Stratix II Device Handbook, Volume 1

101 Innovation Drive

San Jose, CA 95134

www.altera.com

SII5V1-4.5

�Copyright © 2011 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the stylized Altera logo, specific device designations, and all other words and logos that are identified as trademarks and/or service marks are, unless noted otherwise, the trademarks and

service marks of Altera Corporation in the U.S. and other countries. All other product or service names are the property of their respective holders. Altera products are protected under numerous U.S. and foreign patents and pending applications, maskwork rights, and copyrights. Altera warrants

performance of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make

changes to any products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information, product, or service described herein except as

expressly agreed to in writing by Altera Corporation. Altera customers are advised to obtain the latest version of device specifications before relying on any published information and before placing orders for

products or services.

ii

Altera Corporation

�Contents

Chapter Revision Dates .......................................................................... vii

About this Handbook ................................................................................ i

How to Contact Altera ............................................................................................................................... i

Typographic Conventions ......................................................................................................................... i

Section I. Stratix II Device Family Data Sheet

Revision History ....................................................................................................................... Section I–1

Chapter 1. Introduction

Introduction ............................................................................................................................................ 1–1

Features ................................................................................................................................................... 1–1

Document Revision History ................................................................................................................. 1–6

Chapter 2. Stratix II Architecture

Functional Description .......................................................................................................................... 2–1

Logic Array Blocks ................................................................................................................................ 2–3

LAB Interconnects ............................................................................................................................ 2–4

LAB Control Signals ......................................................................................................................... 2–5

Adaptive Logic Modules ...................................................................................................................... 2–6

ALM Operating Modes ................................................................................................................... 2–9

Register Chain ................................................................................................................................. 2–20

Clear & Preset Logic Control ........................................................................................................ 2–22

MultiTrack Interconnect ..................................................................................................................... 2–22

TriMatrix Memory ............................................................................................................................... 2–28

Memory Block Size ......................................................................................................................... 2–29

Digital Signal Processing Block ......................................................................................................... 2–40

Modes of Operation ....................................................................................................................... 2–44

DSP Block Interface ........................................................................................................................ 2–44

PLLs & Clock Networks ..................................................................................................................... 2–48

Global & Hierarchical Clocking ................................................................................................... 2–48

Enhanced & Fast PLLs ................................................................................................................... 2–57

Enhanced PLLs ............................................................................................................................... 2–68

Fast PLLs .......................................................................................................................................... 2–69

I/O Structure ........................................................................................................................................ 2–69

Double Data Rate I/O Pins ........................................................................................................... 2–77

External RAM Interfacing ............................................................................................................. 2–81

Programmable Drive Strength ..................................................................................................... 2–83

Altera Corporation

iii

�Contents

Stratix II Device Handbook, Volume 1

Open-Drain Output ........................................................................................................................ 2–84

Bus Hold .......................................................................................................................................... 2–84

Programmable Pull-Up Resistor .................................................................................................. 2–85

Advanced I/O Standard Support ................................................................................................ 2–85

On-Chip Termination .................................................................................................................... 2–89

MultiVolt I/O Interface ................................................................................................................. 2–93

High-Speed Differential I/O with DPA Support ............................................................................ 2–96

Dedicated Circuitry with DPA Support .................................................................................... 2–100

Fast PLL & Channel Layout ........................................................................................................ 2–102

Document Revision History ............................................................................................................. 2–104

Chapter 3. Configuration & Testing

IEEE Std. 1149.1 JTAG Boundary-Scan Support ............................................................................... 3–1

SignalTap II Embedded Logic Analyzer ............................................................................................ 3–4

Configuration ......................................................................................................................................... 3–4

Operating Modes .............................................................................................................................. 3–5

Configuration Schemes ................................................................................................................... 3–7

Configuring Stratix II FPGAs with JRunner ............................................................................... 3–10

Programming Serial Configuration Devices with SRunner ..................................................... 3–10

Configuring Stratix II FPGAs with the MicroBlaster Driver ................................................... 3–11

PLL Reconfiguration ...................................................................................................................... 3–11

Temperature Sensing Diode (TSD) ................................................................................................... 3–11

Automated Single Event Upset (SEU) Detection ............................................................................ 3–13

Custom-Built Circuitry .................................................................................................................. 3–14

Software Interface ........................................................................................................................... 3–14

Document Revision History ............................................................................................................... 3–14

Chapter 4. Hot Socketing & Power-On Reset

Stratix II

Hot-Socketing Specifications ...............................................................................................................

Devices Can Be Driven Before Power-Up ....................................................................................

I/O Pins Remain Tri-Stated During Power-Up ...........................................................................

Signal Pins Do Not Drive the VCCIO, VCCINT or VCCPD Power Supplies ....................................

Hot Socketing Feature Implementation in Stratix II Devices ..........................................................

Power-On Reset Circuitry ....................................................................................................................

Document Revision History .................................................................................................................

4–1

4–2

4–2

4–2

4–3

4–5

4–6

Chapter 5. DC & Switching Characteristics

Operating Conditions ........................................................................................................................... 5–1

Absolute Maximum Ratings ........................................................................................................... 5–1

Recommended Operating Conditions .......................................................................................... 5–2

DC Electrical Characteristics .......................................................................................................... 5–3

I/O Standard Specifications ........................................................................................................... 5–4

Bus Hold Specifications ................................................................................................................. 5–17

On-Chip Termination Specifications ........................................................................................... 5–17

Pin Capacitance .............................................................................................................................. 5–19

Power Consumption ........................................................................................................................... 5–20

iv

Altera Corporation

�Contents

Contents

Timing Model ....................................................................................................................................... 5–20

Preliminary & Final Timing .......................................................................................................... 5–20

I/O Timing Measurement Methodology .................................................................................... 5–21

Performance .................................................................................................................................... 5–27

Internal Timing Parameters .......................................................................................................... 5–34

Stratix II Clock Timing Parameters .............................................................................................. 5–41

Clock Network Skew Adders ....................................................................................................... 5–50

IOE Programmable Delay ............................................................................................................. 5–51

Default Capacitive Loading of Different I/O Standards .......................................................... 5–52

I/O Delays ....................................................................................................................................... 5–54

Maximum Input & Output Clock Toggle Rate .......................................................................... 5–66

Duty Cycle Distortion ......................................................................................................................... 5–77

DCD Measurement Techniques ................................................................................................... 5–78

High-Speed I/O Specifications .......................................................................................................... 5–87

PLL Timing Specifications .................................................................................................................. 5–91

External Memory Interface Specifications ....................................................................................... 5–94

JTAG Timing Specifications ............................................................................................................... 5–96

Document Revision History ............................................................................................................... 5–97

Chapter 6. Reference & Ordering Information

Software ..................................................................................................................................................

Device Pin-Outs .....................................................................................................................................

Ordering Information ...........................................................................................................................

Document Revision History .................................................................................................................

Altera Corporation

6–1

6–1

6–1

6–2

v

�Contents

vi

Stratix II Device Handbook, Volume 1

Altera Corporation

�Chapter Revision Dates

The chapters in this book, Stratix II Device Handbook, Volume 1, were revised on the following dates.

Where chapters or groups of chapters are available separately, part numbers are listed.

