C01809

COMPONENT SPECIFICATION

M22 SERIES CONNECTORS

AUGUST 2016

CONTENTS:

SECTION

TITLE

PAGE

1

Description of Connector and Intended Application

2

2

Marking of Connector and/or Package

2

3

Ratings

2

Appendix 1

Gauges

5

APPENDICES NOTES:

1.

2.

3.

4.

Third angle projection is used where projected views are shown.

All dimensions are in millimetres.

For explanation of dimensions, etc. see BS8888.

Unless otherwise stated, all dimensions are maximum.

Matthew Perren

PREPARED BY: ................................................

APPROVED BY: ................................................

-1C01809

Date: 31-08-2016

C/Note: 20036 Issue: 9

�C01809

COMPONENT SPECIFICATION

M22 SERIES CONNECTORS

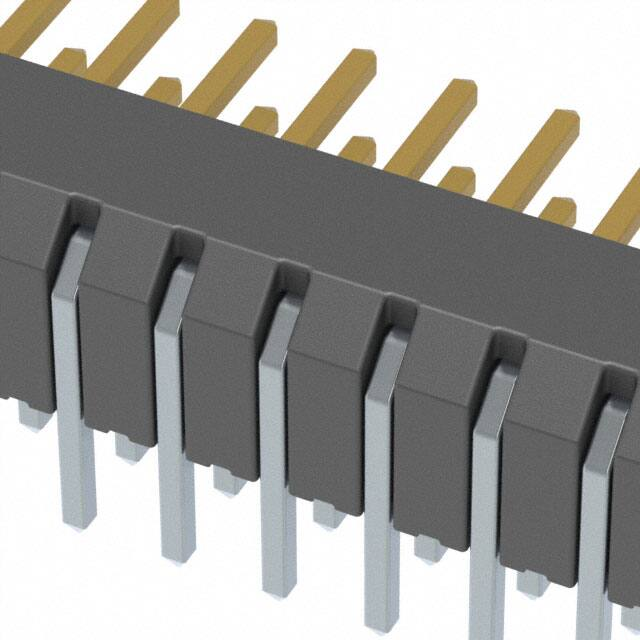

1. DESCRIPTION OF CONNECTOR AND INTENDED APPLICATION.

A range of 2mm pitch square pin connectors for interconnecting board to board. The socket is a box section

design with barbs, to locate and hold in an insulated housing. Terminations are available for through-board

solder or surface mount in a vertical mounting.

The 0.5mm square plug pins are retained in a moulding, and are available in either horizontal or vertical,

through-board solder mounting or surface mount.

Connectors are available in single and double row variations. Contacts may be gold with tin tails, all-over

gold or all-over tin plated.

2. MARKING OF THE CONNECTOR AND/OR PACKAGE (ORDER CODE).

The marking (order code) shall appear on the package and shall be of the following style:

M22

XXX

XX

XX

Product Group

Connector Style

No. of Contacts per row

Contact Finish

The marking (order code) for a pin header variant shall appear on the package and shall be of the following

style:

M22 - XXX XXX X XX XX

Product Group

Dimension A

Dimension B

Connector Style

No. of Contacts per row

Contact Finish

For details of Connector Style, Finish and No. of Contacts per row, see individual drawings or Harwin

catalogue.

3. RATINGS.

For all M22 Pin Headers, including Pin header variants (detailed below as “M22-PH”), but excluding M22-220,

221 and 241. Note: individual components may exceed above ratings – check individual customer information

sheets.

3.1.

MATERIAL & FINISH.

Moulding Material:

For PC Tail or SMT connectors ................................ High Temperature Thermoplastic, UL94V-0

For Cable connectors............................................... See individual drawing

Contact Material ............................................................. Copper alloy

Contact Finish.................................................................. See individual drawing

-2C01809

Date: 31-08-2016

C/Note: 20036 Issue: 9

�C01809

COMPONENT SPECIFICATION

M22 SERIES CONNECTORS

3. RATINGS (CONTINUED)

3.2.

ELECTRICAL CHARACTERISTICS.

Current Rating (per contact):

M22-301/302/304/305 ........................................................................................ 1A max

Other .................................................................................................................... 2A max

Contact Resistance ..................................................................................................... 20m�Ω max

Dielectric Withstanding Voltage (Voltage Proof) ..................................500V AC/DC for 1 minute

Insulation Resistance..................................................................................................1,000M�Ω min

3.3.

ENVIRONMENTAL CHARACTERISTICS.

Operating Temperature Range:

M22-301/302/304/305 ........................................................................................ -25°C to +85°C

M22-220/221/306/307/308 ................................................................................ -25°c to +105°c

Others .................................................................................................................. -40°C to +105°C

Vibration:

M22-PH/241/532/533/543/634/636/654/655 ......................... 50-2000Hz, 3.13Grms, duration 15mins in

each axis

Other .......................................................................................... Not tested

Shock:

M22-PH/241//532/533/543/634/636/654/655.................................................. 30G for 11ms

Other .................................................................................................................... Not tested

3.4. MECHANICAL CHARACTERISTICS.

Durability:

M22-307 ............................................................................................................... 1 operation MAX*

M22-306/308 ....................................................................................................... 100 operations

Others: ................................................................................................................. 300 operations

Insertion force (maximum):

M22-304/305 ....................................................................................................... 2.94N per contact

M22-306/308 ....................................................................................................... 6.9N per contact

M22-533/543/634/636/654/655/713/714 .......................................................... 2.0N per contact

Withdrawal force (minimum):

M22-304/305/306/308 ....................................................................................... 0.98N per contact

M22-533/543/634/636/654/655/713/714 .......................................................... 0.2N per contact

Contact Retention force (minimum):

M22-PH/220/221/306/308/530 .......................................................................... 9.8N per contact

M22-241/532/533/543/655/713/714 ................................................................... 4.9N per contact

3.5. SOLDERING DATA.

Solderability (for PC Tail & SMT products):

M22-220/221 ....................................................................................................... 235°C for 3 seconds

M22-PH/241/532/533/543/634/636/655 ........................................................... 245°C for 5 seconds

M22-530 ............................................................................................................... 250°C for 5 seconds

*M22-307 is not designed to be pulled apart or separated easily. This connector is ideal for one cycle

only.

-3C01809

Date: 31-08-2016

C/Note: 20036 Issue: 9

�C01809

COMPONENT SPECIFICATION

M22 SERIES CONNECTORS

APPENDIX 1 - GAUGES.

NOTES:

1.

2.

3.

4.

Material = Steel to BS1407 or equivalent.

Gauging surfaces to be hardened/ground, 650 HV5 min.

These gauges to be used for testing fully assembled components only.

Ultimate wear limit 0.005mm is allowable on gauging dimensions.

A1.1. SIZING GAUGE.

30°

0.30 square

0.20

LAP

0.505

0.500

0.2

6.25

6.15

A1.2. HOLDING GAUGE (after conditioning)

MASS

+0

20 -1 g

30°

0.30 square

0.20

LAP

0.480 square

0.475

0.1

5.35

5.15

-4C01809

Date: 31-08-2016

C/Note: 20036 Issue: 9

�

很抱歉,暂时无法提供与“M22-2412142”相匹配的价格&库存,您可以联系我们找货

免费人工找货