Please note that Cypress is an Infineon Technologies Company.

The document following this cover page is marked as “Cypress” document as this is the

company that originally developed the product. Please note that Infineon will continue

to offer the product to new and existing customers as part of the Infineon product

portfolio.

Continuity of document content

The fact that Infineon offers the following product as part of the Infineon product

portfolio does not lead to any changes to this document. Future revisions will occur

when appropriate, and any changes will be set out on the document history page.

Continuity of ordering part numbers

Infineon continues to support existing part numbers. Please continue to use the

ordering part numbers listed in the datasheet for ordering.

www.infineon.com

�PSoC® 3: CY8C34 Family Datasheet

®

Programmable System-on-Chip (PSoC )

General Description

PSoC® 3 is a true programmable embedded system-on-chip, integrating configurable analog and digital peripherals, memory, and a

microcontroller on a single chip. The PSoC 3 architecture boosts performance through:

8051 core plus DMA controller at up to 50 MHz

Ultra low power with industry's widest voltage range

Programmable digital and analog peripherals enable custom functions

Flexible routing of any analog or digital peripheral function to any pin

PSoC devices employ a highly configurable system-on-chip architecture for embedded control design. They integrate configurable

analog and digital circuits, controlled by an on-chip microcontroller. A single PSoC device can integrate as many as 100 digital and

analog peripheral functions, reducing design time, board space, power consumption, and system cost while improving system quality.

Features

Operating characteristics

Analog peripherals

Voltage range: 1.71 to 5.5 V, up to six power domains

[1]

Temperature range (ambient) –40 to 85 °C

DC to 50-MHz operation

Power modes

• Active mode 1.2 mA at 6 MHz, and 12 mA at 48 MHz

• 1-µA sleep mode

• 200-nA hibernate mode with RAM retention

Boost regulator from 0.5-V input up to 5-V output

Configurable 8- to 12-bit delta-sigma ADC

Two 8-bit DACs

Four comparators

Two opamps

Two programmable analog blocks, to create:

• Programmable gain amplifier (PGA)

• Transimpedance amplifier (TIA)

• Mixer

• Sample and hold circuit

®

CapSense support, up to 62 sensors

1.024 V ±1% internal voltage reference

Performance

8-bit 8051 CPU, 32 interrupt inputs

24-channel direct memory access (DMA) controller

Versatile I/O system

Memories

29 to 72 I/O pins – up to 62 general-purpose I/Os (GPIOs)

Up to eight performance I/O (SIO) pins

• 25 mA current sink

• Programmable input threshold and output high voltages

• Can act as a general-purpose comparator

• Hot swap capability and overvoltage tolerance

Two USBIO pins that can be used as GPIOs

Route any digital or analog peripheral to any GPIO

LCD direct drive from any GPIO, up to 46 × 16 segments

CapSense support from any GPIO

1.2-V to 5.5-V interface voltages, up to four power domains

Up to 64 KB program flash, with cache and security features

Up to 8 KB additional flash for error correcting code (ECC)

Up to 8 KB RAM

Up to 2 KB EEPROM

Digital peripherals

Four 16-bit timer, counter, and PWM (TCPWM) blocks

I2C, 1 Mbps bus speed

USB 2.0 certified Full-Speed (FS) 12 Mbps peripheral

interface (TID#40770053) using internal oscillator[2]

Full CAN 2.0b, 16 Rx, 8 Tx buffers

16 to 24 universal digital blocks (UDB), programmable to

create any number of functions:

• 8-, 16-, 24-, and 32-bit timers, counters, and PWMs

• I2C, UART, SPI, I2S, LIN 2.0 interfaces

• Cyclic redundancy check (CRC)

• Pseudo random sequence (PRS) generators

• Quadrature decoders

• Gate-level logic functions

Programming and debug

JTAG (4-wire), serial wire debug (SWD) (2-wire), and single

wire viewer (SWV) interfaces

2

Bootloader programming through I C, SPI, UART, USB, and

other interfaces

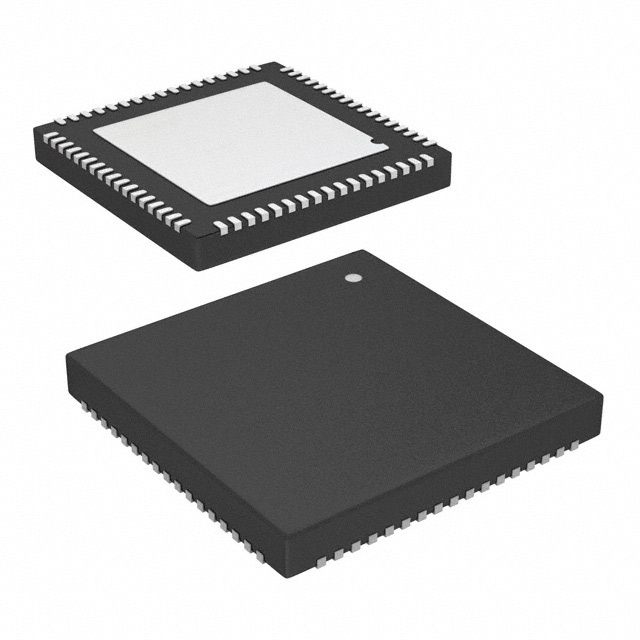

Package options: 48-pin SSOP, 48-pin QFN, 68-pin QFN, and

100-pin TQFP

Development support with free PSoC Creator™ tool

Programmable clocking

3- to 62-MHz internal oscillator, 2% accuracy at 3 MHz

4- to 25-MHz external crystal oscillator

Internal PLL clock generation up to 50 MHz

Low-power internal oscillator at 1, 33, and 100 kHz

32.768-kHz external watch crystal oscillator

12 clock dividers routable to any peripheral or I/O

Schematic and firmware design support

Over 100 PSoC Components™ integrate multiple ICs and

system interfaces into one PSoC. Components are free

embedded ICs represented by icons. Drag and drop

component icons to design systems in PSoC Creator.

Includes free Keil 8051 compiler

Supports device programming and debugging

Notes

1. The maximum storage temperature is 150 °C in compliance with JEDEC Standard JESD22-A103, High Temperature Storage Life.

2. This feature on select devices only. See Ordering Information on page 121 for details.

Cypress Semiconductor Corporation

Document Number: 001-53304 Rev. AA

•

198 Champion Court

•

San Jose, CA 95134-1709

•

408-943-2600

Revised December 3, 2019

�PSoC® 3: CY8C34 Family Datasheet

More Information

Cypress provides a wealth of data at www.cypress.com to help you to select the right PSoC device for your design, and to help you

to quickly and effectively integrate the device into your design. For a comprehensive list of resources, see the knowledge base article

KBA86521, How to Design with PSoC 3, PSoC 4, and PSoC 5LP. Following is an abbreviated list for PSoC 3:

Overview: PSoC Portfolio, PSoC Roadmap

Product Selectors: PSoC 1, PSoC 3, PSoC 4, PSoC 5LP

In addition, PSoC Creator includes a device selection tool.

Application notes: Cypress offers a large number of PSoC

application notes and code examples covering a broad range

of topics, from basic to advanced level. Recommended application notes for getting started with PSoC 3 are:

AN54181: Getting Started With PSoC 3

AN61290: Hardware Design Considerations

AN57821: Mixed Signal Circuit Board Layout

AN58304: Pin Selection for Analog Designs

AN81623: Digital Design Best Practices

AN73854: Introduction To Bootloaders

Development Kits:

CY8CKIT-030 is designed for analog performance, for developing high-precision analog, low-power, and low-voltage applications.

CY8CKIT-001 provides a common development platform for

any one of the PSoC 1, PSoC 3, PSoC 4, or PSoC 5LP

families of devices.

The MiniProg3 device provides an interface for flash programming and debug.

