MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

General Description

The MAX16930/MAX16931 offer two high-voltage,

synchronous step-down controllers and a step-up

preboost controller. They operate with an input voltage

supply from 2V to 42V with preboost active and can

“operate in drop-out condition by running at 95% duty

cycle. The devices are intended for applications with

mid- to high-power requirements that operate at a wide

input voltage range such as during automotive coldcrank or engine stop-start conditions.

The MAX16930/MAX16931 step-down controllers

operate 180° out-of-phase at frequencies up to 2.2MHz

to allow small external components, reduced output

ripple, and to guarantee no AM band interference. The

switching frequency is resistor adjustable. The FSYNC

input programmability enables three frequency modes

for optimized performance: forced fixed-frequency

operation, skip mode with ultra-low quiescent

current (20µA), and synchronization to an external clock.

The devices also provide a spread-spectrum option to

minimize EMI interference.

The MAX16930/MAX16931 are offered with an

asynchronous step-up controller. This preboost circuitry turns on during low input voltage conditions. It is

designed to provide power to step-down controller channels with input voltages as low as 2V.

The devices also feature a power-OK monitor and

overvoltage and undervoltage lockout. Protection

features include cycle-by-cycle current limit and thermal

shutdown.

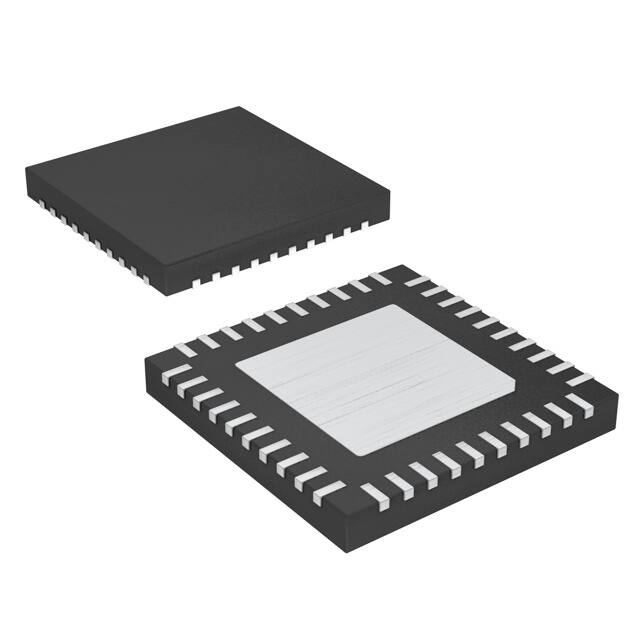

The devices are available in 40-pin TQFN-EP and

side-wettable QFND-EP packages and are specified

for operation over the -40°C to +125°C automotive

temperature range.

Benefits and Features

●● Meets Stringent OEM Module Power Consumption

and Performance Specifications

• 20µA Quiescent Current in Skip Mode

• ±1% Output-Voltage Accuracy: 5.0V/3.3V Fixed or

Adjustable Between 1V and 10V

●● Enables Crank-Ready Designs

• Integrated Preboost for Operation Down to 2V in

Bootstrap Mode

• Wide Input Supply Range from 3.5V to 36V

(without Preboost)

●● EMI Reduction Features Reduce Interference with

Sensitive Radio Bands without Sacrificing Wide Input

Voltage Range

• 50ns (typ) Minimum On-Time Guarantees SkipFree Operation for 3.3V Output from Car Battery

at 2.2MHz

• Frequency-Synchronization Input

• Resistor-Programmable Frequency Between

200kHz and 2.2MHz

●● Integration and Thermally Enhanced Packages Save

Board Space and Cost

• Dual, 2MHz Step-Down Controllers

• 180° Out-of-Phase Operation

• Current-Mode Controllers with Forced-Continuous

and Skip Modes

• Thermally Enhanced 40-Pin TQFN-EP and

Side-Wettable QFND-EP Packages

●● Protection Features Improve System Reliability

• Supply Overvoltage and Undervoltage Lockout

• Overtemperature and Short-Circuit Protection

Applications

POL Applications for Automotive Power

Distributed DC Power Systems

Navigation and Radio Head Units

Selector Guide and Ordering Information appear at end of

data sheet.

19-6631; Rev 13; 7/16

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Absolute Maximum Ratings

IN, INS, CS3P, CS3N, FB3, EN1, EN2,

EN3, TERM to PGND_........................................-0.3V to +42V

CS1, CS2, OUT1, OUT2 to AGND.........................-0.3V to +11V

CS1 to OUT1.........................................................-0.2V to +0.2V

CS2 to OUT2.........................................................-0.2V to +0.2V

CS3P to CS3N.......................................................-0.2V to +0.2V

BIAS, FSYNC, FOSC to AGND..............................-0.3V to +6.0V

COMP1, COMP2, BSTON to AGND......................-0.3V to +6.0V

FB1, FB2, FSELBST, EXTVCC to AGND...............-0.3V to +6.0V

DL_ to PGND_ (Note 1).........................................-0.3V to +6.0V

BST_ to LX_ (Note 1)............................................-0.3V to + 6.0V

DH_ to LX_ (Note 1).............................................-0.3V to + 6.0V

LX_ to PGND_ (Note 1)..........................................-0.3V to +42V

PGND_ to AGND...................................................-0.3V to +0.3V

PGOOD1, PGOOD2 to AGND..............................-0.3V to +6.0V

Continuous Power Dissipation (TA = +70NC)

TQFN (derate 37mW/NC above +70NC).....................2963mW

QFND (derate 29.4mW/NC above +70NC)..................2350mW

Operating Temperature Range......................... -40NC to +125NC

Junction Temperature Range...........................................+150NC

Storage Temperature Range............................. -65NC to +150NC

Lead Temperature (soldering, 10s).................................+300NC

Soldering Temperature (reflow).......................................+260NC

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Package Thermal Characteristics (Note 2)

TQFN

Junction-to-Ambient Thermal Resistance (qJA)...........27°C/W

Junction-to-Case Thermal Resistance (qJC)..................1°C/W

QFND

Junction-to-Ambient Thermal Resistance (qJA)...........34°C/W

Junction-to-Case Thermal Resistance (qJC)...............3.9°C/W

Note 1: Self-protected against transient voltages exceeding these limits for ≤ 50ns under normal operation and loads up to the

maximum rated output current.

Note 2: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-layer

board. For detailed information on package thermal considerations, refer to www.maximintegrated.com/thermal-tutorial.

Electrical Characteristics

(VIN = 14V, VBIAS = 5V, CBIAS = 6.8µF, TA = TJ = -40NC to +125NC, unless otherwise noted.) (Note 3)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNIT

SYNCHRONOUS STEP-DOWN DC-DC CONVERTERS

Normal operation

Supply Voltage Range

Supply Current

VIN

IIN

Buck 1 Fixed Output Voltage

VOUT1

Buck 2 Fixed Output Voltage

VOUT2

Output Voltage Adjustable

Range

www.maximintegrated.com

3.5

36

t < 1s

With preboost after initial startup condition

is satisfied

42

2.0

VEN1 = VEN2 = VEN3 = 0V

8

20

VEN1 = 5V, VOUT1 = 5V, VEN2 = VEN3 =

0V, VEXTVCC = 5V, no switching

30

40

VEN2 = 5V, VOUT2 = 3.3V, VEN1 = VEN3 =

0V, VEXTVCC = 3.3V, no switching

20

30

VEN1 = VEN2 = 5V, VOUT1 = 5V, VOUT2 =

3.3V, VEN3 = 0V, VEXTVCC = 3.3V,

no switching

25

40

VFB1 = VBIAS, PWM mode

4.95

5

5.05

VFB1 = VBIAS, skip mode

4.95

5

5.075

VFB2 = VBIAS, PWM mode

3.234

3.3

3.366

VFB2 = VBIAS, skip mode

3.234

3.3

3.4

Buck 1, buck 2

1

V

36

10

FA

V

V

V

Maxim Integrated │ 2

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Electrical Characteristics (continued)

(VIN = 14V, VBIAS = 5V, CBIAS = 6.8µF, TA = TJ = -40NC to +125NC, unless otherwise noted.) (Note 3)

