Evaluation Kit

Available

Design

Resources

Tools

and Models

Support

Click here to ask an associate for production status of specific part numbers.

MAX20050–MAX20053

2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

General Description

The MAX20050–MAX20053 are high-brightness LED (HB

LED) drivers for automotive exterior lighting applications.

Consisting of a fully synchronous step-down converter

with integrated MOSFETs, the devices are capable of

driving a series string of LEDs at up to 2A, with a minimum number of external components. The MAX20050/

MAX20052 utilize internal loop compensation to minimize component count, while the MAX20051/MAX20053/

MAX20053D use external compensation for full flexibility.

The wide 4.5V to 65V input supply range supports

extreme automotive cold crank and load-dump conditions. A low- and high-switching frequency option (400kHz

or 2.1MHz) provides the designer with the flexibility to

optimize for solution size or efficiency, while avoiding

interference within the AM band. Spread spectrum provides further options for the designer to reduce EMI at the

system level. The MAX20050/MAX20051 have an internal

switching frequency of 400kHz, while the MAX20052/

MAX20053/MAX20053D have an internal switching frequency of 2.1MHz. In addition, the MAX20051B has

spread spectrum disabled.

High-side current regulation means only a single

connection to the LED string is required; grounding of the

string can be done locally. In addition to PWM dimming,

the ICs provide analog dimming using the REFI pin. Fullscale current regulation accuracy is ±2.5%, while the

accuracy is ±8% at 10% of full-scale over the full temperature range of -40°C to +125°C. A 5V, 10mA LDO output is

available for biasing other circuits.

Fault-protection mechanisms include output overload,

short-circuit, and device overtemperature protection. The

devices are specified for operation over the full -40°C to

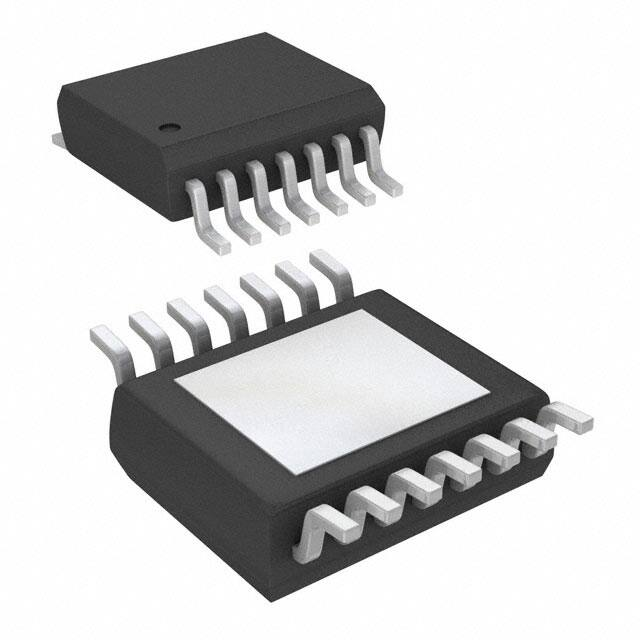

+125°C temperature range and are available in thermally

enhanced 12-pin (3mm x 3mm) TDFN and 14-pin (5mm

x 4.4mm) TSSOP and 24-pin TQFN (4mm x 4mm) packages with an exposed pad.

Benefits and Features

● Automotive Ready: AEC-Q100 Qualified

● Fully Synchronous 2A Step-Down Converter with

Integrated 0.14Ω (typ) MOSFETs

● Wide 4.5V to 65V Input Supply Range

● Two Switching Frequency Options: 400kHz and

2.1MHz

● Internal Loop Compensation (MAX20050/MAX20052)

and External Loop Compensation

(MAX20051/MAX20053/MAX20053D) Options

● Switching Frequency Synchronized to PWM Dimming

Signal

● Active-Low Fault (FLT) Indicator

● Output Short-Circuit Protection

● High-Side Current Regulation Eliminates One

Connection to LED String

● Spread-Spectrum Mode Alleviates EMI Problems

● Low 200mV Full-Scale High-Side Current-Sense

Voltage

● REFI Pin Adjusts LED Current Down to Zero

● PWM Dimming Disconnects Both High- and LowSide MOSFET Drivers

● 5V, 10mA LDO Output Provides Bias to Other

Circuits

● Ultra-Low Shutdown Current (5µA typ)

● Output Overload, Short-Circuit, and Overtemperature

Protections

● 12-Pin (3mm x 3mm) TDFN, 14-Pin (5mm x 4.4mm)

TSSOP, and 24-pin (4mm x 4mm) TQFN Package

Options

Applications

●

●

●

●

●

●

●

●

Daytime Running Lamps (DRLs)

Fog Lamps

Clearance Lamps (CLLs)

Corner Lamps (CLs)

Rear Lamps

Head Lamps

Commercial, Industrial, and Architectural Lighting

Driver Monitoring Systems (DMS)

Ordering Information appears at end of data sheet.

19-6926; Rev 20; 7/21

© 2021 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

One Analog Way, Wilmington, MA 01887 U.S.A.

|

Tel: 781.329.4700

|

© 2021 Analog Devices, Inc. All rights reserved.

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Absolute Maximum Ratings

Continuous Current on IN for TQFN.....................................1.8A

Continuous Current on IN for TSSOP...................................2.1A

Short-Circuit Duration on VCC....................................Continuous

Continuous Power Dissipation (TA = +70°C) (Note 1)

12-Pin TDFN-EP (derate 24.4 mW/°C

above +70°C) .........................................................1951.2mW

14-Pin TSSOP-EP (derate 25.6 mW/°C

above +70°C) .........................................................2051.3mW

Operating Temperature Range...........................-40ºC to +125ºC

Junction Temperature....................................................... +150ºC

Storage Temperature Range..............................-65ºC to +150ºC

Lead Temperature (soldering, 10s).................................. +300ºC

Soldering Temperature (reflow)........................................ +260ºC

IN to AGND............................................................-0.3V to +70V

IN to AGND (MAX20050C/51C/52C/53C/53D only).-0.3V to 40V

PGND to AGND.....................................................-0.3V to +0.3V

CS+, CS-, LX to AGND.................................-0.3V to (IN + 0.3V)

BST to AGND.........................................................-0.3V to +75V

BST to AGND (MAX20050C/51C/52C/53C/53D only).... -0.3V to

45V

BST to LX.................................................................-0.3V to +6V

PWM, FLT to AGND.................................................-0.3V to +6V

VCC to AGND................................-0.3V to MIN (+6V, IN + 0.3V)

COMP, REFI to AGND.................................-0.3V to VCC + 0.3V

CS+ to CS-...........................................................-0.3V to + 0.3V

Continuous Current on LX.....................................................2.1A

Continuous Current on IN for TDFN.....................................1.6A

Package Thermal Characteristics (Note 1)

TDFN

Junction-to-Ambient Thermal Resistance (θJA)...........41°C/W

Junction-to-Case Thermal Resistance (θJC)...............8.5°C/W

TSSOP

Junction-to-Ambient Thermal Resistance (θJA)...........39°C/W

Junction-to-Case Thermal Resistance (θJC)..................3°C/W

TQFN

Junction-to-Ambient Thermal Resistance (θJA)...........36°C/W

Junction-to-Case Thermal Resistance (θJC)..................3°C/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-layer

board. For detailed information on package thermal considerations, refer to www.maximintegrated.com/thermal-tutorial.

