Click here for production status of specific part numbers.

MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

General Description

The MAX20004/MAX20006/MAX20008 are small, synchronous, automotive buck converter devices with integrated

high-side and low-side MOSFETs. The device family can

deliver up to 8A with input voltages from 3.5V to 36V, while

using only 25μA quiescent current at no load. Voltage quality can be monitored by observing the RESET signal. The

devices can operate in dropout by running at 98% duty

cycle, making them ideal for automotive applications.

The devices offer fixed output voltages of 5V and 3.3V,

along with the ability to program the output voltage between

1V and 10V. Frequency is resistor programmable from

220kHz to 2.2MHz. The devices offer a forced fixed-frequency PWM mode (FPWM) and skip mode with ultra-low

quiescent current. The devices can be factory programmed

to enable spread-spectrum switching to reduce EMI.

The MAX20004/MAX20006/MAX20008 are available in a

small, 3.5mm x 3.75mm, 17-pin FC2QFN package and use

very few external components.

Applications

● Point-of-Load (PoL) Applications in Automotive

● Distributed DC Power Systems

● Navigation and Radio Head Units

Benefits and Features

● Multiple Functions for Small Size

• Operating VIN Range of 3.5V to 36V

• 25µA Quiescent Current in Skip Mode

• Synchronous DC-DC Converter with

Integrated FETs

• 220kHz to 2.2MHz Adjustable Frequency

• Fixed 5ms Internal Soft-Start

• Programmable 1V to 10V Output, or 3.3V and

5.0V Fixed-Output Options Available

• 98% Duty-Cycle Operation with Low Dropout

• RESET Output

● High Precision

• ±2% Output-Voltage Accuracy

• Good Load-Transient Performance

● Robust for the Automotive Environment

• Current-Mode, Forced-PWM and Skip Operation

• Overtemperature and Short-Circuit Protection

• 3.5mm x 3.75mm 17-Pin FC2QFN

• -40°C to +125°C Operating Temperature Range

• 40V Load-Dump Tolerant

• AEC-Q100 Qualified

Ordering Information appears at end of data sheet.

Typical Application Circuit

CIN1

4.7µF

CIN2

0.1µF

SUPSW

FOSC

SUP

SYNC

EN

VOUT

COUT

19-100239; Rev 8; 11/19

L

1µH

0.1 µF

CBST

OUT

BST

LX

PGND

12 kΩ

RRESET

20 kΩ

BIAS

RESET

COMP

FB

BIAS

GND

22 kΩ

CBIAS

2.2 µF

1n F

4.7 pF

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Absolute Maximum Ratings

SUP, EN, SUPSW to PGND...................................-0.3V to +40V

LX to PGND (Note 1)......................... -0.3V to (VSUPSW + 0.3V)

BIAS, RESET to GND...........................................-0.3V to +6.0V

FOSC, COMP to GND............................-0.3V to (VBIAS + 0.3V)

SYNC, FB to GND...................................-0.3V to (VBIAS + 0.3V)

GND to PGND.......................................................-0.3V to +0.3V

OUT to PGND........................................................-0.3V to +12V

BST to LX ................................................................-0.3V to +6V

LX Continuous RMS Current ..................................................8A

Output Short-Circuit Duration.....................................Continuous

Continuous Power Dissipation (TA = +70°C)

17-Pin FC2QFN (derate 29.4mW/°C > 70°C)........... 2553mW

Operating Temperature Range.......................... -40°C to +125°C

Junction Temperature.......................................................+150°C

Storage Temperature Range............................. -65°C to +150°C

Lead Temperature Range.................................................+300°C

Soldering Temperature (reflow)........................................+260°C

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may affect

device reliability.

Note 1: Self-protected from transient voltages exceeding these limits in circuit under normal operation.

Package Information

17 FC2QFN

Package Code

F173A3FY+1

Outline Number

21-100155

Land Pattern Number

90-100056

Thermal Resistance, Four-Layer Board:

Junction to Ambient (θJA)

27°C/W

Junction to Case (θJC)

2.6°C/W

For the latest package outline information and land patterns (footprints), go to www.maximintegrated.com/packages. Note that a “+”,

“#”, or “-” in the package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing

pertains to the package regardless of RoHS status.

Package thermal resistances were obtained using the EV kit. For detailed information on package thermal considerations, refer to

www.maximintegrated.com/thermal-tutorial.

Electrical Characteristics

(VSUP = VSUPSW = VEN = 14V. TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C under normal

conditions, unless otherwise noted.) (Note 2)

PARAMETER

SYMBOL

Supply Voltage Range

VSUP,

VSUPSW

Supply Voltage Range

VSUP,

VSUPSW

Supply Current

ISUP

CONDITIONS

MIN

TYP

3.5

After startup

Skip mode, no load

VOUT = 3.3V

25

32

30

42

10

5

BIAS Regulator Voltage

VBIAS

VSUP = VSUPSW = 6V to 40V IBIAS < 10mA,

BIAS not switched over to VOUT

5

www.maximintegrated.com

V

VOUT = 5.0V

VEN = 0V

VBIAS rising

36

V

ISHDN

VUVBIAS

UNITS

3.0

Shutdown Supply Current

BIAS Undervoltage

Lockout

MAX

2.7

3

µA

µA

V

3.3

V

Maxim Integrated │ 2

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Electrical Characteristics (continued)

(VSUP = VSUPSW = VEN = 14V. TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C under normal

conditions, unless otherwise noted.) (Note 2)

PARAMETER

SYMBOL

BIAS Undervoltage

Lockout

VUVBIAS

Thermal-Shutdown

Temperature

TSHDN

Thermal-Shutdown

Hysteresis

THYST

CONDITIONS

MIN

TYP

MAX

UNITS

VBIAS falling

2.5

2.9

V

TJ rising

175

°C

15

°C

OUTPUT VOLTAGE

PWM-Mode Output

Voltage (Note 3)

VOUT_5V

VSUP = VSUPSW = 6V to 28V

4.9

5

5.1

V

Skip-Mode Output Voltage

(Note 4)

