DS1775

Digital Thermometer and Thermostat in SOT23

General Description

The DS1775 digital thermometer and thermostat

provides temperature readings that indicate the device’s

temperature. Thermostat settings and temperature

readings are all communicated to/from the DS1775 over

a simple 2-wire serial interface. No additional components

are required; the device is truly a “temperature-to-digital”

converter.

For applications that require greater temperature resolution,

the user can adjust the readout resolution from 9 to 12

bits. This is particularly useful in applications where

thermal runaway conditions must be detected quickly.

The open-drain thermal alarm output, O.S., becomes

active when the temperature of the device exceeds a

user-defined temperature TOS. The number of consecutive

faults required to set O.S. active is configurable by the

user. The device can also be configured in the interrupt or

comparator mode, to customize the method which clears

the fault condition.

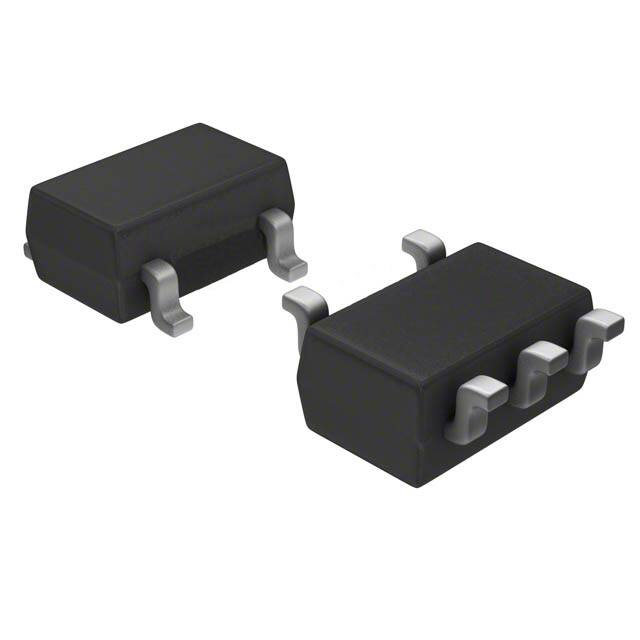

As a digital thermometer, the DS1775 is software compatible

with the DS75 2-wire thermal watchdog. The DS1775 is

assembled in a compact 5-pin SOT23 package, allowing

for low-cost thermal monitoring/control in spaceconstrained applications. The low thermal mass allows for

time constants previously only possible with thermistors.

Applications

●●

●●

●●

●●

Personal Computers/Servers/Workstations

Cell Phones

Office Equipment

Any Thermally-Sensitive System

19-6687; Rev 1; 11/16

Benefits and Features

●● Temperature Measurements Require No External

Components

●● Measures Temperatures from -55°C to +125°C

(-67°F to +257°F)

●● ±2.0°C Thermometer Accuracy

●● Thermometer Resolution is Configurable from 9 Bits

to 12 Bits (0.5°C to 0.0625°C Resolution)

●● User-Definable Thermostat Settings

●● Data is Read From/Written to Through a

●● 2-Wire Serial Interface

●● 2.7V to 5.5V Wide Power-Supply Range

●● Software Compatible with DS75 2-Wire Thermal

Watchdog in Thermometer Mode

●● Space-Conscious 5-Pin SOT23 Package with Low

Thermal Time Constant

Ordering Information appears at end of data sheet.

�DS1775

Digital Thermometer and Thermostat in SOT23

Absolute Maximum Ratings

Storage Temperature Range............................. -55°C to +125°C

Lead Temperature (soldering, 10s).................................. +300°C

Soldering Temperature (reflow)........................................ +260°C

(Voltages relative to ground.)

Voltage Range on VDD..........................................-0.3V to +7.0V

Voltage Range on Any Other Pin..........................-0.3V to +7.0V

Operating Temperature Range.......................... -55°C to +125°C

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may affect

device reliability.

DC Electrical Characteristics

(2.7V ≤ VDD ≤ 5.5V, TA = -55°C to +125°C, unless otherwise noted.)

