EVALUATION KIT AVAILABLE

MAX11068

LE

AVAILAB

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

General Description

The MAX11068 is a programmable, highly integrated,

high-voltage, 12-channel, battery-monitoring smart dataacquisition interface. It is optimized for use with batteries used in automotive systems, hybrid electric battery

packs, electric cars, and any system that stacks long

series strings of secondary metal batteries. This highly

integrated battery sensor incorporates a simple state

machine and a high-speed I2C bus for SMBusK-laddered

serial communication.

The MAX11068 analog front-end combines a 12-channel

voltage measurement data-acquisition system with a highvoltage switch bank input. All measurements are done

differentially across each cell. The full-scale measurement

range is from 0 to 5.0V, with full stated accuracy guaranteed from 0.5V to 4.7V. The input mux/switch bank allows

for differential measurement of each cell in a series stack.

A high-speed, 12-bit successive approximation (SAR) A/D

converter is used to digitize the cell voltages. All 12 cells

can be measured in less than 107Fs. The MAX11068 uses

a two-scan approach for collecting cell measurements

and correcting them for errors. The first phase of the scan

is the acquisition phase where the voltages of all 12 cells

are acquired. The second phase is the error-cancellation

phase where the ADC input is chopped to remove errors.

This two-phase approach yields excellent accuracy over

temperature and in the face of extreme noise in the system. The MAX11068 incorporates an internal oscillator that

generates a 6.0MHz system

clock with Q3.0%

accuracy.

Functional

Diagrams

The MAX11068 consumes less than 2.0mA from the power

supply while in data-acquisition modes. This current is

reduced to 75FA in standby mode and less than 1FA in

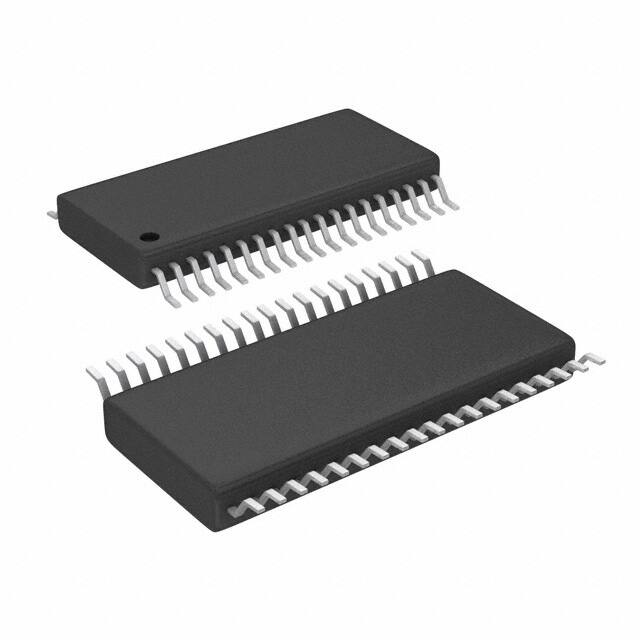

shutdown mode. The device is packaged in a 38-pin,

9.7mm x 4.4mm x 1.0mm TSSOP package that is lead free

and RoHS compliant and is designed to operate over the

AEC-Q100 Grade 2, -40NC to +105NC temperature range.

Applications

High-Voltage, Multicell Series-Stacked-Battery

Systems

Electric and Hybrid Electric Vehicle (HEV)

Battery Packs

Features

S 12-Cell Battery Voltage Measurement with

Temperature Monitoring

Up to 12 Lithium-Ion (Li+), NiMH, or Super-Cap

Cells

Two Auxiliary Analog Inputs for Temperature

Measurement

S High-Accuracy I/Os

Excellent ±0.25% Voltage-Measurement

Accuracy

≤ 5mV Offset Voltage

S Integrated 12-Channel Data-Acquisition System

12-Channel High-Voltage Mux to ADC

Differential Cell-Voltage Measurement

12-Bit Precision, High-Speed SAR ADC

12 Cell Voltages Measured Within 107µs

S Battery-Fault Detection

Overvoltage and Undervoltage Digital Threshold

Detection

Cell Sense Line Open-Circuit Detection

High/Low Temperature Digital Threshold

Detection

S 12 Integrated Cell-Equalization Switches

Support Up to 200mA

S Integrated 6V to 70V Input Linear Regulator

S Integrated 25ppm/NC, 2.5V Precision Reference

S Integrated Level-Shifted, I2C-Compliant SMBus

Ladder Interface

Supports Multiple Devices, Up to 31 SMBus Ladder-Connected ICs

Communications Protocol with Autoaddressing

Fault-Tolerant Hardware Handshake and Data

CRC Checking

S Three General-Purpose Digital I/O Lines

S Ultra-Low Power Dissipation

Standby Mode Quiescent Current Drain 75µA

Shutdown Mode Leakage Current 1µA

S Operating Temperature Range from -40NC to

+105NC (AEC-Q100 Grade 2)

S 38-Pin, Lead-Free/RoHS-Compliant TSSOP

Package (9.7mm x 4.4mm)

Ordering Information

Electric Bikes

High-Power Battery Backup Systems

SuperCap Backup Systems

Pin Configurations appear at end of data sheet.

Power

Tools continued at end of data sheet.

Functional

Diagrams

UCSP

is

a

trademark

of Maxim Integrated Products, Inc.

SMBus is a trademark of Intel Corp.

PART

TEMP RANGE

PIN-PACKAGE

MAX11068GUU+

-40NC to +105NC 38 TSSOP

MAX11068GUU/V+

-40NC to +105NC 38 TSSOP

+Denotes a lead(Pb)-free/RoHS-compliant package.

/V Denotes an automotive qualified part.

For pricing, delivery, and ordering information, please contact Maxim Direct

at 1-888-629-4642, or visit Maxim’s website at www.maximintegrated.com.

19-5192; Rev 0; 6/10

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

ABSOLUTE MAXIMUM RATINGS

HV, VDDU, GNDU, DCIN to AGND.......................-0.3V to +80V

HV to C12.................................................................-0.3V to +6V

C1–C12 to AGND.......................................-0.3V to (VHV + 0.3V)

C(N+1) to C(N)......................................................-0.3V to +9.0V

C0 to AGND..........................................................-0.3V to +4.0V

SHDN to AGND......................................................-0.3V to +60V

VAA to AGND........................................................-0.3V to +4.0V

VDDL to GNDL......................................................-0.3V to +4.0V

VDDU to GNDU. ...................................................-0.3V to +6.0V

GNDU to GNDL. ....................................................-0.3V to +80V

AGND to GNDL.....................................................-0.3V to +0.3V

AUXIN1, AUXIN2, THRM to AGND.......................-0.3V to +6.0V

REF to AGND............................................ -0.3V to (VAA + 0.3V)

SCLL, SDAL, ALRML to GNDL................ -0.3V to (VDDL + 0.3V)

SCLU, SDAU, ALRMU to GNDU..............-0.3V to (VDDU + 0.3V)

CP+ to AGND.......................... (GNDU - 1.0V) to (VDDU + 1.0V)

CP- to AGND.......................................... -0.3V to (GNDU + 0.3V)

GPIO0, GPIO1, GPIO2............................ -0.3V to (VDDL + 0.3V)

ESD Rating (HBM, Note 1)...................................................Q2kV

C0–C12, AUXIN1, AUXIN2, REF, VAA, VDDU, GNDU,

VDDL, GNDL, DCIN, SHDN, CP+, CP-, HV, SCLU, SDAU,

ALRMU, SCLL, SDAL, ALRML, GPIO0, GPIO1, GPIO2

Maximum Continuous Current into Any Pin........................20mA

ESD Diode Maximum Average

Power Dissipation for Hot Plug (Note 2).... ..................14.4/√τ W

Continuous Power: Multilayer Board...........................1269.8mW

Continuous Power: Single-Layer Board

(derating 15.9mW/NC above +70NC).......................1095.9mW

Operating Temperature Range........................ .-40NC to +105NC

Storage Temperature Range............................. -55NC to +150NC

Junction Temperature (continuous).................................+150NC

Lead Temperature (soldering, 10s).................................+300NC

Soldering Temperature (reflow).......................................+260NC

Note 1: Human Body Model to Specification MIL-STD-883 Method 3015.7.