PARAMETER

Regulated Feedback Voltage

SYMBOL

Output Overvoltage Threshold

Feedback Leakage Current

IFB1,2

Feedback Line Regulation Error

Transconductance

(from FB_ to COMP_)

gm

Dead Time

Maximum Duty-Cycle

Minimum On-Time

MIN

TYP

MAX

UNIT

0.99

1.0

1.01

V

FB rising

+10

+15

+20

FB falling (Note 4)

+5

+10

+15

TA = +25NC

0.01

1

VIN = 3.5V to 36V, VFB = 1V

0.00

VFB = 1V, VBIAS = 5V (Note 5)

1200

MAX16930, DL_ low to DH_ high

35

MAX16930, DH_ low to DL_ high

60

MAX16931, DL_ low to DH_ high

60

MAX16931, DH_ low to DL_ high

100

Buck 1, buck 2

tON(MIN)

PWM Switching Frequency

Range

fSW

Spread-Spectrum Range

%

FA

%/V

2400

FS

ns

95

Buck 1, buck 2

50

%

ns

Programmable, high frequency,

MAX16930

1

2.2

Programmable, low frequency,

MAX16931

0.2

1

MHz

MAX16930ATLT/V+,

MAX16930BATLU/V+ only

Buck 2 Switching Frequency

Switching Frequency Accuracy

CONDITIONS

VFB1,2

1/2fSW

MHz

MAX16930, RFOSC = 13.7kI,

VBIAS = 5V

1.98

2.2

2.42

MHz

MAX16931, RFOSC = 80.6kI,

VBIAS = 5V

360

400

440

kHz

Spread spectrum enabled

±6

%

FSYNC INPUT

FSYNC Frequency Range

FSYNC Switching Thresholds

CS Current-Limit Voltage

Threshold

Minimum sync pulse of 100ns, MAX16930

1.2

2.4

MHz

Minimum sync pulse of 100ns, MAX16931

240

1200

kHz

High threshold

1.5

Low threshold

VLIMIT1,2

VCS - VOUT, VBIAS = 5V, VOUT R 2.5V

Skip Mode Threshold

Current sense = 80mV

Soft-Start Ramp Time

Buck 1 and buck 2, fixed soft-start time

regardless of frequency

Phase Shift Between Buck1 and

Buck 2

64

80

96

15

2

6

VIN = 6V, VLX_ = VIN, TA = +25NC

DH1, DH2 Pullup Resistance

DH1, DH2 Pulldown Resistance

V

mV

mV

10

180

LX1, LX2 Leakage Current

www.maximintegrated.com

0.6

ms

°

0.01

1

FA

VBIAS = 5V, IDH_ = -100mA

10

20

I

VBIAS = 5V, IDH_ = +100mA

2

4

I

Maxim Integrated │ 3

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Electrical Characteristics (continued)

(VIN = 14V, VBIAS = 5V, CBIAS = 6.8µF, TA = TJ = -40NC to +125NC, unless otherwise noted.) (Note 3)

TYP

MAX

UNIT

DL1, DL2 Pullup Resistance

PARAMETER

VBIAS = 5V, IDL_ = -100mA

4

8

I

DL1, DL2 Pulldown Resistance

VBIAS = 5V, IDL_ = +100mA

1.5

3

I

PGOOD1, PGOOD2 Threshold

SYMBOL

CONDITIONS

MIN

PGOOD_H

% of VOUT_, rising

85

90

95

PGOOD_F

% of VOUT_, falling

80

85

90

0.01

1

PGOOD1, PGOOD2 Leakage

Current

VPGOOD1,2 = 5V, TA = +25NC

PGOOD1, PGOOD2 Startup

Delay Time

Buck 1 and buck 2 after soft-start

is complete

PGOOD1, PGOOD2 Debounce

Time

Fault detection

64

8

%

FA

Cycles

20

40

Fs

5

5.25

V

3.1

3.4

INTERNAL LDO: BIAS

Internal BIAS Voltage

VIN > 6V

4.75

VBIAS rising

BIAS UVLO Threshold

VBIAS falling

2.7

Hysteresis

External VCC Threshold

2.9

0.2

VTH,EXTVCC

EXTVCC rising, HYST = 110mV

3

V

V

3.2

V

THERMAL OVERLOAD

Thermal Shutdown Temperature

(Note 5)

170

NC

Thermal Shutdown Hysteresis

(Note 5)

20

NC

EN LOGIC INPUT

High Threshold

1.8

V

Low Threshold

Input Current

0.01

EN1, EN2 logic inputs only, TA = +25NC

0.8

V

1

FA

PREBOOST

Minimum On Time

TONBST

60

ns

Minimum Off Time

TOFFBST

60

ns

VFSELBST = 0V, RFOSC = 13.7kI

1.98

2.2

2.42

VFSELBST = VBIAS, RFOSC = 13.7kI

0.4

0.44

0.48

ILIMBST

CS3P - CS3N

108

120

132

mV

VINS,UV

One-time latch during startup; preboost

is disabled until the VINS rises above

this threshold (MAX16930ATLV/V+,

MAX16930BATLW/V+ (Note 6))

1

1.05

1.1

V

Switching Frequency

fBOOST

Current Limit

INS Unlock Threshold

www.maximintegrated.com

MHz

Maxim Integrated │ 4

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Electrical Characteristics (continued)

(VIN = 14V, VBIAS = 5V, CBIAS = 6.8µF, TA = TJ = -40NC to +125NC, unless otherwise noted.) (Note 3)

PARAMETER

INS Off Threshold

INS On Threshold

INS Threshold

Undervoltage Lockout

SYMBOL

VINS,OFF

VINS,ON,SW

CONDITIONS

MIN

TYP

MAX

Battery rising and EN3 high, preboost

turns off if VINS is above this threshold

(MAX16930ATLV/V+, MAX16930BATLW/

V+ (Note 6))

1.2

1.25

1.3

Battery falling and EN3 high, preboost

turns back on when VINS falls below

this threshold (MAX16930ATLV/V+,

MAX16930BATLW/V+ (Note 6))

1.1

1.15

1.2

0.325

0.35

0.375

Battery rising and EN3 high

(MAX16930ATLV/V+, MAX16930BATLW/

V+ (Note 6))

VINS,UV

Battery falling and EN3 high, preboost

turns off when VINS falls below this

threshold (MAX16930ATLV/V+,

MAX16930BATLW/V+ (Note 6))

UNIT

V

V

0.275

0.3

0.325

0.01

1

BSTON Leakage Current

VBSTON = 5V, TA = +25NC

BSTON Debounce Time

Fault detection

10

DL3 Pullup Resistance

VBIAS = 5V, IDL3 = -100mA

4

8

I

DL3 Pulldown resistance

VBIAS = 5V, IDL3 = +100mA

1

2

I

1.25

1.3125

V

Feedback Voltage

Boost Load Regulation Error

EN3 Threshold

VFB3

No load on boost output

1.1875

0mV < VCS3P - VCS3N < 120mV,

error proportional to input current

High threshold

Fs

0.7

%/A

3.5

Low threshold

FA

2

V

EN3 Input Current

VEN3 = 5.5V

7

14

FA

TERM Resistance

ITERM = 10mA

70

150

I

TERM Leakage Current

VTERM = 14V, VEN3 = 0V, TA = +25NC

0.01

1

FA

INS and FB3 Leakage Current

TA = +25NC

0.01

1

FA

Note 3: Limits are 100% production tested at TA = +25°C. Limits over the operating temperature range and relevant supply voltage are guaranteed by design and characterization. Typical values are at TA = +25°C.

Note 4: Overvoltage protection is detected at the FB1/FB2 pins. If the feedback voltage reaches overvoltage threshold of FB1/FB2

+ 15% (typ), the corresponding controllers stop switching. The controllers resume switching once the output drops below

FB1/FB2 + 10% (typ).

Note 5: Guaranteed by design; not production tested.

