FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

Future Technology

Devices International Ltd.

FT602Q IC Datasheet

(FIFO to USB 3.0 UVC

Bridge)

The FT602 is a USB-to-FIFO interface to

SuperSpeed USB (USB 3.1 Gen 1) USB Video

Class (UVC) bridge chip with the following

advanced features:

Supports USB 3.1 GEN 1 Super Speed

(5Gbps) / USB 2.0 High Speed (480Mbps)

Supports USB Transfer Types:

Control/Bulk/Interrupt

Supports UVC version 1.1

Supports up to 4 video input channels on the

FIFO bus.

Supports 2 parallel slave FIFO bus protocols,

245 FIFO and Multi-channel FIFO mode, with a

data burst rate up to 400MB/s with 32 bit

parallel interface

Built-in 16kB FIFO data buffer RAM.

Built-in I2C

configuration

Supports multi voltage I/O: 1.8V, 2.5V and 3.3V.

Internal LDO 1.0V regulator.

Integrated power-on-reset circuit.

User programmable USB and UVC descriptors.

Industrial operating temperature range: -40 to 85⁰C.

Available in compact Pb-free QFN-76 RoHS compliant

package.

master

interface

for

video

device

Neither the whole nor any part of the information contained in, or the product described in this manual, may be adapted or reproduced

in any material or electronic form without the prior written consent of the copyright holder. This product and its documentation are

supplied on an as-is basis and no warranty as to their suitability for any particular purpose is either made or implied. Future Technology

Devices International Ltd will not accept any claim for damages howsoever arising as a result of use or failure of this product. Your

statutory rights are not affected. This product or any variant of it is not intended for use in any medical appliance, device or system in

which the failure of the product might reasonably be expected to result in personal injury. This document provides preliminary

information that may be subject to change without notice. No freedom to use patents or other intellectual property rights is implied by

the publication of this document. Future Technology Devices International Ltd, Unit 1, 2 Seaward Place, Centurion Business Park,

Glasgow G41 1HH United Kingdom. Scotland Registered Company Number: SC136640

Copyright © Future Technology Devices International Limited

1

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

1 Typical Applications

USB 3.1 Digital Video Camera Interface

USB 3.1 Digital Camera

Medical/Industrial imaging devices

USB 3.1 Instrumentation

1.1 Driver Support

USB Video Class Driver

Windows 10

Windows 8.1

Windows 7

Mac OS-X

Linux

1.2 Ordering Information

Part Number

Package

FT602Q-B-x

76 Pin QFN 0.4mm Pitch, body 9mm x 9mm x 0.9mm

Table 1.1 Device Part Numbers

Note: Packaging codes for x is:

-R: Taped and Reel, (VQFN in 3000 pieces per reel)

-T: Tray packing, (VQFN in 260 pieces per tray)

For example: FT602Q-B-R is 3000 QFN pieces in taped and reel packaging

1.3 USB Compliance

The FT602Q is compliant with the USB 3.1 Gen 1 specification. Please contact us for further details on USB

compliance.

Copyright © Future Technology Devices International Limited

2

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

2 Block Diagram

Figure 2.1 Block Diagram

For a description of each function please refer to Section 4.

Copyright © Future Technology Devices International Limited

3

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

Table of Contents

1

Typical Applications............................................................2

1.1

Driver Support ................................................................................ 2

1.2

Ordering Information ...................................................................... 2

1.3

USB Compliance .............................................................................. 2

2

Block Diagram ....................................................................3

3

Device Pin Out and Signal Description ................................6

3.1

Device Pin Out ................................................................................ 6

3.2

Device Pin Out Signal Description ................................................... 6

4

Function Description ........................................................10

4.1

Key Features and Function Description ......................................... 10

4.2

Multi-Channel FIFO mode Protocols .............................................. 11

4.3

245 Synchronous FIFO mode Protocols......................................... 13

4.4

FIFO Bus AC Timing ...................................................................... 13

4.5

Crystal Requirements.................................................................... 14

4.6

I2C Interface ................................................................................. 14

5

Devices Characteristics and Ratings .................................15

5.1

Absolute Maximum Ratings ........................................................... 15

5.2

ESD and Latch-up Specifications ................................................... 15

5.3

DC Characteristics ......................................................................... 16

5.3.1

DC Characteristics (Ambient Temperature = -40°C to +85°C) ........................... 16

5.3.2

DC Characteristics for I/O Interface ................................................................ 17

6

USB Power Configurations ................................................18

6.1

USB Bus-Powered Configuration .................................................. 18

6.2

Self-Powered Configuration .......................................................... 19

7

7.1

8

Application Example .........................................................20

FT602 Connect to FIFO Master Interface ...................................... 20

Package Parameters .........................................................22

8.1

QFN-76 Package Mechanical Dimensions ...................................... 22

8.2

QFN-76 Package Markings ............................................................ 23