Note 2: Maximum average power dissipation for time period τ. Peak current must never exceed 2A. τ is one time constant (in µs) of

hot-plug current waveform through a given diode. For example, if τ is 330µs, the maximum average diode power dissipation

is 0.793W. Actual average power dissipation must be calculated from current waveform for the application circuit.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

ELECTRICAL CHARACTERISTICS

(TA = TMIN to TMAX, unless otherwise noted. VGNDU = VDCIN = 18V to +60V, typical values are at TA = +25NC, unless otherwise

specified from -40NC to +105NC per the application circuit in Figure 4.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

V

C0–C12 INPUTS

Differential Cell Input-Voltage

Range

Cell Input Common-Mode Voltage

Range (Note 5)

Input-Leakage Current

ADC Resolution

Channel- Conversion Time

Channel Accuracy

2

VCELLXIN

VCXIN

Any 2 inputs

CN+1 to CN for C12–C0 (Note 2)

0.5

4.7

Input C1 referred to AGND

0.7

7.0

Inputs C2 through C[TOP] referred to

AGND

0.7

V

C[TOP] referred to AGND

ICXIN

ADCBITS

tS

GNDU

C0 referred to AGND

-0.05

ADC off; C(N) to C(N+1) = 5V

-1.0

ADC ON; C(N) to C(N+1) = 3V

LSB size is +1.22mV

+0.05

+1.0

Q10.0

12

FA

Bits

Highest enabled input

11.34

Enabled inputs except highest

7.66

Fs/

Channel

TA = +25NC (Note 4); VCELL = 3.0V

-5

+5

-10NC < TA < +50NC; VCELL = 3.0V

(Note 3)

-10

+10

-40NC < TA < +85NC; VCELL = 3.0V

(Note 3)

-15

+15

-40NC < TA < +105NC; VCELL = 3.0V

-20

+20

mV

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

ELECTRICAL CHARACTERISTICS (continued)

(TA = TMIN to TMAX, unless otherwise noted. VGNDU = VDCIN = 18V to +60V, typical values are at TA = +25NC, unless otherwise

specified from -40NC to +105NC per the application circuit in Figure 4.)

PARAMETER

Differential Nonlinearity

SYMBOL

DNL

CONDITIONS

MIN

No missing codes at 12 bits

TYP

MAX

UNITS

LSB

Q1.0

Channel Offset Error

CELLVOS

Cells 1 through 12

-5

+5

mV

Channel Gain Error

CELLAV

Cells 1 through 12

-1.0

+1.0

%

RSWITCH from C(N) to C(N+1) when

enabled

1.5

20

I

Cell-Balancing Switch Resistance

6

AUXIN1, AUXIN2 INPUTS

Absolute Differential Input Range

VAUXINXIN

Common-Mode Input-Voltage

Range

Input-Leakage Current

IAUXIN

AUXIN1, AUXIN2 to AGND; ADC REF =

THRM

0

VTHRM

V

Inputs AUXIN1/2 referred to AGND

0

VTHRM

V

-1.0

+1.0

ADC off; input voltage = 3.3V

ADC Resolution

Conversion Time

12

Accuracy

Differential Nonlinearity

DNL

Fs/

AUX_

Input

10

tS

TA = +25NC

-0.5

+0.5

-40NC < TA < +105NC

-1.0

+1.0

No missing codes at 12 bits

FA

Bits

%

LSB

Q1.0

Offset Error

AUXVOS

AUXIN1, AUXIN2

-8

+8

mV

Gain Error

AUXAV

AUXIN1, AUXIN2

-1.0

+1.0

%

THRM Switch Resistance

RTHRM

THRM to VAA (Note 3)

18

28

I

2.50

2.55

5

VOLTAGE REFERENCE

Output REF Voltage

REFVOUT

TA = +25NC

2.45

V

REF Output Short-Circuit Current

IREF-SC

Q12.5

mA

Temperature Coefficient

DREF/

DTEMP

Q25

ppm/NC

Change after

1000hr burn-in

120

ppm

Initial Drift

LOGIC INPUTS AND OUTPUTS (GPIO AND SHDN)

SHDN Voltage High

1.8

V

0.5

SHDN Voltage Low

SHDN Input Leakage Current

VSHDN = 30V

5.15

18

VSHDN = 56V

12.6

45

GPIO Input Voltage Low

GPIO Input Voltage High

I/O pins programmed to high impedance

GPIO Output Voltage Low

ISINK = 3mA

GPIO Output Voltage High

ISOURCE = 3mA

Maxim Integrated

-1

VDDL 0.5

FA

0.8

V

+6.2

FA

0.4

V

2.4

I/O Leakage Current

V

1

VSHDN = 3.4V

V

+2

V

3

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

ELECTRICAL CHARACTERISTICS (continued)

(TA = TMIN to TMAX, unless otherwise noted. VGNDU = VDCIN = 18V to +60V, typical values are at TA = +25NC, unless otherwise

specified from -40NC to +105NC per the application circuit in Figure 4.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

70

V

3.55

V

60

mA

LINEAR REGULATOR +3.4V (VAA)

Input Voltage Range

Output Voltage

VDCIN

0 < ILOAD < 8mA

6.0

VVAA

0 < ILOAD < 8mA;

6V < VDCIN < 70V

3.25

3.4

Short-Circuit Current

VAA = 0V, 6V < VDCIN < 30V

Power-On Reset Threshold

(Note 3)

Falling VAA

2.85

2.95

3.05

Rising VAA

2.9

3.0

3.1

POR threshold hysteresis

0.01

40

80

Thermal Shutdown

Rising temperature

Thermal-Shutdown Hysteresis

V

mV

+145

NC

15

NC

CHARGE PUMP +3.4V

Output Voltage

VVDDU - VGNDU

Charge-Pump Efficiency

Charge-Pump Undervoltage

Threshold

ILOAD = 0 at 0.1FF CP+ to CP-

3.2

3.4

3.55

1mA = ILOAD at 0.1FF CP+ to CP-

3.2

2.5

3.55

IVDDU/IGNDU - IVDDU at 2.7V,

VDDU - GNDU

60

89

99

%

2.0

2.7

3.2

V

VCPUV

V

INTERNAL OSCILLATORS (32.768kHz, 6.0MHz)

Internal 32.768kHz Oscillator

Frequency

fWD-OSC

32.113

32.768

33.423

kHz

Internal 6.0MHz Oscillator

Frequency

fHF-OSC

5.82

6.0

6.18

MHz

0.3 x

VVDDL

V

I2C LOWER PORT SCLL, SDAL, ALRML (Relative to GNDL, VDDL = Nominal 3.4V)

SDAL, SCLL Input Voltage Low

0.7 x

VVDDL

SDAL, SCLL Input Voltage High

SDAL, SCLL Input Hysteresis

0.2

SDAL, ALRML Output Voltage Low

VSDAL = VSCLL = 1.5V

RACTIVE_EDGE Active edge

Managed passive state

SDAL, Managed Resistance

C1_TAU

V

0.4

V

1.0

FA

1

3

35

50

75

1

kI

MI

tONE_SHOT (active edge pulse)

150

250

380

ns

SDAL rises to 70% within active edge

time when loaded with this capacitance

120

280

550

pF

At source = 3mA

VDDL 0.4

ALRML Heartbeat Frequency

OSC = 32.768kHz Q2.0%

16,000

Lower Port Input Capacitance

SCLL, SDAL, ALRML

4

0.5

0.5

Off passive state

tONE_SHOT

ALRML Output High Voltage

0.1 x

VVDDL

At sink = 3mA

SDAL, SCLL Leakage Current

SDAL 1-TAU Capacitance

V

V

16,384

15

16,711

kHz

pF

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

ELECTRICAL CHARACTERISTICS (continued)

(TA = TMIN to TMAX, unless otherwise noted. VGNDU = VDCIN = 18V to +60V, typical values are at TA = +25NC, unless otherwise

specified from -40NC to +105NC per the application circuit in Figure 4.)

