SC2599

Low Voltage DDR

Termination Regulator

POWER MANAGEMENT

Features

Description

The SC2599 is designed to meet the latest JEDEC specification for low power DDR3 and DDR4, while also supporting DDR and DDR2. The SC2599 regulates up to + 3A for

VTT and up to + 40mA for VREF.

Input to linear regulator (VIN): 1.0V to 3.6V

Output (VTT): 0.5V to 1.8V

Bias Voltage (VDD): 2.35V to 3.6V

Up to 3A sink or source from VTT for DDR through

DDR4

+ 1% over temperature (with respect to VDDQ/2, including internal resistor divider variation) VREF and

VTT

Logic-level enable input

Built in soft-start

Thermal shutdown with auto-restart

Over current protection

Minimal output capacitance

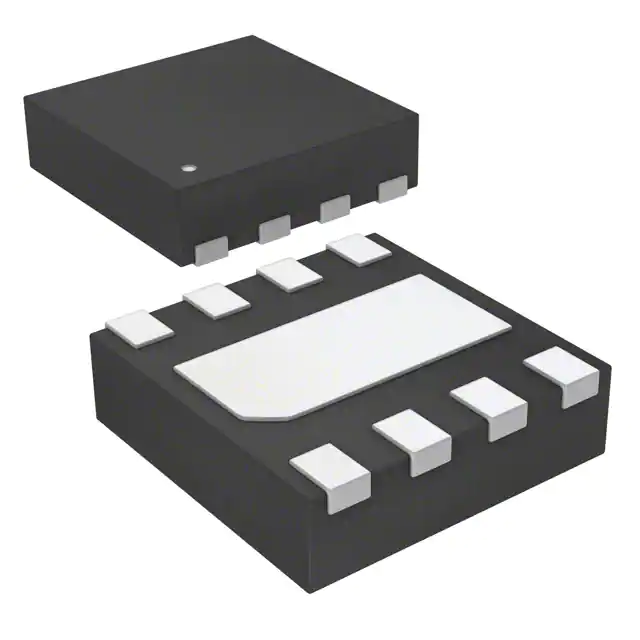

Package: MLPD8 - 2mm x 2mm x 0.6mm

Applications

The SC2599 also provides an accuracy of +1% over temperature (which takes into account the internal resistor

divider) for VREF and VTT for the memory controller and

DRAM.

SC2599 protection features include thermal shutdown

with auto-restart for VTT and over-current limit for both

VTT and VREF.

Under-Voltage-Lock-Out circuits are included to ensure

that the output is off when the bias voltage falls below its

threshold, and that the part behaves elegantly in powerup or power-down.

The low external parts count combined with industry

leading specifications make SC2599 an attractive solution

for DDR through DDR4 termination.

DDR Memory Termination

Typical Application Circuit

C VDD

C IN

1μF

2 x 1 0μF

VDDQ

VDD

V IN

VDDQ

VTT

VTTS

C VTT

VREF

EN

PAD

GND

C V R E F (1 )

3 x1 0 μF

0 .1 μF

Note:

(1) This component is optional.

Rev. 2.0

1

�SC2599

Pin Configuration

VDD

1

V IN

2

VTT

3

GND

4

Ordering Information

T h e rm a l

PAD

8

VDDQ

7

VREF

6

VTTS

5

EN

Device

Package

SC2599ULTRC(1)(2)

MLPD8

SC2599EVB

Evaluation Board

Notes:

(1) Available in tape and reel only. A reel contains 3000 devices.

(2) Lead-free packaging only. Device is WEEE and RoHS compliant

and halogen-free.