Technical Reference Manuals (TRM)

Architecture TRM

Registers TRM

Programming Specification

PSoC Creator

PSoC Creator is a free Windows-based Integrated Design Environment (IDE). It enables concurrent hardware and firmware design

of PSoC 3, PSoC 4, and PSoC 5LP based systems. Create designs using classic, familiar schematic capture supported by over 100

pre-verified, production-ready PSoC Components; see the list of component datasheets. With PSoC Creator, you can:

1. Drag and drop component icons to build your hardware

3. Configure components using the configuration tools

system design in the main design workspace

4. Explore the library of 100+ components

2. Codesign your application firmware with the PSoC hardware,

5. Review component datasheets

using the PSoC Creator IDE C compiler

Figure 1. Multiple-Sensor Example Project in PSoC Creator

Document Number: 001-53304 Rev. AA

Page 2 of 137

�PSoC® 3: CY8C34 Family Datasheet

Contents

1. Architectural Overview ..................................................... 4

2. Pinouts ............................................................................... 6

3. Pin Descriptions .............................................................. 11

4. CPU ................................................................................... 12

4.1 8051 CPU ................................................................. 12

4.2 Addressing Modes .................................................... 12

4.3 Instruction Set .......................................................... 13

4.4 DMA and PHUB ....................................................... 17

4.5 Interrupt Controller ................................................... 18

5. Memory ............................................................................. 22

5.1 Static RAM ............................................................... 22

5.2 Flash Program Memory ............................................ 22

5.3 Flash Security ........................................................... 22

5.4 EEPROM .................................................................. 22

5.5 Nonvolatile Latches (NVLs) ...................................... 23

5.6 External Memory Interface ....................................... 24

5.7 Memory Map ............................................................ 25

6. System Integration .......................................................... 27

6.1 Clocking System ....................................................... 27

6.2 Power System .......................................................... 30

6.3 Reset ........................................................................ 34

6.4 I/O System and Routing ........................................... 36

7. Digital Subsystem ........................................................... 43

7.1 Example Peripherals ................................................ 43

7.2 Universal Digital Block .............................................. 45

7.3 UDB Array Description ............................................. 48

7.4 DSI Routing Interface Description ............................ 49

7.5 CAN .......................................................................... 50

7.6 USB .......................................................................... 52

7.7 Timers, Counters, and PWMs .................................. 53

7.8 I2C ............................................................................ 54

8. Analog Subsystem .......................................................... 56

8.1 Analog Routing ......................................................... 57

8.2 Delta-sigma ADC ...................................................... 59

8.3 Comparators ............................................................. 60

8.4 Opamps .................................................................... 61

8.5 Programmable SC/CT Blocks .................................. 61

8.6 LCD Direct Drive ...................................................... 63

8.7 CapSense ................................................................. 64

8.8 Temp Sensor ............................................................ 64

8.9 DAC .......................................................................... 64

8.10 Up/Down Mixer ....................................................... 64

8.11 Sample and Hold .................................................... 65

Document Number: 001-53304 Rev. AA

9. Programming, Debug Interfaces, Resources ................ 65

9.1 JTAG Interface ......................................................... 66

9.2 Serial Wire Debug Interface ..................................... 67

9.3 Debug Features ........................................................ 68

9.4 Trace Features ......................................................... 68

9.5 Single Wire Viewer Interface .................................... 68

9.6 Programming Features ............................................. 68

9.7 Device Security ........................................................ 68

10. Development Support ................................................... 69

10.1 Documentation ....................................................... 69

10.2 Online ..................................................................... 69

10.3 Tools ....................................................................... 69

11. Electrical Specifications ............................................... 70

11.1 Absolute Maximum Ratings .................................... 70

11.2 Device Level Specifications .................................... 71

11.3 Power Regulators ................................................... 75

11.4 Inputs and Outputs ................................................. 79

11.5 Analog Peripherals ................................................. 88

11.6 Digital Peripherals ................................................ 105

11.7 Memory ................................................................ 108

11.8 PSoC System Resources ..................................... 114

11.9 Clocking ................................................................ 117

12. Ordering Information ................................................... 121

12.1 Part Numbering Conventions ............................... 122

13. Packaging ..................................................................... 123

14. Acronyms ..................................................................... 126

15. Reference Documents ................................................. 127

16. Document Conventions .............................................. 128

16.1 Units of Measure .................................................. 128

17. Revision History .......................................................... 129

18. Sales, Solutions, and Legal Information ................... 137

Worldwide Sales and Design Support.......................... 137

Products ....................................................................... 137

PSoC® Solutions ......................................................... 137

Cypress Developer Community.................................... 137

Technical Support ........................................................ 137

Page 3 of 137

�PSoC® 3: CY8C34 Family Datasheet

1. Architectural Overview

Introducing the CY8C34 family of ultra low-power, flash Programmable System-on-Chip (PSoC®) devices, part of a scalable

8-bit PSoC 3 and 32-bit PSoC 5 platform. The CY8C34 family provides configurable blocks of analog, digital, and interconnect circuitry

around a CPU subsystem. The combination of a CPU with a flexible analog subsystem, digital subsystem, routing, and I/O enables

a high level of integration in a wide variety of consumer, industrial, and medical applications.

Figure 1-1. Simplified Block Diagram

Analog Interconnect

8- Bit

Timer

Quadrature Decoder

UDB

Sequencer

Usage Example for UDB

Universal Digital Block Array ( 24 x UDB)

UDB

UDB

UDB

16- Bit

PWM

UDB

UDB

12- Bit SPI

UDB

UDB

UDB

UDB

8- Bit

Timer

Logic

UDB

UDB

UDB

UDB

UDB

UDB

UDB

Master/

Slave

UDB

8- Bit SPI

I2C Slave

UDB

I2C

CAN

2.0

16- Bit PRS

UDB

FS USB

2.0

4x

Timer

Counter

PWM

Logic

UDB

UDB

UDB

UART

UDB

22 Ω

USB

PHY

GPIOs

GPIOs

IMO

Clock Tree

32.768 KHz

( Optional)

Digital System

System Wide

Resources

Xtal

Osc

SIO

4- 25 MHz

( Optional)

GPIOs

Digital Interconnect

12- Bit PWM

RTC

Timer

System Bus

GPIOs

Memory System

EEPROM

EMIF

SRAM

CPU System

8051 or

Cortex M3

CPU

Interrupt

Controller

Program

Debug &

Trace

PHUB

DMA

FLASH

ILO

Program &

Debug

GPIOs

WDT

and

Wake

Boundary

Scan

Power Management

System

Analog System

LCD Direct

Drive

ADC

POR and

LVD

1.8V LDO

SMP

+

2x

Opamp

-

2 x SC/ CT Blocks

(TIA, PGA, Mixer etc)

Temperature

Sensor

Del Sig

ADC

+

4x

CMP

2x DAC

CapSense

3 per

Opamp

-

GPIOs

1.71 to

5.5V

Sleep

Power

GPIOs

SIOs

Clocking System

0. 5 to 5.5V

( Optional)

Figure 1-1 illustrates the major components of the CY8C34

family. They are:

8051 CPU subsystem

Nonvolatile subsystem

Programming, debug, and test subsystem

Inputs and outputs

Clocking

Power

Digital subsystem

Document Number: 001-53304 Rev. AA

Analog subsystem

PSoC’s digital subsystem provides half of its unique

configurability. It connects a digital signal from any peripheral to

any pin through the digital system interconnect (DSI). It also

provides functional flexibility through an array of small, fast, lowpower UDBs. PSoC Creator provides a library of prebuilt and

tested standard digital peripherals (UART, SPI, LIN, PRS, CRC,

timer, counter, PWM, AND, OR, and so on) that are mapped to

the UDB array. You can also easily create a digital circuit using

boolean primitives by means of graphical design entry. Each

UDB contains programmable array logic (PAL)/PLD functionality,

together with a small state machine engine to support a wide

variety of peripherals.

Page 4 of 137

�PSoC® 3: CY8C34 Family Datasheet

In addition to the flexibility of the UDB array, PSoC also provides

configurable digital blocks targeted at specific functions. For the

CY8C34 family these blocks can include four 16-bit timer,

counter, and PWM blocks; I2C slave, master, and multi-master;

Full-Speed USB; and Full CAN 2.0b.

For more details on the peripherals see the “Example

Peripherals” section on page 43 of this data sheet. For

information on UDBs, DSI, and other digital blocks, see the

“Digital Subsystem” section on page 43 of this data sheet.

PSoC’s analog subsystem is the second half of its unique

configurability. All analog performance is based on a highly

accurate absolute voltage reference with less than 1-percent

error over temperature and voltage. The configurable analog

subsystem includes:

Analog muxes

Comparators

Voltage references

Analog-to-digital converter (ADC)

Digital-to-analog converters (DACs)

All GPIO pins can route analog signals into and out of the device

using the internal analog bus. This allows the device to interface

up to 62 discrete analog signals. The heart of the analog

subsystem is a fast, accurate, configurable delta-sigma ADC

with these features:

Less than 100 µV offset

A gain error of 0.2 percent

INL less than ±1 LSB

DNL less than ±1 LSB

SINAD better than 66 dB

This converter addresses a wide variety of precision analog

applications, including some of the most demanding sensors.

Two high-speed voltage or current DACs support 8-bit output

signals at update rate of 8 Msps in current DAC (IDAC) and

1 Msps in voltage DAC (VDAC). They can be routed out of any

GPIO pin. You can create higher resolution voltage PWM DAC

outputs using the UDB array. This can be used to create a pulse

width modulated (PWM) DAC of up to 10 bits, at up to 48 kHz.