VSKIP_5V

Skip mode, no load, FB = BIAS

4.9

5

5.15

V

PWM-Mode Output

Voltage

VOUT_3.3V

VSUP = VSUPSW = 6V to 28V

3.23

3.3

3.37

V

Skip-Mode Output Voltage

(Note 4)

VSKIP_3.3V

Skip mode, no load, FB = BIAS

3.23

3.3

3.4

V

Load Regulation

LNREG

Line Regulation

LDREG

VFB = VBIAS, 30mA < ILOAD < 6A, PWM mode,

5V

VFB = VBIAS, 6V < VSUPSW < 36V, PWM mode

0.6

%

0.02

%/V

BST Input Current

IBST_ON

High-side MOSFET on, VBST - VLX = 5V

1.5

mA

BST Input Current

IBST_OFF

High-side MOSFET off, VBST - VLX = 5V

0.1

µA

LX Current Limit

LX Rise Time (Note 4)

ILX

SS

High-Side Switch

On-Resistance

RHS

Low-Side Switch

On-Resistance

Low-Side Switch Leakage

5.25

7

8.75

MAX20006 (6A)

7.5

10

12.5

MAX20008 (8A)

10.5

14

17.5

IHS_LKG

RLS

ILS_LKG

A

2

ns

Spread spectrum enabled

±3

%

VBIAS = 5V, ILX = 2A

38

76

mΩ

High-side MOSFET off, VSUPSW = 36V,

VLX = 0V, TA = +25°C

1

5

µA

VBIAS = 5V, ILX = 2A

18

36

mΩ

Low-side MOSFET off, VSUPSW = 36V,

VLX = 36V, TA = +25°C

1

5

µA

30

100

nA

tLX_TR

Spread Spectrum

High-Side Switch Leakage

MAX20004 (4A)

FB Input Current

IFB

TA = +25°C

FB Regulation Voltage

VFB

FB connected to an external resistive divider,

6V < VSUPSW < 36V

0.99

1.00

1.01

V

Transconductance

(from FB to COMP)

gm

VFB = 1V, VBIAS = 5V

500

780

1000

µS

Minimum On-Time

(Note 4)

tON_MIN

Load 500mA (Note 4)

www.maximintegrated.com

75

ns

Maxim Integrated │ 3

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Electrical Characteristics (continued)

(VSUP = VSUPSW = VEN = 14V. TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C under normal

conditions, unless otherwise noted.) (Note 2)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Maximum Duty Cycle

DCMAX

97

98

Oscillator Frequency

fSW1

RFOSC = 73.2kΩ

360

400

440

kHz

Oscillator Frequency

fSW2

RFOSC = 12kΩ

2.0

2.2

2.4

MHz

Soft-Start Time

tSS

%

5

ms

EN, SYNC

External Input Clock

Frequency

RFOSC = 12kΩ (Note 5)

SYNC High Threshold

VSYNC_HI

SYNC Low Threshold

VSYNC_LO

SYNC Leakage Current

ISYNC

EN High Threshold

VEN_HI

EN Low Threshold

VEN_LO

EN Hysteresis

EN Leakage Current

RESET

UV Threshold

1.8

1.4

TA = +25°C

0.1

UVACC

Falling

89

UV Hysteresis

Hold Time (Note 6)

UV Debounce Time

tHOLD1

(Note 6)

tDEB

OVPTHR

Rising

OV Protection Threshold

OVPTHF

Falling

Leakage Current

IRST_LKG

VOUT in regulation, TA = +25°C

Output Low Level

VROL

2:

3:

4:

5:

6:

V

1

µA

V

0.6

V

0.1

2

µA

91

93

%

V

3

%

0.2

ms

25

OV Protection Threshold

Note

Note

Note

Note

Note

0.4

0.2

TA = +25°C

104

MHz

V

2.4

VEN_HYS

IEN

2.6

107

µs

110

105

ISINK = 5mA

%

%

1

µA

0.4

V

All units are 100% production tested at TA = +25˚C. All temperature limits are guaranteed by design.

Device not in dropout condition.

Guaranteed by design. Not production tested.

Contact factory for SYNC frequency outside the specified range.

Contact factory for additional options.

www.maximintegrated.com

Maxim Integrated │ 4

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Typical Operating Characteristics

(VSUP = VSUPSW = 14V, VEN = 14V, VOUT = 5V, VFSYNC = 0V, RFOSC = 12kΩ, TA = +25°C, unless otherwise noted.)

EFFICIENCY vs. LOAD CURRENT

100

100

90

90

80

80

70

70

SKIP MODE

60

EFFICIENCY (%)

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

toc01

PWM MODE

50

40

30

20

10

0

0.001

0.01

0.1

SKIP MODE

60

PWM MODE

50

40

30

20

VIN = 12V

VOUT = 5V

fSW = 400kHz

VIN = 12V

VOUT = 3.3V

fSW = 400kHz

10

1

0

0.001

10

0.01

0.1

EFFICIENCY vs. LOAD CURRENT

100

90

80

EFFICIENCY (%)

EFFICIENCY (%)

70

SKIP MODE

60

PWM MODE

40

30

10

0.01

0.1

1

SKIP MODE

60

50

PWM MODE

40

30

20

VIN = 12V

VOUT = 5V

fSW = 2.2MHz

0

0.001

toc04

100

80

20

VIN = 12V

VOUT = 3.3V

fSW = 2.2MHz

10

0

0.001

10

0.01

LOAD CURRENT (A)

1

10

NO LOAD SUPPLY CURRENT

vs. SUPPLY VOLTAGE

toc05

10

35

VEN = 0V

SUPPLY CURRENT (uA)

7

6

5

4

3

toc06

VOUT = 3.3V

fSW = 2.2MHz

SKIP MODE

30

8

SUPPLY CURRENT (uA)

0.1

LOAD CURRENT (A)

SHUTDOWN CURRENT vs. SUPPLY VOLTAGE

9

10

EFFICIENCY vs. LOAD CURRENT

toc03

90

50

1

LOAD CURRENT (A)

LOAD CURRENT (A)

70

toc02

25

20

15

10

2

5

1

0

6

9

12

15

18

21

24

27

SUPPLY VOLTAGE (V)

www.maximintegrated.com

30

33

36

0

6

9

12

15

18

21

24

27

30

33

36

SUPPLY VOLTAGE (V)

Maxim Integrated │ 5

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Typical Operating Characteristics

(VSUP = VSUPSW = 14V, VEN = 14V, VOUT = 5V, VFSYNC = 0V, RFOSC = 12kΩ, TA = +25°C, unless otherwise noted.)

