EVALUATION KIT AVAILABLE

Click here for production status of specific part numbers.

MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

General Description

The MAX14819/MAX14819A low-power, dual-channel,

IO-Link® master transceiver with sensor/actuator powersupply controllers is fully compliant with the latest IO-Link

and binary input standards and test specifications, IEC

61131-2, IEC 61131-9 SDCI, and IO-Link 1.1.3. This

master transceiver also includes two auxiliary digital input

(DI_) channels.

The MAX14819/MAX14819A is configurable to operate

either with external UARTs or using the integrated framers on the IC.

To ease selection of microcontroller, the master transceiver

features frame handlers with UARTs and FIFOs. These

are designed to simplify time critical control of all IO-Link

M-sequence frame types. The MAX14819/MAX14819A

also features autonomous cycle timers, reducing the need

for accurate controller timing. Integrated establish-communication sequencers also simplify wake-up management.

The device message response delay on the MAX14819A

can be disabled when using the frame handler and

the MAX14819A features higher L+ thresholds than

the MAX14819. The MAX14819A receivers also feature

increased high-frequency signal isolation compared to

the MAX14819.

The MAX14819/MAX14819A integrates two low-power

sensor supply controllers with advanced current limiting,

reverse current-blocking, and reverse polarity protection

capability to enable low-power robust solutions.

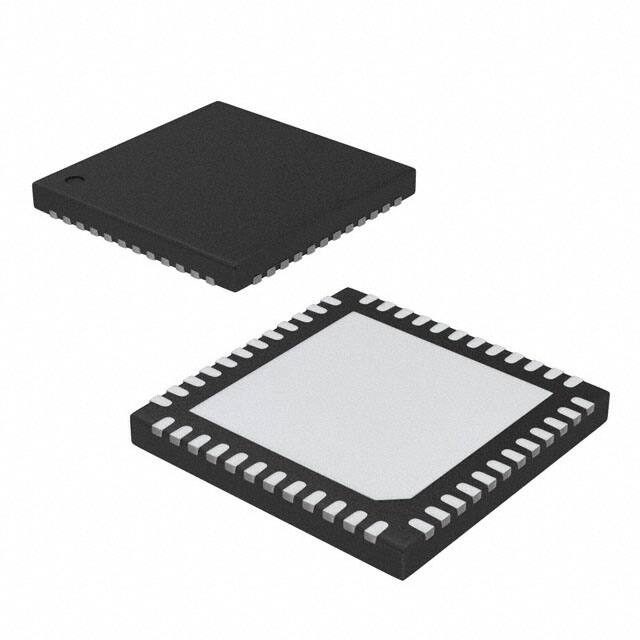

The MAX14819/MAX14819A is available in a 48-pin

(7mm x 7mm) TQFN package and is specified over the

extended -40°C to +125°C temperature range.

Applications

●● IO-Link Master Systems

●● IO-Link Gateways

19-8744; Rev 3; 3/20

Benefits and Features

●● Low-Power Architecture

• 1Ω (typ) Driver On-Resistance

• 1.9mA (typ) Total Supply Current for 2 Channels

• Current Limiters with 15mV Sense Voltage

●● Integrated IO-Link Framer Eliminates Need for

External UARTs

• Integrated Cycle Timer Relieves Microcontroller

from Timing-Critical Tasks

●● High Configurability and Integration Reduce SKUs

• Two Auxiliary Type 1/Type 3 Digital Inputs

• Supports NPN Sensors

• Dual 24V Sensor Supply Controllers Include:

• Large Capacitive Load Charge Capability

• 2A and Higher Load Currents

●● Integrated Protection Enables Robust Systems

• Reverse Polarity Protection on All Interface Pins

• Overvoltage Tolerance on All Interface Pins

• C/Q and DI Fully Compliant with IEC 61131-2

• C/Q Compliant with IO-Link 1.1.3.

• Reverse Current Blocking on L+ and C/Q

• 65V Absolute Max Ratings for TVS Flexibility

• Glitch Filters for Improved Burst Resilience

• -40°C to +125°C Operating Temperature Range

Ordering Information appears at end of data sheet.

IO-Link is a registered trademark of Profibus User Organization

(PNO).

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Typical Operating Circuit

24V

10µF

3.3V

5V

VL V5 REGEN VCC

MAX12930

µC

3.3V

SN2A G2A L+A

IRQ

5V

MAX14931

SN1A

G1A

1µF

100Ω

1µF

XI

14.7456MHz

CQA

MAX14819

MAX14819A

SPI

DIA

330pF

100Ω

XO

CLKO

CLKI

3.3V

A0 A1

TXA

TXENA

GND

RXRDYA/LD1A

RXERRA/LD2A

THE MAX14819/MAX14819A IS A DUAL-CHANNEL MASTER TRANSCEIVER. ONLY ONE CHANNEL IS SHOWN HERE. OPERATED WITH INTERNAL IOLINK FRAMER.

Functional Diagram

VL

V5

MAX14819

MAX14819A

REGEN

VCC

G1A

G1B SN1A

SN1B

SN2A

SN2B G2A

G2B

REG

XI

XO

CLKI

XTAL

OSCILLATOR

CLKO

ESTABLISH

COMM

L+ SUPPLY CONTROLLER

L+A

L+B

RXA

RXB

TXENA

CQA

TXENB

CQB

DRIVER

TXA

TXB

RXERRA/LD2A

RXERRB/LD2B

FRAME HANDLER

RXRDYA/LD1A

DIA

RXRDYB/LD1B

IRQ

SDI

SDO

SCLK

CS

DIB

SYNC

SPI

REGISTERS

A1

www.maximintegrated.com

CYCLE TIMER

A0

CHANNEL A

CHANNEL B

GND

LIB

LIA

Maxim Integrated │ 2

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Absolute Maximum Ratings

(All voltages referenced to GND, unless otherwise noted.)

VCC............................. max [(VPM - 70V), (VCQ_ - 70V)] to +65V

V5, VL.......................................................................-0.3V to +6V

REGEN.............................. -0.3V to the min(VCC + 0.3V or +6V)

CQA, CQB................................................... (VCC - 70V) to +65V

DIA, DIB, L+A, L+B..................................... (VPM - 70V) to +65V

SN1A, SN1B...........................................................-0.3V to +65V

SN2A...................................... (VSN1A - 0.3V) to (VSN1A + 0.3V)

SN2B...................................... (VSN1B - 0.3V) to (VSN1B + 0.3V)

G1A, G2A............max (-0.3V, [VSN1A - 14V]) to (VSN1A + 0.3V)

G1B, G2B............max (-0.3V, [VSN1B - 14V]) to (VSN1B + 0.3V)

XI, XO........................................................... -0.3V to (V5 + 0.3V)

Logic Inputs

CS, SDI, SCLK, A_, TXEN_, TX_, CLKI.... -0.3V to (VL + 0.3V)

Logic Outputs

SDO, IRQ, LI_, RX_, RXRDY_/LD1_,

RXERR_/LD2_, CLKO ............................ -0.3V to (VL + 0.3V)

Continuous Current Into GND and VCC.................................±2A

Continuous Current Into CQA and CQB................................±1A

Continuous Current Into V5.............................................±100mA

Continuous Current Into Any Other Pin.............................±50mA

Continuous Power Dissipation

TQFN (derate 40mW/°C above +70°C)............................3.2W

Operating Temperature Range.......................... -40°C to +125°C

Maximum Junction Temperature.......................Internally Limited

Storage Temperature Range............................. -65°C to +150°C

Soldering Temperature (reflow)........................................+260°C

VPM = max (0V, VCC, DIA, DIB, SN1A, SN1B, L+A, L+B)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may affect

device reliability.

Package Information

PACKAGE TYPE: 48 TQFN-EP

Package Code

T4877+4C

Outline Number

21-0144

Land Pattern Number

90-0130

MULTILAYER BOARD

Junction to Ambient (θJA)

25°C/W

Junction to Case (θJC)

1°C/W

Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-layer board.

For detailed information on package thermal considerations, refer to www.maximintegrated.com/thermal-tutorial.