The digital DACs in each UDB support PWM, PRS, or

delta-sigma algorithms with programmable widths.

In addition to the ADC and DACs, the analog subsystem

provides multiple:

Uncommitted opamps

Configurable switched capacitor/continuous time (SC/CT)

blocks. These support:

Transimpedance amplifiers

Programmable gain amplifiers

Mixers

Other similar analog components

See the “Analog Subsystem” section on page 56 of this data

sheet for more details.

PSoC’s 8051 CPU subsystem is built around a single cycle

pipelined 8051 8-bit processor running at up to 50 MHz. The

CPU subsystem includes a programmable nested vector

interrupt controller, DMA controller, and RAM. PSoC’s nested

vector interrupt controller provides low latency by allowing the

CPU to vector directly to the first address of the interrupt service

routine, bypassing the jump instruction required by other

architectures. The DMA controller enables peripherals to

exchange data without CPU involvement. This allows the CPU

to run slower (saving power) or use those CPU cycles to improve

the performance of firmware algorithms. The single cycle 8051

CPU runs ten times faster than a standard 8051 processor. The

processor speed itself is configurable, allowing you to tune active

power consumption for specific applications.

PSoC’s nonvolatile subsystem consists of flash, byte-writeable

EEPROM, and nonvolatile configuration options. It provides up

to 64 KB of on-chip flash. The CPU can reprogram individual

blocks of flash, enabling bootloaders. You can enable an error

correcting code (ECC) for high reliability applications. A powerful

and flexible protection model secures the user's sensitive

information, allowing selective memory block locking for read

and write protection. Up to 2 KB of byte-writeable EEPROM is

available on-chip to store application data. Additionally, selected

configuration options such as boot speed and pin drive mode are

stored in nonvolatile memory. This allows settings to activate

immediately after power-on reset (POR).

The three types of PSoC I/O are extremely flexible. All I/Os have

many drive modes that are set at POR. PSoC also provides up

to four I/O voltage domains through the VDDIO pins. Every GPIO

has analog I/O, LCD drive[3], CapSense[4], flexible interrupt

generation, slew rate control, and digital I/O capability. The SIOs

on PSoC allow VOH to be set independently of VDDIO when

used as outputs. When SIOs are in input mode they are high

impedance. This is true even when the device is not powered or

when the pin voltage goes above the supply voltage. This makes

the SIO ideally suited for use on an I2C bus where the PSoC may

not be powered when other devices on the bus are. The SIO pins

also have high current sink capability for applications such as

LED drives. The programmable input threshold feature of the

SIO can be used to make the SIO function as a general purpose

analog comparator. For devices with Full-Speed USB the USB

physical interface is also provided (USBIO). When not using

USB these pins may also be used for limited digital functionality

and device programming. All of the features of the PSoC I/Os are

covered in detail in the “I/O System and Routing” section on

page 36 of this data sheet.

The PSoC device incorporates flexible internal clock generators,

designed for high stability and factory trimmed for high accuracy.

The Internal Main Oscillator (IMO) is the clock base for the

system, and has 2-percent accuracy at 3 MHz. The IMO can be

configured to run from 3 MHz up to 24 MHz. Multiple clock

derivatives can be generated from the main clock frequency to

meet application needs.

Notes

3. This feature on select devices only. See Ordering Information on page 121 for details.

4. GPIOs with opamp outputs are not recommended for use with CapSense.

Document Number: 001-53304 Rev. AA

Page 5 of 137

�PSoC® 3: CY8C34 Family Datasheet

The device provides a PLL to generate clock frequencies up to

50 MHz from the IMO, external crystal, or external reference

clock. It also contains a separate, very low-power Internal

low-speed oscillator (ILO) for the sleep and watchdog timers. A

32.768-kHz external watch crystal is also supported for use in

RTC applications. The clocks, together with programmable clock

dividers, provide the flexibility to integrate most timing

requirements.

The CY8C34 family supports a wide supply operating range from

1.71 V to 5.5 V. This allows operation from regulated supplies

such as 1.8 V ± 5 percent, 2.5 V ±10 percent, 3.3 V ± 10 percent,

or 5.0 V ± 10 percent, or directly from a wide range of battery

types. In addition, it provides an integrated high efficiency

synchronous boost converter that can power the device from

supply voltages as low as 0.5 V. This enables the device to be

powered directly from a single battery or solar cell. In addition,

you can use the boost converter to generate other voltages

required by the device, such as a 3.3-V supply for LCD glass

drive. The boost’s output is available on the VBOOST pin, allowing

other devices in the application to be powered from the PSoC.

PSoC supports a wide range of low-power modes. These include

a 200-nA hibernate mode with RAM retention and a 1-µA sleep

mode with RTC. In the second mode the optional 32.768-kHz

watch crystal runs continuously and maintains an accurate RTC.

Power to all major functional blocks, including the programmable

digital and analog peripherals, can be controlled independently

by firmware. This allows low-power background processing

when some peripherals are not in use. This, in turn, provides a

total device current of only 1.2 mA when the CPU is running at

6 MHz, or 0.8 mA running at 3 MHz.

The details of the PSoC power modes are covered in the “Power

System” section on page 30 of this data sheet.

PSoC uses JTAG (4-wire) or SWD (2-wire) interfaces for

programming, debug, and test. The 1-wire SWV may also be

used for ‘printf’ style debugging. By combining SWD and SWV,

you can implement a full debugging interface with just three pins.

Using these standard interfaces enables you to debug or

program the PSoC with a variety of hardware solutions from

Cypress or third party vendors. PSoC supports on-chip break

points and 4 KB instruction and data race memory for debug.

Details of the programming, test, and debugging interfaces are

discussed in the “Programming, Debug Interfaces, Resources”

section on page 65 of this data sheet.

2. Pinouts

Each VDDIO pin powers a specific set of I/O pins. (The USBIOs

are powered from VDDD.) Using the VDDIO pins, a single PSoC

can support multiple voltage levels, reducing the need for

off-chip level shifters. The black lines drawn on the pinout

diagrams in Figure 2-3 through Figure 2-6, as well as Table 2-1,

show the pins that are powered by each VDDIO.

Each VDDIO may source up to 100 mA total to its associated I/O

pins, as shown in Figure 2-1.

Figure 2-1. VDDIO Current Limit

IDDIO X

mA

VDDIO X

I/O Pins

PSoC

Conversely, for the 100-pin and 68-pin devices, the set of I/O

pins associated with any VDDIO may sink up to 100 mA total, as

shown in Figure 2-2.

Figure 2-2. I/O Pins Current Limit

Ipins

VDDIO X

mA

I/O Pins

PSoC

VSSD

For the 48-pin devices, the set of I/O pins associated with

VDDIO0 plus VDDIO2 may sink up to 100 mA total. The set of

I/O pins associated with VDDIO1 plus VDDIO3 may sink up to a

total of 100 mA.

Document Number: 001-53304 Rev. AA

Page 6 of 137

�PSoC® 3: CY8C34 Family Datasheet

Figure 2-3. 48-pin SSOP Part Pinout

(SIO) P12[2]

(SIO) P12[3]

(OPAMP2OUT, GPIO) P0[0]

(OPAMP0OUT, GPIO) P0[1]

(OPAMP0+, GPIO) P0[2]

(OPAMP0-/EXTREF0, GPIO) P0[3]

VDDIO0

(OPAMP2+, GPIO) P0[4]

(OPAMP2-, GPIO) P0[5]

(IDAC0, GPIO) P0[6]

(IDAC2, GPIO) P0[7]

VCCD

VSSD

VDDD

(GPIO) P2[3]

(GPIO) P2[4]

VDDIO2

(GPIO) P2[5]

(GPIO) P2[6]

(GPIO) P2[7]

VSSB

IND

VBOOST

VBAT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

48

47

Lines show

46

VDDIO to I/O

45

supply

44

association

43

42

41

40

39

38

SSOP 37

36

35

34

33

32

31

30

29

28

27

26

25

VDDA

VSSA

VCCA

P15[3] (GPIO, KHZ XTAL: XI)

P15[2] (GPIO, KHZ XTAL: XO)

P12[1] (SIO, I2C1: SDA)

P12[0] (SIO, I2C1: SCL)

VDDIO3

P15[1] (GPIO, MHZ XTAL: XI)

P15[0] (GPIO, MHZ XTAL: XO)

VCCD

VSSD

VDDD

[5]

P15[7] (USBIO, D-, SWDCK)

[5]

P15[6] (USBIO, D+, SWDIO)

P1[7] (GPIO)