SWITCHING FREQUENCY vs. RFOSC

SYNC FUNCTION

toc07

2500

toc08

SWITCHING FREQUENCY (kHz)

2250

2000

1750

VLX

5V/div

VSYNC

1V/div

1500

1250

1000

750

500

250

0

10

30

50

70

90

110

130

150

200ns/div

ROSC (kΩ)

VBIAS vs. VSUP

4.5

IOUT = 6A

4.0

3.5

3.0

0.40

0.35

VSET = 3.3V

0.30

0.25

0.20

VSET = 5V

0.15

0.10

2.5

2.0

VOUT = 95% of VSET

L = COILCRAFT XAL6030-102

0.45

DROPOUT VOLTAGE (V)

VBIAS (V)

5.0

0.05

0.00

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

0

1

2

3

LOAD REGULATION

6

toc12

5.20

VIN = 14V

PWM MODE

VIN = 14V

SKIP MODE

5.15

5.10

5.10

400kHz

5.05

VOUT (V)

VOUT (V)

5

LOAD REGULATION

toc11

5.20

5.15

4

IOUT (A)

VSUP (V)

5.00

400kHz

5.05

5.00

4.95

4.95

2.2MHz

4.90

2.2MHz

4.90

4.85

4.85

4.80

toc10

0.50

IOUT = 0.1A

VOUT = 3.3V

fSW = 2.2MHz

5.5

DROPOUT VOLTAGE vs. IOUT

toc09

6.0

4.80

0

1

2

3

4

IOUT (A)

www.maximintegrated.com

5

6

7

8

0

1

2

3

4

IOUT (A)

5

6

7

8

Maxim Integrated │ 6

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Typical Operating Characteristics

(VSUP = VSUPSW = 14V, VEN = 14V, VOUT = 5V, VFSYNC = 0V, RFOSC = 12kΩ, TA = +25°C, unless otherwise noted.)

ENABLE STARTUP BEHAVIOR

VOUT vs. VIN

toc14

toc13

5.05

VIN = 14V

PWM MODE

ILOAD = 0A

5.04

5V/div

VEN

400kHz

VOUT (V)

5.03

2V/div

VOUT

5.02

5.01

5.00

4.99

2A/div

IOUT

2.2MHz

5V/div

VRESET

6

12

18

24

30

4ms/div

36

VIN (V)

SHORT CIRCUIT AND RECOVERY

VIN STARTUP BEHAVIOR

toc16

toc15

10V/div

VIN

2V/div

VOUT

2V/div

10V/div

VLX

VOUT

2A/div

IOUT

IOUT

VRESET

20A/div

5V/div

EN = VIN

4ms/div

20ms/div

TJ_RISE vs. IOUT

toc17

80

fSW = 2.2MHz

VIN = 14V

PWM MODE

TA = 25°C

60

VOUT = 5V

50

VOUT = 3.3V

40

30

20

VOUT = 5V

toc18

fSW = 400kHz

VIN = 14V

PWM MODE

TA = 25°C

70

TJ_RISE (°C)

TJ_RISE (°C)

TJ_RISE vs. IOUT

140

130

120

110

100

90

80

70

60

50

40

30

20

10

0

VOUT = 3.3V

10

1

2

3

4

5

IOUT (A)

www.maximintegrated.com

6

7

8

0

1

2

3

4

5

6

7

8

IOUT (A)

Maxim Integrated │ 7

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

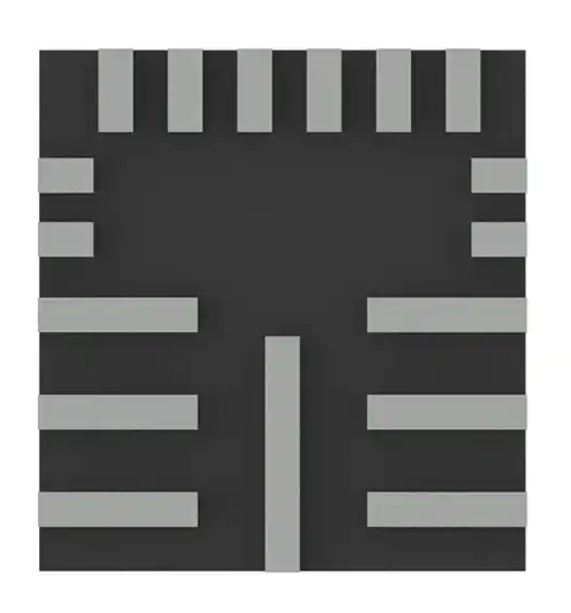

Pin Configuration

FOSC

FB

COMP

GND

BIAS

SYNC

TOP VIEW

17

16

15

14

13

12

OUT

1

11

EN

RESET

2

10

SUP

BST

3

9

SUPSW

PGND

4

8

PGND

PGND

5

7

PGND

LX

6

FC2QFN

3.5mm x 3.75mm

Pin Description

PIN

NAME

FUNCTION

1

OUT

2

RESET

3

BST

4, 5,

7, 8

PGND

6

LX

9

SUPSW

10

SUP

11

EN

12

SYNC

Connect SYNC to GND or leave unconnected to enable skip-mode operation under light loads. Connect SYNC

to BIAS or to an external clock to enable fixed-frequency forced-PWM-mode operation. When driving SYNC

externally, do not exceed the BIAS or OUT voltage.

13

BIAS

Linear Regulator Output. BIAS supplies the internal circuitry. Bypass with a minimum 2.2 µF ceramic capacitor

to ground. The BIAS pin can transition from 5V to VOUT after startup.

14

GND

Analog Ground

Switching Regulator Output. OUT also provides power to the internal circuitry under certain conditions (see the

Linear Regulator Output (BIAS) section for details).

Open-Drain, Active-Low RESET Output. To obtain a logic signal, pullup RESET with an external resistor.

