Please note that Cypress is an Infineon Technologies Company.

The document following this cover page is marked as “Cypress” document as this is the

company that originally developed the product. Please note that Infineon will continue

to offer the product to new and existing customers as part of the Infineon product

portfolio.

Continuity of document content

The fact that Infineon offers the following product as part of the Infineon product

portfolio does not lead to any changes to this document. Future revisions will occur

when appropriate, and any changes will be set out on the document history page.

Continuity of ordering part numbers

Infineon continues to support existing part numbers. Please continue to use the

ordering part numbers listed in the datasheet for ordering.

www.infineon.com

�S70KL1283/S70KS1283

3.0 V/1.8 V, 128 Mb (16 MB), Octal (xSPI)

Interface HyperRAM (Self-Refresh DRAM)

S70KL1283/S70KS1283, 3.0 V/1.8 V, 64 Mb (8 MB), HyperRAM Self-Refresh DRAM

Features

■

Configurable Burst Characteristics

❐ Linear burst

❐ Wrapped burst lengths:

• 16 bytes (8 clocks)

• 32 bytes (16 clocks)

• 64 bytes (32 clocks)

• 128 bytes (64 clocks)

❐ Hybrid option - one wrapped burst followed by linear burst

on 64 Mb. Linear Burst across die boundary is not supported.

Configurable output drive strength

Interface

■

xSPI (Octal) Interface

■

1.8 V / 3.0 V Interface support

❐ Single ended clock (CK) - 11 bus signals

❐ Optional Differential clock (CK, CK#) - 12 bus signals

■

Chip Select (CS#)

■

8-bit data bus (DQ[7:0])

■

■

Hardware reset (RESET#)

■

■

Bidirectional Read-Write Data Strobe (RWDS)

❐ Output at the start of all transactions to indicate refresh

latency

❐ Output during read transactions as Read Data Strobe

❐ Input during write transactions as Write Data Mask

■

Array Refresh

❐ Partial Memory Array (1/8, 1/4, 1/2, and so on)

❐ Full

■

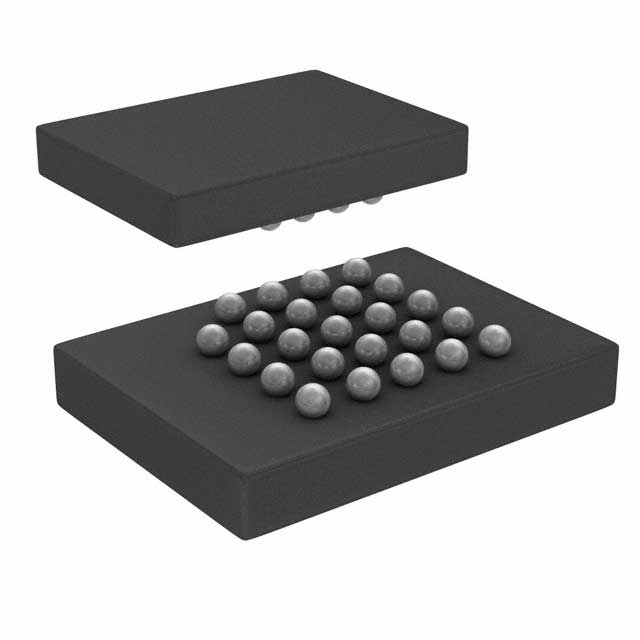

Package

❐ 24-ball FBGA

■

Operating Temperature Range

❐ Industrial (I): –40 °C to +85 °C

❐ Industrial Plus (V): –40 °C to +105 °C

❐ Automotive, AEC-Q100 Grade 3: –40 °C to +85 °C

❐ Automotive, AEC-Q100 Grade 2: –40 °C to +105°C

■

Optional DDR Center-Aligned Read Strobe (DCARS)

❐ During read transactions RWDS is offset by a second clock,

phase shifted from CK

❐ The Phase Shifted Clock is used to move the RWDS

transition edge within the read data eye

Performance, Power, and Packages

Power Modes[1]

❐ Hybrid Sleep Mode

❐ Deep Power Down

■

200-MHz maximum clock rate

■

DDR - transfers data on both edges of the clock

Technology

■

Data throughput up to 400 MBps (3,200 Mbps)

■

38-nm DRAM

Note

1. 128-Mb HyperRAM is a stacked-die chip using two 64-Mb dice. Only one die, at a time, can be programmed to enter Hybrid Sleep Mode mode or Deep Power Down

mode.

Cypress Semiconductor Corporation

Document Number: 002-29418 Rev .**

•

198 Champion Court

•

San Jose, CA 95134-1709

•

408-943-2600

Revised February 07, 2020

�S70KL1283/S70KS1283

Performance Summary

Read Transaction Timings

Unit

Maximum Clock Rate at 1.8 V VCC/VCCQ

200 MHz

Maximum Clock Rate at 3.0 V VCC/VCCQ

200 MHz

Maximum Access Time, (tACC)

35 ns

Maximum Current Consumption

Unit

Burst Read or Write (linear burst at 200 MHz, 1.8 V)

50 mA

Burst Read or Write (linear burst at 200 MHz, 3.0 V)

60 mA

Standby (CS# = VCC = 3.6 V, 105 °C)

750 µA

Deep Power Down (CS# = VCC = 3.6 V, 105 °C)

360 µA

Standby (CS# = VCC = 2.0 V, 105 °C)

660 µA

Deep Power Down (CS# = VCC = 2.0 V, 105 °C)

330 µA

Logic Block Diagram

CS#

CS#

CK/CK#

CK/CK#

RWDS

RWDS

X Decoders

64 Mb

HyperRAM

HyperRAM

1 - Die 0

I/O

DQ[7:0]

Control

Logic

Memory

Y Decoders

DQ[7:0]

Data Latch

RESET#

Data Path

X Decoders

64 Mb

HyperRAM

HyperRAM

2 - Die 1

CS#

CK/CK#

Memory

RWDS

I/O

DQ[7:0]

RESET#

Control

Logic

Y Decoders

Data Latch

RESET#

Data Path

Document Number: 002-29418 Rev .**

Page 2 of 51

�S70KL1283/S70KS1283

Contents

General Description ......................................................... 4

xSPI (Octal) Interface .................................................. 4

Product Overview ............................................................. 6

xSPI (Octal) Interface .................................................. 6

Signal Description ............................................................ 7

Input/Output Summary ................................................ 7

xSPI (Octal) Transaction Details ..................................... 8

Command/Address/Data Bit Assignments .................. 8

RESET ENABLE Transaction ..................................... 9

RESET Transaction ..................................................... 9

READ ID Transaction ................................................ 10

DEEP POWER DOWN Transaction .......................... 11

READ Transaction ..................................................... 12

WRITE Transaction ................................................... 12

WRITE DISABLE Transaction ................................... 13

READ ANY REGISTER Transaction ......................... 14

WRITE ANY REGISTER Transaction ....................... 14

Data Placement During Memory READ/WRITE

Transactions .............................................................. 15

Data Placement During Register READ/WRITE

Transactions .............................................................. 16

Memory Space ................................................................ 17

xSPI (Octal) Interface ................................................ 17

Density and Row Boundaries .................................... 17

Register Space Access .................................................. 17

xSPI (Octal) Interface ................................................ 17

Device Identification Registers .................................. 18

Interface States ............................................................... 24

Power Conservation Modes .......................................... 25

Interface Standby ...................................................... 25

Active Clock Stop ...................................................... 25

Hybrid Sleep .............................................................. 25

Deep Power Down .................................................... 26

Electrical Specifications ................................................ 27

Absolute Maximum Ratings ....................................... 27

Latch-up Characteristics ............................................ 27

Document Number: 002-29418 Rev .**

Operating Ranges ..................................................... 28

DC Characteristics .................................................... 29

Power-up Initialization ............................................... 33

Power Down .............................................................. 34

Hardware Reset ........................................................ 35

Software Reset .......................................................... 35

Timing Specifications .................................................... 36

Key to Switching Waveforms ..................................... 36

AC Test Conditions ................................................... 36

CLK Characteristics ................................................... 37

AC Characteristics ..................................................... 38

Physical Interface ........................................................... 41

FBGA 24-Ball 5 x 5 Array Footprint ........................... 41

Physical Diagrams ..................................................... 42

DDR Center-Aligned Read Strobe (DCARS)

Functionality ................................................................... 43

xSPI HyperRAM Products with DCARS Signal

Descriptions ............................................................... 43

HyperRAM Products with DCARS — FBGA 24-ball, 5 x 5

Array Footprint ........................................................... 44

HyperRAM Memory with DCARS Timing .................. 44

Ordering Information ...................................................... 46

Ordering Part Number ............................................... 46

Valid Combinations ................................................... 47

Valid Combinations — Automotive Grade /

AEC-Q100 ................................................................. 48

Acronyms ........................................................................ 49

Document Conventions ................................................. 49

Revision History ............................................................. 50

Sales, Solutions, and Legal Information ...................... 51

Worldwide Sales and Design Support ....................... 51

Products .................................................................... 51

PSoC® Solutions ...................................................... 51

Cypress Developer Community ................................. 51

Technical Support ..................................................... 51

Page 3 of 51

�S70KL1283/S70KS1283

General Description

The Cypress 128-Mb HyperRAM device is a high-speed CMOS, self-refresh DRAM, with xSPI (Octal) interface. The DRAM array

uses dynamic cells that require periodic refresh. Refresh control logic within the device manages the refresh operations on the DRAM

array when the memory is not being actively read or written by the xSPI interface master (host). Since the host is not required to

manage any refresh operations, the DRAM array appears to the host as though the memory uses static cells that retain data without

refresh. Hence, the memory is more accurately described as Pseudo Static RAM (PSRAM).

