Temperature Compensated Crystal Oscillator (TCXO)

Data sheet

MODEL

:

TG2520SMN 19.200000 MHz MCGNNM

X1G0054210303xx

Product. No. :

Please refer to the 10.Packing information about xx (last 2 digits)

SEIKO EPSON CORPORATION

Pb free.

Complies with EU RoHS directive.

*About the products without the Pb-free mark.

Contains Pb in products exempted by EU RoHS directive.

(Contains Pb in sealing glass, high melting temperature type solder or other.)

INTRODUCTION

1. Any part of this material may not be reproduced or duplicated in any form or any means without the

written permission of Seiko Epson.

2. This sheet is not intended to guarantee or provide an approval of implementation of industrial patents.

�[ 1 ] Characteristics

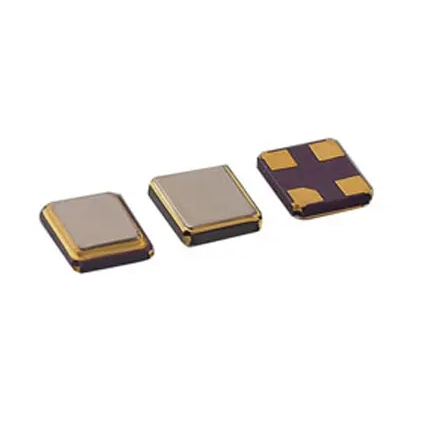

· Package size (2.5 mm×2.0 mm×0.8 mm)

· High stability TCXO

· Output waveform : Clipped sine wave

· Reference weight Typ.15.6mg

[ 2 ] Absolute maximum ratings

Parameter

Supply voltage

Storage temperature range

Symbol

Vcc-GND

T_stg

Min.

-0.5

-40

Specifications

Typ.

-

Max.

+4.0

+90

Unit

Conditions

V

°C

Storage as single product

[ 3 ] Recommended operating conditions

Specifications

Unit

Conditions

Min.

Typ.

Max.

Vcc

2.66

3.465

V

Supply voltage

GND

0

0

V

Operating temperature range

T_use

-40

+85

°C

Load_R

9

10

11

kΩ

Output load

Load_C

9

10

11

pF

DC-cut capacitor *

Cc

0.01

μF

* DC-cut capacitor is not included in this TCXO. Please attach an external DC-cut capacitor to the out pin.

Parameter

Symbol

(Vcc=2.66 to 3.465 V, GND=0.0 V, Load=10 kΩ // 10 pF, T_use=+25°C)

[ 4 ] Frequency characteristics

fo

Min.

-

Specifications

Typ.

19.2

Max.

-

MHz

Frequency tolerance

f_tol

-0.5

-

+0.5

x10⁻⁶

Frequency tolerance *1

f_tol

-1.5

-

+1.5

x10⁻⁶

fo-Tc

-0.5

-

+0.5

x10⁻⁶

Parameter

Output Frequency

Frequency / temperature

characteristics

Frequency / load coefficient

Frequency / voltage coefficient

Symbol

fo-Load

fo-Vcc

-0.1

+0.1

-0.1

+0.1

-0.5

+0.5

Frequency aging

f_age

-3.5

+3.5

*1 Include initial frequency tolerance and frequency deviation after reflow cycles.

*2 Measured in the elapse of 24 hours after reflow soldering.

*3 Vcc +/- 5% must be in operating supply voltage range (2.66 V to 3.465 V)

2

Unit

x10⁻⁶

x10⁻⁶

x10⁻⁶

x10⁻⁶

Conditions

T_use=+25°C+/-2°C

Before reflow

T_use=+25°C+/-2°C

After 2 reflows *2

T_use=-40°C to +85°C

(Reference to +25°C)

Load+/-10%

Vcc +/-5% *3

T_use = +25ºC first year

T_use = +25ºC 10 years

�(Vcc=2.66 to 3.465 V, GND=0.0 V, Load=10 kΩ // 10 pF, T_use=+25°C)

[ 5 ] Electrical characteristics

Parameter

Symbol

Current consumption

Output level

Symmetry

Icc

Vp-p

SYM

Start up time

t_sta

Harmonics

Phase noise

-

L(f)

Min.