Note 6: INS pin functionality is disabled for the MAX16930ATLV/V+, MAX16930BATLW/V+. EN3 directly controls the turn-on and

turn-off of the boost controller.

www.maximintegrated.com

Maxim Integrated │ 5

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

NO-LOAD STARTUP SEQUENCE

(VFSYNC = 0V)

MAX16930 toc01

FULL-LOAD STARTUP SEQUENCE

(VFSYNC = 0V)

MAX16930 toc02

VBAT

5V/div

VOUT1

2V/div

IOUT1

2A/div

VPGOOD1

5V/div

VOUT2

2V/div

IOUT2

2A/div

VPGOOD2

5V/div

VOUT1

2V/div

VOUT2

2V/div

VPGOOD1

5V/div

VPGOOD2

5V/div

4ms/div

VEN1 = 0V

VEN2 = VBAT

EXTVCC = VOUT2

10

70

60

50

40

30

MAX16930 toc04

BUCK 1

EXTVCC = VOUT2

40

30

20

0

20 40 60 80 100 120 140

80

5

10

15

70

60

EXTVCC =

GND

SKIP MODE

50

30

PWM MODE

10

20

25

30

35

EXTVCC =

GND

EXTVCC =

VOUT1

40

20

BUCK 2

EXTVCC = VOUT2

0

fSW = 2.2MHz EXTVCC = VOUT1

L = 2.2µH

VBAT = 14V

VOUT1 = 5V

90

0

1.0E-06 1.0E-05 1.0E-04 1.0E-03 1.0E-02 1.0E-01 1.0E+00 1.0E+01

40

SUPPLY VOLTAGE (V)

IOUT1 (A)

BUCK 2 EFFICIENCY

SWITCHING FREQUENCY

vs. LOAD CURRENT

SWITCHING FREQUENCY

vs. RFOSC (MAX16930)

fSW = 2.2MHz EXTVCC = VOUT2

L = 2.2µH

VBAT = 14V

VOUT2 = 3.3V

SKIP MODE

EXTVCC =

GND

EXTVCC =

VOUT2

20

EXTVCC =

GND

PWM MODE

10

0

1.0E-06 1.0E-05 1.0E-04 1.0E-03 1.0E-02 1.0E-01 1.0E+00 1.0E+01

IOUT1 (A)

www.maximintegrated.com

2.30

2.28

BUCK 2

2.26

2.24

2.22

BUCK 1

2.20

2.18

2.16

2.14

2.12

2.10

0

1

2

3

4

LOAD CURRENT (A)

5

6

MAX16930 toc08

TEMPERATURE (°C)

2.4

SWITCHING FREQUENCY (MHz)

80

50

MAX16930 toc07

90

0

60

10

SWITCHING FREQUENCY (MHz)

100

-60 -40 -20

70

BUCK 1 EFFICIENCY

100

EFFICIENCY (%)

20

80

QUIESCENT CURRENT (µA)

30

MAX16930 toc06

QUIESCENT CURRENT (µA)

40

0

EFFICIENCY (%)

VEN1 = VBAT

VEN2 = 0V

EXTVCC = VOUT1

50

QUIESCENT CURRENT

vs. SUPPLY VOLTAGE

MAX16930 toc03

QUIESCENT CURRENT

vs. TEMPERATURE

MAX16930 toc05

2ms/div

60

VBAT

5V/div

2.2

2.0

VBIAS = 5V

1.8

1.6

VBIAS = 3.3V

1.4

1.2

1.0

10

15

20

25

30

RFOSC (kΩ)

Maxim Integrated │ 6

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

2.40

1.0

0.9

SWITCHING FREQUENCY (MHz)

MAX16930 toc09

SWITCHING FREQUENCY (MHz)

1.1

0.8

0.7

VBIAS = 5V

0.6

0.5

0.4

0.3

0.2

2.35

SWITCHING FREQUENCY

vs. TEMPERATURE

MAX16930 toc10

SWITCHING FREQUENCY

vs. RFOSC (MAX16931)

RFOSC = 13.7kΩ

2.30

2.25

2.20

2.15

2.10

2.05

VBIAS = 3.3V

2.00

30 40 50 60 70 80 90 100 110 120 130 140 150 160 170

-60 -40 -20 0

RFOSC (kΩ)

LOAD TRANSIENT RESPONSE

DIPS AND DROPS

EXTERNAL FSYNC TRANSITION

MAX16930 toc12

MAX16930 toc11

20 40 60 80 100 120 140

TEMPERATURE (ºC)

MAX16930 toc13

VBAT

10V/div

VLX1

10V/div

VOUT1

100mV/div

VLX2

10V/div

IOUT1

1A/div

400µs/div

LOAD DUMP

SLOW VIN RAMP

VOUT2

1V/div

SHORT-CIRCUIT RESPONSE

MAX16930 toc15

MAX16930 toc16

IOUT1

2A/div

VOUT1

2V/div

VPGOOD1

5V/div

VOUT2

2V/div

VPGOOD2

5V/div

VPGOOD2

5V/div

www.maximintegrated.com

40ms/div

VBAT

5V/div

VBAT

10V/div

LOAD DUMP, PWM

100ms/div

VOUT1

5V/div

VFSYNC

2V/div

400ns/div

MAX16930 toc14

VPGOOD1

5V/div

10s/div

200µs/div

VOUT1

1V/div

VPGOOD1

2V/div

Maxim Integrated │ 7

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

MAX16930 toc17

BUCK 1 LOAD REGULATION

4.998

VFSYNC = VBIAS

4.997

VOUT1

1V/div

VPGOOD1

2V/div

MAX16930 toc18

OUTPUT OVERVOLTAGE RESPONSE

4.996

VOUT_ (V)

4.995

4.994

4.993

4.992

4.991

4.990

4.989

1s/div

0

1

2

3

4

5

6

IOUT_ (A)

3.294

3.293

3.292

99.90

99.85

99.80

3.290

99.75

0

1

2

3

4

99.70

6

5

1.005

1.000

-60 -40 -20 0

20 40 60 80 100 120 140

0.990

0

10

15

20

25

30

35

40

VSUP (V)

MINIMUM ON-TIME (BUCK 1)

FB2 LINE REGULATION

MAX16930 toc22

MAX16930 toc23

VOUT1 = 1.8V

IOUT1 = 300mA

VBAT

5V/div

1.000

0.995

0.990

5

TEMPERATURE (ºC)

1.005

VOUT_ (V)

VOUT1 =1.8V

0.995

IOUT_ (A)

1.010

VOUT2

VOUT1

99.95

3.291

3.289

EXTVCC = VGND

VFSYNC = VBIAS

IOUT_ =0A

FB1 LINE REGULATION

1.010

MAX16930 toc21

100.00

VOUT_ (%nominal)

VOUT_ (V)

3.295

100.05

VOUT_ vs. TEMPERATURE

VOUT_ (V)

MAX16930 toc19

VFSYNC = VBIAS

3.296

100.10

MAX16930 toc20

BUCK 2 LOAD REGULATION

3.297

VOUT1

1V/div

0

5

10

15

20

25

30

35

40

200ns/div

VSUP (V)

www.maximintegrated.com

Maxim Integrated │ 8

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

MINIMUM ON-TIME (BUCK 2)

COLD CRANK (PREBOOST ON)

MAX16930 toc24

BOOST ENABLE

MAX16930 toc25

MAX16930 toc26

IOUT2 = 300mA

VBAT

10V/div

VIN

5V/div

VBSTON

5V/div

VOUT1

5V/div

VPGOOD1

5V/div

VOUT2

5V/div

VPGOOD2

5V/div

VBAT

5V/div

VOUT1

1V/div

VIN

5V/div

VSNS

1V/div

VBSTON

5V/div

400ms/div

LX WAVEFORMS

MAX16930 toc27

2s/div

IOUT1 = IOUT2 = 1A

9.95

VLX1

5V/div

9.90

PREBOOST LOAD REGULATION

MAX16930 toc28

200ns/div

VBAT

5V/div

VBAT = 7V

9.85

VOUT_ (V)

9.80

VLX2

5V/div

9.75

9.70

9.65

9.60

VLXBST

5V/div

9.55

9.50

200ns/div

0

1

2

3

4

5

6

IOUT_ (A)

20

10

0

-10

25

20

15

10

5

0

-5

300 320 340 360 380 400 320 440 460 480 500

FREQUENCY (kHz)

www.maximintegrated.com

-10

SPECTRAL ENERGY DENSITY

vs. FREQUENCY

35

MEASURED ON THE MAX16930BATLS/V+

30

25

MAX16930 toc31

30

MEASURED AT VOUT2 ON

THE MAX16930BATLU/V+

OUTPUT SPECTRUM (dBµV)

30

35

SPECTRAL ENERGY DENSITY

vs. FREQUENCY

MAX16930 toc30

40

40

OUTPUT SPECTRUM (dBµV)

MEASURED ON THE MAX16931BATLS/V+

MAX16930 toc29

OUTPUT SPECTRUM (dBµV)

50

SPECTRAL ENERGY DENSITY

vs. FREQUENCY

20

15

10

5

0

-5

800k

960k

1.0M

FREQUENCY (Hz)

1.1M

1.2M

-10

1.8

2.0

2.2

2.4

2.6

FREQUENCY (MHz)

Maxim Integrated │ 9

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

N.C.

