Please note that Cypress is an Infineon Technologies Company.

The document following this cover page is marked as “Cypress” document as this is the

company that originally developed the product. Please note that Infineon will continue

to offer the product to new and existing customers as part of the Infineon product

portfolio.

Continuity of document content

The fact that Infineon offers the following product as part of the Infineon product

portfolio does not lead to any changes to this document. Future revisions will occur

when appropriate, and any changes will be set out on the document history page.

Continuity of ordering part numbers

Infineon continues to support existing part numbers. Please continue to use the

ordering part numbers listed in the datasheet for ordering.

www.infineon.com

�CYW89071

Single-Chip Automotive Grade Bluetooth

Transceiver and Baseband Processor

The Cypress CYW89071 is a monolithic, single-chip, Bluetooth 4.1 compliant, stand-alone baseband processor with an integrated

2.4 GHz transceiver. Manufactured using the industry's most advanced 65 nm CMOS low-power process, the CYW89071 employs

the highest level of integration, eliminating all critical external components, and thereby minimizing the device’s footprint and costs

associated with the implementation of Bluetooth solutions.

The CYW89071 brings current mobile connectivity technology to automotive radio applications and offers automotive Grade 3 (–40°C

to +85°C ambient operating temperature range) performance. The CYW89071 is tested to Automotive Electronics Council (AEC)

guidelines (AEC-Q100) for environmental stress testing and is manufactured in ISO9001 approved and TS16949 certified facilities.

Cypress Part Numbering Scheme

Cypress is converting the acquired IoT part numbers from Broadcom to the Cypress part numbering scheme. Due to this conversion,

there is no change in form, fit, or function as a result of offering the device with Cypress part number marking. The table provides

Cypress ordering part number that matches an existing IoT part number.

Table 1. Mapping Table for Part Number between Broadcom and Cypress

Broadcom Part Number

Cypress Part Number

BCM89071

CYW89071

BCM89071A1CUBXG

CYW89071A1CUBXG

Acronyms and Abbreviations

In most cases, acronyms and abbreviations are defined on first use.

For a comprehensive list of acronyms and other terms used in Cypress documents, go to http://www.cypress.com/glossary.

Applications

■

Bluetooth 4.1 + EDR compliant

■

Class 1 capable with built-in PA

■

Programmable output power control meets Class 1, Class 2,

or Class 3 requirements

■

Uses supply voltages up to 5.5V

■

■

Supports Broadcom SmartAudio® AEC-Q100 environmental

stress guidelines, wide-band speech, subband coding (SBC)

codec, and packet loss concealment (PLC).

■

Automatic frequency detection for standard crystal and TCXO

values when an external 32.768 kHz reference clock is

provided.

■

Ultra-low power consumption

■

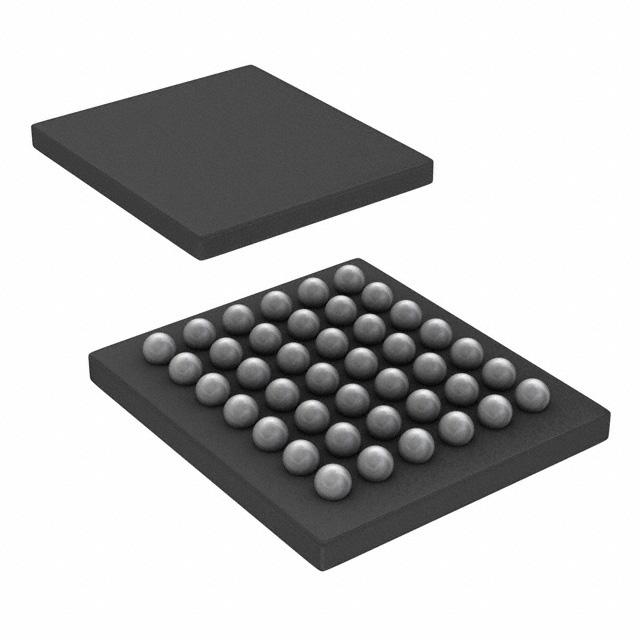

Available in 42-bump WLBGA

■

ARM7TDMI-S™–based microprocessor with integrated ROM

and RAM

■

Supports patch RAM download without external memory

■

Automotive data communication

Fractional-N synthesizer supports frequency references from

12 MHz to 52 MHz

Features

■

Automotive hands-free radios

Cypress Semiconductor Corporation

Document Number: 002-14857 Rev. *H

•

198 Champion Court

•

San Jose, CA 95134-1709

•

408-943-2600

Revised April 25, 2017

�CYW89071

Figure 1. System Block Diagram

PCM

CYW89071

UART

GPIO

Memory

SPI

High-Speed

Peripheral Transport

Unit (PTU)

Radio Transceiver

Microprocessor and

Memory Unit (uPU)

Bluetooth Baseband

Core (BBC)

I2S

TCXO

LPO

IoT Resources

Cypress provides a wealth of data at http://www.cypress.com/internet-things-iot to help you to select the right IoT device for your

design, and quickly and effectively integrate the device into your design. Cypress provides customer access to a wide range of

information, including technical documentation, schematic diagrams, product bill of materials, PCB layout information, and software

updates. Customers can acquire technical documentation and software from the Cypress Support Community website

(http://community.cypress.com/).

Document Number: 002-14857 Rev. *H

Page 2 of 51

�CYW89071

Contents

1. Overview ........................................................................ 4

1.1 Major Features ...................................................... 4

1.2 Block Diagram ....................................................... 6

1.3 Automotive Usage Model ...................................... 7

2. Integrated Radio Transceiver ...................................... 8

2.1 Transmitter Path .................................................... 8

2.2 Receiver Path ........................................................ 8

2.3 Local Oscillator Generation ................................... 8

2.4 Calibration ............................................................. 8

2.5 Internal LDO .......................................................... 9

3. Bluetooth Baseband Core ......................................... 10

3.1 Transmit and Receive Functions ......................... 10

3.2 Bluetooth 4.1 + EDR Features ............................ 10

3.3 Frequency Hopping Generator ............................ 10

3.4 Link Control Layer ............................................... 11

3.5 Test Mode Support .............................................. 11

3.6 Power Management Unit ..................................... 11

3.7 Adaptive Frequency Hopping .............................. 13

3.8 Collaborative Coexistence ................................... 13

3.9 Serial Enhanced Coexistence Interface .............. 13

4. Microprocessor Unit ................................................... 15

4.1 NVRAM Configuration Data and Storage ............ 15

4.2 EEPROM ............................................................. 15

4.3 External Reset ..................................................... 15

4.4 One-Time Programmable Memory ...................... 16

5. Peripheral Transport Unit .......................................... 17

Document Number: 002-14857 Rev. *H

5.1 PCM Interface ..................................................... 17

5.2 HCI Transport Detection Configuration ............... 19

5.3 UART Interface .................................................... 19

5.4 SPI ....................................................................... 20

6. Frequency References ............................................... 21

6.1 Crystal Interface and Clock Generation .............. 21

6.2 Crystal Oscillator ................................................. 22

6.3 External Frequency Reference ............................ 22

6.4 Frequency Selection ............................................ 23

6.5 Frequency Trimming ........................................... 23

6.6 LPO Clock Interface ............................................ 24

7. Pin and Signal Descriptions ...................................... 25

7.1 Pin Descriptions .................................................. 25

8. Ball Grid Arrays .......................................................... 27

9. Electrical Characteristics ........................................... 28

9.1 Electrostatic Discharge Specifications ................ 30

9.2 RF Specifications ................................................ 33

9.3 Timing and AC Characteristics ............................ 36

9.4 I2S Interface ........................................................ 43

10. Mechanical Information ........................................... 46

10.1 Tape, Reel, and Packing Specification .............. 47

11. Package Thermal Characteristics ........................... 48

11.1 Thermal Characteristics .................................... 48

12. Ordering Information ................................................ 49

13. References ................................................................ 49

Document History .......................................................... 50

Page 3 of 38

�CYW89071

1. Overview

The Cypress CYW89071 complies with the Bluetooth Core Specification, version 4.1 and is designed for use with a standard Host

Controller Interface (HCI) UART. The combination of the Bluetooth Baseband Core (BBC), a Peripheral Transport Unit (PTU), and an

ARM®-based microprocessor with on-chip ROM provides a complete lower layer Bluetooth protocol stack, including the Link Controller

(LC), Link Manager (LM), and HCI.