P1[6] (GPIO)

VDDIO1

P1[5] (GPIO, NTRST)

P1[4] (GPIO, TDI)

P1[3] (GPIO, TDO, SWV)

P1[2] (GPIO, CONFIGURABLE XRES)

P1[1] (GPIO, TCK, SWDCK)

P1[0] (GPIO, TMS, SWDIO)

VDDIO1

(GPIO, Configurable XRES) P1[2]

(GPIO, TDO, SWV) P1[3]

(GPIO, TDI) P1[4]

(GPIO, NTRST) P1[5]

7

8

9

10

11

12

46

45

44

43

42

41

40

39

38

37

Lines show

VDDIO to I/O

supply

association

QFN

(TOP VIEW

)

36 P0[3] (OPAMP0-/EXTREF0, GPIO)

35 P0[2] (OPAMP0+, GPIO)

34 P0[1] (OPAMP0OUT, GPIO)

33 P0[0] (OPAMP2OUT, GPIO)

32 P12[3] (SIO)

31 P12[2] (SIO)

30 VDDA

29 VSSA

28 VCCA

27 P15[3] (GPIO, KHZ XTAL: XI)

26 P15[2] (GPIO, KHZ XTAL: XO)

25 P12[1] (SIO, I2C1: SDA)

13

14

15

16

17

18

19

20

21

22

23

24

VSSB

IND

VBOOST

VBAT

(GPIO, TMS, SWDIO) P1[0]

(GPIO, TCK, SWDCK) P1[1]

1

2

3

4

5

6

(GPIO) P1[6]

(GPIO) P1[7]

[6]

(USBIO, D+, SWDIO) P15[6]

[6]

(USBIO, D-, SWDCK) P15[7]

VDDD

VSSD

VCCD

(GPIO, MHZ XTAL: XO) P15[0]

(GPIO, MHZ XTAL: XI) P15[1]

VDDIO3

(SIO, I2C1: SCL) P12[0]

(GPIO) P2[6]

(GPIO) P2[7]

48

47

P2[5] (GPIO)

VDDIO2

P2[4] (GPIO)

P2[3] (GPIO)

VDDD

VSSD

VCCD

P0[7] (IDAC2, GPIO)

P0[6] (IDAC0, GPIO)

P0[5] (OPAMP2-, GPIO)

P0[4] (OPAMP2+, GPIO)

VDDIO0

Figure 2-4. 48-pin QFN Part Pinout[7]

Notes

5. Pins are Do Not Use (DNU) on devices without USB. The pin must be left floating.

6. Pins are Do Not Use (DNU) on devices without USB. The pin must be left floating.

7. The center pad on the QFN package should be connected to digital ground (VSSD) for best mechanical, thermal, and electrical performance. If not connected to

ground, it should be electrically floated and not connected to any other signal. For more information, see AN72845, Design Guidelines for QFN Devices.

Document Number: 001-53304 Rev. AA

Page 7 of 137

�PSoC® 3: CY8C34 Family Datasheet

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

P2[5] (GPIO)

VDDIO2

P2[4] (GPIO)

P2[3] (GPIO)

P2[2] (GPIO)

P2[1] (GPIO)

P2[0] (GPIO)

P15[5] (GPOI)

P15[4] (GPIO)

VDDD

VSSD

VCCD

P0[7] (GPIO, IDAC2)

P0[6] (GPIO, IDAC0)

P0[5] (GPIO, OPAMP2-)

P0[4] (GPIO, OPAMP2+)

VDDIO0

Figure 2-5. 68-Pin QFN Part Pinout[9]

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

51

50

Lines show VDDIO

to I/O supply

association

QFN

(Top View)

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

P0[3] (GPIO, OPAMP0-/EXTREF0)

P0[2] (GPIO, OPAMP0+)

P0[1] (GPIO, OPAMP0OUT)

P0[0] (GPIO, OPAMP2OUT)

P12[3] (SIO)

P12[2] (SIO)

VSSD

VDDA

VSSA

VCCA

P15[3] (GPIO, KHZ XTAL: XI)

P15[2] (GPIO, KHZ XTAL: XO)

P12[1] (SIO, I2C1: SDA)

P12[0] (SIO, 12C1: SCL)

P3[7] (GPIO)

P3[6] (GPIO)

VDDIO3

(GPIO) P1[6]

(GPIO) P1[7]

(SIO) P12[6]

(SIO) P12[7]

[8]

(USBIO, D+, SWDIO) P15[6]

[8] (USBIO, D-, SWDCK) P15[7]

VDDD

VSSD

VCCD

(MHZ XTAL: XO, GPIO) P15[0]

(MHZ XTAL: XI, GPIO) P15[1]

(GPIO) P3[0]

(GPIO) P3[1]

(EXTREF1, GPIO) P3[2]

(GPIO) P3[3]

(GPIO) P3[4]

(GPIO) P3[5]

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

(GPIO) P2[6]

(GPIO) P2[7]

(I2C0: SCL, SIO) P12[4]

(I2C0: SDA, SIO) P12[5]

VSSB

IND

VBOOST

VBAT

VSSD

XRES

(TMS, SWDIO, GPIO) P1[0]

(TCK, SWDCK, GPIO) P1[1]

(CONFIGURABLE XRES, GPIO) P1[2]

(TDO, SWV, GPIO) P1[3]

(TDI, GPIO) P1[4]

(NTRST, GPIO) P1[5]

VDDIO1

Notes

8. Pins are Do Not Use (DNU) on devices without USB. The pin must be left floating.

9. The center pad on the QFN package should be connected to digital ground (VSSD) for best mechanical, thermal, and electrical performance. If not connected to

ground, it should be electrically floated and not connected to any other signal. For more information, see AN72845, Design Guidelines for QFN Devices.

Document Number: 001-53304 Rev. AA

Page 8 of 137

�PSoC® 3: CY8C34 Family Datasheet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

P4[5] (GPIO)

P4[4] (GPIO)

P4[3] (GPIO)

P4[2] (GPIO)

P0[7] (GPIO, IDAC2)

P0[6] (GPIO, IDAC0)

P0[5] (GPIO, OPAMP2-)

P0[4] (GPIO,

OPAMP2+)

75

74

Lines show

VDDIO to I/O

supply

association

TQFP

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

54

53

52

51

VDDIO0

P0[3] (GPIO, OPAMP0-/EXTREF0)

P0[2] (GPIO, OPAMP0+)

P0[1] (GPIO, OPAMP0OUT)

P0[0] (GPIO, OPAMP2OUT)

P4[1] (GPIO)

P4[0] (GPIO)

P12[3] (SIO)

P12[2] (SIO)

VSSD

VDDA

VSSA

VCCA

NC

NC

NC

NC

NC

NC

P15[3] (GPIO, KHZ XTAL: XI)

P15[2] (GPIO, KHZ XTAL: XO)

P12[1] (SIO, I2C1: SDA)

P12[0] (SIO, I2C1: SCL)

P3[7] (GPIO)

P3[6] (GPIO)

VDDIO1

(GPIO) P1[6]

(GPIO) P1[7]

(SIO) P12[6]

(SIO) P12[7]

(GPIO) P5[4]

(GPIO) P5[5]

(GPIO) P5[6]

[10]

(GPIO) P5[7]

[10] (USBIO, D+, SWDIO) P15[6]

(USBIO, D-, SWDCK) P15[7]

VDDD

VSSD

VCCD

NC

NC

(MHZ XTAL: XO, GPIO) P15[0]

(MHZ XTAL: XI, GPIO) P15[1]

(GPIO) P3[0]

(GPIO) P3[1]

(EXTREF1, GPIO) P3[2]

(GPIO) P3[3]

(GPIO) P3[4]

(GPIO) P3[5]

VDDIO3

(GPIO) P2[5]

(GPIO) P2[6]

(GPIO) P2[7]

(I2C0: SCL, SIO) P12[4]

(I2C0: SDA, SIO) P12[5]

(GPIO) P6[4]

(GPIO) P6[5]

(GPIO) P6[6]

(GPIO) P6[7]

VSSB

IND

VBOOST

VBAT

VSSD

XRES

(GPIO) P5[0]

(GPIO) P5[1]

(GPIO) P5[2]

(GPIO) P5[3]

(TMS, SWDIO, GPIO) P1[0]

(TCK, SWDCK, GPIO) P1[1]

(CONFIGURABLE XRES, GPIO) P1[2]

(TDO, SWV, GPIO) P1[3]

(TDI, GPIO) P1[4]

(NTRST, GPIO) P1[5]

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

VDDIO2

P2[4] (GPIO)

P2[3] (GPIO)

P2[2] (GPIO)

P2[1] (GPIO)

P2[0] (GPIO)

P15[5] (GPIO)

P15[4] (GPIO)

P6[3] (GPIO)

P6[2] (GPIO)

P6[1] (GPIO)

P6[0] (GPIO)

VDDD

VSSD

VCCD

P4[7] (GPIO)

P4[6] (GPIO)

Figure 2-6. 100-pin TQFP Part Pinout

Table 2-1. VDDIO and Port Pin Associations

VDDIO

Port Pins

VDDIO0

P0[7:0], P4[7:0], P12[3:2]

VDDIO1

P1[7:0], P5[7:0], P12[7:6]

VDDIO2

P2[7:0], P6[7:0], P12[5:4], P15[5:4]

VDDIO3

P3[7:0], P12[1:0], P15[3:0]

VDDD

P15[7:6] (USB D+, D-)

Note

10. Pins are Do Not Use (DNU) on devices without USB. The pin must be left floating.

Document Number: 001-53304 Rev. AA

Page 9 of 137

�PSoC® 3: CY8C34 Family Datasheet

Figure 2-7 and Figure 2-8 on page 11 show an example schematic and an example PCB layout, for the 100-pin TQFP part, for optimal

analog performance on a two-layer board.