Since the DRAM cells cannot be refreshed during a read or write transaction, there is a requirement that the host limit read or write

burst transfers lengths to allow internal logic refresh operations when they are needed. The host must confine the duration of transactions and allow additional initial access latency, at the beginning of a new transaction, if the memory indicates a refresh operation

is needed. The dual-die, 128-Mb HyperRAM chip supports data transactions with additional (2X) latency only.

xSPI (Octal) Interface

xSPI (Octal) is a SPI-compatible low signal count, DDR interface supporting eight I/Os. The DDR protocol in xSPI (Octal) transfers

two data bytes per clock cycle on the DQ input/output signals. A read or write transaction on xSPI (Octal) consists of a series of 16-bit

wide, one clock cycle data transfers at the internal RAM array with two corresponding 8-bit wide, one-half-clock-cycle data transfers

on the DQ signals. All inputs and outputs are LV-CMOS compatible. Device are available as 1.8 V VCC/VCCQ or 3.0 V VCC/VCCQ

(nominal) for array (VCC) and I/O buffer (VCCQ) supplies, through different Ordering Part Number (OPN).

Each transaction on xSPI (Octal) must include a command whereas address and data are optional. The transactions are structures

as follows:

■

Each transaction begins with CS# going LOW and ends with CS# returning HIGH.

■

The serial clock (CK) marks the transfer of each bit or group of bits between the host and memory. All transfers occur on every CK

edge (DDR mode).

■

Each transaction has a 16-bit command which selects the type of device operation to perform. The 16-bit command is based on

two 8-bit opcodes. The same 8-bit opcode is sent on both edges of the clock.

■

A command may be stand-alone or may be followed by address bits to select a memory location in the device to access data.

■

Read transactions require a latency period after the address bits and can be zero to several CK cycles. CK must continue to toggle

during any read transaction latency period. During the command and address parts of a transaction, the memory indicates that an

additional latency period is needed for a required refresh time (tRFH) by driving the RWDS signal to the HIGH state.

■

Write transactions to registers do not require a latency period.

■

Write transactions to the memory array require a latency period after the address bits and can be zero to several CK cycles. CK

must continue to toggle during any write transaction latency period. During the command and address parts of a transaction, the

memory indicates that an additional latency period is needed for a required refresh time (tRFH) by driving the RWDS signal to the

HIGH state.

■

In all transactions, command and address bits are shifted in the device with the most significant bits (MSb) first. The individual data

bits within a data byte are shifted in and out of the device MSb first as well. All data bytes are transferred with the lowest address

byte sent out first.

Document Number: 002-29418 Rev .**

Page 4 of 51

�S70KL1283/S70KS1283

Figure 1. xSPI (Octal) Command only Transaction (DDR)[1]

CS#

CK#, CK

High: 2X Latency Count

Low: 1X Latency Count

RWDS

CMD

[7:0]

DQ[7:0]

CMD

[7:0]

Command

(Host drives DQ[7:0])

Figure 2. xSPI (Octal) Write with No Latency Transaction (DDR) (Register Writes)[2]

CS#

CK#, CK

High: 2X Latency Count

Low: 1X Latency Count

RWDS

CMD

[7:0]

DQ[7:0]

CMD

[7:0]

ADR

[31:24]

ADR

[23:16]

ADR

[15:8]

ADR

[7:0]

Command - Address

(Host drives DQ[7:0], Memory drives RWDS)

RG

[15:8]

RG

[7:0]

Write Data

Figure 3. xSPI (Octal) Write with 2X Latency Transaction (DDR) (Memory Array Writes)[1, 3, 4]

CS#

CK#, CK

Latency Count (2X)

RWDS

High: 2X Latency Count

Low: 1X Latency Count

RWDS acts as Data Mask

DQ[7:0]

CMD

[7:0]

CMD

[7:0]

ADR

[31:24]

ADR

[23:16]

ADR

[15:8]

ADR

[7:0]

DinA

[7:0]

Command - Address

(Host drives DQ[7:0] and Memory drives RWDS)

DinA+1

[7:0]

DinA+2

[7:0]

DinA+3

[7:0]

Write Data

(Host drives DQ[7:0])

Figure 4. xSPI (Octal) Read with 2X Latency Transaction (DDR) (All Reads)[1, 5]

CS#

CK#, CK

Latency Count (2X)

RWDS

High: 2X Latency Count

Low: 1X Latency Count

RWDS & Data are edge aligned

DQ[7:0]

CMD

[7:0]

CMD

[7:0]

ADR

[31:24]

ADR

[23:16]

ADR

[15:8]

ADR

[7:0]

Command - Address

(Host drives DQ[7:0] and Memory drives RWDS)

DoutA

[7:0]

DoutA+1

[7:0]

DoutA+2

[7:0]

DoutB+3

[7:0]

Read Data

(Memory drives RWDS)

Notes

1. The initial latency "Low = 1x Latency Count" is not applicable in dual-die, 128 Mb HyperRAM.

2. Write with no latency transaction is used for register writes only.

3. RWDS is driven by HyperRAM during Command & Address cycles for 2X latency and then driven by the host for data masking.

4. Data DinA and DinA+2 are masked.

5. RWDS is driven by HyperRAM during Command & Address cycles for 2X latency and then driven again phase aligned with data.

Document Number: 002-29418 Rev .**

Page 5 of 51

�S70KL1283/S70KS1283

Product Overview

The 128-Mb HyperRAM device is 1.8 V or 3.0 V array and I/O, synchronous self-refresh Dynamic RAM (DRAM). The HyperRAM

device provides an xSPI (Octal) slave interface to the host system. The xSPI (Octal) interface has an 8-bit (1 byte) wide DDR data

bus and use only word-wide (16-bit data) address boundaries. Read transactions provide 16 bits of data during each clock cycle

(8 bits on both clock edges). Write transactions take 16 bits of data from each clock cycle (8 bits on each clock edge).

Figure 5. xSPI (Octal) HyperRAM Interface[6]

RESET#

CS#

CK

CK#

VCC

VCCQ

DQ[7:0]

RWDS

VSS

VSSQ

xSPI (Octal) Interface

Read and write transactions require three clock cycles to define the target row/column address and then an initial access latency of

tACC. During the CA part of a transaction, the memory indicates an additional latency for a required refresh time (tRFH) by driving the

RWDS signal to the HIGH state. During a read (or write) transaction, after the initial data value has been output (or input), additional

data can be read from (or written to) the row on subsequent clock cycles in either a wrapped or linear sequence. When configured in

linear burst mode, the device will automatically fetch the next sequential row from the memory array to support a continuous linear

burst. Simultaneously accessing the next row in the array while the read or write data transfer is in progress, allows for a linear

sequential burst operation that can provide a sustained data rate of 400 MBps (1 byte (8 bit data bus) * 2 (data clock edges) *

200 MHz = 400 MBps).

Note

6. CK# is used in Differential Clock mode, but optional.

Document Number: 002-29418 Rev .**

Page 6 of 51

�S70KL1283/S70KS1283

Signal Description

Input/Output Summary

The xSPI (Octal) HyperRAM signals are shown in Table 1. Active Low signal names have a hash symbol (#) suffix.

Table 1. I/O Summary[8]

Symbol

Type

Description

CS#

Chip Select. Bus transactions are initiated with a HIGH to LOW transition. Bus

Master Output, Slave Input transactions are terminated with a Low to High transition. The master device has a

separate CS# for each slave.

CK, CK#[7]

Master Output, Slave Input

Differential Clock. Command, address, and data information is output with respect to

the crossing of the CK and CK# signals. Use of differential clock is optional.

Single Ended Clock. CK# is not used, only a single ended CK is used.

The clock is not required to be free-running.

DQ[7:0]

Input/Output

Data Input/Output. Command, Address, and Data information is transferred on these

signals during Read and Write transactions.

RWDS

Input/Output

Read-Write Data Strobe. During the Command/Address portion of all bus

transactions RWDS is a slave output and indicates whether additional initial latency is

required. Slave output during read data transfer, data is edge aligned with RWDS.

Slave input during data transfer in write transactions to function as a data mask.

The dual-die, 128-Mb HyperRAM chip supports data transactions with additional (2X)

latency only.