For the latest package outline information and land patterns (footprints), go to www.maximintegrated.com/packages. Note that a “+”,

“#”, or “-” in the package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing

pertains to the package regardless of RoHS status.

www.maximintegrated.com

Maxim Integrated │ 3

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

DC Electrical Characteristics

(VCC = 9V to 36V, V5 = 4.5V to 5.5V, VL = 1.62V to 5.5V, VGND = 0V, all logic inputs at VL or GND; TA = -40°C to +125°C, unless otherwise

noted. Typical values are at VCC = 24V, V5 = 5V, VL = 3.3V, and TA = +25°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

9

36

V

7

9

V

VCC POWER

VCC Supply Voltage

VCC Undervoltage-Lockout

Threshold

VCC Undervoltage-LockoutThreshold Hysteresis

VCC Supply Current

VCC

VCCUVLO

VCC rising

VCCUVLO_HYST

ICC

VCC Warning Threshold

VCC_WRN

VCC Warning Threshold

Hysteresis

VCC_WHY

340

REGEN = GND,

L+EnA = L+EnB =

1, external clock

selected, CQ_ in

push-pull

configuration,

CL[1:0] = 00, no

load on CQ_

CQ_ outputs low

0.4

mV

0.75

mA

CQ_ outputs high

0.5

16

0.85

18

500

V

mV

V5 POWER

V5 Supply Voltage

V5 Supply Current

V5

REGEN = GND

IV5

REGEN = GND,

L+EnA = L+EnB =

1, external clock

selected, CQ_ in

push-pull

configuration,

CL[1:0] = 00, no

load on CQ_

4.5

CQ_ outputs low

5

5.5

1.4

1.9

V

mA

CQ outputs high

1.4

1.9

V5 LINEAR REGULATOR

V5 Output Voltage

V5 Current Limit

V5 Load Regulation

REGEN Pullup Current

REGEN Threshold

www.maximintegrated.com

V5

REGEN unconnected, no load on V5,

CQ_ disabled, L+EnA = L+EnB = 0

4.75

ICL_V5

REGEN unconnected, CQ_ disabled,

L+EnA = L+EnB = 0

20

dVV5

REGEN unconnected, CQ_ disabled,

L+EnA = L+EnB = 0, 0mA ≤ ILOAD ≤

20mA

IREGEN

VTH_REGEN

VREGEN = 0V

5.25

mA

-0.1

5

0.2

V

1.8

mV/mA

30

μA

2.6

V

Maxim Integrated │ 4

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

DC Electrical Characteristics (continued)

(VCC = 9V to 36V, V5 = 4.5V to 5.5V, VL = 1.62V to 5.5V, VGND = 0V, all logic inputs at VL or GND; TA = -40°C to +125°C, unless otherwise

noted. Typical values are at VCC = 24V, V5 = 5V, VL = 3.3V, and TA = +25°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

1.62

5.5

V

0.4

1.5

V

VL POWER

VL Logic-Level Supply

Voltage

VL

VL Undervoltage Threshold

VLUVLO

VL Undervoltage Threshold

Hysteresis

VLUVHYS

VL Logic-Level Supply

Current

VL falling

50

mV

IL

All logic inputs at VL or GND, all logic

outputs unconnected

ROH

High-side enabled, ILOAD = -200mA

1.0

2

ROL

Low-side enabled, ILOAD = +200mA

1.0

2.2

5

µA

CQ_ DRIVER

Driver On-Resistance

Driver Current Limit

ICL

VCQ_ = (VCC - 3V)

or 3V

CL[1:0] = 00

100

150

CL[1:0] = 01

190

280

CL[1:0] = 10

280

410

CL[1:0] = 11

500

650

IEC3Th_/DiEC3Th

=0

10.5

13.0

IEC3Th_/DiEC3Th

=1

7.5

11.0

IEC3Th_/DiEC3Th

=0

8.0

11.5

IEC3Th_ /DiEC3Th

=1

6.0

8.0

Ω

mA

CQ_, DI_ RECEIVER

CQ_, DI_ Input Threshold

High

CQ_, DI_ Input Threshold

Low

CQ_, DI_ Input Threshold

Hysteresis

VTH

VTL

VHYS

CQ_ driver disabled

CQ_ driver disabled

CQ_ driver disabled

ICQ_SNK

VCQ_ > 5V,

SourceSink_ = 0

V

IEC3Th_/DiEC3Th

=0

2

IEC3Th_/DiEC3Th

=1

2

2mA pulldown

enabled

CQ_ Current Sink

V

V

2

2.5

2.75

(SinkSel_[1:0] = 10)

5mA pulldown

enabled

mA

5

5.8

6.6

(SinkSel_[1:0] = 01)

www.maximintegrated.com

Maxim Integrated │ 5

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

DC Electrical Characteristics (continued)

(VCC = 9V to 36V, V5 = 4.5V to 5.5V, VL = 1.62V to 5.5V, VGND = 0V, all logic inputs at VL or GND; TA = -40°C to +125°C, unless otherwise

noted. Typical values are at VCC = 24V, V5 = 5V, VL = 3.3V, and TA = +25°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

2mA pullup enabled

CQ_ Current Source

ICQ_SRC

(VCC - VCQ_) > 5V, (SinkSel_[1:0] = 10)

SourceSink_ = 1 5mA pullup enabled

(SinkSel_[1:0] = 01)

MIN

TYP

MAX

-2.75

-2.5

-2

UNITS

mA

-6.6

-5.8

-5

CQ_ Weak Pulldown Current

ICQ_PD

Driver disabled (DrvDis_ = 1),

SourceSink = 0, weak pulldown enabled

(SinkSel_[1:0] = 11), VCQ_ > 5V

150

250

μA

CQ_ Weak Pullup Current

ICQ_PU

Driver disabled (DrvDis_ = 1),

SourceSink = 1, weak pullup enabled

(SinkSel_[1:0] = 11), VCC - VCQ_ > 5V

-250

-150

μA

ICQ

CQ_ driver enabled (DrvDis = 0),

CQ_set to high impedance, pullup and

pulldown disabled (SinkSel_[1:0] = 00),

receiver enabled, VCC = 24V,

-1V < VCQ_ < (VCC + 1V)

-60

+400

μA

ICQ_EXT

CQ_ driver enabled (DrvDis = 0),

CQ_set to high impedance, pullup and

pulldown disabled (SinkSel_[1:0] = 00),

receiver enabled, VCC = 24V,

(VCC - 65V) < VCQ_ < 60V

-200

+500

μA

ICQ_LKG

CQ_ driver disabled (DrvDis = 1), pullup

and pulldown disabled (SinkSel_[1:0] =

00), receiver enabled, VCC = 24V,

(VCC - 65V) < VCQ_ < 60V

-100

+100

μA

CQ_ Push-Pull High

Impedance Current

ICQ_HiZ

CQ_ driver enabled (DrvDis = 0), CQ_in

push-pull, pullup and pulldown disabled

(SinkSel_[1:0] = 00), receiver enabled,

VCC = 24V, 0V < VCQ_ < 24V

-50

+50

μA

DI_ Current Sink

IDI_SNK

VDI_ > 5V, DiCSink = 1

2

2.5

3

mA

DI_ Current Source

IDI_SRC

VCC - VDI_ > 5V, DiCSource = 1

-3

-2.5

-2

mA

IDI

Pullup and pulldown disabled, DI_

receiver enabled, VCC = 24V,

-1V < VDI_ < (VCC + 1V)

-5

+50

μA

IDI_EXT

Pullup and pulldown disabled, DI_

receiver enabled, VCC = 24V,

(VCC - 65V) < VDI_ < 60V

-100

+100

μA

CQ_ Input Current

CQ_ Input Current, Extended

Range

CQ_ Leakage Current

DI_ Input Current

DI_ Input Current, Extended

Range

www.maximintegrated.com

Maxim Integrated │ 6

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

DC Electrical Characteristics (continued)

(VCC = 9V to 36V, V5 = 4.5V to 5.5V, VL = 1.62V to 5.5V, VGND = 0V, all logic inputs at VL or GND; TA = -40°C to +125°C, unless otherwise

noted. Typical values are at VCC = 24V, V5 = 5V, VL = 3.3V, and TA = +25°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

0.2 x VL

V

LOGIC INPUTS (CS, SDI, SCLK, A1, A0, TXENA, TXENB, TXA, TXB, CLKI)

Logic Input Voltage Low

VIL

Logic Input Voltage High

VIH

Logic Input Leakage Current

ILEAK

0.8 x VL

Logic input = GND or VL

V

-1

+1

µA

0.4

V

LOGIC OUTPUTS (SDO, IRQ, LIA, LIB, RXA, RXB, RXRDYA/LD1A, RXERRA/LD2A, RXRDYB/LD1B, RXERRB/LD2B, CLKO)

Logic Output Voltage Low

VOL

IOUT = -5mA

Logic Output Voltage High

VOH

RX_, LI_, SDO, and CLKO, IOUT = 5mA

Output Leakage Current

IOH

RXRDY_/LD1_, RXERR_/LD2_, IRQ,

output is high impedance, output is

pulled up to 5V

VL - 0.4

V

-1

+1

µA

CRYSTAL OSCILLATOR (XI, XO)

Crystal Oscillator Current

Supply

IV5_XTAL

fXTAL = 14.7456MHz, V5 supply current

increase versus external clocking

Crystal Equivalent Series

Resistance

ESRXTAL

fXTAL = 14.7456MHz (Note 2)

75

Ω

COXTAL

fXTAL = 14.7456MHz (Note 2)

8

pF

Crystal Shunt Capacitance

Input Capacitance

CIN

240

µA

XI

10

XO

10

(Notes 3, 4)

55

µA

3.686

MHz

pF

INTERNAL OSCILLATOR

Internal Oscillator Current

Consumption

IV5_OSC

EXTERNAL CLOCK INPUT (CLKI)

External Clock Frequency

fECLK

External Clock Detection

fECLK_DET

CLKI Capacitance

Minimum CLKI frequency for operation

0.5

CCLKI

2

2

MHz

pF

L+ SENSOR SUPPLIES WITH CURRENT LIMITING AND REVERSE BLOCKING (L+A, L+B)

Reverse Current Blocking

Threshold

VTH_RCB

G1_/G2_ Gate-to-Source

On-Voltage

VG_ON

VRCB = (VSN1_ -VCC)

