty Cycle at 50% of Vcc

Rise / Fall Time: 10% to 90%

Minimum

Nominal

Maximum

Units

2.7

-

-4

-

45

-

-

-

-

-

50

-

-

0.3

-

4

55

6.5

V

V

mA

mA

%

ns

-

15

-

pF

Notes

6

Typical Phase Noise Characteristics

Parameter

@ 1 Hz offset

@ 10 Hz offset

@ 100 Hz offset

@ 1 KHz offset

@ 10 KHz offset

@ 100 KHz offset

@ 1MHz offset

Fo=10 MHz

-72

-100

-128

-145

-151

-154

-155

Fo=24.576MHz

-70

-96

-125

-145

-151

-154

-155

Fo=40.0MHz

Attention: System Designers please review Application Note AN2093:

System Design Information and Printed Circuit Board Layout Guidelines

for OCXO Oscillators. @ www.conwin.com/support.html

-67

-90

-116

-139

-147

-153

-153

Units

dBC/Hz

dBC/Hz

dBC/Hz

dBC/Hz

dBC/Hz

dBC/Hz

dBC/Hz

Bulletin

Page

Revision

Date

Specifications subject to change without notification. See Connor-Winfield's website for latest revision.

© Copyright 2019 The Connor-Winfield Corporation Not intended for life support applications.

Notes

Cx270

2 of 4

02

06 May 2019

�2111 Comprehensive Drive

Aurora, Illinois 60505

Phone: 630- 851- 4722

Fax: 630- 851- 5040

www.conwin.com

Input Characteristics - Voltage Controlled Option

Parameter

Control Voltage Range:

Frequency Pullability:

Input Impedance

Linearity

Minimum

0.30

±3.0

100K

-

Nominal

1.65

-

-

-

Maximum

3.00

±10.0

-

±5

Units

V

ppm

Ohms

%

Notes

7

8

Package Characteristics

DOC Package

Package consisting of a FR-4 substrate and Ryton-R-4 cover. Water Resistant package,

non-hermetic seal. (Engineering Properties of Ryton R-4 Application Note AN2100)

Environmental Characteristics

Shock

500 G’s 1ms, Halfsine, 3 shocks per direction, per MIL-STD 202G, Method 213B Test Condition D.

Sinusoidal Vibration

0.06” D.A. or 10G’s Peak, 10 to 500 Hz, per MIL-STD-202G, Method 204D, Test Condition A.

Random Vibration

5.35 G’s rms. 20 to 2000 Hz per MIL-STD-202G, Method 214,Test Condition 1A, 15 minutes each axis.

Moisture

10 cycles, 95% RH, Per MIL-STD-202G, Method 112.

Marking Permanency

Per MIL-STD-202G, Method 215J.

Solder Process Recommendations:

RoHS compliant, lead free. See solder profile on page 4.

In-line reflow:

Refer to recommended reflow pre-heat and reflow temperatures on page 4. Package material

consist of Ryton R-4 high temperature cover with FR4 substrate. Component solder is Pb free high

temperature eutectic alloy with a melting point of 221°C.

In-line oven profile:

We recommend using KIC profiler or similar device placing one of the thermocouples on the

device to insure that the internal package temperature does not exceed 221°C.

Removal of device:

If for any reason the device needs to be removed from the board, use a temperature controlled

repair station with profile monitoring capabilities. Following a monitored profile will insure the

device is properly pre-heated prior to reflow. Refer to IPC 610E for inspection guidelines.

Recommended Cleaning Process: (If required)

Device is non-hermetic, water resistance with four weep holes, one in each corner to allow

moisture to be removed during the drying cycle. We recommend in-line warm water wash

with air knife and drying capabilities. If cleaner does not have drying capability, then use hot air

circulated oven. Boards should be placed in the oven vertically for good water runoff.

Device must be dried properly prior to use!

Note: If saponifier is used make sure the device is rinsed properly to insure all residues are removed. PH of saponifier should

not exceed 10.

Drying Temperature:

Between 85 to 100°C.

Drying Time:

Time will vary depending on the board size.

Caution: Do not submerge the device!

Notes:

1. Frequency stability vs. change in temperature. [±(Fmax - Fmin)/(2*Fo)].

2. Initial calibration @ 25°C. For OCXO with voltage control option, the control voltage must be fixed.

3. After 10 days of operation

4. Inclusive of calibration @ 25°C, frequency vs. change in temperature, change in supply voltage (±5%), load change (±5%), shock and vibration

and 20 years aging

5 Minimum "Power On Time" after rail rises from 0 to within +/-5% of Vcc = 1 second.

Vcc ramp rate must be

很抱歉,暂时无法提供与“DOCSC012F-025.0M”相匹配的价格&库存,您可以联系我们找货

免费人工找货