PARAMETER

SYMBOL

CONDITION

MIN

TYP

MAX

UNITS

Supply Voltage

VDD

(Note 1)

2.7

5.5

V

Input Logic-High

VIH

(Note 1)

0.7 x

VDD

VDD+

0.5

V

Input Logic-Low

VIL

(Note 1)

-0.5

0.3 x

VDD

V

SDA Output Logic-Low Voltage

O.S. Saturation Voltage

VOL1

3mA sink current (Note 1)

0

0.4

VOL2

6mA sink current (Note 1)

0

0.6

VOL

4mA sink current (Notes 1, 9)

0.4 < VI/O < 0.9 x VDD (Note 2)

Input Current Each I/O Pin

I/O Capacitance

CI/O

Standby Current

IDD1

Active Current

IDD

-10

(Notes 3, 4)

V

0.8

V

+10

µA

10

pF

1

µA

Active temp conversions (Notes 3, 4)

1000

Communication only (Notes 3, 4)

100

µA

DIGITAL THERMOMETER

Thermometer Error

TERR

-10°C to +85°C (Notes 9, 10)

±0.5

±2.0

-55°C to +125°C (Notes 9, 10)

±1.0

±3.0

Resolution

Conversion Time

www.maximintegrated.com

9

tCONVT

12

9-bit conversion

125

187.5

10-bit conversion

250

375

11-bit conversion

500

750

12-bit conversion

1000

1500

°C

Bits

ms

Maxim Integrated │ 2

�DS1775

Digital Thermometer and Thermostat in SOT23

AC Electrical Characteristics-2 Wire Interface

(VDD = 2.7V to 5.5V, TA = -55°C to +125°C, unless otherwise noted.) (Figure 5)

PARAMETER

SYMBOL

SCL Clock Frequency

fSCL

Bus Free Time Between a

STOP and START Condition

tBUF

Hold Time (Repeated) START

Condition

tHD:STA

Low Period of SCL

tLOW

High Period of SCL

tHIGH

Setup Time for a

Repeated START

tSU:STA

Data Hold Time

tHD:DAT

Data Setup Time

tSU:DAT

Rise Time of Both SDA and

SCL Signals

tR

Fall Time of Both SDA and SCL

Signals

tF

Setup Time for STOP

tSU:STO

Capacitive Load for Each Bus

Line

CB

Input Capacitance

CI

CONDITIONS

MIN

TYP

MAX

Fast mode

400

Standard mode

100

Fast mode

1.3

Standard mode

4.7

Fast mode (Note 5)

0.6

Standard mode (Note 5)

4.0

Fast mode

1.3

Standard mode

4.7

Fast mode

0.6

Standard mode

4.0

Fast mode

0.6

Standard mode

4.7

µs

µs

µs

µs

0

0.9

Standard mode (Note 6)

0

0.9

100

Standard mode (Note 7)

250

20 + 0.1CB

300

Standard mode (Note 8)

20 + 0.1CB

1000

Fast mode (Note 8)

20 + 0.1CB

300

Standard mode (Note 8)

20 + 0.1CB

300

0.6

Standard mode

4.0

µs

ns

Fast mode (Note 8)

Fast mode

kHz

µs

Fast mode (Note 6)

Fast mode (Note 7)

UNITS

ns

ns

µs

(Note 8)

400

5

pF

pF

Note

Note

Note

Note

Note

Note

Note

1: All voltages are referenced to ground.

2: I/O pins of fast mode devices must not obstruct the SDA and SCL lines if VDD is switched off.

3: IDD specified with O.S. pin open.

4: IDD specified with VDD at 5.0V and VSDA, VSCL = 5.0V, 0°C to +70°C.

5: After this period, the first clock pulse is generated.

6: The maximum tHD:DAT has only to be met if the device does not stretch the low period (tLOW) of the SCL signal.

7: A fast mode device can be used in a standard mode system, but the requirement tSU:DAT ≥ 250ns must then be met. This is

automatically the case if the device does not stretch the low period of the SCL signal. If such a device does stretch the low

period of the SCL signal, it must output the next data bit to the SDA line tR MAX + tSU:DAT = 1000 + 250 = 1250ns before the

SCL line is released.

Note 8: CB = Total capacitance of one bus line in pF.

Note 9: Internal heating caused by O.S. loading causes the DS1775 to read approximately 0.5°C higher if O.S. is sinking the max

rated current.