VSN1_ > 18V

VSN1_ 14V

mV

VSN1_ 11V

V

G2_ Minimum Gate-to-Source

Voltage Under Regulation

VG2_REG

G1_ Gate Turn-Off Switch

Resistance

RG1_OFF

G1_ pulled to SN1_

50

Ω

G2_ Gate Turn-Off Switch

Resistance

RG2_OFF

G2_ pulled to SN2_

50

Ω

www.maximintegrated.com

VSN1_ 0.8V

160

V

Maxim Integrated │ 7

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

DC Electrical Characteristics (continued)

(VCC = 9V to 36V, V5 = 4.5V to 5.5V, VL = 1.62V to 5.5V, VGND = 0V, all logic inputs at VL or GND; TA = -40°C to +125°C, unless otherwise

noted. Typical values are at VCC = 24V, V5 = 5V, VL = 3.3V, and TA = +25°C, unless otherwise noted.) (Note 1)

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

L+_ Current-Limit Threshold

PARAMETER

VCL_T

VCL_T = (VSN1_ - VSN2_), L+CL2X_ = 0

12.75

15

18.5

mV

L+_ Double Current-Limit

Threshold

VCL_2T

VCL_2T = (VSN1_ - VSN2_), L+CL2X_ = 1,

VCC = VSN1_ = 24V, VL+ _ > 18V

25.5

30

36

mV

SN1_ Supply Current

ISN1ACT

VL+ > 18V, L+En_ = 1, L+CL2X_ = 1

0.23

0.325

mA

+10

μA

20

μA

-50

+50

μA

MAX14819

16

18

MAX14819A

18

20

MAX14819

15.5

17.5

MAX14819A

17.5

19.5

SN2_ Input Current

L+_ Input Current

L+_ Extended Range Input

Current

ISN2

IL+

VSN2_ = VSN1_

VL+_ = 30V

IL+_EXT

VCC = VSN1_ = 24V, (VCC - 60V) < VL+_

< 60V

VTL+_R

L+_ rising

VTL+_F

L+_ falling

L+_ Power Good Threshold

L+_ Power Good Hysteresis

L+_ Dynamic Blanking

Threshold

-10

V

V

VTL+H

0.4

V

VLPDTHR

8.8

V

+135

°C

15

°C

THERMAL MANAGEMENT

Thermal-Warning Threshold

TWRN

Thermal-Warning Threshold

Hysteresis

TWRN_HYS

Die junction temperature rising,

TempW and TempWInt bits are set

Die junction temperature falling,

TempW bit cleared

CQ_ Thermal-Shutdown

Temperature

TSHUT

Driver temperature rising, temperature

at which the driver is turned off. ThShut

and ThuShutInt bits are set

+160

°C

Thermal-Shutdown

Temperature Hysteresis

TSHUT_HYS

Driver temperature falling. ThShut bit is

cleared

15

°C

www.maximintegrated.com

Maxim Integrated │ 8

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

AC Electrical Characteristics

(VCC = 18V to 30V, V5 = 4.5V to 5.5V, VL = 1.62V to 5.5V, VGND = 0V; TA = -40°C to +125°C, unless otherwise noted. Typical values

are at VCC = 24V, V5 = 5V, VL = 3.3, and TA = +25°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

0.45

0.90

UNITS

CQ_ DRIVER

Push-pull and PNP configuration, Figure 1

Driver Low-to-High Propagation

Delay

tPDLH

Driver High-to-Low Propagation

Delay

tPDHL

PNP configuration, Figure 1

(no capacitive load)

Driver Skew

tSKEW

|tPDLH - tPDHL|, Figure 1

Driver Rise Time

tRISE

Push-pull and PNP configuration, Figure 1

0.25

Driver Fall Time

tFALL

Push-pull and NPN configuration, Figure 1

0.25

Driver Enable Time High

tENH

Driver Enable Time Low

tENL

Driver Disable Time High

Driver Disable Time Low

NPN configuration, Figure 1

(no capacitive load)

μs

5

Push-pull and NPN configuration, Figure 1

0.43

0.90

μs

5

0.2

μs

0.42

0.75

μs

0.42

0.75

µs

Push-pull and PNP configuration, Figure 2

0.45

0.9

µs

Push-pull and NPN configuration, Figure 3

0.26

0.9

µs

tDISH

Push-pull and PNP configuration, Figure 2

1.9

3

µs

tDISL

Push-pull and NPN configuration, Figure 3

1.7

3

µs

MAX14819

0.28

0.5

MAX14819A

0.53

0.8

MAX14819

1.2

2

MAX14819A

1.5

2.3

MAX14819

0.25

0.5

MAX14819A

0.31

0.8

MAX14819

1.2

2

MAX14819A

1.3

2.3

CQ_ RECEIVER (Figure 4)

CQ_ Receiver Low-to-High

Propagation Delay

CQ_ Receiver High-to-Low

Propagation Delay

CQ_ Receiver Skew

www.maximintegrated.com

CQFilterEn_ = 0

tCPRLH

CQFilterEn_ = 1

CQFilterEn_ = 0

tCPRHL

CQFilterEn_ = 1

tCRSKEW

|tCPRLH tCPRHL|

(Note 3)

CQ

FilterEn_ = 0

MAX14819

0.1

MAX14819A

0.4

CQ

FilterEn_ = 1

MAX14819

0.1

MAX14819A

0.4

µs

µs

µs

µs

Maxim Integrated │ 9

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

AC Electrical Characteristics (continued)

(VCC = 18V to 30V, V5 = 4.5V to 5.5V, VL = 1.62V to 5.5V, VGND = 0V; TA = -40°C to +125°C, unless otherwise noted. Typical values

are at VCC = 24V, V5 = 5V, VL = 3.3, and TA = +25°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

MAX14819

1.9

3

MAX14819A

1.3

3

MAX14819

2.9

4.2

MAX14819A

2.3

4.2

MAX14819

1.3

3

MAX14819A

1.0

3

MAX14819

2.3

4.2

MAX14819A

2.0

4.2

DiFilterEn_

=0

0.5

1

0.3

1

DiFilterEn_

=1

0.5

1

0.3

1

UNITS

DI_ RECEIVER (Figure 4)

DI_ Receiver Low-to-High

Propagation Delay

DI_ Receiver High-to-Low

Propagation Delay

DI_ Receiver Skew

DiFilterEn = 0

tDPRLH

DiFilterEn = 1

DiFilterEn = 0

tDPRHL

DiFilterEn = 1

tDRSKEW

|tDPRLH - tDPRHL|

µs

µs

µs

WAKE-UP PULSE

Delay Time to Wake-Up Pulse

tSU_WU

Wake-Up Pulse Duration

tWU

On-Time After Wake-Up

tON_WU

(Figure 9)

Wake-up (WU) pulse has the opposite

polarity of the CQ_ line before the WU pulse

was generated

80

75

80

µs

85

µs

Driver enabled with original polarity on

CQ_ line

2

µs

Delay between (VRCB rising > VTH_RCB)

and IGATE2_ turned off

10

μs

L+ CURRENT LIMITING

Reverse Current Blocking

Response Time

tRCB

Reverse Current Blocking

Threshold

VTH_RCB

Current-Limit Blanking Time

tL+CLBL

VRCB = (VSN1_ - VCC)

L+BL_[1:0] = 00

5

5.5

L+BL_[1:0] = 01

15

16.5

L+BL_[1:0] = 10

50

55

L+BL_[1:0] = 11

150

165

L+RT_[1:0] = 00, latched off

Current-Limit Retry Delay

www.maximintegrated.com

tL+CLRT

160

mV

ms

∞

L+RT_[1:0] = 01

0.5

L+RT_[1:0] = 10

4

L+RT_[1:0] = 11

10

s

Maxim Integrated │ 10

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

AC Electrical Characteristics (continued)

(VCC = 18V to 30V, V5 = 4.5V to 5.5V, VL = 1.62V to 5.5V, VGND = 0V; TA = -40°C to +125°C, unless otherwise noted. Typical values

are at VCC = 24V, V5 = 5V, VL = 3.3, and TA = +25°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

tCYCL

Actual cycle time relative to programmed

cycle time, using an external clock or crystal

with 100ppm accuracy

0

4

5

%

CYCLE TIMER

Cycle Time

SPI TIMING (CS, SCLK, SDI, SDO) (Figure 5)

1.6V ≤ VL < 2.5V

Maximum SPI Clock Frequency

SCLK Clock Period

VL ≥ 2.5V

tCH+CL

SCLK Pulse-Width High

tCH

SCLK Pulse-Width Low

tCL

CS Fall to SCLK Rise Time

tCSS

SDI Hold Time

tDH

SDI Setup Time

tDS

SDO Output Data Propagation

Delay

tDO

SDO Rise and Fall Times

tFT

Minimum CS Pulse High

tCSW

CS Hold Time

tCSH

15.6

1.6V ≤ VL < 2.5V

20

64

VL ≥ 2.5V

50

1.6V ≤ VL < 2.5V

32

VL ≥ 2.5V

25

1.6V ≤ VL < 2.5V

32

VL ≥ 2.5V

25

1.6V ≤ VL < 2.5V

10

VL ≥ 2.5V

7

1.6V ≤ VL < 2.5V

0

VL ≥ 2.5V

0

1.6V ≤ VL < 2.5V

25

VL ≥ 2.5V

23

MHz

ns

ns

ns

ns

ns

ns

1.6V ≤ VL < 2.5V

35

VL ≥ 2.5V

15

VL = 1.8V

1.4

VL ≥ 2.5V

0.7

1.6V ≤ VL < 2.5V

10

VL ≥ 2.5V

10

1.6V ≤ VL < 2.5V

32

VL ≥ 2.5V

25

ns

ns

ns

Note 1: All devices are 100% production tested at TA = +25°C. Limits over the operating temperature range are guaranteed by

design.