8.3

Solder Reflow Profile .................................................................... 24

Copyright © Future Technology Devices International Limited

4

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

9

Clearance No.: FTDI#519

Contact Information .........................................................25

Appendix A – References ........................................................26

Document References ........................................................................... 26

Acronyms and Abbreviations................................................................. 26

Appendix B – List of Figures and Tables ..................................27

List of Figures ....................................................................................... 27

List of Tables......................................................................................... 27

Appendix C – Revision History ................................................28

Copyright © Future Technology Devices International Limited

5

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

3 Device Pin Out and Signal Description

3.1 Device Pin Out

Figure 3.1 FT602 Pin Out

3.2 Device Pin Out Signal Description

Pin Name

Description

Type

O

CLK

Parallel FIFO bus clock output pin to the FIFO bus master.

The Frequency can be configured as 66Mhz or 100Mhz for

both FIFO bus modes.

DATA_0

Parallel FIFO bus data input bit 0.

I

40

DATA_1

Parallel FIFO bus data input bit 1.

I

41

DATA_2

Parallel FIFO bus data input bit 2.

I

42

Copyright © Future Technology Devices International Limited

Pin No.

58

6

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

DATA_3

Parallel FIFO bus data input bit 3.

I

43

DATA_4

Parallel FIFO bus data input bit 4.

I

44

DATA_5

Parallel FIFO bus data input bit 5.

I

45

DATA_6

Parallel FIFO bus data input bit 6.

I

46

DATA_7

Parallel FIFO bus data input bit 7.

I

47

DATA_8

Parallel FIFO bus data I/O bit 8.

I/O

50

DATA_9

Parallel FIFO bus data I/O bit 9.

I/O

51

DATA_10

Parallel FIFO bus data I/O bit 10.

I/O

52

DATA_11

Parallel FIFO bus data I/O bit 11.

I/O

53

DATA_12

Parallel FIFO bus data I/O bit 12.

I/O

54

DATA_13

Parallel FIFO bus data I/O bit 13.

I/O

55

DATA_14

Parallel FIFO bus data I/O bit 14.

I/O

56

DATA_15

Parallel FIFO bus data I/O bit 15.

I/O

57

DATA_16

Parallel FIFO bus data input bit 16.

I

60

DATA_17

Parallel FIFO bus data input bit 17.

I

61

DATA_18

Parallel FIFO bus data input bit 18.

I

62

DATA_19

Parallel FIFO bus data input bit 19.

I

63

DATA_20

Parallel FIFO bus data input bit 20.

I

64

DATA_21

Parallel FIFO bus data input bit 21.

I

65

DATA_22

Parallel FIFO bus data input bit 22.

I

66

DATA_23

Parallel FIFO bus data input bit 23.

I

67

DATA_24

Parallel FIFO bus data input bit 24.

I

69

DATA_25

Parallel FIFO bus data input bit 25.

I

70

DATA_26

Parallel FIFO bus data input bit 26.

I

71

DATA_27

Parallel FIFO bus data input bit 27.

I

72

DATA_28

Parallel FIFO bus data input bit 28.

I

73

DATA_29

Parallel FIFO bus data input bit 29.

I

74

DATA_30

Parallel FIFO bus data input bit 30.

I

75

DATA_31

Parallel FIFO bus data input bit 31.

I

76

Copyright © Future Technology Devices International Limited

7

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

BE_0

Parallel FIFO bus byte enable I/O bit 0.

I/O

4

BE_1

Parallel FIFO bus byte enable I/O bit 1.

I/O

5

BE_2

Parallel FIFO bus byte enable I/O bit 2.

I/O

6

BE_3

Parallel FIFO bus byte enable I/O bit 3.

I/O

7

245 Synchronous FIFO mode: Transmit FIFO Empty output

signal. The signal indicates there is a minimum of 1 byte

of space available to write to. Only write to the FIFO when

this signal is logic 0.

O

TXE_N

Multi-Channel FIFO mode: Status Valid output signal

(optional).

O

RXF_N

245 Synchronous FIFO mode: Add external pull up in

normal operation.

Multi-Channel FIFO mode: Data Receive Acknowledge

output signal.

RESERVED1

Reserved. Add external pull up in normal operation.

I

8

9

10

245 Synchronous FIFO mode: Write Enable input signal.

Multi-Channel FIFO mode: Data Transaction Request input

signal.

I

WR_N

The signal is active low.

RESERVED2

Add external pull up in normal operation.

I

12

RESERVED3

Add external pull up in normal operation.

I

13

RESET_N

Chip Reset input, Active low.

I

15

INT_N

Interrupt input pin, active low.

I

16

RESERVED4

Reserved. Do not connect.

