EVALUATION KIT AVAILABLE

Click here to ask an associate for production status of specific part numbers.

MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

General Description

Benefits and Features

The MAX16956 is a small, synchronous buck converter

with integrated high-side and low-side switches. The device is designed to deliver up to 300mA with input voltages

from 3.5V to 36V, while using only 1.1µA quiescent current

at no load (fixed-output versions). Voltage quality can be

monitored by observing the RESET signal. The device can

operate near dropout by running at 97% duty cycle, making it ideal for automotive applications under cold-crank.

● Integration and High-Switching Frequency Saves

Space

• DC-DC Converter Up to 300mA Capability

• Fixed 5V/3.3V or Programmable Output-Voltage

Options (1V to 15V)

• Current-Mode-Control Architecture

• 2.1MHz Operating Frequency

• Fixed 5.4ms Internal Soft-Start

The device offers fixed-output voltages of 5V and 3.3V, as

well as an adjustable version. The adjustable version allows the user to program the output voltage between 1V

and 15V by using a resistor-divider. Frequency is fixed at

2.1MHz, which allows for small external components, reduced output ripple, and minimized AM radio interference.

The device offers both forced-PWM and skip modes of operation, with ultra-low quiescent current of 1.1µA in skip

mode. The device can be ordered with spread- spectrum

frequency modulation designed to minimize EMI-radiated

emissions due to the switching frequency.

● Spread-Spectrum Frequency Modulation Reduces

EMI Emissions

● Low IQ Enables Designers to Meet Stringent OEM

Module Power-Consumption Requirements

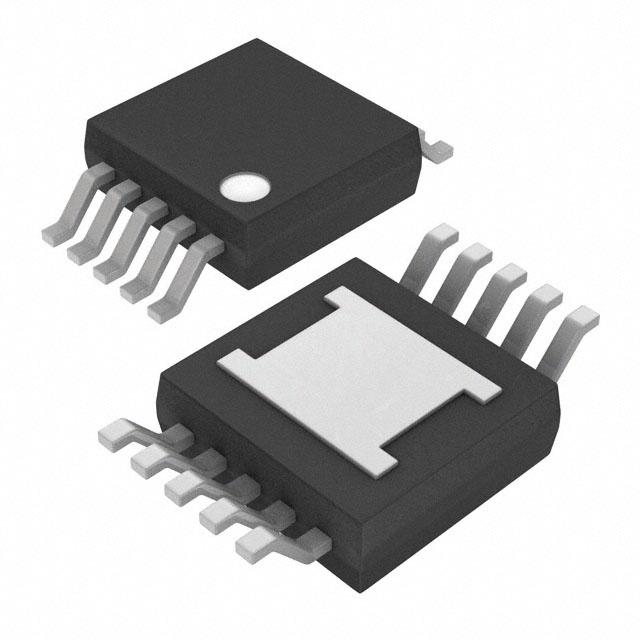

The MAX16956 is available in a small (3mm x 3mm)

10-pin µMAX® package and operates across the full automotive temperature range of -40°C to +125°C. The device

is AEC-Q100 qualified.

● Robust Performance Supports Wide Range of

Automotive Applications

• Short-Circuit, Thermal Protections

• -40°C to +125°C Automotive Temperature Range

• AEC-Q100 Qualified

Applications

● Automotive Body ECUs

● Point-of-Load Applications

● Distributed DC Power Systems

• 1.1μA Quiescent Current in Standby Mode (FixedOutput-Voltage Versions Only)

● Wide Input Voltage Range Supports Automotive

Applications

• Operating VIN Range: 3.5V to 36V (42V Tolerant)

• 97% (Max) Duty-Cycle Operation with Low Dropout

Simplified Block Diagram

VBAT

SUP

BST

CIN

0.1µF

MAX16956

L1

LX

VOUT

COUT

MODE

OUT/FB

EN

BIAS

1µF

RESET

AGND

PGND

μMAX is a registered trademark of Maxim Integrated Products, Inc.

Ordering Information appears at end of data sheet.

19-6737; Rev 6; 2/21

© 2021 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

One Analog Way, Wilmington, MA 01887 U.S.A. | Tel: 781.329.4700 | © 2021 Analog Devices, Inc. All rights reserved.

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Absolute Maximum Ratings

(Voltages Referenced to PGND) ..................................................

