POLY-FUSE® Temperature Indicators

Surface Mount > setP™ Series

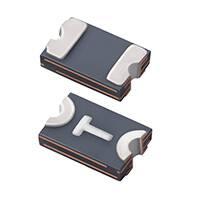

setP™ Temperature Indicators for USB Type-C

RoHS

Description

The Littelfuse setP™ temperature indicator helps

protect USB Type-C plugs from overheating. It has been

designed to the unique specifications of USB Type-C and

is capable of helping to protect even the highest levels

of USB Power Delivery.

Features

• Compact footprint:

0805 mils (2.0 x 1.2mm)

• Sensitive and reliable

temperature indication

• SMD compatible with

reflow soldering process

• Zero IR loss contribution

Agency Approvals

Agency

Agency File Number

Pending

• Easy part selection

• USB Power Delivery

compliant

• Protects systems with

100W or higher power

Pending

Applications

• �USB Type-C Plugs

• Chargers with captive

Type-C Cables

• Fast charging standards

and protocols compliant

with USB-C and USB-PD

Temperature Indication Characteristics

Part Number

Marking

SETP0805-100-SE

RT

Indicating Temperature (°C)

Min

90

Typical

100

1

Resistance (Ω)

Max

Max at 25°C 2

Rind 3

10

12

35,000

Notes:

1. Tind = Typical indicating temperature: Typical temperature when device switches to indicating resistance (Rind)

2. Maximum post reflow resistance measured at 25°C in still air

3. Rind = Indicating resistance when device reaches the indicating temperature (Tind)

© 2018 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 07/12/18

�POLY-FUSE® Temperature Indicators

Surface Mount > setP™ Series

Electrical Characteristics

Part Number

Marking

Ihold 1

(A)

SETP0805-100-SE

RT

0.06

Itrip 2

(A)

Vmax 3

(Vdc)

Imax 4

(A)

0.25

6

1

Maximum

Time-To-Trip

Pd 5 typ.

(W)

Current Time

(A)

(Sec.)

0.6

0.3

1

Resistance

Rmin 6

(Ω)

R1max 7

(Ω)

0.5

12

Agency

Approvals

P

P

Notes:

1. Ihold = Hold current: maximum current device will pass without tripping in 20°C still air

2. Itrip = Trip current: minimum current at which the device will trip in 20°C still air

3. Vmax = Maximum voltage device can withstand without damage at rated current (Imax)

4. Imax = Maximum fault current device can withstand without damage at rated voltage (Vmax)

5. Pd = Power dissipated from device when in the tripped state at 20°C still air

6. Rmin = Minimum resistance of device in initial (un-soldered) state

7. R1max = Maximum resistance of device at 20°C measured one hour after tripping or reflow Soldering of 260°C for 20 seconds

(Values specified were determined using PCBs with 0.115in x 1.0in ounce copper traces)

Caution: Operation beyond the specified rating may result in damage and possible arcing and flame

Environmental Specifications

Percentage of Rated Current

Temperature Rerating Curve

170%

Operating Temperature

-40°C to +85°C

150%

Maximum Device Surface

Temperature in Tripped State

125°C

Passive Aging

+70°C, 1000 hours

-/+10% typical resistance change

Humidity Aging

+60°C, 85% R.H.,100 hours

-/+15% typical resistance change

Thermal Shock

MIL–STD–202, Method 215

No change

-40°C to +85°C, 10 Cycles

Solvent Resistance

MIL–STD–202, Method 215

No change

Vibration

MIL–STD–883, Method 2007,

Condition A No change

Moisture Sensitivity Level

Level 2a, J–STD–020

130%

110%

90%

70%

50%

30%

10%

-40

-30 -20

-10

0

10

20 30

40

Temperature (°C)

50

60

70

80

Physical Specifications

Terminal Material

Solder-Plated Copper

(Solder Material: Matte Tin (Sn))

Lead Solderability

Meets EIA Specification RS186-9E,

ANSI/J-STD-002, Category 3.