1.1 Major Features

Core features of the CYW89071 include:

■

Support for Bluetooth 4.1 + EDR, including the following options:

❐ A whitelist size of 25

❐ Enhanced Power Control

❐ HCI Read Encryption Key Size command

■

Full support for Bluetooth 2.1 + EDR additional features:

❐ Secure Simple Pairing (SSP)

❐ Encryption Pause Resume (EPR)

❐ Enhance Inquiry Response (EIR)

❐ Link Supervision Time Out (LSTO)

❐ Sniff SubRating (SSR)

❐ Erroneous Data (ED)

❐ Packet Boundary Flag (PBF)

■

Built-in Low Drop-Out (LDO) regulators (2)

❐ 1.63 to 5.5V input voltage range

❐ 1.8 to 3.3V intermediate programmable output voltage

■

Integrated RF section

❐ Single-ended, 50 RF interface

❐ Built-in TX/RX switch functionality

❐ TX Class 1 output power capability

❐ -88 dBm RX sensitivity basic rate

■

Supports maximum Bluetooth data rates over HCI UART and SPI interfaces

■

Multipoint operation, with up to seven active slaves

❐ Maximum of seven simultaneous active ACL links

❐ Maximum of three simultaneous active SCO and eSCO links, with Scatternet support

■

Scatternet operation, with up to four active piconets (with background scan and support for ScatterMode)

■

High-speed HCI UART transport support

❐ H4 five-wire UART (four signal wires, one ground wire)

❐ H5 three-wire UART (two signal wires, one ground wire)

❐ Maximum UART baud rates of 4 Mbps

❐ Low-power out-of-band BT_WAKE and HOST_WAKE signaling

❐ VSC from host transport to UART

❐ Proprietary compressing scheme (allows more than two simultaneous A2DP packets and up to five devices at a time)

■

Channel Quality-Driven Data Rate (CQDDR) and packet type selection

■

Standard Bluetooth test modes

■

Extended radio and production test mode features

■

Full support for power savings modes:

❐ Bluetooth standard Hold and Sniff

❐ Deep sleep modes and regulator shutdown

Document Number: 002-14857 Rev. *H

Page 4 of 51

�CYW89071

■

Supports Wide-Band Speech (WBS) over PCM and Packet Loss Concealment (PLC) for better audio quality

■

2-, 3-, and 4-wire coexistence

■

Power Amplifier (PA) shutdown for externally controlled coexistence, such as WIMAX

■

Built-in LPO clock or operation using an external LPO clock

■

TCXO input and auto-detection of all standard handset clock frequencies (supports low-power crystal, which can be used during

Power Saving mode with better timing accuracy)

■

OR gate for combining a host clock request with a Bluetooth clock request (operates even when the Bluetooth core logic is powered

off)

■

Larger patch RAM space to support future enhancements

■

Serial flash Interface with native support for devices from several manufacturers

■

One-Time Programmable (OTP) memory

Document Number: 002-14857 Rev. *H

Page 5 of 51

�CYW89071

1.2 Block Diagram

Figure 2 on page 6 shows the interconnect of the major CYW89071 physical blocks and associated external interfaces.

Figure 2. Functional Block Diagram

JTAG

ARM7TDMI‐S

DMA

Scan JTAG

Address Decoder

Bus Arb

Trap & Patch

Flash

I/F

32‐bit AHB

AHB2EBI

External

Bus I/F

AHB2APB

WD Timer

Remap &

Pause

GPIO+Aux

SW

Timers

AHB2MEM

ROM

384 KB

RAM

112 KB

Calibration &

Control

Digital Demod

Bit Sync

Low Power

Scan

Blue RF Registers

Interrupt

Controller

PCM

32‐bit APB

Bluetooth Radio

LCU

UART

Buffer

APU

Debug UART

Blue RF I/F

SPI/EMPSPI

(Spiffy)

BT Clk/

Hopper

I2C_Master

Rx/Tx

Buffer

FIFO 1

COEX

PMU

LPO

POR

SPIM

JTAG Master

Digital

Modulator

RF

PMU Control

I/O

Port Control

OTP

(128 bytes)

AHB2MEM

Digital

I/O

FIFO 2

SECI

PTU

Document Number: 002-14857 Rev. *H

Page 6 of 16

�CYW89071

1.3 Automotive Usage Model

The CYW89071 is designed to provide a direct interface to automotive systems, as shown in Figure 3. The device has flexible PCM

and UART interfaces, enabling it to transparently connect to existing circuits.

The device incorporates a number of unique features to accommodate integration into automotive systems.

■

The PCM interface provides multiple modes of operation to support both master and slave, as well as hybrid interfacing to one or

more external codec devices.

■

The UART interface supports hardware flow control with tight integration to power control sideband signaling to support the lowest

power operation.

■

Few external components are required for integration.

Figure 3. Automotive Usage Model

Voice

Codec

PCM

1.63V to 5.5V SUPPLY

UART

20 or 26 MHz CRYSTAL

OSCILLATOR *

Host

BT_WAKE

HOST_WAKE

LPO Clock

CYW89071

* The external LPO clock is required if

the main clock is not 20 MHz.

LPO_INPUT

Document Number: 002-14857 Rev. *H

Page 7 of 51

�CYW89071

2. Integrated Radio Transceiver

The CYW89071 has an integrated radio transceiver that has been optimized for use in 2.4 GHz Bluetooth wireless systems. It has

been designed to provide low-power, low-cost, robust communications for applications operating in the globally available 2.4 GHz

unlicensed ISM band. The CYW89071 is fully compliant with the Bluetooth Radio Specification and enhanced data rate specification

and meets or exceeds the requirements to provide the highest communication link quality of service.

2.1 Transmitter Path

The CYW89071 features a fully integrated zero IF transmitter. The baseband transmitted data is digitally modulated in the modem

block and up-converted to the 2.4 GHz ISM band in the transmitter path. The transmitter path consists of signal filtering, I/Q upconversion, a high-output power amplifier (PA), and RF filtering.

The CYW89071 also incorporates modulation schemes to support enhanced data rates.

■

P/4-DQPSK for 2 Mbps

■

8-DPSK for 3 Mbps

2.1.1 Digital Modulator

The digital modulator performs the data modulation and filtering required for the GFSK, /4DQPSK, and 8-DPSK signals. The fully

digital modulator minimizes any frequency drift or anomalies in the modulation characteristics of the transmitted signal and is much

more stable than direct VCO modulation schemes.

2.1.2 Power Amplifier

The CYW89071’s integrated PA can be configured for Class 2 operation, transmitting up to +4 dBm. The PA can also be configured

for Class 1 operation, transmitting up +10 dBm at the chip in gFSK mode, when a minimum supply voltage of 2.5V is applied to VDDTF.

Because of the linear nature of the PA, combined with integrated filtering, minimal external filtering is required to meet Bluetooth and

regulatory harmonic and spurious requirements.

Using a highly linearized, temperature compensated design, the PA can transmit +10 dBm for basic rate and +8 dBm for enhanced

data rates (2 to 3 Mbps). A flexible supply voltage range allows the PA to operate from 1.2V to 3.3V. A minimum supply voltage of

2.5V is required at VDDTF to achieve +10 dBm of transmit power.

2.2 Receiver Path

The receiver path uses a low IF scheme to downconvert the received signal for demodulation in the digital demodulator and bit

synchronizer. The receiver path provides a high degree of linearity, an extended dynamic range, and high order on-chip channel

filtering to ensure reliable operation in the noisy 2.4 GHz ISM band. The front-end topology, with built-in out-of-band attenuation,

enables the device to be used in most applications without off-chip filtering. For integrated handset operation where the Bluetooth

function is integrated close to the cellular transmitter, minimal external filtering is required to eliminate the desensitization of the

receiver by the cellular transmit signal.

2.2.1 Digital Demodulator and Bit Synchronizer

The digital demodulator and bit synchronizer uses the low IF received signal to perform an optimal frequency tracking and bit synchronization algorithm.

2.2.2 Receiver Signal Strength Indicator

The CYW89071 radio provides a Receiver Signal Strength Indicator (RSSI) signal to the baseband so that the controller can take part

in a Bluetooth power-controlled link by providing a metric of its own receiver signal strength to determine whether the transmitter

should increase or decrease its output power.

2.3 Local Oscillator Generation

Local Oscillator (LO) generation provides fast frequency hopping (1600 hops/second) across the 79 maximum available channels.

The LO generation subblock employs an architecture for high immunity to LO pulling during PA operation. The device uses fullyintegrated PLL loop filters.

2.4 Calibration

The radio transceiver features an automated calibration scheme that is fully self-contained in the radio. User interaction is not required

during normal operation or during manufacturing to provide the optimal performance. Calibration optimizes the performance of all

major blocks in the radio, including gain and phase characteristics of filters, matching between key components, and key gain blocks.

Calibration, which takes process and temperature variations into account, occurs transparently during the settling time of the hops,

adjusting for temperature variations as the device cools and heats during normal operation.

