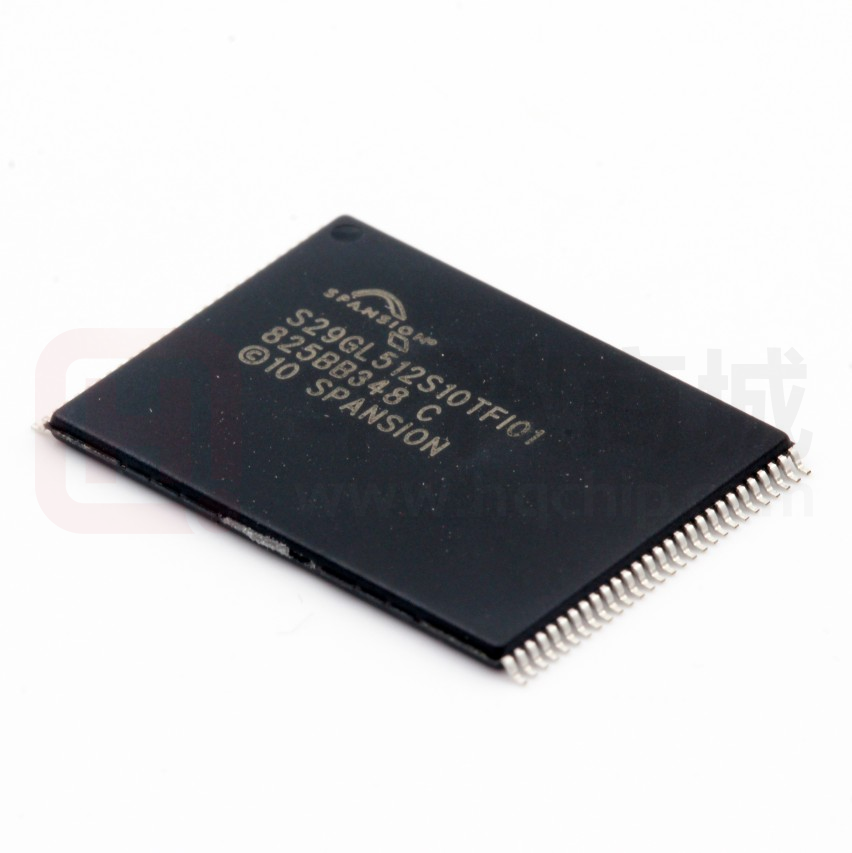

S29GL01GS/S29GL512S

S29GL256S/S29GL128S

1-Gbit (128 Mbyte)/512-Mbit (64 Mbyte)/

256-Mbit (32 Mbyte)/128-Mbit (16 Mbyte),

3.0 V, GL-S Flash Memory

General Description

The Cypress® S29GL01G/512/256/128S are MirrorBit® Eclipse flash products fabricated on 65 nm process technology. These

devices offer a fast page access time as fast as 15 ns with a corresponding random access time as fast as 90 ns. They feature a

Write Buffer that allows a maximum of 256 words/512 bytes to be programmed in one operation, resulting in faster effective

programming time than standard programming algorithms. This makes these devices ideal for today’s embedded applications that

require higher density, better performance and lower power consumption.

Distinctive Characteristics

CMOS 3.0 Volt Core with Versatile I/O

65 nm MirrorBit Eclipse Technology

Single supply (VCC) for read / program / erase (2.7 V to

3.6 V)

Versatile I/O Feature

– Wide I/O voltage range (VIO): 1.65 V to VCC

×16 data bus

Asynchronous 32-byte Page read

512-byte Programming Buffer

– Programming in Page multiples, up to a maximum of

512 bytes

Single word and multiple program on same word options

Automatic Error Checking and Correction (ECC) – internal

hardware ECC with single bit error correction

Sector Erase

– Uniform 128-kbyte sectors

Suspend and Resume commands for Program and Erase

operations

Cypress Semiconductor Corporation

Document Number: 001-98285 Rev. *R

•

Status Register, Data Polling, and Ready/Busy pin methods

to determine device status

Advanced Sector Protection (ASP)

– Volatile and non-volatile protection methods for each

sector

Separate 1024-byte One Time Program (OTP) array with two

lockable regions

Common Flash Interface (CFI) parameter table

Temperature Range / Grade

– Industrial (-40 °C to +85 °C)

– Industrial Plus(-40 °C to +105 °C)

– Automotive, AEC-Q100 Grade 3 (-40 °C to +85 °C)

– Automotive, AEC-Q100 Grade 2 (-40 °C to +105 °C)

100,000 Program / Erase Cycles

20 Years Data Retention

Packaging Options

– 56-pin TSOP

– 64-ball LAA Fortified BGA, 13 mm × 11 mm

– 64-ball LAE Fortified BGA, 9 mm × 9 mm

– 56-ball VBU Fortified BGA, 9 mm × 7 mm

198 Champion Court

•

San Jose, CA 95134-1709

•

408-943-2600

Revised June 21, 2018

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

Performance Summary

Maximum Read Access Times

Density

128 Mb

256 Mb

512 Mb

1 Gb

Voltage Range

Random Access

Time (tACC)

Page Access Time

(tPACC)

CE# Access Time

(tCE)

OE# Access Time

(tOE)

Full VCC = VIO

90

15

90

25

VersatileIO VIO

100

25

100

35

Full VCC = VIO

90

15

90

25

VersatileIO VIO

100

25

100

35

Full VCC = VIO

100

15

100

25

VersatileIO VIO

110

25

110

35

Full VCC = VIO

100

15

100

25

VersatileIO VIO

110

25

110

35

Typical Program and Erase Rates

Buffer Programming

(512 bytes)

1.5 MB/s

Sector Erase (128 kbytes)

477 kB/s

Maximum Current Consumption

Active Read at 5 MHz, 30 pF

60 mA

Program

100 mA

Erase

100 mA

Standby

100 µA

Document Number: 001-98285 Rev. *R

Page 3 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

Contents

General Description ............................................................. 2

Distinctive Characteristics .................................................. 2

Performance Summary ........................................................ 3

1.

Product Overview ........................................................ 4

2.

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

Address Space Maps ................................................... 6

Flash Memory Array....................................................... 7

Device ID and CFI (ID-CFI) ASO ................................... 8

Device ID and Common Flash Interface (ID-CFI)

ASO Map — Automotive Only ....................................... 9

Status Register ASO.................................................... 10

Data Polling Status ASO.............................................. 10

Secure Silicon Region ASO ......................................... 10

Sector Protection Control............................................. 11

ECC Status ASO.......................................................... 11

3.

3.1

3.2

3.3

3.4

Data Protection ..........................................................

Device Protection Methods ..........................................

Command Protection ...................................................

Secure Silicon Region (OTP).......................................

Sector Protection Methods...........................................

4.

4.1

4.2

Read Operations ........................................................ 19

Asynchronous Read..................................................... 19

Page Mode Read ......................................................... 19

5.

5.1

5.2

5.3

5.4

5.5

5.6

5.7

Embedded Operations...............................................

Embedded Algorithm Controller (EAC) ........................

Program and Erase Summary .....................................

Automatic ECC ............................................................

Command Set ..............................................................

Status Monitoring .........................................................

Error Types and Clearing Procedures .........................

Embedded Algorithm Performance Table....................

6.

6.1

6.2

Data Integrity .............................................................. 54

Erase Endurance ......................................................... 54

Data Retention ............................................................. 54

7.

7.1

7.2

Software Interface Reference ...................................

Command Summary ....................................................

Device ID and Common Flash Interface (ID-CFI)

ASO Map .....................................................................

Device ID and Common Flash Interface (ID-CFI)

ASO Map .....................................................................

55

55

8.

8.1

8.2

8.3

8.4

8.5

Signal Descriptions ...................................................

Address and Data Configuration..................................

Input/Output Summary.................................................