Note 2: Includes stray capacitance or resistance. Required characteristic of the external crystal.

Note 3: Not production tested. Guaranteed by design.

Note 4: V5 supply current increases when the internal oscillator is selected.

www.maximintegrated.com

Maxim Integrated │ 11

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

VCC

TXEN_

TXEN_

MAX14819

MAX14819A

TX_

TX_

CQ_

3.3nF

GND

5kΩ

MAX14819

MAX14819A

5kΩ

3.3nF

GND

PUSH-PULL AND PNP MODE

CQ_

NPN MODE

(a) INVCQ_ = 0

VL

TXEN_

0V

VL

TX_

50%

50%

tPDHL

CQ_

0V

tPDLH

50%

90%

90%

10%

10%

tFALL

VCC

50%

0V

tRISE

(b) INVCQ_ = 1

VL

TXEN_

0V

VL

TX_

50%

50%

tPDHL

CQ_

0V

tPDLH

50%

90%

90%

10%

10%

tRISE

VCC

50%

0V

tFALL

Figure 1. C/Q Driver Propagation Delays and Rise/Fall Times

www.maximintegrated.com

Maxim Integrated │ 12

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

VCC

TXEN_

VL

TX_

MAX14819

MAX14819A

5kΩ

CQ_

3.3nF

GND

VL

TXEN_

0V

tDISH

tENL

VCC

CQ_

50%

10%

0V

Figure 2. C/Q Driver Enable Low and Disable High Timing with External Pullup Resistor (INVCQ_ = 0)

TXEN_

TX_

MAX14819

MAX14819A

CQ_

GND

3.3nF

5kΩ

VL

TXEN_

0V

tDISL

tENH

CQ_

50%

90%

VCC

0V

Figure 3. C/Q Driver Enable High and Disable Low Timing (INVCQ_ = 0)

www.maximintegrated.com

Maxim Integrated │ 13

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

TXEN_

CQ_

OR DI_

MAX14819

MAX14819A

GND

RX_

OR LI_

15pF

(a) INVCQ_ = 0

CQ_

OR DI_

VCC

50%

50%

0V

tPRHL

tPRLH

RX_

OR LI_

VL

50%

50%

0V

(a) INVCQ_ = 1

CQ_

OR DI_

50%

50%

0V

tPRHL

tPRLH

RX_

OR LI_

VCC

VL

50%

50%

0V

Figure 4. C/Q Receiver Propagation Delays

www.maximintegrated.com

Maxim Integrated │ 14

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

CS

tCSS

tCSW

tCL

tCSH

tCH

SCLK

tDS

tDH

SDI

tDO

SDO

90%

90%

10%

10%

tFT

tFT

Figure 5. SPI Timing Diagram

www.maximintegrated.com

Maxim Integrated │ 15

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Typical Operating Characteristics

(VCC = 24V, VL = 3.3V, REGEN is unconnected, CQ_ is in push-pull configuration, TA = +25°C, unless otherwise noted.)

CQ_ ON-RESISTANCE vs

LOAD CURRENT

1.8

9

1.6

8

1.4

1.0

0.8

REGEN = OPEN

5

REGEN = GND,

V5 = EXTERNAL 5V

3

2

0.4

DRIVER IN PUSH PULL MODE

HIGHEST CURRENT LIMIT SETTING

0.2

0.0

6

4

LOW SIDE

0.6

0

100

200

300

400

500

1

0

600

0.1

1

V5 SUPPLY CURRENT vs

CQ_ DATARATE

2.0

toc03

-200

SOURCE CURRENT (mA)

1.4

I5 (mA)

1.2

1.0

0.8

REGEN = GND

CQA AND CQB ARE PUSH PULL

TXENA = TXENB

SQUARE WAVE ON TXA = TXB

NO LOAD ON CQA OR CQB

0.2

0.1

1

10

100

CL[1:0] = 10

-400

-500

CL[1:0] = 11

-600

-700

-800

1000

CQ_ IN PUSH PULL

CQ_ IS HIGH

0

5

CL[1:0] = 10

300

CL[1:0] = 01

200

CL[1:0] = 00

25

30

toc06

300

250

200

150

100

50

100

0

20

LED_ _ IS ENABLED

350

500

400

15

LED_ _ VOLTAGE vs

LED_ _ SINK CURRENT

400

LED_ _ VOLTAGE (mV)

SINK CURRENT (mA)

600

toc05

CQ_ IN PUSH PULL

CQ_ IS LOW

CL[1:0] = 11

10

CQ_ OUTPUT VOLTAGE (V)

CQ_ CURRENT LIMIT

(LOWSIDE)

700

toc04

CL[1:0] = 01

-300

CQ_ DATA RATE (kbps)

800

1000

CL[1:0] = 00

-100

1.6

0.4

100

CQ_ CURRENT LIMIT

(HIGH SIDE)

0

1.8

0.6

10

CQ_ DATA RATE (kbps)

LOAD CURRENT (mA)

0.0

toc02

CQA AND CQB ARE PUSH PULL

TXENA = TXENB

SQUARE WAVE ON TXA = TXB

NO LOAD ON CQA OR CQB

7

HIGH SIDE

1.2

VCC SUPPLYCURRENT vs

CQ_ DATARATE

10

ICC (mA)

ON-RESISTANCE (Ω)

2.0

toc01

0

5

10

15

20

CQ_ OUTPUT VOLTAGE (V)

www.maximintegrated.com

25

30

0

0

5

10

15

20

25

30

35

LED_ _ SINK CURRENT (mA)

40

Maxim Integrated │ 16

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Typical Operating Characteristics (continued)

(VCC = 24V, VL = 3.3V, REGEN is unconnected, CQ_ is in push-pull configuration, TA = +25°C, unless otherwise noted.)

VCC = 30V

L+CL2x_ = 1

L+EN_ = 1

165ms blanking time enabled

1mF capacitor on L+_

toc07

L+_

20V/div

0V

ILOAD

1A/div

(SN1_ - SN2_) THRESHOLD (mV)

L+_ SHORT CIRCUIT

RESPONSE TIME

0A

4ms/div

0

-2

G1_ OUTPUT VOLTAGE vs

TEMPERATURE

toc09

0

REFERENCED TO SN1_

L+_ ENABLED

-2

(VG2_-VSNS2_) (V)

-6

-8

-12

-12

18

-40 -25 -10 5

-14

20 35 50 65 80 95 110 125

TEMPERATURE (ºC)

L+_ INPUT CURRENT vs

TEMPERATURE

toc11

10

L+_ = 24V

8

16

6

14

4

12

2

10

8

G2_ OUTPUT VOLTAGE vs

TEMPERATURE

toc10

REFERENCED TO SN2_

L+_ ENABLED

-4

-6

2

-8

www.maximintegrated.com

20 35 50 65 80 95 110 125

TEMPERATURE (ºC)

20 35 50 65 80 95 110 125

TEMPERATURE (ºC)

SN2_ INPUT CURRENT vs

TEMPERATURE

toc12

L+En_ = 1

SN1_ = SN2_

0

4

-40 -25 -10 5

-40 -25 -10 5

-2

6

0

20 35 50 65 80 95 110 125

TEMPERATURE (ºC)

-8

-10

20

-40 -25 -10 5

-6

-10

-14

(SN1_ - SN2_) VOLTAGE vs

TEMPERATURE

toc08

-4

ISNS2_ (µA)

(VG1_ -VSNS1_) (V)

-4

IL+_ (µA)

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

-10

-40 -25 -10 5

20 35 50 65 80 95 110 125

TEMPERATURE (ºC)

Maxim Integrated │ 17

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

G2B

SN2B

SN1B

VCC

G1B

LIB

RXB

TXENB

TXB

TXA

RXA

TOP VIEW

TXENA

Pin Configuration

36 35 34 33 32 31 30 29 28 27 26 25

LIA

37

24 L+B

A0

38

23 DIB

A1

39

22 N.C.

VL

40

21 N.C.

XI

41

20 CQB

MAX14819

MAX14819A

19 N.C.

XO

42

CLKI

43

CLKO

44

17 CQA

18 N.C.

SDI

45

16 N.C.

SDO

46

15 N.C.

SCLK

47

CS

48

+

14 DIA

6

7

IRQ

RXERRA/LD2A

RXRDYB/LD1B

RXERRB/LD2B

V5

REGEN

8

9

10 11 12

G2A

5

SN2A

4

SN1A

3

VCC

2

G1A

1

RXRDYA/LD1A

13 L+A

TQFN

(7mm x 7mm)

Pin Description

PIN

NAME

1

IRQ

2

RXRDYA/LD1A

www.maximintegrated.com

FUNCTION

REFERENCE

Open-drain Interrupt Output. Connect a pullup resistor to IRQ. IRQ asserts

whenever a bit that has been enabled in the InterruptEn register is set in the

Interrupt register. See the Register Description for more information.