Document Number: 002-14857 Rev. *H

Page 8 of 51

�CYW89071

2.5 Internal LDO

Two internal Low Drop-Out (LDO) voltage regulators eliminate the need for external voltage regulators and therefore reduce the BOM.

The first LDO is a preregulator (HV LDO). The second LDO (Main LDO) supplies the main power to the CYW89071 (see Figure 2 on

page 6).

The HV LDO has an input voltage range of 2.3V to 5.5V. The input VBAT is ideal for batteries. The VREGHV output is programmable

from 1.8V to 3.3V, in 100 mV steps. The dropout voltage is 200 mV. The HV LDO can supply up to 95 mA, which leaves spare power

for external circuitry such as an RF power amp for higher transmit power. If the HV LDO is not used, to turn off the HV LDO and

minimize current consumption, connect the VBAT input to the VREGHV output. Firmware can then disable the HV LDO, saving the

quiescent current.

The HV LDO default output voltage is 2.9V, allowing this regulator to be used to power external NV memory devices, as well as the

VDDO rail. The firmware can then adjust this output to as low as 1.8V, if desired, to power VDDTF.

The main LDO has a 1.22V output (VREG) and is used to supply main power to the CYW89071 (see Figure 4). The input of this LDO

(VREGHV) has an input voltage range of from 1.63V to 3.63V. The output of the HV LDO is internally connected to the input to the

main LDO. Power can be applied to VREGHV when the HV LDO is not used. The main LDO supplies power to the entire device for

Class 2 operation. The main LDO can drive up to 60 mA, which leaves spare power for external circuitry. The main LDO is bypassed

by not connecting anything to its output (VREG) and driving 1.12V–1.32V directly to VDDC and VDDRF.

REG_EN provides a control signal for the host to control power to the CYW89071. When power is enabled, the CYW89071 will require

complete initialization.

Figure 4. LDO Functional Block Diagram

CYW89071

HV LDO

REG_EN

Document Number: 002-14857 Rev. *H

VBAT

Main LDO

VREGHV

VREG

Page 9 of 51

�CYW89071

3. Bluetooth Baseband Core

The Bluetooth Baseband Core (BBC) implements the time critical functions required for high-performance Bluetooth operation. The

BBC manages buffering, segmentation, and data routing for all connections. It also buffers data that passes through it, handles data

flow control, schedules SCO/ACL Tx/Rx transactions, monitors Bluetooth slot usage, optimally segments and packages data into

baseband packets, manages connection status indicators, and composes and decodes HCI packets. In addition to these functions, it

independently handles HCI event types and HCI command types.

3.1 Transmit and Receive Functions

The following transmit and receive functions are implemented in the BBC hardware to increase the reliability and security of the Tx/

Rx data before sending the data over the air:

In the transmitter:

■

Data framing

■

Forward Error Correction (FEC) generation

■

Header Error Control (HEC) generation

■

Cyclic Redundancy Check (CRC) generation

■

Key generation

■

Data encryption

■

Data whitening

In the receiver:

■

Symbol timing recovery

■

Data deframing

■

FEC

■

HEC

■

CRC

■

Data decryption

■

Data dewhitening

3.2 Bluetooth 4.1 + EDR Features

The CYW89071 supports Bluetooth 4.1 + EDR, including the following options:

■

A whitelist size of 25

■

Enhanced Power Control

■

HCI Read Encryption Key Size command

The CYW89071 provides full support for Bluetooth 2.1 + EDR additional features:

■

Secure Simple Pairing (SSP)

■

Encryption Pause Resume (EPR)

■

Enhance Inquiry Response (EIR)

■

Link Supervision Time Out (LSTO)

■

Sniff SubRating (SSR)

■

Erroneous Data (ED)

■

Packet Boundary Flag (PBF)

3.3 Frequency Hopping Generator

The frequency hopping sequence generator selects the correct hopping channel number, based on the link controller state, Bluetooth

clock, and device address.

Document Number: 002-14857 Rev. *H

Page 10 of 51

�CYW89071

3.4 Link Control Layer

The Link Control layer is part of the Bluetooth link control functions implemented in dedicated logic in the Link Control Unit (LCU).

This layer consists of the Command Controller that takes commands from the software and other controllers that are activated or

configured by the Command Controller to perform the link control tasks.

There are two major states–Standby and Connection. Each task establishes a different state in the Bluetooth Link Controller. In

addition, there are eight substates—Page, Page Scan, Inquiry, Inquiry Scan, Park, Sniff Subrate, and Hold.

3.5 Test Mode Support

The CYW89071 fully supports Bluetooth Test Mode, including the transmitter tests, normal and delayed loopback tests, and the

reduced hopping sequence.

In addition to the standard Bluetooth Test mode, the device supports enhanced testing features to simplify RF debugging and qualification and type approval testing.

These test features include:

■

Fixed frequency carrier wave (unmodulated) transmission

❐ Simplifies some type approval measurements (Japan)

❐ Aids in transmitter performance analysis

■

Fixed frequency constant receiver mode

❐ Directs receiver output to I/O pin

❐ Allows for direct BER measurements using standard RF test equipment

❐ Facilitates spurious emissions testing for receive mode

■

Fixed frequency constant bit stream transmission

❐ Unmodulated, 8-bit fixed pattern, PRBS-9, or PRBS-15

❐ Enables modulated signal measurements with standard RF test equipment

■

Packetized connectionless transmitter test

❐ Hopping or fixed frequency

❐ Multiple packet types supported

❐ Multiple data patterns supported

■

Packetized connectionless receiver test

❐ Fixed frequency

❐ Multiple packet types supported

❐ Multiple data patterns supported

3.6 Power Management Unit

The Power Management Unit (PMU) provides power management features that can be invoked through power management registers

or packet handling in the baseband core. This section contains descriptions of the PMU features.

3.6.1 RF Power Management

The BBC generates power-down control signals for the transmit path, receive path, PLL, and power amplifier to the 2.4 GHz transceiver. The transceiver then processes the power-down functions, accordingly.

Document Number: 002-14857 Rev. *H

Page 11 of 51

�CYW89071

3.6.2 Host Controller Power Management

The host can place the device in a sleep state, in which all nonessential blocks are powered off and all nonessential clocks are

disabled. Power to the digital core is maintained so that the state of the registers and RAM is not lost. In addition, the LPO clock is

applied to the internal sleep controller so that the chip can wake automatically at a specified time or based on signaling from the host.

The goal is to limit the current consumption to a minimum, while maintaining the ability to wake up and resume a connection with

minimal latency.

If a scan or sniff session is enabled while the device is in Sleep mode, the device automatically will wake up for the scan/sniff event,

then go back to sleep when the event is done. In this case, the device uses its internal LPO-based timers to trigger the periodic wake

up. While in Sleep mode, the transports are idle. However, the host can signal the device to wake up at any time. If signaled to wake

up while a scan or sniff session is in progress, the session continues but the device will not sleep between scan/sniff events. Once

Sleep mode is enabled, the wake signaling mechanism can also be thought of as a sleep signaling mechanism, since removing the

wake status will often cause the device to sleep.

In addition to a Bluetooth device wake signaling mechanism, there is a host wake signaling mechanism. This feature provides a way

for the Bluetooth device to wake up a host that is in a reduced power state.

There are two mechanisms for the device and the host to signal wake status to each other:

Bluetooth WAKE (BT_WAKE) and

Host WAKE (and HOST_WAKE) signaling

The BT_WAKE pin (GPIO_0) allows the host to wake the BT device, and

HOST_WAKE (GPIO_1) is an output that allows the BT device to wake the host.

In-band UART signaling

The CTS and RTS signals of the UART interface are used for BT wake (CTS) and

Host wake (RTS) functions in addition to their normal function on the UART

interface. Note that this applies for both H4 and H5 protocols.

When running in SPI mode, the CYW89071 has a mode where it enters Sleep mode when there is no activity on the SPI interface for

a specified (programmable) amount of time. Idle mode is detected when the SPI_CSN is left deasserted. Whether to sleep on an idle

interface and the amount of time to wait before entering Sleep mode can be programed by the host. Once the CYW89071 enters

sleep, the host can wake it by asserting SPI_CSN. If the host decides to sleep, the CYW89071 will wake up the host by asserting

SPI_INT when it has data for it.

Note: Successful operation of the power management handshaking signals requires coordinated support between the device

firmware and the host software.

Table 2. Power Control Pin Summary

Pin

Direction

Description

Bluetooth device wake-up: Signal from the host to the Bluetooth device that the host requires

attention.

BT_WAKE

(GPIO_0)

Host output

BT input

■

Asserted = Bluetooth device must wake up or remain awake.