Versatile I/O Feature....................................................

Ready/Busy# (RY/BY#) ...............................................

Hardware Reset ...........................................................

64

64

64

65

65

65

9.

9.1

9.2

9.3

Signal Protocols.........................................................

Interface States............................................................

Power-Off with Hardware Data Protection ...................

Power Conservation Modes.........................................

66

66

66

67

7.3

Document Number: 001-98285 Rev. *R

13

13

13

13

14

20

20

21

22

23

34

40

43

9.4

9.5

Read ............................................................................. 67

Write ............................................................................. 68

10.

10.1

10.2

10.3

10.4

10.5

10.6

Electrical Specifications............................................. 69

Absolute Maximum Ratings .......................................... 69

Latchup Characteristics ................................................ 69

Thermal Resistance ...................................................... 69

Operating Ranges......................................................... 69

DC Characteristics ........................................................ 72

Capacitance Characteristics ......................................... 74

11.

11.1

11.2

11.3

11.4

Timing Specifications................................................. 75

Key to Switching Waveforms ........................................ 75

AC Test Conditions ....................................................... 75

Power-On Reset (POR) and Warm Reset .................... 76

AC Characteristics ........................................................ 78

12.

12.1

12.2

12.3

Physical Interface ....................................................... 90

56-pin TSOP ................................................................. 90

64-Ball FBGA ................................................................ 92

56-Ball FBGA ................................................................ 95

13.

Special Handling Instructions

for FBGA Package ...................................................... 96

14.

Ordering Information .................................................. 97

15.

15.1

15.2

15.3

Other Resources ....................................................... 102

Cypress Flash Memory Roadmap .............................. 102

Links to Software ........................................................ 102

Links to Application Notes........................................... 102

16.

Revision History........................................................ 103

58

63

Page 3 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

1.

Product Overview

The GL-S family consists of 128-Mbit to 1Gbit, 3.0 V core, Versatile I/O, non-volatile, flash memory devices. These devices have a

16-bit (word) wide data bus and use only word boundary addresses. All read accesses provide 16 bits of data on each bus transfer

cycle. All writes take 16 bits of data from each bus transfer cycle.

Figure 1.1 Block Diagram

DQ15–DQ0

RY/BY#

VCC

Sector Switches

VSS

VIO

Erase Voltage

Generator

Input/Output

Buffers

RESET#

WE#

WP#

State

Control

Command

Register

PGM Voltage

Generator

Chip Enable

Output Enable

Logic

CE#

OE#

AMax**–A0

Address Latch

Timer

Data

Latch

Y-Decoder

Y-Gating

X-Decoder

Cell Matrix

STB

VCC Detector

STB

:

Note:

** AMAX GL01GS = A25, AMAX GL512S = A24, AMAX GL256S = A23, AMAX GL128S = A22

The GL-S family combines the best features of eXecute In Place (XIP) and Data Storage flash memories. This family has the fast

random access of XIP flash along with the high density and fast program speed of Data Storage flash.

Read access to any random location takes 90 ns to 120 ns depending on device density and I/O power supply voltage. Each random

(initial) access reads an entire 32-byte aligned group of data called a Page. Other words within the same Page may be read by

changing only the low order 4 bits of word address. Each access within the same Page takes 15 ns to 30 ns. This is called Page

Mode read. Changing any of the higher word address bits will select a different Page and begin a new initial access. All read

accesses are asynchronous.

Document Number: 001-98285 Rev. *R

Page 4 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

Table 1.1 S29GL-S Address Map

Type

Address within Page

Count

Addresses

16

A3–A0

Address within Write Buffer

256

A7–A0

Page

4096

A15–A4

Write-Buffer-Line

256

A15–A8

1024 (1 Gb)

512 (512 Mb)

256 (256 Mb)

128 (128 Mb)

AMAX–A16

Sector

The device control logic is subdivided into two parallel operating sections, the Host Interface Controller (HIC) and the Embedded

Algorithm Controller (EAC). HIC monitors signal levels on the device inputs and drives outputs as needed to complete read and write

data transfers with the host system. HIC delivers data from the currently entered address map on read transfers; places write

transfer address and data information into the EAC command memory; notifies the EAC of power transition, hardware reset, and

write transfers. The EAC looks in the command memory, after a write transfer, for legal command sequences and performs the

related Embedded Algorithms.

Changing the non-volatile data in the memory array requires a complex sequence of operations that are called Embedded

Algorithms (EA). The algorithms are managed entirely by the device internal EAC. The main algorithms perform programming and

erase of the main array data. The host system writes command codes to the flash device address space. The EAC receives the

commands, performs all the necessary steps to complete the command, and provides status information during the progress of an

EA.

The erased state of each memory bit is a logic 1. Programming changes a logic 1 (High) to a logic 0 (Low). Only an Erase operation

is able to change a 0 to a 1. An erase operation must be performed on an entire 128-kbyte aligned and length group of data call a

Sector. When shipped from Cypress all Sectors are erased.

Programming is done via a 512-byte Write Buffer. It is possible to write from 1 to 256 words, anywhere within the Write Buffer before

starting a programming operation. Within the flash memory array, each 512-byte aligned group of 512 bytes is called a Line. A

programming operation transfers volatile data from the Write Buffer to a non-volatile memory array Line. The operation is called

Write Buffer Programming.

As the device transfers each 32-byte aligned page of data that was loaded into the Write buffer to the 512-byte Flash array line,

internal logic programs an ECC Code for the Page into a portion of the memory array not visible to the host system software. The

internal logic checks the ECC information during the initial access of every array read operation. If needed, the ECC information

corrects a one bit error during the initial access time.

The Write Buffer is filled with 1’s after reset or the completion of any operation using the Write Buffer. Any locations not written to a 0

by a Write to Buffer command are by default still filled with 1’s. Any 1’s in the Write Buffer do not affect data in the memory array

during a programming operation.

As each Page of data that was loaded into the Write Buffer is transferred to a memory array Line.

Sectors may be individually protected from program and erase operations by the Advanced Sector Protection (ASP) feature set.

ASP provides several, hardware and software controlled, volatile and non-volatile, methods to select which sectors are protected

from program and erase operations.

Document Number: 001-98285 Rev. *R

Page 5 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

Software Interface

2. Address Space Maps

There are several separate address spaces that may appear within the address range of the flash memory device. One address

space is visible (entered) at any given time.

Flash Memory Array: the main non-volatile memory array used for storage of data that may be randomly accessed by

asynchronous read operations.

ID/CFI: a memory array used for Cypress factory programmed device characteristics information. This area contains the

Device Identification (ID) and Common Flash Interface (CFI) information tables.

Secure Silicon Region (SSR): a One Time Programmable (OTP) non-volatile memory array used for Cypress factory

programmed permanent data, and customer programmable permanent data.

Lock Register: an OTP non-volatile word used to configure the ASP features and lock the SSR.

Persistent Protection Bits (PPB): a non-volatile flash memory array with one bit for each Sector. When programmed, each

bit protects the related Sector from erasure and programming.

PPB Lock: a volatile register bit used to enable or disable programming and erasure of the PPB bits.

Password: an OTP non-volatile array used to store a 64-bit password used to enable changing the state of the PPB Lock

Bit when using Password Mode sector protection.

Dynamic Protection Bits (DYB): a volatile array with one bit for each Sector. When set, each bit protects the related Sector

from erasure and programming.

Status Register: a volatile register used to display Embedded Algorithm status.

Data Polling Status: a volatile register used as an alternate, legacy software compatible, way to display Embedded

Algorithm status.

ECC Status: provides the status of any error detection or correction action taken when reading the selected Page.

The main Flash Memory Array is the primary and default address space but, it may be overlaid by one other address space, at any

one time. Each alternate address space is called an Address Space Overlay (ASO).