GND

Channel A Configurable Open-Drain Receive Data Ready Output/LD1A Driver.

Set the RxRdyEnA bit to 1 in the LEDCtrl register to enable RXRDYA/LD1A as

an interrupt output. In this configuration, RXRDYA/LD1A asserts when the RxDataEnRdyA interrupt bit is set in the Interrupt register. Set the RxRdyA bit to 0

to configure RXRDYA/LD1A as an open-drain LED driver. When configured as

an LED driver, RXRDYA/LD1A is controlled by the LEDEn1A bit in the LEDCtrl

register. Connect a resistor in series to limit the LED current. See the Register

Description for more information.

GND

Maxim Integrated │ 18

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Pin Description (continued)

PIN

NAME

FUNCTION

REFERENCE

RXERRA/LD2A

Channel A Configurable Open-Drain Receive Error Output/LD2A Driver. Set

the RxErrEnA bit in the LEDCtrl register to enable RXERRA/LD2A as an

interrupt output. In this configuration, RXERRA/LD2A asserts when the

RxErrorA bit in the Interrupt register is set. Set the RxErrEnA bit to 0 to

configure RXERRA/LD2A as an open-drain LED driver. When configured as

a LED driver, RXERRA/LD2A is controlled by the LEDEn2A bit in the LEDCtrl

register. Connect a resistor in series to limit the LED current. See the Register

Description for more information.

GND

RXRDYB/LD1B

Channel B Configurable Open-Drain Receive Data Ready Output/LD1B Driver.

Set the RxRdyEnB bit to 1 in the LEDCtrl register to enable RXRDYB/LD1B

as an interrupt output. In this configuration, RXRDYB/LD1B asserts when the

RxDataRdyB interrupt bit is set in the Interrupt register. Set the RxRdyEnB bit to

0 to configure RXRDYB/LD1B as an open-drain LED driver. When configured as

an LED driver, RXRDYB/LD1B is controlled by the LEDEn1B bit in the LEDCtrl

register. Connect a resistor in series to limit the LED current. See the Register

Description for more information.

GND

RXERRB/LD2B

Channel B Configurable Open-Drain Receive Error Output/LD2B Driver. Set

the RxErrEnB bit in the LEDCtrl register to enable RXERRB/LD2B as an interrupt output. In this configuration, RXERRB/LD2B asserts when the RxErrorB bit

in the Interrupt register is set. Set the RxErrEnB bit to 0 to configure RXERRB/

LD2B as an open-drain LED driver. When configured as an LED driver, RXERRB/LD2B is controlled by the LEDEn2B bit in the LEDCtrl register. Connect a

resistor in series to limit the LED current. See the

Register Description for more information.

GND

6

V5

5V Supply Input/Linear Regulator Voltage Output. Connect a 1μF bypass

capacitor as close as possible to the IC. Apply an external 5V supply to V5 if the

internal 5V regulator is disabled (REGEN = GND). 5V must be present on V5 at

all times for normal operation.

GND

7

REGEN

5V Linear Regulator Enable Input. Leave REGEN unconnected to enable the

internal 5V regulator. Connect REGEN to GND to disable the internal 5V

regulator.

GND

8, 29

VCC

VCC Supply Input. Bypass VCC to GND with a 1μF capacitor as close as

possible to the device.

GND

9

G1A

Channel A Gate Drive Output 1. Connect G1A to the gate of the external

PMOS1A to control the external reverse-current-blocking transistor of sensor

supply A (L+A). Leave G1A unconnected if the external PMOS1A is not used.

SN1A

10

SN1A

Channel A Sense Input 1/PMOS1A Source Connection. Connect a currentlimiting resistor between SN1A and SN2A. Leave SN1A unconnected when the

channel A supply controller is not used.

GND

11

SN2A

Channel A Sense Input 2/PMOS2A Source Connection. Connect a currentlimiting resistor between SN1A and SN2A. Connect SN2A to SN1A when

current sensing is not used.

SN1A, GND

12

G2A

Channel A Gate Drive Output 2. Connect G2A to the gate of the external

PMOS2A for the channel A sensor supply (L+A). Leave G2A unconnected if the

external PMOS2A is not used.

SNA1, GND

3

4

5

www.maximintegrated.com

Maxim Integrated │ 19

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Pin Description (continued)

PIN

NAME

FUNCTION

REFERENCE

13

L+A

Channel A L+ Sensor Supply Monitoring Input. Connect L+A to the drain of the

external PMOS2A current-limiting transistor. Bypass L+A to GND with 0.47μF.

Connect a 100Ω resistor in series with L+A (see Typical Operating Circuit).

Connect L+A to GND or leave unconnected if not used.

14

DIA

Channel A Auxiliary Digital Input. Connect a 100Ω resistor in series with DIA

(see Typical Operating Circuit).

15, 16,

18 ,19,

21, 22

N.C.

No Connection. Not internally connected.

—

17

CQA

Channel A C/Q Transceiver Input/Output

VCC, GND

20

CQB

Channel B C/Q Transceiver Input/Output

VCC, GND

23

DIB

Channel B Auxiliary Digital Input. Connect a 100Ω resistor in series with DIB

(see Typical Operating Circuit).

GND

24

L+B

Channel B L+ Sensor Supply Monitoring Input. Connect L+B to the drain of the

external PMOS2B transistor to limit the load current sourced by the channel

B source supply. Bypass L+B to GND with 0.47μF. Connect a 100Ω resistor in

series with L+B (see Typical Operating Circuit). Connect L+B to VCC or GND, or

leave unconnected if not used.

GND

25

G2B

Channel B Gate Drive Output 2. Connect G2B to the gate of the external

PMOS2B for the channel B sensor supply (L+B). Leave G2B unconnected if the

external PMOS2B is not used.

SN1B

SN1B

GND

GND

26

SN2B

Channel B Sense Input 2/PMOS2B Drain Connection. Connect a currentlimiting resistor between SN1B and SN2B. Connect SN2B to SN1B or leave

unconnected when current sensing is not used.

27

SN1B

Channel B Sense Input 1/PMOS1B Source Connection. Connect a current-limiting resistor between SN1B and SN2B. Leave SN1B unconnected when supply

controller B is not used.

VCC

28

G1B

Channel B Gate Drive Output 1. Connect G1B to the gate of the external

PMOS1B to control the external reverse-current-blocking transistor of sensor

supply B (L+B). Leave G1B unconnected if the external PMOS1B is not used.

SN1B

30

LIB

Channel B Logic Output of the Digital Input (DIB). LIB is the logic inverse of the

signal on DIB.

VL, GND

31

RXB

Channel B Logic Output of the CQB Receiver. RXB is the logic inverse of the

signal on CQB (when InvCQB = 0).

VL, GND

32

TXENB

Channel B CQB Transmitter Output Enable. Drive TXENB high to enable the

CQB driver. Drive TXENB low at power-up.

VL, GND

33

TXB

Channel B CQB Transmitter Logic Input. CQB is the logic inverse of the signal

on TXB (when InvCQB = 0 ).

VL, GND

34

TXA

Channel A CQA Transmitter Logic Input. CQA is the logic inverse of the signal

on TXA (when InvCQA = 0).

VL, GND

35

TXENA

Channel A CQA Transmitter Output Enable. Drive TXENA high to enable the

CQA driver. Drive TXENA low at power-up.

VL, GND

www.maximintegrated.com

Maxim Integrated │ 20

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Pin Description (continued)

PIN

NAME

36

RXA

Channel A Logic Output of the CQA Receiver. RXA is the logic inverse of the

signal on CQA (when InvCQA = 0).

VL, GND

37

LIA

Channel A Logic Output of the Digital Input (DIA). LIA is the logic inverse of the

signal on DIA.

VL, GND

A0

SPI Chip Address Input A0. The MAX14819/MAX14819A is designed to allow

up to 4 transceivers on the SPI at one time with a shared CS signal. Connect A1

and A0 high or low to set the individual IC SPI address. Do not leave A0

unconnected.

VL, GND

39

A1

SPI Chip Address Input A1. The MAX14819/MAX14819A is designed to allow

up to 4 transceivers on the SPI at one time with a shared CS signal.

Connect A1 and A0 high or low to set the individual IC SPI address.

Do not leave A1 unconnected.

VL, GND

40

VL

Logic Level Supply Input. VL sets the logic level of all logic inputs and outputs

(TXEN_, TX_, RX_, LI_, and the SPI interface). Bypass VL to GND with a 0.1μF

capacitor as close as possible to the device.

GND

41

XI

Crystal Oscillator Input for Internal Framer Operation. Connect a crystal between XI and XO to use crystal clocking. Leave XI unconnected if crystal clocking is not used.

V5, GND

42

XO

Crystal Oscillator Output for Internal Framer Operation. Connect a crystal

between XI and XO to use crystal clocking. Leave XO unconnected if crystal

clocking is not used.