SUP ........................................................................ -0.3V to +42V

EN............................................................... -0.3V to VSUP + 0.3V

BST to LX ............................................................................... +6V

BST......................................................................... -0.3V to +47V

MODE, OUT/FB, RESET............................-0.3V to VBIAS + 0.3V

AGND .................................................................... -0.3V to +0.3V

BIAS ...................................................................... -0.3V to +6.0V

OUT/FB Short-Circuit Duration ...................................Continuous

Continuous Power Dissipation (TA = +70°C)

(derate 12.9mW/ºC above +70°C)...............................1031mW

Operating Temperature Range ...........................-40°C to +125°C

Junction Temperature ....................................................... +150°C

Storage Temperature Range ..............................-65°C to +150°C

Lead Temperature (soldering, 10s)..................................... 300°C

Soldering Temperature (reflow) ........................................ +260°C

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the

device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

Package Information

10 μMAX

Package Code

U10E+3

Outline Number

21-0109

Land Pattern Number

90-0148

THERMAL RESISTANCE, SINGLE-LAYER BOARD

Junction to Ambient (θJA)

77.6°C/W

Junction to Case (θJC)

5°C/W

For the latest package outline information and land patterns (footprints), go to www.maximintegrated.com/packages.

Note that a “+”, “#”, or “-” in the package code indicates RoHS status only. Package drawings may show a different

suffix character, but the drawing pertains to the package regardless of RoHS status.

Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a

four-layer board. For detailed information on package thermal considerations, refer to www.maximintegrated.com/

thermal-tutorial.

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7,

using a four-layer board. For detailed information on package thermal considerations, refer to

www.maximintegrated.com/thermal-tutorial.

Electrical Characteristics

(VSUP = VEN = 14V, VMODE = 0V, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C, unless

otherwise noted.) (Note 2)

PARAMETER

Supply Voltage

Supply Current

UV Lockout

www.analog.com

SYMBOL

VSUP

ISUP

CONDITIONS

MIN

TYP

3.5

MAX

36

T < 500ms (Note 3)

42

VEN = 0V

0.75

3.0

No load, fixed 3.3V VOUT

1.1

3.0

No load, fixed 5V VOUT

1.8

5.0

No load, adjustable VOUT

32

70

VMODE = VBIAS , no load, FPWM, no

switching

0.5

1

1.5

VBIAS rising

3.0

3.2

3.4

Hysteresis

0.4

UNITS

V

µA

mA

V

Analog Devices | 2

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Electrical Characteristics (continued)

(VSUP = VEN = 14V, VMODE = 0V, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C, unless

otherwise noted.) (Note 2)

PARAMETER

SYMBOL

CONDITIONS

BIAS Regulator Voltage

VBIAS

VSUP = 5.5V to 36V (MAX16956C/F only)

BIAS Current Limit

MIN

TYP

MAX

5

UNITS

V

10

mA

BUCK CONVERTER

VOUT,5V

VOUT = 5V

6V ≤ VSUP ≤ 36V,

ILOAD = 0 to

300mA

4.9

VOUT = 3.3V

6V ≤ VSUP ≤ 36V,

ILOAD = 0 to

300mA

3.2

3.3

3.4

0.98

1.0

1.03

Voltage Accuracy

VOUT,3.3V

FB Voltage Accuracy

VFB

Adjustable output versions, 6V ≤ VSUP ≤

36V

FB Input Current

IFB

VFB = 1V

5.0

5.2

V

0.02

V

µA

FB Load Regulation

ΔVLOAD

ILOAD = 0.3mA to 300mA

1

%

FB Line Regulation

ΔVLINE

6V ≤ VSUP ≤ 36V

0.02

%/V

High-Side DMOS

RDSON

RON,HS

VBIAS = 5V, ILX = 200mA

1000

2200

mΩ

Low-Side DMOS

RDSON

RON,LS

VBIAS = 5V, ILX = 200mA

500

1200

mΩ

DMOS High-Side

Current-Limit Threshold

IMAX

0.425

0.5

0.575

A

DMOS High-Side SkipMode Peak-Current

Threshold

ISKIP

70

100

130

mA

DMOS Low-Side ZeroCrossing Threshold

IZX

DMOS Low-Side

Negative Current-Limit

Threshold

INEG

Soft-Start Ramp Time

FPWM mode

tSS

mA

-0.320

A

5.4

ms

6

ns

LX Rise Time

tRISE,LX

Minimum On-Time

tON_MIN

60

ns

Maximum Duty Cycle

DCMAX

97

%

PWM Switching

Frequency

fSW

Spread-Spectrum

Range

SS

(Note 3)