FSYNC

FOSC

COMP2

FB2

CS2

OUT2

PGND2

LX2

TOP VIEW

DL2

Pin Configuration

30 29 28 27 26 25 24 23 22 21

DH2 31

20 PGOOD2

BST2 32

19 PGND3

18 DL3

FSELBST 33

17 TERM

BSTON 34

MAX16930

MAX16931

EN2 35

EN1 36

16 CS3N

15 CS3P

EN3 37

14 INS

N.C. 38

13 FB3

BST1 39

12 PGOOD1

+

4

5

6

7

PGND1

CS1

OUT1

FB1

COMP1

8

9

10

EXTVCC

3

AGND

2

BIAS

1

LX1

11 IN

DL1

DH1 40

TQFN/SIDE-WETTABLE QFND

Pin Description

PIN

NAME

FUNCTION

1

LX1

Inductor Connection for Buck 1. Connect LX1 to the switched side of the inductor. LX1 serves as the

lower supply rail for the DH1 high-side gate drive.

2

DL1

Low-Side Gate Drive Output for Buck 1. DL1 output voltage swings from VPGND1 to VBIAS.

3

PGND1

4

CS1

Positive Current-Sense Input for Buck 1. Connect CS1 to the positive terminal of the current-sense

resistor. See the Current Limiting and Current-Sense Inputs and Current-Sense Measurement

sections.

5

OUT1

Output Sense and Negative Current-Sense Input for Buck 1. When using the internal preset 5V

feedback divider (FB1 = BIAS), the buck uses OUT1 to sense the output voltage. Connect OUT1

to the negative terminal of the current-sense resistor. See the Current Limiting and Current-Sense

Inputs and Current-Sense Measurement sections.

6

FB1

7

COMP1

8

BIAS

9

AGND

10

EXTVCC

www.maximintegrated.com

Power Ground for Buck 1

Feedback Input for Buck 1. Connect FB1 to BIAS for the 5V fixed output or to a resistive divider

between OUT1 and GND to adjust the output voltage between 1V and 10V. In adjustable mode,

FB1 regulates to 1V (typ). See the Setting the Output Voltage in Buck Converters section.

Buck 1 Error-Amplifier Output. Connect an RC network to COMP1 to compensate buck 1.

5V Internal Linear Regulator Output. Bypass BIAS to GND with a low-ESR ceramic capacitor of 6.8FF

minimum value. BIAS provides the power to the internal circuitry and external loads. See the Fixed

5V Linear Regulator (BIAS) section.

Signal Ground for IC

3.1V to 5.2V Input to the Switchover Comparator

Maxim Integrated │ 10

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Pin Description (continued)

PIN

11

12

NAME

IN

PGOOD1

FUNCTION

Supply Input. Connect IN to the output of the preboost. Bypass IN with sufficient capacitance to

supply the two out-of-phase buck converters.

Open-Drain Power-Good Output for Buck 1. PGOOD1 is low if OUT1 is more than 15% (typ) below

the normal regulation point. PGOOD1 asserts low during soft-start and in shutdown. PGOOD1

becomes high impedance when OUT1 is in regulation. To obtain a logic signal, pullup PGOOD1

with an external resistor connected to a positive voltage lower than 5.5V. Place a minimum of 100W

(RPGOOD1) in series with PGOOD1. See the Voltage Monitoring (PGOOD_) section for details.

FB3

Preboost Feedback Input. Connect FB3 to the center tap of a resistive-divider between the boost

regulator output and TERM to adjust the output voltage. FB3 regulates to 1.25V (typ). Ensure that the

parallel combination of the resistor-divider network is > 500W. See the Setting the Output Voltage in

Boost Converter section.

14

INS

Input Voltage Sense for Preboost. The voltage at INS is compared to internal comparator reference.

Program the preboost threshold by using resistor-divider from BAT to INS to TERM pin. Ensure

that the parallel combination of the resistor-divider network is > 500W. For the MAX16930ATLV/V+

and MAX16930BATLW/V+, the INS functionality is disabled; however, the INS pin should still be

connected using the resistor-divider between VBAT and the TERM pin.

15

CS3P

Positive Current-Sense Input for Preboost. Connect CS3P to the positive terminal of the currentsense resistor. See the Current Limit in Boost Controller and Shunt Resistor Selection in Boost

Converter sections.

16

CS3N

Negative Current-Sense Input for Preboost. Connect CS3N to the negative terminal of the currentsense resistor. See the Current Limit in Boost Controller and Shunt Resistor Selection in Boost

Converter sections.

17

TERM

Ground Switch. TERM opens when the voltage at EN3 is logic-low. Use TERM to terminate the

preboost feedback and INS resistive divider.

18

DL3

19

PGND3

13

Preboost n-Channel MOSFET Gate-Drive Output

Power Ground for Preboost. All the high-current paths for the preboost should terminate to this

ground.

Open-Drain Power-Good Output for Buck 2. PGOOD2 is low if OUT2 is more than 90% (typ) below

the normal regulation point. PGOOD2 asserts low during soft-start and in shutdown. PGOOD2

becomes high impedance when OUT2 is in regulation. To obtain a logic signal, pullup PGOOD2 with

an external resistor connected to a positive voltage lower than 5.5V.

20

PGOOD2

21, 38

N.C.

22

FSYNC

External Clock Synchronization Input. Synchronization to the controller operating frequency ratio is

1. Keep fSYNC a minimum of 10% greater than the maximum internal switching frequency for stable

operation. See the Switching Frequency/External Synchronization section.

23

FOSC

Frequency Setting Input. Connect a resistor from FOSC to AGND to set the switching frequency of

the DC-DC converters.

24

COMP2

25

FB2

www.maximintegrated.com

No Connection

Buck 2 Error Amplifier Output. Connect an RC network to COMP2 to compensate buck 2.

Feedback Input for Buck 2. Connect FB2 to BIAS for the 3.3V fixed output or to a resistive divider

between OUT2 and GND to adjust the output voltage between 1V and 10V. In adjustable mode, FB2

regulates to 1V (typ). See the Setting the Output Voltage in Buck Converters section.

Maxim Integrated │ 11

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Pin Description (continued)

PIN

NAME

FUNCTION

26

OUT2

Output Sense and Negative Current-Sense Input for Buck 2. When using the internal preset 3.3V

feedback-divider (FB2 = BIAS), the buck uses OUT2 to sense the output voltage. Connect OUT2

to the negative terminal of the current-sense resistor. See the Current Limiting and Current-Sense

Inputs and Current-Sense Measurement sections.

27

CS2

Positive Current-Sense Input for Buck 2. Connect CS2 to the positive terminal of the current-sense

resistor. See the Current Limiting and Current-Sense Inputs and Current-Sense Measurement

sections.

28

PGND2

29

DL2

Low-Side Gate Drive Output for Buck 2. DL2 output voltage swings from VPGND2 to VBIAS.

30

LX2

Inductor Connection for Buck 2. Connect LX2 to the switched side of the inductor. LX2 serves as the

lower supply rail for the DH2 high-side gate drive.

31

DH2

High-Side Gate Drive Output for Buck 2. DH2 output voltage swings from VLX2 to VBST2.

32

BST2

Boost Capacitor Connection for High-Side Gate Voltage of Buck 2. Connect a high-voltage diode

between BIAS and BST2. Connect a ceramic capacitor between BST2 and LX2. See the High-Side

Gate-Driver Supply (BST_) section.

33

FSELBST

Frequency Select Pin for the Preboost. When pulled low, the preboost will have the same switching

frequency as buck 1. When pulled high, the preboost will have a switching frequency that is 1/5th

that of buck 1. FSELBST is only active for the MAX16930. FSELBST should be connected to ground

for the MAX16931.

34

BSTON

35

EN2

High-Voltage Tolerant, Active-High Digital Enable Input for Buck 2. Driving EN2 high enables

buck 2.

36

EN1

High-Voltage Tolerant, Active-High Digital Enable Input for Buck 1. Driving EN1 high enables

buck 1.