High-Side Driver Supply. Connect a 0.1μF capacitor between LX and BST for proper operation.

Power Ground. Connect all PGND pins together.

Inductor Connection. Connect LX to the switched side of the inductor.

Internal High-Side Switch Supply Input. SUPSW provides power to the internal switch. Bypass SUPSW to

PGND with 0.1μF and 4.7μF ceramic capacitors. Place the 0.1μF capacitor as close as possible to the SUPSW

and PGND pins, followed by the 4.7μF capacitor.

Voltage Supply Input. SUP supplies the internal linear regulator. Connect SUP directly to SUPSW as close as

possible to the IC. SUP and SUPSW are connected together internally.

SUP Voltage-Compatible Enable Input. Drive EN low to disable the device. Drive EN high to enable the device.

For a safe startup, ensure that VSUP > 7.5V when EN is toggled high.

www.maximintegrated.com

Maxim Integrated │ 8

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Pin Description (continued)

PIN

NAME

15

COMP

16

FB

17

FOSC

FUNCTION

Error-Amplifier Output. Connect an RC network from COMP to GND for stable operation. See the

Compensation Network section for more details.

Feedback Input. Connect an external resistive divider from OUT to FB and GND to set the output voltage.

Connect FB to BIAS to set the output voltage to 5V or 3.3V.

Resistor-Programmable Switching Frequency Setting Control Input. Connect a resistor from FOSC to GND to

set the switching frequency.

Internal Block Diagram

CURRENT-SENSE

AMP

MAX20004

MAX20006

MAX20008

SUPSW

SKIP CURRENT

COMP

BST

CLK

PEAK CURRENT

COMP

RAMP

GENERATOR

CONTROL LOGIC

∑

LX

LX

BIAS

PWM

COMP

PGND

COMP

VREF

ERROR

AMP

SOFT-START

GENERATOR

OUT

FB

PGOOD

COMP

OSC

ZX

COMP

PGND

POK

FEEDBACK

SELECT

SYNC

FOSC

FPWM CLK

CLK

FPWM

POK

OTP

VOLTAGE

REFERENCE

SUP

TRIMBITS

BIAS LDO

VREF

BIAS

RESET

EN

MAIN

CONTROL

LOGIC

GND

SEL

GND

www.maximintegrated.com

Maxim Integrated │ 9

�MAX20004/MAX20006/

MAX20008

Detailed Description

The MAX20004/MAX20006/MAX2008 are 4A, 6A, and

8A current-mode step-down converters, respectively,

with integrated high-side and low-side MOSFETs. The

low-side MOSFET enables fixed-frequency FPWM operation in light-load applications. The devices operate with

3.5V to 36V input voltages, while using only 25μA (typ)

quiescent current at no load. The switching frequency

is resistor programmable from 220kHz to 2.2MHz and

can be synchronized to an external clock. The devices’

output voltage is available as fixed 5V or 3.3V, or adjustable between 1V and 10V. The wide input voltage range,

along with the ability to operate at 99% duty cycle during

undervoltage transients, make these devices ideal for

automotive applications.

In light-load applications, a logic input (SYNC) allows

the devices to operate either in skip mode for reduced

current consumption, or fixed-frequency FPWM mode

to eliminate frequency variation and help minimize EMI.

Protection features include cycle-by-cycle current limit,

and thermal shutdown with automatic recovery.

Thermal Considerations

The devices are available in 4A, 6A, or 8A versions; however, the average output-current capability is dependent on

several factors. Some of the key factors include the maximum ambient temperature (TA(MAX)), switching frequency

(fSW), and the number of layers and the size of the PCB.

See the Typical Operating Characteristics for a guideline.

Wide Input Voltage Range

The devices include two separate supply inputs (SUP and

SUPSW) specified for a wide 3.5V to 36V input voltage

range. VSUP provides power to the device and VSUPSW

provides power to the internal switch. When the device is

operating with a 3.5V input supply, conditions such as cold

crank can cause the voltage at the SUP and SUPSW pins

to drop below the programmed output voltage. Under such

conditions, the devices operate in a high duty-cycle mode

to facilitate minimum dropout from input to output.

Maximum Duty-Cycle Operation

The devices have an effective maximum duty cycle of 98%

(typ). The IC continuously monitors the time between lowside FET switching cycles in both PWM and skip modes.

Whenever the low-side FET has not switched for more than

13.5µs (typ), the low-side FET is forced on for 150ns (typ)

to refresh the BST capacitor. The input voltage at which

the device enters dropout changes depending on the input

voltage, output voltage, switching frequency, load current,

and the efficiency of the design.

www.maximintegrated.com

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

The input voltage at which the device enters dropout can

be approximated as:

VSUP =

VOUT

+ I OUT × R HS

0.98

where RHS is the high-side switch on-resistance, which

should also include the inductor DC resistance for better

accuracy.

Linear Regulator Output (BIAS)

The devices include a 5V linear regulator (VBIAS) that

provides power to the internal circuit blocks. Connect

a 2.2μF ceramic capacitor from BIAS to GND. Under

certain conditions, the BIAS regulator turns off and the

BIAS pin switches to OUT (i.e., switches over) after

startup to increase efficiency. For IC versions that are

factory trimmed for 3.3V fixed output, BIAS switches to

OUT under light load conditions in skip mode only. For IC

versions that are factory trimmed for 5V fixed output, the

BIAS pin switches to OUT after startup regardless of load

or skip/PWM mode. In any case, BIAS only switches over

if OUT is between 2.8V and 5.6V. In summary, BIAS can

transition from 5V to VOUT after startup depending on

load, mode and IC version.

Soft-Start

The devices include a fixed, internal soft-start. Soft-start

limits startup inrush current by forcing the output voltage

to ramp up towards its regulation point.

Reset Output (RESET)

The devices feature an open-drain reset output (RESET).

RESET asserts when VOUT drops below the specified

falling threshold. RESET deasserts when VOUT rises

above the specified rising threshold after the specified

hold time. Connect RESET to the output or I/O voltage

of choice (within pin voltage limits) with a pullup resistor.