40

1.95

2.1

2.25

Spread-spectrum option only

±6

VTHR_RES

VOUT rising

90

92

94

VTHF_RES

VOUT falling

88

90

92

MHz

%

RESET OUTPUT (RESET)

RESET Threshold

RESET Debounce

tDEB

12

%VOUT

µs

RESET High Leakage

Current

ILEAK,RES

TA = +25°C

1

µA

RESET Low Level

VOUT,RES

Sinking 1mA

0.4

V

www.analog.com

Analog Devices | 3

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Electrical Characteristics (continued)

(VSUP = VEN = 14V, VMODE = 0V, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C, unless

otherwise noted.) (Note 2)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

LOGIC LEVELS

EN Input High Threshold

VIH,EN

EN Input Low Threshold

VIL,EN

EN Input Current

IIN,EN

MODE Input High

Threshold

VIH,MODE

MODE Input Low

Threshold

VIL,MODE

MODE Internal Pulldown

RPD,MODE

2.4

V

0.4

0.1

V

µA

1.4

V

0.4

V

1000

kΩ

THERMAL PROTECTION

Thermal Shutdown

TSHDN

(Note 3)

+175

°C

Thermal-Shutdown

Hysteresis

TSHDN,HYS

(Note 3)

+15

°C

Note 2: Limits are 100% tested at TA = +25°C (and/or TA = +125°C). Limits over the operating temperature range and relevant supply

voltage range are guaranteed by design and characterization.

Note 3: Guaranteed by design; not production tested.

Note 4: When the typical minimum on-time of 80ns is violated, the device skips pulses.

www.analog.com

Analog Devices | 4

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Typical Operating Characteristics

(VCC = +3.5V, RSEN = 6.8Ω, TA = +25°C unless otherwise noted.)

80

EFFICIENCY (%)

70

90

60

50

40

60

50

40

70

50

40

30

20

20

20

10

10

10

0

0.000001

0.0001

0.01

0.00001

0.001

IOUT1 (A)

0

0.0001

0.00005

0.0002

0.00015

IOUT1 (A)

0

0.0003

0.00005

0.00025

5V EFFICIENCY v s . L OA D CURRENT

SKIP

90

80

0.0002

0.00015

IOUT1 (A)

0.00025

MAX16956 toc06

VSUP

10V/div

VSUP

10V/div

VOUT

2V/div

60

50

1

0.1

5V FIXED-OUTPUT STA RTUP

WA VEFORMS (SK IP, 300m A L OA D)

MAX16956 toc05

PWM

70

0.0003

3.3V FIXED-OUTPUT STA RTUP

WA VEFORM (PWM, 300m A L OA D)

MAX16956 toc04

100

0.0001

PWM

60

30

0

SKIP

80

30

0

EFFICIENCY (%)

70

90

EFFICIENCY (%)

80

3.3V EFFICIENCY v s . L OA D CURRENT

100

MAX16956 toc02

90

EFFICIENCY (%)

100

MAX16956 toc01

100

5V EFFICIENCY v s . L OA D

CURRENT—SK IP MODE (1μ A t o 300μ A )

MAX16956 toc03

3.3V EFFICIENCY v s . L OA D

CURRENT—SK IP MODE (1μ A t o 300μ A )

VOUT

5V/div

40

30

20

VRESET

5V/div

VRESET

5V/div

VLX

10V/div

VLX

10V/div

10

2ms/div

NO-L OA D SUPPL Y CURRENT

v s . TEMPERA TURE (SK IP MODE)

L OA D REGUL A TION (3.3V OUTPUT)

2.0

1.5

1.0

0.5

L OA D REGUL A TION (5V OUTPUT)

2

PWM

1

0

SKIP

-1

-2

-3

0

-40 -20

0

20

40

60

80 100 120 140

TEMPERATURE (°C)

www.analog.com

3

MAX16956 toc09

VOUT = 3.3V

2.5

OUTPUT-VOLTAGE CHANGE (%)

3

MAX16956 toc07

NO-LOAD SUPPLY CURRENT (μA)

3.0

2ms/div

OUTPUT-VOLTAGE CHANGE (%)

0.1

1

MAX16956 toc08

0

0.000001

0.0001

0.01

0.00001

0.001

IOUT1 (A)

2

PWM

1

0

SKIP

-1

-2

-3

0

0.05

0.10

0.15

0.20

LOAD CURRENT (A)

0.25

0.30

0

0.05

0.10

0.15

0.20

0.25

0.30

LOAD CURRENT (A)

Analog Devices | 5

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Typical Operating Characteristics (continued)

(VCC = +3.5V, RSEN = 6.8Ω, TA = +25°C unless otherwise noted.)