Each ASO replaces (overlays) the entire flash device address range. Any address range not defined by a particular ASO address

map, is reserved for future use. All read accesses outside of an ASO address map returns non-valid (undefined) data. The locations

will display actively driven data but the meaning of whatever 1’s or 0’s appear are not defined.

There are four device operating modes that determine what appears in the flash device address space at any given time:

Read Mode

Data Polling Mode

Status Register (SR) Mode

Address Space Overlay (ASO) Mode

In Read Mode the entire Flash Memory Array may be directly read by the host system memory controller. The memory device

Embedded Algorithm Controller (EAC), puts the device in Read mode during Power-on, after a Hardware Reset, after a Command

Reset, or after an Embedded Algorithm (EA) is suspended. Read accesses and command writes are accepted in read mode. A

subset of commands are accepted in read mode when an EA is suspended.

While in any mode, the Status Register read command may be issued to cause the Status Register ASO to appear at every word

address in the device address space. In this Status Register ASO Mode, the device interface waits for a read access and, any write

access is ignored. The next read access to the device accesses the content of the status register, exits the Status Register ASO,

and returns to the previous (calling) mode in which the Status Register read command was received.

In EA mode the EAC is performing an Embedded Algorithm, such as programming or erasing a non-volatile memory array. While in

EA mode, none of the main Flash Memory Array is readable because the entire flash device address space is replaced by the Data

Polling Status ASO. Data Polling Status will appear at every word location in the device address space.

Document Number: 001-98285 Rev. *R

Page 6 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

While in EA mode, only a Program / Erase suspend command or the Status Register Read command will be accepted. All other

commands are ignored. Thus, no other ASO may be entered from the EA mode.

When an Embedded Algorithm is suspended, the Data Polling ASO is visible until the device has suspended the EA. When the EA

is suspended the Data Polling ASO is exited and Flash Array data is available. The Data Polling ASO is reentered when the

suspended EA is resumed, until the EA is again suspended or finished. When an Embedded Algorithm is completed, the Data

Polling ASO is exited and the device goes to the previous (calling) mode (from which the Embedded Algorithm was started).

In ASO mode, one of the remaining overlay address spaces is entered (overlaid on the main Flash Array address map). Only one

ASO may be entered at any one time. Commands to the device affect the currently entered ASO. Only certain commands are valid

for each ASO. These are listed in the Table 7.1 on page 55, in each ASO related section of the table.

The following ASOs have non-volatile data that may be programmed to change 1’s to 0’s:

Secure Silicon Region

Lock Register

Persistent Protection Bits (PPB)

Password

Only the PPB ASO has non-volatile data that may be erased to change 0’s to 1’s

When a program or erase command is issued while one of the non-volatile ASOs is entered, the EA operates on the ASO. The ASO

is not readable while the EA is active. When the EA is completed the ASO remains entered and is again readable. Suspend and

Resume commands are ignored during an EA operating on any of these ASOs.

2.1

Flash Memory Array

The S29GL-S family has uniform sector architecture with a sector size of 128 kB. Table 2.1 to Table 2.4 shows the sector

architecture of the four devices.

Table 2.1 S29GL01GS Sector and Memory Address Map

Sector Size (kbyte)

128

Sector Count

1024

Sector Range

Address Range

(16-Bit)

Notes

SA00

0000000h–000FFFFh

Sector Starting Address

:

:

–

SA1023

3FF0000h–3FFFFFFh

Sector Ending Address

Sector Range

Address Range

(16-Bit)

Notes

SA00

0000000h–000FFFFh

Sector Starting Address

:

:

–

SA511

1FF0000h–1FFFFFFh

Sector Ending Address

Sector Range

Address Range

(16-Bit)

Notes

SA00

0000000h–000FFFFh

Sector Starting Address

Table 2.2 S29GL512S Sector and Memory Address Map

Sector Size (kbyte)

Sector Count

128

512

Table 2.3 S29GL256S Sector and Memory Address Map

Sector Size (kbyte)

128

Sector Count

256

Document Number: 001-98285 Rev. *R

:

:

–

SA255

0FF0000h–0FFFFFFh

Sector Ending Address

Page 7 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

Table 2.4 S29GL128S Sector and Memory Address Map

Sector Size (kbyte)

Sector Count

128

Sector Range

Address Range

(16-Bit)

Notes

SA00

0000000h–000FFFFh

Sector Starting Address

128

:

:

–

SA127

07F0000h–07FFFFFh

Sector Ending Address

Note: These tables have been condensed to show sector related information for an entire device on a single page Sectors and their

address ranges that are not explicitly listed (such as SA001-SA510) have sectors starting and ending addresses that form the same

pattern as all other sectors of that size. For example, all 128 kB sectors have the pattern XXX0000h–XXXFFFFh.

2.2

Device ID and CFI (ID-CFI) ASO

There are two traditional methods for systems to identify the type of flash memory installed in the system. One has traditionally been

called Autoselect and is now referred to as Device Identification (ID). The other method is called Common Flash Interface (CFI).

For ID, a command is used to enable an address space overlay where up to 16 word locations can be read to get JEDEC

manufacturer identification (ID), device ID, and some configuration and protection status information from the flash memory. The

system can use the manufacturer and device IDs to select the appropriate driver software to use with the flash device.

CFI also uses a command to enable an address space overlay where an extendable table of standard information about how the

flash memory is organized and operates can be read. With this method the driver software does not have to be written with the

specifics of each possible memory device in mind. Instead the driver software is written in a more general way to handle many

different devices but adjusts the driver behavior based on the information in the CFI table.

Traditionally these two address spaces have used separate commands and were separate overlays. However, the mapping of these

two address spaces are non-overlapping and so can be combined in to a single address space and appear together in a single

overlay. Either of the traditional commands used to access (enter) the Autoselect (ID) or CFI overlay will cause the now combined

ID-CFI address map to appear.

The ID-CFI address map appears within, and overlays the Flash Array data of, the sector selected by the address used in the ID-CFI

enter command. While the ID-CFI ASO is entered the content of all other sectors is undefined.

The ID-CFI address map starts at location 0 of the selected sector. Locations above the maximum defined address of the ID-CFI

ASO to the maximum address of the selected sector have undefined data. The ID-CFI enter commands use the same address and

data values used on previous generation memories to access the JEDEC Manufacturer ID (Autoselect) and Common Flash

Interface (CFI) information, respectively. See Figure 11.16 on page 87 for ASO Entry timing requirements.

Table 2.5 ID-CFI Address Map Overview

Word Address

Description

Read / Write

(SA) + 0000h to 000Fh

Device ID

(traditional Autoselect values)

Read Only

(SA) + 0010h to 0079h

CFI data structure

Read Only

(SA) + 0080h to FFFFh

Undefined

Read Only

For the complete address map see Table 7.2 on page 58.

Document Number: 001-98285 Rev. *R

Page 8 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

2.3

Device ID and Common Flash Interface (ID-CFI) ASO Map — Automotive Only

Word Address

Data Field

# of bytes

Data Format

Example of

Actual Data

Hex Read Out of Example

Data

(SA) + 0080h

Size of Electronic

Marking

1

Hex

19

0013h

(SA) + 0081h

Revision of Electronic

Marking

1

Hex

1

0001h

(SA) + 0082h

Fab Lot #

7

Ascii

LD87270

004Ch, 0044h, 0038h, 0037h,

0032h, 0037h, 0030h

(SA) + 0089h

Wafer #

1

Hex

23

0017h

(SA) + 008Ah

Die X Coordinate

1

Hex

10

000Ah

(SA) + 008Bh

Die Y Coordinate

1

Hex

15

000Fh

(SA) + 008Ch

Class Lot #

7

Ascii

BR33150

0042h, 0052h, 0033h, 0033h,

0031h, 0035h, 0030h

(SA) + 0093h

Reserved for Future

13

n/a

n/a

undefined

Fab Lot # + Wafer # + Die X Coordinate + Die Y Coordinate gives a unique ID for each device.

2.3.1

Device ID

The Joint Electron Device Engineering Council (JEDEC) standard JEP106T defines the manufacturer ID for a compliant memory.

Common industry usage defined a method and format for reading the manufacturer ID and a device specific ID from a memory

device. The manufacturer and device ID information is primarily intended for programming equipment to automatically match a

device with the corresponding programming algorithm. Cypress has added additional fields within this 32-byte address space.

The original industry format was structured to work with any memory data bus width e. g. ×8, ×16, ×32. The ID code values are

traditionally byte wide but are located at bus width address boundaries such that incrementing the device address inputs will read

successive byte, word, or double word locations with the ID codes always located in the least significant byte location of the data

bus. Because the device data bus is word wide each code byte is located in the lower half of each word location. The original

industry format made the high order byte always 0. Cypress has modified the format to use both bytes in some words of the address

space. For the detail description of the Device ID address map see Table 7.2 on page 58.

2.3.2

Common Flash Memory Interface

The JEDEC Common Flash Interface (CFI) specification (JESD68.01) defines a standardized data structure that may be read from a

flash memory device, which allows vendor-specified software algorithms to be used for entire families of devices. The data structure

contains information for system configuration such as various electrical and timing parameters, and special functions supported by

the device. Software support can then be device-independent, Device ID-independent, and forward-and-backward-compatible for

entire Flash device families.

The system can read CFI information at the addresses within the selected sector as shown in Device ID and Common Flash

Interface (ID-CFI) ASO Map on page 58.

Like the Device ID information, CFI information is structured to work with any memory data bus width e. g. ×8, ×16, ×32. The code

values are always byte wide but are located at data bus width address boundaries such that incrementing the device address reads

successive byte, word, or double word locations with the codes always located in the least significant byte location of the data bus.

Because the data bus is word wide each code byte is located in the lower half of each word location and the high order byte is

always 0.

For further information, please refer to the Cypress CFI Specification, Version 1.4 (or later), and the JEDEC publications JEP137-A

and JESD68.01. Please contact JEDEC (http://www.jedec.org) for their standards and the Cypress CFI Specification may be found

at the Cypress Website (http://www.cypress.com/cypressappnotes) at the time of this document’s publication), or contact the local

Cypress sales office listed in the website.

Document Number: 001-98285 Rev. *R

Page 9 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

2.4

Status Register ASO

The Status Register ASO contains a single word of registered volatile status for Embedded Algorithms. When the Status Register

read command is issued, the current status is captured (by the rising edge of WE#) into the register and the ASO is entered. The

Status Register content appears on all word locations. The first read access exits the Status Register ASO (with the rising edge of

CE# or OE#) and returns to the address space map in use when the Status Register read command was issued. Write commands

will not exit the Status Register ASO state.

2.5

Data Polling Status ASO

The Data Polling Status ASO contains a single word of volatile memory indicating the progress of an EA. The Data Polling Status

ASO is entered immediately following the last write cycle of any command sequence that initiates an EA. Commands that initiate an

EA are:

Word Program

Program Buffer to Flash

Chip Erase

Sector Erase

Erase Resume / Program Resume

Program Resume Enhanced Method

Blank Check

Lock Register Program

Password Program

PPB Program

All PPB Erase

Engineering Note: The reset and write buffer abort reset commands require very short time to execute so data polling is not

supported for these commands.The Data Polling Status word appears at all word locations in the device address space. When an

EA is completed the Data Polling Status ASO is exited and the device address space returns to the address map mode where the

EA was started.

2.6

Secure Silicon Region ASO

The Secure Silicon Region (SSR) provides an extra flash memory area that can be programmed once and permanently protected

from further changes i. e. it is a One Time Program (OTP) area. The SSR is

1024 bytes in length. It consists of 512 bytes for Factory Locked Secure Silicon Region and 512 bytes for Customer Locked Secure

Silicon Region.

The sector address supplied during the Secure Silicon Entry command selects the Flash Memory Array sector that is overlaid by the

Secure Silicon Region address map. See Figure 11.16 on page 87 for ASO Entry timing requirements. The SSR is overlaid starting

at location 0 in the selected sector. Use of the sector 0 address is recommended for future compatibility. While the SSR ASO is

entered the content of all other sectors is undefined. Locations above the maximum defined address of the SSR ASO to the

maximum address of the selected sector have undefined data.

Table 2.6 Secure Silicon Region

Word Address Range

Content

Size

(SA) + 0000h to 00FFh

Factory Locked Secure Silicon Region

512 bytes

(SA) + 0100h to 01FFh

Customer Locked Secure Silicon Region

512 bytes

(SA) + 0200h to FFFFh

Undefined

127 kbytes

Document Number: 001-98285 Rev. *R

Page 10 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

2.7

Sector Protection Control

2.7.1

Lock Register ASO

The Lock register ASO contains a single word of OTP memory. When the ASO is entered the Lock Register appears at all word

locations in the device address space. See Figure 11.16 on page 87 for ASO Entry timing requirements. However, it is

recommended to read or program the Lock Register only at location 0 of the device address space for future compatibility.

2.7.2

Persistent Protection Bits (PPB) ASO

The PPB ASO contains one bit of a Flash Memory Array for each Sector in the device. When the PPB ASO is entered, the PPB bit

for a sector appears in the Least Significant Bit (LSB) of each address in the sector. See Figure 11.16 on page 87 for ASO Entry

timing requirements. Reading any address in a sector displays data where the LSB indicates the non-volatile protection status for

that sector. However, it is recommended to read or program the PPB only at address 0 of the sector for future compatibility. If the bit

is 0 the sector is protected against programming and erase operations. If the bit is 1 the sector is not protected by the PPB. The

sector may be protected by other features of ASP.

2.7.3

PPB LOCK ASO

The PPB Lock ASO contains a single bit of volatile memory. The bit controls whether the bits in the PPB ASO may be programmed

or erased. If the bit is 0 the PPB ASO is protected against programming and erase operations. If the bit is 1 the PPB ASO is not

protected. When the PPB Lock ASO is entered the PPB Lock bit appears in the Least Significant Bit (LSB) of each address in the

device address space. See Figure 11.16 on page 87 for ASO Entry timing requirements. However, it is recommended to read or

program the PPB Lock only at address 0 of the device for future compatibility.

2.7.4

Password ASO

The Password ASO contains four words of OTP memory. When the ASO is entered the Password appears starting at address 0 in

the device address space. See Figure 11.16 on page 87 for ASO Entry timing requirements. All locations above the forth word are

undefined.

2.7.5

Dynamic Protection Bits (DYB) ASO

The DYB ASO contains one bit of a volatile memory array for each Sector in the device. When the DYB ASO is entered, the DYB bit

for a sector appears in the Least Significant Bit (LSB) of each address in the sector. See Figure 11.16 on page 87 for ASO Entry

timing requirements. Reading any address in a sector displays data where the LSB indicates the non-volatile protection status for

that sector. However, it is recommended to read, set, or clear the DYB only at address 0 of the sector for future compatibility. If the

bit is 0 the sector is protected against programming and erase operations. If the bit is 1 the sector is not protected by the DYB. The

sector may be protected by other features of ASP.

2.8

ECC Status ASO

The system can access the ECC Status ASO by issuing the ECC Status entry command sequence during Read Mode. The ECC

Status ASO provides the status of a Single Bit Error correction when reading the selected page. Automatic ECC on page 22

describes the ECC function in more detail. See Figure 11.16 on page 87 for ASO Entry timing requirements.

The ECC Status ASO allows the following activities:

Read ECC Status for the selected page.

ASO Exit.

2.8.1

ECC Status

The contents of the ECC Status ASO indicates, for the selected ECC page, whether ECC protection has corrected an error in the

eight-bit error correction code or the 16 Words of data in the ECC page. The address specified in the ECC Status Read Command,

provided in Table 7.1 on page 55 selects the ECC Page.

Document Number: 001-98285 Rev. *R

Page 11 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

Table 2.7 ECC Status Word – Upper Byte

Bit

15

14

13

12

11

10

9

8

Name

RFU

RFU

RFU

RFU

RFU

RFU

RFU

RFU

Value

X

X

X

X

X

X

X

X

Table 2.8 ECC Status Word – Lower Byte

Bit

7

6

5

4

3

2

1

0

Name

RFU

RFU

RFU

RFU

RFU

Single Bit Error corrected in the 8-bit

error correction code

Single Bit Error corrected in

16 words of data

RFU

Value

X

X

X

X

X

0 = No Error Corrected

1 = Single Bit Error Corrected

0 = No Error Corrected

1 = Single Bit Error Corrected

X

Document Number: 001-98285 Rev. *R

Page 12 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

3.

Data Protection

The device offers several features to prevent malicious or accidental modification of any sector via hardware means.

3.1

Device Protection Methods

3.1.1

Power-Up Write Inhibit

RESET#, CE#, WE#, and, OE# are ignored during Power-On Reset (POR). During POR, the device can not be selected, will not

accept commands on the rising edge of WE#, and does not drive outputs. The Host Interface Controller (HIC) and Embedded

Algorithm Controller (EAC) are reset to their standby states, ready for reading array data, during POR. CE# or OE# must go to VIH

before the end of POR (tVCS).

At the end of POR the device conditions are:

all internal configuration information is loaded,

the device is in read mode,

the Status Register is at default value,

all bits in the DYB ASO are set to un-protect all sectors,

the Write Buffer is loaded with all 1’s,

the EAC is in the standby state.

3.1.2

Low VCC Write Inhibit

When VCC is less than VLKO, the HIC does not accept any write cycles and the EAC resets. This protects data during VCC power-up

and power-down. The system must provide the proper signals to the control pins to prevent unintentional writes when VCC is greater

than VLKO.

3.2

Command Protection

Embedded Algorithms are initiated by writing command sequences into the EAC command memory. The command memory array is

not readable by the host system and has no ASO. Each host interface write is a command or part of a command sequence to the

device. The EAC examines the address and data in each write transfer to determine if the write is part of a legal command

sequence. When a legal command sequence is complete the EAC will initiate the appropriate EA.

Writing incorrect address or data values, or writing them in an improper sequence, will generally result in the EAC returning to its

Standby state. However, such an improper command sequence may place the device in an unknown state, in which case the

system must write the reset command, or possibly provide a hardware reset by driving the RESET# signal Low, to return the EAC to

its Standby state, ready for random read.

The address provided in each write may contain a bit pattern used to help identify the write as a command to the device. The upper

portion of the address may also select the sector address on which the command operation is to be performed. The Sector Address

(SA) includes AMAX through A16 flash address bits (system byte address signals amax through a17). A command bit pattern is located

in A10 to A0 flash address bits (system byte address signals a11 through a1).

The data in each write may be: a bit pattern used to help identify the write as a command, a code that identifies the command

operation to be performed, or supply information needed to perform the operation. See Table 7.1 on page 55 for a listing of all

commands accepted by the device.

3.3

Secure Silicon Region (OTP)

The Secure Silicon Region (SSR) provides an extra flash memory area that can be programmed once and permanently protected

from further changes i. e. it is a One Time Program (OTP) area. The SSR is 1024 bytes in length. It consists of 512 bytes for Factory

Locked Secure Silicon Region and 512 bytes for Customer Locked Secure Silicon Region.

Document Number: 001-98285 Rev. *R

Page 13 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

3.4

3.4.1

Sector Protection Methods

Write Protect Signal

If WP# = VIL, the lowest or highest address sector is protected from program or erase operations independent of any other ASP

configuration. Whether it is the lowest or highest sector depends on the device ordering option (model) selected. If WP# = VIH, the

lowest or highest address sector is not protected by the WP# signal but it may be protected by other aspects of ASP configuration.

WP# has an internal pull-up; when unconnected, WP# is at VIH.

3.4.2

ASP

Advanced Sector Protection (ASP) is a set of independent hardware and software methods used to disable or enable programming

or erase operations, individually, in any or all sectors. This section describes the various methods of protecting data stored in the

memory array. An overview of these methods is shown in Figure 3.1.

Figure 3.1 Advanced Sector Protection Overview

Lock Register

(One Time Programmable)

Password Method

Persistent Method

(DQ2)

(DQ1)

64-bit Password

(One Time Protect)

PPB Lock Bit1,2,3

0 = PPBs Locked

1 = PPBs Unlocked

1. Bit is volatile, and defaults to “1” on reset (to

“0” if in Password Mode).

2. Programming to “0” locks all PPBs to their

current state.

3. Once programmed to “0”, requires hardware

reset to unlock or application of the

password.

Memory Array

Persistent

Protection Bit

(PPB)5,6

Sector 0

PPB 0

DYB 0

Sector 1

PPB 1

DYB 1

Sector 2

PPB 2

DYB 2

Sector N-2

PPB N-2

DYB N-2

Sector N-1

PPB N-1

DYB N-1

PPB N

DYB N

4

Sector N

4. N = Highest Address Sector.

5. 0 = Sector Protected,

1 = Sector Unprotected.

6. PPBs programmed individually,

but cleared collectively

Dynamic

Protection Bit

(DYB)7,8,9

7. 0 = Sector Protected,

1 = Sector Unprotected.

8. Protect effective only if corresponding PPB

is “1” (unprotected).

9. Volatile Bits: defaults to user choice upon

power-up (see ordering options).

Every main flash array sector has a non-volatile (PPB) and a volatile (DYB) protection bit associated with it. When either bit is 0, the

sector is protected from program and erase operations.

The PPB bits are protected from program and erase when the PPB Lock bit is 0. There are two methods for managing the state of

the PPB Lock bit, Persistent Protection and Password Protection.

Document Number: 001-98285 Rev. *R

Page 14 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

The Persistent Protection method sets the PPB Lock to 1 during POR or Hardware Reset so that the PPB bits are unprotected by a

device reset. There is a command to clear the PPB Lock bit to 0 to protect the PPB bits. There is no command in the Persistent

Protection method to set the PPB Lock bit therefore the PPB Lock bit will remain at 0 until the next power-off or hardware reset. The

Persistent Protection method allows boot code the option of changing sector protection by programming or erasing the PPB, then

protecting the PPB from further change for the remainder of normal system operation by clearing the PPB Lock bit. This is

sometimes called Boot-code controlled sector protection.

The Password method clears the PPB Lock bit to 0 during POR or Hardware Reset to protect the PPB. A 64-bit password may be

permanently programmed and hidden for the password method. A command can be used to provide a password for comparison with

the hidden password. If the password matches the PPB Lock bit is set to 1 to unprotect the PPB. A command can be used to clear

the PPB Lock bit to 0.

The selection of the PPB Lock management method is made by programming OTP bits in the Lock Register so as to permanently

select the method used.

The Lock Register also contains OTP bits, for protecting the SSR.

The PPB bits are erased so that all main flash array sectors are unprotected when shipped from Cypress. The Secured Silicon

Region can be factory protected or left unprotected depending on the ordering option (model) ordered.

3.4.3

PPB Lock

The Persistent Protection Bit Lock is a volatile bit for protecting all PPB bits. When cleared to 0, it locks all PPBs and when set to 1,

it allows the PPBs to be changed. There is only one PPB Lock Bit per device.

The PPB Lock command is used to clear the bit to 0. The PPB Lock Bit must be cleared to 0 only after all the PPBs are configured

to the desired settings.