Chapter 1. Introduction

Revised:

Part number:

May 2007

SII51001-4.2

Chapter 2. Stratix II Architecture

Revised:

May 2007

Part number: SII51002-4.3

Chapter 3. Configuration & Testing

Revised:

May 2007

Part number: SII51003-4.2

Chapter 4. Hot Socketing & Power-On Reset

Revised:

May 2007

Part number: SII51004-3.2

Chapter 5. DC & Switching Characteristics

Revised:

April 2011

Part number: SII51005-4.5

Chapter 6. Reference & Ordering Information

Revised:

April 2011

Part number: SII51006-2.2

Altera Corporation

vii

�Chapter Revision Dates

viii

Stratix II Device Handbook, Volume 1

Altera Corporation

�About this Handbook

This handbook provides comprehensive information about the Altera®

Stratix® II family of devices.

How to Contact

Altera

For the most up-to-date information about Altera products, refer to the

following table.

Contact (1)

Contact

Method

Address

Technical support

Website

www.altera.com/support

Technical training

Website

www.altera.com/training

Email

custrain@altera.com

Product literature

Email

www.altera.com/literature

Altera literature services

Website

literature@altera.com

Non-technical support (General) Email

(Software Licensing)

Email

nacomp@altera.com

authorization@altera.com

Note to table:

(1)

Typographic

Conventions

Visual Cue

You can also contact your local Altera sales office or sales representative.

This document uses the typographic conventions shown below.

Meaning

Bold Type with Initial

Capital Letters

Command names, dialog box titles, checkbox options, and dialog box options are

shown in bold, initial capital letters. Example: Save As dialog box.

bold type

External timing parameters, directory names, project names, disk drive names,

filenames, filename extensions, and software utility names are shown in bold

type. Examples: fMAX, \qdesigns directory, d: drive, chiptrip.gdf file.

Italic Type with Initial Capital

Letters

Document titles are shown in italic type with initial capital letters. Example: AN 75:

High-Speed Board Design.

Altera Corporation

i

Preliminary

�Typographic Conventions

Visual Cue

Italic type

Stratix II Device Handbook, Volume 1

Meaning

Internal timing parameters and variables are shown in italic type.

Examples: tPIA, n + 1.

Variable names are enclosed in angle brackets (< >) and shown in italic type.

Example: , .pof file.

Initial Capital Letters

Keyboard keys and menu names are shown with initial capital letters. Examples:

Delete key, the Options menu.

“Subheading Title”

References to sections within a document and titles of on-line help topics are

shown in quotation marks. Example: “Typographic Conventions.”

Courier type

Signal and port names are shown in lowercase Courier type. Examples: data1,

tdi, input. Active-low signals are denoted by suffix n, e.g., resetn.

Anything that must be typed exactly as it appears is shown in Courier type. For

example: c:\qdesigns\tutorial\chiptrip.gdf. Also, sections of an

actual file, such as a Report File, references to parts of files (e.g., the AHDL

keyword SUBDESIGN), as well as logic function names (e.g., TRI) are shown in

Courier.

1., 2., 3., and

a., b., c., etc.

Numbered steps are used in a list of items when the sequence of the items is

important, such as the steps listed in a procedure.

■

Bullets are used in a list of items when the sequence of the items is not important.

●

•

v

The checkmark indicates a procedure that consists of one step only.

1

The hand points to information that requires special attention.

c

The caution indicates required information that needs special consideration and

understanding and should be read prior to starting or continuing with the

procedure or process.

w

The warning indicates information that should be read prior to starting or

continuing the procedure or processes

r

The angled arrow indicates you should press the Enter key.

f

The feet direct you to more information on a particular topic.

ii

Preliminary

Altera Corporation

�Section I. Stratix II Device

Family Data Sheet

This section provides the data sheet specifications for Stratix® II devices.

This section contains feature definitions of the internal architecture,

configuration and JTAG boundary-scan testing information, DC

operating conditions, AC timing parameters, a reference to power

consumption, and ordering information for Stratix II devices.

This section contains the following chapters:

Revision History

Altera Corporation

■

Chapter 1, Introduction

■

Chapter 2, Stratix II Architecture

■

Chapter 3, Configuration & Testing

■

Chapter 4, Hot Socketing & Power-On Reset

■

Chapter 5, DC & Switching Characteristics

■

Chapter 6, Reference & Ordering Information

Refer to each chapter for its own specific revision history. For information

on when each chapter was updated, refer to the Chapter Revision Dates

section, which appears in the full handbook.

Section I–1

�Stratix II Device Family Data Sheet

Section I–2

Stratix II Device Handbook, Volume 1

Altera Corporation

�1. Introduction

SII51001-4.2

Introduction

The Stratix® II FPGA family is based on a 1.2-V, 90-nm, all-layer copper

SRAM process and features a new logic structure that maximizes

performance, and enables device densities approaching 180,000

equivalent logic elements (LEs). Stratix II devices offer up to 9 Mbits of

on-chip, TriMatrix™ memory for demanding, memory intensive

applications and has up to 96 DSP blocks with up to 384 (18-bit × 18-bit)

multipliers for efficient implementation of high performance filters and

other DSP functions. Various high-speed external memory interfaces are

supported, including double data rate (DDR) SDRAM and DDR2

SDRAM, RLDRAM II, quad data rate (QDR) II SRAM, and single data

rate (SDR) SDRAM. Stratix II devices support various I/O standards

along with support for 1-gigabit per second (Gbps) source synchronous

signaling with DPA circuitry. Stratix II devices offer a complete clock

management solution with internal clock frequency of up to 550 MHz

and up to 12 phase-locked loops (PLLs). Stratix II devices are also the

industry’s first FPGAs with the ability to decrypt a configuration

bitstream using the Advanced Encryption Standard (AES) algorithm to

protect designs.

Features

The Stratix II family offers the following features:

■

■

■

■

■

■

■

■

Altera Corporation

May 2007

15,600 to 179,400 equivalent LEs; see Table 1–1

New and innovative adaptive logic module (ALM), the basic

building block of the Stratix II architecture, maximizes performance

and resource usage efficiency

Up to 9,383,040 RAM bits (1,172,880 bytes) available without

reducing logic resources

TriMatrix memory consisting of three RAM block sizes to implement

true dual-port memory and first-in first-out (FIFO) buffers

High-speed DSP blocks provide dedicated implementation of

multipliers (at up to 450 MHz), multiply-accumulate functions, and

finite impulse response (FIR) filters

Up to 16 global clocks with 24 clocking resources per device region

Clock control blocks support dynamic clock network enable/disable,

which allows clock networks to power down to reduce power

consumption in user mode

Up to 12 PLLs (four enhanced PLLs and eight fast PLLs) per device

provide spread spectrum, programmable bandwidth, clock switchover, real-time PLL reconfiguration, and advanced multiplication

and phase shifting

1–1

�Features

■

■

■

■

■

■

■

Support for numerous single-ended and differential I/O standards

High-speed differential I/O support with DPA circuitry for 1-Gbps

performance

Support for high-speed networking and communications bus

standards including Parallel RapidIO, SPI-4 Phase 2 (POS-PHY

Level 4), HyperTransport™ technology, and SFI-4

Support for high-speed external memory, including DDR and DDR2

SDRAM, RLDRAM II, QDR II SRAM, and SDR SDRAM

Support for multiple intellectual property megafunctions from

Altera MegaCore® functions and Altera Megafunction Partners

Program (AMPPSM) megafunctions

Support for design security using configuration bitstream

encryption

Support for remote configuration updates

Table 1–1. Stratix II FPGA Family Features

Feature

EP2S15

EP2S30

EP2S60

EP2S90

EP2S130

EP2S180

ALMs

6,240

13,552

24,176

36,384

53,016

71,760

Adaptive look-up tables (ALUTs) (1)