V5, GND

43

CLKI

Logic Clock Input for Internal Framer Operation. When not using a crystal for

framer operation, connect a 3.686MHz clock signal to CLKI. Connect CLKI to

GND when not used.

V5, GND

44

CLKO

Logic Clock Output for Internal Framer Operation. CLKO outputs a 3.686MHz

clock signal when enabled (ClkOEn = 1). When using multiple MAX14819/

MAX14819A ICs on a board, these can be clocked with a single crystal by

connecting the CLKO output of one device to the CLKI inputs of the other(s).

V5, GND

45

SDI

SPI Data Input. Connect SDI to the MOSI output of the microcontroller.

V5, GND

46

SDO

SPI Data Output. Connect SDO to the MISO input of the microcontroller.

V5, GND

47

SCLK

SPI Clock Input. Connect SCLK to the CLK output of the microcontroller.

V5, GND

48

CS

SPI Chip-Select Input. The SPI cycle begins when CS is driven low and ends

when CS is driven high. Up to 4 MAX14819/MAX14819A ICs can share a single

SPI bus and CS input using the A1 and A0 address inputs.

V5, GND

EP

―

38

www.maximintegrated.com

FUNCTION

Exposed Pad. Connect to GND.

REFERENCE

GND

Maxim Integrated │ 21

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Detailed Description

5V Linear Regulator

The MAX14819/MAX14819A low-power dual-channel

industrial IO-Link master transceiver is fully compliant

with the latest SDCI/ IO-Link standards and test specifications. The MAX14819/MAX14819A features two integrated framers but can alternatively operate with external

UARTs.

The MAX14819/MAX14819A includes an integrated regulator to generate 5V (V5). To enable the internal regulator,

leave REGEN unconnected and connect a 1μF bypass

capacitor between V5 and ground as close as possible to

the device. The internal V5 regulator is capable of driving

external loads up to 20mA.

The MAX14819/MAX14819A features a high-speed SPI

interface for system-side data and control interfacing.

Integrated IO-Link message frame handlers and FIFOs

simplify time critical control and cycle time management of all IO-Link M-sequence communication, easing

data link layer control. Autonomous cycle timers also

reduce the need for accurate controller timing. Integrated

establish-communication sequencers simplify wake-up

management.

When the internal 5V linear regulator is not used, V5 is the

supply input for the internal analog and digital functions and

must be supplied externally. Connect REGEN to ground to

disable the internal regulator when applying an external 5V

to V5. Ensure that V5 is present for normal operation.

The MAX14819/MAX14819A further includes two sensor supply controllers (L+A, L+B) with current limiting

and reverse current blocking. The current limit is set with

external sense resistors.

POWER

Power-Up

The CQ_ driver outputs are high impedance when the

VCC supply, V5, and VL voltages are below their respective undervoltage thresholds during power-up.

The drivers are automatically disabled when the VCC

voltage falls below the 9V (typ) UVLO threshold. The SPI

interface remains active while V5 and VL are present.

VCC Low Voltage and Undervoltage Detection

The MAX14819/MAX14819A monitors the VCC supply

for low-voltage and undervoltage conditions. Low-voltage

warnings are reported in the Status register and can be

configured to generate an interrupt on the IRQ output.

When VCC falls below the 18V (max) low-voltage warning threshold, the VCCWarn and VCCWarnCOR bits in

the Status register are set. If VCCWarnCOR in the Clock

register is set, a StatusInt interrupt is generated and IRQ

asserts.

When VCC falls below the 9V (max) undervoltage-lockout

(UVLO) threshold, the VCCUV and VCCUVCOR bits in the

Status register are set. A StatusInt interrupt is generated

and IRQ asserts.

www.maximintegrated.com

An internal undervoltage lockout comparator detects

when the V5 voltage falls below the 3.5V (typ) V5_UVLO

threshold. When the V5 voltage drops below this level,

the device is under reset: SPI registers are reset to their

power-up state, the CQ_ outputs and L+_ supplies are

disabled, internal pullups/pulldowns are turned off, the

CQ_ and DI_ receivers are disabled, and the LED outputs

are high impedance. When the V5 voltage rises above the

UVLO threshold, the MAX14819/MAX14819A restarts in

the default power-on configuration.

The internal V5 regulator output is not protected against

short circuits.

Logic Supply (VL)

The VL input is the logic-level supply for all the digital I/

Os. Apply a voltage between 1.62V and 5.5V to VL for

normal operation.

Internal UVLO circuitry monitors the VL supply. If VL falls

below the 0.7V (typ) VL UVLO threshold, all the digital

I/Os referred to VL are ignored and either set to high

impedance or are low.

L+ Sensor Supply Controllers

The MAX14819/MAX14819A includes one sensor/actuator

supply controller for each IO-Link channel, L+A and L+B.

Each sensor supply is configurable through the SPI interface and must be enabled by setting the L+En_ bit in the

L+Cnfg_ register. Using external pMOS transistors, these

controllers provide active current limiting, reverse current

blocking, and undervoltage detection. The 24V VCC field

supply input is tolerant to reverse voltage and the L+A/L+B

output is negative voltage capable down to VCC - 60V.

Maxim Integrated │ 22

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Setting the L+_ Current Limit

CQ_ Current Limit and Thermal Protection

The L+_ sensor supply current is limited by placing a

sense resistor between the SN1_ and SN2_ currentsense inputs. When the voltage across the resistor

reaches the VCL_T (15mV, typ) threshold, the gate of the

pMOS (G2_) is actively controlled to limit the load current

such that:

The MAX14819/MAX14819A features a selectable current

limit for both CQ_ drivers ranging from 100mA to 500mA.

Set the CL[1:0] bits in the DrvrCurrLim register to select the

current limit for the drivers.

ILIM = VCL_T/RSENSE

If the L+_ voltage is pulled below ground (< -3V), the

current limit is reduced to about 10% of normal value to

reduce the power dissipated in the external pMOS.

L+_ Blanking Time and Autoretry Functionality

The L+_ controllers have programmable variables (set in

the L+Cnfg_ registers) that allow the system to optimize

turn-on and charging large loads while protecting the

pMOS FETs in cases of shorts and challenging load conditions.

If the load current is in current limiting for a period exceeding the set blanking time, the gate drive (G2_) is turned

off. The sensor supply is then either turned off until the

controller reenables it, or is turned on again following the

autoretry delay.

To further reduce the power dissipated in the pMOS transistors during turn-on of loads that require large inrush

currents (e.g., capacitive loads), the current limiter includes

a dynamic blanking time mode that reduces the blanking

time when the voltage across the pMOS is high, limiting

the pulse energy during the initial turn-on phase. Dynamic

blanking time mode is operational when the L+_ output

voltage is below 18V and must be enabled by setting the

L+DynBl_ bit in the L+Cnfg_ register.

The MAX14819/MAX14819A current-limit circuitry also

includes the option to double the L+_ load current when the L+_

supply voltage is above 18V. This functionality is enabled by

setting the L+CL2x_ bit in the L+Cnfg_ register.

Bypassing the L+_ Sensor Supplies

When the internal L+_ supply controllers are not used,

leave all the associated pins (G1_, G2_, SN1_, SN2_,

L+_) unconnected. L+_ can also be connected to GND.

CQ_ Transceivers

The CQA and CQB drivers are independently configurable as push-pull, NPN, PNP mode outputs in the

SPI registers. Set the bits in the CQCfgA and CQCfgB

registers to configure the drivers, enable or disable

internal pullup and pulldown current sources on the CQ_

I/Os, and to set the digital input thresholds. The CQ_

drivers can also be enabled/disabled in these registers.

www.maximintegrated.com

The CQ_ drivers are independently thermally protected.

If one output driver temperature rises above the 160°C

threshold, that output is disabled until the temperature

drops below 145°C.

CQ_ Driver Fault Detection

The MAX14819/MAX14819A senses a fault condition

on the CQ_ driver when an overcurrent event exists

for longer than the blanking time. Both the current limit

and blanking time can be configured in the DrvrCurrLim

register.

When a short-circuit fault occurs on CQ_, the CQFault_

and CQFaultCOR_ bits in the ChanStat_ register are set

and can trigger an interrupt.

When an overcurrent event occurs on CQ_, the driver can

either be set to continue supplying the selected current

until the device enters thermal shutdown (autoretry is disabled), or to enter autoretry mode. In autoretry mode, the

driver is automatically disabled after the current blanking

time and is then reenabled.

CQ_ Reverse-Polarity Protection

The CQ_ outputs are protected against reverse polarity

vs. ground. If CQ_ is connected to a negative voltage,

the driver is automatically disabled and CQ_ is set to high

impedance.

When CQ_ is shorted to a voltage above VCC, the driver

is automatically disabled and the output is set to high

impedance.

During a reverse condition, positive or negative, when no

fault is detected on CQ_ but the internal diode begins to

overheat, the L+_ supply is immediately disabled (turning

off the external transistors) to protect the device.

Reverse conditions do not generate a fault or interrupt.