MLPD8 - 2mm x 2mm x 0.6mm

Marking Information

C 99

Yw

nnn = Part Number (Example: C99)

Yw = Datecode

2

�SC2599

Absolute Maximum Ratings

Thermal Information

VIN (V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to 4.3

Thermal Resistance, Junction to Ambient(2) (°C/W) . . . 57

VDD to GND (V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to 4.3

Thermal Resistance, Junction to Ambient(3) (°C/W) . . . 45

VTT to GND (V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to VDD

Maximum Junction Temperature (°C) . . . . . . . . . . . . . . +150

EN (V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to 6.0

Storage Temperature Range (°C) . . . . . . . . . . . . -65 to +150

Other pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to 4.3

Peak IR Reflow Temperature (10s to 30s) (°C) . . . . . . . +260

(1)

2.5

(1)

1

ESD Protection Level (HBM) (kV) . . . . . . . . . . .

ESD Protection Level (CDM) (kV). . . . . . . . . . .

Exceeding the above specifications may result in permanent damage to the device or device malfunction. Operation outside of the parameters

specified in the Electrical Characteristics section is not recommended.

Notes:

(1) HBM: tested according to ANSI/ESDA/JEDEC JS-001. CDM: tested according to JESD-C101E.

(2) Calculated from package in still air, mounted to 3 x 4.5 (in), 4 layer FR4 PCB with thermal vias under the exposed pad per JESD51 standards.

(3) Based upon lab measurement on EVB board: 3 x 2 (in), 4 layer FR4 PCB with thermal vias under the exposed pad.

Electrical Characteristics

Unless otherwise noted TJ = -40 to +125°C, VIN = 1.2V, VDD = 3.3V . Typical values are at TA = 25°C.

Parameter

Symbol

Conditions

Min

Typ

Max

Units

Input Supplies

LDO Supply Voltage

VIN

1

3.6

V

VDD Supply Voltage

VDD

2.35

3.6

V

Measured at VDD pin, rising edge

2.0

2.25

Measured at VDD pin, falling edge

1.95

2.15

VDD UVLO Threshold

V

VDD UVLO Hysteresis

0.1

Quiescent Current for VDD

IQ

Shutdown Current for VDD

IQSD

V

Load =0A, EN = High, VVDDQ > 1V

415

700

μA

Load =0A, EN = Low, VVDDQ > 1V, IREF = 0A

160

400

μA

Load =0A, EN = Low, VVDDQ = 0V, IREF = 0A

100

160

μA

Quiescent Current for VIN

IIN

Load =0A, EN = High

3

30

μA

Shutdown Current for VIN

IINSD

Load =0A, EN = Low

3

20

μA

0.5

1.8

V

-1

+1

%

VTT Output

Output Voltage Range

Output Voltage Tolerance with

respect to VDDQ/2

VTT

Load = 0A, VTT = 0.5V to 1.8V

3

�SC2599

Electrical Characteristics (continued)

Parameter

Load Regulation

Symbol

Conditions

Min

Typ

Max

Units

-2A < Load < 2A

-25

+25

mV

High-Side MOSFET (source), Load = 0.1A

40

100

150

Low-Side MOSFET (sink), Load = 0.1A

50

140

300

On-Resistance

Discharge MOSFET On-Resistance

mΩ

EN = Low

8

Ω

Reference Input/Output

VDDQ Voltage Range

1

3.6

V

VDDQ Input Bias Current

0

10

μA

-1

1

%

Tolerance with respect to VDDQ/2

Load = 0A, VREF = 0.5V to 1.8V

VREF Source Current Limit

40

VREF Sink Current Limit

- 40

mA

Protection

Thermal Shutdown Threshold

160

0

Thermal Restart Hysteresis

20

0

4.3

A

40

μs

Output Current Limit Threshold

Ambient Temperature: 25 0C

3.7

C

C

Soft-Start

VTT Soft-Start Time

From EN = High to V TT = 90% VREF

Logic

EN = High

1.7

EN Logic Threshold

V

EN = Low

EN Input Current

0.3

-1

1

μA

4

�SC2599

Block Diagram

T h e rm a l

S h u td o w n

VDD

1

EN

5

VDDQ

8

U VLO

2

V IN

3

VTT

4

GND

6

VTTS

S o ft-S ta rt

R

+

R

D R IV E R

L O G IC

-

+

-

EN\

VREF

7

Pin Descriptions

Pin #

Pin Name

Pin Function

1

VDD

Input bias voltage — 2.35V to 3.6V . Connect a ceramic capacitor from this pin to GND.