RESET#

Hardware RESET. When LOW, the slave device will self initialize and return to the

Master Output, Slave Input, Standby state. RWDS and DQ[7:0] are placed into the HIGH-Z state when RESET# is

LOW. The slave RESET# input includes a weak pull-up, if RESET# is left unconnected

Internal Pull-up

it will be pulled up to the HIGH state.

VCC

Power Supply

Array Power.

VCCQ

Power Supply

Input/Output Power.

VSS

Power Supply

Array Ground.

VSSQ

Power Supply

Input/Output Ground.

RFU

No Connect

Reserved for Future Use. May or may not be connected internally, the signal/ball

location should be left unconnected and unused by PCB routing channel for future

compatibility. The signal/ball may be used by a signal in the future.

Notes

7. CK# is used in Differential Clock mode, but optional connection. Tie the CK# input pin to either VccQ or VssQ if not connected to the host controller, but do not

leave it floating.

8. Optional DCARS pinout and pin description are outlined in section DDR Center-Aligned Read Strobe (DCARS) Functionality on page 43.

Document Number: 002-29418 Rev .**

Page 7 of 51

�S70KL1283/S70KS1283

xSPI (Octal) Transaction Details

The xSPI (Octal) master begins a transaction by driving CS# LOW while clock is idle. Then the clock begins toggling while CA words

are transferred.

For memory Read and Write transactions, the xSPI (Octal) master then continues clocking for a number of cycles defined by the

latency count setting in configuration register 0 (Register Write transactions do not require any latency count). The initial latency

count required for a particular clock frequency is based on RWDS. If RWDS is LOW during the CA cycles, one latency count is

inserted. If RWDS is HIGH during the CA cycles, an additional latency count is inserted. Once these latency clocks have been

completed the memory starts to simultaneously transition the RWDS and output the target data. The dual-die, 128-Mb HyperRAM

chip supports data transactions with additional (2X) latency only.

During the read data transfers, read data is output edge aligned with every transition of RWDS. Data will continue to be output as

long as the host continues to transition the clock while CS# is LOW. Note that burst transactions should not be so long as to prevent

the memory from doing distributed refreshes.

During the write data transfers, write data is center-aligned with the clock edges. The first byte of data in each word is captured by

the memory on the rising edge of CK and the second byte is captured on the falling edge of CK. RWDS is driven by the host master

interface as a data mask. When data is being written and RWDS is HIGH the byte will be masked and the array will not be altered.

When data is being written and RWDS is LOW the data will be placed into the array. Because the master is driving RWDS during

write data transfers, neither the master nor the HyperRAM device are able to indicate a need for latency within the data transfer

portion of a write transaction. The acceptable write data burst length setting is also shown in configuration register 0.

Wrapped bursts will continue to wrap within the burst length and linear burst will output data in a sequential manner across row

boundaries. When a linear burst read reaches the last address in the array, continuing the burst beyond the last address will provide

data from the beginning of the address range. Read transfers can be ended at any time by bringing CS# HIGH when the clock is

idle. The clock is not required to be free-running. The clock may remain idle while CS# is HIGH.

Command/Address/Data Bit Assignments

Table 2. Command Set[9, 10, 11, 12, 13]

Code

CA-Data

Address

(Bytes)

Latency

Cycles

Data

(Bytes)

REST ENABLE

0x66

8-0-0

0

0

0

RESET

0x99

8-0-0

0

0

0

0x9F

8-8-8

4 (0x00)

3-7

4

0xB9

8-0-0

0

0

0

0xEE

8-8-8

4

3-7

1 to

0xDE

8-8-8

4

3-7

1 to

WRITE ENABLE

0x06

8-0-0

0

0

0

WRITE DISABLE

0x04

8-0-0

0

0

0

0x65

8-8-8

4

3-7

2

Command

Prerequisite

Software Reset

RESET

ENABLE

Identification

READ ID[9]

Power Modes

DEEP POWER DOWN

Read Memory Array

READ (DDR)

Write Memory Array

WRITE (DDR)

WRITE

ENABLE

Write Enable / Disable

Read Registers

READ ANY REGISTER

Write Registers

Notes

9. The two identification registers contents are read together - identification 0 followed by identification 1.

10. Write Enable provides protection against inadvertent changes to memory or register values. It sets the internal write enable latch (WEL) which allows write transactions

to execute afterwards.

11. Write Disable can be used to disable write transactions from execution. It resets the internal write enable latch (WEL).

12. The WEL latch stays set to ‘1’ at the end of any successful memory write transaction. After a power down / power up sequence, or a hardware/software reset, WEL

latch is cleared to ‘0’.

13. The internal WEL latch is cleared to ‘0’ at the end of any successful register write transaction.

Document Number: 002-29418 Rev .**

Page 8 of 51

�S70KL1283/S70KS1283

Table 2. Command Set[9, 10, 11, 12, 13] (Continued)

Command

WRITE ANY

REGISTER

Code

CA-Data

Address

(Bytes)

Latency

Cycles

Data

(Bytes)

Prerequisite

0x71

8-8-8

4

0

2

WRITE

ENABLE

Notes

9. The two identification registers contents are read together - identification 0 followed by identification 1.

10. Write Enable provides protection against inadvertent changes to memory or register values. It sets the internal write enable latch (WEL) which allows write transactions

to execute afterwards.

11. Write Disable can be used to disable write transactions from execution. It resets the internal write enable latch (WEL).

12. The WEL latch stays set to ‘1’ at the end of any successful memory write transaction. After a power down / power up sequence, or a hardware/software reset, WEL

latch is cleared to ‘0’.

13. The internal WEL latch is cleared to ‘0’ at the end of any successful register write transaction.

RESET ENABLE Transaction

The RESET ENABLE transaction is required immediately before a RESET transaction. Any transaction other than RESET following

RESET ENABLE will clear the reset enable condition and prevent a later RESET transaction from being recognized.

Figure 6. RESET ENABLE Transaction (DDR)[14]

CS#

CK#, CK

RWDS

DQ[7:0]

High: 2X Latency Count

Low: 1X Latency Count

CMD

[7:0]

CMD

[7:0]

Command

(Host drives DQ[7:0])

RESET Transaction

The RESET transaction immediately following a RESET ENABLE will initiate the software reset process.

Figure 7. RESET Transaction (DDR)[14]

CS#

CK#, CK

RWDS

DQ[7:0]

High: 2X Latency Count

Low: 1X Latency Count

CMD

[7:0]

CMD

[7:0]

Command

(Host drives DQ[7:0])

Note

14. The initial latency "Low = 1x Latency Count" is not applicable in dual-die,128-Mb HyperRAM.

Document Number: 002-29418 Rev .**

Page 9 of 51

�S70KL1283/S70KS1283

READ ID Transaction

The READ ID transaction provides read access to device identification registers 0 and 1. The registers contain the manufacturer’s

identification along with device identification. The read data sequence is as follows.

Table 3. READ ID Data Sequence

Address Space

Byte Order

Byte Position

A

Register 0

Big-endian

B

A

Register 1

Big-endian

B

Document Number: 002-29418 Rev .**

Word Data Bit

DQ

15

7

14

6

13

5

12

4

11

3

10

2

9

1

8

0

7

7

6

6

5

5

4

4

3

3

2

2

1

1

0

0

15

7

14

6

13

5

12

4

11

3

10

2

9

1

8

0

7

7

6

6

5

5

4

4

3

3

2

2

1

1

0

0

Page 10 of 51

�S70KL1283/S70KS1283

Figure 8. READ ID with 2X Latency Transaction (DDR) [15]

CS#

CK#, CK

Latency Count (2X)

RWDS

High: 2X Latency Count

Low: 1X Latency Count

RWDS & Data are edge aligned

DQ[7:0]

CMD

[7:0]

CMD

[7:0]

0x00

0x00

0x00

IDRG 0

[15:8]

0x00

Command - Address

(Host drives DQ[7:0] and Memory drives RWDS)

IDRG 0

[7:0]

IDRG 1

[15:8]

IDRG 1

[7:0]

Read Data

(Memory drives RWDS)

DEEP POWER DOWN Transaction

DEEP POWER DOWN transaction brings the device into Deep Power Down state which is the lowest power consumption state.

Writing a “0” to CR0[15] will also bring the device in Deep Power Down State. All register contents are lost in Deep Power Down

State and the device powers-up in its default state.

Figure 9. DEEP POWER DOWN Transaction (DDR)[15]

CS#

CK#, CK

RWDS

DQ[7:0]

High: 2X Latency Count

Low: 1X Latency Count

CMD

[7:0]

CMD

[7:0]

Command

(Host drives DQ[7:0])

Note

15. The initial latency "Low = 1x Latency Count" is not applicable in dual-die,128-Mb HyperRAM.

Document Number: 002-29418 Rev .**

Page 11 of 51

�S70KL1283/S70KS1283

READ Transaction

The READ transaction reads data from the memory array. It has a latency requirement (dummy cycles) which allows the device’s

internal circuitry enough time to access the addressed memory location. During these latency cycles, the host can tristate the data

bus DQ[7:0].