37

EN3

High-Voltage Tolerant, Active-High Digital Enable Input for Preboost. When EN3 is high, the external

preboost is enabled and begins switching if VINS drops below VINS,OLV and required conditions are

met (see the Preboost section).

39

BST1

Boost Capacitor Connection for High-Side Gate Voltage of Buck 1. Connect a high-voltage diode

between BIAS and BST1. Connect a ceramic capacitor between BST1 and LX1. See the High-Side

Gate-Driver Supply (BST_) section.

40

DH1

High-Side Gate-Drive Output for Buck 1. DH1 output voltage swings from VLX1 to VBST1.

—

EP

www.maximintegrated.com

Power Ground for Buck 2

Preboost On-Indicator Output. To obtain a logic signal, pull up BSTON with an external resistor

connected to a positive voltage lower than 5.5V. BSTON goes high to indicate that the preboost

is on.

Exposed Pad. Connect the exposed pad to ground. Connecting the exposed pad to ground does

not remove the requirement for proper ground connections to PGND1, PGND2, PGND3, and AGND.

The exposed pad is attached with epoxy to the substrate of the die, making it an excellent path to

remove heat from the IC.

Maxim Integrated │ 12

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Detailed Description

EXTVCC Switchover

The MAX16930/MAX16931 are automotive-rated tripleoutput switching power supplies. These devices integrate two synchronous step-down controllers and an

asynchronous step-up controller and can provide up to

three independently controlled power rails as follows:

The internal linear regulator can be bypassed by connecting an external supply (3V to 5.2V) or the output

of one of the buck converters to EXTVCC. BIAS internally switches to EXTVCC and the internal linear regulator

turns off. This configuration has several advantages:

• A preboost with adjustable output voltage.

• It reduces the internal power dissipation of the

MAX16930/MAX16931.

• A buck controller with a fixed 5V output voltage or an

adjustable 1V to 10V output voltage.

• A buck controller with a fixed 3.3V output voltage or

an adjustable 1V to 10V output voltage.

• The low-load efficiency improves as the internal supply current gets scaled down proportionally to the

duty cycle.

The buck controllers and the preboost can each provide

up to 10A output current and are independently controllable.

If VEXTVCC drops below VTH,EXTVCC = 3.0V (min), the

internal regulator enables and switches back to BIAS.

Buck 1, buck 2, and the preboost are enabled and

disabled by the EN1, EN2, and EN3 control inputs,

respectively. These are active-high inputs and can be

connected directly to car battery.

Undervoltage Lockout (UVLO)

• EN1 and EN2 enable the respective buck controllers.

Connect EN1 and EN2 directly to VBAT or to powersupply sequencing logic.

The BIAS input undervoltage-lockout (UVLO) circuitry

inhibits switching if the 5V bias supply (BIAS) is below

its 2.9V (typ) UVLO falling threshold. Once the 5V bias

supply (BIAS) rises above its UVLO rising threshold and

EN1 and EN2 enable the buck controllers, the controllers

start switching and the output voltages begin to ramp up

using soft-start.

• EN3 controls the boost controller

Buck Controllers

In standby mode (only buck 2 is active), the total supply

current is reduced to 30µA (typ). When all three controllers are disabled, the total current drawn is further

reduced to 6.8µA.

The MAX16930/MAX16931 provide two buck

controllers with synchronous rectification. The step-down

controllers use a PWM, current-mode control scheme.

External logic-level MOSFETs allow for optimized loadcurrent design. Fixed-frequency operation with optimal

interleaving minimizes input ripple current from the

minimum to the maximum input voltages. Output-current

sensing provides an accurate current limit with a sense

resistor or power dissipation can be reduced using lossless current sensing across the inductor.

Fixed 5V Linear Regulator (BIAS)

The internal circuitry of the MAX16930/MAX16931 requires

a 5V bias supply. An internal 5V linear regulator (BIAS)

generates this bias supply. Bypass BIAS with a 6.8µF or

greater ceramic capacitor to guarantee stability under the

full-load condition.

The internal linear regulator can source up to 100mA

(150mA under EXTVCC switchover, see the EXTVCC

Switchover section). Use the following equation to estimate the internal current requirements for the MAX16930/

MAX16931:

IBIAS = ICC + fSW(QG_DL3 + QG_DH1 + QG_DL1 +

QG_DH2 + QG_DL2) = 10mA to 50mA (typ)

where ICC is the internal supply current, 5mA (typ), fSW

is the switching frequency, and QG_ is the MOSFET’s

total gate charge (specification limits at VGS = 5V). To

minimize the internal power dissipation, bypass BIAS to

an external 5V rail.

www.maximintegrated.com

Soft-Start

Once a buck converter is enabled by driving the corresponding EN_ high, the soft-start circuitry gradually

ramps up the reference voltage during soft-start time

(tSSTART = 6ms (typ)) to reduce the input surge currents

during startup. Before the device can begin the soft-start,

the following conditions must be met:

1) VBIAS exceeds the 3.4V (max) undervoltage lockout

threshold.

2) VEN_ is logic-high.

Maxim Integrated │ 13

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Switching Frequency/External Synchronization

Maximum Duty-Cycle Operation

The MAX16930 provides an internal oscillator adjustable from 1MHz to 2.2MHz. The MAX16931 provides

an internal oscillator adjustable from 200kHz to 1MHz.

High-frequency operation optimizes the application for

the smallest component size, trading off efficiency to

higher switching losses. Low-frequency operation offers

the best overall efficiency at the expense of component

size and board space. To set the switching frequency,

connect a resistor RFOSC from FOSC to AGND. See

TOCs 8 and 9 in the Typical Operating Characteristics

section to determine the relationship between switching

frequency and RFOSC.

The devices have a maximum duty cycle of 95%. The

internal logic of the IC looks for approximately 8 to 10

consecutive high-side FET ON pulses and decides to

turn ON the low-side FET for 150ns (typ) every 12μs. The

input voltage at which the devices enter dropout changes

depending on the input voltage, output voltage, switching

frequency, load current, and the efficiency of the design.

The input voltage at which the devices enter dropout can

be approximated as:

Buck 1 and the boost converter are synchronized with

the internal clock-signal rising edge, while buck 2 is

synchronized with the clock-signal falling edge. The

preboost enables the low-side switch (DL3) with the

rising edge of the cycle while buck 1 turns on its highside n-channel MOSFET (DH1).

The devices can be synchronized to an external clock by

connecting the external clock signal to FSYNC. A rising

edge on FSYNC resets the internal clock. Keep the FSYNC

frequency between 110% and 125% of the internal

frequency. The FSYNC signal should have a 50% duty cycle.

Light-Load Efficiency Skip Mode (VFSYNC = 0V)

Drive FSYNC low to enable skip mode. In skip mode, the

devices stop switching until the FB voltage drops below

the reference voltage. Once the FB voltage has dropped

below the reference voltage, the devices begin switching

until the inductor current reaches 30% (skip threshold)

of the maximum current defined by the inductor DCR or

output shunt resistor.

Forced-PWM Mode (VFSYNC)

Driving FSYNC high prevents the devices from entering skip mode by disabling the zero-crossing detection

of the inductor current. This forces the low-side gatedriver waveform to constantly be the complement of

the high-side gate-drive waveform, so the inductor current reverses at light loads and discharges the output

capacitor. The benefit of forced PWM mode is to keep the

switching frequency constant under all load conditions.

However, forced-frequency operation diverts a considerable amount of the output current to PGND, reducing the

efficiency under light-load conditions.

Forced-PWM mode is useful for improving load-transient

response and eliminating unknown frequency harmonics

that can interfere with AM radio bands.

www.maximintegrated.com

VOUT = [VOUT + (IOUT x RON_H)]/0.95

Note: The above equation does not take into account the

efficiency and switching frequency, but is a good firstorder approximation. Use the RON_H max number from

the data sheet of the high-side MOSFET used.

Spread Spectrum

The MAX16930AGLS/MAX16930BAGLU/MAX16931BAGLS

feature enhanced EMI performance. They perform Q6%

dithering of the switching frequency to reduce peak

emission noise at the clock frequency and its harmonics, making it easier to meet stringent emission limits.

When using an external clock source (i.e., driving the

FSYNC input with an external clock), spread spectrum

is disabled.