2

VIN

LDO input range — 1V to 3.6V. Connect ceramic capacitors from this pin to GND.

3

VTT

Output of the linear regulator. Connect ceramic capacitors from this pin to GND.

4

GND

Ground reference for the IC.

5

EN

Logic input to enable or disable the VTT output. If EN pin is grounded to shut down the linear regulator,

VREF remains active.

6

VTTS

VTT output sense input. Connect VTTS to the output at the output capacitor to implement remote sense.

7

VREF

The reference output, equal to one half of VDDQ. Connect a 100nF capacitor from this pin to GND.

8

VDDQ

External reference input; range 1V to 3.6V.

PAD

GND

Thermal pad. This pad must be connected to GND. For optimal heat sinking, connect to the GND plane using multiple vias.

5

�SC2599

Detailed Application Circuit

C1

4 GND

PAD

5 EN

EN

C2

C3

VTT

VTT 3

V IN 2

C4

6 VTTS

VDD 1

7 VREF

VDDQ 8

C7

V IN

3 .3 V

C6

VREF

C5

R1

100 O hm

C8

Bill Of Materials

Reference Designator

Description

Value

Part Number

Manufacture

C1, C2, C3, C4, C5,

Ceramic Capacitor

10uF/0805/X7R

GRM21BR71A106KE51

Murata

C6

Ceramic Capacitor

1uF/0603/X7R

GRM188R71A105KA61D

Murata

C7, C8

Ceramic Capacitor

0.1uF/0603/X7R

GRM188R71H104KA93D

Murata

6

�SC2599

Typical Characteristics

Characteristics in this section are based upon the detailed application circuit on page 6.

0.6V VREF Regulation Sink/Source

0.6V VTT Regulation Sink/Source

VIN = 1.2V, VDDQ = 1.2V, VDD = 3.3V

VIN = 1.2V, VDDQ = 1.2V, VDD = 3.3V

0.620

Sink

Source

0.610

VREF Regulation (V)

VTT Regulation (V)

Sink

250C

850C

-400C

0.600

-3

-2

0.580

0.580

1

2

-0.05 -0.04 -0.03 -0.02 -0.01

3

VTT Current (A)

VREF Regulation (V)

VTT Regulation (V)

Sink

Source

0.760

250C

850C

-400C

0.750

Source

250C

850C

-400C

0.730

0

1

2

3

0

0.01

0.02

0.03

0.04

0.05

VREF Current (A)

0.9V VREF Regulation Sink/Source

VIN = 1.8V, VDDQ = 1.8V, VDD = 3.3V

VIN = 1.8V, VDDQ = 1.8V, VDD = 3.3V

Sink

Source

VREF Regulation (V)

0.920

VTT Regulation (V)

0.770

-0.05 -0.04 -0.03 -0.02 -0.01

0.9V VTT Regulation Sink/Source

250C

850C

-400C

0.910

0.900

0.880

0

VTT Current (A)

0.920

Source

250C

850C

-400C

0.910

0.900

0.890

0.890

-1

0.05

0.740

VTT Current (A)

-2

0.04

0.750

0.730

-3

0.03

0.760

0.740

Sink

0.02

VIN = 1.5V, VDDQ = 1.5V, VDD = 3.3V

0.770

-1

0.01

0.75V VREF Regulation Sink/Source

VIN = 1.5V, VDDQ = 1.5V, VDD = 3.3V

-2

0

VREF Current (A)

0.75V VTT Regulation Sink/Source

-3

250C

850C

-400C

0.600

0.590

0

Source

0.610

0.590

-1

Sink

0.620

0.880

1

2

3

-0.05 -0.04 -0.03 -0.02 -0.01

0

0.01

0.02

0.03

0.04

0.05

VREF Current (A)

7

�SC2599

Typical Characteristics

Characteristics in this section are based upon the detailed application circuit on page 6.