Synchronization Input (SYNC)

SYNC is a logic-level input used for operating-mode

selection and frequency control. Connecting SYNC to

BIAS or to an external clock enables forced fixed-frequency (FPWM) operation. Connecting SYNC to GND enables

automatic skip-mode operation for light load efficiency.

The external clock frequency at SYNC can be higher or

lower than the internal clock by 20%. If the external clock

frequency is greater than 120% of the internal clock, contact the factory to verify the design. The devices synchronize to the external clock in two cycles. When the external

clock signal at SYNC is absent for more than two clock

cycles, the devices use the internal clock. There is a diode

Maxim Integrated │ 10

�MAX20004/MAX20006/

MAX20008

between SYNC and BIAS, so it is important when driving

SYNC with an external source that the voltage be less

than or equal to BIAS (or OUT in the case of switchover).

If this cannot be guaranteed, place a series resistor in-line

with SYNC ≥ 20kΩ to limit the input current. If EN is low,

BIAS is turned off so a voltage should not be present on

SYNC without the series resistor.

System Enable (EN)

An enable control input (EN) activates the devices from

their low-power shutdown mode. EN is compatible with

inputs from automotive battery level down to 3.5V.

EN turns on the internal linear (BIAS) regulator. Once

VBIAS is above the internal lockout threshold (VUVBIAS =

3V (typ)), the converter activates and the output voltage

ramps up with the programmed soft-start time.

A logic-low at EN shuts down the device. During shutdown, the BIAS regulator and gate drivers turn off.

Shutdown is the lowest power state and reduces the

quiescent current to 5μA (typ). Drive EN high to bring the

device out of shutdown.

For safe startup, ensure that VSUP > 7.5V when EN is

toggled high. In all applications, BIAS capacitance guidelines must be followed to ensure safe operation of the IC.

Note: In all applications, BIAS must start from < 0.3V or

> 1.6V during startup.

Spread-Spectrum Option

The devices can be ordered with spread spectrum

enabled. See the Ordering Information/Selector Guide

section. When the spread spectrum is factory enabled,

the operating frequency is varied ±3% centered on FOSC.

The modulation signal is a triangular wave with a frequency of 4.5kHz at 2.2MHz.

For operations at FOSC values other than 2.2MHz, the

modulation signal scales proportionally (e.g., at 400kHz,

the modulation frequency reduces by 0.4MHz/2.2MHz).

The internal spread spectrum is disabled if the devices

are synchronized to an external clock. However, the

devices do not filter the input clock on the SYNC pin and

pass any modulation (including spread spectrum) present

driving the external clock.

Internal Oscillator (FOSC)

The switching frequency (fSW) is set by a resistor

(RFOSC) connected from FOSC to GND. To determine

the approximate value of RFOSC for a given fSW, use the

www.maximintegrated.com

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

graph in the Typical Operating Characteristics section or

the following equation:

R=

FOSC

29,600

− 1.48

f SW

where fSW is in kHz and RFOSC is in kΩ. For example, a

400kHz switching frequency is set with RFOSC = 72.5kΩ.

Higher frequencies allow designs with lower inductor

values and less output capacitance at the expense of

reduced efficiency and higher EMI.

Thermal-Shutdown Protection

Thermal shutdown protects the device from excessive

operating temperature. When the junction temperature

exceeds the specified threshold, an internal sensor shuts

down the internal bias regulator and the step-down converter, allowing the IC to cool. The sensor turns the IC on

again after the junction temperature cools by the specified

hysteresis.

Current Limit/Short-Circuit Protection

The devices feature a current limit that protects them

against short-circuit and overload conditions at the output. In the event of a short-circuit or overload condition,

the high-side MOSFET remains on until the inductor

current reaches the specified LX current-limit threshold.

The converter then turns the high-side MOSFET off and

the low-side MOSFET on to allow the inductor current to

ramp down. Once the inductor current crosses below the

current-limit threshold, the converter turns on the highside MOSFET again. This cycle repeats until the short or

overload condition is removed.

A hard short is detected when the output voltage falls

below 50% of the target while in current limit. If this

occurs, hiccup mode activates, and the output turns off

for four times the soft-start time. The output then enters

soft-start and powers back up. This repeats indefinitely

while the short circuit is present. Hiccup mode is disabled

during soft-start.

Overvoltage Protection

If the output voltage exceeds the OV protection rising

threshold, the high-side MOSFET turns off and the lowside MOSFET turns on. Normal operation resumes when

the output voltage goes below the falling OV threshold.

Maxim Integrated │ 11

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Applications Information

Forced-PWM and Skip Modes

Maximum Output Current

While there are device versions that supply up to 8A,

there are many factors that may limit the average output

current to less than the maximum. The devices can be

thermally limited based on the selected fSW, number of

PCB layers, PCB size, and the maximum ambient temperature. See the Typical Operating Characteristics section for guidance on the maximum average current. For a

more precise value, the θJA needs to be measured in the

application environment.

Setting the Output Voltage

Connect FB to BIAS for a fixed 5V or 3.3V output voltage. To set the output to other voltages between 1V and

10V, connect a resistive divider from output (OUT) to FB

(Figure 1). Select RFB2 (FB to GND resistor) less than or

equal to 100kΩ. Calculate RFB1 (OUT to FB resistor) with

the following equation:

V

=

R FB1 R FB2 OUT − 1

V

FB

where VFB is the feedback regulation voltage. See the

Electrical Characteristics table.

Add a capacitor, CFB1, as shown to compensate the pole

formed by the divider resistance and FB pin capacitance

as follows:

R FB2

C=

FB1 10pf ×

R FB1

Note: Applications that use a resistor divider to set

output voltages below 4.5V should use IC versions

that are factory trimmed for 3.3V fixed output voltage

to ensure full output current capability.

In forced-PWM (FPWM) mode, the devices switch at a

constant frequency with variable on-time. In skip mode,

the converter’s switching frequency is load-dependent.

At higher load current, the switching frequency becomes

fixed and operation is similar to PWM mode. Skip mode

helps improve efficiency in light-load applications by

allowing switching only when the output voltage falls

below a set threshold. Since the effective switching

frequency is lower in skip mode at light load, gate charge

and switching losses are lower and efficiency is increased.

