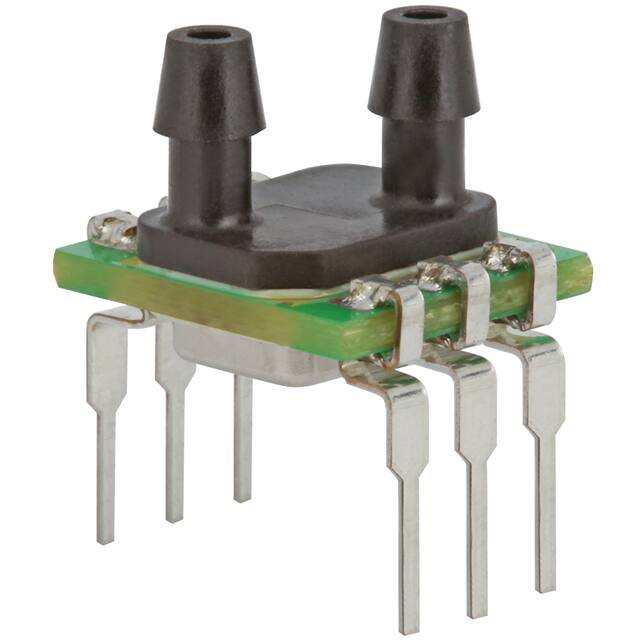

ABP2 SERIES

32350268

Issue A

Board Mount Pressure Sensors

High Accuracy, Compensated/Amplified

4 bar to 12 bar | 400 kPa to 1.2 MPa | 60 psi to 175 psi

Digital Output, Liquid Media Capable

DESCRIPTION

The ABP2 Series are piezoresistive

silicon pressure sensors offering a digital

output for reading pressure over the

specified full scale pressure span and

temperature range. They are calibrated

and temperature compensated for

sensor offset, sensitivity, temperature

effects and accuracy errors (which

include non-linearity, repeatability

and hysteresis) using an on-board

Application Specific Integrated Circuit

(ASIC). Calibrated output values for

pressure and temperature are updated at

approximately 200 Hz. All products are

designed and manufactured according

to ISO 9001 standards. The liquid

media option includes an additional

silicone-based gel coating to protect

the electronics under port P1, which

enables use with non-corrosive liquids

(e.g. water and saline) and in applications

where condensation can occur. The ABP2

Series is available in tube packaging.

Pocket tape and reel packaging is

available upon request.

VALUE TO CUSTOMERS

• Simplifies design-in: Small size

saves room on the PC board (PCB),

simplifying design in smaller and lower

power devices. Meets IPC/JEDEC

J-STD-020E Moisture Sensitivity Level

1 requirements :

- Allows avoidance of thermal and

mechanical damage during solder

reflow attachment and/or repair that

lesser rated sensors may incur.

- Allows unlimited floor life when stored

as specified (simplifying storage and

reducing scrap).

- Eliminates lengthy bakes prior to

reflow.

- Allows for lean manufacturing due

to stability and usability shortly after

reflow.

• Cost-effective: Small size helps

engineers reduce design and

manufacturing costs while maintaining

enhanced performance and reliability

of the systems they design.

• Accurate: Total Error Band (TEB) and

wide pressure range enable engineers

to optimize system performance by

improving resolution and system accuracy.

• Flexible: Supply voltage range, variety

of pressure units, types and ranges,

output options, and wide operating

temperature range simplify use in the

application

• Versatile: Wet-media compatibility, low

power, and temperature output options

make the sensor a versatile choice for

Internet of Things applications

DIFFERENTIATION

• Application-specific design ensures

suitability for a wide array of customer

requirements.