Start-Up and Shutdown Using EN

Shutdown Using VDD

VREF = 40mA, VTT = 1A

VIN = 1.2V, VDD = 3.3V, VREF = 0A, VTT = 0A

VIN = VDDQ (200mV/div)

EN (2V/div)

VDDQ (200mV/div)

VTT (200mV/div)

VDD (1V/div)

VREF (200mV/div)

VTT (200mV/div)

VREF (200mV/div)

500us/div

5ms/div

Start-Up Using VDDQ

Start-Up Using VDD

VREF = 0A, VTT = 0A, VIN = 1.2V

VREF = 40mA, VTT = 1A

VDDQ (200mV/div)

VIN = VDDQ (200mV/div)

VDD (1V/div)

VDD (1V/div)

VTT (200mV/div)

VTT (200mV/div)

VREF (200mV/div)

VREF (200mV/div)

2ms/div

Load Transient Source and Sink: -1A to +1A

1ms/div

Current Limit with VTT Shorted

VDDQ = 1.2V, VIN = 1.2V, VDD = 3.3V

VDDQ = 1.2V, VIN = 1.2V, VDD = 3.3V

Input Current (1A/div)

VTT (20mV/div)

7mV

VTT (100mV/div)

Source Current Load (1A/div)

Sink Current Load (1A/div)

200us/div

10ms/div

8

�SC2599

Applications Information

VTT Output

VTT starts to ramp up when EN and VDD meet their startup

thresholds. SC2599 regulates VTT to the voltage at VREF

and can support up to 3A for sourcing or sinking

capability.

theory tells us that the input capacitance can be chosen to

be half of the output capacitance.

To achieve tight regulation and fast dynamic response at

VTT, it is recommended to connect the VTTS sense signal

to VTT at the ceramic output capacitors.

Ceramic capacitors have a capacitance value that degrades

with temperature, DC and AC bias, and their chemistry.

Usually, ceramic capacitors need to be derated by 50%

when operated at their rated DC voltage. Therefore, it is

recommended to use capacitors with a voltage rating of

6.3V or higher for 3.3V or lower applications.

VREF Output

Stability and VTT Capacitor

VREF starts to ramp up when VDD meets the UVLO threshold. SC2599 regulates VREF to one-half of VDDQ. To

reduce the component count and provide a good accuracy reference for VTT, SC2599 includes an internal resistor

divider network. SC2599 is capable of sinking or sourcing

up to 60mA at VREF. To reduce the component count

further, SC2599 does not require the user to have a local

ceramic capacitor at the VREF pin - but it is recommended

to layout with a capacitor place holder.

Figure 1 shows the small signal model for the sourcing

current loop stability. The low frequency pole is formed

by COUT and RL. Since this pole depends on those variables,

it is recommended to have a minimum of 10uF COUT for

stable condition. SC2599 has an internal compensation

network to ensure the stability as the load changes. Figure

2 shows the bode plot with the crossover frequency at

around 0.8MHz and 36 degree phase margin. Another

parameter effecting to the loop stability is parasitic inductance in PCB layout and output capacitor ESL. The gain

plot shows that a peaking rising after the crossing frequency is due to ESL effect. Minimizing the ESL reduces

this peaking.

EN Input

The EN pin is used to enable and disable VTT only; it does

not control VREF. When EN is pulled low, the VTT output is

discharged internally to ground through an 8Ω FET.

V IN

Protection

SC2599 has thermal protection with auto-restart. When

the junction temperature is above the thermal shutdown

threshold (160 OC), SC2599 disables VTT, while VREF

remains present. When the junction temperature drops

below the hysteretic window, typically at 140OC, SC2599

will be enabled again.

SC2599 has a built-in current limit feature to prevent

damage to the sink and source FETs. If VTT is shorted to

VDD or ground, SC2599 will sink or source current up to

the current limit threshold.