Note 10: Contact the factory for operation requiring temperature readings greater than +120°C.

www.maximintegrated.com

Maxim Integrated │ 3

�DS1775

Digital Thermometer and Thermostat in SOT23

Pin Configuration

TOP VIEW

SCL 1

+

GND 2

5

SDA

4

VDD

DS1775

O.S. 3

SOT-23

GND

GROUND

SCL

2-WIRE SERIAL CLOCK

SDA

2-WIRE SERIAL DATA INPUT/OUTPUT

VDD

POWER-SUPPLY VOLTAGE

O.S.

THERMOSTAT OUTPUT SIGNAL

Pin Description

PIN

NAME

1

SCL

Clock Input/Output for 2-Wire Serial Communication Port. This input should be tied to GND for

stand-alone thermostat operation.

2

GND

Ground

3

O.S.

Thermostat Output. Open-drain output becomes active when temperature exceeds TOS.

Device configuration defines means to clear overtemperature state.

4

VDD

Supply Voltage 2.7V to 5.5V Input Power Pin

5

SDA

Data Input/Output for 2-Wire Serial Communication Port. In the stand-alone thermostat mode,

this input selects hysteresis.

www.maximintegrated.com

FUNCTION

Maxim Integrated │ 4

�DS1775

Digital Thermometer and Thermostat in SOT23

Detailed Description

Figure 1 shows a block diagram of the DS1775. The

DS1775 consists of five major components:

1) Precision temperature sensor

2) Analog-to-digital converter

3) 2-wire interface electronics

4) Data registers

5) Thermostat comparator

The factory-calibrated temperature sensor requires no

external components. Upon power-up, the DS1775 begins

temperature conversions with the default resolution of 9

bits (0.5°C resolution). The host can periodically read the

value in the temperature register, which contains the last

completed conversion. As conversions are performed in

the background, reading the temperature register does

not affect the conversion in progress.

In power-sensitive applications, the user can put the

DS1775 into a shutdown mode, under which the sensor

complete and store the conversion in progress and revert

to a low-power standby state. In applications where small

incremental temperature changes are critical, the user

can change the conversion resolution from 9 bits to 10,

11, or 12. Each additional bit of resolution approximately

doubles the conversion time. This is accomplished by

programming the configuration register. The configuration

register defines the conversion state, thermometer resolution/conversion time, active state of the thermostat output,

number of consecutive faults to trigger an alarm condition,

and the method to terminate an alarm condition.

The user can also program overtemperature (TOS) and

undertemperature (THYST) setpoints for thermostatic

operation. The power-up state of TOS is +80°C and that

for THYST is +75°C. The result of each temperature conversion is compared with the TOS and THYST setpoints.

The DS1775 offers two modes for temperature control,

the comparator mode and the interrupt mode. This allows

the user the flexibility to customize the condition that

would generate and clear a fault condition. Regardless of

the mode chosen, the O.S. output becomes active only

after the measured temperature exceeds the respective

trip-point a consecutive number of times; the number of

consecutive conversions beyond the limit to generate an

O.S. is programmable. The power-up state of the DS1775

is in the comparator mode with a single fault generating

an active O.S.

Digital data is written to/read from the DS1775 via a

2-wire interface, and all communication is MSb first.

Block Diagram

2.7V - 5.5V

SUPPLY

VDD

PRECISION

REFERENCE

SDA

TO

CPU

OVERSAMPLING

MODULATOR

CONFIGURATION

REGISTER

SCL

I/O CONTROL

INPUT SENSE

DIGITAL

DECIMATOR

DS1775

THERMOMETER

REGISTER

O.S.

THERMOSTAT

REGISTERS

THERMOSTAT

COMPARATOR

GND

Figure 1. Block Diagram

www.maximintegrated.com

Maxim Integrated │ 5

�DS1775

Digital Thermometer and Thermostat in SOT23

Operation

Measuring Temperature

The core of DS1775 functionality is its direct-to-digital

temperature sensor. The DS1775 measures temperature

through the use of an on-chip temperature measurement

technique with an operating range from -55°C to +125°C.

Temperature conversions are initiated upon power-up, and

the most recent result is stored in the thermometer register.