Figure 10. READ with 2X Latency Transaction (DDR)[16, 17]

CS#

CK#, CK

Latency Count (2X)

High: 2X Latency Count

Low: 1X Latency Count

RWDS

RWDS & Data are edge aligned

CMD

[7:0]

DQ[7:0]

CMD

[7:0]

ADR

[31:24]

ADR

[23:16]

ADR

[15:8]

ADR

[7:0]

DoutA

[7:0]

Command - Address

(Host drives DQ[7:0] and Memory drives RWDS)

DoutA+1

[7:0]

DoutA+2

[7:0]

DoutB+3

[7:0]

Read Data

(Memory drives RWDS)

WRITE Transaction

The WRITE transaction writes data to the memory array. It has a latency requirement (dummy cycles) which allows the device’s

internal circuitry enough time to access the addressed memory location. During these latency cycles, the host can tristate the data

bus DQ[7:0].

WRITE ENABLE transaction which sets the WEL latch must be executed before the first WRITE. The WEL latch stays set to ‘1’ at

the end of any successful memory write transaction. It must be reset by WRITE DISABLE transaction to prevent any inadvertent

writes to the memory array.

Figure 11. WRITE with 2X Latency Transaction (DDR)[16, 17, 18]

CS#

CK#, CK

Latency Count (2X)

RWDS

DQ[7:0]

High: 2X Latency Count

Low: 1X Latency Count

RWDS acts as Data Mask

CMD

[7:0]

CMD

[7:0]

ADR

[31:24]

ADR

[23:16]

ADR

[15:8]

ADR

[7:0]

Command - Address

(Host drives DQ[7:0] and Memory drives RWDS)

DinA

[7:0]

DinA+1

[7:0]

DinA+2

[7:0]

DinA+3

[7:0]

Write Data

(Host drives DQ[7:0])

Notes

16. RWDS is driven by HyperRAM during Command & Address cycles for 2X latency and then is driven again phase aligned with data.

17. The initial latency "Low = 1x Latency Count" is not applicable in dual-die,128-Mb HyperRAM.

18. Data DinA and DinA+2 are masked.

Document Number: 002-29418 Rev .**

Page 12 of 51

�S70KL1283/S70KS1283

WRITE ENABLE Transaction

The WRITE ENABLE transaction must be executed prior to any transaction that modifies data either in the memory array or the

registers.

Figure 12. WRITE ENABLE Transaction (DDR)[19]

CS#

CK#, CK

RWDS

DQ[7:0]

High: 2X Latency Count

Low: 1X Latency Count

CMD

[7:0]

CMD

[7:0]

Command

(Host drives DQ[7:0])

WRITE DISABLE Transaction

The WRITE DISABLE transaction inhibits writing data either in the memory array or the registers.

Figure 13. WRITE DISABLE Transaction (DDR)[19]

CS#

CK#, CK

RWDS

DQ[7:0]

High: 2X Latency Count

Low: 1X Latency Count

CMD

[7:0]

CMD

[7:0]

Command

(Host drives DQ[7:0])

Note

19. The initial latency "Low = 1x Latency Count" is not applicable in dual-die,128-Mb HyperRAM.

Document Number: 002-29418 Rev .**

Page 13 of 51

�S70KL1283/S70KS1283

READ ANY REGISTER Transaction

The READ ANY REGISTER transaction reads all the device registers. It has a latency requirement (dummy cycles) which allows the

device’s internal circuitry enough time to access the addressed register location. During these latency cycles, the host can tristate

the data bus DQ[7:0].

Figure 14. READ ANY REGISTER with 2X Latency Transaction (DDR)[20, 21]

CS#

CK#, CK

Latency Count (2X)

High: 2X Latency Count

Low: 1X Latency Count

RWDS

RWDS & Data are edge aligned

CMD

[7:0]

DQ[7:0]

CMD

[7:0]

ADR

[31:24]

ADR

[23:16]

ADR

[15:8]

ADR

[7:0]

RG

[15:8]

Command - Address

(Host drives DQ[7:0] and Memory drives RWDS)

RG

[7:0]

Read Data

(Memory drives RWDS)

WRITE ANY REGISTER Transaction

The WRITE ANY REGISTER transaction writes to the device registers. It does not have a latency requirement (dummy cycles).

Figure 15. xSPI (Octal) Write with No Latency Transaction (DDR) (Register Writes)[21, 22, 23]

CS#

CK#, CK

RWDS

DQ[7:0]

High: 2X Latency Count

Low: 1X Latency Count

CMD

[7:0]

CMD

[7:0]

ADR

[31:24]

ADR

[23:16]

ADR

[15:8]

Command - Address

(Host drives DQ[7:0], Memory drives RWDS)

ADR

[7:0]

RG

[15:8]

RG

[7:0]

Write Data

Notes

20. RWDS is driven by HyperRAM during Command & Address cycles for 2X latency and then driven again phase aligned with data.

21. The initial latency "Low = 1x Latency Count" is not applicable in dual-die,128-Mb HyperRAM.

22. Write with no latency transaction is used for register writes only.

23. Data Mask on RWDS is not supported.

Document Number: 002-29418 Rev .**

Page 14 of 51

�S70KL1283/S70KS1283

Data Placement During Memory READ/WRITE Transactions

Data placement during memory Read/Write is dependent upon the host. The device will output data (read) as it was written in

(write). Hence both Big Endian and Little Endian are supported for the memory array.

Table 4. Data Placement during Memory READ and WRITE

Address

Space

Byte

Order

Byte

Position

A

Bigendian

B

Memory

A

Littleendian

B

Word

Data

Bit

DQ

15

7

14

6

13

5

12

4

11

3

10

2

9

1

8

0

7

7

6

6

5

5

4

4

3

3

2

2

1

1

0

0

7

7

6

6

5

5

4

4

3

3

2

2

1

1

0

0

15

7

14

6

13

5

12

4

11

3

10

2

9

1

8

0

Document Number: 002-29418 Rev .**

Bit Order

When data is being accessed in memory space:

The first byte of each word read or written is the “A” byte and the second is the “B” byte.

The bits of the word within the A and B bytes depend on how the data was written. If the word

lower address bits 7-0 are written in the A byte position and bits 15-8 are written into the B byte

position, or vice versa, they will be read back in the same order.

So, memory space can be stored and read in either little-endian or big-endian order.

Page 15 of 51

�S70KL1283/S70KS1283

Data Placement During Register READ/WRITE Transactions

Data placement during register Read/Write is Big Endian.

Table 5. Data Placement during Register READ/WRITE Transactions

Address

Space

Byte

Order

Byte

Position

A

Register

Bigendian

B

Word

Data

Bit

DQ

15

7

14

6

13

5

12

4

11

3

10

2

9

1

8

0

7

7

6

6

5

5

4

4

3

3

2

2

1

1

0

0

Document Number: 002-29418 Rev .**

Bit Order

When data is being accessed in register space:

During a Read transaction on the xSPI (Octal) two bytes are transferred on each clock cycle. The

upper order byte A (Word[15:8]) is transferred between the rising and falling edges of RWDS

(edge aligned). The lower order byte B (Word[7:0]) is transferred between the falling and rising

edges of RWDS.

During a write, the upper order byte A (Word[15:8]) is transferred on the CK rising edge and the

lower order byte B (Word[7:0]) is transferred on the CK falling edge.

So, register space is always read and written in Big-endian order because registers have device

dependent fixed bit location and meaning definitions.

Page 16 of 51

�S70KL1283/S70KS1283

Memory Space

xSPI (Octal) Interface

Table 6. Memory Space Address Map (byte based - 8 bits with least significant bit A(0) always set to ‘0’)

Unit Type

Count

System Byte Address Bits

Address Bits

Rows within 128-Mb

device

16384 (rows)

A22 - A9

35 - 22

Rows within 64-Mb

device

8192 (rows)

A22 - A10

22 - 10

1 (row)

A9 - A4

9-4

512 (16-bit word) or 1 KB

16 (byte addresses)

A3 - A0

3-0

16 bytes (8 words)

A0 always set to “0”

Row

Half-page

Notes

Density and Row Boundaries

The DRAM array size (density) of the device can be determined from the total number of system address bits used for the row and

column addresses as indicated by the Row Address Bit Count and Column Address Bit Count fields in the ID0 register. For example:

a 64-Mb HyperRAM device has 10 column address bits and 13 row address bits for a total of 23 address bits (byte address) = 223 =

8MB (4M words). The 10 column address bits indicate that each row holds 210 = 512 words = 1KB. The row address bit count indicates

there are 8196 rows to be refreshed within each array refresh interval. The row count is used in calculating the refresh interval.