0.8

45

Specifications

Typ.

50

Max.

1.5

55

-

-

2.0

ms

-

-

1.0

ms

-

-70

-98

-125

-144

-155

-160

-161

-5.0

-

dBc

3

Unit

Conditions

mA

V

%

Peak to peak voltage

GND level (DC-cut)

Until frequency has been

reached within +/-0.5x10⁻⁶ of

final freq.

Until output signal has been

reached min 90% of final

3rd harmonics

1Hz offset

10Hz offset

100Hz offset

dBc/Hz

1kHz offset

10kHz offset

100kHz offset

1MHz offset

�[ 6 ] Test circuit

1) Output Load : Load_R // Load_C = 10 kΩ // 10 pF

DC-cut

Capacitor

Supply

Voltage

Vcc

OUT

N.C.

GND

By-pass

Capacitor

Load_C

Test Point

Load_R

0.01 to

0.1 F

2) Current consumption

DC-cut

Capacitor

A

Supply

Voltage

Vcc

OUT

N.C.

GND

By-pass

Capacitor

Load_C

Load_R

0.01 to

0.1 F

3) Conditions

1. Oscilloscope: Impedance Min. 1MΩ

Input capacitance Max. 10 pF

Band width Min. 300 MHz

Impossible to measure both frequency and wave form at the same time.

(In case of using oscilloscope's amplifier output, possible to measure both at the same time.)

2. Load_C includes probe capacitance.

3. A capacitor (By-pass:0.01 to 0.1 μF) is placed between Vcc and GND,and closely to TCXO.

4. Use the current meter whose internal impedance value is small.

5. Power Supply

Impedance of power supply should be as low as possible.

6. GND pin should be connected to low impedance GND.

4

�[ 7 ] Outline drawing unit:mm

[ 8 ] Recommended foot print unit:mm

#3

#1

1.4

0.8±0.1

(0.38)

#1

#4

Connection

N.C. (*1)

GND

OUT

Vcc

For stable operation, please add a bypass

capacitor(0.01uF to 0.1uF) between Vcc and GND.

Please place it as close to TCXO as possible.

Material

Ceramics(Cavity)

Au plated nickel(Electric terminal)

Fe-Ni-Co(Lid)

Please do not place any pattern between

footprint pads.

[ 9 ] Reflow profile

Temperature[C]

300

TP

;+260C

+255C

250

;+217C

Tsmax;+200C

TL

200

150

Tsmin;+150C

tp;20sto40s

Avg. Ramp-up

3C/sMax.

tL

60sto150s

(+217Cover)

Ramp-down

6C/sMax.

ts

60sto180s

(+150Cto+200C)

100

50

Time +25CtoPeak

0

60

#2

*1) Please keep “N.C.” pin OPEN condition

or GND connection.

"N.C." pin doesn’t work as a ground pin.

#3

1.5±0.1

(0.55)

0.6±0.1

(0.75)

#2

C0.2

2.1

Pin #

1

2

3

4

0.5±0.1

#1

#3

1.0

#2

2.5±0.2

0.8

#4

2.0±0.2

#4

120 180 240 300 360 420 480 540 600 660 720 780

Time[s]

5

�[ 10 ] Packing information

1) Product number last 2 digits code(xx) description. The recommended code is "27"

X1G0054210303xx

Condition

Code

Any Q'ty vinyl bag(Tape cut)