Deasserted = Bluetooth device may sleep when sleep criteria are met.

The polarity of this signal is software configurable and can be asserted high or low. By default,

BT_WAKE is active-low (if BT-WAKE is low it requires the device to wake up or remain awake).

■

Host wake-up. Signal from the Bluetooth device to the host indicating that Bluetooth device

requires attention.

HOST_WAKE

(GPIO_1)

BT output

Host input

■

Asserted = Host device must wake up or remain awake.

Deasserted = Host device may sleep when sleep criteria are met.

The polarity of this signal is software configurable and can be asserted high or low.

■

Clock request

CLK_REQ

(GPIO_5)

BT output

■

Asserted = External clock reference required

■

Deasserted = External clock reference may be powered down.

Enables the internal preregulator and main regulator outputs. REG_EN is active-high.

REG_EN

BT input

■

1 = Enabled

■

0 = Disabled

Document Number: 002-14857 Rev. *H

Page 12 of 51

�CYW89071

3.6.3 BBC Power Management

The device provides the following low-power operations for the BBC:

■

Physical layer packet handling turns RF on and off dynamically within packet TX and RX.

■

Bluetooth specified low-power connection modes—Sniff, Hold, and Park. While in these low-power connection modes, the device

runs on the Low Power Oscillator and wakes up after a predefined time period.

Backdrive Protection

The CYW89071 provides a backdrive protection feature that allows the device to be turned off while the host and other devices in the

system remain operational. When the device is not needed in the system, VDD_RF and VDDC are shut down and VDDO remains

powered. This allows the device to be effectively off, while keeping the I/O pins powered so that they do not draw extra current from

other devices connected to the I/O.

Note: VDD_RF collectively refers to the VDDTF, VDDPX, and VDDRF RF power supplies.

Note: Never apply voltage to I/O pins if VDDO is not applied.

During the low power shutdown state and as long as VDDO remains applied to the device, all outputs are tristated and all digital and

analog clocks are disabled. Input voltages must remain within the limits defined for normal operation. This is done to either prevent

current draw and back loading on digital signals in the system. It also enables the device to be fully integrated in an embedded device

and take full advantage of the lowest power savings modes. If VDDC is powered up externally (not connected to VREG), VDDC

requires 750 K to ground during low-power shutdown. If VDDC is powered up by VREG, VDDC does not require 750 K to ground

because the internal main LDO has about 750 K to ground when turned off.

Several signals, including the frequency reference input (XTAL_IN) and external LPO input (LPO_IN), are designed to be highimpedance inputs that will not load down the driving signal, even if VDDO power is not applied to the chip. The other signals with back

drive prevention are RST_N, COEX_OUT0, COEX_OUT1, COEX_IN, PCM_SYNC, PCM_CLK, PCM_OUT, PCM_IN, UART_RTS_N,

UART_CTS_N, UART_RXD, UART_TXD, GPIO_0, GPIO_1, GPIO_2, GPIO_4, GPIO_7, and OTP_DIS.

All other IO signals must remain at VSS until VDDO is applied. Failing to do this can result in unreliable startup behavior.

When powered on, using REG_EN is the same as applying power to the CYW89071. The device does not have information about its

state before being powered-down.

3.7 Adaptive Frequency Hopping

The CYW89071 supports host channel classification and dynamic channel classification Adaptive Frequency Hopping (AFH)

schemes, as defined in the Bluetooth specification.

Host channel classification enables the host to set a predefined hopping map for the device to follow.

If dynamic channel classification is enabled, the device gathers link quality statistics on a channel-by-channel basis to facilitate channel

assessment and channel map selection. To provide a more accurate frequency hop map, link quality is determined using both RF and

baseband signal processing.

3.8 Collaborative Coexistence

The CYW89071 provides extensions and collaborative coexistence to the standard Bluetooth AFH for direct communication with

WLAN devices. Collaborative coexistence enables WLAN and Bluetooth to operate simultaneously in a single device. The device

supports industry-standard coexistence signaling, including 802.15.2, and supports Broadcom and third-party WLAN solutions.

Using a multitiered prioritization approach, relative priorities between data types and applications can be set. This approach maximizes

the performance-WLAN data throughput vs. voice quality versus link performance.

A PA shutdown pin is available to allow full external control of the RF output for other types of coexistence, such as WIMAX.

3.9 Serial Enhanced Coexistence Interface

The Serial Enhanced Coexistence Interface (Serial ECI or SECI) is a proprietary Broadcom interface between Broadcom WLAN

devices and Bluetooth devices. It is an optional replacement to the legacy 3- or 4-wire coexistence feature, which is also available.

The following key features are associated with the interface:

■

Enhanced coexistence data can be exchanged over SECI_IN and SECI_OUT.

■

It supports generic UART communication between WLAN and Bluetooth devices.

■

To conserve power, it is disabled when inactive.

■

It supports automatic resynchronizaton upon waking from sleep mode.

■

It supports a baud rate of up to 4 Mbps.

Document Number: 002-14857 Rev. *H

Page 13 of 51

�CYW89071

3.9.1 SECI Advantages

The advantages of the SECI over the legacy 3-wire coexistence interface are:

■

Only two wires are required: SECI_IN and SECI_OUT.

■

Up to 48-bits of coexistence data can be exchanged.

Previous Cypress stand-alone Bluetooth devices such as the CYW2070 supported only a 3-wire or 4-wire coexistence interface.

Previous Cypress WLAN and Bluetooth combination devices such as the CYW4325, CYW4329, and CYW4330 support an internal

parallel enhanced coexistence interface for more efficient WLAN and Bluetooth information exchange. The SECI allows enhanced

coexistence information to be passed to a companion Broadcom WLAN chip through a serial interface using fewer I/O than the 3-wire

coexistence scheme.

The 48-bits of the SECI significantly enhance WLAN and Bluetooth coexistence by sharing such information as frequencies used and

radio usage times. The exact contents of the SECI are Cypress confidential.

3.9.2 SECI I/O

The CYW89071 does not have dedicated SECI_IN or SECI_OUT pins, but the two pin functions can be mapped to the following digital

I/O: the UART, GPIO, SPIM (or BSC), PCM, and COEX pins. Pin function mapping is controlled by the config file that is either stored

in NVRAM or downloaded directly into on-chip RAM from the host.

Document Number: 002-14857 Rev. *H

Page 14 of 51

�CYW89071

4. Microprocessor Unit

The CYW89071 microprocessor unit runs software from the Link Control (LC) layer up to the Host Controller Interface (HCI). The

microprocessor is based on the ARM7TDMIS 32-bit RISC processor with embedded ICE-RT debug and JTAG interface units. The

microprocessor also includes 384 KB of ROM memory for program storage and boot ROM, 112 KB of RAM for data scratch-pad, and

patch RAM code.

The internal boot ROM provides flexibility during power-on reset to enable the same device to be used in various configurations,

including automatic host transport selection from SPI or UART, with or without external NVRAM. At power-up, the lower layer protocol

stack is executed from the internal ROM.

External patches can be applied to the ROM-based firmware to provide flexibility for bug fixes and features additions. These patches

can be downloaded from the host to the device through the SPI or UART transports, or using external NVRAM. The device can also

support the integration of user applications and profiles using an external serial flash memory.

4.1 NVRAM Configuration Data and Storage

4.1.1 Serial Interface

The CYW89071 includes an SPI master controller that can be used to access serial flash memory. The SPI master contains an AHB

slave interface, transmit and receive FIFOs, and the SPI core PHY logic. Data is transferred to and from the module by the system

CPU. DMA operation is not supported.

The CYW89071 supports serial flash vendors Atmel, MXIC, and Numonyx. The most commonly used parts from two of these vendors

are:

■

AT25BCM512B, manufactured by Atmel

■

MX25V512ZUI-20G, manufactured by MXIC

4.2 EEPROM

The CYW89071 includes a Broadcom Serial Control (BSC) master interface. The BSC interface supports low-speed and fast mode

devices and is compatible with I2C slave devices. Multiple I2C master devices and flexible wait state insertion by the master interface

or slave devices are not supported. The CYW89071 provides 400 kHz, full speed clock support.

The BSC interface is programmed by the CPU to generate the following BSC transfer types on the bus:

■

Read-only

■

Write-only

■

Combined read/write

■

Combined write-read

NVRAM may contain configuration information about the customer application, including the following:

■

Fractional-N information

■

BD_ADDR

■

UART baud rate

■

SDP service record

■

File system information used for code, code patches, or data

4.3 External Reset

The CYW89071 has an integrated power-on reset circuit which completely resets all circuits to a known power on state. This action

can also be driven by an external reset signal, which can be used to externally control the device, forcing it into a power-on reset state.