Inductor Selection

Three key parameters must be considered when selecting an inductor: inductance value (L), inductor saturation

current (ISAT), and DC resistance (RDCR). The devises

are designed to operate with the ratio of inductor peakto-peak AC current to DC average current (LIR) between

15% and 30% (typ). The switching frequency, input voltage, and output voltage then determine the inductor value

as follows:

LMIN1 =

(VSUP − VOUT ) × VOUT

VSUP × f SW × IMAX × 30%

where VSUP and VOUT are typical values (so that efficiency is optimum for typical conditions) and IMAX is 4A

for MAX20004, 6A for MAX20006, and 8A for MAX20008,

and fSW is the switching frequency set by RFOSC. Note

that IMAX is the maximum rated output current for the

device, not the maximum load current in the application.

The next equation ensures that the internal compensating

slope is greater than 50% of the inductor current down slope:

m≥

m2

2

where m is the internal compensating slope and m2 is the

sensed inductor current down-slope as follows:

VOUT

RFB1

FB

RFB2

Figure 1. Adjustable Output-Voltage Setting

www.maximintegrated.com

=

m2

CFB1

VOUT

× R CS

L

where RCS is 0.38 for MAX20004, 0.28 for MAX20006,

and 0.21 for MAX20008.

=

m 1.35

V

f

× SW

µs 2.2MHz

Solving for L and using a 1.3 multiplier to account for

tolerances in the system:

R

L MIN2 = VOUT × CS × 1.3

2×m

Maxim Integrated │ 12

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

To satisfy both LMIN1 and LMIN2, LMIN must be set to the

larger of the two as follows:

L MIN = max ( L MIN1, L MIN2 )

The maximum nominal inductor value recommended is 2

times the chosen value from the above formula:

L MAX=

2 × L MIN

Select a nominal inductor value based on the following

formula:

input capacitance and ESR required for a specified input

voltage ripple using the following equations:

∆VESR

ESR IN =

∆I

I OUT + L

2

where:

(V − VOUT ) × VOUT

∆IL = SUP

VSUP × f SW × L

and:

C IN =

L MIN < L NOM < L MAX

The best choice of inductor is usually the standard inductor value closest to LNOM.

D=

Input Capacitor

The input filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage

ripple on the input due to high speed switching.

Place a 0.1μF capacitor as close as possible to the

SUPSW and PGND pins, followed by a 4.7μF (or larger)

ceramic capacitor. A bulk capacitor with higher ESR

(such as an electrolytic capacitor) is normally required as

well to lower the Q of the front-end circuit and provide the

remaining capacitance needed to minimize input voltage

ripple.

The input capacitor RMS current requirement (IRMS) is

defined by the following equation:

=

IRMS ILOAD(MAX) ×

VOUT × (VSUP − VOUT )

VSUP

IRMS has a maximum value when the input voltage

equals twice the output voltage:

VSUP= 2 × VOUT

therefore:

IRMS =

ILOAD(MAX)

2

Choose an input capacitor that exhibits less than +10°C

self-heating temperature rise at the RMS input current for

optimal long-term reliability.

The input-voltage ripple is composed of ∆VQ (caused by

the capacitor discharge) and ∆VESR (caused by the ESR

of the capacitor). Use low-ESR ceramic capacitors with

high ripple-current capability at the input. Calculate the

www.maximintegrated.com

I OUT × D(1 − D)

∆VQ × f SW

VOUT

VSUPSW

where:

IOUT is the maximum output current and D is the duty

cycle.

Output Capacitor

The output filter capacitor must have enough capacitance

and sufficiently low ESR to meet output-ripple requirements. In addition, the output capacitance must be high

enough to maintain the output voltage within specification

while the control loop responds to load changes.

When using high-capacitance, low-ESR capacitors, the

filter capacitor’s ESR dominates the output-voltage ripple,

so the size of the output capacitor depends largely on the

maximum ESR allowed to meet the output-voltage ripple

specifications as follows:

VRIPPLE(P−=

P) ESR × ∆IL

When using low-ESR (e.g. ceramic) output capacitors,

size is usually determined by the capacitance required

to maintain the output voltage within specification during

load transients and can be estimated as follows:

C OUT =

∆I

∆V × 2π × f C

where ∆I is the load change, ∆V is the allowed voltage

droop, and fC is the loop crossover frequency, which can

be assumed to be the lesser of fSW/10 or 100kHz. Any

calculations involving COUT should consider capacitance

tolerance, temperature, and voltage derating.

Maxim Integrated │ 13

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

VREF +

VERR

C(s)

VCOMP

M(s)

VOUT

-

VFB

F(s)

Figure 2. Control System

Compensation Network

The devices use a transconductance amplifier for external

frequency compensation. The compensation network in

conjunction with the output capacitance primarily determine the loop stability and response. The inductor and the

output capacitor are chosen based on performance, size,

and cost. The compensation network is used to optimize

the loop stability and response.

The converter uses a peak current mode control scheme

that regulates the output voltage by forcing the required

peak current through the external inductor. The devices

use the voltage drop across the high-side MOSFET to

sense inductor current. Current-mode control eliminates

the double pole in the feedback loop caused by the inductor and output capacitor, resulting in a smaller phase shift

and requiring less elaborate error-amplifier compensation

than voltage-mode control.

The final control system can be modeled according to

Figure 2 from which the following transfer function is

derived:

VOUT (s)

C(s)M(s)

=

VREF

1 + F(s)C(s)M(s)

where M(s), C(s) and F(s) are the modulator, compensator

and feedback transfer functions, respectively, VOUT is the

regulated output voltage and VREF is the internal voltage

reference. The product of the modulator, compensator and

feedback transfer functions is typically referred to as the

loop transfer function.

www.maximintegrated.com

A simplified condition for stability is that the denominator

of the transfer function never equals zero. Accordingly,

the loop transfer function should never equal -1, which

correspondingly means that the phase must not equal

-180 degrees when the magnitude equals 1. In addition,

the loop gain should be much less than zero when the

phase equals -180 degrees. The frequency at which the

magnitude of the loop gain equals 1 (or 0dB) is defined as

the crossover frequency (fc). The difference between the

loop phase at the crossover frequency and -180 degrees

is defined as the phase margin. The phase margin represents the additional loop phase lag that must occur at

the crossover frequency for the system to be unstable.