NC

19

SCL

I2C Serial Clock line

OD

17

SDA

I2C Serial Data line

OD

18

VBUS

USB BUS power detect pin. The input voltage should be

greater than 2.7V.

I

XI

Crystal input. This terminal is the crystal input for the

internal oscillator.

I

XO

Crystal Output. This terminal is the crystal output for the

internal oscillator.

O

DP

Hi-speed USB differential transceiver (positive)

I/O

23

DM

Hi-speed USB differential transceiver (negative)

I/O

25

Copyright © Future Technology Devices International Limited

11

37

21

22

8

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

I

RREF

PHY reference resistor input pin. Connect 1.6k Ω 1%

resistor to ground, provides reference voltage to USB2

PHY.

TODN

Super Speed USB transmitter differential pair (negative)

O

31

TODP

Super Speed USB transmitter differential pair (positive)

O

32

RIDN

Super Speed USB receiver differential pair (negative)

I

34

RIDP

Super Speed USB receiver differential pair (positive)

I

35

VCC33

+3.3V power input for chip and internal LDO.

PWR

20,24,3

8

DV10

+1.0V power output from internal LDO. Connecting to

VD10 and AVDD, with a 4.7uF cap to ground is

recommended.

VD10

+1.0V core voltage input.

VCCIO

Power input for I/O block, supports +2.5/+3.3V.

VDDA

27

O

39

PWR

3,30,33

,48

PWR

14,49,5

9,68

+3.3V power input for USB2.0 and USB3.0 PHYs.

PWR

28

AVDD

+1.0V power input for PLL.

PWR

2

GND

Ground

GND

1,26,

29,36

Table 3.1 Device pinout signal descriptions

Copyright © Future Technology Devices International Limited

9

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

4 Function Description

The FT602 is a high performance USB 3.1 UVC bridge with a FIFO interface. It is designed to transfer

uncompressed YUV422 video data from the 32bit FIFO interface to the USB 3.1 bus. It supports resolutions

and frame rates up to 1920x1080@60 frames per second. In FT600 multi-channel mode, up to 4 UVC

channels of video may be transported. It can be used in those applications which require high resolution

imaging devices.

The FIFO interface supports multi-voltage I/O of 1.8V, 2.5V or 3.3V and operating frequencies of 66MHz or

100MHz. At 100MHz operation only 2.5V or 3.3V I/O voltages are supported.

There are 2 different proprietary synchronous bus protocols supported; one FIFO bus protocol is called the

“Multi-Channel FIFO” bus protocol, also known as the FT600 FIFO protocol and the other is the “245

Synchronous FIFO” bus protocol. The latter being an extension of the interface introduced in the

FT232H/FT2232H devices.

*FIFO bus data lines are driven by the FIFO master, the FT602 only reads data from the FIFO master.

4.1 Key Features and Function Description

Functional Integration

The following features are integral to the IC design: FIFO protocol management, USB 3.1 (Gen 1) controller,

USB3.0 and USB2.0 PHYs, power management, clock generation, power-on-reset (POR) and LDO regulator.

USB 3.1 Protocol Controller

The USB 3.1 Protocol Controller manages the data stream from the device USB control endpoint. It handles

the USB protocol requests generated by the USB host controller and the commands for controlling the

functional parameters of the endpoint in accordance with the USB 3.1 specification. 32KB of burst buffers are

available in the protocol controller. These buffers are allocated to the UVC channels according to the required

video bandwidth. The factory programmed default is for a single UVC channel and all burst buffers are

allocated to the single channel. The default configuration may be customised by using the FT602 Chip

Configuration utility.

FIFO Management

This unit is used to manage all PIPE data or buffers in the FIFO memory; the data is sent or received through

the FIFO protocol layer. Through this block the FIFO memory can be allocated to each PIPE with any size of

memory as long as the total memory allocated to all PIPEs does not exceed the maximum FIFO memory size

which is 16KB. Additionally, the FIFO signals have a configurable high drive strength capability and can be set

to 18Ω, 25Ω, 35Ω and 50Ω.

Multi-Channel FIFO Bus protocol

The multi-Channel FIFO bus is a slave bus and is designed to handle Multi-Channel FIFO connectivity. The bus

protocol supports a total of 4 IN channels. CLK is the clock output to the FIFO bus master.

245 Synchronous FIFO Bus protocol

The 245 Synchronous FIFO bus is a slave bus with one IN FIFO channel supported by this bus protocol. CLK is

the clock output to the FIFO bus master.

FIFO Bus Clock Option

The device provides the following FIFO bus clock frequency option: 66MHz, 100MHz.

Copyright © Future Technology Devices International Limited

10

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

FIFO Buffer (16K bytes)

Data written into the FIFO is stored in the FIFO buffer and transferred to the USB endpoint buffers and

prepared for transmission to the USB host. The data is transferred to the host whenever the IN endpoint is

ready to receive data.