The RST_N signal input is an active-low signal for all versions of the CYW89071. The CYW89071 requires an external pull-up resistor

on the RST_N input. Alternatively, the RST_N input can be connected to REG_EN or driven directly by a host GPIO.

Document Number: 002-14857 Rev. *H

Page 15 of 51

�CYW89071

4.4 One-Time Programmable Memory

The CYW89071 includes a One-Time Programmable (OTP) memory, allowing manufacturing customization and avoiding the need

for an on-board NVRAM.If customization is not required, then the OTP does not need to be programmed. Whether the OTP is

programmed or not, it is disabled after the boot process completes to save power.

The OTP size is 128 bytes.

The OTP is designed to store a minimal amount of information. Aside from OTP data, most user configuration information will be

downloaded into RAM after the CYW89071 boots up and is ready for host transport communication. The OTP contents are limited to:

■

Parameters required prior to downloading user configuration to RAM.

■

Parameters unique to a customer design.

4.4.1 Contents

The following are typical parameters programmed into the OTP memory:

■

BD_ADDR

■

Software license key

■

Output power calibration

■

Frequency trimming

■

Initial status LED drive configuration

The OTP contents also include a static error correction table to improve yield during the programming process as well as forward error

correction codes to eliminate any long-term reliability problems. The OTP contents associated with error correction are not visible by

customers.

4.4.2 Programming

OTP memory programming takes place through a combination of Broadcom software integrated with the manufacturing test software

and code embedded in CYW89071 firmware.

Programming the OTP requires a 3.3V supply. The OTP programming supply comes from the VDDO pin. The OTP power supply can

be as low as 1.8V in order to read the OTP contents. OTP_DIS is brought out to a pin on the WLBGA package. If the OTP_DIS pin

is left floating or externally pulled low, then the OTP will be enabled. if the OTP_DIS pins is externally pulled high, then the OTP will

be disabled.

Document Number: 002-14857 Rev. *H

Page 16 of 51

�CYW89071

5. Peripheral Transport Unit

This section covers the PCM, UART, and SPI peripheral interfaces. The CYW89071 has a 1040 byte transmit and receive FIFO, which

is large enough to hold the entire payload of the largest EDR BT packet (3-DH5).

5.1 PCM Interface

The CYW89071 PCM interface can connect to linear PCM codec devices in master or slave mode. In master mode, the device

generates the PCM_BCLK and PCM_SYNC signals. In slave mode, these signals are provided by another master on the PCM

interface as inputs to the device.

The device supports up to three SCO or eSCO channels through the PCM interface and each channel can be independently mapped

to any available slot in a frame.

The host can adjust the PCM interface configuration using vendor-specific HCI commands or it can be setup in the configuration file.

5.1.1 System Diagram

Figure 5 shows options for connecting the device to a PCM codec device as a master or a slave.

Figure 5. PCM Interface with Linear PCM Codec

PCM Codec

(Master)

PCM_IN

PCM_OUT

PCM_BCLK

PCM_SYNC

CYW89071

(Slave)

PCM Interface Slave Mode

PCM Codec

(Slave)

PCM_IN

PCM_OUT

PCM_BCLK

PCM_SYNC

CYW89071

(Master)

PCM Interface Master Mode

PCM Codec

(Hybrid)

PCM_IN

PCM_OUT

PCM_BCLK

PCM_SYNC

CYW89071

(Hybrid)

PCM Interface Hybrid Mode

Document Number: 002-14857 Rev. *H

Page 17 of 51

�CYW89071

5.1.2 Slot Mapping

The device supports up to three simultaneous, full-duplex SCO or eSCO channels. These channels are time-multiplexed onto the

PCM interface using a time slotting scheme based on the audio sampling rate, as described in Table 3.

Table 3. PCM Interface Time Slotting Scheme

Audio Sample Rate

Time Slotting Scheme

8 kHz

The number of slots depends on the selected interface rate, as follows:

Interface rate

Slot

128

1

256

2

512

4

1024

8

2048

16

16 kHz

The number of slots depends on the selected interface rate, as follows:

Interface rate

Slot

256

1

512

2

1024

4

2048

8

Transmit and receive PCM data from an SCO channel is always mapped to the same slot. The PCM data output driver tristates its

output on unused slots to allow other devices to share the same PCM interface signals. The data output driver tristates its output after

the falling edge of the PCM clock during the last bit of the slot.

5.1.3 Wideband Speech

The CYW89071 provides support for Wideband Speech (WBS) in two ways:

■

Transparent mode: The host encodes WBS packets and the encoded packets are transferred over the PCM bus for SCO or eSCO

voice connections. In Transparent mode, the PCM bus is typically configured in master mode for a 4 kHz sync rate with 16-bit

samples, resulting in a 64 kbps bit rate.

■

On-chip SmartAudio technology: The CYW89071 can perform SBC encoding and decoding of linear 16 bits at 16 kHz (256 kbps

rate) transferred over the PCM bus.

5.1.4 Frame Synchronization

The device supports both short and long frame synchronization types in both master and slave configurations. In short frame synchronization mode, the frame synchronization signal is an active-high pulse at the 8 kHz audio frame rate (which is a single bit period in

width) and synchronized to the rising edge of the bit clock. The PCM slave expects PCM_SYNC to be high on the falling edge of the

bit clock and the first bit of the first slot to start at the next rising edge of the clock. In the long frame synchronization mode, the frame

synchronization signal is an active-high pulse at the 8 kHz audio frame rate. However, the duration is 3-bit periods and the pulse starts

coincident with the first bit of the first slot.

5.1.5 Data Formatting

The device can be configured to generate and accept several different data formats. The device uses 13 of the 16 bits in each PCM

frame. The location and order of these 13 bits is configurable to support various data formats on the PCM interface. The remaining

three bits are ignored on the input, and may be filled with zeros, ones, a sign bit, or a programmed value on the output. The default

format is 13-bit two’s complement data, left justified, and clocked most significant bit first.

Document Number: 002-14857 Rev. *H

Page 18 of 51

�CYW89071

5.2 HCI Transport Detection Configuration

The CYW89071 supports the following interface types for the HCI transport from the host:

■

UART (H4 and H5)

■

SPI

Only one host interface can be active at a time. The firmware performs a transport detect function at boot-time to determine which

host is the active transport. It can auto-detect the UART interface, but the SPI interface must be selected by strapping the SCL pin to 0.

The complete algorithm is summarized as follows:

1. Determine if SCL is pulled low. If it is, select SPI as HCI host transport.

2. Determine if any local NVRAM contains a valid configuration file. If it does and a transport configuration entry is present, select the

active transport according to entry, and then exit the transport detection routine.

3. Search for CTS_N = 0 on the UART interface. If it is present, select UART.

4. Repeat Step 3 until transport is determined.

5.3 UART Interface

The UART physical interface is a standard, 4-wire interface (RX, TX, RTS, CTS) with adjustable baud rates from 9600 bps to 4.0

Mbps. The interface features an automatic baud rate detection capability that returns a baud rate selection. Alternatively, the baud

rate can be selected via a vendor-specific UART HCI command. The interface supports Bluetooth UART HCI (H4) specifications. The

default baud rate for H4 is 115.2 Kbaud.

The following baud rates are supported:

■

9600

■

14400

■

19200

■

28800

■

38400

■

57600

■

115200

■

230400

■

460800

■

921600

■

1444444

■

1500000

■

2000000

■

3000000

■

3250000

■

3692000

■

4000000

Normally, the UART baud rate is set by a configuration record downloaded after reset or by automatic baud rate detection. The host

does not need to adjust the baud rate. Support for changing the baud rate during normal HCI UART operation is provided through a

vendor-specific command.

The CYW89071 UART operates with the host UART correctly, provided the combined baud rate error of the two devices is within ±2%.

5.3.1 HCI 3-Wire Transport (UART H5)

The CYW89071 supports H5 UART transport for serial UART communications. H5 reduces the number of signal lines required by

eliminating CTS and RTS, when compared to H4. In addition, in-band sleep signaling is supported over the same interface so that

the 4-wire UART and the 2-wire sleep signaling interface can be reduced to a 2-wire UART interface, saving four IOs on the host.

H5 requires the use of an external LPO. CTS must be pulled low.

Document Number: 002-14857 Rev. *H

Page 19 of 51

�CYW89071

5.4 SPI

The CYW89071 supports a slave SPI HCI transport with an input clock range of up to 16 MHz. Higher clock rates may be possible.

