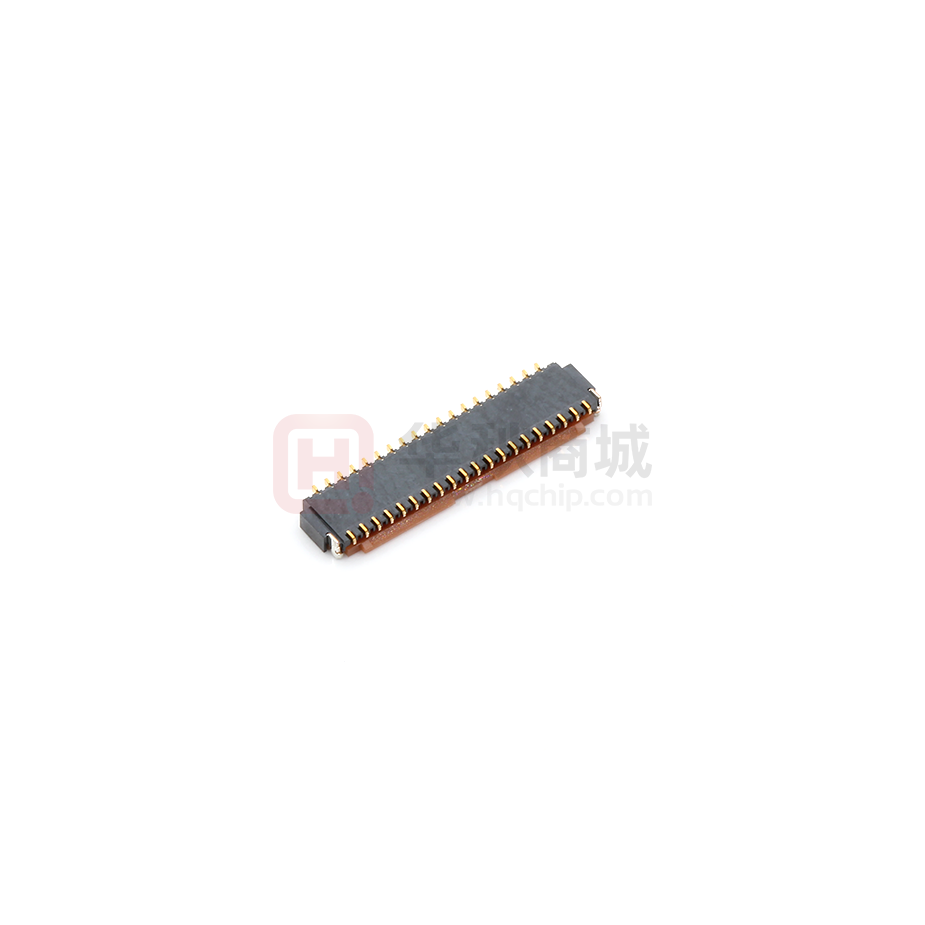

FH26W-39S-0.3SHW(60) 数据手册

0.3mm Pitch, 1.0mm Height FPC Connector

FH26 Series

1.0mm

●Space saving(51 pos. shown)

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

3.2mm

16.8mm

Metal fittings do no protrude

outside of the connector body

■Features

●Can be mounted over conductive traces.

1. Low-profile 0.3mm pitch FPC connector

Ultra-thin design, 1.0mm height, 3.2mm width all add up

to a compact, space saving form factor.

*30% reduction in PCB footprint

*40% reduction in weight

(Compared to our 0.3mm pitch FH23 Series 51 position connector.)

2. Easy PCB Mounting

The leads are double sided and have a 0.6mm mounting

lead pitch to simplify mounting.

No exposed contacts on the bottom

of the connector

3. Fully molded structure aids PCB layout

The bottom of this connector is enclosed by a fully molded

structure that protects the contacts and removes any

restrictions from PCB patterning and design.

4. Rotating one-touch ZIF mechanism

●Operation

(1)

(1) Actuator

Actuator open

open

(2)

(2) Insert

Insert FPC

FPC

The one-touch rotating ZIF mechanism is easier to operate and

works with a light force, and a clear tactile click is delivered upon

the successful completion of the mating process.

Actuator

q

5. Easy FPC insertion

The metal FPC insertion guides helps to make this the

FPC insertion process easier.

w

6. FPC. Accepts standard 0.2mm thick FPC

This connector accepts standard 0.2mm thick FPC. (The

proper FPC stiffener thickness will prevent FPC

deformation and ease insertion and mating.)