PARAMETER

I2C

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

0.3 x

VVDDU

V

UPPER PORT SCLU, SDAU, ALRMU (Relative to GNDU, VDDU)

SDAU, ALRMU Input Voltage Low

0.7 x

VVDDU

SDAU, ALRMU Input Voltage High

SDAU, ALRMU Input Hysteresis

0.05

0.1 x

VVDDU

Q1.0

SDAU, SCLU Output Voltage Low

At sink = 3mA

SDAU, SCLU Leakage Current

VSDAU = VSCLU = 1.5V

-1

Active edge

0.5

Managed passive state

30

SDAU, Managed Resistance

Off passive state

tONE_SHOT

SDAU 1-TAU Capacitance

ALRMU Clamp Current

V

0.4

V

+1

FA

1

3

kI

50

75

1

kI

MI

150

250

480

ns

SDAU rises to 70% within active edge

time when loaded with this capacitance,

i.e., choose 100pF to guarantee 3H rising

edge

120

280

550

pF

VALRMU = VDDU + 0.15V

1

VALRMU = GNDU - 0.15V

1

ALRMU Clamp Voltage

GNDU

-0.49

FA

V

VDDU +

0.49

250FA current pulling above VDDU

SCLU, SDAU, ALRMU

8

From SHDN or from POR

3

Port-to-Port Level Delay

V

pF

1

Interface Startup

V

tONE_SHOT (active edge pulse)

250FA current pulling below GNDU

Upper Port Input Capacitance

0.4

Fs

ms

I2C TIMING CHARACTERISTICS

I2C Clock Frequency

fI2C

Bus Timeout Period

tTIMEOUT

Bus Free Time

tBUF

Bus Hold Time

tHD-STA

Bus START Command Setup Time

tSU-STA

Bus STOP Command Setup Time

SDA Data Hold Time

Maxim Integrated

tSU-STOP

10

Timeout for maximum clock low/high time

Master to slave delay from a STOP to the

next START command

Master hold time after a START

command

Repeated START setup time

STOP condition setup time

SLAVE PORT Transmit

tHD-DAT

Receive

MASTER PORT Transmit

tHD-DAT

Receive (Note 7)

200

27.4

kHz

ms

500

Fs

350

Fs

1

Fs

100

ns

500

-30

400

ns

400

5

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

ELECTRICAL CHARACTERISTICS (continued)

(TA = TMIN to TMAX, unless otherwise noted. VGNDU = VDCIN = 18V to +60V, typical values are at TA = +25NC otherwise specified

from -40NC to +105NC per the application circuit in Figure 4.)

PARAMETER

SDA Data Setup Time

SYMBOL

CONDITIONS

MIN

SLAVE PORT Transmit (Note 7)

tSU-DAT

Receive

250

MASTER PORT Transmit (Note 7)

tSU-DAT

Receive

250

TYP

MAX

250

UNITS

ns

1000

SCLL Low Time

tLOW

1.25

Fs

SCLL High Time

tHIGH

1.25

Fs

tMCL-MIN

1

us

Remastered Clock Minimum High

Time

LEVEL-SHIFT TIMING

Level Shift Delay (SDAL to SDAU

or SDAU to SDAL)

tLS-DAT

Rising or falling edge at 1.5V threshold;

pin-to-pin delay with 100pF loading

400

1100

ns

Level Shift Delay (SCLL to SCLU)

tLS-CLK

Rising or falling edge at 1.5V threshold;

pin-to-pin delay with 100pF loading

600

800

ns

POWER-SUPPLY REQUIREMENTS DCIN

IDCIN

Acquisition

Mode

High-voltage mux enabled, ADC

converting 12 channels; VDCIN = 30V

IHV Acquisition

Mode

Current Consumption

(Note: IDDQ testing is done in

production test with a coverage

of 71%)

IDCIN

Standy Mode No conversions or cell balancing; LDO,

REF, and OSC running, SHDN = 1

IGNDU

Standby Mode

IGNDU

Shutdown Mode

Note

Note

Note

Note

Note

6

6

mA

4.1

IDCIN

Cell-Balancing

Cell balancing enabled for four switches,

Mode

LDO, REF, and OSC running; VDCIN =

IGNDU

VGNDU = 6V

Cell-Balancing

Mode

IDCIN

Shutdown Mode

3.0

9.6

70

63

55

150

20

130

0.25

2

0.3

2

FA

SHDN = 0

3: Guaranteed by design and not production tested.

4: Differential input voltage range for which channel gain and offset error applies.

5: Common-mode level at each pin required for specified operation of the high-voltage mux.

6: Offset and gain error are calibrated at +25NC and 3.0V per cell at the factory, assuming that VCXIN is met.

7: This is a derived specification. No characterization required. These specifications involve the clock low time and clock high

time used.

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Pin Configuration

TOP VIEW

+

DCIN

1

38

HV

CP+

2

37

C12

CP-

3

36

C11

C10

VDDU

4

35

GNDU

5

34

C9

SCLU

6

33

C8

SDAU

7

32

C7

ALRMU

8

31

C6

N.C.

9

30

C5

GPIO2

10

29

C4

GPIO1

11

28

C3

GPIO0

12

27

C2

C1

MAX11068

VDDL

13

26

GNDL

14

25

CO

SCLL

15

24

VAA

SDAL

16

23

AGND

ALRML

17

22

REF

SHDN

18

21

AUXIN1

AUXIN2

19

20

THRM

TSSOP

9.7mm x 4.4mm

Pin Description

PIN

NAME

FUNCTION

1

DCIN

DC Power-Supply Input. DCIN supplies the internal 3.4V regulator, which provides low-voltage power to the

device. Bypass DCIN to GND with a 1FF capacitor.

2

CP+

Charge-Pump Capacitor Plus Input for the Internal Charge Pump. Connect a 0.1FF high-voltage capacitor

between CP+ and CP-.

3

CP-

Charge-Pump Capacitor Minus Input for the Internal Charge Pump. Connect a 0.1FF high-voltage capacitor

between CP+ and CP-.

4

VDDU

Level-Shifted Upper I2C Port Digital Supply for Use in Communicating with an Upper, Neighboring Battery

Module. This is a regulated output voltage from the internal charge pump that is level shifted above the DCIN

pin voltage level.

5

GNDU

Level-Shifted Upper I2C Port Ground. This pin is the reference level and ground return for VDDU and also the

supply input for the charge pump. It should be tied to the DCIN takeoff point on the battery stack as shown in

the application diagrams.

6

SCLU

Level-Shifted Upper Port I2C Clock Line. SCLU is the I2C clock line communicating with the upper

neighboring battery module. This pin swings between VDDU and GNDU.

7

SDAU

Level-Shifted Upper Port I2C Bidirectional Serial Data Line. SDAU is the I2C data line communicating with the

upper neighboring battery module. This pin swings between VDDU and GNDU.

Maxim Integrated

7

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Pin Description (continued)

PIN

NAME

8

ALRMU

Upper Port Alarm Input. Overvoltage, undervoltage, over/undertemperature, cell mismatch, and

communication fault. The alarm signal is laddered. This signal is referenced to VDDU and GNDU. Connect

this signal to VDDU through a pullup resistor.

9

N.C.

10

GPIO2

General-Purpose I/O 2. This pin swings between VDDL and GNDL.

11

GPIO1

General-Purpose I/O 1. This pin swings between VDDL and GNDL.

12

GPIO0

General-Purpose I/O 0. This pin swings between VDDL and GNDL.

13

VDDL

Lower Port I2C + 3.4V Digital Supply Input. Connect to VAA and decouple to GNDL with a 0.47FF capacitor.

14

GNDL

Lower Port I2C Common or Ground. A star ground connection to AGND is recommended.

15

SCLL

Lower Port I2C Clock. SCLL is the I2C clock line communicating with the lower neighboring battery module.

This pin swings between VDDL and GNDL.

16

SDAL

Lower Port I2C Data I/O. SDAL is the I2C serial data line communicating with the lower neighboring battery

module. This pin swings between VDDL and GNDL.

ALRML

Lower Port Alarm Output. Overvoltage, undervoltage, over/undertemperature, cell mismatch, and

communication faults. The alarm signal is laddered and driven from the highest module down to the lowest.

The alarm output is nominally a clocked heartbeat signal that provides a 16kHz clock when no alarm is

present and is held at logic-high during an alarm. This signal swings between VDDL and GNDL.

SHDN

Active-Low Shutdown/Input. This pin completely shuts down the MAX11068 internal regulators and oscillators

when the pin is less than +0.6V as referenced to AGND. The I2C bus is nonresponsive when shutdown is

asserted. SHDN for the first pack should be driven by the host controller through the recommended interface

circuit. SHDN for laddered modules should be tied to the lower neighboring battery module through the

recommended interface circuit. The shutdown pin is 60V tolerant for connection directly to the top of the

battery stack.

17

18

Not Internally Connected/Test I/O. Leave open; do not connect any external circuit to this pin.

19

AUXIN2

Auxiliary Analog Input 2. A low-voltage analog input pin with a full-scale range of AGND to VAA that can be

used for monitoring an external NTC or general-purpose measurements. This channel uses the VAA voltage

as the reference voltage for the ADC conversion. When used with the THRM pin and a resistor-divider,

ratiometric measurements can be made.

20

THRM

External Thermistor Bias Output. This is a switched connection for supplying a bias voltage from the internal

+3.4V regulator (VAA) to an external NTC device for measuring the temperature of the battery module. This

pin can supply up to 2mA from the VAA regulator.

AUXIN1

Auxiliary Analog Input 1. A low-voltage analog input pin with a full-scale range of AGND to VAA that can be

used for monitoring an external NTC or general-purpose measurements. This channel uses the VAA voltage

as the reference voltage for the ADC conversion. When used with the THRM pin, ratiometric measurements

can be made.