In addition to stability, phase margin is also related to

the transient response of the system. Insufficient phase

margin causes overshoot and ringing, whereas excessive

phase margin causes slow response.

The goal of the system is to have a high crossover frequency, so there is adequate gain to regulate against load

transients and other variations in the relevant frequency

range, while maintaining adequate phase margin to guard

against instability, overshoot, and ringing. In practice,

these are fundamentally conflicting criteria that must be

managed along with other design goals. According to

sampling theory, the crossover frequency cannot exceed

one half the switching frequency. In practice, noise and

phase margin considerations limit crossover frequency to

below one tenth the switching frequency with a practical

limit of approximately 100kHz.

Maxim Integrated │ 14

�MAX20004/MAX20006/

MAX20008

The modulator control (COMP) to output transfer function

of a current-mode buck regulator can be approximated

as follows:

s

1 + ωz_esr

VOUT (s)

R OUT

=

×

VCOMP (s) R CS

s

s

s2

+

+

+

1

1

ωp_load ωnQ

ωn 2

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

VOUT

gm

VREF

The first term is the DC gain, which is the quotient of the

equivalent load resistance (ROUT) and the current-sense

gain (RCS). The numerator is the zero due to the output

capacitance (COUT) and its equivalent series resistance

(RESR), which occurs at the following frequency:

1

fz_esr =

2π × R ESR × C OUT

The first term in the denominator is the pole due to the

load resistance and output capacitance, and occurs at the

following frequency:

1

fpload =

2π × R OUT × C OUT

The last term in the denominator is the sampling double

pole, which occurs at 1/2 of the switching frequency

(fSW/2). The sampling double pole typically occurs at

high frequency relative to the crossover frequency and

can generally be ignored if there is adequate slope compensation (i.e., low Q). In the typical application, where

the ESR is very low due to ceramic output capacitors,

the ESR zero also occurs at high frequency and can be

ignored as well. In these cases, the transfer function

simplifies to the low-frequency dominate pole model as

follows:

VOUT (s)

R OUT

1

=

×

s

VCOMP (s) R CS

1 + ωp_load

The type 2 compensation network (Figure 3) introduces

a zero, a low-frequency pole, and a high frequency pole

according to the simplified transfer function below:

s

1 + ωz_comp

= G EA × R EA ×

s

s

VERR (s)

1 + ωp1_comp 1 + ωp2_comp

VCOMP (s)

www.maximintegrated.com

COMP

RC

CF

CC

Figure 3. Compensation Network

where GEA and REA (1.5MΩ typ) are the transconductance

and output resistance of the error amplifier, respectively, and

the frequency of the poles and zeros are approximately as

follows:

1

fz_comp =

2π × R C × C C

fp1_comp =

1

2π × R EA × C C

fp2_comp =

1

2π × R C × C F

Compensation resistor, RC, primarily determines the compensator gain and, thus, crossover frequency, while the

separation of the compensator zero and high-frequency

pole determine the phase margin. The high-frequency

compensator pole is used to cancel the ESR zero or, in

the case of very high ESR zero frequency, limit the bandwidth for noise immunity. The low frequency compensator

pole is then placed to achieve adequate phase margin

and response, typically at the load pole frequency. The

selection of CC, therefore, becomes a tradeoff between

phase margin and response.The complete loop transfer

Maxim Integrated │ 15

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

function is the product of the product of the modulator,

compensator, and feedback transfer functions as follows:

F(s)C(s)M(s) =

VREF R OUT

×

× G EA × R EA

VOUT R CS

s

s

1 + ωz_esr 1 + ωz_comp

×

s

s

s

1 + ωp_load 1 + ωp1_comp 1 + ωp2_comp

The goal of compensation design is to reduce the loop

transfer function to an approximate single-pole system

with -20dB/decade gain slope and 90 degrees phase

margin at the crossover frequency. To achieve this, the

compensator zero is used to cancel the load pole, and

the compensator high frequency pole is used to cancel

the ESR zero. Assuming these cancellations, the loop

transfer function reduces to the following:

F(s)C(s)M(s)

=

× G EA × R EA ×

VREF R OUT

×

VOUT R CS

1

s

1 + ωp1_comp

To derive the compensation components, the magnitude

of the loop gain at the crossover frequency is set equal to

1 and solved for CC as follows (assuming the magnitude of

the compensator pole at the crossover frequency is >>1):

VREF R OUT

×

× G EA × R EA

VOUT R CS

Setting the compensator zero frequency equal to the load

pole frequency and solving for RC yields:

1

1

=

2π × R C × C C 2π × R OUT × C OUT

RC =

2π × C OUT × R CS × VOUT × f C

VREF × G EA

The above leads to an alternative equation for CC as

follows:

× C OUT

R

C C = OUT

RC

Finally, setting the high-frequency compensator pole

equal to the minimum of the ESR zero frequency or 1/2

the switching frequency and solving for CF yields:

f

1

1

= Min SW ,

2π × R C × C F

2

2

R

C

π

×

×

ESR

OUT

CF =

1

f

1

2π × R C × Min SW ,

π

×

×

2

2

R

C

ESR

OUT

The above equation leads to the following compensation

design procedure:

1) Select a crossover frequency equal to one tenth of

the switching frequency (fSW/10) or 100kHz, whichever is lower.

2) Calculate and select the compensation resistor, RC.

3) Calculate and select the compensation capacitor, CC.

1

4) Calculate and select compensation capacitor CF.

1

×

=

(2π × f C × R EA × C C )

5) Evaluate the gain and phase of the final loop transfer

function at the crossover frequency and adjust crossover frequency and/or compensation as required.