Electrical Characteristics

(VIN = 12V, VREFI = 1.2V, VPWM = VCC, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C.) (Note 2)

PARAMETER

Input Supply Voltage

IN Undervoltage Lockout

IN Undervoltage Hysteresis

SYMBOL

VIN

VINUVLO

CONDITIONS

MAX20050C/51C/52C/53C/53D only (Note 5)

MAX

4.5

65

4.5

36

4.45

VINHYSTL

IINQ

TYP

VIN rising inferred by VCCUVLOR

225

PWM = 0

(no switching)

Supply Current

MIN

PWM = 100%

(and during regulation

switching)

V

V

mV

VIN = 12V

5

8

VIN = 65V

8

20

VIN = 12V

(MAX20050/51/

50C/51C)

5

10

VIN = 12V

(MAX20052/53/

/52C/53C/53D)

VIN = 65V

(MAX20050/51)

UNITS

μA

mA

20

10

VCC REGULATOR (VCC)

IVCC = 1mA, 5.5V < VIN < 65V

VCC Output Voltage

VCC

IVCC = 1mA, 5.5V < VIN < 36V

(MAX20050C/51C/52C/53C/53D only)

4.875

5

5.125

V

IVCC = 10mA, 6V < VIN < 25V

www.analog.com

Analog Devices │ 2

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Electrical Characteristics (continued)

(VIN = 12V, VREFI = 1.2V, VPWM = VCC, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C.) (Note 2)

PARAMETER

SYMBOL

MIN

TYP

MAX

UNITS

50

100

mV

VCC = 0V

50

80

110

VCC = 0V, MAX20053D

40

80

110

VCCUVLOR

Rising

4

4.2

4.35

V

VCCUVLHYS

Hysteresis

150

200

250

mV

1.20

V

VCC Dropout Voltage

VCC Short-Circuit Current

VCC Undervoltage Lockout

REFI Input Voltage Range

REFI Zero-Current

Threshold

REFI Clamp Voltage

CONDITIONS

IVCC = 5mA, VIN = 4.5V

VCCIMAX

REFIRNG

REFIZC_VTH

REFICLMP

0.2

mA

CSDIFF < 5mV

0.165

0.18

0.195

V

IREFI sink = 1μA

1.274

1.3

1.326

V

VREFI = 0 to VCC

0

20

200

VREFI = 0 to VCC (MAX200051B only)

0

20

300

Input Bias Current

REFIIIN

Common-Mode Input Range

CSCMIN

-0.2

+65

V

Differential Signal Range

CSDIFF

0

200

mV

CS+ Input Bias Current

IBCS+

VCS+ = 60V

CS- Input Bias Current

IBCS-

VCS- = 60V

VCS+ - VCS- = 200mV

40

70

VCS+ - VCS- = 0V

8

15

VCS+ - VCS- = 200mV

100

150

VCS+ - VCS- = 0V

66

110

TJ = 25°C, CSCMIN 3V to 60V

Current-Sense Input Offset

CSOS

3V < CSCMIN < 60V

Regulation Voltage

Accuracy

Regulation Voltage

Accuracy Low Range

www.analog.com

CSGAIN

-1.8

CSACC

CSACC

+1.8

5

5.05

4.91

5

5.08

REFI = 1.4V, 3V < CSCMIN < 60V

215

220

225

REFI = 1.2V, 3V < CSCMIN < 60V

196

200

204

REFI = 1.2V, 3V < CSCMIN < 60V,

MAX20053D

196

200

205

B,C,D versions

μA

mV

-0.1

4.95

(CS+ - CS-) = 200mV,

3V < CSCMIN < 60V

μA

-0.1

3V < CSCMIN < 60V, MAX20053D

Current-Sense Voltage Gain

nA

REFI = 0.7V, 3V < CSCMIN < 60V

V/V

mV

100

REFI = 0.4V, 3V < CSCMIN < 60V

37.8

40

42.2

REFI = 0.4V, 3V < CSCMIN < 60V,

MAX20053D

37.8

40

43.1

VREFI = 1.2V 0V < CSCMIN < 3V

192

200

208

VREFI = 0.4V 0V < CSCMIN < 3V

35

40

45

VREFI = 1.2V 0V < CSCMIN < 3V,

MAX20053D

192

200

209.1

VREFI = 0.4V 0V < CSCMIN < 3V,

MAX20053D

35

40

46.5

mV

Analog Devices │ 3

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Electrical Characteristics (continued)

(VIN = 12V, VREFI = 1.2V, VPWM = VCC, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C.) (Note 2)

PARAMETER

CS Common-Mode Range

Input Selector

Cycle-by-Cycle Current

Limit

Transconductance

SYMBOL

RNGSEL

CSLIM

CONDITIONS

TYP

VCS+ rising

2.7

2.85

3.0

2.45

2.6

2.75

VCS- > OUTVTH_LOW

285

300

315

VCS- > OUTVTH_LOW, MAX20053D

282

300

315

VCS+ - VCS- = 200mV

CSACC

CSACC

CSACC

-5

+5

480

Open-Loop DC Gain

COMP Bias Current

MAX

VCS+ falling

VCS- < OUTVTH_LOW

gM

MIN

600

720

75

COMPIBIAS

COMP Sink Current

COMPISINK

COMP Source Current

COMPISRC

PWM = 0

-200

UNITS

V

mV

μS

dB

+200

VCOMP = 5V

85

100

115

VCOMP = 5V, MAX20053D

80

100

115

VCOMP = 0V

85

100

115

VCOMP = 0V, MAX20053D

80

100

115

nA

μA

μA

High-Side DMOS RDSON

RON,HS

ILX = 200mA, VCS+ = 3V

170

340

mΩ

Low-Side DMOS RDSON

RON,LS

VCC = 5V, ILX = 200mA

140

300

mΩ

LX Rise Time

tRISE,LS

Switching Frequency

fSW

Minimum On-Time

tON_MIN

Minimum Off-Time

tOFF_MIN

Spread-Spectrum Range

PWM Input Frequency

PWM-to-LX Delay

PWM Threshold

PWM Pullup Current

PWM Shutdown Timer

Startup Time

Thermal Shutdown

www.analog.com

SS

10

MAX20050/MAX20051, frequency dither

disabled

360

MAX20052/MAX20053, frequency dither

disabled

1890

2100

2310

50

80

120

50

80

120

40

60

90

MAX20053D

2000

5

Falling (during regulation)

2

5

Falling

VIN = 12V

ns

ns

%

2

Rising

tSTUP

±3

10

PWMVTHF

PWMRIN

440

Rising (during regulation)

PWMVTHR

PWMSHDW

400

kHz

Not applicable to B version

PWMFR

PWMDLY

ns

2

800

Hz

μs

V

mV

1

2

3

μA

PWM low time to enter shutdown mode

140

210

300

ms

IN, PWM rising to LX delay

180

250

350

μs

Rising

165

°C

Hysteresis

10

°C

Analog Devices │ 4

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Electrical Characteristics (continued)

(VIN = 12V, VREFI = 1.2V, VPWM = VCC, TA = TJ = -40°C to +125°C, unless otherwise noted. Typical values are at TA = +25°C.) (Note 2)

PARAMETER

LED Open-Fault REFI

Range

SYMBOL

CONDITIONS

LOFREFI_RNG VREFI rising

MIN

TYP

MAX

UNITS

300

325

350

mV

LED Open-Fault Enable

Rising Threshold

LOFIN_RNG

VIN rising

8

9

10

V

LED Open-Fault Enable

Falling Threshold

LOFIN_FLNG

VIN falling

7.3

8.3

9.3

V

CSDIFF falling, duty = max

10

25

40

%

3

6

9

%

1.35

1.5

1.65

V

0.05

0.3

V

µs

LED Open-Fault Threshold

LOFVTH

LED Open-Fault Hysteresis

LOFVTH_HYS

Output-Voltage Low

Threshold

OUTVTH_LOW VCS- falling

FAULT Output Voltage

FAULTVOL

ISINK = 1mA, VCS+ = 1V, after FAULTDEG

elapsed

FAULT Deglitch Timer

FAULTDEG

(Note 3)

70

105

150

FAULT Mask Timer

FAULTMASK

(Note 4)

140

210

300

µs

1

µA

FAULT Leakage Current

FAULTLGK

VFAULT = 5.5V

Note 2: 100% tested at TA = +25°C. All limits over temperature are guaranteed by design, not production tested.