FPC

7. Supports automatic pick-n-place mounting

Offered in tape and reel packaging that is compatible with

automatic machine mounting. (5,000 pieces per reel)

(3)

(3) Close

Close the

the actuator

actuator

(4)

(4) FPC

FPC connected

connected

8. Halogen-free

All materials and substances used to produce this product

comply with Halogen-free standards.

* Defined according to IEC61249-2-21

Br : 900ppm max, Cl : 900ppm max, Br+Cl : 1,500ppm max.

e

9. Multiple packing options

The standard packaging is 5,000 pieces per reel, but it is

also offered in a 500 piece reel. (The outer diameter of the

reel will be Ø180mm in this case.)

r

2017.5③

1

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

■Product Specifications

Rating

Storage temperature range -10ç to +50ç (Note 3)

Storage humidity range

Relative humidity 90%

max.

Thickness : = 0.2±0.03mm gold plated

Recommended FPC :

Item

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Operating temperature range -55 ç to +85ç (Note 2)

Operating humidity range

Relative humidity 90% max.

(No condensation)

Current rating 0.2A DC (Note 1)

Voltage rating 30V AC

Specification

Conditions

1. Insulation resistance

50Mø min.

100V DC

2. Withstanding voltage

No flashover or insulation breakdown.

90V AC /1 minute

3. Contact resistance

100mø max.

* Including FPC conductor resistance

1mA

4. Durability

(Insertion/ withdrawal)

Contact resistance : 100mø max.

No damage, cracks, or parts dislocation.

10 cycles

5. Vibration

No electrical discontinuity of 1μs or more.

Contact resistance : 100mø max.

No damage, cracks, or parts dislocation.

Frequency : 10 to 55 Hz, single amplitude of 0.75mm, 10 cycles,

3 directions.

6. Shock

No electrical discontinuity of 1μs. min.

Contact resistance : 100mø max.

No damage, cracks, or parts dislocation.

Acceleration of 981 m/s2, 6 ms duration, sine half-wave waveform,

3 cycles in each of the 3 axis

7. Humidity

(Steady state)

Contact resistance : 100mø max.

Insulation resistance : 50Mø min.

No affect on appearance or performance.

96 hours at temperature of 40±2ç and humidity of 90% to 95%.

8. Temperature cycle

Contact resistance : 100mø max.

Insulation resistance : 50Mø min.

No damage, cracks, or parts looseness.

Temperature : -55 ç/+15ç to +35ç/+85ç/+15ç to +35ç

Time : 30 / 2 to 3 / 30 / 2 to 3 (Minutes)

5 cycles

9. Resistance to soldering heat

No deformation of components affecting

performance.

Reflow : At the recommended temperature profile

Manual soldering: 350ç +/-10ç for 5±1 seconds

Note 1 : When passing the current through all of the contacts, use 70% of the rated current.

Note 2 : Includes temperature rise caused by current flow.

Note 3 : The term "storage" refers to products stored for long period of time prior to mounting and use. Operating

Temperature Range and Humidity range covers non- conducting condition of installed connectors in storage,

shipment or during transportation.

■Materials / Finish

Part

Material

Insulator

Contacts

Metalfittings

Finish

Remarks

LCP

Color : Black

UL94V-0

PA

FH26W series : Light brown

UL94HB

Gold plating

---------------

Pure tin reflow plating

---------------

Phosphor bronze

■Product Number Structure

Refer to the chart below when determining the product specifications from the product number.

Please select from the product numbers listed in this catalog when placing orders.

FH 26W - 51S - 0.3 SHW (05)

1

2

2

3

4

5

6

1 Series name : FH

5 Termination type SHW : SMT horizontal staggered mounting type

2 Series No. : 26W

6 Specifications

3 Number of Contacts : 13 to 71

(60)…Gold plating with nickel barrier, 5,000pcs/reel

4 Contact pitch : 0.3mm

(97)…Gold plating with nickel barrier, 500pcs/reel

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

■Connector Dimensions

0.3

A

B

Number of contacts indicator

(0.12)

C

1

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

0.6

(0.3)

3.2

(1.25)

(0.12)

0.6

0.5

0.3

3.2

(D : FPC insertion slot dimension)

0.1

1

0.1

1

E

Notes 1 The coplanarity of each terminal lead within specified dimension is 0.1mm Max.

2 Packaged on tape and reel only. Check packaging specification.

3 Slight variations in color of the plastic compounds do not affect form, fit or function of the connector.

4 After reflow, the terminal plating may change color, however this does not represent a quality issue.

All dimensions : mm

Part No.

HRS No.

No. of Contacts

A

FH26W-13S-0.3SHW(**)

580-2401-1 **

13

FH26W-15S-0.3SHW(**)

580-2402-4 **

15

FH26W-17S-0.3SHW(**)

580-2403-7 **

FH26W-19S-0.3SHW(**)

580-2437-9 **

FH26W-21S-0.3SHW(**)

FH26W-23S-0.3SHW(**)

B

C

D

E

5.4

3

3.6

4.23

4.9

6.0

3.6

4.2

4.83

5.5

17

6.6

4.2

4.8

5.43

6.1

19

7.2

4.8

5.4

6.03

6.7

580-2404-0 **

21

7.8

5.4

6.0

6.63

7.3

580-2405-2 **

23

8.4

6.0

6.6

7.23

7.9

FH26W-25S-0.3SHW(**)

580-2406-5 **

25

9.0

6.6

7.2

7.83

8.5

FH26W-27S-0.3SHW(**)

580-2400-9 **

27

9.6

7.2

7.8

8.43

9.1

FH26W-29S-0.3SHW(**)

580-2407-8 **

29

10.2

7.8

8.4

9.03

9.7

FH26W-31S-0.3SHW(**)

580-2408-0 **

31

10.8

8.4

9.0

9.63

10.3

FH26W-33S-0.3SHW(**)

580-2409-3 **

33

11.4

9.0

9.6

10.23

10.9

FH26W-35S-0.3SHW(**)

580-2410-2 **

35

12.0

9.6

10.2

10.83

11.5

FH26W-37S-0.3SHW(**)

580-2411-5 **

37

12.6

10.2

10.8

11.43

12.1

FH26W-39S-0.3SHW(**)

580-2412-8 **

39

13.2

10.8

11.4

12.03

12.7

FH26W-41S-0.3SHW(**)

580-2413-0 **

41

13.8

11.4

12.0

12.63

13.3

FH26W-45S-0.3SHW(**)

580-2414-3 **

45

15.0

12.6

13.2

13.83

14.5

FH26W-51S-0.3SHW(**)

580-2415-6 **

51

16.8

14.4

15.0

15.63

16.3

FH26W-57S-0.3SHW(**)

580-2417-1 **

57

18.6

16.2

16.8

17.43

18.1

FH26W-61S-0.3SHW(**)

580-2418-4 **

61

19.8

17.4

18.0

18.63

19.3

FH26W-71S-0.3SHW(**)

580-2419-7 **

71

22.8

20.4

21.0

21.63

22.3

Note 1 : Embossed tape reel packaging (5,000pcs/reel, 500pcs/reel). Order by number of reels.

3

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

(0.55 : Metal mask)

Recommended metal mask thickness : t=0.1

0.95±0.05

2.15±0.05

(0.7 : Metal mask)

(0.2)

0.6±0.05

(0.3 : Metal mask)

0.4±0.05

0.2±0.05

Outline of

the connector

0.6±0.05

0.3±0.03

(0.23 : Metal mask)

C±0.05

0.5±0.05

BRecommended FPC Dimensions

Detail H

(Lead plated 0.1 MAX)

F±0.05

0.3±0.07

(0.15)

0.2±0.03

1

M

2.25±0.1

(2.5)

(0.5)

2.5±0.3

B

A

2.1±0.1

AX

1.1±0.1

0.3+0.04

-0.03

0.3±0.02

H

M

0.3±0.1

.2

1±0.1

0.6±0.02

R0

0.3+0.04

-0.03

0.1±0.02

(0.2)

(0.2)

(0.07)

0.6±0.07

(0.05)

B±0.03

1

(0.15)

0.6±0.07

Dimention M must be 0.5mm minimum when the stiffener is shorter than 3.5 min.

All dimensions : mm

Part No.