The FIFO and EPC burst buffers in the FT602 may be configured to correspond to the required throughput of

the UVC channel. The factory programmed default configuration is for a single UVC channel with the entire

16KB FIFO buffer allocated to the single IN channel. The default configuration may be customised by using the

FT602 Chip Configuration utility.

Internal LDO Regulator

The LDO regulator generates the +1.0V power supply for driving the internal core of the device. This supply is

not to be used for external devices and is meant for decoupling.

Reset Generator

The integrated Reset Generator module provides a reliable power-on reset to the device internal circuitry at

power up. The RESET_N input pin allows an external device to reset the FT602. This pin is an active low input.

Interrupt

One interrupt pin is provided; this pin can be used for I2C interrupt request or to wake up the FT602 device

from sleep mode.

I2C bus

The FT602 provides an I2C bus which operates as master, the transmission speed defaults to 800 Kb/s.

USB Video Class Device

The UVC device has configurations for SuperSpeed, Hi-speed, and full speed devices. The device is compliant

to UVC Version 1.1 and supports the following features.

Up to 14 customisable resolutions each in FS, HS, SS modes, up to UHD.

Up to 4 UVC sources simultaneously.

Up to 60fps of F-HD input.

4.2 Multi-Channel FIFO mode Protocols

The FIFO interface is a slave bus and is designed to handle multi-channel connectivity. The bus protocol

supports a total of 4 IN channels; each has a corresponding USB IN endpoint. CLK is the clock output from the

bus slave to the bus master.

The channel numbers denoted in this document as channels 1 to 4 are mapped to USB endpoint numbers 1 to

4. The USB IN endpoint in Channel 1 is denoted as USB IN channel 1.

Correspondingly, the FIFO IN is for data transmitted from the USB device to the host.

WR_N is the bus master to bus slave data transaction request signal, and it is active low.

RXF_N is the bus slave to bus master data receive acknowledge signal, and it is active low.

TXE_N (optional signal, the master can ignore this signal) is the bus slave to bus master FIFO idle status valid

signal, and it is active low.

DATA[31:0] is used as the 32-bit data bus during the data transfer phase. When the bus is in the idle state

DATA[31:16], DATA[7:0] and BE[3:0] are driven to logic”1” by the bus master, and DATA[15:8] is driven by

the bus slave to provide the FIFO status to the bus master. The lower nibble (DATA[11:8]) provides the 4 IN

channels FIFO status. They are all active low.

Copyright © Future Technology Devices International Limited

11

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

For example, at idle, DATA[8] is logic”0”, which indicates USB IN channel 1 FIFO space is empty and able to

receive data . The external bus master will start a transfer cycle by asserting WR_N based on the channel

FIFO status. The first cycle after WR_N is asserted is the command phase, followed by the data phase when

RXF_N is asserted. At the command phase, the bus master will send the channel number which it intends to

transfer data with on DATA[7:0] and the Write command on BE[3:0]. BE[3:0] = ‘h1 indicates a master write.

There may also be a required turn-a-round for DATA[31:0] and BE[3:0] after the command phase and at the

end of data transaction.

Table 4.1 shows Multi-Channel FIFO mode command phase master write and channel address setting.

Command Phase

FT602 Command

BE[3:0]

Channel Address DATA[7:0]

Master Write

0001

8’h1=Channel 1

8’h2=Channel 2

8’h3=Channel 3

8’h4=Channel 4

All other values are reserved and shall be ignored

Table 4.1 Multi-Channel FIFO mode Command phase

Note: The channels can be configured by using the FT602 Chip Configuration utility.

The waveform below shows a FT602 master write transaction for 14 bytes at channel 1 with the bus master

terminating the transaction. There are turn-a-round cycles for DATA[15:8] after the command phase and at

the end of the data transaction. The BE[3:0] shows that the lower 2 bytes in D3 are valid at the last word

strobe in this transaction.

Figure 4.1 Multi-Channel FIFO mode master write transaction 1

NOTE: There is no turnaround phase for BE pins as these remain inputs when the FIFO is being written to by

the master.

The waveform below shows a FT602 master write transaction where the FIFO at channel 1 uses all data space

first, the RXF_N reasserts when the FIFO data space is not available after D3. There are turn-a-round cycles

for DATA[15:8] after the command phase and at the end of the data transaction. The BE[3:0] shows that the

transaction is all word aligned, all 4 bytes in D3 are valid at the last word strobe in this transaction.

Copyright © Future Technology Devices International Limited

12

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

Figure 4.2 Multi-Channel FIFO mode master write transaction 2

4.3 245 Synchronous FIFO mode Protocols

This FT602 slave FIFO bus uses one IN FIFO channel while in this mode.

CLK is the clock output to the bus master; it can be configured as 66 MHz or 100 MHz

TXE_N is an output signal, Transmit FIFO Empty. It is active low and when active it indicates the Transmit

FIFO has space and it is ready to receive data from the FIFO master.

WR_N is an input signal, Write Enable. It is active low and when it is driven low by the bus master, the master

has write cycle access.

BE[3:0] is the byte enable signal. In bus master write operation, the bus master asserts the signal for the

valid bytes in a word strobe. Normally, all 4 bytes should be valid in a bus transaction except in the last word

strobe when the data transaction length is not aligned at a word boundary.

The waveform below shows 245 synchronous FIFO bus master write cycles.

Figure 4.3 245 Synchronous FIFO mode bus master write cycle

*In 245 Synchronous FIFO mode master write operation, if the bus master expects the data to be transferred

on the USB bus in a maximum possible packet length, it should write the data to the FIFO in a single bus

transaction.

4.4 FIFO Bus AC Timing

The FT602 device FIFO bus is a synchronous parallel bus. The CLK signal is generated by the device, with the

typical FIFO clock duty cycle of 50%. Both Multi-Channel and 245 synchronous FIFO modes’ worst case AC

timing are shown in

Figure 4.4 and Table 4.2.

In this figure, ‘Input Data’ includes all control signals and data lines driven by the FIFO master. ‘Output Data’

includes all control signals driven by the FIFO slave - FT602.

Copyright © Future Technology Devices International Limited

13

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

CLK

T1

T2

T4

T3

Output Data

Input Data

Figure 4.4 FIFO Bus AC timing diagram

Time

Description

Minimum

Maximum

Unit

T1

Slave Drive Data Set Up Time

3.0

-

ns

T2

Slave Drive Data Hold Time

3.5

-

ns

T3

Master Drive Data Set Up Time

1

-

ns

T4

Master Drive Date Hold Time

4.8

-

ns

Table 4.2 FIFO Bus AC timing

4.5 Crystal Requirements

The FT602 device requires an external clock source to control the internal circuitry.

The recommended parameters for the crystal are: 30MHz ±20ppm Crystal 18pF 50 Ohm -40°C ~ 85°C.

The crystal should be connected across the XI and XO pins.

Note: Replacing the crystal with an oscillator or other clock source by tying XO to GND is not supported

4.6 I2C Interface

The I2C master supports 3 operating frequencies, 800 kHz, 400 kHz and 100 kHz. The frequency may be set

through the FT602 configuration utility. The I2C master issues repeated start for read operations and it does

not support arbitration and clock stretching.

I2C commands are issued by FT602 under the following conditions:

1. FT602 defined commands to convey video resolution selection and start of streaming

2. UVC command (camera and processing unit) pass through to I2C slave device

3. Side-band pass through (opaque data) by user supplied host application via configuration interface.

Slave device initiated communication can be retrieved

AN_434_FT602_UVC_Bus_Master_Sample describes the I2C slave register map.

Copyright © Future Technology Devices International Limited

14

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

5 Devices Characteristics and Ratings

5.1 Absolute Maximum Ratings

The absolute maximum ratings for the FT602 devices are as follows. These are in accordance with the

Absolute Maximum Rating System (IEC 60134). Exceeding these may cause permanent damage to the device.

Parameter

Value

Unit

Storage Temperature

-65°C to 150°C

Degrees C

Ambient Operating Temperature (Power Applied)

-40°C to 85°C

Degrees C

VCC33/VDDA Supply Voltage

-0.3 to +4.6

V

VCCIO Supply Voltage

-0.3 to +4.0

V

VD10 Core Supply Voltage

-0.5 to +1.4

V

AVDD PLL Supply Voltage

-0.5 to +1.4

V

IOs DC Input Voltage

-0.5 to +VCCIO+0.5

V

Table 5.1 Absolute Maximum Ratings

5.2 ESD and Latch-up Specifications

Description

Human Body Mode

(HBM)

Machine mode

(MM)

Charged Device

Reference

JEDEC EIA/JESD22- A114B, Class 2

JEDEC EIA/JESD22- A115A, Class B

Mode (CDM)

JEDEC EIA/ JESD22-C101D, Class-III

Latch-up

JESD78, Trigger Class-II

Min

Typical

Max

Units

-

±2kV

-

kV

-

±200V

-

V

-

±500V

-

V

-

±200mA

-

mA

Table 5.2 ESD and Latch-Up Specifications

Copyright © Future Technology Devices International Limited

15

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

5.3 DC Characteristics

5.3.1 DC Characteristics (Ambient Temperature = -40°C to +85°C)

Parameter

Description

Min

Typical

Max

Units

Conditions

VCC33/VDDA

VCC Operating Supply

Voltage

3.0

3.3

3.6

V

VCCIO_1

VCCIO Operating

Supply Voltage

3.0

3.3

3.6

V

VCCIO=3.3V

VCCIO_2

VCCIO Operating

Supply Voltage

2.3

2.5

2.7

V

VCCIO=2.5V

VCCIO_3

VCCIO Operating

Supply Voltage

1.65

1.8

1.95

V

VCCIO=1.8V

VD10/AVDD

Core/PLL Operating

Supply Voltage

0.9

1.0

1.1

V

Icc_1

VCC Operating Supply

Current

-

85

-

mA

Idle, SuperSpeed

Icc_2

VCC Operating Supply

Current

-

69

-

mA

Idle, High Speed

Icc_3

VCC Operating Supply

Current

-

185

-

mA

FHD 1080P@60fps

Output

Icc_3

VCC Operating Supply

Current

-

4

-

mA

USB Suspend

Iccio_1

VCCIO Operating

Supply Current

-

4.5

-

mA

No data transfer

Iccio_2

VCCIO Operating

Supply Current

9.5

mA

Data transfer

Iccio_3

VCCIO Operating

Supply Current

70

μA

USB Suspend

Table 5.3 DC Characteristics

Copyright © Future Technology Devices International Limited

16

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

5.3.2 DC Characteristics for I/O Interface

Parameter

Description

Min

Typical

Max

Units

3.0

3.3

3.6

V

Normal

Operation

2.3

2.5

2.7

V

Normal

Operation

VCCIO_1.8V

1.65

1.8

1.95

V

Normal

Operation

VIH

VCCIO*0

.7

-

-

V

Normal

Operation

VIL

-

-

VCCI

O*0.

3

V

Normal

Operation

Input/output Leakage

-10

-

10

uA

Without pullup/down

Input pull-up/pull down

resistance

30

50

75

KΩ

Vout=0~

VCCIO

Iout(VCCIO=3.3V)

Output drive strength

10

-

-

mA

Total current

Iout(VCCIO=2.5V)

Output drive strength

9.4

-

-

mA

Total current

-

-

2.0

pF

VCCIO_3.3V

VCCIO_2.5V

Iin/Iout(3.3V)

Rpu/Rpd

Cp

VCCIO Operating

Supply Voltage

Pin Capacitance

Conditions

Table 5.4 DC Characteristics for I/O Interface (Except USB PHY pins)

Copyright © Future Technology Devices International Limited

17

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

6 USB Power Configurations

The following sections illustrate possible USB power configurations for the FT602. The illustrations have

omitted pin numbers for ease of understanding.

6.1 USB Bus-Powered Configuration

Note: The reference designs here are for USB 3.1 Standard B or Micro-B connectors.

Figure 6.1 Bus-Powered Configuration-1.8V/2.5V I/O

Figure 6.1 illustrate the FT602 in a typical USB bus powered design configuration. The FT602 device gets its

power(VCC33) from the USB bus via an external LDO(LDO_3V3) stepping the voltage down to +3.3V. Another

external LDO stepping the voltage down to +2.5V for supplying the VCCIO power, connect VCCIO pins to

same LDO(LDO_3V3) if VCCIO is configured to 3.3V.

A ferrite bead is connected in series with the USB power supply to reduce EMI noise from the FT602 and

associated circuitry being radiated down the USB cable to the USB host. The value of the Ferrite Bead

depends on the total current drawn by the application.

Copyright © Future Technology Devices International Limited

18

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

6.2 Self-Powered Configuration

Figure 6.2 Self-Powered Configuration

Figure 6.2 illustrates the FT602 in a typical USB self-powered configuration. The FT602 device gets its power

from its own power supply, VCC33 and VCCIO, and does not draw current from the USB bus.

The basic rules for USB self-powered devices are as follows –

i)

A self-powered device should not force current down the USB bus when the USB host or hub controller

is powered down.

ii) A self-powered device can use as much current as it needs during normal operation and USB suspend

as it has its own power supply.

iii) A self-powered device can be used with any USB host, a bus powered USB hub or a self-powered USB

hub.

Copyright © Future Technology Devices International Limited

19

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

7 Application Example

The following sections illustrate the typical application of the FT602 UVC bridge device. The illustrations have

omitted pin numbers for ease of understanding.

A typical example of the FT602 UVC Bridge to FIFO Master Interface is illustrated in Figure 7.1 and Figure 7.2.

7.1 FT602 Connect to FIFO Master Interface

Figure 7.1 FT602 Connect to FIFO Master Interface (Multi-Channel FIFO Mode)

Copyright © Future Technology Devices International Limited

20

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

Figure 7.2 FT602 Connect to FIFO Master Interface (245 Synchronous FIFO Mode)

Note: I2C bus can connect to others I2C slave device, e.g. I2C interface EEPROM.

Copyright © Future Technology Devices International Limited

21

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

8 Package Parameters

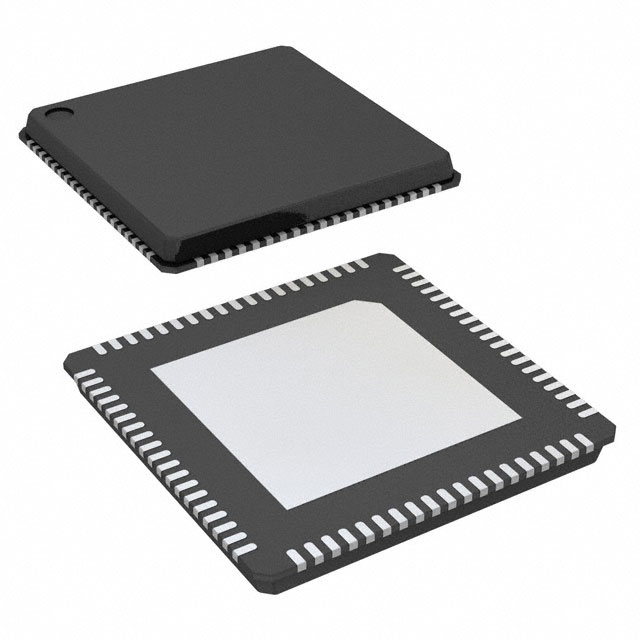

The FT602 is available in a QFN-76 package.

8.1 QFN-76 Package Mechanical Dimensions

Figure 8.1 QFN-76 Package Dimensions

The FT602Q is supplied in a RoHS compliant leadless QFN-76 package. The package is lead ( Pb ) free, and

uses a ‘green’ compound. The package is fully compliant with European Union directive 2002/95/EC.

This package is nominally 9.0mm x 9.0mm body. The solder pads are on a 0.40mm pitch. The above

mechanical drawing shows the QFN-76 package.

The centre pad on the base of the FT602Q is internally connected to GND, the PCB should connect to ground

and not have signal tracking on the same layer as chip in this area.

Copyright © Future Technology Devices International Limited

22

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

8.2 QFN-76 Package Markings

76

1

FTDI

XXXXXXXXXX

FT602Q

YYWW-B

Line 1 – FTDI Logo

Line 2 – Wafer Lot Number

Line 3 – FTDI Part Number

Line 4 – Date Code, Revision

Figure 8.2 QFN-76 Package Markings

Notes:

1.

2.

3.

4.

YYWW = Date Code, where YY is year and WW is week number

Marking alignment should be centre justified

Laser Marking should be used

All marking dimensions should be marked proportionally. Marking font should be using Greatek

standard font (Roman Simplex)

Copyright © Future Technology Devices International Limited

23

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

8.3 Solder Reflow Profile

Figure 8.3 Solder Reflow Profile

Copyright © Future Technology Devices International Limited

24

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

9 Contact Information

Head Office – Glasgow, UK

Branch Office – Tigard, Oregon, USA

Future Technology Devices International Limited

Unit 1, 2 Seaward Place, Centurion Business Park

Glasgow G41 1HH

United Kingdom

Tel: +44 (0) 141 429 2777

Fax: +44 (0) 141 429 2758

Future Technology Devices International Limited (USA)

7130 SW Fir Loop

Tigard, OR 97223-8160

USA

Tel: +1 (503) 547 0988

Fax: +1 (503) 547 0987

E-mail (Sales)

E-mail (Support)

E-mail (General Enquiries)

E-mail (Sales)

E-mail (Support)

E-mail (General Enquiries)

sales1@ftdichip.com

support1@ftdichip.com

admin1@ftdichip.com

us.sales@ftdichip.com

us.support@ftdichip.com

us.admin@ftdichip.com

Branch Office – Taipei, Taiwan

Branch Office – Shanghai, China

Future Technology Devices International Limited (Taiwan)

2F, No. 516, Sec. 1, NeiHu Road

Taipei 114

Taiwan, R.O.C.

Tel: +886 (0) 2 8797 1330

Fax: +886 (0) 2 8751 9737

Future Technology Devices International Limited (China)

Room 1103, No. 666 West Huaihai Road,

Shanghai, 200052

China

Tel: +86 21 62351596

Fax: +86 21 62351595

E-mail (Sales)

E-mail (Support)

E-mail (General Enquiries)

E-mail (Sales)

E-mail (Support)

E-mail (General Enquiries)

tw.sales1@ftdichip.com

tw.support1@ftdichip.com

tw.admin1@ftdichip.com

cn.sales@ftdichip.com

cn.support@ftdichip.com

cn.admin@ftdichip.com

Web Site

http://ftdichip.com

Distributor and Sales Representatives

Please visit the Sales Network page of the FTDI Web site for the contact details of our distributor(s) and sales

representative(s) in your country.

System and equipment manufacturers and designers are responsible to ensure that their systems, and any Future Technology Devices

International Ltd (FTDI) devices incorporated in their systems, meet all applicable safety, regulatory and system-level performance

requirements. All application-related information in this document (including application descriptions, suggested FTDI devices and other

materials) is provided for reference only. While FTDI has taken care to assure it is accurate, this information is subject to customer

confirmation, and FTDI disclaims all liability for system designs and for any applications assistance provided by FTDI. Use of FTDI devices in

life support and/or safety applications is entirely at the user’s risk, and the user agrees to defend, indemnify and hold har mless FTDI from

any and all damages, claims, suits or expense resulting from such use. This document is subject to change without notice. No freedom to use

patents or other intellectual property rights is implied by the publication of this document. Neither the whole nor any part of the information

contained in, or the product described in this document, may be adapted or reproduced in any material or electronic form without the prior

written consent of the copyright holder. Future Technology Devices International Ltd, Unit 1, 2 Seaward Place, Centurion Business Park,

Glasgow G41 1HH, United Kingdom. Scotland Registered Company Number: SC136640

Copyright © Future Technology Devices International Limited

25

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

Appendix A – References

Document References

Useful Application Notes

AN_434_FT602_UVC_Bus_Master_Sample

Modules Datasheet

DS_UMFT602EVM module datasheet

Utility

FT602ChipConfigurationProg

Acronyms and Abbreviations

Terms

Description

ESD

Electro Static Discharge

FIFO

First In First Out

FPGA

Field Programmable Gate Array

I2C

Inter-Integrated Circuit

LDO

Low Drop Out regulator

QFN

Quad Flat Non-leaded package

RoHS

USB

VQFN

Restriction of Hazardous Substances Directive

Universal Serial Bus

Very Thin Quad Flat Non-Leaded Package

Copyright © Future Technology Devices International Limited

26

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

Appendix B – List of Figures and Tables

List of Figures

Figure 2.1 Block Diagram .................................................................................................................... 3

Figure 3.1 FT602 Pin Out ..................................................................................................................... 6

Figure 4.1 Multi-Channel FIFO mode master write transaction 1 .............................................................. 12

Figure 4.2 Multi-Channel FIFO mode master write transaction 2 .............................................................. 13

Figure 4.3 245 Synchronous FIFO mode bus master write cycle ............................................................... 13

Figure 4.4 FIFO Bus AC timing diagram ................................................................................................ 14

Figure 6.1 Bus-Powered Configuration-1.8V/2.5V I/O ............................................................................. 18

Figure 6.2 Self-Powered Configuration .................................................................................................. 19

Figure 7.1 FT602 Connect to FIFO Master Interface (Multi-Channel FIFO Mode) ......................................... 20

Figure 7.2 FT602 Connect to FIFO Master Interface (245 Synchronous FIFO Mode) .................................... 21

Figure 8.1 QFN-76 Package Dimensions ............................................................................................... 22

Figure 8.2 QFN-76 Package Markings .................................................................................................. 23

List of Tables

Table 1.1 Device Part Numbers............................................................................................................. 2

Table 3.1 Device pinout signal descriptions ............................................................................................ 9

Table 4.1 Multi-Channel FIFO mode Command phase ............................................................................. 12

Table 4.2 FIFO Bus AC timing .............................................................................................................. 14

Table 5.1 Absolute Maximum Ratings ................................................................................................... 15

Table 5.2 ESD and Latch-Up Specifications ........................................................................................... 15

Table 5.3 DC Characteristics ............................................................................................................... 16

Table 5.4 DC Characteristics for I/O Interface (Except USB PHY pins) ....................................................... 17

Copyright © Future Technology Devices International Limited

27

�FT602Q IC Datasheet

Version 1.4

Document No.: FT001389

Clearance No.: FTDI#519

Appendix C – Revision History

Document Title:

FT602Q IC Datasheet

Document Reference No.:

FT001389

Clearance No.:

FTDI#519

Product Page:

http://www.ftdichip.com/FTProducts.htm

Document Feedback:

Send Feedback

Revision

Changes

Date

Version 1.0

Initial Release

2017-02-21

Version 1.1

Updated Release (Data_8 to

Data_15 change to I/O from

input in section 3.2

2017-05-05

Corrected section 4.2 Multichannel mode descriptions)

Version 1.2

Table 4.2 has been updated with

new timing values

2017-11-03

Version 1.3

Updated the Part Number in

section 1.2; Updated section1.3

and Figure 2.1; Updated package

marking in section 8.2

2017-12-11

Version 1.4

Updated Figure 4.4 and figure

references throughout the

document.

2019-11-29

Copyright © Future Technology Devices International Limited

28