Conversions are performed continuously unless the user

intervenes by altering the configuration register to put the

DS1775 into a shutdown mode. Regardless of the mode

used, the digital temperature can be retrieved from the

temperature register by setting the pointer to that location

(00h, power-up default). The DS1775 power-up default

has the sensor automatically performing 9-bit conversions

continuously. Details on how to change the settings after

power-up are contained in the Programming section.

The resolution of the temperature conversion is configurable (9, 10, 11, or 12 bits), with 9-bit readings the default

state. This equates to a temperature resolution of 0.5°C,

0.25°C, 0.125°C, or 0.0625°C. Following each conversion, thermal data is stored in the thermometer register in

two’s complement format; the information can be retrieved

over the 2-wire interface with the device pointer set to the

temperature register. Table 1 describes the exact relationship of output data to measured temperature. The table

assumes the DS1775 is configured for 12-bit resolution; if

the device is configured in a lower resolution mode, those

bits contain zeros. The data is transmitted serially over the

2-wire serial interface, MSb first. The MSb of the temperature register contains the sign (S) bit, denoting whether the

temperature is positive or negative. For Fahrenheit usage,

a lookup table or conversion routine must be used.

Thermostat Control

In its comparator operating mode, the DS1775 functions

as a thermostat with programmable hysteresis, as shown

in Figure 2. When the DS1775’s temperature meets or

exceeds the value stored in the high temperature trip

register (TOS) a consecutive number of times, as defined

by the configuration register, the output becomes active

and stays active until the first time that the temperature

falls below the temperature stored in the low temperature

trigger register (THYST). In this way, any amount of hysteresis may be obtained. The DS1775 powers up in the

comparator mode with TOS = +80°C and THYST = +75°C

and can be used as a stand-alone thermostat (no 2-wire

interface required) with those setpoints.

In the interrupt mode, the O.S. output first becomes active

following the programmed number of consecutive conversions above TOS. The fault can only be cleared by either

setting the DS1775 in a shutdown mode or by reading any

register (temperature, configuration, TOS, or THYST) on

Table 1. Temperature/Data Relationships

S

26

25

24

2-2

2-3

2-4

MSb

2-1

23

22

21

(UNIT = °C)

20

MSB

LSb

0

0

0

0

LSB

TEMPERATURE

(°C)

DIGITAL OUTPUT

(BINARY)

DIGITAL OUTPUT

(HEX)

+125

0111 1101 0000 0000

7D00h

+25.0625

0000 1010 0010 0000

1910h

+10.125

0000 1010 0010 0000

0A20h

+0.5

0000 0000 1000 0000

0080h

0

0000 0000 0000 0000

0000h

-0.5

1111 1111 1000 0000

FF80h

-10.125

1111 0101 1110 0000

F5E0h

-25.0625

1110 0110 1111 0000

E6F0h

-55

1100 1001 0000 0000

C900h

www.maximintegrated.com

Maxim Integrated │ 6

�DS1775

Digital Thermometer and Thermostat in SOT23

the device. Following a clear, a subsequent fault can only

occur if consecutive conversions fall below THYST. This

interrupt/clear process is thus cyclical (TOS, clear, THYST,

clear, TOS, clear, THYST, clear, etc.). Only the first of

multiple consecutive TOS violations activates O.S., even

if each fault is separated by a clearing function. The same

situation applies to multiple consecutive THYST events.

Regardless of the mode chosen, the O.S. output is

open-drain and the active state is set in the configuration register. The power-up default is active low. See the

Programming section for instructions in adjusting the thermostat setpoints, thermostat mode, and O.S. active state.

Programming

There are three areas of interest in programming the

DS1775: the configuration register, the TOS register, and

the THYST register. All programming is done via the 2-wire

interface by setting the pointer to the appropriate location.

Table 2 illustrates the pointer settings for the four registers

of the DS1775.

TOS

MEASURED

TEMPERATURE

THYST

CONVERSIONS

COMPARATOR MODE

INACTIVE

O.S.

OUTPUT

ACTIVE

CONVERSIONS

INTERRUPT MODE

INACTIVE

O.S.

OUTPUT

ACTIVE

ASSUMES A READ

HAS OCCURRED

THIS TRANSFER FUNCTION ASSUMES THE DS1775 IS CONFIGURED SUCH THAT 2

CONSECUTIVE CONVERSIONS OUT OF TOLERANCE CONSTITUTE AND O.S. FAULT

Figure 2. O.S. Output Transfer Function

Table 2. Pointer Register Structure

www.maximintegrated.com

POINTER

ACTIVE REGISTER

00h

Temperature (default)

01h

Configuration

02h

THYST

03h

TOS

Maxim Integrated │ 7

�DS1775

Digital Thermometer and Thermostat in SOT23

The DS1775 powers up with the temperature register

selected. If the host wishes to change the data pointer, it

simply addresses the DS1775 in the write mode (R/W=

0), receives an acknowledge, and writes the 8 bits that

correspond to the new desired location. The last pointer

location is always maintained so that consecutive reads

from the same register do not require the host to always

provide a pointer address. The only exception is at powerup, in which case the pointer is always set to 00h, the

temperature register. The pointer address must always

precede data in writing to a register, regardless of which

address is currently selected. See the 2-Wire Serial Data

Bus section for details of the 2-wire bus protocol.

Configuration Register Programming

The configuration register is accessed if the DS1775

pointer is currently set to the 01h location. Writing to or

reading from the register is determined by the R/W bit of

the 2-wire control byte (see the 2-Wire Serial Data Bus

section). Data is read from or written to the configuration

register MSb first. The format of the register is illustrated

in Table 3. The effect each bit has on DS1775 functionality

is described below along with the power-up state of the

bit. The user has read/write access to all bits in the configuration register. The entire register is volatile, and thus

it powers up in the default state.

SD = Shutdown bit. If SD is 0, the DS1775 continuously

performs temperature conversions and stores the last

completed result in the thermometer register. If SD is

changed to 1, the conversion in progress is completed

and stored; then the device reverts to a low-power standby mode. The O.S. output is cleared if the device is in the

interrupt mode and remains unchanged in the comparator mode. The 2-wire port remains active. The power-up

default state is 0 (continuous conversion mode).

TM = Thermostat mode. If TM = 0, the DS1775 is in the

comparator mode. TM = 1 sets the device to the interrupt

mode. See the Thermostat Control section for a description of the difference between the two modes. The powerup default state of the TM bit is 0 (comparator mode).

POL = O.S. Polarity Bit. If POL = 1, the active state of

the O.S. output is high. A 0 stored in this location sets the

thermostat output to an active-low state. The user has

read/write access to the POL bit, and the power-up default

state is 0 (active low).

F0, F1 = O.S. Fault Tolerance bits. The fault tolerance

defines the number of consecutive conversions returning

a temperature beyond limits is required to set the O.S.

output in an active state. This may be necessary to add

margin in noisy environments. Table 4 defines the four

settings. The DS1775 powers up with F0 = F1 = 0, such

that a single occurrence triggers a fault.

R0, R1 = Thermometer resolution bits. Table 5 defines

the resolution of the digital thermometer, based on the

settings of these two bits. There is a direct trade-off

between resolution and conversion time, as shown in the

AC Electrical Characteristics. The default state is R0 = 0

and R1 = 0 (9-bit conversions).

Table 3. Configuration/Status Register

0

R1

R0

F1

F0

POL

TM

MSb

SD

LSb

Table 4. Fault Tolerance Configuration

F1

F0

CONSECUTIVE CONVERSIONS BEYOND LIMITS TO GENERATE FAULT

0

0

1

0

1

2

1

0

4

1

1

6

Table 5. Thermometer Resolution Configuration

R1

R0

THERMOMETER RESOLUTION (BITS)

MAX CONVERSION TIME (SECONDS)

0

0

0

9

0.1875

1

10

0.375

1

0

11

0.75

1

1

12

1.5

www.maximintegrated.com

Maxim Integrated │ 8

�DS1775

Digital Thermometer and Thermostat in SOT23

Thermostat Setpoints Programming

The thermostat registers (TOS and THYST) can be

programmed or read via the 2-wire interface. TOS is

accessed by setting the DS1775 data pointer to the 03h

location, and to the 02h location for THYST.