CQ_ Current Sources/Sinks

The MAX14819/MAX14819A features programmable

internal 2.5mA/5.8mA pullup/pulldown current sources

on the CQ_ receivers. Select the pullup/pulldown current

for each CQ_ I/O by setting the SinkSel_[1:0] bits in the

CQCfg_ register. The internal pullup/pulldown currents

are automatically disabled when the CQ_ output is driven

(i.e., push-pull not in high-impedance state, NPN mode is

set low, or NPN mode is set high).

Maxim Integrated │ 23

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

CQ_ Receiver Output (RXA/RXB)

RX_ is the output of the CQ_ receiver. By default, the RX_

output is the inverse logic of the CQ_ input. Setting the

InvCQ_ bit in the MsgCtrl_ register inverts CQ_ so that

the RX_ output is the same logic of the CQ_ input. RX_

cannot be disabled/three-stated.

CQ_ Receiver Threshold

The CQ_ receiver thresholds are compliant with the

IO-Link standard by default. The receiver thresholds are

also configurable to be compatible with the IEC 61131-2

type 1 and type 2/3 digital inputs. Set the IEC3Th_ bit

in the CQCfg_ register to select the input thresholds for

each receiver.

CQ_ Receiver Deglitch

The CQ_ receivers feature a selectable glitch filter

for improved noise immunity. Enable/disable this filter

by setting the CQFilterEn_ bit in the CQCfg_ register.

Transients longer than 1.3µs (typ) are ignored when the

glitch filter is enabled.

DI_ Receiver

The MAX14819/MAX14819A includes two auxiliary digital

inputs: DIA and DIB. These inputs are protected against

reverse polarity (referred to VCC and/or GND).

DI_ inputs are configurable in the IOStCfg_ registers. Set

the DiCSource__ bit to enable the internal 2.4mA source

on the DI_ input. Set the DiCSink_ bit to enable the 2.4mA

sink on the input.

Each DI_ input also features a selectable glitch filter for

improved noise immunity. Transients longer than 1.3µs

(typ) are ignored when the glitch filter is enabled. Set the

DiFilterEn_ bit to enable or disable this filter. When the

glitch filter is enabled, signal pulses less than 1μs are

ignored on the DI_ input.

The DI_ receiver thresholds are configurable to be

compatible with the IEC 61131-2 type 1, and type 2/3

digital inputs. Set the DiEC3Th_ bit in the IOStCfg_ register

to select the input thresholds for each receiver.

SPI Interface

The MAX14819/MAX14819A is connected to a microcontroller or SPI-host through an SPI-compatible serial interface. The interface has three inputs: clock (SCLK), chip

select (CS), and data in (SDI), and one output, data out

(SDO). SDO is high impedance when CS is high, allowing

multiple SPI slave devices to share a common bus. The

SPI is not daisy-chainable. The maximum SPI clock rate

is 20MHz when VL > 2.5V.

The SPI interface logic complies with SPI clock

polarity (CPOL = 0) and clock phase (CPHA = 0). The SPI

www.maximintegrated.com

interface supports both byte-by-byte cycle and burst

mode read and write.

In both read and write cycles, the SDO signals the IRQ

status, as well as the receive-data-ready and receive-dataerror for both receivers A and B (Figure 6 and Figure 7).

The SPI interface is not available when the VL voltage

is below the 0.7V (typ) VL UVLO threshold or when 5V

is not present on V5. The SPI registers are reset to their

default state when the V5 voltage falls below the 3.5V V5

UVLO threshold.

SPI Chip Address (A1, A0)

The MAX14819/MAx14819A is designed to allow up to four

master transceivers on a single bus with a single/shared CS.

This is accomplished using SPI-addressable devices with

logic address inputs A1 and A0. See Table 1. Do not leave

the A1 or A0 address input unconnected. Each chip on the

SPI bus should be assigned an individual chip address.

The MAX14819/MAX14819A monitors the SPI address in

each read/write cycle and responds when the SPI address

matches the pin-programmed address for that IC.

SPI trigger commands are global and are not filtered by the

chip address. All MAX14819/MAX14819A devices connected to the SPI bus will react to a received trigger command.

SPI In-Band IRQ Interrupt

The addressed MAX14819/MAX14819A sends out an

IRQ bit on SDO in every SPI cycle (both in single cycle as

well as burst mode), beginning on the third SPI clock. This

bit is equivalent to the IRQ interrupt output pin logic, but

inverted (active high). The IRQ bit is set when the IRQ pin

is asserted. Similarly, when the IRQ output is high impedance, the IRQ bit is 0. See Figure 6 and Figure 7.

The IRQ bit cannot be masked.

SPI In-Band Device-Message-Ready Signaling

In addition to sending IRQ status, the addressed

MAX14819/MAX14819A can be enabled to also send out

2 bits per channel in every SPI cycle that provide information, whether the IO-Link device answer message was

received correctly (RRDY_) or in error (RERR_) (Figure 6

and Figure 7). Set the RMessgRdy_ bits in the MesgCrtl_

register to enable this functionality.

Table 1. SPI MAX14819/MAX14819A Chip

Address Select

A1

A0

DEVICE ADDRESS

LOW

LOW

00

LOW

HIGH

01

HIGH

LOW

10

HIGH

HIGH

11

Maxim Integrated │ 24

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

CS

SCLK

SDI

W

A1

A0

SDO

R4

R3

R2

R1

R0

D7

D6

D5

D4

D3

D2

D1

D0

0

A1

A0

R4

R3

R2

R1

R0

IRQ RERRB RRDYB RERRA RRDYA D7

D6

D5

D4

IRQ RERRB RRDYB RERRA RRDYA

A_ = Chip Address

R_ = Register Address

D_ = Data Bit

IRQ = IRQ Bit

RRDY_ = Receive Data Ready Interrupt

RERR_ = Receive Data Error Interrupt

= Clock Edge upon which SDI data is latched

= Clock Edge upon which SDO is generated

Figure 6. SPI Byte-by-Byte Write Cycle

CS

SCLK

SDI

R

SDO

A1

A0

R4

R3

R2

R1

R0

D3

D2

D1

D0

A_ = Chip Address

R_ = Register Address

D_ = Data Bit

IRQ = IRQ Bit

RRDY_ = Receive Data Ready Interrupt

RERR_ = Receive Data Error Interrupt

= Clock Edge upon which SDI data is latched

= Clock Edge upon which SDO is generated

Figure 7. SPI Byte-by-Byte Read Cycle

www.maximintegrated.com

Maxim Integrated │ 25

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

The RRDY_ bits are equivalent to the DtaRdy_ hardware

outputs. Similarly, the RERR_ bits are the equivalent to

the RxErr_ hardware outputs. The SDO bit logic is the

inverse of the pin logic: when the pin output is low, the

associated bit is set to 1, and when the pin output is high,

the associated bit is 0.

The SPI clock must continue clocking throughout the

burst access cycle. Only the initial register address is

sent, followed by multiple bytes of data. The burst cycle

ends when the SPI master pulls CS high. See Figure 8.

When performing a burst read or write of/to the TxRxData_

registers, the register address remains the same, allowing

fast loading of a master message into the TxFIFO_ and

reading of the device message out of the RxFIFO_.

The RRDY_ bits and the RXRDY_ pins are cleared automatically when the device message is read out of the

RxFIFO_.

When burst reading or writing of registers having a

higher address than the TxRxData_ registers, the register

address is automatically incremented, allowing reading

and writing of a consecutive register block by only defining the initial register address in the SPI command byte.

SPI Burst Access

Burst access allows SPI reading/writing of two or more

bytes in a single SPI cycle. The chip-select input (CS)

must be held low during the entire burst write/read cycle.

IC AND

REGISTER ADDRESS

SPI BURST WRITE

CS

SDI

COMND

SDO

Data0

Data1

Data2

Data3

Data(N-1)

DataN

COMND

Data1

Data2

Data(N-2)

Data(N-1)

Data(N-1)

DataN

SPI BURST READ

CS

SDI

COMND

SDO

Data0

Data1

IC AND

REGISTER ADDRESS

Data2

Data3

SPI BYTE-BY-BYTE WRITE

CS

SDI

COMND

SDO

Data0

Data1

COMND

COMND

Data0

Data2

COMND

COMND

Data0

Data3

COMND

SPI BYTE-BY-BYTE READ

CS

SDI

COMND

SDO

Data0

COMND

Data1

Data0

COMND

Data2

Data0

Data3

Figure 8. SPI Burst Read/Write and Byte-by-Byte Read/Write Overview

www.maximintegrated.com

Maxim Integrated │ 26

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

Wake-Up Pulse Generation

The MAX14819/MAX14819A can automatically generate

a wake-up pulse to initiate IO-Link communication. Set

the CQ_ driver into receive mode (TXEN = low or TxEn_

= 0), and drive TX_ low or set the Tx_ bit to 0 before the

wake-up sequence begins. Set the WuPuls_ bit to begin

the wake-up sequence. When the WuPuls_ bit is set, the

MAX14819/MAX14819A samples the CQ_ voltage level

and then automatically enables the CQ_ driver. A 500mA

current pulse of opposite polarity is applied to the CQ_ line

for 80μs (typ). During the wake-up pulse, the CQ_ current

limit is temporarily set above 500mA internally, although

the CL_ register bits are not changed. The driver remains

enabled, the line returns to the original polarity, and after a

100μs (typ) delay the MAX14819/MAX14819A CQ_ driver

is set to high impedance (Figure 9). The WuPuls_ bit is

automatically cleared after the tON_WU delay.