Register Space Access

xSPI (Octal) Interface

Table 7. Register Space Address Map (Address bit A0 always set to ‘0’)

Registers

Address (Byte Addressable)

Identification Registers 0 (ID0[15:0]) - Die 0

0x00000000

Identification Registers 0 (ID0[15:0]) - Die 1

0x00400000

Identification Registers 1 (ID1[15:0]) - Die 0

0x00000002

Identification Registers 1 (ID1[15:0]) - Die 1

0x00400002

Configuration Registers 0 (ID0[15:0]) - Die 0

0x00000004

Configuration Registers 0 (ID0[15:0]) - Die 1

0x00400004

Configuration Registers 1 (ID1[15:0]) - Die 0

0x00000006

Configuration Registers 1 (ID1[15:0]) - Die 1

0x00400006

Die Manufacture Information Register (Registers 0 to Register 17)

0x00000008, 0x0000000A to 0x0000002A

- Die 0

Die Manufacture Information Register (Registers 0 to Register 17)

0x00400008, 0x0040000A to 0x0040002A

- Die 1

Document Number: 002-29418 Rev .**

Page 17 of 51

�S70KL1283/S70KS1283

Device Identification Registers

There are two read-only, nonvolatile, word registers, that provide information on the device selected when CS# is LOW. The device

information fields identify:

■

Manufacturer

■

Type

■

Density

❐ Row address bit count

❐ Column address bit count

Refresh Type

Table 8. Identification Register 0 (ID0) Bit Assignments

Bits

Function

[15:14]

Reserved

00b - Die 0

01b - Die 1

13

Reserved

0 - Default

[12:8]

Settings (Binary)

00000 - One row address bit

...

Row Address Bit Count 11111 - Thirty-two row address bits

...

01100 - 64 Mb - Thirteen row address bits (default)

[7:4]

Column Address Bit

Count

[3:0]

Manufacturer

0000 - One column address bits

...

1000 - Nine column address bits (default)

...

1111 - Sixteen column address bits

0000 - Reserved

0001 - Cypress (default)

0010 to 1111 - Reserved

Table 9. Identification Register 1 (ID1) Bit Assignments

Bits

Function

[15:4]

Reserved

[3:0]

Device Type

Document Number: 002-29418 Rev .**

Settings (Binary)

0000_0000_0000 (default)

0001 - HyperRAM 2.0

0000, 0010 to 1111 - Reserved

Page 18 of 51

�S70KL1283/S70KS1283

Device Configuration Registers

Configuration Register 0 (CR0)

Configuration Register 0 (CR0) is used to define the power state and access protocol operating conditions for the HyperRAM device.

Configurable characteristics include:

■

Wrapped Burst Length (16, 32, 64, or 128 byte aligned and length data group)

■

Wrapped Burst Type

❐ Legacy wrap (sequential access with wrap around within a selected length and aligned group)

❐ Hybrid wrap (Legacy wrap once then linear burst at start of the next sequential group)

Initial Latency

■

■

Variable Latency

❐ Whether an array read or write transaction will use fixed or variable latency. If fixed latency is selected the memory will always

indicate a refresh latency and delay the read data transfer accordingly. If variable latency is selected, latency for a refresh is only

added when a refresh is required at the same time a new transaction is starting.

Output Drive Strength

■

Deep Power Down (DPD) Mode

■

Table 10. Configuration Register 0 (CR0) Bit Assignments

CR0 Bit

[15]

Function

Deep Power Down Enable

Settings (Binary)

1 - Normal operation (default). HyperRAM will automatically set this value to ‘1’ after

DPD exit

0 - Writing 0 causes the device to enter Deep Power Down

Only one die of the 128-Mb stack-die HyperRAM can be programmed to enter DPD

mode at a time.

[14:12]

Drive Strength

[11:8]

Reserved

[7:4]

Initial Latency

000 - 34 ohms (default)

001 - 115 ohms

010 - 67 ohms

011 - 46 ohms

100 - 34 ohms

101 - 27 ohms

110 - 22 ohms

111 - 19 ohms

1 - Reserved (default)

Reserved for Future Use. When writing this register, these bits should be set to 1 for

future compatibility.

0000 - 5 Clock Latency @ 133 Max Frequency

0001 - 6 Clock Latency @ 166 Max Frequency

0010 - 7 Clock Latency @ 200 MHz/166 MHz Max Frequency (default)

0011 - Reserved

0100 - Reserved

...

1101 - Reserved

1110 - 3 Clock Latency @ 85 Max Frequency

1111 - 4 Clock Latency @ 104 Max Frequency

0 - Reserved

1 - Fixed 2 times Initial Latency (default)

[3]

Fixed Latency Enable

Document Number: 002-29418 Rev .**

The 128-Mb dual-die stack only supports fixed latency. In fixed latency mode, when

CS# asserted LOW,

1. The RWDS signal of each die of dual-die 128-Mb will always drive to HIGH during

CA phase.

2. The RWDS signal of the non-selected die of dual-die 128-Mb will always drive to

Hi-Z after CA phase.

3. The RWDS signal of the selected die of dual-die 128-Mb will drive to L after CA

phase.

Page 19 of 51

�S70KL1283/S70KS1283

Table 10. Configuration Register 0 (CR0) Bit Assignments (Continued)

CR0 Bit

Function

[2]

Hybrid Burst Enable

Settings (Binary)

0: Wrapped burst sequence to follow hybrid burst sequencing

1: Wrapped burst sequence in legacy wrapped burst manner (default)

This bit setting is effective only when the "Burst Type" bit in the Command/Address

register is set to '0', i.e. CA[45] = '0'; otherwise, it is ignored.

[1:0]

Burst Length

00 - 128 bytes

01 - 64 bytes

10- 16 bytes

11 - 32 bytes (default)

Wrapped Burst

A wrapped burst transaction accesses memory within a group of words aligned on a word boundary matching the length of the

configured group. Wrapped access groups can be configured as 16, 32, 64, or 128 bytes alignment and length. During wrapped

transactions, access starts at the CA selected location within the group, continues to the end of the configured word group aligned

boundary, then wraps around to the beginning location in the group, then continues back to the starting location. Wrapped bursts are

generally used for critical word first instruction or data cache line fill read accesses. Wrapped burst across die boundary is not

supported.

Hybrid Burst

The beginning of a hybrid burst will wrap within the target address wrapped burst group length before continuing to the next

half-page of data beyond the end of the wrap group. Continued access is in linear burst order until the transfer is ended by returning

CS# HIGH. This hybrid of a wrapped burst followed by a linear burst starting at the beginning of the next burst group, allows multiple

sequential address cache lines to be filled in a single access. The first cache line is filled starting at the critical word. Then the next

sequential line in memory can be read in to the cache while the first line is being processed. Hybrid burst across die boundary is not

supported.

Table 11. CR0[2] Control of Wrapped Burst Sequence

Bit

Default Value

CR0[2]

1b

Setting Details

Hybrid Burst Enable

CR0[2] = 0: Wrapped burst sequence to follow hybrid burst sequencing

CR0[2] = 1: Wrapped burst sequence in legacy wrapped burst manner

Table 12. Example Wrapped Burst Sequences (Addressing)

Burst Type

Wrap

Boundary

(bytes)

Start Address

(Hex)

Hybrid 128

128 Wrap

once then

Linear

XXXXXX03

Hybrid 64

64 Wrap

once then

Linear

XXXXXX02

Hybrid 64

64 Wrap

once then

Linear

XXXXXX2E

Hybrid 16

16 Wrap

once then

Linear

XXXXXX02

Document Number: 002-29418 Rev .**

Sequence of Byte Addresses (Hex) of Data Words

03, 04, 05, 06, 07, 08, 09, 0A, 0B, 0C, 0D, 0E, 0F, 10, 11, 12, 13, 14, 15, 16,

17, 18, 19, 1A, 1B, 1C, 1D, 1E, 1F, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 2A,

2B, 2C, 2D, 2E, 2F, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 3A, 3B, 3C, 3D, 3E,

3F, 00, 01, 02

(Wrap complete, now linear beyond the end of the initial 128 byte wrap group)

40, 41, 42, 43, 44, 45, 46, 47, 48, 49, 4A, 4B, 4C, 4D, 4E, 4F, 50, 51, ...

02, 04, 06, 08, 0A, 0C, 0E, 10, 12, 14, 16, 18, 1A, 1C, 1E, 20, 22, 24, 26, 28, 2A, 2C,

2E, 30, 32, 34, 36, 38, 3A, 3C, 3E, 00

(wrap complete, now linear beyond the end of the initial 64 byte wrap group)

40, 42, 44, 46, 48, 4A, 4C, 4E, 50, 52, ...

2E, 30, 32, 34, 36, 38, 3A, 3C, 3E,

00, 02, 04, 06, 08, 0A, 0C, 0E, 10, 12, 14, 16, 18, 1A, 1C, 1E, 20, 22, 24, 26, 28, 2A,

2C, (wrap complete,

now linear beyond the end of the initial 64 byte wrap group)

40, 42, 44, 46, 48, 4A, 4B, 4C, 4D, 4E, 4F, 50, 52, ...

02, 04, 06, 08, 0A, 0C, 0E, 00

(wrap complete, now linear beyond the end of the initial 16 byte wrap group)

10, 12, 14, 16, 18, 1A, ..

Page 20 of 51

�S70KL1283/S70KS1283

Table 12. Example Wrapped Burst Sequences (Addressing) (Continued)

Wrap

Boundary

(bytes)

16 Wrap

once then

Linear

Burst Type

Hybrid 16

Start Address

(Hex)

XXXXXX0C

Hybrid 32

32 Wrap

once then

Linear

XXXXXX0A

Wrap 64

64

XXXXXX02

Wrap 64

64

XXXXXX2E

Wrap 16

Wrap 16

Wrap 32

Linear

16

16

32

Linear Burst

XXXXXX02

XXXXXX0C

XXXXXX0A

XXXXXX02

Sequence of Byte Addresses (Hex) of Data Words

0C, 0E, 00, 02, 04, 06, 08, 0A

(wrap complete, now linear beyond the end of the initial 16 byte wrap group)

10, 12, 14, 16, 18, 1A, ...

0A, 0C, 0E, 10, 12, 14, 16, 18, 1A, 1C, 1E, 00, 02, 04, 06, 08

(wrap complete, now linear beyond the end of the initial 32 byte wrap group)

20, 22, 24, 26, 28, 2A, ...

02, 04, 06, 08, 0A, 0C, 0E, 10, 12, 14, 16, 18, 1A, 1C, 1E, 20, 22, 24, 26, 28, 2A, 2C,

2E, 30, 32, 34, 36, 38, 3A, 3C, 3E, 00, ...

2E, 30, 32, 34, 36, 38, 3A, 3C, 3E,

00, 02, 04, 06, 08, 0A, 0C, 0E, 10, 12, 14, 16, 18, 1A, 1C, 1E, 20, 22, 24, 26, 28, 2A,

2C, 2E, 30, ….

02, 04, 06, 08, 0A, 0C, 0E, 00, ...

0C, 0E, 00, 02, 04, 06, 08, 0A, ...

0A, 0C, 0E, 10, 12, 14, 16, 18, 1A, 1C, 1E, 00, 02, 04, 06, 08, ...

02, 04, 06, 08, 0A, 0C, 0E, 10, 12, 14, 16, 18, 1A, 1C, 1E, 20, 22, ...

Initial Latency

Memory Space read and write transactions or Register Space read transactions require some initial latency to open the row selected

by the CA. This initial latency is tACC. The number of latency clocks needed to satisfy tACC depends on the clock input frequency can

vary from 3 to 7 clocks. The value in CR0[7:4] selects the number of clocks for initial latency. The default value is 7 clocks, allowing

for operation up to a maximum frequency of 200MHz prior to the host system setting a lower initial latency value that may be more

optimal for the system.

In the event a distributed refresh is required at the time a Memory Space read or write transaction or Register Space read transaction

begins, the RWDS signal goes High during the CA to indicate that an additional initial latency is being inserted to allow a refresh

operation to complete before opening the selected row.

Register Space write transactions always have zero initial latency. RWDS may be HIGH or LOW during the CA period. The level of

RWDS during the CA period does not affect the placement of register data immediately after the CA, as there is no initial latency

needed to capture the register data. A refresh operation may be performed in the memory array in parallel with the capture of register

data.

Fixed Latency

A configuration register option bit CR0[3] is provided to make all Memory Space read and write transactions or Register Space read

transactions require the same initial latency by always driving RWDS HIGH during the CA to indicate that two initial latency periods

are required. This fixed initial latency is independent of any need for a distributed refresh, it simply provides a fixed (deterministic)

initial latency for all of these transaction types. Fixed latency is the default POR or reset configuration.

Drive Strength

DQ and RWDS signal line loading, length, and impedance vary depending on each system design. Configuration register bits

CR0[14:12] provide a means to adjust the DQ[7:0] and RWDS signal output impedance to customize the DQ and RWDS signal

impedance to the system conditions to minimize high speed signal behaviors such as overshoot, undershoot, and ringing. The

default POR or reset configuration value is 000b to select the mid point of the available output impedance options.

The impedance values shown are typical for both pull-up and pull-down drivers at typical silicon process conditions, nominal

operating voltage (1.8 V or 3.0 V) and 50°C. The impedance values may vary from the typical values depending on the Process,

Voltage, and Temperature (PVT) conditions. Impedance will increase with slower process, lower voltage, or higher temperature.

Impedance will decrease with faster process, higher voltage, or lower temperature.

Each system design should evaluate the data signal integrity across the operating voltage and temperature ranges to select the best

drive strength settings for the operating conditions.

Deep Power Down

When the HyperRAM device is not needed for system operation, it may be placed in a very low power consuming state called Deep

Power Down (DPD), by writing 0 to CR0[15]. When CR0[15] is cleared to 0, the device enters the DPD state within tDPDIN time and

all refresh operations stop. The data in RAM is lost, (becomes invalid without refresh) during DPD state. Exiting DPD requires driving

CS# LOW then HIGH, POR, or a reset. Only CS# and RESET# signals are monitored during DPD mode. For additional details, see

Deep Power Down on page 26.

Document Number: 002-29418 Rev .**

Page 21 of 51

�S70KL1283/S70KS1283

Note: The 128-Mb HyperRAM is a stacked-die chip using two 64-Mb dice. Of the two dice, only one die at a time can be

programmed to enter the DPD mode. It is not feasible to program both the dice to enter the DPD mode together because entering

the DPD mode for one die would require CS# HIGH to LOW transition which would cause to exit the DPD mode in the other die, and

vice versa.

Configuration Register 1

Configuration Register 1 (CR1) is used to define the refresh array size, refresh rate and hybrid sleep for the HyperRAM device.

Configurable characteristics include:

■

Partial Array Refresh

■

Hybrid Sleep State

■

Refresh Rate

Table 13. Configuration Register 1 (CR1) Bit Assignments

CR1 Bit

Function

[15:8]

Reserved

FFh - Reserved (default)

These bits should always be set to FFh

[7]

Burst Type

1 - Linear Burst (default)

0 - Wrapped Burst

[6]

Master Clock Type

[5]

Hybrid Sleep

[4:2]

Partial Array

Refresh

[1:0]

Distributed Refresh

Interval (Read Only)

Setting (Binary)

1 - Single Ended - CK (default)

0 - Differential - CK#, CK

1 - Causes the device to enter Hybrid Sleep State

0 - Normal operation (default)

Only one die of the 128-Mb stack-die HyperRAM can be programmed to enter

Hybrid Sleep mode at a time.

000 - Full Array (default)

001 - Bottom 1/2 Array

010 - Bottom 1/4 Array

011 - Bottom 1/8 Array

100 - none

101 - Top 1/2 Array

110 - Top 1/4 Array

111 - Top 1/8 Array

10 - 1µs tCSM (Industrial Plus temperature range devices)

11 - Reserved

00 - Reserved

01 - 4µs tCSM (Industrial temperature range devices)

Burst Type

Two burst types, namely Linear and Wrapped, are supported in xSPI (Octal) mode by HyperRAM. CR1[7] selects which type to use.

Master Clock Type

Two clock types, namely single ended and differential, are supported. CR1[6] selects which type to use.

Partial Array Refresh

The partial array refresh configuration restricts the refresh operation in HyperRAM to a portion of the memory array specified by

CR1[5:3]. This reduces the standby current. The default configuration refreshes the whole array.

Hybrid Sleep (HS)

When the HyperRAM is not needed for system operation but data in the device needs to be retained, it may be placed in Hybrid

Sleep state to save more power. Enter Hybrid Sleep state by writing 0 to CR1[5]. Bringing CS# LOW will cause the device to exit HS

state and set CR1[5] to 1. Also, POR, or a hardware reset will cause the device to exit Hybrid Sleep state. Note that a POR or a

hardware reset disables refresh where the memory core data can potentially get lost.

Note: The 128-Mb HyperRAM is a stacked-die chip using two 64-Mb dice. Of the two dice, only one die at a time can be

programmed to enter the HS mode. It is not feasible to program both the dice to enter the HS mode together because entering the

HS mode for one die would require CS# HIGH to LOW transition which would cause to exit the HS mode in the other die, and vice

versa.

Document Number: 002-29418 Rev .**

Page 22 of 51

�S70KL1283/S70KS1283

Distributed Refresh Interval

The DRAM array requires periodic refresh of all bits in the array. This can be done by the host system by reading or writing a location

in each row within a specified time limit. The read or write access copies a row of bits to an internal buffer. At the end of the access

the bits in the buffer are written back to the row in memory, thereby recharging (refreshing) the bits in the row of DRAM memory

cells.