Input Capacitor

The primary purpose of input capacitance is to provide the

charge to the VTT output capacitor when there is a load

transient at VTT. In the typical application circuit, VDDQ

equals VIN, and VTT equals one-half of VDDQ. As a result,

VTT

g m *V G S

+

VGS

C IN

+

C OUT

RL

VREF

ZC

Figure 1 — Small Signal Model

PCB Layout

The SC2599 requires minimal external components to

provide a VTT solution. Figure 3 shows the component

placement and layout for the application circuit on page

6. The thermal pad should be connected to the GND plane

using multiple vias.

9

�SC2599

P G N D on top and bottom layers

C3

V TT copper pour on top

and bottom layers

C2

C1

R oute V TT sense

trace on inner layer

C4

V IN copper pour on top

and/or bottom layer

C5

R1

C7

C8

C 4,C 5 show n located

on bottom side

R 1 show n located on

Thermal pad must connect to the

bottom side

GND plane using multiple vias.

C6

Figure 2 — Gain and Phase Bode Plot

Fc = 810KHz, PM = 36 degree at 1A Source

Figure 3 — Component Placement and Layout

Critical Layout Guidelines

C VTT

Bias and Reference Capacitors:

S in kin g C u rre n t L o o p

A 1μF capacitor must be placed as close as possible to the

IC and connected between pin 6 (VDD) and the ground

plane.

VTT

GND

QB

A 0.1μF capacitor must be placed as close as possible to

the IC and connected between pin 4 (VREF) and the

ground plane. The user has an option to add this capacitor to the circuit but it is recommended to layout with a

capacitor place holder.

V IN

C V IN

C VTT

VDDQ Reference Capacitor:

An R-C filter from the supply used for VDDQ consisting of

a 100 Ω resistor and a 0.1μF capacitor should be placed as

close as possible to the IC and connected between pin 5

(VDDQ) and the ground plane, as shown on page 6.

GND

S o u rcin g C u rre n t

Loop

QT

VTT

V IN

C V IN

VTT and VIN Capacitors:

Since SC2599 provides both sink and source capabilities,

the loop impedance through the input and VTT capacitors

plays an important role in circuit stability. Figure 4 shows

both sink and source current loops. Close attention to

board layout is needed to reduce ESL in these loops.

During a bode plot measurement for the sourcing current

loop, an injected small AC signal flows around the loop

from CIN to QT through CVTT and then returns to CVIN through

the ground plane. Therefore, it is recommended to keep

the CIN and CVTT capacitors as close as possible to reduce

Figure 4 — Small AC Signal Current Loops

the ESL impedance between them. Similarly in the sinking

current loop, an injected small AC signal flows from CVTT

through QB and then returns to C VTT through the GND

plane. Therefore, it is recommended to keep ESL small for

this loop. Balancing the ESL of those loops gives the best

case for stability.

10

�SC2599

Outline Drawing — MLPD8

11

�SC2599

Land Pattern — MLPD8

12

�SC2599

© Semtech 2015

All rights reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright

owner. The information presented in this document does not form part of any quotation or contract, is believed to be

accurate and reliable and may be changed without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license under patent or other industrial or intellectual property rights. Semtech assumes no responsibility or liability whatsoever for any failure or unexpected operation

resulting from misuse, neglect improper installation, repair or improper handling or unusual physical or electrical stress

including, but not limited to, exposure to parameters beyond the specified maximum ratings or operation outside the

specified range.

SEMTECH PRODUCTS ARE NOT DESIGNED, INTENDED, AUTHORIZED OR WARRANTED TO BE SUITABLE FOR USE IN LIFESUPPORT APPLICATIONS, DEVICES OR SYSTEMS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF SEMTECH PRODUCTS

IN SUCH APPLICATIONS IS UNDERSTOOD TO BE UNDERTAKEN SOLELY AT THE CUSTOMER’S OWN RISK. Should a customer

purchase or use Semtech products for any such unauthorized application, the customer shall indemnify and hold

Semtech and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs damages

and attorney fees which could arise.

Notice: All referenced brands, product names, service names and trademarks are the property of their respective

owners.

Contact Information

Semtech Corporation

Power Mangement Products Division

200 Flynn Road, Camarillo, CA 93012

Phone: (805) 498-2111 Fax: (805) 498-3804

www.semtech.com

13