The two pins labeled VDDD must be connected together.

The two pins labeled VCCD must be connected together, with capacitance added, as shown in Figure 2-7 and Power System on

page 30. The trace between the two VCCD pins should be as short as possible.

The two pins labeled VSSD must be connected together.

For information on circuit board layout issues for mixed signals, refer to the application note AN57821 - Mixed Signal Circuit Board

Layout Considerations for PSoC® 3 and PSoC 5.

Figure 2-7. Example Schematic for 100-pin TQFP Part With Power Connections

VDDD

C1

1uF

VDDD

VSSD

VSSD

VDDD

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

VDDA

C8

0.1uF

VSSD

VSSD

VDDA

VSSA

VCCA

C17

1uF

VSSA

VDDA

C9

1uF

C10

0.1uF

VSSA

VDDD

C11

0.1uF

VCCD

VDDD

VSSD

C12

0.1uF

VSSD

VDDD

VDDIO0

OA0-, REF0, P0[3]

OA0+, P0[2]

OA0OUT, P0[1]

OA2OUT, P0[0]

P4[1]

P4[0]

SIO, P12[3]

SIO, P12[2]

VSSD

VDDA

VSSA

VCCA

NC

NC

NC

NC

NC

NC

KHZXIN, P15[3]

KHZXOUT, P15[2]

SIO, P12[1]

SIO, P12[0]

OA3OUT, P3[7]

OA1OUT, P3[6]

VDDIO1

P1[6]

P1[7]

P12[6], SIO

P12[7], SIO

P5[4]

P5[5]

P5[6]

P5[7]

P15[6], USB D+

P15[7], USB DVDDD

VSSD

VCCD

NC

NC

P15[0], MHZXOUT

P15[1], MHZXIN

P3[0], IDAC1

P3[1], IDAC3

P3[2], OA3-, REF1

P3[3], OA3+

P3[4], OA1P3[5], OA1+

VDDIO3

P2[5]

P2[6]

P2[7]

P12[4], SIO

P12[5], SIO

P6[4]

P6[5]

P6[6]

P6[7]

VSSB

IND

VBOOST

VBAT

VSSD

XRES

P5[0]

P5[1]

P5[2]

P5[3]

P1[0], SWIO, TMS

P1[1], SWDIO, TCK

P1[2]

P1[3], SWV, TDO

P1[4], TDI

P1[5], NTRST

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

VSSD

VCCD

VSSD

VDDIO2

P2[4]

P2[3]

P2[2]

P2[1]

P2[0]

P15[5]

P15[4]

P6[3]

P6[2]

P6[1]

P6[0]

VDDD

VSSD

VCCD

P4[7]

P4[6]

P4[5]

P4[4]

P4[3]

P4[2]

IDAC2, P0[7]

IDAC0, P0[6]

OA2-, P0[5]

OA2+, P0[4]

VSSD

VSSD

C2

0.1uF

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

C6

0.1uF

VDDD

VDDD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

VDDD

C15

1uF

C16

0.1uF

VSSD

VSSD

Note The two VCCD pins must be connected together with as short a trace as possible. A trace under the device is recommended,

as shown in Figure 2-8 on page 11.

For more information on pad layout, refer to http://www.cypress.com/cad-resources/psoc-3-cad-libraries.

Document Number: 001-53304 Rev. AA

Page 10 of 137

�PSoC® 3: CY8C34 Family Datasheet

Figure 2-8. Example PCB Layout for 100-pin TQFP Part for Optimal Analog Performance

VSSA

VDDD

VSSD

VDDA

VSSA

Plane

VSSD

Plane

3. Pin Descriptions

IDAC0, IDAC2

Low resistance output pin for high current DACs (IDAC).

OpAmp0out, OpAmp2out

High current output of uncommitted opamp[11].

Extref0, Extref1

MHz XTAL: Xo, MHz XTAL: Xi

4- to 25-MHz crystal oscillator pin.

nTRST

Optional JTAG test reset programming and debug port

connection to reset the JTAG connection.

SIO

Opamp0–, Opamp2–

Special I/O provides interfaces to the CPU, digital peripherals

and interrupts with a programmable high threshold voltage,

analog comparator, high sink current, and high impedance state

when the device is unpowered.

Inverting input to uncommitted opamp.

SWDCK

Opamp0+, Opamp2+

Noninverting input to uncommitted opamp.

Serial wire debug clock programming and debug port

connection.

GPIO

SWDIO

General purpose I/O pin provides interfaces to the CPU, digital

peripherals, analog peripherals, interrupts, LCD segment drive,

and CapSense[11].

Serial wire debug input and output programming and debug port

connection.

I2C0: SCL, I2C1: SCL

Single wire viewer debug output.

External reference input to the analog system.

I2C SCL line providing wake from sleep on an address match.

Any I/O pin can be used for I2C SCL if wake from sleep is not

required.

SWV

TCK

JTAG test clock programming and debug port connection.

I2C0: SDA, I2C1: SDA

TDI

I2C

JTAG test data In programming and debug port connection.

SDA line providing wake from sleep on an address match.

Any I/O pin can be used for I2C SDA if wake from sleep is not

required.

Ind

Inductor connection to boost pump.

kHz XTAL: Xo, kHz XTAL: Xi

TDO

JTAG test data out programming and debug port connection.

TMS

JTAG test mode select programming and debug port connection.

32.768-kHz crystal oscillator pin.

Note

11. GPIOs with opamp outputs are not recommended for use with CapSense.

Document Number: 001-53304 Rev. AA

Page 11 of 137

�PSoC® 3: CY8C34 Family Datasheet

USBIO, D+

XRES (and configurable XRES)

Provides D+ connection directly to a USB 2.0 bus. May be used

as a digital I/O pin. Pins are Do Not Use (DNU) on devices

without USB.

External reset pin. Active low with internal pull-up. Pin P1[2] may

be configured to be a XRES pin; see “Nonvolatile Latches

(NVLs)” on page 23.

USBIO, D–

Provides D– connection directly to a USB 2.0 bus. May be used

as a digital I/O pin. Pins are No Connect (NC) on devices without

USB.

VBOOST

Power sense connection to boost pump.

VBAT

Battery supply to boost pump.

VCCA.

Output of the analog core regulator or the input to the

analog core. Requires a 1uF capacitor to VSSA. The regulator

output is not designed to drive external circuits. Note that if you

use the device with an external core regulator (externally

regulated mode), the voltage applied to this pin must not

exceed the allowable range of 1.71 V to 1.89 V. When using

the internal core regulator, (internally regulated mode, the

default), do not tie any power to this pin. For details see Power

System on page 30.

VCCD.

Output of the digital core regulator or the input to the digital

core. The two VCCD pins must be shorted together, with the

trace between them as short as possible, and a 1uF capacitor to

VSSD. The regulator output is not designed to drive external

circuits. Note that if you use the device with an external core

regulator (externally regulated mode), the voltage applied to

this pin must not exceed the allowable range of 1.71 V to

1.89 V. When using the internal core regulator (internally

regulated mode, the default), do not tie any power to this pin. For

details see Power System on page 30.

VDDA

Supply for all analog peripherals and analog core regulator.

VDDA must be the highest voltage present on the device. All

other supply pins must be less than or equal to VDDA.

VDDD

Supply for all digital peripherals and digital core regulator. VDDD

must be less than or equal to VDDA.

VSSA

Ground for all analog peripherals.

VSSB

Ground connection for boost pump.