In Persistent Protection mode, the PPB Lock is set to 1 during POR or a hardware reset. When cleared, no software command

sequence can set the PPB Lock, only another hardware reset or power-up can set the PPB Lock bit.

In the Password Protection mode, the PPB Lock is cleared to 0 during POR or a hardware reset. The PPB Lock can only set to 1 by

the Password Unlock command sequence. The PPB Lock can be cleared by the PPB Lock Bit Clear command.

3.4.4

Persistent Protection Bits (PPB)

The Persistent Protection Bits (PPB) are located in a separate nonvolatile flash array. One of the PPB bits is assigned to each

sector. When a PPB is 0 its related sector is protected from program and erase operations. The PPB are programmed individually

but must be erased as a group, similar to the way individual words may be programmed in the main array but an entire sector must

be erased at the same time. Preprogramming and verification prior to erasure are handled by the EAC.

Programming a PPB bit requires the typical word programming time. During a PPB bit programming operation or PPB bit erasing,

Data polling Status DQ6 Toggle Bit I will toggle until the operation is complete. Erasing all the PPBs requires typical sector erase

time.

If the PPB Lock is 0, the PPB Program or erase commands do not execute and time-out without programming or erasing the PPB.

The protection state of a PPB for a given sector can be verified by executing a PPB Status Read command when entered in the PPB

ASO.

3.4.5

Dynamic Protection Bits (DYB)

Dynamic Protection Bits are volatile and unique for each sector and can be individually modified. DYBs only control protection for

sectors that have their PPBs erased. By issuing the DYB Set or Clear command sequences, the DYB are set to 0 or cleared to 1,

thus placing each sector in the protected or unprotected state respectively, if the PPB for the Sector is 1. This feature allows

software to easily protect sectors against inadvertent changes, yet does not prevent the easy removal of protection when changes

are needed.

The DYB can be set to 0 or cleared to 1 as often as needed.

Document Number: 001-98285 Rev. *R

Page 15 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

3.4.6

Sector Protection States Summary

Each sector can be in one of the following protection states:

Unlocked – The sector is unprotected and protection can be changed by a simple command. The protection state defaults

to unprotected after a power cycle or hardware reset.

Dynamically Locked – A sector is protected and protection can be changed by a simple command. The protection state is

not saved across a power cycle or hardware reset.

Persistently Locked – A sector is protected and protection can only be changed if the PPB Lock Bit is set to 1. The

protection state is non-volatile and saved across a power cycle or hardware reset. Changing the protection state requires

programming or erase of the PPB bits.

Table 3.1 Sector Protection States

Protection Bit Values

Sector State

PPB Lock

PPB

DYB

1

1

1

Unprotected - PPB and DYB are changeable

1

1

0

Protected - PPB and DYB are changeable

1

0

1

Protected - PPB and DYB are changeable

1

0

0

Protected - PPB and DYB are changeable

0

1

1

Unprotected - PPB not changeable, DYB is changeable

0

1

0

Protected - PPB not changeable, DYB is changeable

0

0

1

Protected - PPB not changeable, DYB is changeable

0

0

0

Protected - PPB not changeable, DYB is changeable

3.4.7

Lock Register

The Lock Register holds the non-volatile OTP bits for controlling protection of the SSR, and determining the PPB Lock bit

management method (protection mode).

Table 3.2 Lock Register

Bit

Default Value

Name

15-9

1

Reserved

8

0

Reserved

7

X

Reserved

6

1

SSR Region 1 (Customer) Lock Bit

5

1

Reserved

4

1

Reserved

3

1

Reserved

2

1

Password Protection Mode Lock Bit

1

1

Persistent Protection Mode Lock Bit

0

0

SSR Region 0 (Factory) Lock Bit

The Secure Silicon Region (SSR) protection bits must be used with caution, as once locked, there is no procedure available for

unlocking the protected portion of the Secure Silicon Region and none of the bits in the protected Secure Silicon Region memory

space can be modified in any way. Once the Secure Silicon Region area is protected, any further attempts to program in the area will

fail with status indicating the area being programmed is protected. The Region 0 Indicator Bit is located in the Lock Register at bit

location 0 and Region 1 in bit location 6.

Document Number: 001-98285 Rev. *R

Page 16 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

As shipped from the factory, all devices default to the Persistent Protection method, with all sectors unprotected, when power is

applied. The device programmer or host system can then choose which sector protection method to use. Programming either of the

following two, one-time programmable, non-volatile bits, locks the part permanently in that mode:

Persistent Protection Mode Lock Bit (DQ1)

Password Protection Mode Lock Bit (DQ2)

If both lock bits are selected to be programmed at the same time, the operation will abort. Once the Password Mode Lock Bit is

programmed, the Persistent Mode Lock Bit is permanently disabled and no changes to the protection scheme are allowed. Similarly,

if the Persistent Mode Lock Bit is programmed, the Password Mode is permanently disabled.

If the password mode is to be chosen, the password must be programmed prior to setting the corresponding lock register bit. Setting

the Password Protection Mode Lock Bit is programmed, a power cycle, hardware reset, or PPB Lock Bit Set command is required to

set the PPB Lock bit to 0 to protect the PPB array.

The programming time of the Lock Register is the same as the typical word programming time. During a Lock Register programming

EA, Data polling Status DQ6 Toggle Bit I will toggle until the programming has completed. The system can also determine the status

of the lock register programming by reading the Status Register. See Status Register on page 34 for information on these status

bits.

The user is not required to program DQ2 or DQ1, and DQ6 or DQ0 bits at the same time. This allows the user to lock the SSR before

or after choosing the device protection scheme. When programming the Lock Bits, the Reserved Bits must be 1 (masked).

3.4.8

Persistent Protection Mode

The Persistent Protection method sets the PPB Lock to 1 during POR or Hardware Reset so that the PPB bits are unprotected by a

device reset. There is a command to clear the PPB Lock bit to 0 to protect the PPB. There is no command in the Persistent

Protection method to set the PPB Lock bit to 1 therefore the PPB Lock bit will remain at 0 until the next power-off or hardware reset.

3.4.9

3.4.9.1

Password Protection Mode

PPB Password Protection Mode

PPB Password Protection Mode allows an even higher level of security than the Persistent Sector Protection Mode, by requiring a

64-bit password for setting the PPB Lock. In addition to this password requirement, after power up and reset, the PPB Lock is

cleared to 0 to ensure protection at power-up. Successful execution of the Password Unlock command by entering the entire

password sets the PPB Lock to 1, allowing for sector PPB modifications.

Password Protection Notes:

The Password Program Command is only capable of programming 0’s.

The password is all 1’s when shipped from Cypress. It is located in its own memory space and is accessible through the

use of the Password Program and Password Read commands.

All 64-bit password combinations are valid as a password.

Once the Password is programmed and verified, the Password Mode Locking Bit must be set in order to prevent reading or

modification of the password.

The Password Mode Lock Bit, once programmed, prevents reading the 64-bit password on the data bus and further

password programming. All further program and read commands to the password region are disabled (data is read as 1's)

and these commands are ignored. There is no means to verify what the password is after the Password Protection Mode

Lock Bit is programmed. Password verification is only allowed before selecting the Password Protection mode.

The Password Mode Lock Bit is not erasable.

The exact password must be entered in order for the unlocking function to occur.

The addresses can be loaded in any order but all 4 words are required for a successful match to occur.

Document Number: 001-98285 Rev. *R

Page 17 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

The Sector Addresses and Word Line Addresses are compared while the password address/data are loaded. If the Sector

Address don't match than the error will be reported at the end of that write cycle. The status register will return to the ready

state with the Program Status Bit set to 1, Program Status Register Bit set to 1, and Write Buffer Abort Status Bit set to 1

indicating a failed programming operation. It is a failure to change the state of the PPB Lock bit because it is still protected

by the lack of a valid password. The data polling status will remain active, with DQ7 set to the complement of the DQ7 bit in

the last word of the password unlock command, and DQ6 toggling. RY/BY# will remain low.