The physical interface between the SPI master and the CYW89071 consists of the four SPI signals (SPI_CSB, SPI_CLK, SPI_SI, and

SPI_SO) and one interrupt signal (SPI_INT). The CYW89071 can be configured to accept active-low or active-high polarity on the

SPI_CSB chip select signal. It can also be configured to drive an active-low or active-high SPI_INT interrupt signal. Bit ordering on

the SPI_SI and SPI_SO data lines can be configured as either little-endian or big-endian. Additionally, proprietary sleep mode, halfduplex handshaking is implemented between the SPI master and the CYW89071.

SPI_INT is required to negotiate the start of a transaction. The SPI interface does not require flow control in the middle of a payload.

The FIFO is large enough to handle the largest packet size. Only the SPI master can stop the flow of bytes on the data lines, since it

controls SPI_CSB and SPI_CLK. Flow control should be implemented in higher layer protocols.

Document Number: 002-14857 Rev. *H

Page 20 of 51

�CYW89071

6. Frequency References

The CYW89071 uses two different frequency references for normal and low-power operational modes. An external crystal or

frequency reference driven by a Temperature Compensated Crystal Oscillator (TCXO) signal is used to generate the radio frequencies

and normal operation clocking. Either an external 32.768 kHz or fully integrated internal Low-Power Oscillator (LPO) is used for lowpower mode timing.

6.1 Crystal Interface and Clock Generation

The CYW89071 uses a fractional-N synthesizer to generate the radio frequencies, clocks, and data/packet timing, enabling it to

operate from any of a multitude of frequency sources. The source can be external, such as a TCXO, or a crystal interfaced directly to

the device. The default frequency reference setting is for a 20 MHz crystal or TCXO. The signal characteristics for the crystal interface

are listed in Table 4.

Table 4. Crystal Interface Signal Characteristics

Parameter

Crystal

External Frequency Reference

a

Acceptable frequencies

12–52 MHz in 2 ppm steps

Crystal load capacitance

12 (typical)

12–52 MHz in 2

ppma

Units

steps

–

N/A

pF

ESR

60 (max)

–

Power dissipation

200 (max)

–

W

Input signal amplitude

N/A

400 to 2000

2000 to 3300 (requires a 10 pF DC blocking

capacitor to attenuate the signal)

mVp-p

Signal type

N/A

Square-wave or sine-wave

–

Input impedance

N/A

1

2

M

pF

Phase noise

@ 1 kHz

@ 10 kHz

@ 100 kHz

@ 1 MHz

N/A

N/A

N/A

N/A

N/A

–

< –120b

< –131b

< –136b

< –136b

–

dBc/Hz

dBc/Hz

dBc/Hz

dBc/Hz

12, 13, 14.4, 15.36, 16.2, 16.8, 18, 19.2, 19.44,

19.68, 19.8, 20, 24, 26, 33.6, 37.4, and 38.4

MHz

Auto-detection frequencies when 12, 13, 14.4, 15.36, 16.2, 16.8, 18,

using external LPOc

19.2, 19.44, 19.68, 19.8, 20, 24,

26, 33.6, 37.4, and 38.4

Tolerance without frequency

trimmingd

±20

±20

ppm

Initial frequency tolerance

trimming range

±50

±50

ppm

a. The frequency step size is approximately 80 Hz resolution.

b. With a 26 MHz reference clock. For a 13 MHz clock, subtract 6 dB. For a 52 MHz clock, add 6 dB.

c. Auto-detection of the frequency requires the crystal or external frequency reference to have less than ±50 ppm of variation and also requires an external LPO frequency

which has less than ±250 ppm of variation at the time of detection.

d. AT-Cut crystal or TXCO recommended.

Document Number: 002-14857 Rev. *H

Page 21 of 51

�CYW89071

6.2 Crystal Oscillator

The CYW89071 can use an external crystal to provide a frequency reference. The recommended configuration for the crystal oscillator,

including all external components, is shown in Figure 6.

Figure 6. Recommended Oscillator Configuration

XIN

0 to 18 pF*

Crystal

Oscillator

XOUT

0 to 18 pF*

*Capacitor value range depends

on the manufacturer of the XTAL

as well as board layout.

6.3 External Frequency Reference

An external frequency reference generated by a TCXO signal may be directly connected to the crystal input pin on the CYW89071,

as shown in Figure 7. The external frequency reference input is designed to not change loading on the TCXO when the CYW89071

is powered up or powered down.

When using the CYW89071 with the TXCO OR gate option, GPIO 6 must be driven active high or active low. Excessive leakage

current results if GPIO6 is allowed to float.

Figure 7. Recommended TCXO Connection

TCXO

XIN

10–1000 pF*

No Connection

XOUT

* Recommended value is 100 pF.

Higher values produce a longer startup time.

Lower values have greater isolation.

Larger values help small signal swings.

6.3.1 TCXO Clock Request Support

If the application utilizes an external TCXO as a clock reference, the CYW89071 provides a clock request output to allow the system

to power off the TCXO when not in use. The CYW89071 supports a TCXO OR function that allows a clock request in the system to

be combined with the CYW89071 clock request output, without requiring an extra component on the board.

Clock Request Output

The CLK_REQ signal on the GPIO_5 lead is asserted whenever the CYW89071 is in the Awake state. It is deasserted when in Sleep

state. When the CYW89071 is sleeping, it uses an LPO clock (external or internal) as the timing reference. In the CYW89071, the

clock request output (CLK_REQ) is configured as active high. If the clock request feature is not desired, GPIO_5 can be configured

for other functions.

Document Number: 002-14857 Rev. *H

Page 22 of 51

�CYW89071

TCXO OR Option

The CYW89071 has an optional feature that allows the application to perform a logical OR function on a system TCXO clock request

signal and the CYW89071 clock request to form one clock request output to the TCXO device. This logical OR function is embedded

in the pad ring so that it is available at any time, as long as the pad ring is receiving a VDDO supply. The function works even if the

CYW89071’s digital core is sleeping or completely powered off.

Table 5 shows the truth table.

Table 5. Truth Table

GPIO_6

CLK_REQ_IN

Internal Clock Request State

(0 = sleep)

GPIO_5

CLK_REQ

0

0

0

0

1

1

1

0

1

1

1

1

6.4 Frequency Selection

Any frequency within the range specified for the crystal and TCXO reference can be used. These frequencies include standard handset

reference frequencies (12, 13, 14.4, 15.36, 16.2, 16.8, 18, 19.2, 19.44, 19.68, 19.8, 20, 24, 26, 33.6, 37.4, and 38.4 MHz) and any

frequency between these reference frequencies, as desired by the system designer. Since bit timing is derived from the reference

frequency, the CYW89071 must have the reference frequency set correctly in order for the UART and PCM interfaces to function

properly.

The CYW89071 reference frequency can be set in one of three ways.

■

Use the default 20 MHz frequency

■

Designate the reference frequency in external NVRAM

■

Auto-detect the standard handset reference frequencies using an external LPO clock

The CYW89071 is set to a default frequency of 20 MHz at the factory. For a typical design using a crystal, it is recommended that the

default frequency be used, since this simplifies the design by removing the need for either external NVRAM or external LPO clock.

If the application requires a frequency other than the default, the value can be stored in an external NVRAM. Programming the

reference frequency in NVRAM provides the maximum flexibility in the selection of the reference frequency, since any frequency within

the specified range for crystal and external frequency reference can be used. During power-on reset (POR), the device downloads

the parameter settings stored in NVRAM, which can be programmed to include the reference frequency and frequency trim values.

Typically, this is how a PC Bluetooth application is configured.

For applications such as handsets and portable smart communication devices, where the reference frequency is one of the standard

frequencies commonly used, the CYW89071 automatically detects the reference frequency and programs itself to the correct

reference frequency. In order for auto-frequency detection to work properly, the CYW89071 must have a valid and stable 32.768 kHz

external LPO clock present during POR. This eliminates the need for NVRAM in applications where the external LPO clock is available

and an external NVRAM is typically not used.

6.5 Frequency Trimming

The CYW89071 uses a fractional-N synthesizer to digitally fine-tune the frequency reference input to within ±2 ppm tuning accuracy.

This trimming function can be applied to either the crystal or an external frequency source such as a TCXO. Unlike the typical crystaltrimming methods used, the CYW89071 changes the frequency using a fully digital implementation and is much more stable and

unaffected by crystal characteristics or temperature. Input impedance and loading characteristics remain unchanged on the TCXO or

crystal during the trimming process and are unaffected by process and temperature variations.

The option to use or not use frequency trimming is based on the system designer’s cost trade-off between bill-of-materials (BOM) cost

of the crystal and the added manufacturing cost associated with frequency trimming. The frequency trimming value can either be

stored in the host and written to the CYW89071 as a vendor-specific HCI command or stored in NVRAM and subsequently recalled

during POR.