L INE REGUL A TION (3.3V OUTPUT)

L INE REGUL A TION (5V OUTPUT)

2

1

0

-1

-2

ILOAD = 300mA

-3

L OA D-TRA NSIENT RESPONSE

(3.3V, SK IP MODE)

MAX16956 toc11

OUTPUT-VOLTAGE CHANGE (%)

ILOAD = 300mA

3

OUTPUT-VOLTAGE CHANGE (%)

MAX16956 toc10

3

2

MAX16956 toc12

ILOAD

200mA/div

1

0

3.3V

VOUT

100mV/div

AC-COUPLED

3.3V

VPGOOD

5V/div

-1

-2

-3

6

11

16

21

26

31

36

6

INPUT VOLTAGE (V)

11

16

L OA D-TRA NSIENT RESPONSE

(3.3V, PWM MODE)

5V

36

200µs/div

L OA D-TRA NSIENT RESPONSE

(5V, PWM MODE)

MAX16956 toc15

ILOAD

200mA/div

VOUT

5V

50mV/div

AC-COUPLED

VOUT

5V

100mV/div

AC-COUPLED

VOUT

50mV/div

AC-COUPLED

VPGOOD

5V/div

VPGOOD

5V/div

VPGOOD

5V/div

200µs/div

5V

200µs/div

ILOAD

200mA/div

5V

200µs/div

5V FIXED-OUTPUT COL D-CRA NK

RESPONSE (SK IP, NO L OA D)

MAX16956 toc16

3.3V FIXED-OUTPUT DIPS A ND DROPS

RESPONSE (PWM, 300m A L OA D)

MAX16956 toc17

MAX16956 toc18

VSUP

10V/div

VSUP

10V/div

VOUT

2V/div

www.analog.com

31

ILOAD

200mA/div

3.3V FIXED-OUTPUT COL D-CRA NK

RESPONSE (PWM, 300m A L OA D)

400ms/div

26

MAX16956 toc14

MAX16956 toc13

3.3V

21

INPUT VOLTAGE (V)

L OA D-TRA NSIENT RESPONSE

(5V, SK IP MODE)

VSUP

10V/div

VOUT

5V/div

VBIAS

5V/div

VBIAS

5V/div

VLX

10V/div

VLX

10V/div

400ms/div

VOUT

2V/div

VBIAS

5V/div

VLX

10V/div

40ms/div

Analog Devices | 6

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Typical Operating Characteristics (continued)

(VCC = +3.5V, RSEN = 6.8Ω, TA = +25°C unless otherwise noted.)

5V FIXED DIPS A ND DROPS

RESPONSE (SK IP, NO L OA D)

3.3V FIXED-OUTPUT SL OW VSUP

RESPONSE (PWM, NO L OA D)

MAX16956 toc19

MAX16956 toc20

VSUP

10V/div

VSUP

10V/div

VOUT

5V/div

VOUT

2V/div

VOUT

5V/div

VBIAS

5V/div

VBIAS

5V/div

VBIAS

5V/div

VLX

10V/div

VLX

10V/div

VLX

10V/div

10s/div

SHORT-CIRCUIT RESPONSE

(PWM MODE)

MAX16956 toc22

2.10

VLX

10V/div

2.05

3.3V

2.00

VOUT

2V/div

VPGOOD

5V/div

5V

1.95

-40 -20

0

20

40

60

80 100 120 140

1.6

ILX

500mA/div

0A

2.15

2.0

MAX16956 toc23

SHUTDOWN CURRENT (μA)

SWITCHING FREQUENCY (MHz)

2.20

10s/div

SHUTDOWN CURRENT

v s . T E MP E R A T U R E

MAX16956 toc24

40ms/div

VOUT = 3.3V

MAX16956 toc21

VSUP

10V/div

SWITCHING FREQUENCY

v s . TEMPERA TURE

2.25

5V FIXED-OUTPUT SL OW VSUP

RESPONSE (SK IP, NO L OA D)

1.2

0.8

0.4

0

-40 -20

4ms/div

TEMPERATURE (°C)

0

20

40

60

80 100 120 140

TEMPERATURE (°C)

5V FIXED-OUTPUT L OA D-DUMP RESPONSE

(SK IP, VSUP = 13.5V TO 42V, NO L OA D)

MAX16956 toc25

VSUP

10V/div

VOUT

5V/div

VBIAS

5V/div

100ms/div

www.analog.com

Analog Devices | 7

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Pin Configuration

MAX16956

+

BST

1

10

EN

SUP

2

9

OUT/FB

LX

3

8

BIAS

PGND

4

7

MODE

AGND

5

6

RESET

*EXPOSED PAD

MAX16956

*

µMAX

Pin Description

PIN

NAME

1

BST

High-Side Driver Supply. Connect a 0.1μF bootstrap capacitor between LX and BST.