Buck 2 Switching Frequency

For the MAX16930ATLT and MAX16930BATLU, the switching frequency of buck 2 is set to 1/2 of fSW (buck 1 switching

frequency). When using these devices, the external components of buck 2 should be sized to account for the reduced

switching frequencies (see the Design Procedure section).

MOSFET Gate Drivers (DH_ and DL_)

The DH_ high-side n-channel MOSFET drivers are powered from capacitors at BST_ while the low-side drivers

(DL_) are powered by the 5V linear regulator (BIAS). On

each channel, a shoot-through protection circuit monitors

the gate-to-source voltage of the external MOSFETs to

prevent a MOSFET from turning on until the complementary switch is fully off. There must be a low-resistance,

low-inductance path from the DL_ and DH_ drivers to the

MOSFET gates for the protection circuits to work properly.

Follow the instructions listed to provide the necessary lowresistance and low-inductance path:

• Use very short, wide traces (50 mils to 100 mils wide

if the MOSFET is 1in from the driver).

It may be necessary to decrease the slew rate for the

gate drivers to reduce switching noise or to compensate

for low-gate charge capacitors. For the low-side drivers,

Maxim Integrated │ 14

�MAX16930/MAX16931

use gate capacitors in the range of 1nF to 5nF from DL_

to GND. For the high-side drivers, connect a small 5I to

10I resistor between BST_ and the bootstrap capacitor.

Note: Gate drivers must be protected during shutdown,

at the absence of the supply voltage (VBIAS = 0V) when

the gate is pulled high either capacitively or by the leakage path on the PCB. Therefore, external gate pulldown

resistors are needed, especially at DL3 to prevent making a direct path from VBAT to GND.

High-Side Gate-Driver Supply (BST_)

The high-side MOSFET is turned on by closing an internal switch between BST_ and DH_ and transferring the

bootstrap capacitor’s (at BST_) charge to the gate of

the high-side MOSFET. This charge refreshes when the

high-side MOSFET turns off and the LX_ voltage drops

down to ground potential, taking the negative terminal

of the capacitor to the same potential. At this time the

bootstrap diode recharges the positive terminal of the

bootstrap capacitor.

The selected n-channel high-side MOSFET determines the

appropriate boost capacitance values (CBST_ in the Typical

Operating Circuit) according to the following equation:

C BST_ =

QG

∆VBST_

where QG is the total gate charge of the high-side

MOSFET and DVBST_ is the voltage variation allowed on

the high-side MOSFET driver after turn-on. Choose

DVBST_ such that the available gate-drive voltage is not

significantly degraded (e.g., DVBST_ = 100mV to 300mV)

when determining CBST_. The boost capacitor should be

a low-ESR ceramic capacitor. A minimum value of 100nF

works in most cases.

Current Limiting and Current-Sense Inputs

(OUT_ and CS_)

The current-limit circuit uses differential current-sense

inputs (OUT_ and CS_) to limit the peak inductor current.

If the magnitude of the current-sense signal exceeds the

current-limit threshold (VLIMIT1,2 = 80mV (typ)), the PWM

controller turns off the high-side MOSFET. The actual

maximum load current is less than the peak currentlimit threshold by an amount equal to half of the inductor

ripple current. Therefore, the maximum load capability is

a function of the current-sense resistance, inductor value,

switching frequency, and duty cycle (VOUT_/VIN).

For the most accurate current sensing, use a current-sense

shunt resistor (RSH) between the inductor and the output

www.maximintegrated.com

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

capacitor. Connect CS_ to the inductor side of RSH and

OUT_ to the capacitor side. Dimension RSH such that

the maximum inductor current (IL,MAX = ILOAD,MAX+1/2

IRIPPLE,PP) induces a voltage of VLIMIT1,2 across RSH

including all tolerances. For higher efficiency, the current

can also be measured directly across the inductor. This

method could cause up to 30% error over the entire temperature range and requires a filter network in the currentsense circuit. See the Current-Sense Measurement section.

Voltage Monitoring (PGOOD_)

The MAX16930/MAX16931 include several power

monitoring signals to facilitate power-supply sequencing

and supervision. PGOOD_ can be used to enable circuits

that are supplied by the corresponding voltage rail, or to

turn on subsequent supplies.

Each PGOOD_ goes high (high impedance) when the

corresponding regulator output voltage is in regulation.

Each PGOOD_ goes low when the corresponding regulator output voltage drops below 15% (typ) or rises above

15% (typ) of its nominal regulated voltage. Connect a

10kI (typ) pullup resistor from PGOOD_ to the relevant

logic rail to level-shift the signal. PGOOD_ asserts low

during soft-start, soft-discharge, and when either buck

converter is disabled (either EN1 or EN2 is low). To

ensure latchup immunity on the PGOOD1 pin in compliance with the AEC-Q100 guidelines, a minimum resistance of 100I should be placed between the PGOOD1

pin and any other external components.

Supply Monitoring (INS)

The supply voltage in automotive systems can vary significantly and indicate potentially dangerous situations

for the application. Undervoltage transients can indicate

impending loss of power (for example during engine-start

with a weak battery), while overvoltage conditions can

quickly exceed the thermal budget of the application.

The devices include a dedicated battery voltage sensor

at INS to quickly detect overvoltage and undervoltage for

the boost converter.

SIGNAL

VBAT(MIN)

(V)

VBAT(TYP)

(V)

VBAT(MAX)

(V)

VINS,OFF

10.38

10.81

11.25

VINS,ON,SW

9.515

9.95

10.38

VINS,UV

Rising

2.81

3.0275

3.24

VINS,UV

Falling

2.38

2.6

2.81

Maxim Integrated │ 15

�MAX16930/MAX16931

Connect INS to the center tap of a resistive divider from

the input voltage (battery) to TERM to set the threshold

voltage for VINS,OFF, VINS,ON,SW, and VINS,UV. For

example, with a 153kI ±1% resistor between INS and

VBAT and a 20kI ±1% resistor between INS and TERM,

the following typical automotive VBAT levels can be

sensed, allowing for proper turn-on/turn-off of the preboost. If this setting is not sufficient, optimize the divider

for the most critical level. For the MAX16930ATLV/V+

and MAX16930BATLW/V+, the INS pin functionality is

disabled; however, the INS pin should still be connected

using the resistor-divider between VBAT and the TERM

pin, as explained above.

Preboost

The MAX16930/MAX16931 include an asynchronous

current-mode preboost with adjustable output. This preboost can be used independently, but is ideally suited

for applications that need to stay fully functional during

input voltage dropouts typical for automotive cold-crank

or start-stop.

The preboost is turned on by bringing EN3 high.

EN3 can be used for power-supply sequencing and

implementing a boost timeout to prevent overheating the

components used for the boost converter.

While the boost circuit is essential to maintain functionality

during undervoltage events, it reduces system efficiency.

During normal operation, the boost diode dissipates

power and the resistive dividers at INS and FB3 sink

significant amounts of quiescent current. To ensure

latchup immunity on the INS and FB3 pins in compliance with the AEC-Q100 guidelines, ensure that the

parallel combination of this resistor-divider network used

on these pins is > 500ω.

Increasing the Efficiency of the Boost Circuit

(TERM)

The MAX16930/MAX16931 provide a feature to improve

the efficiency of the boost circuit when it is not active:

• TERM provides a switch to GND for the INS and FB3

voltage-dividers. This switch opens during standby

mode and shutdown mode to reduce the quiescent

current by 240µA, assuming that resistors used in the

voltage-divider network are in the range of 100kI.

Preboost n-Channel MOSFET Driver (DL3)

DL3 drives the gate of an external n-channel MOSFET.

The driver is powered by the 5V (typ) internal regulator

(BIAS) or the external bypass supply (EVTVCC). DL3

asserts low during standby mode.

www.maximintegrated.com

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Switching Frequency in Boost Controller

The preboost switching frequency (fBOOST) is derived

from the buck controllers switching frequency (fSW) by

setting FOSC. See the Electrical Characteristics table.

On the MAX16930, fBOOST can be set equal to fSW by

connecting FBSTSEL to ground or to 1/5fSW by connecting FBSTSEL to BIAS. The gate driver of the preboost

turns on simultaneously with the high-side driver of buck

1. FSELBST should be connected to ground on the

MAX16931.

Current Limit in Boost Controller

A current-sense resistor (RCS), connected CS3P and

CS3N, sets the current limit of the boost converter. The

CS input has a voltage trip level (VCS) of 120mV (typ).