Frequency trimming is not a substitute for the poor use of tuning capacitors at an crystal oscillator (XTAL). Occasionally, trimming can

help alleviate hardware changes.

Document Number: 002-14857 Rev. *H

Page 23 of 51

�CYW89071

6.6 LPO Clock Interface

The LPO clock is the second frequency reference that the CYW89071 uses to provide low-power mode timing for park, hold, and sniff.

The LPO clock can be provided to the device externally, from a 32.768 kHz source or the CYW89071 can operate using the internal

LPO clock.

The LPO can be internally driven from the main clock. However, sleep current will be impacted.

The accuracy of the internal LPO limits the maximum park, hold, and sniff intervals.

Table 6. External LPO Signal Requirements

Parameter

Nominal input frequency

Frequency accuracy

Input signal amplitude

Signal type

Input impedance (when power is applied or power is off)

Document Number: 002-14857 Rev. *H

External LPO Clock

Units

32.768

kHz

±250

ppm

200 to 3600

mVp-p

Square-wave or sine-wave

–

>100

3 MHz adjacent channel

GFSK, 0.1% BER

–

–

–40.0

dB

C/I image channel

GFSK, 0.1% BER

–

–

–9.0

dB

C/I 1 MHz adjacent to image channel

GFSK, 0.1% BER

–

–

–20.0

dB

C/I cochannel

–

–

13

dB

–

–

0

dB

C/I 2 MHz adjacent channel

/4-DQPSK, 0.1% BER

/4-DQPSK, 0.1% BER

/4-DQPSK, 0.1% BER

–

–

–30.0

dB

C/I > 3 MHz adjacent channel

8-DPSK, 0.1% BER

–

–

–40.0

dB

C/I image channel

–

–

–7.0

dB

C/I 1 MHz adjacent to image channel

/4-DQPSK, 0.1% BER

/4-DQPSK, 0.1% BER

–

–

–20.0

dB

C/I cochannel

8-DPSK, 0.1% BER

–

–

21

dB

C/I 1 MHz adjacent channel

8-DPSK, 0.1% BER

–

–

5

dB

C/I 2 MHz adjacent channel

8-DPSK, 0.1% BER

–

–

–25.0

dB

C/I 1 MHz adjacent channel

C/I > 3 MHz adjacent channel

8-DPSK, 0.1% BER

–

–

–33.0

dB

C/I Image channel

8-DPSK, 0.1% BER

–

–

0

dB

C/I 1 MHz adjacent to image channel

8-DPSK, 0.1% BER

–

–

–13.0

dB

Out-of-Band Blocking Performance (CW)

e

30 MHz–2000 MHz

0.1% BER

–

–10.0

–

dBm

2000–2399 MHz

0.1% BER

–

–27

–

dBm

2498–3000 MHz

0.1% BER

–

–27

–

dBm

3000 MHz–12.75 GHz

0.1% BER

–

–10.0

–

dBm

Document Number: 002-14857 Rev. *H

Page 33 of 51

�CYW89071

Table 20. Receiver RF Specificationsa b (Cont.)

Parameter

Conditions

Minimum

Typical c

Maximum

Unit

Out-of-Band Blocking Performance, Modulated Interferer

776–764 MHz

CDMA

–

–15

–

dBm

824–849 MHz

CDMA

–

–15

–

dBm

1850–1910 MHz

CDMA

–

–20

–

dBm

824–849 MHz

EDGE/GSM

–

–10

–

dBm

880–915 MHz

EDGE/GSM

–

–10

–

dBm

1710–1785 MHz

EDGE/GSM

–

–15

–

dBm

1850–1910 MHz

EDGE/GSM

–

–15

–

dBm

1850–1910 MHz

WCDMA

–

–25

–

dBm

1920–1980 MHz

WCDMA

–

–25

–

dBm

–39.0

–

–

dBm

Intermodulation Performance f

BT, Df = 5 MHz

–

Spurious Emissions

g

30 MHz to 1 GHz

–

–

–

–57

dBm

1 GHz to 12.75 GHz

–

–

–

–47

dBm

65 MHz to 108 MHz

FM Rx

–

–145

–

dBm/Hz

746 MHz to 764 MHz

CDMA

–

–145

–

dBm/Hz

851–894 MHz

CDMA

–

–145

–

dBm/Hz

925–960 MHz

EDGE/GSM

–

–145

–

dBm/Hz

1805–1880 MHz

EDGE/GSM

–

–145

–

dBm/Hz

1930–1990 MHz

PCS

–

–145

–

dBm/Hz

2110–2170 MHz

WCDMA

–

–145

–

dBm/Hz

a.

b.

c.

d.

e.

f.

All specifications are single ended. Unused inputs are left open.

All specifications, except typical, are for automotive grade 3 temperatures. For details see Table 19 on page 33.

Typical operating conditions are 1.22V operating voltage and 25°C ambient temperature.

The receiver sensitivity is measured at BER of 0.1% on the device interface.

Meets this specification using front-end bandpass filter.

f0 = -64 dBm Bluetooth-modulated signal, f1 = –39 dBm sine wave, f2 = –39 dBm Bluetooth-modulated signal, f0 = 2f1 – f2, and |f2 – f1| = n*1 MHz, where n is 3, 4, or

5. For the typical case, n = 5.

g. Includes baseband radiated emissions.

Document Number: 002-14857 Rev. *H

Page 34 of 51

�CYW89071

Table 21. Transmitter RF Specifications a b

Parameter

Conditions

Minimum

Typical

Maximum

Unit

–

2402

–

2480

MHz

–

6.5

10

–

dBm

General

Frequency range

Class1: GFSK Tx power

c

d

–

4.5

8

–

dBm

Class 2: GFSK Tx power

–

–1.5

2

–

dBm

Power control step

–

2

4

8

dB

Class1: EDR Tx power

Modulation Accuracy

/4-DQPSK Frequency Stability

/4-DQPSK RMS DEVM

/4-QPSK Peak DEVM

/4-DQPSK 99% DEVM

–

–10

–

10

kHz

–

–

–

20

%

–

–

–

35

%

–

–

–

30

%

8-DPSK frequency stability

–

–10

–

10

kHz

8-DPSK RMS DEVM

–

–

–

13

%

8-DPSK Peak DEVM

–

–

–

25

%

8-DPSK 99% DEVM

–

–

–

20

%

In-Band Spurious Emissions

+500 kHz

–

–

–

–20

dBc

1.0 MHz < |M – N| < 1.5 MHz

–

–

–

–26

dBc

1.5 MHz < |M – N| < 2.5 MHz

–

–

–

–20

dBm

–

–

–

–40

dBm

–

–

–36.0 e

|M – N| > 2.5 MHz

Out-of-Band Spurious Emissions

30 MHz to 1 GHz

–

–30.0

e, f

dBm

dBm

1 GHz to 12.75 GHz

–

–

–

1.8 GHz to 1.9 GHz

–

–

–

–47.0

dBm

5.15 GHz to 5.3 GHz

–

–

–

–47.0

dBm

–127

dBm/Hz

GPS Band Noise Emission (without a front-end band pass filter)

1572.92 MHz to 1577.92 MHz

–

–

–150

Out-of-Band Noise Emissions (without a front-end band pass filter)

65 MHz to 108 MHz

FM Rx

–

–145

–

dBm/Hz

746 MHz to 764 MHz

CDMA

–

–145

–

dBm/Hz

869 MHz to 960 MHz

CDMA

–

–145

–

dBm/Hz

925 MHz to 960 MHz

EDGE/GSM

–

–145

–

dBm/Hz

1805 MHz to 1880 MHz

EDGE/GSM

–

–145

–

dBm/Hz

1930 MHz to 1990 MHz

PCS

–

–145

–

dBm/Hz

2110 MHz to 2170 MHz

WCDMA

–

–145

–

dBm/Hz

a.

b.

c.

d.

e.

f.

All specifications are for automotive grade 3 temperatures. For details, see Table 19 on page 33.

All specifications are single-ended. Unused input are left open.

+10 dBm output for GFSK measured with VDDTF = 2.9 V.

+8 dBm output for EDR measured with VDDTF = 2.9 V.

Maximum value is the value required for Bluetooth qualification.

Meets this spec using a front-end bandpass filter.

Document Number: 002-14857 Rev. *H

Page 35 of 51

�CYW89071

9.3 Timing and AC Characteristics

In this section, use the numbers listed in the reference column to interpret the timing diagrams.

9.3.1 Startup Timing

There are two basic startup scenarios. In one scenario, the chip startup and firmware boot is held off while the RST_N pin is asserted.