FUNCTION

2

SUP

IC Supply Input. Connect a minimum of 4.7μF ceramic capacitor from SUP to PGND.

3

LX

4

PGND

Power Ground. Connect to AGND under the device in a star configuration.

5

AGND

Analog Ground. Connect to PGND under the device in a star configuration.

6

RESET

Open-Drain Reset Output. An external pullup resistor is required.

7

MODE

Mode Switch-Control Input. Connect to ground or leave open to enable skip-mode operation under

light loads. Connect to BIAS to enable forced-PWM mode. MODE has a 1MΩ internal pulldown.

8

BIAS

Buck Switching Node. LX is high impedance when the device is off.

5V Internal Logic Supply. Connect a 1μF ceramic capacitor to AGND.

MAX16956A/B/D/E (Fixed Output): Buck Regulator Voltage-Sense Input. Bypass OUT to PGND

with a minimum 22μF X7R ceramic capacitor.

9

OUT/FB

MAX16956C/F (Adjustable Output): Feedback Input. Connect FB to a resistive divider between the

buck output and AGND to set the output voltage.

10

EN

SUP Voltage-Compatible Enable Input. Drive EN low to disable the device. Drive EN high to

enable the device.

—

EP

Exposed Pad. Connect EP to a large copper ground plane for effective power dissipation. Do not

use EP as the only IC ground connection. EP must be connected to PGND.

www.analog.com

Analog Devices | 8

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Block Diagram

MODE

HVLDO

EN

BANDGAP

REF

OSC

BIAS

BST

SOFTSTART

MAX16956

LOGIC

CONTROL

OUT/

FB

SUP

CLK

CURRENT SENSE

+

SLOPE COMP

OUT

or FB

OUT

PWM

LX

BIAS

EAMP

FB

SW1

VGOOD

COMP

SW2

PGND

RESET

AGND

Note1: For Internal feedback version SW1 is open and SW2 closed. External pin is called OUT

Note2: For external feedback version SW1 is closed and SW2 is open. External pin is called FB

www.analog.com

Analog Devices | 9

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Detailed Description

The MAX16956 is a small, current-mode buck converter that features synchronous rectification and requires no external

compensation network. The device operates from a 3.5V to 36V supply voltage and can deliver up to 300mA output

current. Frequency is fixed at 2.1MHz, which allows for small external components, reduced output ripple, and

guarantees no AM-band interference.

The device offers fixed output voltages of 5V and 3.3V. The device also offers adjustable output-voltage versions that

can be set by using an external resistive divider. Voltage quality can be monitored by observing the RESET signal. The

device offers both forced-PWM and skip mode, with ultra-low-quiescent cur- rent of 1.1µA in skip mode.

DC-DC Converter Control Architecture

The device step-down converter uses a PWM peak current- mode control scheme, with a load-line architecture. Peak

current-mode control provides several advantages over voltage-mode control, including precise control of the induc- tor

current on a cycle-by-cycle basis, simpler compensa- tion, and inherent compensation for line voltage variation.

An internal transconductance amplifier establishes an integrated error voltage. The heart of the PWM control- ler is an

open-loop comparator: one input is the inte- grated voltage-feedback signal; the other consists of the amplified currentsense signal plus slope-compensation ramp. Integrated high-side current sensing is used, which reduces component

count and layout risk by eliminating the need to carefully route sensitive external signals. Error-amplifier compensation is

also integrated, once again simplifying the power-supply designer’s task while eliminating external components.

At each rising edge of the internal clock, the high-side MOSFET turns on until the PWM comparator trips, the maximum

duty cycle is reached, or the peak current limit is reached (see the Current Limit /Short-Circuit Protection section). During

this on-time, current ramps up through the inductor, storing energy in a magnetic field and sourcing current to the output.

The current-mode feed- back system regulates the peak inductor current as a function of the output-voltage error signal.

During the second-half of the cycle, the high-side MOSFET turns off and the low-side MOSFET turns on. The inductor

releases the stored energy as the current ramps down, providing current to the output. The output capacitor stores

charge when the inductor current exceeds the required load current and discharges when the inductor current is lower,

smoothing the voltage across the load.