21

8

FUNCTION

22

REF

23

AGND

24

VAA

25

C0

Cell 1 Minus Connection. Bypass to AGND with a 1.0FF capacitor.

26

C1

Cell 2 Minus Connection and Cell 1 Plus Connection

27

C2

Cell 3 Minus Connection and Cell 2 Plus Connection

+2.5V Voltage Reference. Bypass REF to AGND with a 1FF capacitor placed close to the device.

Analog Ground. Should be tied to the negative terminal of cell 1.

+3.4V Analog Supply Output. Connect to VDDL and bypass with a 1.0FF capacitor to AGND.

28

C3

Cell 4 Minus Connection and Cell 3 Plus Connection

29

C4

Cell 5 Minus connection and Cell 4 Plus Connection

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Pin Description (continued)

PIN

NAME

30

C5

FUNCTION

Cell 6 Minus Connection and Cell 5 Plus Connection

31

C6

Cell 7 Minus Connection and Cell 6 Plus Connection

32

C7

Cell 8 Minus Connection and Cell 7 Plus Connection

33

C8

Cell 9 Minus Connection and Cell 8 Plus Connection

34

C9

Cell 10 Minus Connection and Cell 9 Plus Connection

35

C10

Cell 11 Minus Connection and Cell 10 Plus Connection

36

C11

Cell 12 Minus Connection and Cell 11 Plus Connection

37

C12

Cell 12 Plus Connection. Top of battery module stack.

38

HV

High-Voltage Bias Pin. HV is biased through a diode connection to the charge pump. It is used internally to

supply the high-voltage mux. Connect to DCIN through a 3.3FF capacitor.

HV

DCIN

VAA

GNDU VDDU

REF

+6V TO

72V

THRM

+3.4V

LINEAR

REGULATOR

AUXIN2

PRECISION

+2.5V

REFERENCE

ALRMU

I2C

UPPER

PORT

POR

6.0MHz

OSC

AUXIN1

C12

C11

CP+

GNDU

C9

GNDU

C8

C7

C5

SDAU

VDDU

C10

C6

SCLU

CELL

EQUALIZATION

SWITCH

BANK

C4

LEVEL

SHIFT

CP-

COM

C3

+3.4V

C2

AGND

ALRML

32kHz

OSC

C1

C0

AGND

12-BIT

ADC

INSTR

AMP

CONTROL

AND

STATUS

12

27

MAX11068

+3.4V

SW_SEL(26:0)

I2C

SCLL

LOWER

PORT

SDAL

SHDN

DIS_SEL(11:0)

GPIO0 GPIO1 GPIO2

GNDL

VDDL

Figure 1. Functional Diagram

Maxim Integrated

9

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

CELLBALANCING

SWITCHES

HIGHVOLTAGE

MUX

C12

C11

C10

C9

C8

REF

THRM

C7

C6

INSTR

AMP

ADC IN +

C5

LV

MUX

C4

C3

12-BIT ADC

ADC IN -

SELFDIAGNOSTIC

REF

C2

C1

C0

AUXIN2

AUXIN1

AGND

Figure 2. Analog Front-End Block Diagram

10

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

HV

VDDU

6V

CP+

DCIN

ALRMU/SDAU/SCLU

GNDU

C12

80V

80V

80V

9V

CP-

C11

9V

VAA

C3 TO C10 MATCH

OTHER INPUTS

MAX11068

ESD DIODES

C2

REF/THRM

SHDN

VDDL

9V

AIN0/1

C1

GPIO0/1/2

9V

C0

ALRML/SDAL/SCLL

4V

4V

80V

4V

4V

AGND

GNDL

NOTE: ALL DIODES ARE RATED FOR ESD CLAMPING CONDITIONS. THEY ARE NOT INTENDED TO

ACCURATELY CLAMP DC VOLTAGE. ALL DIODES SHOWN HAVE A PARASITIC PN DIODE FROM

THEIR CATHODE TO AGND THAT IS OMITTED FOR CLARITY. THIS PARASITIC DIODE HAS ITS

ANODE AT AGND.

Figure 3. MAX11068 ESD Diode Diagram

Maxim Integrated

11

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Typical Operating Circuit Diagrams

MODULE N+1

CELL STACK

MODULE-(N+1)

MODULE N+1 GND

REFERENCE

A KELVIN CONNECTION IS OPTIONAL FOR

THE DCIN TAKEOFF IN HIGH-CURRENT

APPLICATIONS. SEE THE NOISE TOLERANCE

SECTION FOR DETAILS.

CHV

3.3µF, 6V

MODULE+ (N)

22I

FUSE

22I

100kI

GNDU

HV

DDCIN

BUS BAR

CDCIN

1.0µF

80V

DCIN

CDD

1.0µF,

6V

VDDU

SMCJ70

BAT46

R3DC

150kI

5.6V

R1DC

150kI

D12

SMBus-LADDERED

TO UPPER MODULES

R13

C12

R12

SCLU

C10

C9

SDAU

C8

GNDU

C8

R8

MAX11068

C7

CELL #7

CP-

C5

VAA

VDDL

C4

RT2

10kI

1%

SCLL

C2

SDAL

C1

ALRML

C0

SHDN

AUXIN2

AUXIN1

CT1

t

100pF

t

LOCAL

GROUND

MODULE N-1 CELL

STACK

CA

1µF

6V

RP2

150kI

RP3

150kI

ISOLATOR

AND

CONTROL

INTERFACE

200kI

THRM

RT1

10kI

1%

BUS BAR

CT2

100pF

100nF

1kI

MODULE-(N)

CT3

100pF

C3

CL

0.47µF

6V

C1

R1

C0

1µ F

5.6V

C2

R2

CELL #1

TO SHDN

S1B

C3

R3

CELL #2

GNDL

C4

R4

CELL #3

CP

0.1µF

100V

150I

GNDU

C5

R5

CELL #4

HV

C6

R6

CELL #5

C6

MODULE

N+1

DHV

GNDU

CP+

C7

R7

CELL #6

SDAL

C9

R9

CELL #8

SCLL

C1DC

3.3nF, 630V

C10

R10

CELL #9

ALRML

C2DC

3.3nF, 630V

C11

R11

CELL #10

C3DC

3.3nF, 630V

ALRMU

C11

CELL #11

GNDU

GNDU

C12

CELL #12

68nF

5.6V

GPIO0

GPIO1

GPIO2

AGND

REF

CREF

1µF

THERMISTORS

10kI AT +25NC

Figure 4. Operating Circuit Diagram for a 12-Cell System

12

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

HV

MODULE+ (N)

R9

CELL 8

CELL 7

CELL 6

CELL 5

CELL 4

CELL 3

CELL 2

CELL 1

MODULE-(N)

DCIN

DHV

R8

R7

R6

R5

R4

R3

R2

R1

C12

VDDU

C11

ALRMU

C10

SCLU

C9

SDAU

C8

GNDU

C8

C7

MAX11068

CP+

C7

C6

CP-

C5

VAA

C4

VDDL

C3

SCLL

C2

SDAL

C1

ALRML

C0

SHDN

THRM

GNDL

C6

C5

C4

C3

C2

C1

C0

1µF

AUXIN2

GPIO0

AUXIN1

GPIO1

GPIO2

AGND

REF

Figure 5. Simplified Operating Circuit Diagram for an 8-Cell System

Maxim Integrated

13

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Detailed Description

The MAX11068 has two auxiliary analog inputs that can

be used to measure external resistance temperature

detector (RTD) components. A negative temperature

coefficient (NTC) RTD can be configured with the

AUXIN1 or AUXIN2 analog inputs to accurately monitor

module or battery-cell temperature. An internal temperature monitor on the die is used to detect thermal

overload and disables the MAX11068 cell-balancing

switches and linear regulator should the +145NC thermal

limit be exceeded.

The MAX11068 has 12 built-in cell-balancing/discharge

switches that can support up to 200mA cell discharge

currents. The MAX11068 package can support up to

1.2W of power dissipation, which limits the number of

balancing/discharge switches that can be enabled when

using a 200mA set current to three nonconsecutive cells

at no more than +75NC ambient temperature. With a

110mA cell set current, all 12 internal cell switches can

be enabled at the same time. The balancing switches

can also be used to detect an open circuit on any of the

cell sense wire connections.

The MAX11068 contains a 25ppm/NC precision bandgap reference and an internal regulator that creates the

supply for the analog front end and the interchip, levelshifted, communication bus. The regulator can operate

from a 6.0V to 72V supply input. The external shutdown

pin can be used to reset the MAX11068.