01

Any Q'ty / Reel

11

250pcs / Reel

12

1000pcs / Reel

14

2000pcs / Reel

15

10000pcs / Reel

27

2) Taping specification

Subject to EIA-481 & IEC-60286

(1) Tape dimensions TE0804L

Material of the Carrier Tape : PS

Material of the Top Tape : PET+PE

unit:mm

2.30.1

(2) Reel dimensions

Center material

: PS

Material of the Reel : PS

User direction of feed

13.41. 0

φ 13.00. 2

9.41.0

2.0 0 . 5

6

φ 330.0 2 . 0

4.00.1

EPSON

EPSON

φ1.0+0.1/-0

1.150.1

0.250.005

2.80.1

4.00.1

φ 100.0

2.00.1

8.00.2

+0.1

-0

3.50.1

φ1.5

1.750.1

10 P: 400.1

�[ 11 ] Handling precautions

Prior to using this product, please carefully read the section entitled “Precautions” on our Web site for

instructions on how to handle and use the product properly to ensure optimal performance of the

product in your equipment. Before using the product under any conditions other than those specified

therein,

please consult with us to verify and confirm that the performance of the product will not be negatively

affected by use under such conditions.

In addition to the foregoing precautions, in order to avoid the deteriorating performance of the product,

we strongly recommend that you DO NOT use the product under ANY of the following conditions:

(1) Mounting the product on a board using water-soluble solder flux and using the product without

removing the residue of the flux completely from the board. The residue of such flux that is soluble

in water or water-soluble cleaning agent, especially the residues which contains active halogens,

will negatively affect the performance and reliability of the product.

(2) Using the product in any manner that will result in any shock or impact to the product.

(3) Using the product in places where the product is exposed to water, chemicals, organic solvent,

sunlight, dust, corrosive gasses, or other materials.

(4) Using the product in places where the product is exposed to static electricity or electromagnetic

waves.

(5) Applying ultrasonic cleaning without advance verification and confirmation that the product will

not be affected by such a cleaning process, because it may damage the crystal,

IC and/or metal line of the product.

(6) Touching the IC surface with tweezers or other hard materials directly.

(7) Using the product under any other conditions that may negatively affect the performance and/or

reliability of the product.

(8) Power supply with ripple may cause of incorrect operation or degradation of phase noise characteristics,

so please evaluate before use.

(9) Frequency aging is from environmental tests results to the expectation of the amount

of the frequency variation. This doesn't guarantee the product-life cycle.

(10)This components used underfill material at the back side of package.

After mounting this components on the board, there’s possibility of IC damage happened

by thermal expansion of adhesive, if adhesive will break into between TCXO and the board.

Please do not use adhesive, this will cause oscillation stop in case of IC damaged by adhesive.

(11)Supply voltage should be increased monotonically

In addidion,please do not power on at midpoint potential since that may cause malfunction or not output.

(12)This warranty shall be invalidated by any abuse,misuse,misapplication or improper installation

of the product.

Should any customer use the product in any manner contrary to the precautions and/or advice herein,

such use shall be done at the customer’s own risk.

7

�[Notice]

· This material is subject to change without notice.

· Any part of this material may not be reproduced or duplicated in any form or any means without

the written permission of SeJQo Epson.

· The information about applied data,circuitry, software, usage, etc. written in this material is intended

for reference only. SeJQo Epson does not assume any liability for the occurrence of customer damage

or infringing on any patent or copyright of a third party.

This material does not authorize the licensing for any patent or intellectual copyrights.

· When exporting the products or technology described in this material, you should comply with the applicable

export control laws and regulations and follow the procedures required by such laws and regulations.

· You are requested not to use the products (and any technical information furnished, if any)

for the development and/or manufacture of weapon of mass destruction or for other military purposes.

You are also requested that

you

would

the

who

maynot

usemake

the products

for such prohibited purposes.

· These products are intended for general use in electronic equipment. When using them in specific

applications that require extremely high reliability, such as the applications stated below,

you must obtain permission from SeJQo Epson in advance.

/ Space equipment (artificial satellites, rockets, etc.)

/ Transportation vehicles and related (automobiles, aircraft, trains, vessels, etc.)

/ Medical instruments to sustain life

/ Submarine transmitters

/ Power stations and related

/ Fire work equipment and security equipment

/ Traffic control equipment

/ And others requiring equivalent reliability.

· All brands or product names mentioned herein are trademarks and/or registered trademarks of their respective.

8