VSSD

Ground for all digital logic and I/O pins.

VDDIO0, VDDIO1, VDDIO2, VDDIO3

Supply for I/O pins. See pinouts for specific I/O pin to VDDIO

mapping. Each VDDIO must be tied to a valid operating voltage

(1.71 V to 5.5 V), and must be less than or equal to VDDA.

Document Number: 001-53304 Rev. AA

4. CPU

4.1 8051 CPU

The CY8C34 devices use a single cycle 8051 CPU, which is fully

compatible with the original MCS-51 instruction set. The

CY8C34 family uses a pipelined RISC architecture, which

executes most instructions in 1 to 2 cycles to provide peak

performance of up to 24 MIPS with an average of 2 cycles per

instruction. The single cycle 8051 CPU runs ten times faster than

a standard 8051 processor.

The 8051 CPU subsystem includes these features:

Single cycle 8051 CPU

Up to 64 KB of flash memory, up to 2 KB of EEPROM, and up

to 8 KB of SRAM

512-byte instruction cache between CPU and flash

Programmable nested vector interrupt controller

Direct memory access (DMA) controller

Peripheral HUB (PHUB)

External memory interface (EMIF)

4.2 Addressing Modes

The following addressing modes are supported by the 8051:

Direct Addressing: The operand is specified by a direct 8-bit

address field. Only the internal RAM and the SFRs can be

accessed using this mode.

Indirect Addressing: The instruction specifies the register which

contains the address of the operand. The registers R0 or R1

are used to specify the 8-bit address, while the data pointer

(DPTR) register is used to specify the 16-bit address.

Register Addressing: Certain instructions access one of the

registers (R0 to R7) in the specified register bank. These

instructions are more efficient because there is no need for an

address field.

Register Specific Instructions: Some instructions are specific

to certain registers. For example, some instructions always act

on the accumulator. In this case, there is no need to specify the

operand.

Immediate Constants: Some instructions carry the value of the

constants directly instead of an address.

Indexed Addressing: This type of addressing can be used only

for a read of the program memory. This mode uses the Data

Pointer as the base and the accumulator value as an offset to

read a program memory.

Bit Addressing: In this mode, the operand is one of 256 bits.

Page 12 of 137

�PSoC® 3: CY8C34 Family Datasheet

4.3 Instruction Set

4.3.1 Instruction Set Summary

The 8051 instruction set is highly optimized for 8-bit handling and

Boolean operations. The types of instructions supported include:

4.3.1.1 Arithmetic Instructions

Arithmetic instructions

Logical instructions

Data transfer instructions

Arithmetic instructions support the direct, indirect, register,

immediate constant, and register-specific instructions.

Arithmetic modes are used for addition, subtraction,

multiplication, division, increment, and decrement operations.

Table 4-1 lists the different arithmetic instructions.

Boolean instructions

Program branching instructions

Table 4-1. Arithmetic Instructions

Mnemonic

Description

Bytes

Cycles

ADD

A,Rn

Add register to accumulator

1

1

ADD

A,Direct

Add direct byte to accumulator

2

2

ADD

A,@Ri

Add indirect RAM to accumulator

1

2

ADD

A,#data

Add immediate data to accumulator

2

2

ADDC A,Rn

Add register to accumulator with carry

1

1

ADDC A,Direct

Add direct byte to accumulator with carry

2

2

ADDC A,@Ri

Add indirect RAM to accumulator with carry

1

2

ADDC A,#data

Add immediate data to accumulator with carry

2

2

SUBB A,Rn

Subtract register from accumulator with borrow

1

1

SUBB A,Direct

Subtract direct byte from accumulator with borrow

2

2

SUBB A,@Ri

Subtract indirect RAM from accumulator with borrow

1

2

SUBB A,#data

Subtract immediate data from accumulator with borrow

2

2

INC

A

Increment accumulator

1

1

INC

Rn

Increment register

1

2

INC

Direct

Increment direct byte

2

3

INC

@Ri

Increment indirect RAM

1

3

DEC

A

Decrement accumulator

1

1

DEC

Rn

Decrement register

1

2

DEC

Direct

Decrement direct byte

2

3

DEC

@Ri

Decrement indirect RAM

1

3

INC

DPTR

Increment data pointer

1

1

MUL

Multiply accumulator and B

1

2

DIV

Divide accumulator by B

1

6

DAA

Decimal adjust accumulator

1

3

Document Number: 001-53304 Rev. AA

Page 13 of 137

�PSoC® 3: CY8C34 Family Datasheet

4.3.1.2 Logical Instructions

The logical instructions perform Boolean operations such as AND, OR, XOR on bytes, rotate of accumulator contents, and swap of

nibbles in an accumulator. The Boolean operations on the bytes are performed on the bit-by-bit basis. Table 4-2 shows the list of

logical instructions and their description.

Table 4-2. Logical Instructions

Mnemonic

Description

Bytes

Cycles

ANL

A,Rn

AND register to accumulator

1

1

ANL

A,Direct

AND direct byte to accumulator

2

2

ANL

A,@Ri

AND indirect RAM to accumulator

1

2

ANL

A,#data

AND immediate data to accumulator

2

2

ANL

Direct, A

AND accumulator to direct byte

2

3

ANL

Direct, #data

AND immediate data to direct byte

3

3

ORL

A,Rn

OR register to accumulator

1

1

ORL

A,Direct

OR direct byte to accumulator

2

2

ORL

A,@Ri

OR indirect RAM to accumulator

1

2

ORL

A,#data

OR immediate data to accumulator

2

2

ORL

Direct, A

OR accumulator to direct byte

2

3

ORL

Direct, #data

OR immediate data to direct byte

3

3

XRL

A,Rn

XOR register to accumulator

1

1

XRL

A,Direct

XOR direct byte to accumulator

2

2

XRL

A,@Ri

XOR indirect RAM to accumulator

1

2

XRL

A,#data

XOR immediate data to accumulator

2

2

XRL

Direct, A

XOR accumulator to direct byte

2

3

XRL

Direct, #data

XOR immediate data to direct byte

3

3

CLR

A

Clear accumulator

1

1

CPL

A

Complement accumulator

1

1

RL

A

Rotate accumulator left

1

1

RLC

A

Rotate accumulator left through carry

1

1

RR

A

Rotate accumulator right

1

1

RRC A

Rotate accumulator right though carry

1

1

SWAP A

Swap nibbles within accumulator

1

1

Document Number: 001-53304 Rev. AA

Page 14 of 137

�PSoC® 3: CY8C34 Family Datasheet

4.3.1.3 Data Transfer Instructions

4.3.1.4 Boolean Instructions

The data transfer instructions are of three types: the core RAM,

xdata RAM, and the lookup tables. The core RAM transfer

includes transfer between any two core RAM locations or SFRs.

These instructions can use direct, indirect, register, and

immediate addressing. The xdata RAM transfer includes only the

transfer between the accumulator and the xdata RAM location.

It can use only indirect addressing. The lookup tables involve

nothing but the read of program memory using the Indexed

addressing mode. Table 4-3 lists the various data transfer

instructions available.

The 8051 core has a separate bit addressable memory location.

It has 128 bits of bit-addressable RAM and a set of SFRs that are

bit addressable. The instruction set includes the whole menu of

bit operations such as move, set, clear, toggle, OR, and AND

instructions and the conditional jump instructions. Table 4-4 on

page 16 lists the available Boolean instructions.