FH26W-13S-0.3SHW(**)

FH26W-15S-0.3SHW(**)

FH26W-17S-0.3SHW(**)

FH26W-19S-0.3SHW(**)

FH26W-21S-0.3SHW(**)

FH26W-23S-0.3SHW(**)

FH26W-25S-0.3SHW(**)

FH26W-27S-0.3SHW(**)

FH26W-29S-0.3SHW(**)

FH26W-31S-0.3SHW(**)

FH26W-33S-0.3SHW(**)

FH26W-35S-0.3SHW(**)

FH26W-37S-0.3SHW(**)

FH26W-39S-0.3SHW(**)

FH26W-41S-0.3SHW(**)

FH26W-45S-0.3SHW(**)

FH26W-51S-0.3SHW(**)

FH26W-57S-0.3SHW(**)

FH26W-61S-0.3SHW(**)

FH26W-71S-0.3SHW(**)

4

HRS No.

580-2401-1 **

580-2402-4 **

580-2403-7 **

580-2437-9 **

580-2404-0 **

580-2405-2 **

580-2406-5 **

580-2400-9 **

580-2407-8 **

580-2408-0 **

580-2409-3 **

580-2410-2 **

580-2411-5 **

580-2412-8 **

580-2413-0 **

580-2414-3 **

580-2415-6 **

580-2417-1 **

580-2418-4 **

580-2419-7 **

No. of Contacts

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

45

51

57

61

71

B

3.0

3.6

4.2

4.8

5.4

6.0

6.6

7.2

7.8

8.4

9.0

9.6

10.2

10.8

11.4

12.6

14.4

16.2

17.4

20.4

0±0.03

1.1±0.1

1±0.1

C±0.03

3.5 MIN.(Stiffener)

0.3±0.07

C

3.6

4.2

4.8

5.4

6.0

6.6

7.2

7.8

8.4

9.0

9.6

10.2

10.8

11.4

12.0

13.2

15.0

16.8

18.0

21.0

F

4.2

4.8

5.4

6.0

6.6

7.2

7.8

8.4

9.0

9.6

10.2

10.8

11.4

12.0

12.6

13.8

15.6

17.4

18.6

21.6

πRELATIVE

POSITIONS

OF POINT-A dnd B

0.3±0.03

(0.23 : Metal mask)

(0.45)

B±0.05

0.3±0.05

(0.65 : Metal mask)

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

0.8±0.05

(3.6)

0.65±0.05

BRecommended PCB mounting pattern and metal mask dimensions

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

BRecommended FPC Construction

●Contact FPC manufacturer for specific details.

1. Using Single-sided FPC

Connecting side

Material Name

Covering film layer.

Material

Polyimide

1 mil thick.

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Cover adhesive

Thickness (μm)

25

25

Surface treatment

1μm to 5μm Nickel underplated

0.2μm Gold plated

Copper foil

Cu

Base adhesive

Thermosetting adhesive

25

Base film

Polyimide

1 mil thick

25

Reinforcement material adhesive

Thermosetting adhesive

40

Stiffener

Polyimide

75

1oz

3 mil thick

Total

3

35

203

Back side

2. Using Double-sided FPC

Connecting side

Material

Material Name

Covering layer film

Polyimide

1 mil thick

25

25

Cover adhesive

Surface treatment

1μm to 5μm Nickel underplated

0.2μm Gold plated

Through-hole copper

Cu

Copper foil

Cu

Base adhesive

Thermosetting adhesive

18

Base film

Polyimide

1 mil thick

25

Base adhesive

Thermosetting adhesive

18

Copper foil

Cu

18

Cover adhesive

Thermosetting adhesive

25

Covering layer film

Polyimide

1 mil thick

25

Reinforcement material adhesive Thermosetting adhesive

25

Stiffener

Back side

Thickness (μm)

Polyimide

3

15

1/2oz

1/2oz

1 mil thick

Total

18

25

197

●To prevent release of the FPC due to it's bending, use of double sided FPC with copper foil on the back side is NOT RECOMMENDED.

3. Precautions

1. This specification is a recommendation for the construction of the FH26 Series FPC (t=0.2 ± 0.03).

2. For details about the construction, please contact the FPC manufacturers.

5

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

BPackaging Specification

●Embossed Carrier Tape Dimensions

●Embossed Carrier Tape Dimensions

(3.05)

(4.55)

+

0

0 .1

G±0.3

(K)

J±0.1

H±0.1

(0.3)

Flat surface,

for placement with

automatic equipment

(1.25)

Unreeling direction

(3.05)

(4.55)

1.5+0.1

0

1.7 +0.15

0

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Unreeling direction

Ø1

.5

(1.6)

(K)

J±0.1

(0.3)

1.75±0.1

+

0

0 .