12,480

27,104

48,352

72,768

106,032

143,520

Equivalent LEs (2)

15,600

33,880

60,440

90,960

132,540

179,400

M512 RAM blocks

104

202

329

488

699

930

M4K RAM blocks

78

144

255

408

609

768

M-RAM blocks

0

1

2

4

6

9

Total RAM bits

419,328

1,369,728

2,544,192

4,520,488

6,747,840

9,383,040

DSP blocks

12

16

36

48

63

96

18-bit × 18-bit multipliers (3)

48

64

144

192

252

384

Enhanced PLLs

2

2

4

4

4

4

Fast PLLs

Maximum user I/O pins

4

4

8

8

8

8

366

500

718

902

1,126

1,170

Notes to Table 1–1:

(1)

(2)

(3)

One ALM contains two ALUTs. The ALUT is the cell used in the Quartus® II software for logic synthesis.

This is the equivalent number of LEs in a Stratix device (four-input LUT-based architecture).

These multipliers are implemented using the DSP blocks.

1–2

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Introduction

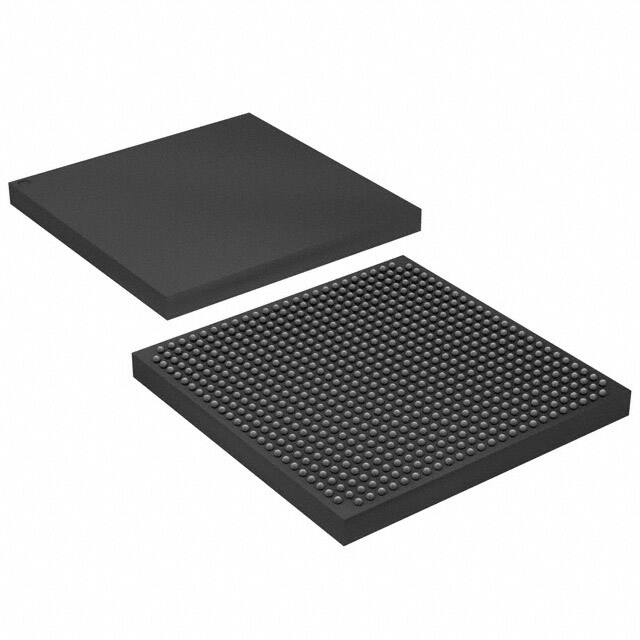

Stratix II devices are available in space-saving FineLine BGA® packages

(see Tables 1–2 and 1–3).

Table 1–2. Stratix II Package Options & I/O Pin Counts

Device

484-Pin

FineLine BGA

484-Pin

Hybrid

FineLine

BGA

672-Pin

FineLine

BGA

EP2S15

342

366

EP2S30

342

500

EP2S60 (3)

334

EP2S90 (3)

Notes (1), (2)

780-Pin

FineLine

BGA

492

308

EP2S130 (3)

1,020-Pin

FineLine BGA

1,508-Pin

FineLine BGA

718

534

758

902

534

742

1,126

742

1,170

EP2S180 (3)

Notes to Table 1–2:

(1)

(2)

(3)

All I/O pin counts include eight dedicated clock input pins (clk1p, clk1n, clk3p, clk3n, clk9p, clk9n,

clk11p, and clk11n) that can be used for data inputs.

The Quartus II software I/O pin counts include one additional pin, PLL_ENA, which is not available as generalpurpose I/O pins. The PLL_ENA pin can only be used to enable the PLLs within the device.

The I/O pin counts for the EP2S60, EP2S90, EP2S130, and EP2S180 devices in the 1020-pin and 1508-pin packages

include eight dedicated fast PLL clock inputs (FPLL7CLKp/n, FPLL8CLKp/n, FPLL9CLKp/n, and

FPLL10CLKp/n) that can be used for data inputs.

Table 1–3. Stratix II FineLine BGA Package Sizes

Dimension

Pitch (mm)

Area (mm2)

Length × width

(mm × mm)

484 Pin

484-Pin

Hybrid

672 Pin

780 Pin

1,020 Pin

1,508 Pin

1.00

1.00

1.00

1.00

1.00

1.00

529

729

729

841

1,089

1,600

23 × 23

27 × 27

27 × 27

29 × 29

33 × 33

40 × 40

All Stratix II devices support vertical migration within the same package

(for example, you can migrate between the EP2S15, EP2S30, and EP2S60

devices in the 672-pin FineLine BGA package). Vertical migration means

that you can migrate to devices whose dedicated pins, configuration pins,

and power pins are the same for a given package across device densities.

To ensure that a board layout supports migratable densities within one

package offering, enable the applicable vertical migration path within the

Quartus II software (Assignments menu > Device > Migration Devices).

Altera Corporation

May 2007

1–3

Stratix II Device Handbook, Volume 1

�Features

After compilation, check the information messages for a full list of I/O,

DQ, LVDS, and other pins that are not available because of the selected

migration path.

Table 1–4 lists the Stratix II device package offerings and shows the total

number of non-migratable user I/O pins when migrating from one

density device to a larger density device. Additional I/O pins may not be

migratable if migrating from the larger device to the smaller density

device.

1

When moving from one density to a larger density, the larger

density device may have fewer user I/O pins. The larger device

requires more power and ground pins to support the additional

logic within the device. Use the Quartus II Pin Planner to

determine which user I/O pins are migratable between the two

devices.

Table 1–4. Total Number of Non-Migratable I/O Pins for Stratix II Vertical Migration Paths

Vertical Migration

Path

484-Pin

FineLine BGA

672-Pin

FineLine BGA

EP2S15 to EP2S30

0 (1)

0

EP2S15 to EP2S60

8 (1)

0

EP2S30 to EP2S60

8 (1)

8

780-Pin

FineLine BGA

1020-Pin

FineLine BGA

EP2S60 to EP2S90

0

EP2S60 to EP2S130

0

EP2S60 to EP2S180

0

0 (1)

EP2S90 to EP2S130

1508-Pin

FineLine BGA

16

17

EP2S90 to EP2S180

16

0

EP2S130 to EP2S180

0

0

Note to Table 1–4:

(1)

Some of the DQ/DQS pins are not migratable. Refer to the Quartus II software information messages for more

detailed information.

1

f

To determine if your user I/O assignments are correct, run the

I/O Assignment Analysis command in the Quartus II software

(Processing > Start > Start I/O Assignment Analysis).

Refer to the I/O Management chapter in volume 2 of the Quartus II

Handbook for more information on pin migration.

1–4

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Introduction

Stratix II devices are available in up to three speed grades, -3, -4, and -5,

with -3 being the fastest. Table 1–5 shows Stratix II device speed-grade

offerings.