The specific address and data are compared after the Program Buffer To Flash command has been given. If they don't

match to the internal set value than the status register will return to the ready state with the Program Status Bit set to 1 and

Program Status Register Bit set to 1 indicating a failed programming operation. It is a failure to change the state of the PPB

Lock bit because it is still protected by the lack of a valid password. The data polling status will remain active, with DQ7 set

to the complement of the DQ7 bit in the last word of the password unlock command, and DQ6 toggling. RY/BY# will remain

low.

The device requires approximately 100 µs for setting the PPB Lock after the valid 64-bit password is given to the device.

The Password Unlock command cannot be accepted any faster than once every 100 µs ± 20 µs. This makes it take an

unreasonably long time (58 million years) for a hacker to run through all the 64-bit combinations in an attempt to correctly

match a password. The EA status checking methods may be used to determine when the EAC is ready to accept a new

password command.

If the password is lost after setting the Password Mode Lock Bit, there is no way to clear the PPB Lock.

Document Number: 001-98285 Rev. *R

Page 18 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

4.

4.1

Read Operations

Asynchronous Read

Each read access may be made to any location in the memory (random access). Each random access is self-timed with the same

latency from CE# or address to valid data (tACC or tCE).

4.2

Page Mode Read

Each random read accesses an entire 32-byte Page in parallel. Subsequent reads within the same Page have faster read access

speed. The Page is selected by the higher address bits (AMAX–A4), while the specific word of that page is selected by the least

significant address bits A3–A0. The higher address bits are kept constant and only A3–A0 changed to select a different word in the

same Page. This is an asynchronous access with data appearing on DQ15-DQ0 when CE# remains Low, OE# remains Low, and

the asynchronous Page access time (tPACC) is satisfied. If CE# goes High and returns Low for a subsequent access, a random read

access is performed and time is required (tACC or tCE).

Document Number: 001-98285 Rev. *R

Page 19 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

5.

Embedded Operations

5.1

Embedded Algorithm Controller (EAC)

The EAC takes commands from the host system for programming and erasing the flash memory array and performs all the complex

operations needed to change the non-volatile memory state. This frees the host system from any need to manage the program and

erase processes.

There are four EAC operation categories:

Standby (Read Mode)

Address Space Switching

Embedded Algorithms (EA)

Advanced Sector Protection (ASP) Management

5.1.1

EAC Standby

In the standby mode current consumption is greatly reduced. The EAC enters its standby mode when no command is being

processed and no Embedded Algorithm is in progress. If the device is deselected

(CE# = High) during an Embedded Algorithm, the device still draws active current until the operation is completed (ICC3). ICC4 in DC

Characteristics on page 72 represents the standby current specification when both the Host Interface and EAC are in their Standby

state.

5.1.2

Address Space Switching

Writing specific address and data sequences (command sequences) switch the memory device address space from the main flash

array to one of the Address Space Overlays (ASO).

Embedded Algorithms operate on the information visible in the currently active (entered) ASO. The system continues to have access

to the ASO until the system issues an ASO Exit command, performs a Hardware RESET, or until power is removed from the device.

An ASO Exit Command switches from an ASO back to the main flash array address space. The commands accepted when a

particular ASO is entered are listed between the ASO enter and exit commands in the command definitions table. See Command

Summary on page 55 for address and data requirements for all command sequences.

5.1.3

Embedded Algorithms (EA)

Changing the non-volatile data in the memory array requires a complex sequence of operations that are called Embedded

Algorithms (EA). The algorithms are managed entirely by the device internal Embedded Algorithm Controller (EAC). The main

algorithms perform programming and erasing of the main array data and the ASO’s. The host system writes command codes to the

flash device address space. The EAC receives the commands, performs all the necessary steps to complete the command, and

provides status information during the progress of an EA.

Document Number: 001-98285 Rev. *R

Page 20 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

5.2

Program and Erase Summary

Flash data bits are erased in parallel in a large group called a sector. The Erase operation places each data bit in the sector in the

logical 1 state (High). Flash data bits may be individually programmed from the erased 1 state to the programmed logical 0 (low)

state. A data bit of 0 cannot be programmed back to a 1. A succeeding read shows that the data is still 0. Only erase operations can

convert a 0 to a 1. Programming the same word location more than once with different 0 bits will result in the logical AND of the

previous data and the new data being programmed.

The duration of program and erase operations is shown in Embedded Algorithm Performance Table on page 43.

Program and erase operations may be suspended.

An erase operation may be suspended to allow either programming or reading of another sector (not in the erase sector).

No other erase operation can be started during an erase suspend.

A program operation may be suspended to allow reading of another location (not in the Line being programmed).

No other program or erase operation may be started during a suspended program operation - program or erase commands

will be ignored during a suspended program operation.

After an intervening program operation or read access is complete the suspended erase or program operation may be

resumed. The resume can happen at any time after the suspend assuming the device is not in the process of executing

another command.

Program and Erase operations may be interrupted as often as necessary but in order for a program or erase operation to

progress to completion there must be some periods of time between resume and the next suspend commands greater than

or equal to tPRS or tERS in Embedded Algorithm Performance Table on page 43.

When an Embedded Algorithm (EA) is complete, the EAC returns to the operation state and address space from which the

EA was started (Erase Suspend or EAC Standby).

The system can determine the status of a program or erase operation by reading the Status Register or using Data Polling Status.

Refer to Status Register on page 34 for information on these status bits. Refer to Data Polling Status on page 35 for more

information.

Any commands written to the device during the Embedded Program Algorithm are ignored except the Program Suspend, and Status

Read command.

Any commands written to the device during the Embedded Erase Algorithm are ignored except Erase Suspend and Status Read

command.

A hardware reset immediately terminates any in progress program / erase operation and returns to read mode after tRPH time. The

terminated operation should be reinitiated once the device has returned to the idle state, to ensure data integrity.

For performance and reliability reasons reading and programming is internally done on full 32-byte Pages.

ICC3 in DC Characteristics on page 72 represents the active current specification for a write (Embedded Algorithm) operation.

5.2.1

Program Granularity

The S29GL-S supports two methods of programming, Word or Write Buffer Programming. Each Page can be programmed by either

method. Pages programmed by different methods may be mixed within a Line for the Industrial Temperature version (–40 °C to

+85 °C). For the In-Cabin version (–40 °C to +105 °C) the device will only support one programming operation on each 32-byte page

between erase operations and Single Word Programming command is not supported.

Word programming examines the data word supplied by the command and programs 0’s in the addressed memory array word to

match the 0’s in the command data word.

Write Buffer Programming examines the write buffer and programs 0’s in the addressed memory array Pages to match the 0’s in the

write buffer. The write buffer does not need to be completely filled with data. It is allowed to program as little as a single bit, several

bits, a single word, a few words, a Page, multiple Pages, or the entire buffer as one programming operation. Use of the write buffer

method reduces host system overhead in writing program commands and reduces memory device internal overhead in

programming operations to make Write Buffer Programming more efficient and thus faster than programming individual words with

the Word Programming command.

Document Number: 001-98285 Rev. *R

Page 21 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

5.2.2

Incremental Programming

The same word location may be programmed more than once, by either the Word or Write Buffer Programming methods, to

incrementally change 1’s to 0’s. Note that if additional programming is performed on a page its ECC coverage is disabled.

5.3

5.3.1

Automatic ECC

ECC Overview

The Automatic ECC feature works transparently with normal program, erase, and read operations. As the device transfers each

Page of data from the Write Buffer is to the memory array, internal ECC logic programs ECC Code for the Page into a portion of the

memory array that is not visible to the host system. The device evaluates the Page data and the ECC Code during each initial Page

access. If needed, the internal ECC logic corrects a one bit error during the initial access.