The device features load-line architecture to reduce the output capacitance needed, potentially saving system cost and

size. The output voltage is positioned slightly positive at no load, still within the tolerance window, to take advantage of

the fact that any load disturbance is a load step only. This increases the amount of margin available to the undershoot

that occurs on a load step, allowing a reduction in the required output capacitance. As the load increases, a small but

controlled amount

of load regulation (“load-line”) error occurs, so that at heavier loads the voltage is positioned slightly

below nominal. This takes advantage of the fact that any load disturbance is load released, increasing the amount of

margin available to the overshoot that occurs.

The device can operate in either forced-PWM or skip mode. In forced-PWM mode, the converter maintains a constant

switching frequency, regardless of load, to allow for easier filtering of the switching noise. The device includes proprietary

circuitry that dramatically reduces quiescent current consumption in skip mode, improving light-load efficiency. See the

Forced PWM/Skip Modes section for further details.

System Enable (EN)

An enable control input (EN) activates the device from its low-power shutdown mode. EN is compatible with inputs from

automotive battery level down to 3.5V. The high-voltage compatibility allows EN to be connected to SUP, KEY/KL30, or

the inhibit pin (INH) of a CAN transceiver.

Linear Regulator Output (BIAS)

The device includes a 5V linear regulator output (BIAS) that provides power to the internal circuit blocks. Connect a 1µF

ceramic capacitor from BIAS to AGND. Do not load this pin externally.

Undervoltage Lockout

When VBIAS drops below the undervoltage-lockout (UVLO) level of VUVLO = 2.8V (typ), the device assumes that the

supply voltage is too low for proper operation, so the UVLO circuitry inhibits switching. When VBIAS rises above the

www.analog.com

Analog Devices | 10

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

UVLO rising threshold, the controller enters the startup sequence and then resumes normal operation.

Startup and Soft-Start

The device features an internal soft-start timer. The output-voltage soft-start ramp time is 5.4ms (typ). If a short circuit

or undervoltage is encountered after the soft- start timer has expired, the device is disabled for 13.4ms (typ) and then

reattempts soft-start again. This pattern repeats until the short circuit has been removed.

RESET Output

The device features an open-drain RESET output to monitor the output voltage. The RESET output requires an external

pullup resistor. RESET goes high (high impedance) after the regulator output increases above 92% of the nominal

regulated voltage. RESET goes low when the regulator output drops to below 90% of the nominal regulated voltage.

Forced PWM/Skip Modes

The device features a logic-level input (MODE) to switch between forced-PWM and skip modes. Connecting MODE to

BIAS enables the forced-PWM operation. Connecting MODE to ground, or leaving unconnected, enables skip-mode

operation with ultra-low-quiescent current of 1.1µA. In skip-mode operation, the converter’s switching frequency is load

dependent until the output load reaches the skip threshold. At higher load current, the switching frequency does not

change and the operating mode is similar to the forced-PWM mode. Skip mode helps improve efficiency in light-load

applications by allowing the converter to turn on the high-side switch only when the output voltage falls below a set

threshold. As such, the converter does not switch the MOSFETs on and off as often as is the case in the forced-PWM

mode. Consequently, the gate charge and switching losses are much lower in skip mode.

Current Limit /Short-Circuit Protection

The device has fault protection designed to protect itself from abnormal conditions. If the output is soft shorted (meaning

the output is overloaded but over 50% of regulation), cycle-by-cycle current limit limits how high the inductor current goes

for any cycle. If the output is hard shorted to ground and the output falls to less than 50% of regulation, the part goes into

a mode where it switches until 15 cycles are ended by current limit, then waits for 13.4ms before trying to soft-start again.

This mode of operation limits the amount of power dissipated by the device under these conditions. The device also has

overtemperature protection. If the die temperature exceeds approximately 175°C, the device stops switching until the die

temperature drops by approximately 15°C and then resumes operation, including going through soft-start again.