The MAX11068 incorporates an I2C physical interface

for interchip communication and control. The I2C bus

system is designed to allow SMBus laddering of up to

31 devices without the need for any interchip isolation.

14

These bidirectional serial buses can withstand large

differences in interchip grounds and system noise. The

built-in level-shifting and predefined command protocol

provide a low-cost, flexible, and reliable communication

bus. Command-up forwarding relays communication

along the bus from chip to chip for fast response. A

1Fs delay is incurred in relaying command messages,

bounding the maximum delay in response to a command to 1Fs multiplied by the number of chips used in

the stack minus 1. For a 31-chip stack, a maximum 30Fs

delay is incurred before the top module responds. This

means that up to 372 cells can be measured with an

elapsed measurement time from start to finish of 137Fs.

For a 16-chip stack, a 15Fs delay is incurred. This allows

measurement of up to 192 cells with an elapsed measurement time from start to finish of 122Fs.

The MAX11068 incorporates an internal oscillator that

generates a 6.0MHz system clock with Q3.0% accuracy.

Architectural Overview

The MAX11068 is a complete data-acquisition system on

a chip designed for rugged, high-voltage measurement

applications. It can measure up to 12 channels of voltages from batteries or SuperCaps with a high-accuracy,

high-speed SAR ADC. Two auxiliary input channels

may be configured for general-purpose measurements

or as specialized temperature conversion inputs when

used with RTD devices. Simple, yet fast and powerful

digital command and control is implemented through

unique, high-performance, level-shifted I2C communication ports. This allows SMBus laddering the communication and control bus on up to 31 battery modules using

the MAX11068.

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Battery Pack Architectures

Battery packs are designed in a modular fashion to allow

for multiple configurations, and fast and flexible assembly. This reduces cost by streamlining the build or repair

process. The definition of a battery pack is a system

comprising one or more battery modules connected in

either a series or matrix configuration to create a highvoltage power source. Transportation or high-power

battery-backup-system applications typically use many

series-connected battery modules to generate voltages

of up to several hundred volts. This voltage can then be

inverted and transformed to levels suitable for the given

load. A battery module is a series of cells configured as

a subsystem that can be combined with other modules

to build a high-voltage pack. For the MAX11068, the

minimum cell count per module is limited by the 6.0V

input requirement of the regulator, while the maximum

cell count is 12. The 6.0V minimum requirement usually

limits configurations to at least two lithium-ion (Li+), six

NiMH, or six SuperCap cells per module. Figure 6 is the

module system with redundant fault-detection application schematic.

Battery packs used in transportation applications may

be composed of various battery technologies (NiMH,

Li+, SuperCap, or lead acid) and typically include an

electronic battery-management system (BMS), environment control, and several safety features. Figure 7

shows the electric vehicle system (EVS).

Maxim Integrated

In hybrid electric vehicles (HEVs), plug-in hybrid electric

vehicles (PHEVs), electric vehicles (EVs), or fuel-cell

vehicles (FCVs), cell counts can range from 36 cells to

200 cells using Li+ batteries and up to as high as 200 to

500 cells using NiMH batteries. SuperCaps are typically

used in fast-charge holding applications such as regenerative braking energy storage.

There are two fundamental battery-pack management

architectures that can be realized with the MAX11068:

U Distributed module communication

U SMBus-laddered module communication

A distributed module system deploys a point-to-point

connection from each battery module back to a master

microcontroller in the BMS. Because the battery modules operate from the high-voltage battery stack, galvanic isolation must be used when communicating with the

master microcontroller. Figure 8 shows the distributed

communication battery pack.

An SMBus-laddered module system deploys a serial

communication bus that travels through each battery

module and is then accessed at one entry point in the

system by the master microcontroller in the BMS. The

SMBus ladder method reduces cost and requires at

most a single galvanic isolator between the high-voltage

batteries and the main power net. Galvanic isolation may

not be required in certain low-voltage applications. See

Figure 9.

15

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

MODULE

MODULE

N+1 CELL N+1 GND

STACK REFERECNCE

MODULE - (N+1)

SHDN

ALRMU

VDDU

GNDU

CP+

3210

OVSEL

CP-

ALRML

210

UVSEL

TOPSEL SHDN

ALRML

HV

11068

CD

ALRML

11068

VAA

MAX11080/MAX11081

DCIN

BUS BAR

C12

C11

C10

C9

C8

C7

C6

AGND

C5

C4

C3

C2

C1

ISOLATOR AND

CONTROL

INTERFACE FOR

FIRST MODULE

SCLL

SDAL

C0

C23

C22

C21

C20

C19

C18

C17

C16

C15

C14

R24

R23

R22

R21

R20

R19

R18

R17

R16

R15

C13

C24

R25

GPIO

R26

MODULE + (N)

HV

R13

R12

C12

CELL 11

R11

C11

CELL 10

R10

C10

CELL 9

R9

C9

CELL 8

R8

C8

CELL 7

R7

C7

CELL 6

R6

C6

CELL 5

R5

C5

CELL 4

R4

C4

CELL 3

R3

C3

CELL 2

R2

C2

CELL 1

R1

C1

CELL 12

BUS BAR

MODULE-(N)

BATTERY

CONNECTOR

C0

LOCAL

GROUND

C12

VDDU

C11

ALRMU

C10

SCLU

C9

SDAU

C8

GNDU

C7

MAX11068

CP+

C6

CP-

C5

VAA

C4

VDDL

C3

SCLL

C2

SDAL

C1

ALRML

C0

SHDN

THRM

GNDL

AUXIN2

GPIO0

GPIO1

GPIO2

REF

AUXIN1

AGND

MODULE N-1

CELL STACK

DCIN

NOTE: REFER TO EACH DEVICE’S APPLICATION REFERENCE CIRCUITS FOR COMPONENTS

AND VALUES NOT SHOWN ON THIS SIMPLIFIED SYSTEM-LEVEL SCHEMATIC.

Figure 6. Battery Module System with Redundant Fault-Detection Application Schematic

16

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

BATTERY PACK

MAIN

SWITCH

CONN

MOTOR DRIVE+

VEHICLE

12V PWR

COMM BUS

INVERTER

COMM BUS

VEHICLE

CONTROL

SYSTEM

(VCS)

VEHICLE GND

COMM BUS

BATTERY

MANAGEMENT

SYSTEM

(BMS)

CELL PACK

(Li 40–90 CELLS)

(NiMH 100–300 CELLS)

MOTOR DRIVECONN

Figure 7. Electric Vehicle System

INVERTER+

PACK

SWITCHES

ISOLATOR

BATTERY

MODULE

SLAVE MONITOR

AND CONTROL

TEMP

ISOLATOR

BATTERY

MODULE

SLAVE MONITOR

AND CONTROL

TEMP

ISOLATOR

BATTERY

MODULE

SLAVE MONITOR

AND CONTROL

TEMP

VEHICLE 12V PWR

MASTER

CONTROLLER

VEHICLE GND

ISOLATOR

BATTERY

MODULE

SLAVE MONITOR

AND CONTROL

COMM BUS

FAULT CHECK

TEMP

INVERTER-

PACK

SWITCHES

CURRENT

SENSE

Figure 8. Distributed Communication Battery Pack

Maxim Integrated

17

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

INVERTER+

PACK

SWITCHES

BATTERY

MODULE

SLAVE MONITOR

AND CONTROL

STUB

TEMP

BATTERY

MODULE

SLAVE MONITOR

AND CONTROL

TEMP

VEHICLE 12V PWR

MASTER

CONTROLLER

VEHICLE GND

ISO

BATTERY

MODULE

SLAVE MONITOR

AND CONTROL

COMM BUS

RPACK1

FAULT

CHECK

TEMP

RPACK2

PACK V/I

MEASUREMENT

µI

SHUNT

INVERTER-

PACK

SWITCHES

Figure 9. SMBus-Laddered Battery Module Communication

18

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Battery-Management

System (BMS)

The BMS in an electric vehicle monitors cell voltage,

pack current, and temperature. The BMS is composed

of two components. The first is the master controller of

the system that handles all communication with the VCS.

It also handles state of charge, state of health, and faultmanagement features of the battery pack. The second

component is the data-monitoring function, which gathers information on the conditions of the battery cells,

takes voltage/current/temperature measurements, and

signals safety faults.

The slave monitor controller (SLC) is directly connected

to the series stack battery cells. The SLC measures cell

voltages and module temperature, as well as controls

the cell-charge equalization feature that keeps all cells

balanced to equal states of charge. The SLCs are also

designed to report alarm conditions such as cell overvoltage or undervoltage, sense wire-open circuits, and

in the case of Li+ battery chemistries, overtemperature

situations. The SLCs are managed by the master controller. The master controller orchestrates all data acquisition and cell-balancing tasks in the slaves. The master

also measures the pack current coincident to voltage

measurements so that state of health of the battery pack

can be determined. Measurement of the current through

the pack is made across a low-value shunt resistor or

hall sensor.