8±0.1

Ø1

.5

4±0.1 2±0.15

(1.6)

(1.25)

(Ø1

3)

●Reel Dimensions

Unreeling direction

(Ø80)

(Ø380)

(L : INSIDE)

(M : OUTSIDE)

End section

Mounting section

Lead section (400mm min.)

Connectors

Blank section

(10 pockets min.)

6

Embossed carrier tape

Blank section

(10 pockets min.)

Top cover tape

G±0.3

1.75±0.1

(Tape width of 32mm min.)

1

(Tape width of 24mm max.)

Flat surface,

for placement with

automatic equipment

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

HRS No.

No. of Contacts

G

H

J

K

L

M

FH26W-13S-0.3SHW(**)

580-2401-1 **

13

16

−−

7.5

5.6

17.4

21.4

FH26W-15S-0.3SHW(**)

580-2402-4 **

15

16

−−

7.5

6.2

17.4

21.4

FH26W-17S-0.3SHW(**)

580-2403-7 **

17

16

−−

7.5

6.8

17.4

21.4

FH26W-19S-0.3SHW(**)

580-2437-9 **

19

16

−−

7.5

7.4

17.4

21.4

FH26W-21S-0.3SHW(**)

580-2404-0 **

21

16

−−

7.5

8.0

17.4

21.4

FH26W-23S-0.3SHW(**)

580-2405-2 **

23

16

−−

7.5

8.6

17.4

21.4

FH26W-25S-0.3SHW(**)

580-2406-5 **

25

16

−−

7.5

9.2

17.4

21.4

FH26W-27S-0.3SHW(**)

580-2400-9 **

27

16

−−

7.5

9.8

17.4

21.4

FH26W-29S-0.3SHW(**)

580-2407-8 **

29

24

−−

11.5

10.4

25.4

29.4

FH26W-31S-0.3SHW(**)

580-2408-0 **

31

24

−−

11.5

11.0

25.4

29.4

FH26W-33S-0.3SHW(**)

580-2409-3 **

33

24

−−

11.5

11.6

25.4

29.4

FH26W-35S-0.3SHW(**)

580-2410-2 **

35

24

−−

11.5

12.2

25.4

29.4

−−

11.5

12.8

25.4

29.4

FH26W-37S-0.3SHW(**)

580-2411-5 **

37

24

FH26W-39S-0.3SHW(**)

580-2412-8 **

39

24

−−

11.5

13.4

25.4

29.4

FH26W-41S-0.3SHW(**)

580-2413-0 **

41

24

−−

11.5

14.0

25.4

29.4

FH26W-45S-0.3SHW(**)

580-2414-3 **

45

24

−−

11.5

15.2

25.4

29.4

FH26W-51S-0.3SHW(**)

580-2415-6 **

51

24

−−

11.5

17.0

25.4

29.4

FH26W-57S-0.3SHW(**)

580-2417-1 **

57

32

28.4

14.2

18.8

33.4

37.4

FH26W-61S-0.3SHW(**)

580-2418-4 **

61

32

28.4

14.2

20.0

33.4

37.4

FH26W-71S-0.3SHW(**)

580-2419-7 **

71

44

40.4

20.2

23.0

45.4

49.4

BRecommended Temperature Profile

MAX 250ç

250

230ç

Temperature

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

All dimensions : mm

Part No.

200

200ç

150

150ç

(ç)

100

50

25ç

(60sec.)

90 sec. to 120 sec.

0

Start

60

Preheating

120

Time (Seconds)

(60sec.)

Soldering

HRS test conditions

Solder method

: Reflow, IR/hot air

Environment

: Room air

Solder composition : Paste,

96.5%Sn/3.0%Ag/0.5%Cu

(Senju Metal Industry,

Co., Ltd.'s

Part Number: M705221CM5-32-10.5)

Test board

: Glass epoxy

25mm∞50mm∞0.8mm thick

Land dimensions

: 0.3mm∞0.65mm,

0.3mm∞0.8mm

Metal mask

: 0.23∞0.55∞0.1mm thick,

0.23∞0.65∞0.1mm thick

The temperature profiles are based on the above

conditions.

In individual applications the actual temperature

may vary, depending on solder paste type,

volume/thickness and board size/thickness.

Consult your solder paste and equipment

manufacturer for specific recommendations.

7

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

BOperation and Precautions

Operation

1.FPC insertion procedure. Connector installed on the board.