Table 1–5. Stratix II Device Speed Grades

484-Pin

Hybrid

FineLine

BGA

Device

Temperature

Grade

484-Pin

FineLine

BGA

EP2S15

Commercial

-3, -4, -5

Industrial

-4

-4

EP2S30

Commercial

-3, -4, -5

-3, -4, -5

Industrial

-4

-4

EP2S60

Commercial

-3, -4, -5

-3, -4, -5

Industrial

-4

EP2S90

Commercial

EP2S130

Commercial

Industrial

-4

-4

EP2S180

Commercial

-3, -4, -5

-3, -4, -5

Industrial

-4

-4

672-Pin

FineLine

BGA

780-Pin

FineLine

BGA

1,508-Pin

FineLine

BGA

-3, -4, -5

-3, -4, -5

-4

-4, -5

-4

-4, -5

-3, -4, -5

-4

-4

-4, -5

-3, -4, -5

-3, -4, -5

Industrial

Altera Corporation

May 2007

1,020-Pin

FineLine

BGA

-3, -4, -5

1–5

Stratix II Device Handbook, Volume 1

�Document Revision History

Document

Revision History

Table 1–6 shows the revision history for this chapter.

Table 1–6. Document Revision History

Date and

Document

Version

Changes Made

May 2007, v4.2

Moved Document Revision History to the end of the

chapter.

April 2006, v4.1

●

●

●

December 2005,

v4.0

●

July 2005, v3.1

●

●

●

May 2005, v3.0

●

●

Summary of Changes

—

Updated “Features” section.

Removed Note 4 from Table 1–2.

Updated Table 1–4.

—

Updated Tables 1–2, 1–4, and 1–5.

Updated Figure 2–43.

—

Added vertical migration information, including

Table 1–4.

Updated Table 1–5.

—

Updated “Features” section.

Updated Table 1–2.

—

March 2005,

v2.1

Updated “Introduction” and “Features” sections.

—

January 2005,

v2.0

Added note to Table 1–2.

—

October 2004,

v1.2

Updated Tables 1–2, 1–3, and 1–5.

—

July 2004, v1.1

●

Updated Tables 1–1 and 1–2.

Updated “Features” section.

—

●

February 2004,

v1.0

Added document to the Stratix II Device Handbook.

1–6

Stratix II Device Handbook, Volume 1

—

Altera Corporation

May 2007

�2. Stratix II Architecture

SII51002-4.3

Functional

Description

Stratix® II devices contain a two-dimensional row- and column-based

architecture to implement custom logic. A series of column and row

interconnects of varying length and speed provides signal interconnects

between logic array blocks (LABs), memory block structures (M512 RAM,

M4K RAM, and M-RAM blocks), and digital signal processing (DSP)

blocks.

Each LAB consists of eight adaptive logic modules (ALMs). An ALM is

the Stratix II device family’s basic building block of logic providing

efficient implementation of user logic functions. LABs are grouped into

rows and columns across the device.

M512 RAM blocks are simple dual-port memory blocks with 512 bits plus

parity (576 bits). These blocks provide dedicated simple dual-port or

single-port memory up to 18-bits wide at up to 500 MHz. M512 blocks are

grouped into columns across the device in between certain LABs.

M4K RAM blocks are true dual-port memory blocks with 4K bits plus

parity (4,608 bits). These blocks provide dedicated true dual-port, simple

dual-port, or single-port memory up to 36-bits wide at up to 550 MHz.

These blocks are grouped into columns across the device in between

certain LABs.

M-RAM blocks are true dual-port memory blocks with 512K bits plus

parity (589,824 bits). These blocks provide dedicated true dual-port,

simple dual-port, or single-port memory up to 144-bits wide at up to

420 MHz. Several M-RAM blocks are located individually in the device's

logic array.

DSP blocks can implement up to either eight full-precision 9 × 9-bit

multipliers, four full-precision 18 × 18-bit multipliers, or one

full-precision 36 × 36-bit multiplier with add or subtract features. The

DSP blocks support Q1.15 format rounding and saturation in the

multiplier and accumulator stages. These blocks also contain shift

registers for digital signal processing applications, including finite

impulse response (FIR) and infinite impulse response (IIR) filters. DSP

blocks are grouped into columns across the device and operate at up to

450 MHz.

Altera Corporation

May 2007

2–1

�Functional Description

Each Stratix II device I/O pin is fed by an I/O element (IOE) located at

the end of LAB rows and columns around the periphery of the device.

I/O pins support numerous single-ended and differential I/O standards.

Each IOE contains a bidirectional I/O buffer and six registers for

registering input, output, and output-enable signals. When used with

dedicated clocks, these registers provide exceptional performance and

interface support with external memory devices such as DDR and DDR2

SDRAM, RLDRAM II, and QDR II SRAM devices. High-speed serial

interface channels with dynamic phase alignment (DPA) support data

transfer at up to 1 Gbps using LVDS or HyperTransportTM technology I/O

standards.

Figure 2–1 shows an overview of the Stratix II device.

Figure 2–1. Stratix II Block Diagram

M4K RAM Blocks

DSP Blocks for

for True Dual-Port

Multiplication and Full

Memory & Other Embedded

Implementation of FIR Filters Memory Functions

M512 RAM Blocks for

Dual-Port Memory, Shift

Registers, & FIFO Buffers

IOEs Support DDR, PCI, PCI-X,

SSTL-3, SSTL-2, HSTL-1, HSTL-2,

LVDS, HyperTransport & other

I/O Standards

IOEs

IOEs

IOEs

IOEs

LABs

LABs

LABs

LABs

LABs

IOEs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

LABs

IOEs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

LABs

M-RAM Block

DSP

Block

2–2

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

The number of M512 RAM, M4K RAM, and DSP blocks varies by device

along with row and column numbers and M-RAM blocks. Table 2–1 lists

the resources available in Stratix II devices.

Table 2–1. Stratix II Device Resources

Device

M512 RAM

Columns/Blocks

M4K RAM

Columns/Blocks

M-RAM

Blocks

DSP Block

Columns/Blocks

LAB

Columns

LAB Rows

EP2S15

4 / 104

3 / 78

0

2 / 12

30

26

EP2S30

6 / 202

4 / 144

1

2 / 16

49

36

EP2S60

7 / 329

5 / 255

2

3 / 36

62

51

EP2S90

8 / 488

6 / 408

4

3 / 48

71

68

EP2S130

9 / 699

7 / 609

6

3 / 63

81

87

EP2S180

11 / 930

8 / 768

9

4 / 96

100

96

Logic Array

Blocks

Altera Corporation

May 2007

Each LAB consists of eight ALMs, carry chains, shared arithmetic chains,

LAB control signals, local interconnect, and register chain connection

lines. The local interconnect transfers signals between ALMs in the same

LAB. Register chain connections transfer the output of an ALM register to

the adjacent ALM register in an LAB. The Quartus® II Compiler places

associated logic in an LAB or adjacent LABs, allowing the use of local,

shared arithmetic chain, and register chain connections for performance

and area efficiency. Figure 2–2 shows the Stratix II LAB structure.

2–3

Stratix II Device Handbook, Volume 1

�Logic Array Blocks

Figure 2–2. Stratix II LAB Structure

Row Interconnects of

Variable Speed & Length

ALMs

Direct link

interconnect from

adjacent block

Direct link

interconnect from

adjacent block

Direct link

interconnect to

adjacent block

Direct link

interconnect to

adjacent block

Local Interconnect

LAB

Local Interconnect is Driven

from Either Side by Columns & LABs,

& from Above by Rows

Column Interconnects of

Variable Speed & Length

LAB Interconnects

The LAB local interconnect can drive ALMs in the same LAB. It is driven

by column and row interconnects and ALM outputs in the same LAB.