The format of the TOS and THYST registers is identical to

that of the Thermometer register; that is, 12-bit 2’s complement representation of the temperature in °C. The user

can program the number of bits (9, 10, 11, or 12) for each

TOS and THYST that corresponds to the thermometer

resolution mode chosen. For example, if the 9-bit mode is

chosen the three least significant bits of TOS and THYST

are ignored by the thermostat comparator. Table 6 shows

the format for both TOS and THYST. The power-up default

for TOS is +80°C and for THYST is +75°C.

If the user does not wish to take advantage of the thermostat capabilities of the DS1775, the 24 bits can be

used for general storage of system data that need not be

maintained following a power loss.

2-WIRE Serial Data Bus

The DS1775 supports a bidirectional 2-wire bus and data

transmission protocol. A device that sends data onto the

bus is defined as a transmitter, and a device receiving

data as a receiver. The device that controls the message

is called a “master”. The devices that are controlled by

the master are “slaves”. The bus must be controlled by

a master device which generates the serial clock (SCL),

controls the bus access, and generates the START and

STOP conditions. The DS1775 operates as a slave on

the 2-wire bus. Connections to the bus are made via the

open-drain I/O lines SDA and SCL.

The following

(see Figure 3):

bus

protocol

has

been

defined

●● Data transfer may be initiated only when the bus is

not busy.

●● During data transfer, the data line must remain stable

whenever the clock line is HIGH. Changes in the data

line while the clock line is high are interpreted as control signals.

Table 6. Thermostat Setpoint (TOS/THYST) Format

S

26

25

24

2-2

2-3

2-4

MSb

2-1

23

22

21

0

0

(UNIT = °C)

20

MSB

LSb

0

0

LSB

TEMPERATURE

(°C)

DIGITAL OUTPUT

(BINARY)

DIGITAL OUTPUT

(HEX)

+80

0101 0000 0000 0000

5000h

+75

0100 1011 0000 0000

4B00h

+10.125

0000 1010 0010 0000

0A20h

+0.5

0000 0000 1000 0000

0080h

0

0000 0000 0000 0000

0000h

-0.5

1111 1111 1000 0000

FF80h

-10.125

1111 0101 1110 0000

F5E0h

-25.0625

1110 0110 1111 0000

E6F0h

-55

1100 1001 0000 0000

C900h

www.maximintegrated.com

Maxim Integrated │ 9

�DS1775

Digital Thermometer and Thermostat in SOT23

Accordingly, the following bus conditions have been

defined:

The information is transferred byte-wise and each receiver acknowledges with a ninth bit.

Bus not busy: Both data and clock lines remain HIGH.

Within the bus specifications a standard mode (100kHz

clock rate) and a fast mode (400kHz clock rate) are

defined. The DS1775 works in both modes.

Start data transfer: A change in the state of the data

line, from HIGH to LOW, while the clock is HIGH, defines

a START condition.

Stop data transfer: A change in the state of the data line,

from LOW to HIGH, while the clock line is HIGH, defines

the STOP condition.

Data valid: The state of the data line represents valid

data when, after a START condition, the data line is stable

for the duration of the HIGH period of the clock signal.

The data on the line must be changed during the LOW

period of the clock signal. There is one clock pulse per

bit of data.

Each data transfer is initiated with a START condition and

terminated with a STOP condition. The number of data

bytes transferred between START and STOP conditions

is not limited, and is determined by the master device.

Acknowledge: Each receiving device, when addressed,

is obliged to generate an acknowledge after the reception

of each byte. The master device must generate an extra

clock pulse which is associated with this acknowledge bit.

A device that acknowledges must pull down the SDA line

during the acknowledge clock pulse in such a way that

the SDA line is stable LOW during the HIGH period of the

acknowledge related clock pulse. Of course, setup and

hold times must be taken into account. A master must

signal an end of data to the slave by not generating an

acknowledge bit on the last byte that has been clocked

out of the slave. In this case, the slave must leave the

data line HIGH to enable the master to generate the

STOP condition.