Cell Inputs C0–C12

The MAX11068 contains 13 analog inputs that are used

for the differential measurement of as many as 12 battery cells. Each differential cell input can withstand up

to 9.0V and can be included in the measurement cycle

through the cell-channel scan-enable bits of the CELLEN

register (address 0x09). Cell inputs are measured differentially and level shifted down to the internal ADC by a

high-voltage mux and ADC preamp. The common-mode

range of the cell inputs from C2 to C12 is 0.5V to VHV 2.9V. Common-mode range for C1 is limited to 7.0V and

for C0 it is limited to voltages within 50mV of AGND for

proper measurements. The absolute maximum differential input between two inputs must always be observed,

which is 9.0V.

The application circuit shows RC filtering for each cell

input. The values of the resistors are chosen in large

part depending on the cell-balancing functionality that is

desired. The capacitor value chosen complements the

Maxim Integrated

resistor values to provide lowpass filtering of the ADC

measurement. Capacitor values should be in the 100nF

to 1FF range.

The first cell position between C1 and C0 must be populated for all applications with a voltage of at least 500mV.

This ensures accurate measurements for all other cell

positions as defined by the ADC specifications. When

implementing a module configuration with fewer than 12

cells, the first cell position should always be used, and

then other cell positions may be used in any configuration. Any unused cell positions should have their inputs

shorted together. Random connection of cells or the

high-voltage supplies during module configuration does

not cause adverse effects.

Measurement Scanning

When a cell is enabled for acquisition by setting the

associated scan-enable bits in the CELLEN register

(address 0x09), the appropriate cell differential input is

scheduled for conversion. The auxiliary input channels

along with the self-diagnostic channel may be similarly

enabled using their enable bits in the ADCCFG register

(address 0x08).

Conversion begins with the setting of the SCAN bit in the

SCANCTRL register. The setting of the SCAN bit may

be accomplished using either the WRITEALL command

or the WRITEDEVICE command, depending on whether

all devices are expected to perform the conversion. If

the ADC is still busy from a previous acquisition scan,

the scan command is ignored. Each module in a system begins the measurement scan cycle as soon as it

receives the scan signal. The measurement order of the

inputs during a cycle is as follows:

1) All enabled cell inputs phase 1, descending order

(12–1)

2) All enabled cell inputs phase 2, descending order

(12–1)

3) Self-diagnostic measurement phase 1, if enabled

4) Self-diagnostic measurement phase 2, if enabled

5) All enabled auxiliary inputs phase 1, ascending order

(AUXIN1, AUXIN2)

The complete acquisition of the cell voltages takes place

in two phases, which is shown in Figure 10. The first

phase is the raw cell-voltage acquisition. In this stage,

the ADC scans through all the enabled cell input channels, starting with the highest cell.

19

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

B12+

B12B11+

B11B10+

B10B9+

B8+

B8-

CELL SAMPLE

B7+

B7B6+

B6-

TOP CELL MEASURE - 5.67µs

TOP CELL SETUP - 5µs

B5+

MUX POWERUP - 6.3µs

TOP CELL SAMPLING TIME = 5.67µs

OTHER CELLS SAMPLING TIME = 3.83µs

B9-

B5B4+

B4B3+

B3B2+

B2B1-

B1+

t0 + 16.97µs

t0 - STROBE POINT

t0 + 59.1µs

t0 + 106.9µs

TIME

Figure 10. Cell-Scanning Timing

The second stage in the channel-scanning process

is the correction phase, where the front-end amplifier

chops out any offset and reference-induced errors. This

provides a high-accuracy cell voltage result. In this

stage, the channels are converted in the same highest

to lowest order as the initial measurement. The moduleto-module sampling points differ by the communication

forwarding delay from the I2C command. With the measurements from the two scan phases complete, the ADC

data is then offset corrected, averaged, and updated in

the cell data registers.

After the cell-measurement cycle is complete, the selfdiagnostic channel is acquired when enabled. It is a

two-phase measurement as described for the cell-voltage inputs, with each phase measured one immediately

after the other. Finally, the enabled auxiliary inputs are

measured. They are measured in a single conversion,

with results reported in the AIN1 and AIN2 registers.

The auxiliary channels have a configurable option to

increase settling time that is set in the lower byte of the

ACQCFG register (address 0x0C). The configured extra

settling time is implemented just before the conversion

for each AUXIN channel that is enabled for measure20

ment. So, when both auxiliary channels are measured,

the extra settling time occurs twice. Extra settling time

is not needed by the MAX11068 ADC; it is only for the

benefit of the external application circuit.

Calculating Measurement Time

The first requirement for performing a measurement

conversion is setting the SCAN bit. This can be done

by using the WRITEALL or WRITEDEVICE commands.

The write commands require 5 full bytes of data, plus 5

acknowledge bits and the start and stop bits. This totals

47 bits of data sent by the host, which would require

235Fs at a 200kHz I2C clock rate.

The timing of the cell measurements is shown in Figure

10. At the start of the measurement cycle, there is a

measurement setup time prior to the measurement of the

highest cell totaling 11.3Fs. The highest cell measured

requires a sampling time of 5.67Fs, while the rest of the

inputs are sampled at 3.83Fs per channel. When all 12

channels are enabled, the 12-cell voltages for one phase

are acquired in 47.8Fs, not including the measurement

setup time. The total acquisition time for 12 cells is

106.9Fs

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

For every module in the battery pack, a 1Fs communication delay is incurred while the scan command is forwarded up the SMBus ladder. Therefore, the difference

in the scan completion time from the first module to the

last module in a chain is no more than 1Fs x (no. of modules in the chain - 1) as shown in Figure 11.

Thus, from the time the first device receives the scan

command until the last device completes its measurement conversion, 109.9Fs elapse.

The final aspect of the measurement conversion is the

retrieval of data from all devices. A READALL command

is the only way to transfer data from each device. Since

up to 12 cells are measured, the READALL command

must be performed for each cell whose data must be

transferred. For each READALL command, there are 5

total bytes of overhead. These include the broadcast

address byte, the command code byte (register address

to be read), the I2C address byte, the data check byte,

and the packet-error check (PEC) byte. Each of these

bytes has an acknowledge bit associated with it. The

register data from each device consists of 2 more bytes

plus 2 acknowledge bits. Finally, the overall data stream

consists of 3 more bits, start, stop, and repeated start.

Thus, for a read of a single register from all modules, the

total bit count is:

Taking the module conversion time and combining it with

the communication delay, the overall sampling window

of the system can be calculated:

Sampling window = 11.3Fs + (5.67Fs + (no. of cells

enabled per module -1) x 3.83Fs) x 2 phases + ((no. of

modules per pack - 1) x 1Fs per module)

So, for a battery pack that uses 12 cells per module and

a system with four modules (total cell count = 48), the

sampling window would be:

Sampling Window = 11.3 + (5.67 + 11 x 3.83Fs) x 2 +

((4 Modules -1) x 1Fs)

Sampling Window = (106.9Fs) + (3Fs) = 109.9Fs

READALL bit count = 3 + 5 x 8 + 5 + no. of modules x

(2 x 8 + 2) = 120

MODULE N

MODULE 5

COMMAND FORWARDING

DELAY = 1µs

MODULE 4

MODULE 3

MODULE 2

MODULE 1

SCAN AT t0

tALL MODULES

tALL MODULES = (NO. OF MODULES X 1µs) + 107µs

Figure 11. Measurement Scan Timing for a Multimodule System

Maxim Integrated

21

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

For the example with four modules and 12 cells per module, the total READALL bit count would be 120 bits per

cell or 1440 bits for all 12 cells. At a 200kHz I2C clock

rate, the total time for this command would be 7.2ms.

The overall time from the host issuing the scan command

to the last data being received by the host includes the

write time for the scan command, the measurement conversion time, and the time for the READALL command.

For this 12-cell, four-module, 200kHz I2C example the

total is:

235Fs + 106.9Fs + 7200Fs = 7.542ms

Effectively, the number of complete 12-cell measurements that can be acquired and transferred back to the

host is no more than 132 per second. If the data from

every measurement is not transferred back to the host,

then significantly more measurements may be taken per

second. Enabling the auxiliary or self-diagnostic channels would decrease the effective sampling rate.

Cell Overvoltage

and Undervoltage

The MAX11068 incorporates cell-voltage monitoring with

alert and alarm capability for diagnosing system status.