Neighboring LABs, M512 RAM blocks, M4K RAM blocks, M-RAM

blocks, or DSP blocks from the left and right can also drive an LAB's local

interconnect through the direct link connection. The direct link

connection feature minimizes the use of row and column interconnects,

providing higher performance and flexibility. Each ALM can drive

24 ALMs through fast local and direct link interconnects. Figure 2–3

shows the direct link connection.

2–4

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

Figure 2–3. Direct Link Connection

Direct link interconnect from

left LAB, TriMatrix memory

block, DSP block, or IOE output

Direct link interconnect from

right LAB, TriMatrix memory

block, DSP block, or IOE output

ALMs

Direct link

interconnect

to right

Direct link

interconnect

to left

Local

Interconnect

LAB Control Signals

Each LAB contains dedicated logic for driving control signals to its ALMs.

The control signals include three clocks, three clock enables, two

asynchronous clears, synchronous clear, asynchronous preset/load, and

synchronous load control signals. This gives a maximum of 11 control

signals at a time. Although synchronous load and clear signals are

generally used when implementing counters, they can also be used with

other functions.

Each LAB can use three clocks and three clock enable signals. However,

there can only be up to two unique clocks per LAB, as shown in the LAB

control signal generation circuit in Figure 2–4. Each LAB's clock and clock

enable signals are linked. For example, any ALM in a particular LAB

using the labclk1 signal also uses labclkena1. If the LAB uses both

the rising and falling edges of a clock, it also uses two LAB-wide clock

signals. De-asserting the clock enable signal turns off the corresponding

LAB-wide clock.

Each LAB can use two asynchronous clear signals and an asynchronous

load/preset signal. By default, the Quartus II software uses a NOT gate

push-back technique to achieve preset. If you disable the NOT gate

push-up option or assign a given register to power up high using the

Quartus II software, the preset is achieved using the asynchronous load

Altera Corporation

May 2007

2–5

Stratix II Device Handbook, Volume 1

�Adaptive Logic Modules

signal with asynchronous load data input tied high. When the

asynchronous load/preset signal is used, the labclkena0 signal is no

longer available.

The LAB row clocks [5..0] and LAB local interconnect generate the

LAB-wide control signals. The MultiTrackTM interconnect's inherent low

skew allows clock and control signal distribution in addition to data.

Figure 2–4 shows the LAB control signal generation circuit.

Figure 2–4. LAB-Wide Control Signals

There are two unique

clock signals per LAB.

6

Dedicated Row LAB Clocks

6

6

Local Interconnect

Local Interconnect

Local Interconnect

Local Interconnect

Local Interconnect

Local Interconnect

labclk0

labclk1

labclkena0

or asyncload

or labpreset

Adaptive Logic

Modules

labclk2

labclkena1

labclkena2

labclr1

syncload

labclr0

synclr

The basic building block of logic in the Stratix II architecture, the adaptive

logic module (ALM), provides advanced features with efficient logic

utilization. Each ALM contains a variety of look-up table (LUT)-based

resources that can be divided between two adaptive LUTs (ALUTs). With

up to eight inputs to the two ALUTs, one ALM can implement various

combinations of two functions. This adaptability allows the ALM to be

2–6

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

completely backward-compatible with four-input LUT architectures. One

ALM can also implement any function of up to six inputs and certain

seven-input functions.

In addition to the adaptive LUT-based resources, each ALM contains two

programmable registers, two dedicated full adders, a carry chain, a

shared arithmetic chain, and a register chain. Through these dedicated

resources, the ALM can efficiently implement various arithmetic

functions and shift registers. Each ALM drives all types of interconnects:

local, row, column, carry chain, shared arithmetic chain, register chain,

and direct link interconnects. Figure 2–5 shows a high-level block

diagram of the Stratix II ALM while Figure 2–6 shows a detailed view of

all the connections in the ALM.

Figure 2–5. High-Level Block Diagram of the Stratix II ALM

carry_in

shared_arith_in

reg_chain_in

To general or

local routing

dataf0

adder0

datae0

D

dataa

datab

datac

datad

Q

To general or

local routing

reg0

Combinational

Logic

adder1

D

Q

datae1

To general or

local routing

reg1

dataf1

To general or

local routing

carry_out

shared_arith_out

Altera Corporation

May 2007

reg_chain_out

2–7

Stratix II Device Handbook, Volume 1

�2–8

Stratix II Device Handbook, Volume 1

datae0

datac

Local

Interconnect

Local

datad

datae1

Local

Interconnect

Local

Interconnect

dataf1

datab

Local

Interconnect

Local

Interconnect

dataa

Local

Interconnect

Interconnect

dataf0

Local

Interconnect

3-Input

LUT

3-Input

LUT

4-Input

LUT

3-Input

LUT

3-Input

LUT

4-Input

LUT

shared_arith_out

shared_arith_in

carry_out

carry_in

VCC

sclr

syncload

reg_chain_out

reg_chain_in

clk[2..0]

aclr[1..0]

ENA

CLRN

PRN/ALD

D

Q

ADATA

ENA

CLRN

PRN/ALD

D

Q

ADATA

asyncload

ena[2..0]

Local

Interconnect

Row, column &

direct link routing

Row, column &

direct link routing

Local

Interconnect

Row, column &

direct link routing

Row, column &

direct link routing

Adaptive Logic Modules

Figure 2–6. Stratix II ALM Details

Altera Corporation

May 2007

�Stratix II Architecture

One ALM contains two programmable registers. Each register has data,

clock, clock enable, synchronous and asynchronous clear, asynchronous

load data, and synchronous and asynchronous load/preset inputs.

Global signals, general-purpose I/O pins, or any internal logic can drive

the register's clock and clear control signals. Either general-purpose I/O

pins or internal logic can drive the clock enable, preset, asynchronous

load, and asynchronous load data. The asynchronous load data input

comes from the datae or dataf input of the ALM, which are the same

inputs that can be used for register packing. For combinational functions,

the register is bypassed and the output of the LUT drives directly to the

outputs of the ALM.

Each ALM has two sets of outputs that drive the local, row, and column

routing resources. The LUT, adder, or register output can drive these

output drivers independently (see Figure 2–6). For each set of output

drivers, two ALM outputs can drive column, row, or direct link routing

connections, and one of these ALM outputs can also drive local

interconnect resources. This allows the LUT or adder to drive one output

while the register drives another output. This feature, called register

packing, improves device utilization because the device can use the

register and the combinational logic for unrelated functions. Another

special packing mode allows the register output to feed back into the LUT

of the same ALM so that the register is packed with its own fan-out LUT.

This provides another mechanism for improved fitting. The ALM can also

drive out registered and unregistered versions of the LUT or adder

output.

f

See the Performance & Logic Efficiency Analysis of Stratix II Devices White

Paper for more information on the efficiencies of the Stratix II ALM and

comparisons with previous architectures.

ALM Operating Modes

The Stratix II ALM can operate in one of the following modes:

■

■

■

■

Normal mode

Extended LUT mode

Arithmetic mode

Shared arithmetic mode

Each mode uses ALM resources differently. In each mode, eleven

available inputs to the ALM--the eight data inputs from the LAB local

interconnect; carry-in from the previous ALM or LAB; the shared

arithmetic chain connection from the previous ALM or LAB; and the

register chain connection--are directed to different destinations to

implement the desired logic function. LAB-wide signals provide clock,

asynchronous clear, asynchronous preset/load, synchronous clear,

Altera Corporation

May 2007

2–9

Stratix II Device Handbook, Volume 1

�Adaptive Logic Modules

synchronous load, and clock enable control for the register. These LABwide signals are available in all ALM modes. See the “LAB Control

Signals” section for more information on the LAB-wide control signals.

The Quartus II software and supported third-party synthesis tools, in

conjunction with parameterized functions such as library of

parameterized modules (LPM) functions, automatically choose the

appropriate mode for common functions such as counters, adders,

subtractors, and arithmetic functions. If required, you can also create

special-purpose functions that specify which ALM operating mode to use

for optimal performance.

Normal Mode

The normal mode is suitable for general logic applications and

combinational functions. In this mode, up to eight data inputs from the

LAB local interconnect are inputs to the combinational logic. The normal

mode allows two functions to be implemented in one Stratix II ALM, or

an ALM to implement a single function of up to six inputs. The ALM can

support certain combinations of completely independent functions and

various combinations of functions which have common inputs.

Figure 2–7 shows the supported LUT combinations in normal mode.

2–10

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

Figure 2–7. ALM in Normal Mode Note (1)

dataf0

datae0

datac

dataa

4-Input

LUT

combout0

datab

datad

datae1

dataf1

4-Input

LUT

combout1

dataf0

datae0

datac

dataa

datab

5-Input

LUT

combout0

datad

datae1

dataf1

dataf0

datae0

datac

dataa

datab

datad

datae1

dataf1

3-Input

LUT

5-Input

LUT

combout0

5-Input

LUT

combout1

dataf0

datae0

dataa

datab

datac

datad

6-Input

LUT

combout0

dataf0

datae0

dataa

datab

datac

datad

6-Input

LUT

combout0

6-Input

LUT

combout1

datad

datae1

dataf1

combout1

5-Input

LUT

4-Input

LUT

dataf0

datae0

datac

dataa

datab

combout0

combout1

datae1

dataf1

Note to Figure 2–7:

(1)

Combinations of functions with fewer inputs than those shown are also supported. For example, combinations of

functions with the following number of inputs are supported: 4 and 3, 3 and 3, 3 and 2, 5 and 2, etc.

The normal mode provides complete backward compatibility with fourinput LUT architectures. Two independent functions of four inputs or less

can be implemented in one Stratix II ALM. In addition, a five-input

function and an independent three-input function can be implemented

without sharing inputs.

Altera Corporation

May 2007

2–11

Stratix II Device Handbook, Volume 1

�Adaptive Logic Modules

For the packing of two five-input functions into one ALM, the functions

must have at least two common inputs. The common inputs are dataa

and datab. The combination of a four-input function with a five-input

function requires one common input (either dataa or datab).

In the case of implementing two six-input functions in one ALM, four

inputs must be shared and the combinational function must be the same.

For example, a 4 × 2 crossbar switch (two 4-to-1 multiplexers with

common inputs and unique select lines) can be implemented in one ALM,

as shown in Figure 2–8. The shared inputs are dataa, datab, datac, and

datad, while the unique select lines are datae0 and dataf0 for

function0, and datae1 and dataf1 for function1. This crossbar

switch consumes four LUTs in a four-input LUT-based architecture.

Figure 2–8. 4 × 2 Crossbar Switch Example

4 × 2 Crossbar Switch

sel0[1..0]

inputa

inputb

out0

inputc

inputd

Implementation in 1 ALM

dataf0

datae0

dataa

datab

datac

datad

Six-Input

LUT

(Function0)

combout0

Six-Input

LUT

(Function1)

combout1

out1

sel1[1..0]

datae1

dataf1

In a sparsely used device, functions that could be placed into one ALM

may be implemented in separate ALMs. The Quartus II Compiler spreads

a design out to achieve the best possible performance. As a device begins

to fill up, the Quartus II software automatically utilizes the full potential

of the Stratix II ALM. The Quartus II Compiler automatically searches for

functions of common inputs or completely independent functions to be

placed into one ALM and to make efficient use of the device resources. In

addition, you can manually control resource usage by setting location

assignments.

Any six-input function can be implemented utilizing inputs dataa,

datab, datac, datad, and either datae0 and dataf0 or datae1 and

dataf1. If datae0 and dataf0 are utilized, the output is driven to

register0, and/or register0 is bypassed and the data drives out to

the interconnect using the top set of output drivers (see Figure 2–9). If

2–12

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

datae1 and dataf1 are utilized, the output drives to register1

and/or bypasses register1 and drives to the interconnect using the

bottom set of output drivers. The Quartus II Compiler automatically

selects the inputs to the LUT. Asynchronous load data for the register

comes from the datae or dataf input of the ALM. ALMs in normal

mode support register packing.

Figure 2–9. 6-Input Function in Normal Mode Notes (1), (2)

dataf0

datae0

dataa

datab

datac

datad

To general or

local routing

6-Input

LUT

D

Q

To general or

local routing

reg0

datae1

dataf1

(2)

D

These inputs are available for register packing.

Q

To general or

local routing

reg1

Notes to Figure 2–9:

(1)

(2)

If datae1 and dataf1 are used as inputs to the six-input function, then datae0

and dataf0 are available for register packing.

The dataf1 input is available for register packing only if the six-input function is

un-registered.

Extended LUT Mode

The extended LUT mode is used to implement a specific set of

seven-input functions. The set must be a 2-to-1 multiplexer fed by two

arbitrary five-input functions sharing four inputs. Figure 2–10 shows the

template of supported seven-input functions utilizing extended LUT

mode. In this mode, if the seven-input function is unregistered, the

unused eighth input is available for register packing.

Functions that fit into the template shown in Figure 2–10 occur naturally

in designs. These functions often appear in designs as “if-else” statements

in Verilog HDL or VHDL code.

Altera Corporation

May 2007

2–13

Stratix II Device Handbook, Volume 1

�Adaptive Logic Modules

Figure 2–10. Template for Supported Seven-Input Functions in Extended LUT Mode

datae0

datac

dataa

datab

datad

dataf0

5-Input

LUT

To general or

local routing

combout0

D

5-Input

LUT

Q

To general or

local routing

reg0

datae1

dataf1

(1)

This input is available

for register packing.

Note to Figure 2–10:

(1)

If the seven-input function is unregistered, the unused eighth input is available for register packing. The second

register, reg1, is not available.

Arithmetic Mode

The arithmetic mode is ideal for implementing adders, counters,

accumulators, wide parity functions, and comparators. An ALM in

arithmetic mode uses two sets of two four-input LUTs along with two

dedicated full adders. The dedicated adders allow the LUTs to be

available to perform pre-adder logic; therefore, each adder can add the

output of two four-input functions. The four LUTs share the dataa and

datab inputs. As shown in Figure 2–11, the carry-in signal feeds to

adder0, and the carry-out from adder0 feeds to carry-in of adder1. The

carry-out from adder1 drives to adder0 of the next ALM in the LAB.

ALMs in arithmetic mode can drive out registered and/or unregistered

versions of the adder outputs.

2–14

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

Figure 2–11. ALM in Arithmetic Mode

carry_in

adder0

datae0

4-Input

LUT

To general or

local routing

D

dataf0

datac

datab

dataa

Q

To general or

local routing

reg0

4-Input

LUT

adder1

datad

datae1

4-Input

LUT

To general or

local routing

D

4-Input

LUT

Q

To general or

local routing

reg1

dataf1

carry_out

While operating in arithmetic mode, the ALM can support simultaneous

use of the adder's carry output along with combinational logic outputs. In

this operation, the adder output is ignored. This usage of the adder with

the combinational logic output provides resource savings of up to 50% for

functions that can use this ability. An example of such functionality is a

conditional operation, such as the one shown in Figure 2–12. The

equation for this example is:

R = (X < Y) ? Y : X

To implement this function, the adder is used to subtract ‘Y’ from ‘X.’ If

‘X’ is less than ‘Y,’ the carry_out signal is ‘1.’ The carry_out signal is

fed to an adder where it drives out to the LAB local interconnect. It then

feeds to the LAB-wide syncload signal. When asserted, syncload

selects the syncdata input. In this case, the data ‘Y’ drives the

syncdata inputs to the registers. If ‘X’ is greater than or equal to ‘Y,’ the

syncload signal is de-asserted and ‘X’ drives the data port of the

registers.

Altera Corporation

May 2007

2–15

Stratix II Device Handbook, Volume 1

�Adaptive Logic Modules

Figure 2–12. Conditional Operation Example

Adder output

is not used.

ALM 1

X[0]

Comb &

Adder

Logic

Y[0]

X[0]

D

R[0]

To general or

local routing

R[1]

To general or

local routing

R[2]

To general or

local routing

Q

reg0

syncdata

syncload

X[1]

Comb &

Adder

Logic

Y[1]

X[1]

D

Q

reg1

syncload

Carry Chain

ALM 2

X[2]

Y[2]

Comb &

Adder

Logic

X[2]

D

Q

reg0

syncload

Comb &

Adder

Logic

carry_out

To local routing &

then to LAB-wide

syncload

The arithmetic mode also offers clock enable, counter enable,

synchronous up/down control, add/subtract control, synchronous clear,

synchronous load. The LAB local interconnect data inputs generate the

clock enable, counter enable, synchronous up/down and add/subtract

control signals. These control signals are good candidates for the inputs

that are shared between the four LUTs in the ALM. The synchronous clear

and synchronous load options are LAB-wide signals that affect all

registers in the LAB. The Quartus II software automatically places any

registers that are not used by the counter into other LABs.

Carry Chain

The carry chain provides a fast carry function between the dedicated

adders in arithmetic or shared arithmetic mode. Carry chains can begin in

either the first ALM or the fifth ALM in an LAB. The final carry-out signal

is routed to an ALM, where it is fed to local, row, or column interconnects.

2–16

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

The Quartus II Compiler automatically creates carry chain logic during

design processing, or you can create it manually during design entry.

Parameterized functions such as LPM functions automatically take

advantage of carry chains for the appropriate functions.

The Quartus II Compiler creates carry chains longer than 16 (8 ALMs in

arithmetic or shared arithmetic mode) by linking LABs together

automatically. For enhanced fitting, a long carry chain runs vertically

allowing fast horizontal connections to TriMatrix memory and DSP

blocks. A carry chain can continue as far as a full column.

To avoid routing congestion in one small area of the device when a high

fan-in arithmetic function is implemented, the LAB can support carry

chains that only utilize either the top half or the bottom half of the LAB

before connecting to the next LAB. This leaves the other half of the ALMs

in the LAB available for implementing narrower fan-in functions in

normal mode. Carry chains that use the top four ALMs in the first LAB

carry into the top half of the ALMs in the next LAB within the column.

Carry chains that use the bottom four ALMs in the first LAB carry into the

bottom half of the ALMs in the next LAB within the column. Every other

column of LABs is top-half bypassable, while the other LAB columns are

bottom-half bypassable.

See the “MultiTrack Interconnect” on page 2–22 section for more

information on carry chain interconnect.

Shared Arithmetic Mode

In shared arithmetic mode, the ALM can implement a three-input add. In

this mode, the ALM is configured with four 4-input LUTs. Each LUT

either computes the sum of three inputs or the carry of three inputs. The

output of the carry computation is fed to the next adder (either to adder1

in the same ALM or to adder0 of the next ALM in the LAB) via a

dedicated connection called the shared arithmetic chain. This shared

arithmetic chain can significantly improve the performance of an adder

tree by reducing the number of summation stages required to implement

an adder tree. Figure 2–13 shows the ALM in shared arithmetic mode.

Altera Corporation

May 2007

2–17

Stratix II Device Handbook, Volume 1

�Adaptive Logic Modules

Figure 2–13. ALM in Shared Arithmetic Mode

shared_arith_in

carry_in

4-Input

LUT

To general or

local routing

D

datae0

datac

datab

dataa

datad

datae1

Q

To general or

local routing

reg0

4-Input

LUT

4-Input

LUT

To general or

local routing

D

4-Input

LUT

Q

To general or

local routing

reg1

carry_out

shared_arith_out

Note to Figure 2–13:

(1)

Inputs dataf0 and dataf1 are available for register packing in shared arithmetic mode.

Adder trees can be found in many different applications. For example, the

summation of the partial products in a logic-based multiplier can be

implemented in a tree structure. Another example is a correlator function

that can use a large adder tree to sum filtered data samples in a given time

frame to recover or to de-spread data which was transmitted utilizing

spread spectrum technology.

An example of a three-bit add operation utilizing the shared arithmetic

mode is shown in Figure 2–14. The partial sum (S[2..0]) and the

partial carry (C[2..0]) is obtained using the LUTs, while the result

(R[2..0]) is computed using the dedicated adders.

2–18

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

Figure 2–14. Example of a 3-bit Add Utilizing Shared Arithmetic Mode

shared_arith_in = '0'

carry_in = '0'

3-Bit Add Example

ALM Implementation

ALM 1

1st stage add is

implemented in LUTs.

X2 X1 X0

Y2 Y1 Y0

+ Z2 Z1 Z0

2nd stage add is

implemented in adders.

S2 S1 S0

+ C2 C1 C0

R3 R2 R1 R0

Binary Add

Decimal

Equivalents

1 1 0

1 0 1

+ 0 1 0

6

5

+ 2

0 0 1

+ 1 1 0

1

+ 2x6

1 1 0 1

13

3-Input

LUT

S0

R0

X0

Y0

Z0

3-Input

LUT

C0

X1

Y1

Z1

3-Input

LUT

S1

R1

3-Input

LUT

C1

3-Input

LUT

S2

ALM 2

R2

X2

Y2

Z2

3-Input

LUT

C2

3-Input

LUT

'0'

R3

3-Input

LUT

Shared Arithmetic Chain

In addition to the dedicated carry chain routing, the shared arithmetic

chain available in shared arithmetic mode allows the ALM to implement

a three-input add. This significantly reduces the resources necessary to

implement large adder trees or correlator functions.

The shared arithmetic chains can begin in either the first or fifth ALM in

an LAB. The Quartus II Compiler creates shared arithmetic chains longer

than 16 (8 ALMs in arithmetic or shared arithmetic mode) by linking

LABs together automatically. For enhanced fitting, a long shared

Altera Corporation

May 2007

2–19

Stratix II Device Handbook, Volume 1

�Adaptive Logic Modules

arithmetic chain runs vertically allowing fast horizontal connections to

TriMatrix memory and DSP blocks. A shared arithmetic chain can

continue as far as a full column.

Similar to the carry chains, the shared arithmetic chains are also top- or

bottom-half bypassable. This capability allows the shared arithmetic

chain to cascade through half of the ALMs in a LAB while leaving the

other half available for narrower fan-in functionality. Every other LAB

column is top-half bypassable, while the other LAB columns are bottomhalf bypassable.

See the “MultiTrack Interconnect” on page 2–22 section for more

information on shared arithmetic chain interconnect.

Register Chain

In addition to the general routing outputs, the ALMs in an LAB have

register chain outputs. The register chain routing allows registers in the

same LAB to be cascaded together. The register chain interconnect allows

an LAB to use LUTs for a single combinational function and the registers

to be used for an unrelated shift register implementation. These resources

speed up connections between ALMs while saving local interconnect

resources (see Figure 2–15). The Quartus II Compiler automatically takes

advantage of these resources to improve utilization and performance.

2–20

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

Figure 2–15. Register Chain within an LAB Note (1)

From Previous ALM

Within The LAB

reg_chain_in

To general or

local routing

adder0

D

Q

To general or

local routing

reg0

Combinational

Logic

adder1

D

Q

To general or

local routing

reg1

To general or

local routing

To general or

local routing

adder0

D

Q

To general or

local routing

reg0

Combinational

Logic

adder1

D

Q

To general or

local routing

reg1

To general or

local routing

reg_chain_out

To Next ALM

within the LAB

Note to Figure 2–15:

(1)

The combinational or adder logic can be utilized to implement an unrelated, un-registered function.

See the “MultiTrack Interconnect” on page 2–22 section for more

information on register chain interconnect.

Altera Corporation

May 2007

2–21

Stratix II Device Handbook, Volume 1

�MultiTrack Interconnect

Clear & Preset Logic Control

LAB-wide signals control the logic for the register's clear and load/preset

signals. The ALM directly supports an asynchronous clear and preset

function. The register preset is achieved through the asynchronous load

of a logic high. The direct asynchronous preset does not require a NOTgate push-back technique. Stratix II devices support simultaneous

asynchronous load/preset, and clear signals. An asynchronous clear

signal takes precedence if both signals are asserted simultaneously. Each

LAB supports up to two clears and one load/preset signal.

In addition to the clear and load/preset ports, Stratix II devices provide a

device-wide reset pin (DEV_CLRn) that resets all registers in the device.

An option set before compilation in the Quartus II software controls this

pin. This device-wide reset overrides all other control signals.

MultiTrack

Interconnect

In the Stratix II architecture, connections between ALMs, TriMatrix

memory, DSP blocks, and device I/O pins are provided by the MultiTrack

interconnect structure with DirectDriveTM technology. The MultiTrack

interconnect consists of continuous, performance-optimized routing lines

of different lengths and speeds used for inter- and intra-design block

connectivity. The Quartus II Compiler automatically places critical design

paths on faster interconnects to improve design performance.

DirectDrive technology is a deterministic routing technology that ensures

identical routing resource usage for any function regardless of placement

in the device. The MultiTrack interconnect and DirectDrive technology

simplify the integration stage of block-based designing by eliminating the

re-optimization cycles that typically follow design changes and

additions.

The MultiTrack interconnect consists of row and column interconnects

that span fixed distances. A routing structure with fixed length resources

for all devices allows predictable and repeatable performance when

migrating through different device densities. Dedicated row

interconnects route signals to and from LABs, DSP blocks, and TriMatrix

memory in the same row. These row resources include:

■

■

■

Direct link interconnects between LABs and adjacent blocks

R4 interconnects traversing four blocks to the right or left

R24 row interconnects for high-speed access across the length of the

device

2–22

Stratix II Device Handbook, Volume 1

Altera Corporation

May 2007

�Stratix II Architecture

The direct link interconnect allows an LAB, DSP block, or TriMatrix

memory block to drive into the local interconnect of its left and right

neighbors and then back into itself. This provides fast communication

between adjacent LABs and/or blocks without using row interconnect

resources.

The R4 interconnects span four LABs, three LABs and one M512 RAM

block, two LABs and one M4K RAM block, or two LABs and one DSP

block to the right or left of a source LAB. These resources are used for fast

row connections in a four-LAB region. Every LAB has its own set of R4

interconnects to drive either left or right. Figure 2–16 shows R4

interconnect connections from an LAB. R4 interconnects can drive and be

driven by DSP blocks and RAM blocks and row IOEs. For LAB

interfacing, a primary LAB or LAB neighbor can drive a given R4

interconnect. For R4 interconnects that drive to the right, the primary

LAB and right neighbor can drive on to the interconnect. For R4

interconnects that drive to the left, the primary LAB and its left neighbor

can drive on to the interconnect. R4 interconnects can drive other R4

interconnects to extend the range of LABs they can drive. R4

interconnects can also drive C4 and C16 interconnects for connections

from one row to another. Additionally, R4 interconnects can drive R24

interconnects.

Figure 2–16. R4 Interconnect Connections

Notes (1), (2), (3)

Adjacent LAB can

Drive onto Another

LAB's R4 Interconnect

C4 and C16

Column Interconnects (1)

R4 Interconnect

Driving Right

R4 Interconnect

Driving Left

LAB

Neighbor

Primary

LAB (2)

LAB

Neighbor

Notes to Figure 2–16:

(1)

(2)

(3)

C4 and C16 interconnects can drive R4 interconnects.

This pattern is repeated for every LAB in the LAB row.

The LABs in Figure 2–16 show the 16 possible logical outputs per LAB.

Altera Corporation

May 2007

2–23

Stratix II Device Handbook, Volume 1

�MultiTrack Interconnect

R24 row interconnects span 24 LABs and provide the fastest resource for

long row connections between LABs, TriMatrix memory, DSP blocks, and

Row IOEs. The R24 row interconnects can cross M-RAM blocks. R24 row

interconnects drive to other row or column interconnects at every fourth

LAB and do not drive directly to LAB local interconnects. R24 row

interconnects drive LAB local interconnects via R4 and C4 interconnects.

R24 interconnects can drive R24, R4, C16, and C4 interconnects.

The column interconnect operates similarly to the row interconnect and

vertically routes signals to and from LABs, TriMatrix memory, DSP

blocks, and IOEs. Each column of LABs is served by a dedicated column

interconnect. These column resources include:

■

■

■

■

■

Shared arithmetic chain interconnects in an LAB

Carry chain interconnects in an LAB and from LAB to LAB

Register chain interconnects in an LAB

C4 interconnects traversing a distance of four blocks in up and down

direction

C16 column interconnects for high-speed vertical routing through

the device

Stratix II devices include an enhanced interconnect structure in LABs for

routing shared arithmetic chains and carry chains for efficient arithmetic

functions. The register chain connection allows the register output of one

ALM to connect directly to the register input of the next ALM in the LAB

for fast shift registers. These ALM to ALM connections bypass the local

interconnect. The Quartus II Compiler automatically takes advantage of

these resources to improve utilization and performance. Figure 2–17