SDA

MSB

SLAVE

ADDRESS

R/W

DIRECTION

BIT

ACKNOWLEDGEMENT

SIGNAL FROM

RECEIVER

ACKNOWLEDGEMENT

SIGNAL FROM

RECEIVER

SCL

1

2

6

7

8

9

1

2

3–8

8

ACK

START

CONDITION

9

ACK

REPEATED IF

MORE BYTES ARE

TRANSFERRED

STOP CONDITION

OR REPEATED

START CONDITION

Figure 3. Data Transfer on 2-Wire Serial Bus

www.maximintegrated.com

Maxim Integrated │ 10

�DS1775

Digital Thermometer and Thermostat in SOT23

Figure 3 details how data transfer is accomplished on the

2-wire bus. Depending upon the state of the R/W bit, two

types of data transfer are possible:

1) Data transfer from a master transmitter to a slave

receiver. The first byte transmitted by the master is

the slave address. Next follows a number of data

bytes. The slave returns an acknowledge bit after

each received byte.

2) Data transfer from a slave transmitter to a master

receiver. The first byte (the slave address) is transmitted by the master. The slave then returns an acknowledge bit. Next follows a number of data bytes

transmitted by the slave to the master. The master returns an acknowledge bit after all received bytes other

than the last byte. At the end of the last received byte,

a ‘not acknowledge’ is returned.

The master device generates all the serial clock pulses

and the START and STOP conditions. A transfer is ended

with a STOP condition or with a repeated START condition. Since a repeated START condition is also the beginning of the next serial transfer, the bus is not released.

The DS1775 can operate in the following two modes:

1) Slave receiver mode: Serial data and clock are received through SDA and SCL. After each byte is received, an acknowledge bit is transmitted. START

and STOP conditions are recognized as the beginning and end of a serial transfer. Address recognition

is performed by hardware after reception of the slave

address and direction bit.

www.maximintegrated.com

2) Slave transmitter mode: The first byte is received

and handled as in the slave receiver mode. However,

in this mode, the direction bit indicates that the transfer direction is reversed. Serial data is transmitted on

SDA by the DS1775 while the serial clock is input on

SCL. START and STOP conditions are recognized as

the beginning and end of a serial transfer.

Slave Address

A control byte is the first byte received following the

START condition from the master device. The control

byte consists of a 4-bit control code; for the DS1775, this

is set as 1001 binary for read and write operations. The

next three bits of the control byte are the device select bits

(A2, A1, A0). These bits are set to 000 (A2 = 0, A1 = 0, A0

= 0) for the DS1775R and vary according to the device’s

part number as specified in the Ordering Information

table. They are used by the master device to select which

of eight devices are to be accessed. The set bits are in

effect the three least significant bits of the slave address.

The last bit of the control byte (R/W) defines the operation to be performed. When set to a 1 a read operation is

selected; when set to a 0 a write operation is selected.

Following the START condition, the DS1775 monitors the

SDA bus checking the device type identifier being transmitted. Upon receiving the 1001 code and appropriate

device select bits of 000, the DS1775 outputs an acknowledge signal on the SDA line. See Figure 4.

Maxim Integrated │ 11

�DS1775

Digital Thermometer and Thermostat in SOT23

WRITE TO POINTER ADDRESS

SCL

SDA

S

1

0

0

1

0

0

0

W

0

A

0

0

0

0 P1 P0

POINTER BYTE

ADDRESS BYTE

DS1775

ACK

WRITE TO CONFIGURATION REGISTER (SINGLE BYTE)

START

0

A

P

DS1775

ACK

STOP

SCL

SDA

S

1

0

0

1

0

0

0

W

A

0

0

0

0

0

POINTER BYTE

DS1775

ACK

WRITE TO TOS / THYST REGISTER (TWO–BYTE)

ADDRESS BYTE

START

0

0

A

1

D7 D6 D5 D4 D3 D2 D1 D0

A

DATA BYTE

DS1775

ACK

P

DS1775 STOP

ACK

SCL

SDA

S

1

0

0

1

0

0

0

W

0

0

0

0

0

A D7 D6 D5 D4 D3 D2 D1 D0

0 P1 P0

POINTER BYTE

DS1775

ACK

ADDRESS BYTE

START

A

MSBYTE

DS1775

ACK

A

DS1775

ACK

SCL

A

D7 D6 D5 D4 D3 D2 D1 D0

SDA

P

DS1775 STOP

ACK

LSBYTE

READ SINGLE BYTE FROM CURRENT POINTER LOCATION (CONFIGURATION)