The low 120mV current-limit threshold reduces the power

dissipation in the current-sense resistor. Use a currentsense filter to reduce capacitive coupling during turn

on. See the Shunt Resistor Selection in Boost Converter

section.

Thermal-Overload, Overcurrent, and

Overvoltage and Undervoltage Behavior

Thermal-Overload Protection

Thermal-overload protection limits total power dissipation

in the devices. When the junction temperature exceeds

+170NC, an internal thermal sensor shuts down the

devices, allowing them to cool. The thermal sensor turns

on the devices again after the junction temperature cools

by 20NC.

Overcurrent Protection

If the inductor current on the MAX16930 and MAX16931

exceed the maximum current limit programmed at

CS_ and OUT_, the respective driver turns off. In an

overcurrent mode, this results in shorter and shorter highside pulses.

A hard short results in a minimum on-time pulse every

clock cycle.

Choose the components so they can withstand the shortcircuit current if required.

Overvoltage Protection

The devices limit the output voltage of the buck converters by turning off the high-side gate driver at approximately 115% of the regulated output voltage. The output

voltage needs to come back in regulation before the

high-side gate driver starts switching again.

Maxim Integrated │ 16

�MAX16930/MAX16931

Design Procedure

Buck Converter Design Procedure

Effective Input Voltage Range in Buck Converters

Although the MAX16930/MAX16931 can operate from

input supplies up to 36V (42V transients) and regulate

down to 1V, the minimum voltage conversion ratio (VOUT/

VIN) might be limited by the minimum controllable on-time.

For proper fixed-frequency PWM operation and optimal

efficiency, buck 1 and buck 2 should operate in continuous conduction during normal operating conditions. For

continuous conduction, set the voltage conversion ratio

as follows:

VOUT

VIN

> t ON(MIN) × fSW

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

DC output accuracy specifications in the Electrical

Characteristics table refer to the error comparator’s

threshold, VFB_ = 1V (typ). When the inductor conducts

continuously, the devices regulate the peak of the output

ripple, so the actual DC output voltage is lower than the

slope-compensated trip level by 50% of the output ripple

voltage.

In discontinuous conduction mode (skip or STDBY active

and IOUT < ILOAD(SKIP)), the devices regulate the valley of

the output ripple, so the output voltage has a DC regulation

level higher than the error-comparator threshold.

Inductor Selection in Buck Converters

Three key inductor parameters must be specified for

operation with the MAX16930/MAX16931: inductance

value (L), inductor saturation current (ISAT), and DC

resistance (RDCR). To determine the optimum inductance, knowing the typical duty cycle (D) is important.

where tON(MIN) is 50ns (typ) and fSW is the switching

frequency in Hz. If the desired voltage conversion does

not meet the above condition, pulse skipping occurs to

VOUT

VOUT

decrease the effective duty cycle. Decrease the switching=

D =

OR D

V

V

I

(R

−

IN

IN OUT DS(ON) + R DCR )

frequency if constant switching frequency is required. The

same is true for the maximum voltage conversion ratio.

if the RDCR of the inductor and RDS(ON) of the MOSFET

The maximum voltage conversion ratio is limited by the

are available with VIN = (VBAT - VDIODE). All values

maximum duty cycle (95%).

should be typical to optimize the design for normal

operation.

VOUT

< 0.95

VIN − VDROP

Inductance

The exact inductor value is not critical and can be

where VDROP = IOUT (RON,HS + RDCR) is the sum of the

adjusted in order to make trade-offs among size, cost,

parasitic voltage drops in the high-side path and fSW is

efficiency, and transient response requirements.

the programmed switching frequency. During low drop

• Lower inductor values increase LIR, which minimizes

operation, the devices reduce fSW to 25% (max) of the

size and cost and improves transient response at the

programmed frequency. In practice, the above condition

cost of reduced efficiency due to higher peak currents.

should be met with adequate margin for good load-transient response.

• Higher inductance values decrease LIR, which

increases efficiency by reducing the RMS current at

Setting the Output Voltage in Buck Converters

the cost of requiring larger output capacitors to meet

Connect FB1 and FB2 to BIAS to enable the fixed buck

load-transient specifications.

controller output voltages (5V and 3.3V) set by a preset

The

ratio of the inductor peak-to-peak AC current to DC

internal resistive voltage-divider connected between the

average

current (LIR) must be selected first. A good inifeedback (FB_) and AGND. To externally adjust the output

tial value is a 30% peak-to-peak ripple current to averagevoltage between 1V and 10V, connect a resistive divider

current ratio (LIR = 0.3). The switching frequency, input

from the output (OUT_) to FB_ to AGND (see the Typical

voltage, output voltage, and selected LIR then determine

Operating Circuit. Calculate RFB_1 and RFB_2 with the

the inductor value as follows:

following equation:

VOUT_

(VIN − VOUT )x D

R FB_1 R FB_2

=

− 1

L[µH] =

VFB_

fSW [MHz]x IOUT x LIR

where VFB_ = 1V (typ) (see the Electrical Characteristics

table).

www.maximintegrated.com

where VIN, VOUT, and IOUT are typical values (so that

efficiency is optimum for typical conditions).

Maxim Integrated │ 17

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Peak Inductor Current

Current-Sense Measurement

Inductors are rated for maximum saturation current. The

maximum inductor current equals the maximum load

current in addition to half of the peak-to-peak ripple

current:

=

IPEAK ILOAD(MAX) +

∆IINDUCTOR

2

For the selected inductance value, the actual peak-to-peak

inductor ripple current (DIINDUCTOR) is calculated as:

VOUT (VIN − VOUT )

∆IINDUCTOR =

VIN x fSW x L

For the best current-sense accuracy and overcurrent protection, use a ±1% tolerance current-sense

resistor between the inductor and output as shown in

Figure 1A. This configuration constantly monitors the

inductor current, allowing accurate current-limit protection. Use low-inductance current-sense resistors

for accurate measurement.

Alternatively, high-power applications that do not require

highly accurate current-limit protection can reduce the

overall power dissipation by connecting a series RC

circuit across the inductor (Figure 1B) with an equivalent

time constant:

R2

R CSHL =

R DCR

R1 + R2

where DIINDUCTOR is in mA, L is in µH, and fSW is in kHz.

Once the peak current and the inductance are known, the

inductor can be selected. The saturation current should

be larger than IPEAK or at least in a range where the

inductance does not degrade significantly. The MOSFETs

are required to handle the same range of current without

dissipating too much power.

MOSFET Selection in Buck Converters

Each step-down controller drives two external logic-level

n-channel MOSFETs as the circuit switch elements. The

key selection parameters to choose these MOSFETs

include the items in the following sections.

Threshold Voltage

All four n-channel MOSFETs must be a logic-level type

with guaranteed on-resistance specifications at VGS =

4.5V. If the internal regulator is bypassed (for example:

VEXTVCC = 3.3V), then the n-channel MOSFETs should

be chosen to have guaranteed on-resistance at that

gate-to-source voltage.

Maximum Drain-to-Source Voltage (VDS(MAX))

All MOSFETs must be chosen with an appropriate VDS

rating to handle all VIN voltage conditions.

Current Capability

The n-channel MOSFETs must deliver the average current

to the load and the peak current during switching. Choose

MOSFETs with the appropriate average current at VGS =

4.5V or VGS = VEXTVCC when the internal linear regulator

is bypassed. For load currents below approximately 3A,

dual MOSFETs in a single package can be an economical

solution. To reduce switching noise for smaller MOSFETs,

use a series resistor in the BST_ path and additional gate

capacitance. Contact the factory for guidance using gate

resistors.

www.maximintegrated.com

and:

R DCR

=

L

C EQ

1

1

R1 + R2

where RCSHL is the required current-sense resistor and

RDCR is the inductor’s series DC resistor. Use the inductance and RDCR values provided by the inductor

manufacturer.

Carefully observe the PCB layout guidelines to ensure

the noise and DC errors do no corrupt the differential

current-sense signals seen by CS_ and OUT_. Place

the sense resistor close to the devices with short, direct

traces, making a Kelvin-sense connection to the currentsense resistor.