Microcontroller Data Interface

The MAX14819/MAX14819A offers two interface options

for IO-Link communication. When used as a transceiver,

external UARTs are required in the microcontroller and

these are interfaced to the TX_, RX_ and TXEN_ pins.

If the IO-Link framers in the MAX14819/MAX14819A are

used, then the SPI is used for interfacing to the microcontroller.

Framer Communication

The MAX14819/MAX14819A includes two independent

IO-Link framers with UARTs, one for each CQ_ channel. Each

framer operates in a Master-message (TX)/Device-message

WuPuls_ Bit

0

(RX) doublet, verifying communication timing and data

transmitted/received. After a channel has completed transmission of a master message, the framer is

automatically switched into receive mode. When the

expected number of bytes has been received, the framer

automatically exits from receive mode and any further

received data is ignored.

Shortly before, during, and after the frame handler sends

and receives messages, its transmitter must be disabled.

Disable the transmitter by either driving the associated

TXEN_ pin low, or by setting the TXTXENDis bit to 1. Note

that the TXTXENDis bit is global and acts on both channels.

UART Framing

The UART frame is made up of one start bit, 8 data bits

with 1 even parity bit and 1 STOP bit. When transmitting,

the idle time between the STOP bit and the following

START bit is less than 1 bit interval.

Frame Handler FIFOs (TxRxFIFOA/TxRxFIFOB)

Each IO-Link channel on the MAX14819/MAX14819A

(CQA and CQB) has a transmit and receive FIFO for

buffering the IO-Link M-sequence messages that are

sent and received. These FIFOs have a depth (66 bytes)

to buffer the largest M-sequence, Type 2.V, in addition to

the two length bytes.

Transmit/Receive FIFO Data Structure

To ensure proper communication, the message from the

SPI master to the TxFIFO_ must follow the sequence

shown in Figure 10.

1

WAKE-UP PULSE

tWU

CQ_ VOLTAGE

tSU_WU

tON_WU

Figure 9. Wake-Up Timing

SDI

RxBytes

TxBytes

TxData-1

(MC)

TxData-2

(CKT)

TxData-n

Figure 10. Transmit SPI Data Write Sequence

www.maximintegrated.com

Maxim Integrated │ 27

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

RxBytes is the number of octets the IO-Link device

is expected to reply with after it receives this master

message. TxBytes is the number of bytes that the master will send to the device in this message (the master

message length).

The IO-Link device answers with the device message,

which is stored in the RxFIFO_. When the RxFIFO_ on the

MAX14819/MAX14819A is read, the data is formatted as

shown in Figure 11. RxBytesAct is the actual number of

bytes received from the device and available for readout

from the RxFIFO_. This may differ from the expected number of receive bytes (RxBytes).

Loading the Transmit FIFO (TxFIFO_)

The master message is loaded into the transmit

FIFO (TxFIFO_) through the SPI interface. The SPI

master needs to send three pieces of information to the

TxRxData_ register for a complete master message

(Figure 12):

1) A byte describing the expected number of bytes of

the IO-Link device reply message. This is RxBytes.

2) A byte describing the number of bytes in the master

message (the length that will be transmitted). This is

TxBytes.

3) The data for the master message.

The TxBytes byte signals the number of octets in the

master message and the RxBytes indicates the number of octets expected from the device in the response

message.

SDO

Set the TSizeEn_ bit in the MsgCtrl_ register to compare

the TxBytes information to the number of octets loaded

in the TxFIFO_ and verify that the full message has been

received by the SPI master. The TSizeEn_ functionality

can be used either for byte-by-byte FIFO loading or for

burst loading. When a size error is detected, a TSizeErr_

interrupt is generated.

The TxFIFO_ can be written to using byte-by-byte write

or a burst write. When loading the TxFIFO_ with byteby-byte writing, the CQ_ transmission can be started

before the complete master message is loaded into the

TxFIFO_ (transmission and TxFIFO_ loading can be

done in parallel). In this case, the SPI controller must set

the InsChks bit in the MsgCtrl_ register to 0 and include

the 6-bit checksum in the master message CKT octet,

since the MAX14819/MAX14819A cannot calculate it. The

MAX14819/MAX14819A can only generate a TChkSmEr_

interrupt after the whole message is loaded into the

TxFIFO_; if transmission is started before the full message was loaded, it is possible that the IO-Link device will

receive a message with a checksum in error.

When transmission starts after the TxFIFO_ is completely loaded, the MAX14819/MAX14819A can calculate

and insert the checksum (when InsChk_= 1) into the

CKT octet. Alternatively, the SPI master can insert the

checksum in the master message and the MAX14819/

MAX14819A will verify the data (SPIChks_ = 1). If a

checksum error is detected, a TChksmEr_ interrupt is

generated and the MAX14819/MAX14819A does one of

RxByte-1

RxBytesAct

RxBytes-m

(CKS)

RxByte-2

Figure 11. Receive SPI Data Read Sequence

MASTER

MESSAGE

DEVICE

RESPONSE

UART

FRAME

UART

FRAME

t1

UART

FRAME

t1

UART

FRAME

UART

FRAME

tA

t2

UART

FRAME

t2

tM-sequence

Figure 12. Message Timing

www.maximintegrated.com

Maxim Integrated │ 28

�MAX14819/MAX14819A

Dual IO-Link Master Transceiver with Integrated

Framers and L+ Supply Controllers

two things, depending on the state of the TxErDestroy_ bit

in the MsgCtrl_ register:

●● If TxErDestroy = 1: The MAX14819/MAX14819A will

not send the message, so the SPI master must reload

the message into the TxFIFO_ in time for the cycle

time.

●● If TxErDestroy = 0: The MAX14819/MAX14819A

sends the message with the error.

Initiating Transmission

Transmission on CQ_ is initiated either by setting the

CQSend_ bit in the CQCtrl_ register or by using a trigger

command (see the TrigAssgn_ register for more information). Transmission can also be initiated cyclically when

the internal cycle time is enabled (CyclTmrEn_=1).

When SPI burst write mode is used, transmission

must be initiated after the TxFIFO_ is loaded or the

MAX14819/MAX14819A generates a cycle error interrupt

(TCycleErr_ = 1).

When using byte-by-byte SPI write mode, transmission

can be initiated before the complete master message is

loaded. When using this mode, ensure that the TxFIFO_

always has at least 1 data byte stored in it to avoid any

idle time or errors. The TxFIFO_ transmission is halted

and the CQ_ transceiver is configured to receive mode as

soon as the TxFIFO_ is empty.

During transmission, the CQ_ transmitter is set to pushpull mode. CQ_ is restored to the previous state when

transmission is complete.

Transmit Loopback Check

The internal framers automatically verify transmitted

data through a loopback check. During transmission, the

signal at CQ_ is automatically routed to the receiver and the

message sent is checked against the data sent out. If

inconsistencies are detected (e.g., when a CQ_ line is

shorted), the TransmErr_ bit is set and a TxError_ interrupt

can be generated.

Receiving the Device Message

When the MAX14819/MAX14819A completes transmission of the master message to the IO-Link

device, the CQ_ transmitter is set to receive mode

within 3μs (typ) and the master waits for the device

reply message. The MAX14819/MAX14819A waits for

9 to 24 bit times (set by the DDelay_ bits in the DeviceDly_

register) for a valid START from the device.

From the RxBytes data in the master message, the

MAX14819/MAX14819A already knows the number of

bytes expected to be returned from the device. If the number

of bytes received is not the expected number, a RSizeErr_

www.maximintegrated.com

interrupt is generated. The receiver stops reception when

the number of received bytes equals the value in RxBytes

and any further data sent from the device is ignored.

Reception is also terminated when less bytes are received

than expected. The MAX14819/MAX14819A determines

this to be the case when no START bit occurs within 2 to

5 bit times (as set in the BDelay_ bits in the DeviceDly_

register) after the last character’s STOP bit.

When the device message is received successfully (without any errors), an RxDataRdy_ interrupt is

signaled to the host SPI controller by asserting the IRQ pin

(if (RDaRdyIntEn = 1) and/or by asserting the RXRDY_/

LD1_ pin when the received data (device message) is

ready for readout from the RxFIFO_. The host controller

can read out the message from the RxFIFO_ in byte-bybyte mode or in a single-burst SPI cycle. The IRQ and/or

RXRDY/LD1_ interrupts are automatically cleared when

the first byte of the message is read out of the RxFIFO_, or

alternatively, by reading the Interrupt register.

If the device message is not received successfully (i.e.,

received with an error), an RxError_ interrupt is signaled to

the host controller by asserting the IRQ pin (if RxErrIntEn_

= 1) and/or by asserting the RXERR_/LD2_ pin. Detected

errors in the received data can include checksum, parity,

UART framing, or size deviations. The RxError_ interrupt is

cleared only when the Interrupt register is read.

Monitoring Message Timing

The IO-Link standard requires that the device reply

message must be fully received within a time of

tM-sequence after the start of the communication cycle: