DataSheeT – enpirion® power solutions

EN6340QI 4A PowerSoC

Step-Down DC-DC Switching Converter with Integrated Inductor

DESCRIPTION

The EN6340QI is an Intel® Enpirion® Power System on

a Chip (PowerSoC) DC-DC converter. It integrates the

inductor, MOSFET switches, small-signal circuits and

compensation in an advanced 4mm x 6mm x 2.5mm

34-pin QFN package.

FEATURES

• High Efficiency (Up to 95%)

• Excellent Ripple and EMI Performance

• Up to 4A Continuous Operating Current

• 2.7V to 6.6V Input Voltage Range

The EN6340QI is specifically designed to meet the

precise voltage and fast transient requirements of

present and future high-performance, low-power

processor, DSP, FPGA, memory boards and system

level applications in distributed power architectures.

The device’s advanced circuit techniques, high

switching frequency, and proprietary integrated

inductor technology deliver high-quality, ultra

compact, non-isolated DC-DC conversion.

• 0.5% VFB Initial Accuracy

Intel Enpirion Power Solutions significantly help in

system design and productivity by offering greatly

simplified board design, layout and manufacturing

requirements. In addition, a reduction in the number

of components required for the complete power

solution helps to enable an overall system cost

saving.

• Pin Compatible with EN6363QI (6A)

All Enpirion products are RoHS compliant and leadfree manufacturing environment compatible.

• Space Constrained Applications Needing High

Power Density

• 1.5% VOUT Accuracy (Line, Load, Temp)

• 2MHz Switching Frequency

• 60mm2 Optimized Total Solution Size

• Programmable Soft-Start

• Power OK Indicator

• Thermal, Over-Current, Short Circuit, UnderVoltage and Pre-Bias Protections

• RoHS Compliant, MSL Level 3, 260°C Reflow

APPLICATIONS

• Point of Load Regulation for FPGAs, Distributed

Power Architectures, Low-Power ASICs, MultiCore, Communication Processors and DSPs

• 5V/3.3V Bus Architectures Needing High Efficiency

Efficiency vs. Output Current

VOUT

VIN

10Ω

2x

22µF

0805

VOUT

EN6340QI

AVIN

PGND

2x

47µF

0805

95

RA

CA

RC

ENABLE

POK

VFB

PGND

85

80

VOUT = 3.3V

75

VOUT = 2.5V

70

VOUT = 1.8V

65

VOUT = 1.5V

60

SS

15nF

90

EFFICIENCY (%)

PVIN

100

AGND

RB

CONDITIONS

VIN = 5.0V

55

VOUT = 1.2V

VOUT = 1.0V

50

0

0.5

1

1.5

2

2.5

3

3.5

4

OUTPUT CURRENT (A)

Figure 1: Simplified Applications Circuit

Figure 2: Efficiency at VIN = 5V

Page 1

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

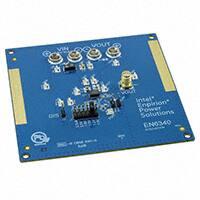

ORDERING INFORMATION

Part Number

Package Markings

TA Rating

Package Description

EN6340QI

EN6340QI

-40°C to +85°C

34-pin (4mm x 6mm x 2.5mm) QFN

EVB-EN6340QI

EN6340QI

QFN Evaluation Board

Packing and Marking Information: https://www.altera.com/support/quality-and-reliability/packing.html

PIN FUNCTIONS

NC(SW)

NC(SW)

NC(SW)

NC(SW)

NC(SW)

AGND

POK

AGND

AVIN

SS

VFB

34

33

32

31

30

29

28

27

26

25

24

23 NC

NC(SW) 1

KEEP-OUT

NC(SW) 2

4

VOUT

5

VOUT

6

KEEP-OUT

18 NC

13

14

15

16

17

PVIN

PVIN

PVIN

VOUT

12

PGND

VOUT

11

PGND

VOUT

10

NC(SW)

9

19 NC

VOUT

8

20 ENABLE

VOUT

7

KEEP-OUT

NC

21 NC

35

PGND

3

KEEP-OUT

NC

22 NC

Figure 3: Pin Diagram (Top View)

NOTE A: NC pins are not to be electrically connected to each other or to any external signal, ground or voltage. However,

they must be soldered to the PCB. Failure to follow this guideline may result in part malfunction or damage.

NOTE B: White ‘dot’ on top left is pin 1 indicator on top of the device package.

NOTE C: Keep-Out are No Connect pads that should not to be electrically connected to each other or to any external

signal, ground or voltage. They do not need to be soldered to the PCB.

Page 2

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

PIN DESCRIPTIONS

PIN

1, 2,

12, 30,

31, 32,

33, 34

3, 4,

18, 19,

21, 22,

23

5, 6, 7,

8, 9,

10, 11

NAME

NC(SW)

NC

VOUT

TYPE

FUNCTION

-

No Connect. These pins are internally connected to the common

switching node of the internal MOSFETs. They must be soldered to PCB

but not be electrically connected to any external signal, ground, or

voltage. Failure to follow this guideline may result in device damage.

-

No Connect. These pins must be soldered to PCB but not electrically

connected to each other or to any external signal, voltage, or ground.

These pins may be connected internally. Failure to follow this guideline

may result in device damage.

Power

Regulated converter output. Connect to the load and place output filter

capacitor(s) between these pins and PGND pins. Refer to the Layout

Recommendation section.

13, 14

PGND

Ground

Input/Output power ground. Connect to the ground electrode of the

input and output filter capacitors. See VOUT and PVIN pin descriptions

for more details.

15, 16,

17

PVIN

Power

Input power supply. Connect to input power supply. Decouple with input

capacitor to PGND pin. Refer to the Layout Recommendation section.

Analog

Input Enable. Applying logic high or floating the ENABLE pin will enable

the device and initiate a soft-start. Applying logic low disables the output

and switching stops.

Analog

External feedback input pin. A resistor divider connects from the output

to AGND. The mid-point of the resistor divider is connected to VFB. A

feed-forward capacitor (CA) and resistor (RC) are required in parallel to the

upper feedback resistor (RA). The output voltage regulation is based on

the VFB node voltage being equal to 0.6V.

20

24

ENABLE

VFB

25

SS

Analog

A soft-start capacitor is connected between this pin and AGND. The value

of the capacitor controls the soft-start interval. Refer to Soft-Start

Operation in the Functional Description section for more details.

26

AVIN

Power

Input power supply for the controller. Connect to input voltage at a quiet

point. Refer to the Layout Recommendation section.

27, 29

AGND

Power

Ground for internal control circuits. Connect to the power ground plane

with a via right next to the pin.

28

POK

Digital

Power OK is an open drain transistor used for power system state

indication. POK is logic high when VOUT is within ±10% of VOUT nominal

and has an internal 100kΩ pull-up resistance to AVIN.

Ground

Power ground thermal pad. Not a perimeter pin. Connect thermal pad to

the system GND plane for heat-sinking purposes. Refer to the Layout

Recommendation section.

35

PGND

Page 3

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

ABSOLUTE MAXIMUM RATINGS

CAUTION: Absolute Maximum ratings are stress ratings only. Functional operation beyond the recommended

operating conditions is not implied. Stress beyond the absolute maximum ratings may impair device

life. Exposure to absolute maximum rated conditions for extended periods may affect device reliability.

Absolute Maximum Pin Ratings

PARAMETER

SYMBOL

MIN

MAX

UNITS

PVIN, AVIN, VOUT

-0.3

7.0

V

ENABLE, POK

-0.3

VIN+0.3

V

VFB, SS

-0.3

2.5

V

7.0

V

NC(SW) Voltage DC

VSW

NC(SW) Voltage Peak < 5ns

VSW_PEAK

-2.0

10.5

V

CONDITION

MIN

MAX

UNITS

+150

°C

+150

°C

+260

°C

MAX

UNITS

Absolute Maximum Thermal Ratings

PARAMETER

Maximum Operating Junction

Temperature

Storage Temperature Range

Reflow Peak Body

Temperature

-65

(10 Sec) MSL3 JEDEC J-STD-020A

Absolute Maximum ESD Ratings

PARAMETER

CONDITION

MIN

HBM (Human Body Model)

±2000

V

CDM (Charged Device Model)

±500

V

RECOMMENDED OPERATING CONDITIONS

PARAMETER

SYMBOL

MIN

MAX

UNITS

VIN

2.7

6.6

V

Output Voltage Range

VOUT

0.75

VIN – VDO (1)

V

Output Current Range

IOUT

4

A

Operating Ambient Temperature Range

TA

-40

+85

°C

Operating Junction Temperature

TJ

-40

+125

°C

Input Voltage Range

Page 4

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

THERMAL CHARACTERISTICS

PARAMETER

SYMBOL

TYPICAL

UNITS

TSD

160

°C

TSDHYS

25

°C

Thermal Resistance: Junction to Ambient (0 LFM) (2)

JA

12.5

°C/W

Thermal Resistance: Junction to Case (0 LFM)

JC

1

°C/W

Thermal Shutdown

Thermal Shutdown Hysteresis

(1) VDO (dropout voltage) is defined as (ILOAD x Droput Resistance). Please refer to Electrical Characteristics Table.

(2) Based on 2oz. external copper layers and proper thermal design in line with EIJ/JEDEC JESD51-7 standard for high

thermal conductivity boards.

Page 5

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

ELECTRICAL CHARACTERISTICS

NOTE: VIN = PVIN = AVIN = 5V, Minimum and Maximum values are over operating ambient temperature range

unless otherwise noted. Typical values are at TA = TJ = 25°C.

PARAMETER

Operating Input

Voltage

SYMBOL

VIN

TEST CONDITIONS

MIN

PVIN = AVIN

2.7

TYP

MAX

UNITS

6.6

V

Under Voltage LockOut – VIN Rising

VUVLOR

Voltage above which UVLO is

not asserted

2.2

2.3

2.4

V

Under Voltage LockOut – VIN Falling

VUVLOF

Voltage below which UVLO is

asserted

1.7

2.075

2.2

V

Under Voltage LockOut Hysteresis

VUVLOHYS

Shut-Down Supply

Current

IS

AVIN Quiescent Current

IAVINQ

No Load Quiescent

Current

IVINQ

Feedback Pin Voltage (3)

VFB

Feedback Pin Voltage

(Line, Load, Temp.)

225

mV

ENABLE = 0V

500

700

A

AVIN only

3.5

10

mA

PVIN and AVIN

40

VOUT = 1.2V

VOUT = 0.6V, ILOAD = 0,

TA =25°C

mA

0.597

0.6

0.603

V

0.591

0.6

0.609

V

2.7V ≤ VIN ≤ 6.6V

VFB

0A ≤ ILOAD ≤ 4A

-40°C ≤ TA ≤ 85°C

Feedback pin Input

Leakage Current (4)

VFB pin input leakage current

-10

10

nA

Capacitor programmable

0.2

20

ms

CSS_RANGE

10

100

nF

Soft-Start Charging

Current

ISS

3.5

5

6.5

µA

Drop-Out Voltage (4)

VDO

VINMIN - VOUT at full load

200

320

mV

Drop-Out Resistance (4)

RDO

Input to output resistance

50

80

m

Continuous Output

Current

IOUT

4

A

Over Current Trip Level

IOCP

VOUT Rise Time Range (4)

Soft Start Capacitance

Range (4)

IFB

tRISE

0

VIN = 5V, VOUT = 1.2V

4.5

6.5

A

Page 6

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

Current Limit Retry

Time (4)

TCL_TRY

Precision Disable

Threshold

VDISABLE

ENABLE pin logic going low

0.95

1.01

1.07

V

Precision Enable

Threshold

VEN

ENABLE pin logic going high

1.08

1.12

1.16

V

ENABLE Hysteresis

ENHYS

ENABLE Pin Input

Current

IEN

ENABLE Pull-Up

Resistance

17

ms

110

mV

Device not switching;

40

ENABLE pin has ~110k pull

down

90

A

REN_UP

Not a passive element and

changes with VIN

190

kΩ

REN_DOWN

Not a passive element and

changes with VIN

110

kΩ

FSW

Free running frequency of

oscillator

POK High Range

POKRANGE

Typical percentage range

within VOUT nominal when

POK is asserted high

POK Low Voltage

VPOKL

With 4mA current sink into

POK

0.4

V

POK High Voltage

VPOKH

2.7V ≤ VIN ≤ 6.6V

VIN

V

POK Pin Leakage

Current (4)

IPOKH

POK is high

1

µA

ENABLE Pull-Down

Resistance

Switching Frequency

1.8

2.0

2.2

±10

MHz

%

(3) The VFB pin is a sensitive node. Do not touch VFB while the device is in regulation.

(4) Parameter not production tested but is guaranteed by design.

Page 7

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

TYPICAL PERFORMANCE CURVES

Efficiency vs. Output Current

100

100

95

95

90

90

85

85

80

EFFICIENCY (%)

EFFICIENCY (%)

Efficiency vs. Output Current

VOUT = 3.3V

75

VOUT = 2.5V

70

VOUT = 1.8V

65

VOUT = 1.5V

CONDITIONS

VIN = 5.0V

60

55

80

VOUT = 1.8V

70

VOUT = 1.5V

65

VOUT = 1.2V

60

VOUT = 1.0V

55

50

VOUT = 2.5V

75

CONDITIONS

VIN = 3.3V

0.5

1

1.5

2

2.5

3

3.5

4

0

0.5

OUTPUT CURRENT (A)

1

1.5

2

2.5

3

3.5

4

OUTPUT CURRENT (A)

Output Voltage vs. Output Current

Output Voltage vs. Output Current

1.006

1.006

CONDITIONS

VIN = 3.3V

1.004

VOUT = 1.0V

OUTPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

VOUT = 1.0V

50

0

1.002

1

0.998

0.996

0.994

CONDITIONS

VIN = 5.0V

1.004

VOUT = 1.0V

1.002

1

0.998

0.996

0.994

0

0.5

1

1.5

2

2.5

3

3.5

4

0

0.5

OUTPUT CURRENT (A)

1

1.5

2

2.5

3

3.5

4

OUTPUT CURRENT (A)

Output Voltage vs. Output Current

Output Voltage vs. Output Current

1.806

1.806

CONDITIONS

VIN = 3.3V

1.804

VOUT = 1.8V

OUTPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

VOUT = 1.2V

1.802

1.8

1.798

1.796

CONDITIONS

VIN = 5.0V

1.804

VOUT = 1.8V

1.802

1.8

1.798

1.796

1.794

1.794

0

0.5

1

1.5

2

2.5

3

3.5

4

0

0.5

1

1.5

2

2.5

3

3.5

4

OUTPUT CURRENT (A)

OUTPUT CURRENT (A)

Page 8

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

TYPICAL PERFORMANCE CURVES (CONTINUED)

Output Voltage vs. Output Current

Output Voltage vs. Output Current

3.306

CONDITIONS

VIN = 3.3V

2.504

VOUT = 2.5V

OUTPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

2.506

2.502

2.5

2.498

2.496

2.494

CONDITIONS

VIN = 5.0V

3.304

3.302

3.3

3.298

3.296

3.294

0

0.5

1

1.5

2

2.5

3

3.5

4

0

0.5

1

OUTPUT CURRENT (A)

Output Voltage vs. Temperature

2

2.5

3

3.5

4

Output Voltage vs. Temperature

1.806

1.804

LOAD = 2A

LOAD = 0.01A

VOUT = 1.8V

LOAD = 4A

1.802

CONDITIONS

VIN = 2.7V

OUTPUT VOLTAGE (V)

LOAD = 0.01A

OUTPUT VOLTAGE (V)

1.5

OUTPUT CURRENT (A)

1.806

1.8

1.798

1.796

1.794

1.804

LOAD = 2A

VOUT = 1.8V

LOAD = 4A

1.802

CONDITIONS

VIN = 3.3V

1.8

1.798

1.796

1.794

-40

-20

0

20

40

60

80

100

-40

AMBIENT TEMPERATURE ( C)

-20

0

20

40

60

80

100

AMBIENT TEMPERATURE ( C)

Output Voltage vs. Temperature

Output Voltage vs. Temperature

1.806

1.806

1.804

LOAD = 2A

LOAD = 0.01A

VOUT = 1.8V

LOAD = 4A

1.802

CONDITIONS

VIN = 5.0V

OUTPUT VOLTAGE (V)

LOAD = 0.01A

OUTPUT VOLTAGE (V)

VOUT = 3.3V

1.8

1.798

1.796

1.794

1.804

LOAD = 2A

VOUT = 1.8V

LOAD = 4A

1.802

CONDITIONS

VIN = 6.6V

1.8

1.798

1.796

1.794

-40

-20

0

20

40

60

80

100

AMBIENT TEMPERATURE ( C)

-40

-20

0

20

40

60

80

100

AMBIENT TEMPERATURE ( C)

Page 9

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

TYPICAL PERFORMANCE CURVES (CONTINUED)

Input Voltage vs. Output Voltage

Input Voltage vs. Output Voltage

1.81

CONDITIONS

VOUT = 1.8V

TA = 25°C

1.804

1.802

LOAD = 0.01A

1.808

TA = -40°C

TA = 0°C

LOAD = 2A

1.806

TA = 25°C

TA = 85°C

OUTPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

1.806

LOAD = 4A

1.8

1.798

1.796

1.804

1.802

1.8

1.798

1.796

CONDITIONS

VOUT = 1.8V

LOAD = 2A

1.794

1.792

1.79

1.794

2.5

3

3.5

4

4.5

5

5.5

6

6.5

2.5

7

3

No Thermal Derating

4.5

5

5.5

6

6.5

7

No Thermal Derating

5

5

4.5

4.5

MAX LOAD

4

OUTPUT CURRENT (A)

OUTPUT CURRENT (A)

4

INPUT VOLTAGE (V)

INPUT VOLTAGE (V)

3.5

3

2.5

2

1.5

CONDITIONS

VIN = 5.0V

1

0.5

MAX LOAD

4

3.5

3

2.5

2

1.5

CONDITIONS

VIN = 5.0V

1

0.5

VOUT = 3.3V

0

VOUT = 1.0V

0

-40

-20

0

20

40

60

80

100

-40

AMBIENT TEMPERATURE ( C)

60.0

40.0

HORIZONTAL

VERTICAL

CISPR 22 Class B 3m

30.0

20

40

60

CONDITIONS

VIN = 5.0V

VOUT_NOM = 3.3V

LOAD = 1Ω

50.0

LEVEL (dBµV/m)

50.0

0

80

100

EMI Performance

60.0

CONDITIONS

VIN = 5.0V

VOUT_NOM = 1.2V

LOAD = 0.33Ω

-20

AMBIENT TEMPERATURE ( C)

EMI Performance

LEVEL (dBµV/m)

3.5

20.0

10.0

40.0

HORIZONTAL

VERTICAL

CISPR 22 Class B 3m

30.0

20.0

10.0

0.0

0.0

10

100

1000

FREQUENCY (MHz)

10

100

1000

FREQUENCY (MHz)

Page 10

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

TYPICAL PERFORMANCE CHARACTERISTICS

Output Ripple at 20MHz Bandwidth

Output Ripple at 20MHz Bandwidth

CONDITIONS

VIN = 5V

COUT = 2x47µF

No Load

VOUT = 1.0V

(AC Coupled)

10mV / DIV

VOUT = 1.8V

(AC Coupled)

10mV / DIV

VOUT = 1.8V

(AC Coupled)

10mV / DIV

VOUT = 3.3V

(AC Coupled)

10mV / DIV

VOUT = 3.3V

(AC Coupled)

10mV / DIV

Output Ripple at 500MHz Bandwidth

CONDITIONS

VIN = 5V

COUT = 2x47µF

4A Load

VOUT = 1.0V

(AC Coupled)

10mV / DIV

Output Ripple at 500MHz Bandwidth

VOUT = 1.0V

VOUT = 3.3V

(AC Coupled at 2mV / DIV)

VOUT = 1.8V

(AC Coupled at 2mV / DIV)

VOUT = 1.8V

VOUT = 3.3V

VOUT = 1.0V

(AC Coupled at 2mV / DIV)

CONDITIONS

VIN = 5V, 4A Load

COUT = 2 x 47µF + 0.1µF

CONDITIONS

VIN = 5V

COUT = 2 x (47µF, 22µF,10µF, 4.7µF, 2.2µF, 1µF, 0.1µF)

Improved Load Transient 0 to 4A

Load Transient 0 to 4A

VOUT

(AC Coupled)

VOUT

(AC Coupled)

4A

CONDITIONS

VIN = 3.3V

VOUT = 1.2V

CA = 47pF

COUT = 2x47µF + 3x100µF

CONDITIONS

VIN = 3.3V

VOUT = 1.2V

CA = 15pF

COUT = 2x47µF

4A

LOAD = 0A

LOAD = 0A

Page 11

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

TYPICAL PERFORMANCE CHARACTERISTICS (CONTINUED)

Improved Load Transient 0 to 4A

Load Transient 0 to 4A

VOUT

(AC Coupled)

VOUT

(AC Coupled)

CONDITIONS

VIN = 5V

VOUT = 1.2V

CA = 47pF

COUT = 2x47µF + 3x100µF

CONDITIONS

VIN = 5V

VOUT = 1.2V

CA = 15pF

COUT = 2x47µF

4A

4A

LOAD = 0A

LOAD = 0A

Improved Load Transient 0 to 4A

Load Transient 0 to 4A

VOUT

(AC Coupled)

VOUT

(AC Coupled)

CONDITIONS

VIN = 5V

VOUT = 3.3V

CA = 33pF

COUT = 2x47µF + 3x100µF

CONDITIONS

VIN = 5V

VOUT = 3.3V

CA = 10pF

COUT = 2x47µF

4A

4A

LOAD = 0A

LOAD = 0A

Startup and Shutdown at 4A Load

Startup and Shutdown at No Load

EN

VOUT

CONDITIONS

VIN = 5V

VOUT = 3.3V

CA = 10pF

COUT = 2 x 47µF

No Load

VOUT Floats

EN

CONDITIONS

VIN = 5V

VOUT = 3.3V

CA = 10pF

COUT = 2 x 47µF

VOUT

POK

POK

SS

SS

Page 12

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

TYPICAL PERFORMANCE CHARACTERISTICS (CONTINUED)

VIN Startup at No Load

VIN Shutdown at No Load

CONDITIONS

VIN = 5V

VOUT = 3.3V

CA = 10pF

COUT = 2 x 47µF

PVIN

CONDITIONS

VIN = 5V

VOUT = 3.3V

CA = 10pF

COUT = 2 x 47µF

VOUT

PVIN

POK

VOUT

SS

POK

SS

VIN Startup at 4A Load

VIN Shutdown at 4A Load

PVIN

CONDITIONS

VIN = 5V

VOUT = 3.3V

CA = 10pF

COUT = 2 x 47µF

VOUT

PVIN

POK

VOUT

LOAD

POK

CONDITIONS

VIN = 5V

VOUT = 3.3V

CA = 10pF

COUT = 2 x 47µF

LOAD

Pre-Bias Startup

Pre-Bias Startup

EN

EN

90% Pre-Bias

90% Pre-Bias

VOUT 50% Pre-Bias

VOUT 50% Pre-Bias

10% Pre-Bias

POK

10% Pre-Bias

CONDITIONS

VIN = 5V

VOUT = 1V

POK

CONDITIONS

VIN = 5V

VOUT = 3.3V

Page 13

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

TYPICAL PERFORMANCE CHARACTERISTICS (CONTINUED)

Short Circuit and Recovery

Short Circuit and Recovery

CONDITIONS

VIN = 6.6V, VOUT = 3.3V

POK

POK

“Re-Try”

VOUT

VOUT

VSW

VSW

LOAD

SS

CONDITIONS

VIN = 6.6V, VOUT = 3.3V

Page 14

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

FUNCTIONAL BLOCK DIAGRAM

PVIN

UVLO

Thermal Limit

LDO

Current Limit

NC(SW)

P-Drive

(-)

Logic

PWM

Comp

(+)

VOUT

N-Drive

PGND

PLL/Sawtooth

Generator

Compensation

Network

AVIN

Prebias Sense

(-)

Error

Amp

(+)

AVIN

Power

OK

100k

POK

ENABLE

Soft-Start

Internal

Reference

VFB

Internal

Regulator

AGND

AVIN

SS

Figure 4: Functional Block Diagram

FUNCTIONAL DESCRIPTION

Synchronous DC-DC Step-Down PowerSoC

The EN6340QI is a synchronous DC-DC PowerSoC with integrated power MOSFET switches and integrated

inductor. The nominal input voltage range is 2.7V to 6.6V. The output voltage is programmed using an external

resistor divider network. The control loop is voltage-mode with a type III compensation network. Much of the

compensation circuitry is internal to the device, but a phase-lead capacitor and resistor are required to

complete the compensation network. The type III voltage mode architecture with integrated compensation

maximizes loop bandwidth without increasing complexity. This architecture is designed to maintain stability

with excellent gain and phase margin and improve transient response. The enhanced voltage mode

architecture also provides high noise immunity at light load and maintains excellent line and load regulation.

Up to 4A of continuous output current can be drawn from this converter. The 2MHz switching frequency allows

the use of smaller case size input and output capacitors within a small footprint.

Page 15

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

The EN6340QI architecture includes the following features.

Operational Features:

•

Precision enable circuit with tight threshold range

•

Soft-start circuit allowing controlled startup when the converter is initially powered up

•

Power OK circuit indicating the output voltage is greater than 90% of programmed value

Protection Features:

•

Over-current protection from short circuit or excessive load current

•

Thermal shutdown with hysteresis to prevent over temperature stress

•

Output voltage pre-bias startup protection for smooth monotonic startup

•

Under-voltage lockout protection to prevent under-voltage operation

Precision Enable Operation

The enable (ENABLE) pin provides a mean to startup or to shutdown the device. When the ENABLE pin is

asserted high, the device will undergo a normal soft-start where the output will rise monotonically into

regulation. Asserting a logic low on this pin will deactivate the device by turning off the internal power switches

and the POK flag will also be pulled low. The ENABLE pin is connected through an internal divider network to

AVIN and AGND. If left floating, the ENABLE voltage will be equal to the AVIN voltage and the value set by the

divider network ratio (~2.5):

VEN (FLOATING) ≈ AVIN / 2.5

The precision enable circuit ensures the device will enable or disable within a tight voltage range for both high

or low logic. In order to ensure a known state the ENABLE pin should be pulled high or low. See the Electrical

Characteristics Table for technical specifications for the ENABLE pin.

Soft-Start Operation

The soft-start circuitry will reduce inrush current during startup as the regulator charges the output voltage up

to nominal level gradually. The output rise time is controlled by the soft-start capacitor, which is placed

between the SS pin and the AGND pin. When the part is enabled, the soft-start (SS) current generator charges

the SS capacitor in a linear manner. Once the voltage on the SS capacitor reaches 0.6V, the controller selects

the intenral bandgap voltage as the reference. The voltage across the SS capacitor will continue ramping up

until it reaches around 1.27V. The rise time is defined as the time needed by the output voltage to go from

zero to the programmed value. The rise time (tRISE) is given by the following equation:

tRISE [ms] = Css [nF] x 0.13

With a 10nF soft-start capacitance on the SS pin, the soft-start rise time will be set to 1.3ms. The recommended

range for the value of the SS capacitor is between 10nF and 100nF. Note that excessive bulk capacitance on

the output can cause an over current event on startup if the soft-start time is too low. Refer to the

Compensation and Transient Response section for details on proper bulk capacitance usage.

POK Operation

The Power OK (POK) is an open drain signal (with internal 100kΩ pull-up to AVIN) to indicate if the output

voltage is within the specified range. POK is asserted high when the rising output voltage exceeds 90% of the

programmed output voltage. For a stronger pull-up, an external resistor may be connected to AVIN. If the

Page 16

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

nominal output voltage falls outside the set range (typically 90% to 110% of nominal) the POK signal will be

asserted low by an internal 4mA pull-down transistor.

Over-Current Protection (OCP)

The current limit function is achieved by sensing the current flowing through the topside power PFET. When

the sensed current exceeds the over current trip point (see Electrical Characteristics Table), both power FETs

are turned off for the remainder of the switching cycle. If the over-current condition is removed, the overcurrent protection circuit will enable normal PWM operation. In the event the OCP circuit trips at least 7

consecutive PWM cycles, the device enters a retry mode; the device is disabled for about 17ms and restarted

with a normal soft-start. This cycle can continue indefinitely as long as the over current condition persists. The

OCP circuit will disable operation and protect the device from excessive current during operation without

compromising the full load capability of the device.

Thermal Protection

The thermal shutdown circuit disables the device operation (switching stops) when the junction temperature

exceeds 160°C. When the junction temperature drops by approximately 25°C, the converter will re-start with

a normal soft-start. By preventing operation at excessive temperatures, the thermal shutdown circuit will

protect the device from overstress.

Pre-Bias Startup Protection

The EN6340QI supports startup into a pre-biased output. A proprietary circuit ensures the output voltage rises

from the pre-bias voltage level to the programmed output voltage on startup. During this soft-start period, the

voltage rise is monotonic for output voltage range from 0% to 90% of nominal. If the pre-bias voltage is above

90% on startup, there might be a slight dip (~3%) in output voltage before it rises monotonically. If the prebias voltage is above 100% of nominal during startup, the device will not switch until the soft-start period is

over. Note that when the device begins switching and the pre-bias output voltage is higher than nominal, the

bottomside NFET will discharge the output quickly (but limited to 2-cycles to prevent excessive current) to

bring the voltage back into regulation. The pre-bias protection circuit is designed to prevent improper behavior

on startup regardless of the pre-bias output voltage during soft-start.

Input Under-Voltage Lock-Out (UVLO)

When the device input voltage falls below UVLO, switching is disabled to prevent operation at insufficient

voltage levels. During startup, the UVLO circuit ensures that the converter will not start switching until the

input voltage is above the specified minimum voltage. Hysteresis and input de-glitch circuits are incorporated

in order to ensure high noise immunity and prevent a false trigger in the UVLO voltage region.

APPLICATION INFORMATION

Output Voltage Setting

The EN6340QI output voltage is programmed using a simple resistor divider network (RA and RB). Figure 5

shows the resistor divider configuration.

Page 17

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

EN6340QI

VOUT

VOUT

PGND

VFB

COUT

(100µF to 400µF)

RA

249k

CA

(10pF to 47pF)

RC

10k

VFB = 0.6V

RB =

VFB x RA

VOUT - VFB

AGND

Figure 5: VOUT Resistor Divider & Compensation Capacitor

The recommended RA resistor value is 249kΩ and the feedback voltage is typically 0.6V. Depending on the

output voltage (VOUT), the RB resistor value may be calculated as shown in Figure 5. Since the accuracy of the

output voltage setting is dependent upon the feedback voltage and the external ressitors, 1% or better

resistors are recommended. The external compensation capacitor (CA) and resistor (RC) is also required in

parallel with RA. Depending on input and output voltage, the recommended external compensation values are

shown in Table 1.

Table 1: External Compensation Recommendations

VIN

3.3V

VOUT

RB

CA

1.0V

374kΩ

18pF

1.2V

249kΩ

15pF

1.5V

165kΩ

15pF

1.8V

124kΩ

15pF

2.5V

78.7kΩ

12pF

1.0V

374kΩ

15pF

1.2V

249kΩ

15pF

1.5V

165kΩ

15pF

1.8V

124kΩ

12pF

2.5V

78.7kΩ

12pF

3.3V

54.9kΩ

10pF

5V

RA

RC

COUT (0805)

249kΩ

10kΩ

2 x 47µF

249kΩ

10kΩ

2 x 47µF

Page 18

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

Compensation and Transient Response

The EN6340QI uses an enhanced type III voltage mode control architecture. Most of the compensation is

internal, which simplifies the design. In some applications, improved transient performance may be desired

with additional output capacitors (COUT). In such an instance, the phase-lead capacitor (CA) can be adjusted

depending on the total output capacitance. Using Table 1 as the reference for CA, if COUT is increased, then the

CA should also be increased. The relationship is linearly shown below:

ΔCOUT ≈ +100µF ΔCA ≈ +10pF

As COUT increases and the CA value is adjusted, the device bandwidth will reach its optimization level (at around

1/10th of the switching frequency). As shown in Table 1, the recommended CA value is lower for the 5V input

than 3.3V input. This is to ensure that the loop bandwidth is not over extended due to the increased gain at

the higher input voltage range. The CA value may be extrapolated for other input voltages. The limitation for

adjusting the compensation is based on diminished return. Further adjustments by increasing COUT and

increasing CA may not yield better transient response or in some situations cause lower gain and phase margin.

Over compensating with excessive output capacitance may also cause the device to trigger current limit on

startup due to the energy required to charge the output up to regulation level. Due to such limitations, the

recommended maximum output capacitance (COUT_MAX) is 400µF and the recommended maximum phase-lead

capacitance (CA_MAX) is 47pF.

Input Capacitor Selection

The input of synchronous buck regulators can be very noisy and should be decoupled properly in order to

ensure stable operation. In addition, input parasitic line inductance can attribute to higher input voltage ripple.

The EN6340QI requires a minimum of 2 x 22µF 0805 input capacitors. As the distance of the input power

source to the input of the EN6340QI is increased, it is recommended to increase input capacitance in order to

mitigate the line inductance from the source. Low-ESR ceramic capacitors should be used. The dielectric must

be X5R or X7R rated and the size must be at least 0805 (EIA) due to derating. Y5V or equivalent dielectric

formulations must not be used as these lose too much capacitance with frequency, temperature and bias

voltage. In some applications, lower value capacitors are needed in parallel with the larger capacitors in order

to provide high frequency decoupling. Larger electrolytic or tantalum bulk capacitors may be used in

conjunction to increase total input capacitance but should not be used solely as a replacement for the ceramic

capacitors.

Table 2: Recommended Input Capacitors

DESCRIPTION

MFG

Taiyo Yuden

22µF ±20%, 10V

X5R, 0805

Murata

TDK

P/N

LMK212BBJ226MG-T

GRM21BR61A226ME51

C2012X5R1A226M125AB

Output Capacitor Selection

The output ripple of a synchronous buck converter can be attributed to its inductance, switching frequency

and output decoupling. The EN6340QI requires a minimum of 2 x 47µF 0805 output capacitors. Low ESR

ceramic capacitors should be used. The dielectric must be X5R or X7R rated and the size must be at least 0805

(EIA) due to derating. Y5V or equivalent dielectric formulations must not be used as these lose too much

capacitance with frequency, temperature and bias voltage.

Page 19

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

Table 3: Recommended Output Capacitors

DESCRIPTION

MFG

Taiyo Yuden

47µF ±20%, 6.3V,

Murata

X5R, 0805

TDK

P/N

JMK212BBJ476MG-T

GRM21BR60J476ME15

C2012X5R0J476M125AC

Output ripple voltage is determined by the aggregate output capacitor impedance. Output impedance,

denoted as Z, is comprised of effective series resistance (ESR) and effective series inductance (ESL):

Z = ESR + ESL

The resonant frequency of a ceramic capacitor is inversely proportional to the capacitance. Lower capacitance

corresponds to higher resonant frequency. When two capacitors are placed in parallel, the benefit of both are

combined. It is beneficial to decouple the output with capacitors of various capacitance and size. Placing them

all in parallel reduces the impedance and will hence result in lower output ripple.

1

Z Total

1

1

1

...

Z1 Z 2

Zn

THERMAL CONSIDERATIONS

Thermal considerations are important elements of power supply design. Whenever there are power losses in

a system, the heat that is generated by the power dissipation needs to be taken into account. The Intel Enpirion

PowerSoC technology helps alleviate some of those concerns.

The EN6340QI DC-DC converter is packaged in a 4mm x 6mm x 2.5mm 34-pin QFN package. The QFN package

is constructed with copper lead frames that have exposed thermal pads. The exposed thermal pad on the

package should be soldered directly on to a copper ground pad on the printed circuit board (PCB) to act as a

heat sink. The recommended maximum junction temperature for continuous operation is 125°C. Continuous

operation above 125°C may reduce long-term reliability. The device has a thermal overload protection circuit

designed to turn off the device at an approximate junction temperature value of 160°C.

The following example and calculations illustrate the thermal performance of the EN6340QI with the following

parameters:

VIN = 5V

VOUT = 3.3V

IOUT = 4A

First, calculate the output power.

POUT = VOUT x IOUT = 3.3V x 4A = 13.2W

Next, determine the input power based on the efficiency (η) shown in Figure 6.

Page 20

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

Efficiency vs. Output Current

100

95

EFFICIENCY (%)

90

85

80

75

70

65

60

CONDITIONS

VIN = 5.0V

55

VOUT = 3.3V

50

0

0.5

1

1.5

2

2.5

3

3.5

4

OUTPUT CURRENT (A)

Figure 6: Efficiency vs. Output Current

For VIN = 5V, VOUT = 3.3V at 4A, η ≈ 94%

η = POUT / PIN = 94% = 0.94

PIN = POUT / η

PIN ≈ 13.2W / 0.94 ≈ 14W

The power dissipation (PD) is the power loss in the system and can be calculated by subtracting the output

power from the input power.

PD = PIN – POUT

= 14W – 13.2W ≈ 0.8W

With the power dissipation known, the temperature rise in the device may be estimated based on the theta JA

value (θJA). The θJA parameter estimates how much the temperature will rise in the device for every watt of

power dissipation. The EN6340QI has a θJA value of 12.5°C/W without airflow.

Determine the change in temperature (ΔT) based on PD and θJA.

ΔT = PD x θJA

ΔT ≈ 0.8W x 12.5°C/W ≈ 10°C

The junction temperature (TJ) of the device is approximately the ambient temperature (TA) plus the change in

temperature. We assume the initial ambient temperature to be 25°C.

TJ = TA + ΔT

TJ ≈ 25°C + 10°C ≈ 35°C

The maximum operating junction temperature (TJMAX) of the device is 125°C, so the device can operate at a

higher ambient temperature. The maximum ambient temperature (TAMAX) allowed can be calculated.

TAMAX = TJMAX – PD x θJA

≈ 125°C – 10°C ≈ 115°C

The maximum ambient temperature the device can reach is 115°C given the input and output conditions. Note

that the efficiency will be slightly lower at higher temperatures and this calculation is an estimate.

Page 21

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

APPLICATION CIRCUITS

5V

1.8V @ 4A

PVIN

10Ω

VOUT

EN6340QI

2x

22µF

0805

AVIN

PGND

2x

47µF

0805

249k

12pF

10k

ENABLE

POK

VFB

PGND

SS

15nF

124k

AGND

Figure 7: Smallest Solution Size Application Circuit for VOUT = 1.8V

1.8V @ 4A

5V

PVIN

10Ω

2x

22µF

0805

VOUT

EN6340QI

AVIN

PGND

2x

47µF

0805

249k

3x

100µF

10k

ENABLE

POK

47pF

VFB

PGND

SS

15nF

124k

AGND

Figure 8: Improved Transient Response Application Circuit for VOUT = 1.8V

Page 22

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

LAYOUT RECOMMENDATIONS

Figure 9 shows critical components and layer 1 traces of a recommended minimum footprint EN6340QI layout.

ENABLE and other small signal pins need to be connected and routed according to specific customer

application. Visit the Enpirion Power Solutions website at www.altera.com/powersoc for more information

regarding layout. Please refer to this Figure 9 while reading the layout recommendations in this section.

Figure 9: Top PCB Layer Critical Components and Copper for Minimum Footprint (Top View)

Recommendation 1: Input and output filter capacitors should be placed on the same side of the PCB, and as

close to the EN6340QI package as possible. They should be connected to the device with very short and wide

traces. Do not use thermal reliefs or spokes when connecting the capacitor pads to the respective nodes. The

Voltage and GND traces between the capacitors and the EN6340QI should be as close to each other as possible

so that the gap between the two nodes is minimized, even under the capacitors.

Recommendation 2: Half of the PGND pins are dedicated to the input circuit and the other half to the output

circuit. The slit shown in Figure 9 separating the input and output GND circuits helps minimize noise coupling

between the converter input and output switching loops.

Recommendation 3: The system ground plane should be on the 2nd layer (below the surface layer). This

ground plane should be continuous and un-interrupted.

Recommendation 4: The large thermal pad underneath the device must be connected to the system ground

plane through as many vias as possible. The drill diameter of the vias should be 0.33mm, and the vias must

have at least 1-oz. copper plating on the inside wall, making the finished hole size around 0.2mm to 0.26mm.

Do not use thermal reliefs or spokes to connect the vias to the ground plane. This connection provides the

path for heat dissipation from the converter. Please see Figure 9.

Page 23

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

Recommendation 5: Multiple small vias (the same size as the thermal vias discussed in recommendation 4

should be used to connect ground terminal of the input capacitor and output capacitors to the system ground

plane. Put the vias under the capacitors along the edge of the GND copper closest to the Voltage copper.

Please see Figure 9. These vias connect the input/output filter capacitors to the GND plane, and help reduce

parasitic inductances in the input and output current loops. If the vias cannot be placed under CIN and COUT,

then put them just outside the capacitors along the GND slit separating the two components. Do not use

thermal reliefs or spokes to connect these vias to the ground plane.

Recommendation 6: AVIN is the power supply for the internal small-signal control circuits. It should be

connected to the input voltage at a quiet point. In Figure 9 this connection is made at the input capacitor

furthest from the PVIN pin and on the input source side. Avoid connecting AVIN near the PVIN pin even though

it is the same node as the input ripple is higher there.

Recommendation 7: The VOUT sense point should be connected at the last output filter capacitor furthest from

the VOUT pins. Keep the sense trace as short as possible in order to avoid noise coupling into the control loop.

Recommendation 8: Keep RA, CA, RC and RB close to the VFB pin (see Figure 9). The VFB pin is a high-impedance,

sensitive node. Keep the trace to this pin as short as possible. Whenever possible, connect RB directly to the

AGND pin instead of going through the GND plane. The AGND should connect to the PGND at a single point

from the AGND pin to the PGND plane on the 2nd layer.

Recommendation 9: The layer 1 metal under the device must not be more than shown in Figure 9. See the

following section regarding Exposed Metal on Bottom of Package. As with any switch-mode DC-DC

converter, try not to run sensitive signal or control lines underneath the converter package on other layers.

Page 24

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

DESIGN CONSIDERATIONS FOR LEAD-FRAME BASED MODULES

Exposed Metal on Bottom of Package

Lead-frames offer many advantages in thermal performance such as in reduced electrical lead resistance and

in overall footprint; however, they do require some special considerations.

In the assembly process lead frame construction requires some of the lead-frame cantilevers be exposed at

the point where wire-bond or internal passives are attached for mechanical support. This results in several

small pads being exposed on the bottom of the package, as shown in Figure 10.

Only the thermal pad and the perimeter pads are to be mechanically or electrically connected to the board.

The PCB top layer under the EN6340QI should be clear of any metal (copper pours, traces, or vias) except for

the thermal pad. The “shaded-out” area in Figure 10 represents the area that should be clear of any metal on

the top layer of the PCB. Any layer 1 metal under the shaded-out area runs the risk of undesirable shorted

connections even if it is covered by solder mask.

The solder stencil aperture should be smaller than the PCB ground pad. This will prevent excess solder from

causing bridging between adjacent pins or other exposed metal under the package. See Figure 11 for details.

Figure 10: Lead-Frame exposed metal (Bottom View)

Shaded area highlights exposed metal that is not to be mechanically or electrically connected to the PCB.

Page 25

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

Figure 11: Landing Pattern with Solder Stencil (Top View)

The solder stencil aperture for the thermal PGND pad is shown in Figure 11 and is based on Enpirion power product

manufacturing specifications.

Page 26

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

PACKAGE DIMENSIONS

Figure 12: EN6340QI Package Dimensions

Packing and Marking Information: https://www.altera.com/support/quality-and-reliability/packing.html

Page 27

13519

July 19, 2017

Rev A

�Datasheet | Intel® Enpirion® Power Solutions: EN6340QI

REVISION HISTORY

Rev

A

Date

Change(s)

July, 2017

Initial Release

WHERE TO GET MORE INFORMATION

For more information about Intel® and Enpirion® PowerSoCs, visit:

www.altera.com/enpirion

© 2017 Intel Corporation. All rights reserved. Intel, the Intel logo, Altera, ARRIA, CYCLONE, ENPIRION, MAX, MEGACORE, NIOS, QUARTUS, and STRATIX words and logos are trademarks of Intel

Corporation or its subsidiaries in the U.S. and/or other countries. Other marks and brands may be claimed as the property of others. Intel reserves the right to make changes to any products and

services at any time without notice. Intel assumes no responsibility or liability arising out of the application or use of any information, product, or service described herein except as expressly agreed to

in writing by Intel. Intel customers are advised to obtain the latest version of device specifications before relying on any published information and before placing orders for products or services.

* Other marks and brands may be claimed as the property of others.

Page 28

13519

July 19, 2017

Rev A