© 2018 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 07/12/18

�POLY-FUSE® Temperature Indicators

Surface Mount > setP™ Series

Soldering Parameters

Profile Feature

Pb-Free Assembly

Average Ramp-Up Rate (TS(max) to TP)

3°C/second max

150°C

Temperature Max (Ts(max))

200°C

Time (Min to Max) (ts)

60 – 120 secs

Time Maintained Temperature (TL)

217°C

Above:

60 – 150 seconds

Temperature (tL)

tL

Ramp-do

Ramp-down

Preheat

TS(min)

tS

Peak / Classification Temperature (TP)

260

Time within 5°C of actual peak

Temperature (tp)

30 seconds max

Ramp-down Rate

2°C/second max

-- All temperature refer to topside of the package, measured on the package body surface

Time 25°C to peak Temperature (TP)

8 minutes Max.

-- If reflow temperature exceeds the recommended profile, devices may not meet the

performance requirements

+0/-5

°C

Critical Zone

tL to tP

Ramp-up

TL

TS(max)

Temperature

Pre Heat:

Temperature Min (Ts(min))

tP

TP

25

time to peak temperature

Time

-- Recommended reflow methods: IR, vapor phase oven, hot air oven, N2 environment for lead

-- Recommended maximum paste thickness is �0.25mm (0.010 inch)

-- Devices can be cleaned using standard industry methods and solvents

-- Devices can be reworked using the standard industry practices

Dimensions

Product Dimensions

Solder Pad Layout

Device Dimension

Part Number

A

B

inch

Min

mm

Max

Min

Max

inch

Min

Solder Pad

C

mm

inch

D

mm

E

inch

Max Min Max Min Max Min Max

Min

Max

mm

SIZE

INDICATING TEMP

SINGLE-END CABLE

© 2018 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 07/12/18

- 0.027 -

0.69

G

H

inch mm inch mm inch mm

-

1.00 - 1.20 - 1.50

Packaging

SETP 0805 -100 -SE

SERIES

mm

Min Max Min Max Min Max

SETP0805-100-SE 0.079 0.087 2.00 2.20 0.017 0.025 0.43 0.60 0.051 0.079 1.30 2.00 0.017 0.087 0.43 2.20

Part Ordering Number System

inch

F

Part Number

Ordering

Number

Minimum

Order

Quantity

SETP0805-100-SE

RF4795-000

20,000

Packaging

Quantity

Option

Tape & Reel

4,000

�POLY-FUSE® Temperature Indicators

Surface Mount > setP™ Series

Installation and Handling Guidelines

• Operation of these devices beyond the stated maximum

ratings could result in damage to the devices and lead to

electrical arcing and/or fire.

• These devices are intended to protect against the effects

of temporary over-current or over-temperature conditions

and are not intended to perform as protective devices

where such conditions are expected to be repetitive or

prolonged in duration.

• Exposure to silicon-based oils, solvents, electrolytes, acids,

and similar materials can adversely affect the performance

of these PPTC devices.

• These devices undergo thermal expansion under fault

conditions, and thus shall be provided with adequate space

and be protected against mechanical stresses.

• Circuits with inductance may generate a voltage (L di/dt)

above the rated voltage of the PPTC device.

• Hand-soldering of PTC devices on boards is generally not

recommended. Users shall define and verify this process if

needed.

• Consult Littelfuse when the device is to be applied with

thermal processes other than reflow process on the

circuit board, such as molding, encapsulation. User should

evaluate molding materials used in the charging cable

applications to ensure there are no adverse effect on the

PTC devices.

Tape and Reel Specifications

SETP0805-100-SE

W

8.0 ± 0.30

P0

4.0 ± 0.10

P1

4.0 ± 0.10

P2

2.0 ± 0.05

A0

1.70 ± 0.10

B0

2.45 ± 0.10

B1 max.

4.35

D0

1.55 ± 0.05

F

3.50 ± 0.05

E1

1.75 ± 0.10

E2 min.

6.25

T max.

0.3

T1 max.

0.1

K0

0.86 ± 0.10

A max.

179

N min.

53.5

W1

9.5 ± 0.5

W2 max.

15

Standard Pack Quantity: 4,000 pcs

Minimum Order Quantity: 20,000 pcs

Disclaimer Notice - Information furnished is believed to be accurate and reliable. However, users should independently evaluate the

suitability of and test each product selected for their own applications. Littelfuse products are not designed for, and may not be used

in, all applications. Read complete Disclaimer Notice at www.littelfuse.com/disclaimer-electronics.

© 2018 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 07/12/18

�

很抱歉,暂时无法提供与“SETP0805-100-SE”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 1+2.35343

- 200+0.91077

- 500+0.87880

- 1000+0.86292