Spread-Spectrum Option

The device has an internal spread-spectrum option to optimize EMI performance. This is factory set on the D, E, and

F variants of the device. For spread-spectrum-enabled variants of the device, the operating frequency is varied ±6%

centered on 2.1MHz. The modulation signal is a triangular wave with a period of 230µs at 2.1MHz. Therefore, fSW ramps

down 6% and back to 2.1MHz in 115µs and also ramps up 6% and back to 2.1MHz in 115µs. The cycle repeats.

www.analog.com

Analog Devices | 11

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Applications Information

Setting the Output Voltage

The device’s adjustable output-voltage version (see the Selector Guide for more details) allows the user to set the output

to any voltage between 1V and 15V. Connect a resistive divider from output (VOUT) to FB to AGND to set the output

voltage (Figure 1). Select R2 (FB to AGND resistor) less than or equal to 100kΩ. Calculate R1 (VOUT to FB resistor) with

the following equation

VOUT

R1 = R2 × [( V

) − 1]

FB

where VFB = 1V (see the Electrical Characteristics).

VOUT

MAX16956

R1

FB

R2

Figure 1. Adjustable Output-Voltage Setting

Inductor Selection

Three key inductor parameters must be specified for operation with the device: inductance value (L), inductor saturation

current (ISAT), and DC resistance (RDCR). To select inductance value, the ratio of inductor peak-to-peak AC current to

DC average current (LIR) must be selected first. A good compromise between size and loss is a 30% peak-to-peak ripple

current to average current ratio (LIR = 0.3). The switching frequency, input voltage, output voltage, and selected LIR then

determines the inductor value as follows:

VOUT × (VSUP − VOUT)

L= V

SUP × fSW × IOUT × LIR

where VSUP, VOUT, and IOUT are typical values (so that efficiency is optimum for typical conditions). The switching

frequency is 2.1MHz. Table 1 lists some of the inductor values for 300mA output current and several output voltages.

Input Capacitor

The input filter capacitor reduces peak currents drawn from the power source and reduces noise and voltage ripple on the

input caused by the circuit’s switching. The input capacitor RMS current requirement (IRMS) is defined by the following

equation:

www.analog.com

Analog Devices | 12

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

IRMS = ILOAD(MAX) √

VOUT × (VSUP − VOUT)

VSUP

IRMS has a maximum value when the input voltage equals twice the output voltage (VSUP = 2VOUT), so IRMS(MAX) =

ILOAD(MAX)/2. Choose an input capacitor that exhibits less than +10°C self-heating temperature rise at the RMS input

current for optimal long-term reliability.

Table 1. Inductor Values for 300mA Output Current

VSUP/VOUT (V)

14V/5V

14V/3.3V

INDUCTOR (µH) ILOAD = 300mA

10µH (typ) 22µH (max)

10µH (typ) 22µH (max)

The input voltage ripple is composed of ΔVQ (caused by the capacitor discharge) and ΔVESR (caused by the ESR of the

capacitor). Use low-ESR ceramic capacitors with high ripple current capability at the input. Assume the contribution from

the ESR and capacitor discharge equal to 50%. Calculate the input capacitance and ESR required for a specified input

voltage ripple using the following equations:

△ VESR

ESRIN =

IOUT +

∆ IL

2

where:

∆ IL =

(VSUP − VOUT) × VOUT

VSUP × fSW × L

and:

CIN =

IOUT × D(1 − D)

∆ VQ × fSW

VOUT

and D = V

SUP

where IOUT is the maximum output current and D is the duty cycle.

Output Capacitor

The output filter capacitor must have low enough ESR to meet output ripple and load transient requirements. The

output capacitance must be high enough to absorb the inductor energy while transitioning from full-load to noload

conditions. When using high-capacitance, low-ESR capacitors, the filter capacitor’s ESR dominates the output voltage

ripple. Therefore, the size of the output capacitor depends on the maximum ESR required to meet the output voltage

ripple (VRIPPLE(P-P)) specifications:

VRIPPLE(P−P) = ESR×ILOAD(MAX)×LIR

The actual capacitance value required relates to the physical size needed to achieve low ESR, as well as to the chemistry

of the capacitor technology. Therefore, the capacitor is usually selected by ESR and voltage rating rather than by

capacitance value. When using low-capacity filter capacitors, such as ceramic capacitors, size is usually determined by

the capacity needed to prevent voltage droop and voltage rise from causing problems during load transients. Generally,

once enough capacitance is added to meet the overshoot requirement, undershoot at the rising-load edge is no longer a

problem.

PCB Layout Guidelines

Careful PCB layout is critical to achieve low-switching power losses and clean, stable operation. Use a multi- layer board

whenever possible for better noise immunity and power dissipation. Follow these guidelines for good PCB layout:

1. The input capacitor (4.7μF, see Figures 3 and 4) should be placed immediately next to the SUP pin of the device.

Since the device operates at 2.1MHz switching frequency, this placement is critical for effective decoupling of highfrequency noise from the SUP pin.