Programming more than once to a particular Page will disable the ECC function for that Page. The ECC function will remain disabled

for that Page until the next time the host system erases the Sector containing that Page. The host system may read data stored in

that Page following multiple programming operations; however, ECC is disabled and an error in that Page will not be detected or

corrected.

5.3.2

Program and Erase Summary

For performance and reliability reasons, GL-S devices perform reading and programming on full 32-byte Pages in parallel. The GL-S

device provides ECC on each Page by adding an ECC Code to each Page when it is first programmed. The ECC Code is automatic

and transparent to the host system.

5.3.3

ECC Implementation

Each 32-byte Page in the main flash array and OTP regions features an associated ECC Code. The ECC Code, in combination with

ECC logic, is able to detect and correct any single bit error found in a Page during a read access.

The first Write Buffer program operation applied to a Page programs the ECC Code for that Page. Subsequent programming

operations that occur more than once on a particular Page disable the ECC function for that Page. This allows bit or word

programming; however, note that multiple programming operations to the same Page will disable the ECC function on the Page

where incremental programming occurs. An erase of the Sector containing a Page with ECC disabled will re-enable the ECC

function for that Page.

The ECC function is automatic and transparent to the user. The transparency of the Automatic ECC function enhances data integrity

for typical programming operations that write data once to each Page. The ECC function also facilitates software compatibility to

previous generations of GL Family products by allowing single word programming and bit walking where the same Page or word is

programmed more than once. When a Page has Automatic ECC disabled, the ECC function will not detect or correct an error on a

data read from that Page.

5.3.4

Word Programming

Word programming programs a single word anywhere in the main Flash Memory Array. Programming multiple words in the same

32-byte page disables Automatic ECC protection on that Page. A sector erase of the sector containing that Page will re-enable

Automatic ECC following word programming on that Page.

5.3.5

Write Buffer Programming

Each Write Buffer Program operation allows for programming of 1 bit up to 512 bytes. A 32-byte Page is the smallest program

granularity that features Automatic ECC protection. Programming the same Page more than once will disable the Automatic ECC on

that Page. Cypress recommends that a Write Buffer programming operation program multiple Pages in an operation and write each

Page only once. This keeps the Automatic ECC protection enabled on each Page. For the very best performance, program in full

Lines of 512 bytes aligned on 512-byte boundaries.

Document Number: 001-98285 Rev. *R

Page 22 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

5.4

5.4.1

5.4.1.1

Command Set

Program Methods

Word Programming

Word programming is used to program a single word anywhere in the main Flash Memory Array.

The Word Programming command is a four-write-cycle sequence. The program command sequence is initiated by writing two

unlock write cycles, followed by the program set up command. The program address and data are written next, which in turn initiate

the Embedded Word Program algorithm. The system is not required to provide further controls or timing. The device automatically

generates the program pulses and verifies the programmed cell margin internally. When the Embedded Word Program algorithm is

complete, the EAC then returns to its standby mode.

The system can determine the status of the program operation by using Data Polling Status, reading the Status Register, or

monitoring the RY/BY# output. See Status Register on page 34 for information on these status bits. See Data Polling Status

on page 35 for information on these status bits. See Figure 5.1 on page 23 for a diagram of the programming operation.

Any commands other than Program Suspend written to the device during the Embedded Program algorithm are ignored. Note that a

hardware reset (RESET# = VIL) immediately terminates the programming operation and returns the device to read mode after tRPH

time. To ensure data integrity, the Program command sequence should be reinitiated once the device has completed the hardware

reset operation.

A modified version of the Word Programming command, without unlock write cycles, is used for programming when entered into the

Lock Register, Password, and PPB ASOs. The same command is used to change volatile bits when entered in to the PPB Lock, and

DYB ASOs. See Table 7.1 on page 55 for program command sequences.

Figure 5.1 Word Program Operation

START

Write Program Command

Sequence

Data Poll from System

Embedded

Program

algorithm

in progress

Verify Word?

No

Yes

No

Last Addresss?

Increment Address

Yes

Programming Completed

Document Number: 001-98285 Rev. *R

Page 23 of 108

�S29GL01GS/S29GL512S

S29GL256S/S29GL128S

5.4.1.2

Write Buffer Programming

A write buffer is used to program data within a 512-byte address range aligned on a 512-byte boundary (Line). Thus, a full Write

Buffer Programming operation must be aligned on a Line boundary. Programming operations of less than a full 512 bytes may start

on any word boundary but may not cross a Line boundary. At the start of a Write Buffer programming operation all bit locations in the

buffer are all 1’s (FFFFh words) thus any locations not loaded will retain the existing data. See Product Overview on page 4 for

information on address map.

Write Buffer Programming allows up to 512 bytes to be programmed in one operation. It is possible to program from 1 bit up to 512

bytes in each Write Buffer Programming operation. It is recommended that a multiple of Pages be written and each Page written only

once. For the very best performance, programming should be done in full Lines of 512 bytes aligned on 512-byte boundaries.

Write Buffer Programming is supported only in the main flash array or the SSR ASO.

The Write Buffer Programming operation is initiated by first writing two unlock cycles. This is followed by a third write cycle of the

Write to Buffer command with the Sector Address (SA), in which programming is to occur. Next, the system writes the number of

word locations minus 1. This tells the device how many write buffer addresses are loaded with data and therefore when to expect the

Program Buffer to flash confirm command. The Sector Address must match in the Write to Buffer command and the Write Word

Count command. The Sector to be programmed must be unlocked (unprotected).

The system then writes the starting address / data combination. This starting address is the first address / data pair to be

programmed, and selects the write-buffer-Line address. The Sector address must match the Write to Buffer Sector Address or the

operation will abort and return to the initiating state. All subsequent address / data pairs must be in sequential order. All write buffer

addresses must be within the same Line. If the system attempts to load data outside this range, the operation will abort and return to

the initiating state.

The counter decrements for each data load operation. Note that while counting down the data writes, every write is considered to be

data being loaded into the write buffer. No commands are possible during the write buffer loading period. The only way to stop

loading the write buffer is to write with an address that is outside the Line of the programming operation. This invalid address will

immediately abort the Write to Buffer command.

Once the specified number of write buffer locations has been loaded, the system must then write the Program Buffer to Flash

command at the Sector Address. The device then goes busy. The Embedded Program algorithm automatically programs and

verifies the data for the correct data pattern. The system is not required to provide any controls or timings during these operations. If

an incorrect number of write buffer locations have been loaded the operation will abort and return to the initiating state. The abort

occurs when anything other than the Program Buffer to Flash is written when that command is expected at the end of the word

count.

The write-buffer embedded programming operation can be suspended using the Program Suspend command. When the Embedded

Program algorithm is complete, the EAC then returns to the EAC standby or Erase Suspend standby state where the programming

operation was started.

The system can determine the status of the program operation by using Data Polling Status, reading the Status Register, or

monitoring the RY/BY# output. See Status Register on page 34 for information on these status bits. See Data Polling Status

on page 35 for information on these status bits. See Figure 5.2 on page 25 for a diagram of the programming operation.

The Write Buffer Programming Sequence will be Aborted under the following conditions:

Load a Word Count value greater than the buffer size (255).

Write an address that is outside the Line provided in the Write to Buffer command.

The Program Buffer to Flash command is not issued after the Write Word Count number of data words is loaded.

When any of the conditions that cause an abort of write buffer command occur the abort will happen immediately after the offending

condition, and will indicate a Program Fail in the Status Register at bit location 4 (PSB = 1) due to Write Buffer Abort bit location 3

(WBASB = 1). The next successful program operation will clear the failure status or a Clear Status Register may be issued to clear

the PSB status bit.

The Write Buffer Programming Sequence can be stopped by the following: Hardware Reset or Power cycle. However, these using

either of these methods may leave the area being programmed in an intermediate state with invalid or unstable data values. In this