In the second scenario, the chip startup and firmware boot is directly triggered by the chip power-up. In this case, an internal poweron reset (POR) is held for a few ms, after which the chip commences startup.

The global reset signal in the CYW89071 is a logical OR (actually a wired AND, since the signals are active low) of the RST_N input

and the internal POR signals. The last signal to be released determines the time at which the chip is released from reset. The POR

is typically asserted for 3 ms after VDDC crosses the 0.8V threshold, but it may be as soon as 1.5 ms after this event.

After the chip is released from reset, the both startup scenarios follow the same sequence, as follows:

2. After approximately 120 s, the CLK_REQ (GPIO_5) signal is asserted.

3. The chip remains in sleep state for a minimum of 4.2 ms.

4. If present, the TCXO and LPO clocks must be oscillating by the end of the 4.2 ms period.

If a TCXO clock is not in the system, a crystal is assumed to be present at the XIN and XOUT pins. If an LPO clock is not used, the

firmware will detect the absence of a clock at the LPO_IN lead and use the internal LPO clock instead.

Figure 9 and Figure 10 on page 37 illustrate the two startup timing scenarios.

Figure 9. Startup Timing from RST_N

trampmax = 200 μs

VDDIO, VBAT,REG_EN*

VREG

VDDC > 0.8V

t = 300 μs

RST_N

t =64 to 171 μs

GPIO5 (CLK_REQ)

tmax = 4.2 ms

TCXO

LPO

Document Number: 002-14857 Rev. *H

Page 36 of 51

�CYW89071

Figure 10. Startup Timing from Power-on Reset

trampmax = 200 μs

VDDIO, VBAT,REG_EN*

VDDC > 0.8V

VREG

t = 300 μs

tmin= 1.5 ms

Internal POR

t = 64 to 171 μs

GPIO5 (CLK_REQ)

tmax = 4.2 ms

TCXO

LPO

9.3.2 UART Timing

Table 22. UART Timing Specifications

Reference

Characteristics

Minimum

Maximum

Unit

–

24

Baudout

cycles

1

Delay time, UART_CTS_N low to UART_TXD valid

2

Setup time, UART_CTS_N high before midpoint of stop bit

–

10

ns

3

Delay time, midpoint of stop bit to UART_RTS_N high

–

2

Baudout

cycles

Figure 11. UART Timing

UART_CTS_N

2

1

UART_TXD

Midpoint of STOP

bit

Midpoint of STOP

bit

UART_RXD

3

UART_RTS_N

Document Number: 002-14857 Rev. *H

Page 37 of 51

�CYW89071

9.3.3 PCM Interface Timing

Table 23. PCM Interface Timing Specifications (Short Frame Synchronization, Master Mode)

Reference

Characteristics

Minimum

Maximum

Unit

1

PCM bit clock frequency

128

2048

kHz

2

PCM bit clock HIGH time

128

–

ns

3

PCM bit clock LOW time

209

–

ns

4

Delay from PCM_BCLK rising edge to PCM_SYNC high

–

50

ns

5

Delay from PCM_BCLK rising edge to PCM_SYNC low

–

50

ns

6

Delay from PCM_BCLK rising edge to data valid on PCM_OUT

–

50

ns

7

Setup time for PCM_IN before PCM_BCLK falling edge

50

–

ns

8

Hold time for PCM_IN after PCM_BCLK falling edge

10

–

ns

9

Delay from falling edge of PCM_BCLK during last bit period to

PCM_OUT becoming high impedance

–

50

ns

Figure 12. PCM Interface Timing (Short Frame Synchronization, Master Mode)

2

1

3

PCM_BCLK

4

5

PCM_SYNC

6

PCM_OUT

Bit 15 (Previous Frame)

9

Bit 15

Bit 0

HIGH

IMPEDENCE

7

8

PCM_IN

Bit 15 (Previous Frame)

Document Number: 002-14857 Rev. *H

Bit 0

Bit 15

Page 38 of 51

�CYW89071

Table 24. PCM Interface Timing Specifications (Short Frame Synchronization, Slave Mode)

Reference

Characteristics

Minimum

Maximum

Unit

1

PCM bit clock frequency

128

2048

kHz

2

PCM bit clock HIGH time

209

–

ns

3

PCM bit clock LOW time

209

–

ns

4

Setup time for PCM_SYNC before falling edge of PCM_BCLK

50

–

ns

5

Hold time for PCM_SYNC after falling edge of PCM_BCLK

10

–

ns

6

Hold time of PCM_OUT after PCM_BCLK falling edge

–

175

ns

7

Setup time for PCM_IN before PCM_BCLK falling edge

50

–

ns

8

Hold time for PCM_IN after PCM_BCLK falling edge

10

–

ns

9

Delay from falling edge of PCM_BCLK during last bit period

to PCM_OUT becoming high impedance

–

100

ns

Figure 13. PCM Interface Timing (Short Frame Synchronization, Slave Mode)

2

1

3

PCM_BCLK

4

5

PCM_SYNC

6

PCM_OUT

Bit 15 (Previous Frame)

Bit 0

9

Bit 15

HIGH

IMPEDENCE

7

8

PCM_IN

Bit 15 (Previous Frame)

Document Number: 002-14857 Rev. *H

Bit 0

Bit 15

Page 39 of 51

�CYW89071

Table 25. PCM Interface Timing Specifications (Long Frame Synchronization, Master Mode)

Reference

Characteristics

Minimum

Maximum

Unit

1

PCM bit clock frequency

128

2048

kHz

2

PCM bit clock HIGH time

209

–

ns

3

PCM bit clock LOW time

209

–

ns

4

Delay from PCM_BCLK rising edge to PCM_SYNC HIGH during first

bit time

–

50

ns

5

Delay from PCM_BCLK rising edge to PCM_SYNC LOW during third

bit time

–

50

ns

6

Delay from PCM_BCLK rising edge to data valid on PCM_OUT

–

50

ns

7

Setup time for PCM_IN before PCM_BCLK falling edge

50

–

ns

8

Hold time for PCM_IN after PCM_BCLK falling edge

10

–

ns

9

Delay from falling edge of PCM_BCLK during last bit period to

PCM_OUT becoming high impedance

–

50

ns

Figure 14. PCM Interface Timing (Long Frame Synchronization, Master Mode)

2

1

3

PCM_BCLK

4

5

PCM_SYNC

6

PCM_OUT

Bit 0

Bit 1

9

Bit 2

Bit 15

Bit 2

Bit 15

HIGH

IMPEDENCE

7

8

PCM_IN

Bit 0

Document Number: 002-14857 Rev. *H

Bit 1

Page 40 of 51

�CYW89071

Table 26. PCM Interface Timing Specifications (Long Frame Synchronization, Slave Mode)

Reference

Characteristics

Minimum

Maximum

Unit

1

PCM bit clock frequency.

128

2048

kHz

2

PCM bit clock HIGH time.

209

–

ns

3

PCM bit clock LOW time.

209

–

ns

4

Setup time for PCM_SYNC before falling edge of PCM_BCLK during

first bit time.

50

–

ns

5

Hold time for PCM_SYNC after falling edge of PCM_BCLK during

second bit period. (PCM_SYNC may go low any time from second bit

period to last bit period).

10

–

ns

6

Delay from rising edge of PCM_BCLK or PCM_SYNC

(whichever is later) to data valid for first bit on PCM_OUT.

–

50

ns

7

Hold time of PCM_OUT after PCM_BCLK falling edge.

–

175

ns

8

Setup time for PCM_IN before PCM_BCLK falling edge.

50

–

ns

9

Hold time for PCM_IN after PCM_BCLK falling edge.

10

–

ns

10

Delay from falling edge of PCM_BCLK or PCM_SYNC

(whichever is later) during last bit in slot to PCM_OUT becoming high

impedance.

–

100

ns

Figure 15. PCM Interface Timing (Long Frame Synchronization, Slave Mode)

1

2

PCM_BCLK

3

4

5

PCM_SYNC

7

6

PCM_OUT

Bit 0

Bit 1

10

Bit 15

HIGH

IMPEDENCE

8

9

PCM_IN

Document Number: 002-14857 Rev. *H

Bit 0

Bit 1

Bit 15

Page 41 of 51

�CYW89071

9.3.4 BSC Interface Timing

Table 27. BSC Interface Timing Specifications

Reference

Characteristics

Minimum

Maximum

Unit

–

100

400

800

1000

kHz

1

Clock frequency

2

START condition setup time

650

–

ns

3

START condition hold time

280

–

ns

4

Clock low time

650

–

ns

5

Clock high time

280

–

ns

6

Data input hold timea

0

–

ns

7

Data input setup time

100

–

ns

8

STOP condition setup time

280