2. Solder the exposed pad to a large copper plane area under the device. To effectively use this copper area as heat

exchanger between the PCB and ambient, expose the copper area on the top and bottom sides. Add a few small vias

or one large via on the copper pad for efficient heat transfer. Connect the exposed pad to PGND, ideally at the return

terminal of the output capacitor.

3. Isolate the power components and high-current path from the sensitive analog circuitry. Doing so is essential to

www.analog.com

Analog Devices | 13

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

prevent any noise coupling into the analog signals.

4. Keep the high-current paths short, especially at the ground terminals. This practice is essential for stable, jitter-free

operation.

5. Connect PGND and AGND together at the return terminal of the output capacitor. Do not connect them anywhere

else.

6. Keep the power traces and load connections short. This practice is essential for high efficiency.

7. Place the BIAS capacitor ground next to the AGND pin and connect with a short and wide trace.

Table 2. SELECTOR GUIDE

PART

MAX16956AUBA+

MAX16956AUBA/ V+

VOUT

RESET TIME

(µs)

SPREAD SPECTRUM

PIN-PACKAGE

TOP MARK

Fixed 5V

10

Off

10 µMAX-EP

+AABX

Fixed 5V

10

Off

10 µMAX-EP

+AABH

MAX16956AUBB+

Fixed 3.3V

10

Off

10 µMAX-EP

+AABY

MAX16956AUBB/ V+

Fixed 3.3V

10

Off

10 µMAX-EP

+AABI

MAX16956AUBC +

Adjustable

10

Off

10 µMAX-EP

+AABZ

MAX16956AUBC / V+

Adjustable

10

Off

10 µMAX-EP

+AABJ

MAX16956AUBD / V+

Fixed 5V

10

On

10 µMAX-EP

+AABK

MAX16956AUBE/ V+

Fixed 3.3V

10

On

10 µMAX-EP

+AABL

MAX16956AUBF/ V+

Adjustable

10

On

10 µMAX-EP

+AABM

www.analog.com

Analog Devices | 14

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Typical Application Circuits

MAX16956AUBA/V+ (5.0V Fixed) and MAX16956AUBB/V+ (3.3V Fixed), 10-Pin μMAX

VBAT

CIN1

4.7µF

MAX16956

SUP

BST

CBST

0.1µF

CIN2

0.1µF

L

10µH

LX

NH

VOUT

3.3V/5V

MODE

OUT

EN

COUT

22µF

NL

BIAS

RESET

AGND

PGND

CBIAS

1µF

MAX16956AUBC/V+, Variable Output Voltage, 10-Pin μMAX

VBAT

CIN1

4.7µF

MAX16956

SUP

BST

CBST

0.1µF

CIN2

0.1µF

L

10µH

VOUT

1V-15V

LX

NH

RTOP

VARIES

MODE

COUT

22µF

FB

EN

BIAS

RESET

AGND

www.analog.com

RBOT

50kΩ

NL

PGND

CBIAS

1µF

Analog Devices | 15

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Ordering Information

TEMP RANGE

PIN-PACKAGE

MAX16956AUB_ +

PART

-40°C to +125°C

10 µMAX-EP*

MAX16956AUB_ / V+

-40°C to +125°C

10 µMAX-EP*

Note: Insert the desired suffix letter (from the Selector Guide) into the blank to indicate the output voltage and spread-spectrum

option.

/ V denotes an automotive qualified part.

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed pad.

www.analog.com

Analog Devices | 16

�MAX16956

36V, 300mA, Mini Buck Converter with 1.1μA IQ

Revision History

REVISION

NUMBER

REVISION

DATE

0

6/13

Initial release

1

2/14

Changed PGND to AGND for pin 8 in the Pin Description section, removed C1 from

Figure 1, and added nonautomotive OPNs for MAX16956A, MAX16956B, and

MAX16956C versions

2

3/14

Removed future product references

15

3

2/15

Updated the Benefits and Features section

1

4

8/15

Updated Block Diagram

9

5

10/15

Added top marks to Selector Guide

15

6

2/21

Increasing the output voltage range to 15V.

DESCRIPTION

PAGES

CHANGED

—

8, 11, 15

1,2,10,11,14

Information furnished by Analog Devices is believed to be accurate and reliable. However, no responsibility is

assumed by Analog Devices for its use, nor for any infringements of patents or other rights of third parties that may

result from its use. Specifications subject to change without notice. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and registered trademarks are the property of

their respective owners.

w w w . a n a l o g . c o m

Analog Devices | 17