• Digital output allows the sensor to be

directly plugged into the customer’s

circuitry without requiring major design

changes

• Total Error Band (See Figure 1.):

- Provides true performance over the

compensated temperature range,

minimizing the need to test and calibrate

every sensor, thereby potentially reducing

manufacturing costs

- Improves sensor accuracy

- Offers ease of sensor interchangeability

due to minimal part-to-part variation

POTENTIAL APPLICATIONS

• Medical: Ventilators/portable

ventilators, CPAP, blood analysis, blood

pressure monitoring, breast pumps,

drug dosing, hospital beds, massage

machines, oxygen concentrators,

patient monitoring, sleep apnea

equipment, urine analyzers and wound

therapy

• Industrial: HVAC transmitters, life

sciences, material handling, pneumatic

control and regulation, process gas

monitoring and valve positioning/

positioners

• Commercial: Air beds, coffee makers,

washing machines, level measurement,

dish washers, vacuum cleaners, hand

dryers and rice cookers

• Transportation: Air brakes, CNG

monitoring, fork lifts and fuel level

measurement

FEATURES

• Total Error Band (see Figure 1): As low

as ±1.5 %FSS

• Liquid media option: Compatible with a

variety of liquid media

• Long-term stability: ±0.25 %FSS

• Accuracy: ±0.25 %FSS BFSL

• Wide pressure range: 4 bar to 12 bar |

400 kPa to 1.2 MPa | 60 psi to 175 psi

• High burst pressures (see Table 9.)

• Wide operating temperature range of

-40°C to 110°C [-40°F to 230°F]

• Calibrated over wide temperature range

of -40°C to 110°C [-40°F to 230°F]

• 24-bit digital I2C or SPI-compatible

output

• IoT (Internet of Things) ready interface

• Ultra-low power consumption (as low

as 0.01 mW typ. average power, 1 Hz

measurement frequency)

• Meets IPC/JEDEC J-STD-020E

Moisture Sensitivity Level 1

• REACH and RoHS compliant

• Food grade compatible

• NSF-169, LFGB and BPA compliant

materials

• Temperature output available

Honeywell offers a

variety of board mount

pressure sensors for use in

potential medical and industrial

applications. To view the entire

product portfolio, click here.

�BASIC BOARD MOUNT PRESSURE SENSORS, ABP2 SERIES

Table of Contents

Total Error Band. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Power Consumption and Standby Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Nomenclature and Order Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pressure Range Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.0 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.0 Pinout and Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.0 Start-Up Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.0 Power Supply Requirement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.0 Reference Circuit Design

5.1 I2C and SPI Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Bypass Capacitor Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.0 I2C Communications

6.1 I2C Bus Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2 I2C Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3 I2C Sensor Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.4 I2C Pressure and Temperature Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.5 I2C Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.6 I2C Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.6.1 Output Measurement Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.6.2 I2C Sensor Address of 0x28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.7 I2C Timing and Level Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.8 Reference Code (Arduino/Genuino Uno) for I2C Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.0 SPI Communications

7.1 SPI Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.2 SPI Data Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.3 SPI Pressure and Temperature Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.4 SPI Status Byte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.5 SPI Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.6 SPI Timing and Level Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.7 Reference Code (Arduino/Genuino Uno) for SPI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.0 ABP2 Series Calculations

8.1 Pressure Ouput. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.2 Temperature Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Additional Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . back

TOTAL ERROR BAND

Total Error Band (TEB) is a single specification that includes

the major sources of sensor error, as shown in Figure 1. TEB

should not be confused with accuracy, which is actually a

component of TEB. TEB is the maximum error that the sensor

could experience.

Honeywell uses the TEB specification in its datasheet because

it is the most comprehensive measurement of a sensor’s true

accuracy. Honeywell also provides the accuracy specification

in order to provide a common comparison with competitors’

literature that does not use the TEB specification.

Many competitors do not use TEB—they simply specify the

accuracy of their device. Their accuracy specification, however,

may exclude certain parameters. On their datasheet, the errors

are listed individually. When combined, the total error (or what

would be TEB) could be significant.