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

1 Lift up the actuator. Use thumb or index finger.

2 Fully insert the FPC in the connector par-

allel to mounting surface, with the

exposed conductive traces facing down.

FPC conductor

surface (Bottom side)

3 Rotate down the actuator until firmly closed. It is

critical that the inserted FPC is not moved and

remains fully inserted.

2.FPC removal

1 Lift up the actuator. Carefully withdraw the

FPC.

8

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

Precautions

This connector needs to be handled with care due to its thin design and miniature

stature.

[ Precautions when mounting to PCB ]

The PCB distortion should be kept to a minimum. The maximum coplanarity of this connector is 0.1

mm, but excessive distortion can create solder failure.

SFPC specifications

Stiffeners can be used to improve the rigidity of the FPC. We recommend using a glass epoxy with

the thickness of 0.3mm or more.

SLoad to the connector

Do not apply any excessive force or mate/unmate these connectors until they are mounted, failure to

follow this precaution can lead to deformation or damage to these connectors. Inserting the FPC

prior to mounting is not recommended either.

[ Precautions in handling PCB after mounting ]

SApplied force to the PCB

Do not place any excessive force on the PCB after the connector has been mounted, this type of

action may damage the connectors. (e.g., When separating the PCB into multiple boards or

installing fastening screws onto the PCB)

SPCB bending

For PCB with a width of 100mm, it should not be bent more than a maximum of 0.5 mm. (Please

refer to the diagrams below.) PCB bending places an extra load onto the connector and will lead to

damage or malfunction.

Connector

PCB

100

0.5MAX

Connector

0.5MAX

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

SAcceptable amount of PCB distortion

100

PCB

Precautions When Inserting or Coupling FPC

Pay attention to the following points when inserting FPC.

SActuator operation

1 Do not apply excessive force when opening the actuator prior to FPC insertion. When opening

make sure that the force is applied only to the actuator itself, avoiding touching of the contacts.

Actuator

Damage to the contacts

Damage

Axis of rotation

2 Axis of rotation

Assure free rotation of

the actuator

9

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

Precautions

3 The actuator will rotate 135 degrees

135˚

maximum. Do not apply force to rotate

further. (1N max.)

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

4 When operating the actuator, do so at the

center portion.

5 As illustrated, do not attempt removal or re-

positioning of the actuator.

SFPC Insertionq

The FPC should be aligned parallel with the board surface and perpendicular with the connector (as

shown), then completely inserted.

Perpendicular with

the connector

To assure correct electrical and mechanical connection do not insert FPC at angle. It must be fully

inserted.

Make sure that the FPC is NOT MOVED during the closing of the actuator.

10

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

Precautions

SFPC Insertionw

Do not insert the FPC at any angle from above.

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

As illustrated, angle insertion may cause electrical discontinuity when the FPC is deflected in use.

*To avert insertion of the FPC on an angle, consideration should be given to securing FPC insertion

space at the time of board layout. Insertion will be difficult when the FPC is too short.

*Contact the FPC manufacturer for information about the bending specifications.

SVerification of the fully closed actuator.

The actuator should be fully closed (as illustrated) and the FPC held firmly in the connector.

Do not press against the actuator when is fully closed. Max force applied to the fully closed actuator

should not exceed 1 N.

Routing the FPC (FPC fully inserted/ actuator closed)

SFPC Load

Do not apply force in excess of 0.05N/pin max. in the upward direction (as illustrated). Do not bend

the FPC too close to the actuator.

Load : 0.05N/pin max.

11

�FH26 Series●0.3mm Contact Pitch, 1mm above the board, Flexible Printed Circuit ZIF Connectors

Precautions

Removing the FPC

Rotate the actuator to the open position (maximum open angle of 135). Carefully withdraw the FPC.

Jan.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

135˚

Powered by TCPDF (www.tcpdf.org)

Other Precautions

SHand Soldering Precautions

When hand soldering:

1 Do not perform reflow or hand soldering with the FPC inserted in the connector.

2 Do not apply excessive heat or touch the soldering iron anywhere other than the connector leads.

3 Do not use excessive amount of solder or flux compounds.

Operation of the actuator and contacts may be affected by excessive amounts of solder or flux

compounds.

12

The characteristics and the specifications contained herein are for reference purpose. Please refer to the latest customer drawings prior to use.

The contents of this catalog are current as of date of 05/2017. Contents are subject to change without notice for the purpose of improvements.