Note 3: The time duration for which the fault condition has to remain active before asserting FLT pin.

Note 4: The mask timer occurs each time PWM goes from low to high. Open LED condition cannot be detected during the

mask time period.

Note 5: Device is designed for use in applications with continuous 18V operation, and meets Electrical Characteristics table up to

the maximum supply voltage.

www.analog.com

Analog Devices │ 5

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Typical Operating Characteristics

(VIN = 12V, VREFI = 1.2V, VPWM = VCC, TA = +25°C, unless otherwise noted.)

EFFICIENCY vs.

LED CURRENT

toc01

EFFICIENCY vs.

LED CURRENT

100

80

80

80

70

70

70

VIN = 24V (MAX20053)

VIN = 24V (MAX20051)

50

VIN = 12V (MAX20053)

40

VIN = 12V (MAX20051)

30

60

30

10

10

0.5

1.0

1.5

0

2.0

VIN = 24V (MAX20051)

40

20

0.0

VIN = 12V (MAX20053)

50

20

2 SERIES LEDS

VIN = 12V (MAX20051)

40

30

0.0

0.5

1.0

1.5

LINE REGULATION

0

2.0

toc04

VCC VOLTAGE REGULATION vs.

TEMPERATURE

toc05

5.25

5.20

5.15

5.15

1.02

5.10

5.10

1.01

1.00

VCC (V)

5.20

5.05

5.00

4.95

0.98

4.90

4.90

4.85

4.85

0

10

20

30

40

4.80

4.75

50

VIN (V)

toc07

-50

0

50

100

4.75

150

MINIMUM ON-TIME

vs. TEMPERATURE

200

toc08

160

140

140

4.95

4.90

4.85

4.80

40

IVCC (mA)

www.analog.com

60

120

100

80

60

40

20

VREFI = 0V

20

MINIMUM OFF-TIME (ns)

160

5.10

MINIMUM ON-TIME (ns)

5.15

0

0

10

20

80

0

30

40

50

MINIMUM OFF-TIME

vs. TEMPERATURE

200

180

4.75

VREFI = 0V

60

70

VIN (V)

180

5.00

toc06

MAX20051

4.80

IVCC = 1mA

5.20

5.05

2.0

VCC LINE REGULATION

TEMPERATURE (ºC)

VCC LOAD REGULATION

5.25

1.5

5.00

4.95

MAX20051

2 SERIES LEDS

ILED = 1A

1.0

5.05

0.99

0.95

0.5

5.25

1.03

0.96

0.0

LED CURRENT (A)

1.04

0.97

6 SERIES LEDs

VIN = 48V

MAX20051

LED CURRENT (A)

VCC (V)

ILED (A)

50

10

1 LED

toc03

60

20

LED CURRENT (A)

1.05

EFFICIENCY (%)

90

60

EFFICIENCY vs.

LED CURRENT

100

90

0

VCC (V)

toc02

90

EFFICIENCY (%)

EFFICIENCY (%)

100

toc09

120

100

80

60

40

20

-50

0

50

100

TEMPERATURE (ºC)

150

0

-50

0

50

100

150

TEMPERATURE (ºC)

Analog Devices │ 6

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Typical Operating Characteristics (continued)

(VIN = 12V, VREFI = 1.2V, VPWM = VCC, TA = +25°C, unless otherwise noted.)

SWITCHING FREQUENCY vs.

TEMPERATURE

toc10

2.5

4.25

UVLO RISING

MAX20053

VIN UVLO (V)

SWITCHING FREQUENCY (MHz)

1.5

1.0

0.0

4.15

1A/div

ILED

4.10

-50

0

2V/div

VLED

4.00

50

100

3.95

150

0A

UVLO

FALLING

4.05

MAX20051

2V/div

0V

VREFI

4.20

2.0

0.5

VREFI TRANSIENT RESPONSE

(MAX20051)

toc12

VIN UVLO THRESHOLDS vs.

TEMPERATURE

toc11

0V

-50

0

50

100

150

100µs/div

TEMPERATURE (ºC)

TEMPERATURE (ºC)

VREFI TRANSIENT RESPONSE

(MAX20053)

toc13

250

2V/div

0V

200

1A/div

150

ILED

0A

VLED

VCS+ - VCS- (mV)

VREFI

MAX20051

MAX20053

100

50

2V/div

0

0V

100µs/div

CURRENT SENSE VOLTAGE

vs. VREFI

toc14

-50

3 LEDS

RCS = 100mΩ

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

VREFI (V)

CURRENT SENSE VOLTAGE vs.

TEMPERATURE

toc15

VCS+ - VCS- (mV)

120

16

VCS- = 0V

(MAX20051)

110

100

90

60

-50

0

VIN = 65V (MAX20051)

10

VIN = 12V (MAX20051)

6

2

VREFI = 0.7V

50

100

TEMPERATURE (ºC)

www.analog.com

12

4

VCS- = 3V

(MAX20053)

70

14

8

VCS- = 3V

(MAX20051)

80

toc16

VIN = 12V (MAX20053)

18

VCS- = 0V

(MAX20053)

130

SUPPLY CURRENT

vs.TEMPERATURE

20

IIN (mA)

140

150

0

PWM = 100%

-50

0

50

100

150

TEMPERATURE (ºC)

Analog Devices │ 7

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Pin Configurations

TOP VIEW

LX

LX

12

11

BST VCC REFI AGND

10

9

8

7

MAX20050

MAX20052

+

1

2

3

PGND IN

4

5

6

+

PWM

19

LX

NC

20

12

BST

FLT

21

11

VCC

NC

22

5

10

REFI

COMP

23

PWM

6

9

AGND

FLT

7

8

COMP

AGND

24

PGND

1

IN

2

IN

3

CS+

4

CS-

MAX20051

MAX20053

14

LX

13

CS-

NC CS+ CS+ NC

18

17

16

15

12 IN

10 PGND

MAX20053D

9 NC

8 LX

+

2

3

4

AGND REFI VCC BST

5

6

LX

LX

7 LX

TQFN

TSSOP

TDFN

13

11 PGND

1

CS+ CS- PWM FLT

14

IN

Pin Descriptions

TDFN

TSSOP

MAX20050

MAX20052

MAX20051

MAX20053

NAME

1

1

PGND

2

2, 3

IN

3

4

FUNCTION

Power Ground

Power-Supply Input. Bypass to PGND with a minimum of 1μF ceramic capacitor.

CS+

Current-Sense Positive Pin. This is the positive input of the high-side average currentmode control amplifier. See the Programming the LED Current section for information on

setting the resistor value. The output inductor and current-sense resistor are connected at

this node.

4

5

CS-

Current-Sense Negative Pin. This is the negative input of the high-side average currentmode control amplifier. See the Programming the LED Current section for information on

setting the resistor value. This node goes to the anode of the LED string. One end of the

current-sense resistor connects to this pin.

5

6

PWM

Logic-Level Dimming Input. Drive PWM low to turn off the current regulator. Drive PWM

high to enable the current regulator. If PWM is driven low for greater than 210ms, the

device turns off.

6

7

FLT

Open-Drain Fault Output. Refer to the Fault Pin Behavior section for information on Fault.

—

8

COMP

Compensation Output (MAX20051/MAX20053). Connect an external RC network for loop

compensation. The MAX20050/MAX20052 are internally compensated.

7

9

AGND

Analog Ground

8

10

REFI

9

11

VCC

10

12

BST

11, 12

13, 14

LX

Switching Node. Connect to one end of output inductor.

—

—

EP

Exposed Pad. Connect EP to a large-area ground plane for effective power dissipation.

Connect EP to AGND. Do not use as the only ground connection.

www.analog.com

Analog Dimming-Control Input. Connect an analog voltage from 0 to 1.2V for analog

dimming of LED current.

5V Regulator Output. Connect a 1μF ceramic capacitor to AGND from this pin for stable

operation.

High-Side Power Supply for Gate Drive. Connect a 0.1μF ceramic capacitor from BST to

LX.

Analog Devices │ 8

�MAX20050–MAX20053

2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

Pin Descriptions (continued)

TQFN

MAX20053D

NAME

FUNCTION

1, 24

AGND

2

REFI

Analog Dimming-Control Input. Connect an analog voltage from 0 to 1.2V for analog dimming of

LED current.

3

VCC

5V Regulator Output. Connect a 1μF ceramic capacitor to AGND from this pin for stable operation.

4

BST

High-Side Power Supply for Gate Drive. Connect a 0.1μF ceramic capacitor from BST to LX.

5, 6, 7, 8

LX

Switching Node. Connect to one end of output inductor.

9

NC

No Connect

10, 11

PGND

12, 13

IN

Power-Supply Input. Bypass to PGND with a minimum of 1μF ceramic capacitor.

14

NC

No Connect

15, 16

CS+

Current-Sense Positive Pin. This is the positive input of the high-side average current-mode

control amplifier. See the Programming the LED Current section for information on setting the

resistor value. The output inductor and current-sense resistor are connected at this node.

17

NC

No Connect

18

CS-

Current-Sense Negative Pin. This is the negative input of the high-side average current-mode

control amplifier. See the Programming the LED Current section for information on setting the

resistor value. This node goes to the anode of the LED string. One end of the current-sense

resistor connects to this pin.

19

PWM

Logic-Level Dimming Input. Drive PWM low to turn off the current regulator. Drive PWM high to

enable the current regulator. If PWM is driven low for greater than 210ms, the device turns off.

20

NC

No Connect

21

FLT

Open-Drain Fault Output. Refer to the Fault Pin Behavior section for information on Fault.

22

NC

No Connect

23

COMP

—

EP

www.analog.com

Analog Ground. Pins 1 and 24 should be shorted outside the IC.

Power Ground

Compensation Output. Connect an external RC network for loop compensation.

Exposed Pad. Connect EP to a large-area ground plane for effective power dissipation. Connect

EP to AGND. Do not use as the only ground connection.

Analog Devices │ 9

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

VCCOK

POK

INUVLO

VIN

PWM

VCC

LDO

BG

INUVLO

OSC

SYNC TO RISING

EDGE OF PWM

VCCOK

DITHERING

(NON-B VERSIONS)

DUTY MAX

BLANKING TIME

AGND

POKD

80µs

DELAY

CLOCK

RESET

DOMINANT

S

DH

SET Q

PWM COMP

1.3V

CLAMP

REFI

300mV

Gm

CS-

PEAK

CURRENT

LIMIT

x5

CS+

BST

R CLR Q

VIN

DUTY

MAX

SOFT-OFF

PWM

COMP

D

DH

LX

SET Q

POKD

RESET

DOMINANT

CLR Q SKIP PULSE

4V

PWM

2µA

PWM

FALLING 0.8V

RISING 2.0V

200ms LOW

STATE TIME

COUNTER

MAX20050

MAX20052

S

SHUTDOWN

MODE

0.5V

REFI

SET Q DL

R CLR Q

SOFT-OFF

THERMAL

SHUTDOWN

REFI > 325mV

1.5V

VCC

PGND

LED

SHORT

t = 105µs

FLT

CSTHERMAL

SHUTDOWN

180mV

REFI > 325mV

VIN > 9V

DUTY = MAX

25% REFI

LED

OPEN

t = 105µs

Figure 1. Block Diagram of the MAX20050/MAX20052

www.analog.com

Analog Devices │ 10

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

VCCOK

POK

INUVLO

VIN

PWM

VCC

LDO

BG

INUVLO

OSC

SYNC TO RISING

EDGE OF PWM

VCCOK

DUTY MAX

DITHERING

(NON-B VERSIONS)

BLANKING TIME

AGND

CLOCK

COMP

POKD

80µs

DELAY

RESET

DOMINANT

S

DH

SET Q

PWM COMP

300mV

1.3V

CLAMP

REFI

PEAK

CURRENT

LIMIT

BST

R CLR Q

VIN

DUTY

MAX

Gm

CS-

SOFT-OFF

x5

CS+

PWM

COMP

D

DH

LX

SET Q

POKD

RESET

DOMINANT

CLR Q SKIP PULSE

4V

PWM

2µA

PWM

FALLING 0.8V

RISING 2.0V

200ms LOW

STATE TIME

COUNTER

MAX20051

MAX20053

S

SHUTDOWN

MODE

0.5V

REFI

SET Q DL

R CLR Q

REFI > 325mV

SOFT-OFF

1.5V

PGND

LED

SHORT

t = 105µs

CS-

THERMAL

SHUTDOWN

VCC

FLT

THERMAL

SHORT

180mV

REFI = 325mV

VIN > 9V

DUTY = MAX

25% REFI

LED

OPEN

t = 105µs

Figure 2. Block Diagram of the MAX20051/MAX20053

www.analog.com

Analog Devices │ 11

�MAX20050–MAX20053

Detailed Description

The MAX20050–MAX20053 are HB LED drivers for

automotive exterior lighting applications. Consisting of

a fully synchronous step-down converter with integrated

MOSFETs, the devices are capable of driving a series

string of LEDs at up to 2A, with a minimum number of

external components. The MAX20050/MAX20052 utilize

internal loop compensation to minimize component count,

while the MAX20051/MAX20053 use external compensation for full flexibility.

The wide 4.5V to 65V input supply range supports extreme

automotive cold-crank and load-dump conditions. A lowand high-switching frequency option (400kHz or 2.1MHz)

provides the designer with the flexibility to optimize for

solution size or efficiency, while avoiding interference

within the AM band. Spread spectrum provides further

options for the designer to reduce EMI at the system level.

The MAX20050/MAX20051 have an internal switching

frequency of 400kHz, while the MAX20052/MAX20053

have an internal switching frequency of 2.1MHz.

High-side current regulation means only a single connection to the LED string is required; grounding of the string

can be done locally. In addition to PWM dimming, the ICs

provide analog dimming using the REFI pin. Full-scale

current regulation accuracy is ±2.5%, while the accuracy

is ±8% at 10% of full scale, over the full temperature

range of -40°C to +125°C. A 5V, 10mA LDO output is

available for biasing other circuits.

Fault-protection mechanisms include output overload,

short-circuit, and device overtemperature protections.

Functional Operation of MAX20050–MAX20053

The MAX20050–MAX20051 are monolithic, constant

frequency average current mode step-down DC-DC

LED drivers. A fixed frequency internal oscillator sets the

switching frequency of the devices. For the MAX20050/

MAX20051, the switching frequency is set at 400kHz,

and for the MAX20052/MAX20053, the switching frequency is set at 2.1MHz. Spread spectrum is added to

the internal oscillator to improve the EMI performance

of the LED driver at higher frequencies. The oscillator

turns on the internal top power switch at the beginning of

each clock cycle. Current in the inductor then increases

until the internal PWM comparator trips and turns off the

www.analog.com

2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

top power switch. The duty cycle at which the top switch

turns off is controlled by an internal PWM comparator that

has the output of an error amplifier going to the negative

input of the comparator and a saw tooth ramp going to

the positive input of the comparator. The error amplifier

is a transconductance amplifier that compares the analog

control voltage REFI with an amplified current sense signal. The output of the error amplifier is then fed to a PWM

comparator. The other input of the PWM comparator is

a saw tooth ramp with a peak to peak voltage of 2.25V.

The REFI voltage programs the LED current. When the

top power switch turns off, the synchronous power switch

at the bottom turns on until the next clock cycle begins.

The current sense signal is derived by a current sense

resistor in series with the output inductor. This current

sense signal is amplified by a factor of 5 and is then fed

to the input of the error amplifier. This amplified signal is

also fed to a comparator input which compares the amplified current sense signal with a 300mV reference. If the

amplified current sense signal exceeds 300mV, then the

top switch is immediately turned off independent of the

PWM comparator and the bottom synchronous switch is

turned on until the start of the next oscillator cycle. In the

MAX20050/MAX20052, the output of the error amplifier

is not available and the loop compensation is fixed inside

the device. In the MAX20051/MAX20053, the output of

the error amplifier appears on a pin and the loop can be

compensated externally.

The device also includes a PWM dimming input that is

used for PWM dimming of the LED current. When this signal is low both, the top and bottom switches are turned off

and when the PWM signal goes high the inductor current

is controlled by the device. The rising edge of the PWM

signal also restarts the internal oscillator allowing the top

switch to be turned on at the same instant as the rising

edge of the PWM signal. This provides consistent dimming performance at low dimming duty cycles. The PWM

signal can also be used as an enable input where if the

PWM signal stays low for a period exceeding 200ms the

device goes into a shutdown mode. In shutdown mode,

the quiescent current drawn by the device goes to 5µA at

an input of 12V.

The devices also feature a fault flag that indicates open or

shorts on the output. Thermal shutdown shuts down the

devices to protect them from damage at high temperatures.

Analog Devices │ 12

�MAX20050–MAX20053

Analog Dimming

2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

Switching Node (LX)

The devices have an analog dimming-control input

(REFI). The voltage at REFI sets the LED current level

when VREFI ≤ 1.2V. For VREFI > 1.2V, REFI is clamped

to 220mV (typ). The maximum withstand voltage of this

input is 5.5V. The LED current is guaranteed to be at zero

when the REFI voltage is at or below 0.18V. The LED

current can be linearly adjusted from zero to full scale for

the REFI voltage in the range of 0.2V to 1.2V.

The source of the internal high-side switching MOSFET

and the drain of the low-side synchronous switching

MOSFET is connected to these pins. Connect these pins

together externally and connect them to the inductor and

the boost capacitor. The RDS(ON) of both the high- and

low-side switching MOSFETs is 0.3Ω maximum at a

junction temperature of +125°C.

High-Side Current Sense (CS+, CS-)

The BST pin is used to provide a drive voltage to the

high-side switching MOSFET that is higher than the input

voltage. An internal diode is connected from BST to VCC.

Connect a 0.1µF ceramic capacitor from this pin to the LX

pins. Place the capacitor as close as possible to this pin.

A resistor is connected between the inductor and the

anode of the LED string to program the maximum LED

current. The full-scale signal is 200mV. The CS+ pin

should be connected to the positive terminal of the currentsense resistor (inductor side) and the CS- pin should be

connected to the negative terminal of the current-sense

resistor (LED string anode side).

PWM Dimming Control (PWM)

A low signal on this pin turns off both the high- and lowside MOSFETs. The device goes into shutdown mode if

there is no positive-going dimming pulse for 210ms. In

shutdown mode, the input current is less than 5µA (typ).

In applications where the PWM pin is pulled low with an

open drain transistor to get into shutdown mode, do not

connect a pull up resistor to VCC on this pin. The device

comes out of shutdown mode with the internal current

source pulling the pin high.

5V Regulator (VCC)

A regulated 5V output is provided for biasing other

circuitries up to 10mA load. Bypass VCC to AGND with a

minimum of 1µF ceramic capacitor as close as possible

to the device.

Input Voltage (IN)

The input supply pin (IN) must be locally bypassed with a

minimum of 1µF capacitance close to the pin. All the input

current that is drawn by the LED driver goes through this

pin. The positive terminal of the bypass capacitor must be

placed as close as possible to this pin and the negative

terminal of the bypass capacitor must be placed as close

as possible to the PGND pin.

www.analog.com

Boost Capacitor Node (BST)

Power Ground (PGND)

The source of the internal low-side power MOSFET is

connected to this pin. Place the negative terminal of

the input bypass capacitor as close as possible to the

PGND pin.

Analog Ground (AGND)

This is the analog ground pin for all the control circuitry of

the LED driver. Connect the PGND and the AGND together at the negative terminal of the input bypass capacitor.

Compensation (COMP)

(MAX20051/MAX20053)

The COMP pin is present in the MAX20051/MAX20053.

Connect the external compensation network to this pin for

stable loop compensation.

Fault Pin Behavior

The FLT pin is an open-drain output. See the LED Open

and LED Short sections.

LED Open

The LED open is detected when the following conditions

are true at the same time for a period longer than 105µs:

● Input voltage > 9V

● REFI > 325mV

● Current sense < 25% expected REFI value

● Max duty cycle

Analog Devices │ 13

�MAX20050–MAX20053

If an LED open is detected and the input voltage goes

below 9V or REFI goes below 325mV, the FLT flag

remains asserted until the input voltage goes above 9V

and REFI goes above 325mV. If PWM is high and a LED

open occurs, the FLT pin asserts after a deglitch period

of 105µs. When the PWM goes low, the FLT status is

latched. LED open condition cannot be detected if PWM

pulse width is shorter than the maximum mask timer

period of 300µs.

The LED open condition cannot be detected if the PWM

pulse width is shorter than the mask timer period. The

mask timer counter uses an internal clock (15µs typical

period) to perform the mask timing measurement. If the

PWM dimming pulse is in the range of 140µs to 300µs,

there is a timing window of 1-clock cycle width (210µs

-225µs typical), where the FLT pin can toggle between

high and low state from one PWM dimming pulse to another in case of an LED open fault. If the PWM pulse width is

longer than the mask timer period and an LED open fault

is detected, the FLT flag goes low. Once the open LED

fault condition disappears, the FLT flag goes high.

LED Short

The LED short is detected when the following two conditions

are true at the same time for a period longer than 105µs:

● REFI > 325mV

● Output voltage < 1.5V

After LED short is recovered, the fault flag is deasserted,

irrelevant to the input voltage.

Thermal Shutdown

The FLT pin goes low when thermal shutdown is activated.

Exposed Pad

The device package features an exposed thermal pad

on its underside that should be used as a heat sink. This

pad lowers the package’s thermal resistance by providing

a direct heat-conduction path from the die to the PCB.

Connect the exposed pad and AGND together using a

large pad or ground plane, or multiple vias to the AGND

plane layer.

Inductor Peak Current-Limit Comparator

The peak current comparator provides a path for fast

cycle-by-cycle current limit during extreme fault conditions. The average current-limit threshold, set by the REFI

voltage, limits the output current during short circuit.

www.analog.com

2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

Spread-Spectrum Modulation

The devices include a unique spread-spectrum mode that

reduces emission (EMI) at the switching frequency and

its harmonics.

The spread spectrum uses a pseudorandom dithering

technique, where the switching frequency is varied in the

range of 400kHz ±3% for the MAX20050/MAX20051 and

2.1MHz ±3% for the MAX20052/MAX20053.

Instead of a large amount of spectral energy present at

multiples of the switching frequency, the total energy at

the fundamental and each harmonic is spread over a

wider bandwidth, reducing the energy peak.

Spread-spectrum modulation is disabled in B versions of

the device.

Thermal Protection

The devices feature thermal protection. When the junction

temperature exceeds +165°C, the LX pin starts operating

at the minimum pulse width to reduce the power dissipation in the internal power MOSFETs. The part returns

to regulation mode once the junction temperature goes

below +155°C. This results in a cycled output during

continuous thermal-overload conditions.

High-Side Current-Sense Amplifier

The devices feature a high-bandwidth, high-side currentsense amplifier that is used to sense the inductor current.

The gain of this current-sense amplifier is 5. The differential voltage between CS+ and CS- is fed to the internal

high-side current-sense amplifier. This amplified signal is

then transferred to the low side and is then connected to

the negative input of an internal transconductance amplifier. The 3dB bandwidth of the high-side current-sense

amplifier is 1.5MHz.

Internal Transconductance Amplifier

The devices have a built-in transconductance amplifier

used to amplify the error signal inside the feedback loop.

The output of the high-side current-sense amplifier, plus

an offset voltage of 0.2V, is fed to the negative input of

this internal transconductance amplifier. The positive

input is the voltage on the REFI pin. In the case of the

MAX20050/MAX20052, the loop of this amplifier is internally compensated and is not available as an output pin.

In the case of the MAX20051/MAX20053, the output of

this amplifier is available on the COMP pin and can be

compensated with an external compensation network.

The transconductance of this amplifier is 600µS.

Analog Devices │ 14

�MAX20050–MAX20053

2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

Applications Information

switching frequency of 2.1MHz. Selecting a higher switching frequency reduces the inductance requirements, but

at the cost of efficiency. The charge/discharge cycle of

the gate capacitance of the internal switching MOSFET’s

gate and drain capacitance create switching losses,

which worsen at higher input voltages since the switching

losses are proportional to the square of the input voltage. Choose inductors from the standard high-current,

surface-mount inductor series available from various

manufacturers. High inductor ripple current causes large

peak-to peak flux excursion, increasing the core losses at

higher frequencies.

Programming the LED Current

Normal sensing of the LED current should be done on

the high side where the LED current-sense resistor is

connected to the inductor. The other side of the LED

current-sense resistor goes to the anode of the external

LED string. The LED current is programmed using RCS

(see Figure 3). When REFI is set to a voltage >1.3V, the

internal reference regulates the voltage across RCS to

220mV. The current is given by:

ILED =

0.220

R CS

The LED current can also be programmed using the

voltage on REFI when VREFI ≤ 1.2V (analog dimming).

The current is given by:

ILED =

(VREFI − 0.2)

(5 x R CS )

Inductor Selection

The peak inductor

and the allowable

value and size of

MAX20051 have

400kHz, whereas

current, selected switching frequency,

inductor current ripple determine the

the output inductor. The MAX20050/

an internal switching frequency of

the MAX20052/MAX20053 have a

INPUT

C1

1µF

FAULT FLAG

IN

BST

MAX20051

MAX20053

FLT

C2

1µF

LED CURRENT CONTROL

LX

For the typical operating circuit of Figure 4 (VIN = 12V),

the inductor value has to be in the range of 22µH to 33µH

for the MAX20050 and in the range of 10µH to 68µH

for the MAX20052. For the typical application circuit of

Figure 5 (VIN = 24V), the inductor value has to be in the

range of 33µH to 82µH for the MAX20050. For the typical application circuit of Figure 6 (VIN = 40V to 60V), the

inductor value has to be in the range of 47µH to 150µH

for the MAX20050. For the MAX20051/MAX20053, the

inductor value can be optimized further and can be higher

or lower than the values suggested for the MAX20050/

MAX20052. The MAX20051/MAX20053 have an external

compensation pin for loop stability and this gives more

flexibility for output inductor values.

C3

0.1µF

L1

RCS

LX

CS+

VCC

CSCOMP

AGND

REFI

PGND

PWM

RCOMP

CP

EP

PWM

COUT

CCOMP

Figure 3. Typical Application Circuit Using the MAX20051

www.analog.com

Analog Devices │ 15

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Input Capacitor

The discontinuous input-current waveform of the buck

converter causes large ripple currents in the input capacitor. The switching frequency, peak inductor current, and

the allowable peak-to-peak voltage ripple reflected back

to the source dictate the capacitance requirement. The

input ripple is comprised of ΔVQ (caused by the capacitor

discharge) and ΔVESR (caused by the ESR of the capacitor). Use low-ESR ceramic capacitors with high ripplecurrent capability at the input. A 1µF ceramic capacitor is

recommended for most applications.

Output Capacitor

The function of the output capacitor is to reduce the output ripple to acceptable levels. The ESR, ESL, and the

bulk capacitance of the output capacitor contribute to the

output ripple. In most applications, using low-ESR ceramic capacitors can dramatically reduce the output ESR and

ESL effects. To reduce the ESL effects, connect multiple

INPUT

INPUT FROM

4.5V TO 16V

C1

1µF

FAULT FLAG

C2

1µF

LED CURRENT CONTROL

IN

BST

MAX20050

MAX20052

LX

C3

0.1µF

ceramic capacitors in parallel to achieve the required bulk

capacitance.

The output capacitance COUT is calculated using the

following equation:

C OUT =

((VIN_MIN − VLED ) × VLED )

( ∆VR × 2 × L × VIN_MAX × f SW 2 )

where ΔVR is the maximum allowable voltage ripple.

The output capacitance for MAX20050 in Figure 4 has

to be in the range of 0.22µF to 4.7µF for a stable operation. The output capacitance for MAX20052 has to be in

the range of 0.1uF to 4.7µF. For the application circuit of

Figure 5, the output capacitance has to be in the range

of 0.47µF to 4.7µF for the MAX20050. For the application

circuit of Figure 6, the output capacitance has to be in the

range of 0.1µF to 2.2µF for the MAX20050.

L1

R2

0.133Ω

LX

FLT

CS+

VCC

CSAGND

REFI

PGND

PWM

LED VOLTAGE IS FROM 2V TO 10V

LED CURRENT IS 150mA TO 1.5A

C7

EP

PWM

Figure 4. Typical Input Voltage (12V)

www.analog.com

Analog Devices │ 16

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

INPUT

INPUT FROM

12V TO 32V

C1

1µF

FAULT FLAG

C2

1µF

LED CURRENT CONTROL

IN

BST

MAX20050

LX

C3

0.1µF

L1

R2

0.133Ω

LX

FLT

CS+

VCC

CSAGND

REFI

LED VOLTAGE IS FROM 2V TO 20V

LED CURRENT IS 150mA TO 1.5A

C7

PGND

PWM

EP

PWM

Figure 5. Typical Input Voltage (24V)

INPUT

INPUT FROM

40V TO 60V

C1

1µF

FAULT FLAG

C2

1µF

LED CURRENT CONTROL

IN

BST

LX

MAX20050

C3

0.1µF

L1

R2

0.133Ω

LX

FLT

CS+

VCC

CSAGND

REFI

PGND

PWM

LED VOLTAGE IS FROM 2V TO 50V

LED CURRENT IS 150mA TO 1.5A

C7

EP

PWM

Figure 6. Typical Input Voltage (50V)

www.analog.com

Analog Devices │ 17

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Table 1. Suggested L–C Network for Internally Compensated Parts

L AND C COMPONENT VALUES (MAX20050, fSW = 400kHz)

Output Capacitor Range (C7)

Inductor Range (L1)

VIN = 12V (typ), Figure 4

0.22

4.7

VIN = 24V (typ), Figure 5

0.47

4.7

VIN = 55V (typ), Figure 6

0.1

2.2

VIN = 12V (typ), Figure 4

22

33

VIN = 24V (typ), Figure 5

33

82

VIN = 55V (typ), Figure 6

47

150

µF

µH

L AND C COMPONENT VALUES (MAX20052, fSW = 2.1MHz)

Output Capacitor Range (C7)

VIN = 12V (typ), Figure 4

0.1

4.7

µF

Inductor Range (L1)

VIN = 12V (typ), Figure 4

3.3

10

µH

Compensation

The MAX20050/MAX20052 have internal loop compensation and there is no user-available adjustability of

the loop compensation components. In the case of the

MAX20051/MAX20053, an external COMP pin is present

and an external compensation network is required for

stable operation. See Figure 3 for the typical application

circuit using the MAX20051.

The compensator should be designed as follows. The

high-side current sense amplifier introduces a highfrequency pole to around 420kHz. This is close to the

switching frequency. The current loop gain is:

Ti(s)

=

×

(1 + sRC OUT )

Fm VIN

×

L

R

2

1 + s R + s LC OUT

G m ( sC COMPR COMP + 1) 5R CS

s

sCOMP 1 +

wp

where Gm is the transconductance of the error amplifier inside the MAX20051/MAX20053, RCS is the current

sense resistor, R is the total dynamic resistance of the LED

string, L is the inductance, RCOMP is the compensation

resistor, COUT is the output capacitance, wp is the pole

from the high side current sense amplifier at 2πfp and Fm

is the modulator gain that is given by:

Fm =

1

(s e + s n )Ts

where Ts is 1/fs where fs is the switching frequency, se

is the dv/dt of the ramp in the PWM comparator which is

www.analog.com

2.25fs and sn is the dv/dt of the voltage from the output

of the Gm amplifier.

In the MAX20051 the compensation zero formed by

RCOMPCCOMP should be set at 20kHz and for the

MAX20053 at 100kHz. Initially, the value of the capacitor

CCOMP can be calculated by the formula:

Gm

=

C COMP

0.5 +

Lf s w z

1

F V Rcs5

π m IN

where wz is the zero at RCOMPCCOMP and fs is the

switching frequency. Initially, Fm is assumed as 0.555

and the initial values of CCOMP is calculated and then

RCOMP is calculated based on the zero location at 20kHz

for the MAX20051 and 100kHz for the MAX20053. The

values of RCOMP, CCOMP, and CP may need to be

optimized further when testing, so as to get the optimum

loop response.

LED Current Derating Using REFI

The MAX20050–MAX20053 are designed specifically

for driving high current LEDs. High current LEDs require

derating the maximum current based on operating temperature to prevent damage of the LEDs. Some LEDs

come with an accompanying thermistor in the same

package. The thermistor may be an NTC. Under normal

operating conditions the voltage on the REFI pin is above

the clamp voltage of the MAX20050–MAX20053 .See

Figure 7. As the temperature of the LEDs increase, the

resistance R1 decreases until the voltage on the REFI

pin reaches 1.3V. The resistors R2 and R1 should be

selected so that the voltage on REFI is 1.3V at the desired

temperature T1. It may also be necessary that at a certain

temperature T2, the current in the LEDs are close to zero.

Analog Devices │ 18

�MAX20050–MAX20053

At this temperature, the voltage on REFI pin is:

1.3 =

VCC × R1(T1)

(R1(T1) + R2)

where VCC is 5V and R1(T1) is the resistance of the

resistor from REFI to ground at temperature T1 and R2 is

the resistance from VCC to REFI.

0.2 =

VCC × R1(T1)

(R1(T2) + R2)

where R1(T2) is the resistance of the resistor of the

resistor from REFI to ground at temperature T2. In some

cases, the NTC in the LED can be used as is and in others, an additional resistor in series or in parallel or some

other combination may need to be added to provide the

desired resistance.

High Peak-Current, Low Duty-Cycle

Applications

The MAX20050–MAX20053 family of parts can be used for

applications that require peak currents up to 5A with low

duty cycle. The RMS current should not exceed 1.5A. A 3A

Schottky diode must be added between LX and PGND pins

when used in these applications. See Figure 8.

Low Dimming-Frequency Applications

For applications with low PWM dimming frequencies, it

may be undesirable for the IC to go into shutdown mode

between every PWM pulse. To prevent the IC from entering shutdown mode, a very narrow PWM pulse, typically

20ns to 100ns, can be sent by the microcontroller once

every 100ms. This pulse will be short enough that it does

not turn on the LEDs, but long enough that it keeps the

IC awake.

2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

2) Place an unbroken ground plane on the layer closest

to the surface layer with the inductor, device, and the

input and output capacitors.

3) The surface area of the LX and BST nodes should

be as small as possible to minimize emissions.

4) The exposed pad on the bottom of the package must

be soldered to ground so that the pad is connected

to ground electrically and also acts as a heat sink

thermally. To keep thermal resistance low, extend the

ground plane as much as possible, and add thermal

vias under and near the device to additional ground

planes within the circuit board.

5) Run the current-sense lines (CS+ and CS-) very

close to each other to minimize the loop area. Do not

cross these critical signal lines with power circuitry.

Sense the current right at the pads of the currentsense resistors. The current-sense signal has a

full-scale amplitude of 200mV. To prevent contamination of this signal from high dv/dt and high di/dt

components and traces, use a ground plane layer to

separate the power traces from this signal trace.

6) Use separate ground planes on different layers of

the PCB for AGND and PGND. Connect both of

these planes together at a single point close to the

input bypass capacitor.

7) Use 2oz or thicker copper to keep trace inductances

and resistances to a minimum. Thicker copper conducts heat more effectively, thereby reducing thermal

impedance. Thin copper PCBs compromise efficiency in applications involving high currents.

8) Place capacitor C3 as close as possible to the BST

and LX pins.

PCB Layout

For proper operation and minimum EMI, PCB layout

should follow the guidelines below (also see Figure 9):

1) Large switched currents flow in the IN and PGND

pins and the input capacitor C1 of Figure 3. The loop

formed by the input capacitor should be as small as

possible by placing this capacitor as close as

possible to the IN and PGND pins. The input capacitor, device, output inductor, and output capacitor

should be placed on the same side of the PCB and

the connections should be made on the same layer.

www.analog.com

Analog Devices │ 19

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

INPUT

IN

C1

1µF

MAX20050

MAX20052

FAULT FLAG

C2

1µF

BST

FLT

VCC

LX

C3

0.1µF

L1

RCS

LX

CS+

CS-

R2

AGND

REFI

PGND

R1

PWM

COUT

EP

PWM

Figure 7. Application Circuit for LED Current Derating with Temperature

INPUT

C1

1µF

FAULT FLAG

C2

1µF

IN

BST

MAX20051

MAX20053

FLT

VCC

LX

C3

0.1µF

L1

RCS

LX

CS+

CS-

COMP

LED CURRENT CONTROL

AGND

REFI

PGND

PWM

EP

PWM

B360A

RCOMP

CP

CCOMP

COUT

Figure 8. High-Current Application with MAX20051/MAX20053

www.analog.com

Analog Devices │ 20

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

PGND

VIN

LED+

COUT

5

RFILTER

RSENSE

ROUTE ON INNER SIGNAL LAYER

L

6

3

8

CIN

CBOOST

1

CFILTER

4

COMPENSATION

NETWORK

COMPONENT SIDE

MAX2005x

4

7

SOLDER SIDE

2

SIGNAL + POWER

AGND

SIGNAL

PGND

HEAT

Figure 9. Section from MAX20051 EV Kit PCB Layout

www.analog.com

Analog Devices │ 21

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Ordering Information

TEMP RANGE

SWITCHING

FREQUENCY

COMPENSATION

PIN-PACKAGE

MAX20050ATC/V+

-40°C to +125°C

400kHz

Internal

12 TDFN-EP*

MAX20050ATC+

-40°C to +125°C

400kHz

Internal

12 TDFN-EP*

MAX20050CATC/V+

-40°C to +125°C

400kHz

Internal

12 TDFN-EP*

MAX20051AAUD/V+

-40°C to +125°C

400kHz

External

14 TSSOP-EP*

MAX20051AUD/V+

-40°C to +125°C

400kHz

External

14 TSSOP-EP*

MAX20051AAUD+

-40°C to +125°C

400kHz

External

14 TSSOP-EP*

MAX20051BAUD/V+

-40°C to +125°C

400kHz (No SS)

External

14 TSSOP-EP*

PART

MAX20051CAUD/V+**

-40°C to +125°C

400kHz

External

14 TSSOP-EP*

MAX20052ATC+

-40°C to +125°C

2.1MHz

Internal

12 TDFN-EP*

MAX20052ATC/V+

-40°C to +125°C

2.1MHz

Internal

12 TDFN-EP*

MAX20052BATC+

-40°C to +125°C

2.1MHz (No SS)

Internal

12 TDFN-EP*

MAX20052BATC/V+**

-40°C to +125°C

2.1MHz (No SS)

Internal

12 TDFN-EP*

MAX20052CATC/V+

-40°C to +125°C

2.1MHz

Internal

12 TDFN-EP*

MAX20053AAUD+

-40°C to +125°C

2.1MHz

External

14 TSSOP-EP*

MAX20053AAUD/V+

-40°C to +125°C

2.1MHz

External

14 TSSOP-EP*

MAX20053AUD/V+

-40°C to +125°C

2.1MHz

External

14 TSSOP-EP*

MAX20053CAUD/V+

-40°C to +125°C

2.1MHz

External

14 TSSOP-EP*

MAX20053DATG/V+

-40°C to +125°C

2.1MHz

External

24 TQFN-EP*

/V denotes an automotive qualified part.

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed pad.

**Future product—contact factory for availability.

Chip Information

Package Information

For the latest package outline information and land patterns

(footprints), go to www.maximintegrated.com/packages. Note

that a “+”, “#”, or “-” in the package code indicates RoHS status

only. Package drawings may show a different suffix character, but

the drawing pertains to the package regardless of RoHS status.

PACKAGE

TYPE

PACKAGE

CODE

OUTLINE

NO.

LAND

PATTERN NO.

12 TDFN-EP

TD1233+1C

21-0664

90-0397

14 TSSOP-EP

U14E+4

21-0108

90-0463

14 TSSOP-EP

U14E+4C

21-0108

90-0463

24 TQFN-EP

T2444+4C

21-0139

90-0022

www.analog.com

PROCESS: BiCMOS

Analog Devices │ 22

�2A Synchronous-Buck LED Drivers

with Integrated MOSFETs

MAX20050–MAX20053

Revision History

REVISION

NUMBER

REVISION

DATE

PAGES

CHANGED

0

3/14

Initial release

—

1

11/14

Updated the LED Open-Fault Enable Threshold min/typ values in Electrical

Characteristics table

4

2

12/15

Updated Current-Sense Input Offset, DMOS RDSON, and changed LED Open-Fault

Enable Threshold, LED Open-Fault Enable Hysteresis in Electrical Characteristics table;

changed LED Open and Logic VIN from 10.5V to 9V in Figures 1 and 2 and in the LED

Open section; added new Figure 8 in PCB Layout section

3, 4, 9, 10, 12,

13, 19

3

2/16

Updated VCC Output Voltage in Electrical Characteristics table; removed future product

designations in Ordering Information table

2, 20

DESCRIPTION

4

5/16

Updated Figure 8

19

5

6/16

Added MAX20050ATC+ and MAX20051AUD+ to Ordering Information table

20

6

6/16

Added MAX20050ATC+T and MAX20051AUD+T to Ordering Information table

20

7

6/16

Changed land pattern number for TSSOP package in Package Information table

20

8

7/16

Updated PWM pin in Figures 1 and 2

9

5/18

Added MAX20051AAUD/V+ and MAX20053AAUD/V+ to Ordering Information table, as

well as a new column for Bond Wire

20

10

10/18

Added U14E+4C package code in Package Information table

20

11

3/19

Updated Electrical Characteristics table, block diagrams, and Detailed Description

section for B version, added MAX20051BAUD/V+, MAX20052ATC+, and

MAX20053AAUD+ to Ordering Information table

12

5/19

Updated Ordering Information table to replace MAX20051AUD+ with MAX20051AAUD+

13

1/20

Updated General Description, Absolute Maximum Ratings, Electrical Characteristics,

Applications Information, and Ordering Information to add MAX2005xC parts

1, 2, 3, 14, 17,

18, 20

14

3/20

Updated Electrical Characteristics, Typical Operating Characteristics, and Applications

Information

2, 4, 5, 17, 19

15

4/20

Updated General Description, Benefits and Features, Package Thermal Characteristics,

Electrical Characteristics, Pin Configurations, Pin Descriptions, Typical Operating

Characteristics, and Ordering Information

1, 2, 4, 7, 8,

21

16

8/20

Updated General Description, Benefits and Features, Package Thermal Characteristics,

Electrical Characteristics, and Ordering Information

1–5, 22

17

9/20

Added MAX20052B information to DS, updated Benefits and Features,

Electrical Characteristics, PWM Dimming Control (PWM), and Ordering Information

18

11/20

Updated Applications, Ordering Information

19

7/21

Updated Ordering Information

20

7/21

Updated Electrical Characteristics and Ordering Information

9, 10

3, 4, 9, 10,

13, 20

20

1, 3, 13, 22

1, 22

22

4, 22

Information furnished by Analog Devices is believed to be accurate and reliable. However, no responsibility is

assumed by Analog Devices for its use, nor for any infringements of patents or other rights of third parties that

may result from its use.Specifications subject to change without notice. No license is granted by implicationor

otherwise under any patent or patent rights of Analog Devices. Trademarks andregistered trademarks are the

property of their respective owners.

w w w . a n a l o g . c o m

Analog Devices │ 23