After each ADC voltage conversion, cell-voltage data is

stored in the cell-data registers. Only data registers for

cell positions that were enabled for the previous measurement scan are updated. Cells that were not in the

measurement scan retain their previous value. The data

is also analyzed for the minimum, maximum, and total

V

OVERVOLTAGE SET AND CLEAR THRESHOLDS

POR DEFAULT VALUE (+5.0V)

cell-voltage values, as well as for overvoltage and undervoltage conditions.

The maximum and minimum cell voltage readings are

stored in the upper 12 bits of the MAXCELL and MINCELL

registers (addresses 0x11 and 0x12). Also stored in the

lowest 4 bits of those registers is the cell number corresponding to the data reading. Where multiple cells had

the same minimum or maximum reading, the highest cell

position having that reading is reported. The sum total

value of cell data whose measurements were enabled

in the last scan is stored in the TOTAL register (address

0x10) as a 16-bit value. Where a conversion is initiated

with no enabled cell inputs, the MINCELL, MAXCELL,

and TOTAL registers retain their current value.

Cell-voltage data is also compared against programmable cell overvoltage and undervoltage thresholds. These

thresholds are configured through the overvoltage and

undervoltage set and clear threshold registers (addresses 0x18 to 0x1B). Alerts, when enabled, are triggered

as cell voltage data passes through the set threshold

level. Conversely, alerts are cleared when the cell voltage data passes through the clear threshold level. If the

voltage data is equal to a relevant cell threshold limit,

no action occurs. Therefore, if the set threshold level is

placed at full scale for the overvoltage alert or at zero

scale for the undervoltage alert, the alert cannot trigger

and is effectively disabled. The two thresholds, set and

clear, for each condition allow for digital hysteresis to be

configured in the alarm trigger. Figure 12 is a diagram

of the programmable overvoltage and undervoltage

thresholds.

OVERVOLTAGE ALERT

SET

OVERVOLTAGE SET THRESHOLD (OVTHRSET)

OVERVOLTAGE CLEAR THRESHOLD (OVTHRCLR)

CELLN VOLTAGE

OVERVOLTAGE ALERT

CLEARED

UNDERVOLTAGE ALERT

CLEARED

UNDERVOLTAGE CLEAR THRESHOLD (UVTHRCLR)

UNDERVOLTAGE SET THRESHOLD (UVTHRSET)

UNDERVOLTAGE SET AND CLEAR THRESHOLDS

POR DEFAULT VALUE (+0.0V)

UNDERVOLTAGE ALERT

SET

t

Figure 12. Programmable Overvoltage and Undervoltage Thresholds Diagram

22

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Alerts may be enabled on a per-cell basis. Local enable

bits OVEN and UVEN are found in each cell’s data register (addresses 0x20 to 0x2B). These bits are mapped

to the equivalent bits of the OVALRTEN and UVALRTEN

registers (address 0x06 and 0x07). If these bits are

enabled for a given cell, the cell reports its overvoltage or undervoltage alert status to the appropriate alert

status register (addresses 0x04 and 0x05). The alert

status is updated whenever new cell measurement data

is available. If either of these two alerts are active for

a cell, that cell’s corresponding ALRTCELL register bit

(address 0x03) is also set. All voltage alert status register bits are zero when no alert is present and cannot be

manually cleared. To clear an active voltage alert, the

alert condition must be removed and a new measurement must be taken or the alert must be disabled.

The global ALRTOV and ALRTUV bits in the STATUS register (address 0x02) are set when any cell has an active

alert as indicated in the ALRTOVCELL or ALRTUVCELL

registers. All alerts are automatically cleared following

the next conversion cycle when the alert conditions no

longer exist. Using this tiered approach to alert reporting, the system host may quickly establish whether any

voltage alerts are active and, if necessary, determine

exactly which cells and conditions are affected.

The mismatch alert is another status condition flag that

can be enabled to signal when the minimum and maximum cell voltages are mismatched by more than a

programmed amount. The alert is enabled by setting

the ALRMMMTCHEN bit of the ADCCFG register. The

MSMTCH register (address 0x1C) sets the 12-bit threshold for the mismatch alert, ALRTMSMTCH. Whenever

MAXCELL - MINCELL > MSMTCH, the ALRTMSMTCH bit in

the STATUS register is set. The alert bit is cleared when new

conversion data does not violate the threshold condition.

Cell Balancing

The basic cell-balancing circuit for the MAX11068 incorporates the use of internal 6I switches and external

resistors to set an equalization discharge current that is

dependent on cell voltage. Figure 13 shows the basic

circuit used with the internal cell-balancing switches.

Managing Power

The MAX11068 contains 12 independently controlled

switches that have a typical on-resistance (RSW) of

6I with Q50% variation due to process and temperature. The package used for the MAX11068 is a 38-pin

TSSOP package with a maximum power limit (PMAX) of

1.2698W and a junction-to-ambient thermal resistance of

+63NC/W for a multilayer board. These parameters are

the fundamental limits for the package-power dissipation and require careful consideration when using the

internal cell-balancing switches since the switches are

the dominant power consumers in the device. For operating margin, it is recommended targeting a maximum

power level that is 70% of the absolute maximum rating.

The maximum die junction temperature that is allowed

is +150NC. A built-in overtemperature protection circuit

protects the die at a junction temperature of +145NC,

however. When the overtemperature limit is reached, the

internal cell-balancing switches are disabled. The associated cell-balancing switch enable bits in the Balancing

Switch Control register (BALCFG at address 0x0B) are

not directly affected, but the resulting power down of

the linear regulator may cause a power-on reset (POR)

condition, which would reset the BALCFG register and

deassert all switch-enable bits. The maximum number of

cell-balancing switches that can be enabled at any one

time is calculated as shown below:

Maximum number of enabled switches = (0.7 x PMAX)/

((IBALANCE)2 x RSW)

where:

IBALANCE = VCELL/((2 x REQ) + RSW)

PMAX = 1.2698W

RSW = 6I, typical

Table 1 lists example results obtained based on the

formula above.

CELL BALANCING

F1

REQ

F2

REQ

MAX11068

RSW

CF

The following limitations must be taken into account

when using the basic circuit:

U Maximum power dissipation allowed in the package

CN+1

CN

U Measurement during cell balancing

U Current variation due to enabled adjacent cell switches

U Protection from open-circuit faults in the battery stack

destroying the MAX11068

Maxim Integrated

Figure 13. Cell-Balancing Switch Network

23

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Table 1. Cell-Balancing Circuit Parameter Variation

UNITS

HIGH-SIDE

ACCURACY (%)

LOW-SIDE

ACCURACY (%)

CELL NAME

MIN

TYP

MAX

REQ

5.1

5.2

5.3

I

1

-1

CF

9

10

11

FF

10

-10

RSW

3

6

9

I

50

-50

VCELL

4.1

4.1

4.1

V

NA

NA

IBALANCE

308

250

210

mA

16

-23

FILTER3dB

3435

3061

2755

Hz

—

—

tSETTLE at CN+1 (Note 1)

0.6

0.8

1.1

ms

—

—

Max No. of Switches On

(Note 2)

3

2

2

Switches

—

—

Note 1: tSETTLE is five time constants after the cell-balancing switch is disabled.

Note 2: Nonadjacent cell switches.

Based on the calculations, up to two nonadjacent internal cell-balancing enabled switches are supported for

a discharge current of 250mA per cell. At least a 0.5W

rated REQ is required to handle the 250mA nominal current and its worst-case range of 210mA to 308mA.

Measurements During Cell Balancing

When using the internal cell-balancing switches, the

measured voltage on the CN to CN+1 input is reduced

by the external REQ resistors. For accurate cell-voltage

measurements, disabling the internal cell-balancing

switch is required. These switches are not disabled

automatically during a conversion. After the internal cellbalancing switch is disabled, allow the input voltage to

settle for a time period (tSETTLE), which is determined by

external components CF and REQ, before performing a

cell-measurement sequence:

F1

REQ

F2

REQ

C5

CF

VCELL5

VCELL4

RSW

C4

CF

IDIS

RSW

C3

F3

REQ

Figure 14. Discharge Current Path for Adjacent Enabled

Balancing Switches

tSETTLE = 10 x REQ x CF

Current Variation Due to Enabled

Adjacent Cell Switches

If adjacent internal cell-balancing switches are enabled,

the discharge current would be much higher than the

desired value. Figure 14 shows the adjacent enabled balancing switches and the resulting discharge current (IDIS):

IDIS = (VCELL5 + VCELL4)/(2 x REQ + (2 x RSW))

From the IDIS equation, it is apparent that the discharge

current grows with the number of adjacent active internal

cell-balancing switches. This is because the cell voltages

across the active switches and the RSW values are grow-

24

ing proportionally, but REQ remains fixed no matter how

many adjacent switches are active. Consequently, the

numerator of the discharge current equation grows faster

than the denominator with increasing active switch count

and discharge current increases. Unless this is accounted

for by the host controller, the package power-dissipation

limit could be reached unexpectedly and damage to the

device could occur. To avoid this possibility, it is recommended to use an odd or even switch-enable control

scheme for the internal cell-balancing switches.