HyperRAM devices include self-refresh logic that will refresh rows automatically. The automatic refresh of a row can only be done

when the memory is not being actively read or written by the host system. The refresh logic waits for the end of any active read or

write before doing a refresh, if a refresh is needed at that time. If a new read or write begins before the refresh is completed, the

memory will drive RWDS HIGH during the CA period to indicate that 2X initial latency time is required at the start of the new access

in order to allow the refresh operation to complete before starting the new access.

The required refresh interval for the entire memory array varies with temperature as shown in Table 14. This is the time within which

all rows must be refreshed. Refresh of all rows could be done as a single batch of accesses at the beginning of each interval, in

groups (burst refresh) of several rows at a time, spread throughout each interval, or as single row refreshes evenly distributed

throughout the interval. The self-refresh logic distributes single row refresh operations throughout the interval so that the memory is

not busy doing a burst of refresh operations for a long period, such that the burst refresh would delay host access for a long period.

Table 14. Array Refresh Interval per Temperature

Device Temperature (°C)

Array Refresh Interval (ms)

Array Rows

Recommended tCSM (µs)

85

64

8192

4

105

16

8192

1

The distributed refresh method requires that the host does not do burst transactions that are so long as to prevent the memory from

doing the distributed refreshes when they are needed. This sets an upper limit on the length of read and write transactions so that

the refresh logic can insert a refresh between transactions. This limit is called the CS# LOW maximum time (tCSM). The tCSM value is

determined by the array refresh interval divided by the number of rows in the array, then reducing this calculation by half to ensure

that a distributed refresh interval cannot be entirely missed by a maximum length host access starting immediately before a

distributed refresh is needed. Because tCSM is set to half the required distributed refresh interval, any series of maximum length host

accesses that delay refresh operations will catch up on refresh operations at twice the rate required by the refresh interval divided by

the number of rows.

The host system is required to respect the tCSM value by ending each transaction before violating tCSM. This can be done by host

memory controller logic splitting long transactions when reaching the tCSM limit, or by host system hardware or software not

performing a single read or write transaction that would be longer than tCSM.

As noted in Table 14 the array refresh interval is longer at lower temperatures such that tCSM could be increased to allow longer

transactions. The host system can either use the tCSM value from the table for the maximum operating temperature or, may

determine it dynamically by reading the read only CR1[1:0] bits in order to set the distributed refresh interval prior to every access.

Document Number: 002-29418 Rev .**

Page 23 of 51

�S70KL1283/S70KS1283

Interface States

Table 15 describes the required value of each signal for each interface state.

Table 15. Interface States

Interface State

Power-Off

VCC / VCCQ

CS#

CK, CK#

DQ7-DQ0

RWDS

RESET#

< VLKO

X

X

HIGH-Z

HIGH-Z

X

X

X

HIGH-Z

HIGH-Z

X

X

X

HIGH-Z

HIGH-Z

L

Interface Standby

VCC / VCCQ min

VCC / VCCQ min

VCC / VCCQ min

H

X

HIGH-Z

HIGH-Z

H

CA

VCC / VCCQ min

L

T

Master Output

Valid

Y

H

Read Initial Access Latency

(data bus turn around period)

VCC / VCCQ min

L

T

HIGH-Z

L

H

Write Initial Access Latency

(RWDS turn around period)

VCC / VCCQ min

L

T

HIGH-Z

HIGH-Z

H

Read data transfer

VCC / VCCQ min

L

T

Slave Output

Valid

Slave Output

Valid

Z or T

H

Write data transfer with Initial

Latency

VCC / VCCQ min

L

T

Master Output

Valid

Master Output

Valid

X or T

H

Write data transfer without Initial

Latency [24]

VCC / VCCQ min

L

T

Master Output

Valid

Slave Output

L or HIGH-Z

H

Y

H

Power-On (Cold) Reset

Hardware (Warm) Reset

Active Clock Stop

[25]

Deep Power Down

Hybrid Sleep

VCC / VCCQ min

L

Idle

Master or

Slave Output

Valid or

HIGH-Z

VCC / VCCQ min

VCC / VCCQ min

H

X or T

HIGH-Z

HIGH-Z

H

H

X or T

HIGH-Z

HIGH-Z

H

Legend

L = VIL

H = VIH

X = either VIL or VIH

Y= either VIL or VIH or VOL or VOH

Z = either VOL or VOH

L/H = rising edge

H/L = falling edge

T = Toggling during information transfer

Idle = CK is LOW and CK# is HIGH

Valid = all bus signals have stable L or H level

Notes

24. Writes without initial latency (with zero initial latency), do not have a turn around period for RWDS. The HyperRAM device will always drive RWDS during the CA

period to indicate whether extended latency is required. Since master write data immediately follows the CA period the HyperRAM device may continue to drive

RWDS LOW or may take RWDS to HIGH-Z. The master must not drive RWDS during Writes with zero latency. Writes with zero latency do not use RWDS as a data

mask function. All bytes of write data are written (full word writes).

25. Active Clock Stop is described in Active Clock Stop on page 25. DPD is described in Hybrid Sleep on page 25.

Document Number: 002-29418 Rev .**

Page 24 of 51

�S70KL1283/S70KS1283

Power Conservation Modes

Interface Standby

Standby is the default, low power, state for the interface while the device is not selected by the host for data transfer (CS# = HIGH).

All inputs, and outputs other than CS# and RESET# are ignored in this state.

Active Clock Stop

Design Note: Active Clock Stop feature is pending device characterization to determine if it will be supported.

The Active Clock Stop state reduces device interface energy consumption to the ICC6 level during the data transfer portion of a read

or write operation. The device automatically enables this state when clock remains stable for tACC + 30 ns. While in Active Clock

Stop state, read data is latched and always driven onto the data bus. ICC6 shown in DC Characteristics on page 29.

Active Clock Stop state helps reduce current consumption when the host system clock has stopped to pause the data transfer. Even

though CS# may be LOW throughout these extended data transfer cycles, the memory device host interface will go into the Active

Clock Stop current level at tACC + 30 ns. This allows the device to transition into a lower current state if the data transfer is stalled.

Active read or write current will resume once the data transfer is restarted with a toggling clock. The Active Clock Stop state must not

be used in violation of the tCSM limit. CS# must go HIGH before tCSM is violated. Clock can be stopped during any portion of the

active transaction as long as it is in the LOW state. Note that it is recommended to avoid stopping the clock during register access.

Figure 16. Active Clock Stop During Read Transaction (DDR)

CS#

ClockStopped

CK#, CK

LatencyCount (1X)

High: 2XLatencyCount

Low: 1XLatencyCount

RWDS

RWDS&Dataareedgealigned

CMD

[7:0]

DQ[7:0]

CMD

[7:0]

ADR

[31:24]

ADR

[23:16]

ADR

[15:8]

ADR

[7:0]

DoutA

[7:0]

DoutB

[7:0]

Command- Address

(Host drivesDQ[7:0] andMemorydrivesRWDS)

Output Driven

DoutA+1

[7:0]

DoutB+1

[7:0]

ReadData

Hybrid Sleep

In the Hybrid Sleep (HS) state, the current consumption is reduced (IHS). HS state is entered by writing a 0 to CR1[5]. The device

reduces power within tHSIN time. The data in Memory Space and Register Space is retained during HS state. Bringing CS# LOW will

cause the device to exit HS state and set CR1[5] to 1. Also, POR, or a hardware reset will cause the device to exit Hybrid Sleep

state. Note that a POR or a hardware reset disables refresh where the memory core data can potentially get lost. Returning to

Standby state requires tEXITHS time. Following the exit from HS due to any of these events, the device is in the same state as

entering Hybrid Sleep.

Figure 17. Enter HS Transaction[26]

CS#

C K#, C K

H ig h : 2 X L a te n cy C o u n t

L o w : 1 X L a te n cy C o u n t

RW DS

t H S IN

D Q [7 :0]

CMD

[7 :0 ]

CMD

[7 :0 ]

ADR

[3 1 :2 4 ]

ADR

[2 3 :1 6]

ADR

[1 5 :8 ]

C o m m a n d - A d d re ss

(H o st d rive s D Q [7 :0], M e m o ry d rive s R W D S)

ADR

[7 :0 ]

RG

[1 5:8 ]

RG

[7:0 ]

W rite D a ta

C R 0 V a lu e

E n te r H yb rid S le e p

t H S IN

HS

Figure 18. Exit HS Transaction

CS#

tCSHS

tEXTHS

Note

26. The initial latency "Low = 1x Latency Count" is not applicable in dual-die, 128-Mb HyperRAM. Write with no latency transaction is used for register writes only.