Table 4-3. Data Transfer Instructions

Mnemonic

Description

Bytes

Cycles

MOV

A,Rn

Move register to accumulator

1

1

MOV

A,Direct

Move direct byte to accumulator

2

2

MOV

A,@Ri

Move indirect RAM to accumulator

1

2

MOV

A,#data

Move immediate data to accumulator

2

2

MOV

Rn,A

Move accumulator to register

1

1

MOV

Rn,Direct

Move direct byte to register

2

3

MOV

Rn, #data

Move immediate data to register

2

2

MOV

Direct, A

Move accumulator to direct byte

2

2

MOV

Direct, Rn

Move register to direct byte

2

2

MOV

Direct, Direct

Move direct byte to direct byte

3

3

MOV

Direct, @Ri

Move indirect RAM to direct byte

2

3

MOV

Direct, #data

Move immediate data to direct byte

3

3

MOV

@Ri, A

Move accumulator to indirect RAM

1

2

MOV

@Ri, Direct

Move direct byte to indirect RAM

2

3

MOV

@Ri, #data

Move immediate data to indirect RAM

2

2

MOV

DPTR, #data16

Load data pointer with 16-bit constant

3

3

MOVC A, @A+DPTR

Move code byte relative to DPTR to accumulator

1

5

MOVC A, @A + PC

Move code byte relative to PC to accumulator

1

4

MOVX A,@Ri

Move external RAM (8-bit) to accumulator

1

4

MOVX A, @DPTR

Move external RAM (16-bit) to accumulator

1

3

MOVX @Ri, A

Move accumulator to external RAM (8-bit)

1

5

MOVX @DPTR, A

Move accumulator to external RAM (16-bit)

1

4

PUSH Direct

Push direct byte onto stack

2

3

POP

Direct

Pop direct byte from stack

2

2

XCH

A, Rn

Exchange register with accumulator

1

2

XCH

A, Direct

Exchange direct byte with accumulator

2

3

XCH

A, @Ri

Exchange indirect RAM with accumulator

1

3

Exchange low order indirect digit RAM with accumulator

1

3

XCHD A, @Ri

Document Number: 001-53304 Rev. AA

Page 15 of 137

�PSoC® 3: CY8C34 Family Datasheet

Table 4-4. Boolean Instructions

Mnemonic

Description

Bytes

Cycles

CLR

C

Clear carry

1

1

CLR

bit

Clear direct bit

2

3

SETB C

Set carry

1

1

SETB bit

Set direct bit

2

3

CPL

Complement carry

1

1

C

CPL

bit

Complement direct bit

2

3

ANL

C, bit

AND direct bit to carry

2

2

ANL

C, /bit

AND complement of direct bit to carry

2

2

OR direct bit to carry

2

2

ORL C, /bit

OR complement of direct bit to carry

2

2

MOV C, bit

Move direct bit to carry

2

2

MOV bit, C

Move carry to direct bit

2

3

JC

Jump if carry is set

2

3

JNC rel

Jump if no carry is set

2

3

JB

Jump if direct bit is set

3

5

JNB bit, rel

Jump if direct bit is not set

3

5

JBC bit, rel

Jump if direct bit is set and clear bit

3

5

ORL C, bit

rel

bit, rel

4.3.1.5 Program Branching Instructions

The 8051 supports a set of conditional and unconditional jump instructions that help to modify the program execution flow. Table 4-5

shows the list of jump instructions.

Table 4-5. Jump Instructions

Mnemonic

Description

Bytes

Cycles

ACALL addr11

Absolute subroutine call

2

4

LCALL addr16

Long subroutine call

3

4

RET

Return from subroutine

1

4

RETI

Return from interrupt

1

4

AJMP addr11

Absolute jump

2

3

LJMP addr16

Long jump

3

4

SJMP rel

Short jump (relative address)

2

3

JMP @A + DPTR

Jump indirect relative to DPTR

1

5

JZ rel

Jump if accumulator is zero

2

4

JNZ rel

Jump if accumulator is nonzero

2

4

CJNE A,Direct, rel

Compare direct byte to accumulator and jump if not equal

3

5

CJNE A, #data, rel

Compare immediate data to accumulator and jump if not equal

3

4

CJNE Rn, #data, rel

Compare immediate data to register and jump if not equal

3

4

CJNE @Ri, #data, rel

Compare immediate data to indirect RAM and jump if not equal

3

5

DJNZ Rn,rel

Decrement register and jump if not zero

2

4

DJNZ Direct, rel

Decrement direct byte and jump if not zero

3

5

NOP

No operation

1

1

Document Number: 001-53304 Rev. AA

Page 16 of 137

�PSoC® 3: CY8C34 Family Datasheet

4.4 DMA and PHUB

Any digitally routable signal, the CPU, or another DMA channel,

The PHUB and the DMA controller are responsible for data

transfer between the CPU and peripherals, and also data

transfers between peripherals. The PHUB and DMA also control

device configuration during boot. The PHUB consists of:

A central hub that includes the DMA controller, arbiter, and

router

Multiple spokes that radiate outward from the hub to most

peripherals

There are two PHUB masters: the CPU and the DMA controller.

Both masters may initiate transactions on the bus. The DMA

channels can handle peripheral communication without CPU

intervention. The arbiter in the central hub determines which

DMA channel is the highest priority if there are multiple requests.

4.4.1 PHUB Features

CPU and DMA controller are both bus masters to the PHUB

Eight Multi-layer AHB Bus parallel access paths (spokes) for

peripheral access

Simultaneous CPU and DMA access to peripherals located on

different spokes

Simultaneous DMA source and destination burst transactions

on different spokes

Supports 8, 16, 24, and 32-bit addressing and data

Table 4-6. PHUB Spokes and Peripherals

can trigger a transaction

Each channel can generate up to two interrupts per transfer

Transactions can be stalled or canceled

Supports transaction size of infinite or 1 to 64 KB

TDs may be nested and/or chained for complex transactions

4.4.3 Priority Levels

The CPU always has higher priority than the DMA controller

when their accesses require the same bus resources. Due to the

system architecture, the CPU can never starve the DMA. DMA

channels of higher priority (lower priority number) may interrupt

current DMA transfers. In the case of an interrupt, the current

transfer is allowed to complete its current transaction. To ensure

latency limits when multiple DMA accesses are requested

simultaneously, a fairness algorithm guarantees an interleaved

minimum percentage of bus bandwidth for priority levels 2

through 7. Priority levels 0 and 1 do not take part in the fairness

algorithm and may use 100 percent of the bus bandwidth. If a tie

occurs on two DMA requests of the same priority level, a simple

round robin method is used to evenly share the allocated

bandwidth. The round robin allocation can be disabled for each

DMA channel, allowing it to always be at the head of the line.

Priority levels 2 to 7 are guaranteed the minimum bus bandwidth

shown in Table 4-7 after the CPU and DMA priority levels 0 and

1 have satisfied their requirements.

Table 4-7. Priority Levels

Priority Level

% Bus Bandwidth

SRAM

0

100.0

1

IOs, PICU, EMIF

1

100.0

2

PHUB local configuration, Power manager,

Clocks, IC, SWV, EEPROM, Flash

programming interface

2

50.0

3

25.0

4

12.5

5

6.2

6

3.1

7

1.5

PHUB Spokes

0

Peripherals

3

Analog interface and trim, Decimator

4

USB, CAN, I2C, Timers, Counters, and PWMs

5

Reserved

6

UDBs group 1

7

UDBs group 2

4.4.2 DMA Features

When the fairness algorithm is disabled, DMA access is granted

based solely on the priority level; no bus bandwidth guarantees

are made.

Twenty-four DMA channels

4.4.4 Transaction Modes Supported

Each channel has one or more Transaction Descriptors (TDs)

The flexible configuration of each DMA channel and the ability to

chain multiple channels allow the creation of both simple and

complex use cases. General use cases include, but are not

limited to:

to configure channel behavior. Up to 128 total TDs can be

defined

TDs can be dynamically updated

Eight levels of priority per channel

Document Number: 001-53304 Rev. AA

Page 17 of 137

�PSoC® 3: CY8C34 Family Datasheet

4.4.4.1 Simple DMA

In a simple DMA case, a single TD transfers data between a source and sink (peripherals or memory location). The basic timing

diagrams of DMA read and write cycles are shown in Figure 4-1. For more description on other transfer modes, refer to the Technical

Reference Manual.

Figure 4-1. DMA Timing Diagram

ADDRESS Phase

DATA Phase

ADDRESS Phase

CLK

DATA Phase

CLK

ADDR 16/32

A

ADDR 16/32

B

WRITE

A

B

WRITE

DATA (A)

DATA

READY

DATA (A)

DATA

READY

Basic DMA Write Transfer without wait states

Basic DMA Read Transfer without wait states

A ping pong DMA case uses double buffering to allow one buffer

to be filled by one client while another client is consuming the

data previously received in the other buffer. In its simplest form,

this is done by chaining two TDs together so that each TD calls

the opposite TD when complete.

can set up this configuration information anywhere in system

memory and copy it with a simple TD to the peripheral. After the

configuration phase, a data phase TD (or a series of data phase

TDs) can begin (potentially using scatter gather). When the data

phase TD(s) finish, a status phase TD can be invoked that reads

some memory mapped status information from the peripheral

and copies it to a location in system memory specified by the

CPU for later inspection. Multiple sets of configuration, data, and

status phase “subchains” can be strung together to create larger

chains that transmit multiple packets in this way. A similar

concept exists in the opposite direction to receive the packets.

4.4.4.4 Circular DMA

4.4.4.7 Nested DMA

4.4.4.2 Auto Repeat DMA

Auto repeat DMA is typically used when a static pattern is

repetitively read from system memory and written to a peripheral.

This is done with a single TD that chains to itself.

4.4.4.3 Ping Pong DMA

Circular DMA is similar to ping pong DMA except it contains more

than two buffers. In this case there are multiple TDs; after the last

TD is complete it chains back to the first TD.