Input Capacitor in Buck Converters

The discontinuous input current of the buck converter

causes large input ripple currents and therefore the

input capacitor must be carefully chosen to withstand

the input ripple current and keep the input voltage

ripple within design requirements. The 180° ripple phase

operation increases the frequency of the input capacitor

ripple current to twice the individual converter switching

frequency. When using ripple phasing, the worst-case

input capacitor ripple current is when the converter with

the highest output current is on.

The input voltage ripple is composed of DVQ (caused by

the capacitor discharge) and DVESR (caused by the ESR

of the input capacitor). The total voltage ripple is the sum

of DVQ and DVESR that peaks at the end of an on-cycle.

Maxim Integrated │ 18

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

Calculate the input capacitance and ESR required for a

specific ripple using the following equation:

∆VESR

ESR[ W ] =

∆IP − P

ILOAD(MAX) +

2

V

ILOAD(MAX) x OUT

VIN

CIN [µF] =

(∆VQ x fSW )

where:

(VIN − VOUT ) x VOUT

∆IP −P =

VIN x fSW x L

ILOAD(MAX) is the maximum output current in A, DIP-P is

the peak-to-peak inductor current in A, fSW is the switching frequency in MHz, and L is the inductor value in µH.

The internal 5V linear regulator (BIAS) includes an output

UVLO with hysteresis to avoid unintentional chattering

during turn-on. Use additional bulk capacitance if the

input source impedance is high. At lower input voltage,

additional input capacitance helps avoid possible undershoot below the undervoltage lockout threshold during

transient loading.

INPUT (VIN)

CIN

MAX16930/

MAX16931

DH_

NH

RSENSE

L

LX_

DL_

COUT

NL

GND

CS_

OUT_

A) OUTPUT SERIES RESISTOR SENSING

INPUT (VIN)

CIN

MAX16930/

MAX16931

DH_

NH

INDUCTOR

L

DCR

R1

R2

LX_

DL_

NL

GND

CS_

OUT_

CEQ

COUT

RCSHL =

RDCR =

( )

[ ]

R2

R

R1 + R2 DCR

L

1 + 1

CEQ R1 R2

B) LOSSLESS INDUCTOR SENSING

Figure 1. Current-Sense Configurartions

www.maximintegrated.com

Maxim Integrated │ 19

�MAX16930/MAX16931

Output Capacitor in Buck Converters

The actual capacitance value required relates to the

physical size needed to achieve low ESR, as well as to

the chemistry of the capacitor technology. The capacitor

is usually selected by ESR and the voltage rating rather

than by capacitance value.

When using low-capacity filter capacitors, such as

ceramic capacitors, size is usually determined by the

capacity needed to prevent VSAG and VSOAR from

causing problems during load transients. Generally,

once enough capacitance is added to meet the overshoot requirement, undershoot at the rising load edge is

no longer a problem (see the Transient Considerations

section). However, low-capacity filter capacitors typically

have high-ESR zeros that can affect the overall stability.

The total voltage sag (VSAG) can be calculated as follows:

VSAG =

L( ∆ILOAD(MAX) ) 2

2C OUT ((VIN × D MAX ) − VOUT )

+

∆ILOAD(MAX) (t − ∆t)

C OUT

The amount of overshoot (VSOAR) during a full-load to

no-load transient due to stored inductor energy can be

calculated as:

( ∆ILOAD(MAX) ) 2 L

VSOAR ≈

2C OUT VOUT

ESR Considerations

The output filter capacitor must have low enough

equivalent series resistance (ESR) to meet output

ripple and load-transient requirements, yet have high

enough ESR to satisfy stability requirements. When using

high-capacitance, low-ESR capacitors, the filter

capacitor’s ESR dominates the output-voltage ripple. So

the output capacitor’s size depends on the maximum ESR

required to meet the output-voltage ripple (VRIPPLE(P-P))

specifications:

VRIPPLE(P −P) = ESR x ILOAD(MAX) x LIR

In standby mode, the inductor current becomes discontinuous, with peak currents set by the idle-mode currentsense threshold (VCS,SKIP = 26mV (typ)).

Transient Considerations

The output capacitor must be large enough to absorb

the inductor energy while transitioning from no-load to

full-load condition without tripping the overvoltage fault

www.maximintegrated.com

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

protection. The total output-voltage sag is the sum of

the voltage sag while the inductor is ramping up and the

voltage sag before the next pulse can occur. Therefore:

(

)

2

L ∆ILOAD(MAX)

C OUT =

2VSAG (VIN x D MAX − VOUT )

+

∆ILOAD(MAX) (t − ∆t)

VSAG

where DMAX is the maximum duty factor (approximately

95%), L is the inductor value in µH, COUT is the output

capacitor value in µF, t is the switching period (1/fSW) in

µs, and Dt equals (VOUT/VIN) x t.

The MAX16930/MAX16931 use a current-mode control

scheme that regulates the output voltage by forcing

the required current through the external inductor, so

the controller uses the voltage drop across the DC

resistance of the inductor or the alternate series currentsense resistor to measure the inductor current. Currentmode control eliminates the double pole in the feedback

loop caused by the inductor and output capacitor resulting in a smaller phase shift and requiring less elaborate

error-amplifier compensation than voltage-mode control.

A single series resistor (RC) and capacitor (CC) is all

that is required to have a stable, high-bandwidth loop in

applications where ceramic capacitors are used for output filtering (see Figure 2). For other types of capacitors,

due to the higher capacitance and ESR, the frequency

of the zero created by the capacitance and ESR is

lower than the desired closed-loop crossover frequency.

To stabilize a nonceramic output capacitor loop, add

another compensation capacitor (CF) from COMP to

AGND to cancel this ESR zero.

The basic regulator loop is modeled as a power

modulator, output feedback divider, and an error

amplifier as shown in Figure 2. The power modulator has

a DC gain set by gmc x RLOAD, with a pole and zero pair

set by RLOAD, the output capacitor (COUT), and its ESR.

The loop response is set by the following equations:

GAINMOD(dc)

= g mc × R LOAD

where RLOAD = VOUT/ILOUT(MAX) in I and gmc =

1/(AV_CS x RDC) in S. AV_CS is the voltage gain of the

current-sense amplifier and is typically 11V/V. RDC is the

DC resistance of the inductor or the current-sense

resistor in I.

Maxim Integrated │ 20

�MAX16930/MAX16931

2MHz, 36V, Dual Buck with Preboost and

20µA Quiescent Current

A dominant pole (fdpEA) is set by the compensation

capacitor (CC) and the amplifier output resistance

(ROUT,EA). A zero (fZEA) is set by the compensation

resistor (RC) and the compensation capacitor (CC). There

is an optional pole (fPEA) set by CF and RC to cancel the

output capacitor ESR zero if it occurs near the crossover

frequency (fC), where the loop gain equals 1 (0dB)). Thus:

gmc = 1/(AVCS x RDC)

CS_

CURRENT-MODE

POWER

MODULATION

OUT_

R1

RESR

COUT

gmea = 1200µS

fdpEA =

FB_

COMP_

ERROR

AMP

R2

VREF

30MI

RC

CF

1

2π × C C × (R OUT,EA + R C )

fzEA =

1

2π × C C × R C

fpEA =

1

2π × C F × R C

CC

Figure 2. Compensation Network

In a current-mode step-down converter, the output capacitor and the load resistance introduce a pole at the following frequency:

fpMOD =

1

2π × C OUT × R LOAD

The unity gain frequency of the power stage is set by

COUT and gmc:

g mc

fUGAINpMOD =

2π × C OUT

The output capacitor and its ESR also introduce a zero at:

fzMOD =

1

2π × ESR × C OUT

When COUT is composed of “n” identical capacitors in

parallel, the resulting COUT = n x COUT(EACH), and ESR =

ESR(EACH) /n. Note that the capacitor zero for a parallel

combination of alike capacitors is the same as for an individual capacitor.

The feedback voltage-divider has a gain of GAINFB =

VFB /VOUT, where VFB is 1V (typ).

The transconductance error amplifier has a DC gain of

GAINEA(DC) = gm,EA x ROUT,EA, where gm,EA is the error

amplifier transconductance, which is 1200µS (typ), and

ROUT,EA is the output resistance of the error amplifier,

which is 30MI (typ) (see the Electrical Characteristics

table.)

www.maximintegrated.com

The loop-gain crossover frequency (fC) should be set

below 1/5th of the switching frequency and much higher

than the power-modulator pole (fpMOD). Select a value

for fC in the range:

f

fpMOD