Document Number: 002-29418 Rev .**

Page 25 of 51

�S70KL1283/S70KS1283

Table 16. Hybrid Sleep Timing Parameters

Parameter

Description

Min

Max

Unit

tHSIN

Hybrid Sleep CR1[5] = 0 register write to DPD power level

3

µs

tCSHS

CS# Pulse Width to Exit HS

60

3000

ns

tEXTHS

CS# Exit Hybrid Sleep to Standby wakeup time

100

µs

Deep Power Down

In the Deep Power Down (DPD) state, current consumption is driven to the lowest possible level (IDPD). DPD state is entered by

writing a 0 to CR0[15]. The device reduces power within tDPDIN time and all refresh operations stop. The data in Memory Space is

lost, (becomes invalid without refresh) during DPD state. Driving CS# LOW then HIGH will cause the device to exit DPD state. Also,

POR, or a hardware reset will cause the device to exit DPD state. Returning to Standby state requires tEXTDPD time. Returning to

Standby state following a POR requires tVCS time, as with any other POR. Following the exit from DPD due to any of these events,

the device is in the same state as following POR.

Note In xSPI (Octal), Deep Power Down transaction or Write Any register transaction can be used to enter DPD.

Figure 19. Enter DPD Transaction[27]

CS#

C K#, CK

RW DS

H ig h: 2X La te ncy C o u nt

L o w : 1 X La ten cy C o u nt

t D P D IN

D Q [7 :0]

CMD

[7 :0]

CM D

[7:0]

ADR

[31 :2 4]

ADR

[2 3:16]

ADR

[1 5:8 ]

C o m m a nd - A d d re ss

(H o st drive s D Q [7:0], M e m o ry d rives R W D S)

ADR

[7 :0]

RG

[1 5:8]

RG

[7:0 ]

W rite D a ta

C R 0 V alu e

E n ter D ee p P o w e r D o w n

t D P D IN

D PD

Figure 20. Exit DPD Transaction

CS#

tCSDPD

tEXTDPD

Table 17. Deep Power Down Timing Parameters

Parameter

Description

tDPDIN

Deep Power Down CR0[15] = 0 register write to DPD power level

tCSDPD

CS# Pulse Width to Exit DPD

tEXTDPD

CS# Exit Deep Power Down to Standby wakeup time

Min

Max

Unit

3

µs

200

3000

ns

150

µs

Note

27. The initial latency "Low = 1x Latency Count" is not applicable in dual-die, 128-Mb HyperRAM. Write with no latency transaction is used for register writes only.

Document Number: 002-29418 Rev .**

Page 26 of 51

�S70KL1283/S70KS1283

Electrical Specifications

Absolute Maximum Ratings

Storage Temperature Plastic Packages

Ambient Temperature with Power Applied

65 °C to +150 °C

65 °C to +115 °C

Voltage with Respect to Ground

All signals[28]

0.5V to +(VCC + 0.5V)

Output Short Circuit Current[29]

100 mA

VCC, VCCQ

0.5V to +4.0V

Input Signal Overshoot

During DC conditions, input or I/O signals should remain equal to or between VSS and VCC. During voltage transitions, inputs or I/Os

may negative overshoot VSS to 1.0V or positive overshoot to VCC +1.0V, for periods up to 20 ns.

Figure 21. Maximum Negative Overshoot Waveform

VSSQ to VCCQ

- 1.0V

≤ 20 ns

Figure 22. Maximum Positive Overshoot Waveform

≤ 20 ns

VCCQ + 1.0V

VSSQ to VCCQ

Latch-up Characteristics

Table 18. Latch-up Specification[31]

Description

Min

Max

Unit

Input voltage with respect to VSSQ on all input only connections

1.0

VCCQ + 1.0

V

Input voltage with respect to VSSQ on all I/O connections

1.0

VCCQ + 1.0

V

VCCQ Current

100

+100

mA

Notes

28. Minimum DC voltage on input or I/O signal is -1.0V. During voltage transitions, input or I/O signals may undershoot VSS to -1.0V for periods of up to 20 ns. See

Figure 21. Maximum DC voltage on input or I/O signals is VCC +1.0V. During voltage transitions, input or I/O signals may overshoot to VCC +1.0V for periods up to

20 ns. See Figure 22.

29. No more than one output may be shorted to ground at a time. Duration of the short circuit should not be greater than one second.

30. Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational sections of this data sheet is not implied. Exposure of the device to absolute maximum

rating conditions for extended periods may affect device reliability.

31. Excludes power supplies VCC/VCCQ. Test conditions: VCC = VCCQ, one connection at a time tested, connections not being tested are at VSS.

Document Number: 002-29418 Rev .**

Page 27 of 51

�S70KL1283/S70KS1283

Operating Ranges

Operating ranges define those limits between which the functionality of the device is guaranteed.

Temperature Ranges

Parameter

Ambient Temperature

Symbol

TA

Spec

Device

Unit

Min

Max

Industrial (I)

–40

85

°C

Industrial Plus (V)

–40

105

°C

Automotive, AEC-Q100 Grade 3 (A)

–40

85

°C

Automotive, AEC-Q100 Grade 2 (B)

–40

105

°C

Power Supply Voltages

Description

Min

Max

Unit

1.8 V VCC Power Supply

1.7

2.0

V

3.0 V VCC Power Supply

2.7

3.6

V

Document Number: 002-29418 Rev .**

Page 28 of 51

�S70KL1283/S70KS1283

DC Characteristics

Table 19. DC Characteristics (CMOS Compatible)

Parameter

ILI1

ILI2

ILI3

ILI4

ICC1

ICC2

Description

Input Leakage Current

3.0 V Device Reset Signal High Only

Input Leakage Current

1.8 V Device Reset Signal High Only

Input Leakage Current

3.0 V Device Reset Signal Low Only[33]

Input Leakage Current

1.8 V Device Reset Signal Low Only[33]

VCC Active Read Current

VCC Active Write Current

VCC Standby Current (-40 °C to +85 °C)

ICC4I

VCC Standby Current (-40 °C to +85 °C)

Test Conditions

VIN = VSS to VCC,

VCC = VCC max

VIN = VSS to VCC,

VCC = VCC max

VIN = VSS to VCC,

VCC = VCC max

VIN = VSS to VCC,

VCC = VCC max

CS# = VIL, @200 MHz,

VCC = 2.0 V

CS# = VIL, @166 MHz,

VCC = 3.6 V

CS# = VSS, @200 MHz,

VCC = 3.6V

CS# = VIL, @200 MHz,

VCC = 2.0 V

CS# = VIL, @166 MHz,

VCC = 3.6 V

CS# = VSS, @200 MHz,

VCC = 3.6V

128 Mb

Unit

Min

Typ[32]

Max

2

µA

2

µA

15

µA

15

µA

30

50

mA

30

56

mA

30

60

mA

30

50

mA

30

56

mA

30

60

mA

CS# = VCC, VCC = 2.0 V; Full Array

160

440

µA

CS# = VCC, VCC = 2.0 V; Bottom

1/2 Array

CS# = VCC, VCC = 2.0 V; Bottom

1/4 Array

CS# = VCC, VCC = 2.0 V; Bottom

1/8 Array

CS# = VCC, VCC = 2.0 V; Top 1/2

Array

CS# = VCC, VCC = 2.0 V; Top 1/4

Array

CS# = VCC, VCC = 2.0 V; Top 1/8

Array

420

µA

410

µA

400

µA

420

µA

410

µA

400

µA

CS# = VCC, VCC = 3.6 V; Full Array

180

500

µA

CS# = VCC, VCC = 3.6 V; Bottom

1/2 Array

CS# = VCC, VCC = 3.6 V; Bottom

1/4 Array

CS# = VCC, VCC = 3.6 V; Bottom

1/8 Array

CS# = VCC, VCC = 3.6 V; Top 1/2

Array

CS# = VCC, VCC = 3.6 V; Top 1/4

Array

CS# = VCC, VCC = 3.6 V; Top 1/8

Array

480

µA

450

µA

440

µA

480

µA

450

µA

440

µA

Notes

32. Not 100% tested.

33. Only one of the two-die 128 Mb chip can enter DPD mode, while the other die remains in standby mode. RESET# LOW initiates exits from DPD state and initiates

the draw of ICC5 reset current, making ILI during RESET# LOW insignificant.

Document Number: 002-29418 Rev .**

Page 29 of 51

�S70KL1283/S70KS1283

Table 19. DC Characteristics (CMOS Compatible) (Continued)

Parameter

Description

Test Conditions

128 Mb

Min

CS# = VCC, VCC = 2.0 V; Full Array

VCC Standby Current (-40 °C to +105 °C)

ICC4P

VCC Standby Current (-40 °C to +105 °C)

ICC5

Reset Current

ICC6I

Active Clock Stop Current (40 °C to +85 °C)

ICC6IP

Active Clock Stop Current (40 °C to +105 °C)

ICC7

VCC Current during power up[32]

IDPD[33]

Deep Power Down Current 1.8 V

(40 °C to +85 °C)

Deep Power Down Current 3.0 V

(40 °C to +85 °C)

Deep Power Down Current 1.8 V

(40 °C to +105 °C)

Deep Power Down Current 3.0 V

(40 °C to +105 °C)

IDPD[33]

IDPD[33]

IDPD[33]

Max

160

660

µA

630

µA

615

µA

600

µA

630

µA

615

µA

600

µA

750

µA

720

µA

675

µA

660

µA