4.4.4.5 Scatter Gather DMA

In the case of scatter gather DMA, there are multiple

noncontiguous sources or destinations that are required to

effectively carry out an overall DMA transaction. For example, a

packet may need to be transmitted off of the device and the

packet elements, including the header, payload, and trailer, exist

in various noncontiguous locations in memory. Scatter gather

DMA allows the segments to be concatenated together by using

multiple TDs in a chain. The chain gathers the data from the

multiple locations. A similar concept applies for the reception of

data onto the device. Certain parts of the received data may need

to be scattered to various locations in memory for software

processing convenience. Each TD in the chain specifies the

location for each discrete element in the chain.

One TD may modify another TD, as the TD configuration space

is memory mapped similar to any other peripheral. For example,

a first TD loads a second TD’s configuration and then calls the

second TD. The second TD moves data as required by the

application. When complete, the second TD calls the first TD,

which again updates the second TD’s configuration. This

process repeats as often as necessary.

4.5 Interrupt Controller

The interrupt controller provides a mechanism for hardware

resources to change program execution to a new address,

independent of the current task being executed by the main

code. The interrupt controller provides enhanced features not

found on original 8051 interrupt controllers:

Thirty two interrupt vectors

Jumps directly to ISR anywhere in code space with dynamic

vector addresses

4.4.4.6 Packet Queuing DMA

Multiple sources for each vector

Packet queuing DMA is similar to scatter gather DMA but

specifically refers to packet protocols. With these protocols,

there may be separate configuration, data, and status phases

associated with sending or receiving a packet.

Flexible interrupt to vector matching

For instance, to transmit a packet, a memory mapped

configuration register can be written inside a peripheral,

specifying the overall length of the ensuing data phase. The CPU

Document Number: 001-53304 Rev. AA

Each interrupt vector is independently enabled or disabled

Each interrupt can be dynamically assigned one of eight

priorities

Eight level nestable interrupts

Page 18 of 137

�PSoC® 3: CY8C34 Family Datasheet

Multiple I/O interrupt vectors

direct connections to the most common interrupt sources and provide the lowest

resource cost connection. The DMA interrupt sources provide direct connections to

the two DMA interrupt sources provided per DMA channel. The third interrupt source

for vectors is from the UDB digital routing array. This allows any digital signal

available to the UDB array to be used as an interrupt source. Fixed function interrupts

and all interrupt sources may be routed to any interrupt vector using the UDB interrupt

source connections.

Software can send interrupts

Software can clear pending interrupts

When an interrupt is pending, the current instruction is completed and the program

counter is pushed onto the stack. Code execution then jumps to the program address

provided by the vector. After the ISR is completed, a RETI instruction is executed and

returns execution to the instruction following the previously interrupted instruction. To

do this the RETI instruction pops the program counter from the stack.

Figure 4-2 represents typical flow of events when an interrupt triggered. Figure 4-3

on page 20 shows the interrupt structure and priority polling.

If the same priority level is assigned to two or more interrupts, the interrupt with the

lower vector number is executed first. Each interrupt vector may choose from three

interrupt sources: Fixed Function, DMA, and UDB. The fixed function interrupts are

Figure 4-2. Interrupt Processing Timing Diagram

1

2

3

4

5

6

7

8

9

10

11

S

CLK

Arrival of new Interrupt

INT_INPUT

S

Pend bit is set on next clock active edge

POST and PEND bits cleared after IRQ is sleared

PEND

S

Interrupt is posted to ascertain the priority

POST

S

IRQ cleared after receiving IRA

Interrupt request sent to core for processing

IRQ

ACTIVE_INT_NUM

(#10)

INT_VECT_ADDR

NA

NA

0x0010

S

S

The active interrupt

number is posted to core

The active interrupt ISR

address is posted to core

0x0000

S

S

NA

S

IRA

S

IRC

Interrupt generation and posting to CPU

CPU Response

Int. State

Clear

S

Completing current instruction and branching to vector address

Complete ISR and return

TIME

Notes

1: Interrupt triggered asynchronous to the clock

2: The PEND bit is set on next active clock edge to indicate the interrupt arrival

3: POST bit is set following the PEND bit

4: Interrupt request and the interrupt number sent to CPU core after evaluation priority (Takes 3 clocks)

5: ISR address is posted to CPU core for branching

Document Number: 001-53304 Rev. AA

Page 19 of 137

�PSoC® 3: CY8C34 Family Datasheet

6: CPU acknowledges the interrupt request

7: ISR address is read by CPU for branching

8, 9: PEND and POST bits are cleared respectively after receiving the IRA from core

10: IRA bit is cleared after completing the current instruction and starting the instruction execution from ISR location (takes 7 cycles)

11: IRC is set to indicate the completion of ISR, Active int. status is restored with previous status

The total interrupt latency (ISR execution)

= POST + PEND + IRQ + IRA + Completing current instruction and branching

= 1+1+1+2+7 cycles

= 12 cycles

Figure 4-3. Interrupt Structure

Interrupt Polling logic

Interrupts form Fixed

function blocks, DMA and

UDBs

Highest Priority

Interrupt Enable/

Disable, PEND and

POST logic

Interrupts 0 to 31

from UDBs

0

Interrupts 0 to 31

from Fixed

Function Blocks

1

IRQ

8 Level

Priority

decoder

for all

interrupts

Polling sequence

Interrupt

routing logic

to select 32

sources

Interrupt 2 to 30

Interrupts 0 to

31 from DMA

Individual

Enable Disable

bits

0 to 31

ACTIVE_INT_NUM

[15:0]

INT_VECT_ADDR

IRA

IRC

31

Global Enable

disable bit

Document Number: 001-53304 Rev. AA

Lowest Priority

Page 20 of 137

�PSoC® 3: CY8C34 Family Datasheet

Table 4-8. Interrupt Vector Table

#

Fixed Function

DMA

phub_termout0[0]

UDB

0

LVD

udb_intr[0]

1

Cache/ECC

phub_termout0[1]

udb_intr[1]

2

Reserved

phub_termout0[2]

udb_intr[2]

3

Sleep (Pwr Mgr)

phub_termout0[3]

udb_intr[3]

4

PICU[0]

phub_termout0[4]

udb_intr[4]

5

PICU[1]

phub_termout0[5]

udb_intr[5]

6

PICU[2]

phub_termout0[6]

udb_intr[6]

7

PICU[3]

phub_termout0[7]

udb_intr[7]

8

PICU[4]

phub_termout0[8]

udb_intr[8]

9

PICU[5]

phub_termout0[9]

udb_intr[9]

10

PICU[6]

phub_termout0[10] udb_intr[10]

11

PICU[12]

phub_termout0[11]

12

PICU[15]

phub_termout0[12] udb_intr[12]

13

Comparators

Combined

phub_termout0[13] udb_intr[13]

14

Switched Caps

Combined

phub_termout0[14] udb_intr[14]

15

I2C

phub_termout0[15] udb_intr[15]

16

CAN

phub_termout1[0]

udb_intr[16]

17

Timer/Counter0

phub_termout1[1]

udb_intr[17]

18

Timer/Counter1

phub_termout1[2]

udb_intr[18]

19

Timer/Counter2

phub_termout1[3]

udb_intr[19]

20

Timer/Counter3

phub_termout1[4]

udb_intr[20]

21

USB SOF Int

phub_termout1[5]

udb_intr[21]

22

USB Arb Int

phub_termout1[6]

udb_intr[22]

23

USB Bus Int

phub_termout1[7]

udb_intr[23]

24

USB Endpoint[0]

phub_termout1[8]

udb_intr[24]

25

USB Endpoint Data phub_termout1[9]

udb_intr[25]

26

Reserved

phub_termout1[10] udb_intr[26]

27

LCD

phub_termout1[11]

28

Reserved

phub_termout1[12] udb_intr[28]

udb_intr[11]

udb_intr[27]

29

Decimator Int

phub_termout1[13] udb_intr[29]

30

PHUB Error Int

phub_termout1[14] udb_intr[30]

31

EEPROM Fault Int

phub_termout1[15] udb_intr[31]

Document Number: 001-53304 Rev. AA

Page 21 of 137

�PSoC® 3: CY8C34 Family Datasheet

5. Memory

5.1 Static RAM

CY8C34 Static RAM (SRAM) is used for temporary data storage.

Up to 8 KB of SRAM is provided and can be accessed by the

8051 or the DMA controller. See Memory Map on page 25.

Simultaneous access of SRAM by the 8051 and the DMA

controller is possible if different 4-KB blocks are accessed.

“Device Security” section on page 68). For more information