2

Sensing and Internet of Things

FIGURE 1. TOTAL ERROR BAND

Sources of Error

Offset

Full Scale Span

Pressure Non-Linearity

Pressure Hysteresis

Pressure Non-Repeatability

Thermal Effect on Offset

Thermal Effect on Span

Thermal Hysteresis

Accuracy

BFSL

Total

Error

Band

�BASIC BOARD MOUNT PRESSURE SENSORS, ABP2 SERIES

TABLE 1. ABSOLUTE MAXIMUM SPECIFICATIONS1

CHARACTERISTIC

MINIMUM

MAXIMUM

UNIT

Supply voltage (Vsupply)

-0.3

3.6

Vdc

Voltage on any pin

-0.3

Vsupply + 0.3

Vdc

Digital clock frequency:

I2C

SPI

100

50

400

800

kHz

—

4

kV

-40 [-40]

125 [257]

°C [°F]

ESD susceptibility (human body model)

Storage temperature range

Soldering time and temperature,

15 s max. at 250 °C [482 °F]

peak reflow temperature (Leadless SMT)

1

Absolute maximum ratings are the extreme limits the device will withstand without damage.

TABLE 2. OPERATING SPECIFICATIONS

CHARACTERISTIC

MINIMUM

TYPICAL

MAXIMUM

UNIT

1.8

3.3

3.6

Vdc

3.0

13.0

33.8

43.8

211.0

221.0

nA

—

3.1

—

mW

-40 [-40]

—

110 [230]

°C [°F]

-40 [-40]

—

110 [230]

°C [°F]

—

7.5

—

ms

Data rate (assumes command AA HEX)

161

204

—

samples/s

SPI/I2C voltage level:

low

high

—

80

—

—

20

—

%Vsupply

Pull up on SDA, SCL

1

—

—

kOhm

Total Error Band :

0°C to 50°C

-20°C to 85°C

-40°C to 110°C

—

—

—

—

—

—

±1.5

±3.0

±4.5

%FSS6

%FSS6

%FSS6

Accuracy7

—

—

±0.25

%FSS BFSL

14

—

—

bits

—

±5

—

°C

Supply voltage (Vsupply)

1

Current consumption:

I2C sleep/standby mode

SPI sleep/standby mode

Power consumption

Operating temperature range

2

Compensated temperature range

3

Startup time (power up to data ready)

4

5

Resolution

Temperature output error

8

Sensors are not reverse polarity protected. Incorrect application of supply voltage or ground to the wrong pin may cause electrical

failure.

2

Operating temperature range: The temperature range over which the sensor will produce an output proportional to pressure.

3

Compensated temperature range: The temperature range over which the sensor will produce an output proportional to pressure

within the specified performance limits (see Total Error Band).

4

Startup time: Based on 2.5 ms for power up to receive the first measurement command and average measurement time of 5 ms

(data rate of 204 samples per second). Refer to Section 3.0, Tables 13, 14 and 17 for further details of communication timing.

5

Total Error Band: The maximum deviation from the ideal transfer function over the entire compensated temperature and

pressure range. Includes all errors due to offset, full scale span, pressure non-linearity, pressure hysteresis, repeatability, thermal

effect on offset, thermal effect on span and thermal hysteresis.

6

Full Scale Span (FSS): The algebraic difference between the output signal measured at the maximum (Pmax.) and minimum

(Pmin.) limits of the pressure range. (See Figure 2.)

7

Accuracy: The maximum deviation in output from a Best Fit Straight Line (BFSL) fitted to the output measured over the pressure

range at 25°C [77°F]. Includes all errors due to pressure non-linearity, pressure hysteresis and non-repeatability.

8

Temperature Output Error: The error in Temperature Output reading relative to a thermal reference standard over a temperature

range of -40°C to 125°C.

1

Sensing and Internet of Things

3

�BASIC BOARD MOUNT PRESSURE SENSORS, ABP2 SERIES

TABLE 3. ENVIRONMENTAL SPECIFICATIONS

CHARACTERISTIC

PARAMETER

Humidity:

all external surfaces

internal surfaces of liquid media option “T”

0 %RH to 95 %RH, non-condensing

0 %RH to 100 %RH, condensing

Vibration

15 g, 10 Hz to 2 kHz

Shock

75 g, 6 ms duration

Life

1 million full scale pressure cycles minimum

1

Solder reflow

J-STD-020-E Moisture Sensitivity Level 1 (unlimited shelf life when stored at