SCL

SDA

S

1

0

0

1

0

0

0

Rd

DS1775

ACK

ADDRESS BYTE

START

A D7 D6 D5 D4 D3 D2 D1 D0

DATA BYTE

N

P

MASTER

NACK

STOP

READ MULTIPLE BYTES FROM CURRENT POINTER LOCATION (TEMPERATURE, TOS, THYST)

SCL

SDA

S

1

0

0

1

0

0

0

Rd

A

D7 D6 D5 D4 D3 D2 D1 D0

START

ADDRESS BYTE

DS1775

ACK

READ SINGLE BYTE FROM NEW POINTER ADDRESS REGISTER

MSBYTE

A

D7 D6 D5 D4 D3 D2 D1 D0

MASTER

ACK

LSBYTE

N

P

MASTER

ACK

STOP

SCL

SDA

S

1

START

0

0

1

0

0

0

W

ADDRESS BYTE

A

0

0

0

DS1775

ACK

0

0

0 P1 P0

POINTER BYTE

A

R 1

DS1775 REPEATED

ACK

START

0

0

1 A2 A1 A0 Rd

ADDRESS BYTE

A

DS1775

ACK

SCL

SDA

D7 D6 D5 D4 D3 D2 D1 D0

DATA BYTE

N

P

MASTER

NACK

STOP

Figure 4. 2-Wire Serial Communication with DS1775

www.maximintegrated.com

Maxim Integrated │ 12

�DS1775

Digital Thermometer and Thermostat in SOT23

SDA

tBUF

tLOW

tR

tF

tHD:STA

SCL

tHD:STA

tSU:STO

tSU:STA

tHD:DAT

STOP

tHIGH

tSU:DAT

START

REPEATED

START

Figure 5. Timing Diagram

Ordering Information

PART

ADDRESS

TOP MARK

TEMP RANGE

000

7750

-55°C to +125°C

5 SOT23

001

7751

-55°C to +125°C

5 SOT23

010

7752

-55°C to +125°C

5 SOT23

011

7753

-55°C to +125°C

5 SOT23

100

7754

-55°C to +125°C

5 SOT23

101

7755

-55°C to +125°C

5 SOT23

110

7756

-55°C to +125°C

5 SOT23

111

7757

-55°C to +125°C

5 SOT23

DS1775R+U

DS1775R+T&R

DS1775R1+U

DS1775R1+T&R

DS1775R2+U

DS1775R2+T&R

DS1775R3+U

DS1775R3+T&R

DS1775R4+U

DS1775R4+T&R

DS1775R5+U

DS1775R5+T&R

DS1775R6+U

DS1775R6+T&R

DS1775R7+U

DS1775R7+T&R

PIN-PACKAGE

+Denotes a lead(Pb)-free/RoHS-compliant package.

U = Cut tape.

T&R = Tape and reel.

Package Information

For the latest package outline information and land patterns (footprints), go to www.maximintegrated.com/packages. Note that a “+”,

“#”, or “-” in the package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing

pertains to the package regardless of RoHS status.

PACKAGE TYPE

PACKAGE CODE

OUTLINE NO.

LAND PATTERN NO.

5 SOT23

U5+1

21-0057

90-0174

www.maximintegrated.com

Maxim Integrated │ 13

�DS1775

Digital Thermometer and Thermostat in SOT23

Revision History

REVISION

NUMBER

REVISION

DATE

PAGES

CHANGED

1

5/13

Updated the Absolute Maximum Ratings, Ordering Information, Package Information

sections

2

11/16

Added typical specification to the Thermometer Error parameter in the Electrical

Characteristics table and added Thermometer Error (TERR) typical spec in the

Electrical Characteristics table.

DESCRIPTION

12, 13

2

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642, or visit Maxim Integrated’s website at www.maximintegrated.com.

Maxim Integrated cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim Integrated product. No circuit patent licenses

are implied. Maxim Integrated reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits)

shown in the Electrical Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

Maxim Integrated and the Maxim Integrated logo are trademarks of Maxim Integrated Products, Inc.

© 2016 Maxim Integrated Products, Inc. │ 14