× R OUT × G EA

V

C C = REF

6) Verify the final design with transient line/load response

2π × f C × VOUT × R CS

testing and gain-phase measurements and adjust as

required.

www.maximintegrated.com

Maxim Integrated │ 16

�MAX20004/MAX20006/

MAX20008

PCB Layout Guidelines

Careful PCB layout is critical for stability, low-noise/

EMI and overall performance. Use a multilayer board

whenever possible for better noise immunity and power

dissipation. See Figure 4 for the following guidelines for

good PCB layout:

1) Use the correct footprint for the IC and place as

many copper planes as possible under the IC footprint to ensure efficient heat transfer.

2) Place the ceramic input bypass capacitors (CBP and

CIN) as close as possible to the SUPSW and PGND

pins on the same side as the IC. Use low-impedance

connections (no vias or other discontinuities) between the capacitors and IC pins. CBP should be

located closest to the IC and should have very good

high-frequency performance (small package size,

low inductance, and high. Use flexible terminations

or other technologies instead of series capacitors

for these functions if failure modes are a concern.

This approach provides the best EMI rejection and

minimizes internal noise on the device, which can

degrade performance.

3) Place the inductor (L), output capacitors (COUT),

boost capacitor (CBST) and BIAS capacitor (CB) on

the same side as the IC in such a way as to minimize

the area enclosed by the current loops. Place the

inductor (L) as close as possible to the IC LX pin and

minimize the area of the LX node. Place the output

capacitors (COUT) near the inductor and the ground

side of COUT near the CIN ground connection so as

to minimize the current the loop area. Place the BIAS

capacitor (CB) next to the BIAS pin.

www.maximintegrated.com

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

4) Use a contiguous copper GND plane on the layer

next to the IC to provide an image plane and shield

the entire circuit. GND should also be poured around

the entire circuit on the top side. Use a single GND:

do not separate or isolate PGND and GND connections with separate planes or copper areas. Ensure

that all heat-dissipating components have adequate

connections to copper for cooling. Use multiple vias

to interconnect GND planes/areas for low impedance

and maximum heat dissipation. Place vias at the GND

terminals of the IC, input/output/bypass capacitors,

and other components.

5) Place the compensation network (CF, CC, RC) near

the COMP pin so that the ground connections are as

short as possible to the GND pin. Keep high frequency

signals away from these components.

6) Place the oscillator set resistor (RF) near the FSET

pin so that the ground connection is as short as

possible to the GND pin. Keep high-frequency signals

away from this component.

7) Place the feedback resistor-divider (if used) near

the IC and route the feedback and OUT connections

away from the inductor and LX node and other noisy

signals.

Maxim Integrated │ 17

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

CC

RC

CF

CB

RF

1

VIN

CBST

CBP

CIN

LX

L

COUT

COUT

VOUT

Figure 4. Simplified Layout Example

www.maximintegrated.com

Maxim Integrated │ 18

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Ordering Information/Selector Guide

PART

VOUT

(FB TIED TO BIAS)

VOUT

(EXTERNAL RESISTORDIVIDER) (V)

MAXIMUM

OPERATING

CURRENT (A)

THOLD

(ms)

SPREAD

SPECTRUM

MAX20004AFOA/VY+

5.0

MAX20004AFOB/VY+

3.3

4.5–10

4

0.2

Off

1–10

4

0.2

Off

MAX20004AFOC/VY+

MAX20004AFOD/VY+

5.0

4.5–10

4

0.2

On

3.3

1–10

4

0.2

On

MAX20006AFOA/VY+

5.0

4.5–10

6

0.2

Off

MAX20006AFOB/VY+

3.3

1–10

6

0.2

Off

MAX20006AFOC/VY+

5.0

4.5–10

6

0.2

On

MAX20006AFOD/VY+

3.3

1–10

6

0.2

On

MAX20008AFOA/VY+

5.0

4.5–10

8

0.2

Off

MAX20008AFOB/VY+

3.3

1–10

8

0.2

Off

MAX20008AFOC/VY+

5.0

4.5–10

8

0.2

On

MAX20008AFOD/VY+

3.3

1–10

8

0.2

On

For variants with different options, contact factory.

/V Denotes an automotive-qualified part.

+Denotes a lead(Pb)-free/RoHS-compliant package.

Chip Information

PROCESS: BiCMOS

www.maximintegrated.com

Maxim Integrated │ 19

�MAX20004/MAX20006/

MAX20008

36V, 220kHz to 2.2MHz, 4A/6A/8A

Fully Integrated Automotive

Step-Down Converters

Revision History

REVISION

NUMBER

REVISION

DATE

PAGES

CHANGED

0

3/18

Initial release

—

1

5/18

Removed future product status from MAX20006AFOA/VY+ and

MAX20008AFOC/VY+ variants in the Ordering Information/Selector Guide table

19

2

8/18

Updated the Package Information table, and Reset Output (RESET), Setting

the Output Voltage, Output Capacitor, and Compensation Network sections

; reformatted the Typical Operating Characteristics charts; replaced TOC17

and TOC18; and removed future product designation from MAX2006AFOB/

VY+, MAX2006AFOB/VY+, MAX2006AFOB/VY+, MAX2006AFOB/VY+,

MAX2006AFOB/VY+, and MAX2006AFOB/VY+

3

11/18

Removed future product status from MAX20004AFOA/VY+, MAX20004AFOB/

VY+, MAX20004AFOC/VY+, and MAX20004AFOD/VY+ variants in the Ordering

Information/Selector Guide table

19

4

1/19

Updated land pattern number in Package Information table

2

5

1/19

Updated thermal resistance values in Package Information table and added VOUT

(external resistor-divider) column to Ordering Information/Selector Guide table

2, 19

6

2/19

Added “automotive” to product description

1–19

7

9/19

Updated Typical Application Circuit, Pin Description, and Detailed Description

8

11/19

Updated Pin Description, and Detailed Description

DESCRIPTION

2, 5–7, 10

12–16, 19

1, 8, 11

8, 11

For pricing, delivery, and ordering information, please visit Maxim Integrated’s online storefront at https://www.maximintegrated.com/en/storefront/storefront.html.

Maxim Integrated cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim Integrated product. No circuit patent licenses

are implied. Maxim Integrated reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits)

shown in the Electrical Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

Maxim Integrated and the Maxim Integrated logo are trademarks of Maxim Integrated Products, Inc.

© 2018 Maxim Integrated Products, Inc. │ 20