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

Protection from Open-Cell Faults

There are two methods of protecting the MAX11068 from

damage due to an open circuit occurring in a series battery stack:

U An external fuse placed in series with the internal or

external cell-balancing circuit protects against highvoltage damage. If an external MOSFET is used, as in

the circuits described below, the high-value resistors

protect the MAX11068 inputs from damage during an

open-cell condition.

U Detection of any cell dropping below ground or violating the undervoltage condition indicates an opencell condition and that the electric motor is supplying

voltage to the battery pack. To prevent damage, the

switches connecting the battery stack to the load

should be opened immediately after the undervoltage flag asserts.

External Cell-Balancing Circuit

The MAX11068 allows external cell balancing to be

implemented by using the internal switch to control

the bias network of an external transistor. When the

internal switch is closed, the external resistors RBIAS1

and RBIAS2 form the bias network used to turn on the

external bipolar or MOSFET transistor. The discharge

current of the battery is set with resistor REQ. The following sections describe different external cell-balancing

circuits in more detail. Figure 15 is a simplified external

cell-balancing circuit.

External Cell Balancing with

a Bipolar Transistor

When using an external bipolar transistor, it is recommended to select one with current gain (hFE) greater

than 100 and a VCE voltage that is rated to the overall

pack voltage to avoid damage should an open circuit

occur in the cell stack. If a bipolar transistor with a lower

voltage rating is chosen, then series fuses are recom-

mended to protect the circuit. Typical component values

for a 500mA cell discharge current are (see Figure 16):

RBIAS = 80I

REQ = 8I

Bipolar transistor = MJD50 (for high-voltage tolerance) or

MMBTA05 (for low cost and low voltage)

External Cell Balancing with a MOSFET

When using an external MOSFET, it is recommended to

select one with low VGS (typically around 1.2V) and a

VDS voltage that is rated to the overall pack voltage to

avoid damage should an open circuit occur in the cell

stack. If a MOSFET with lower voltage rating is chosen,

series fuses are recommended to protect the circuit. See

Figure 17. Typical component values for a 500mA cell

discharge current are:

RBIAS1 = 10kI

RGATE = 470ω

REQ = 8I

MOSFET = NTK3134N (for low cost, low voltage)

External cell balancing with a MOSFET switch results in

little to no cell-to-cell interaction. The RBIAS resistor value

combined with the input bias current requirements does

add a small measurement error of less than 1mV worst

case for a 10kω RBIAS value.

The recommended NTK3134N FETs have built-in gateprotection diodes. During hot-plug conditions, inrush

current flows through RBIAS and internal ESD diodes to

charge the HV to DCIN capacitor. This current creates a

negative VGS voltage that can turn on the gate-protection diodes and possibly damage the transistor devices.

A series resistor of no less than 470ω should be placed

in series with the transistor gate to make the circuit

robust under cell hot-plug conditions. For other transistors, the negative VGS condition must be controlled so

that it is tolerated by the devices.

F1

REQ

RBIAS1

RBIAS1

REQ

RSW

RGATE

F2

Figure 15. Simplified External Cell-Balancing Circuit

CF

DCLAMP

RBIAS2

Maxim Integrated

CN+1

RBIAS2

CN

Figure 16. External Cell-Balancing Circuit with a Bipolar

Transistor

25

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

F1

RBIAS1

CN+1

CBPDIV1 CBPDIV0 BIT 3 BIT 2 BIT 1 BIT 0

REQ

CF

32.768kHz

CBPDIV

RGATE

DCLAMP

F2

RBIAS2

CELLBALANCING

SWITCH [n]

ENABLE

BALCFG [bit n]

CBTIMER

ENABLE

CN

Figure 17. External Cell-Balancing Circuit with a MOSFET

Transistor

Cell-Balancing

Watchdog Timeout

The MAX11068 implements a watchdog-style timeout

feature for the cell-balancing switch enables. A countdown timer is clocked at a rate specified by a predivider.

The full range of possible timeout values is 0 to 240s. In

the event of unexepected communication loss, the cellbalancing switches are safely disabled after the timer

reaches zero. The timeout disables the cell switches with

a signal separate from those of the BALCFG register.

Thus, the BALCFG register value is not affected by the

cell-balancing timeout condition. Figure 18 shows the

timeout circuit block diagram.

The cell-balancing timeout feature consists of a 4-bit

countdown timer and a predivider with 2 control bits

for range selection. Both the timer and predivider are

programmed through the MSB of the ACQCFG register

(address 0x0C). The predivider sets the effective LSB

time period of the timer. The user-selectable choices are

shown in Table 2.

The cell-balancing timer counts down at the rate specified by the predivider, CBPDIV[1:0]. The timer starts

when the CBPDIV control bits are written to one of the

three enabled settings. The CBTIMER[3:0] bits are readable and writeable and return the value of the timer as

sampled during the acknowledge bit time of the register

address bit of the READALL command. The host application should periodically rewrite the ACQCFF register

value to ensure that this value does not unintentionally

go to zero. The timeout can be set to any value within the

timer range specified by the CBPDIV setting by choosing the appropriate value to write to the CBTIMER byte.

If the value of the CBTIMER does reach zero, the cellbalancing switches are disabled until the timer is either

disabled or is refreshed by writing a nonzero value. If

26

CBTIMER

ZERO

FLAG

Figure 18. Cell-Balancing Timer Block Diagram

Table 2. Cell-Balancing Predivider

Settings

CBPDIV[1:0]

SETTING

TIMER LSB

PERIOD (s)

TIMER RANGE

(MIN TO MAX) (s)

00

Timer disabled

Timer disabled

01

1

1 to 15

10

4

4 to 60

11

16

16 to 240

the timer is enabled by writing the CBPDIV bits while the

CBTIMER value is at 00h, the cell-balancing switches

are not disabled. The first transition of CBTIMER to the

00h value when the timer is enabled disables the balancing switches.

Internal Regulator and

Charge Pump

The MAX11068 incorporates a linear regulator for generating the internal supply from DCIN. The regulator

can accept a supply voltage on the DCIN pin from 6.0V

to +70V, which it regulates to 3.3V to run the voltagemeasurement system, control logic, and low-side communication interface. The regulator is designed to supply up to 10mA of current. When the SHDN pin and die

temperature protection are not active and a sufficient

voltage is applied to DCIN, the output of the regulator

becomes active. The regulator is paired with a poweron POR circuit that senses its output voltage and holds

the MAX11068 in a reset state until the internal supply

has reached a sustainable threshold of +3.0V (Q5%).

The internal comparator has built-in hysteresis that can

handle noise on the supply line, as well as slow supply ramps of 1V/s. Since secondary metal batteries are

never fully discharged to 0V, the MAX11068 is designed

Maxim Integrated

�MAX11068

12-Channel, High-Voltage Sensor, Smart

Data-Acquisition Interface

for a hot-swap insertion of the battery cells. Once the

POR threshold is reached, the internal RESET signal

disables. A status bit, RSTSTAT in the STATUS register

(address 0x02), is set when power is restored to the

digital logic following a reset event to denote that a reset

has occurred. It should be checked and cleared by the

system controller so that any future reset condition can

be resolved. Figure 19 is the internal low-dropout regulator block diagram.

The MAX11068 power-up sequence is shown in Figure

20. Starting with no DC power applied, the device waits

for a power source and then waits until the SHDN signal

is deactivated. If the internal die temperature limit is

not exceeded, the regulator is enabled. The regulator

begins to regulate the DCIN input voltage down to 3.3V.

After VAA has reached the rising POR threshold, the

internal POR signal is deasserted and the various sections of the device begin to initialize, starting with the

32kHz oscillator. An additional 280Fs after the oscillator

becomes active, the digital logic becomes active and

the charge pump begins operating. The charge pump

reaches full regulation in approximately 3ms depending

on the external circuit components used, at which time

the MAX11068 is ready for operation. When the charge

pump achieves regulation of 3.4V between VDDU and

DCIN

+6.0V TO +72V

GNDU, it switches to a standby mode until the voltage

drops by 20mV to minimize operation during light loading. The specification accuracies and full operation of

the MAX11068 are not guaranteed until a minimum of

6.0V is applied to the DCIN pin. The regulator has built-in