High Temperature 32Kx8 Static RAM

HT6256

The 32K x 8 High Temperature Static RAM is a high performance 32,768

word x 8-bit static random access memory with industry-standard

functionality. It is a fabricated with Honeywell’s HTMOS™ technology,

and is designed for use in systems operating in severe high temperature

environments. The RAM requires only a single 5V ± 10% power supply

and has CMOS compatible I/O.

Power consumption is typically less than 30 mW/MHz in operation, and

less than 10mW when de-selected. The RAM read operation is fully

asynchronous, with a maximum guaranteed access time of 50ns at 5V.

The RAM provides guaranteed performance over the full -55 to +225ºC

temperature range. Typically, parts will operate up to +300ºC for a year, with derated performance. All parts are burned in

at 250ºC.

APPLICATIONS

FEATURES

Down-Hole Oil Well

Turbine Engine Control

Avionics

Industrial Process Control

Nuclear Reactor

Electric Power Conversion

Heavy Duty Internal Combustion Engine

Specified Over -55 to +225°C

Fabricated with HTMOS™ IV Silicon on Insulator (SOI)

Read/Write Cycle Time as Low as 50ns Over the Full

Operating Temperature Range

Asynchronous Operation

Single 5V ± 10% Power Supply

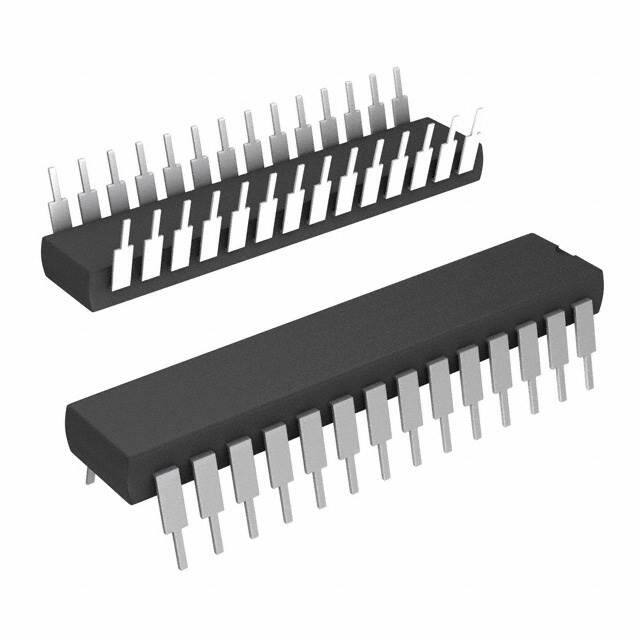

Hermetic 28-Lead Ceramic DIP, or Die

CMOS Input/Output Buffers

SIMPLIFIED FUNCTIONAL BLOCK DIAGRAM

A[0-14]

Row

Driver

Memory Array

Column

Decoder

NWE

NOE

CE (1)

NCS

DQ[0-7]

(1) CE input is not available in 28 lead DIP package, and CE is not supported for the

HT6256 in die form. For deliverable die user must connect CE to VDD.

28 LEAD PACKAGE PINOUT

�HT6256

SIGNAL DEFINITIONS

Pin

Name

Timing Definition

Symbol

A[0-14]

A

Address input pins. Selects a particular 8-bit word within the memory array.

DQ[0-7]

D

Q

Bi-directional data I/O pins. Data inputs (D) during a write operation. Data outputs (Q)

during a read operation.

NCS

S

Negative chip select. Low allows normal read or write operation. High puts the SRAM into

a deselected condition and holds the data output drivers in a high impedance (High-Z)

state. If not used, it must be connected to VSS.

NWE

W

Negative write enable. Low activates a write operation and holds the data output drivers in

a high impedance (High-Z) state. High allows normal read operation.

NOE

G

Negative output enable. High holds the data output drivers in a high impedance (High-Z)

state. Low the data output driver state is defined by NCS, CE and NWE. If not used, it

must be connected to VSS.

CE

Chip Enable. This control input is wire-bonded to VDD in the 28 lead package. Use of the

CE signal as an enable input is not supported for the HT6256 in die form. For deliverable

die, the user must connect CE to VDD.

n/a

VDD

Power input. Supplies power to the SRAM.

VSS

Ground

TRUTH TABLE

NCS

NWE

NOE

Mode

DQ Mode

H

X

X

Deselected

High-Z

L

H

L

Read

Data Out

L

H

H

Read Standby

High-Z

L

L

X

Write

Data In

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS (1)

Symbol

Parameter

Ratings

Min

Unit

Max

VDD

Positive Supply Voltage Referenced to VSS

-0.5

7.0

V

VIO

Voltage on Any Input or Output Pin Referenced to VSS

-0.5

VDD + 0.5

V

IOUT

Average Output Current

25

mA

TSTORE

Storage Temperature

-65

250

C

270

C

TSOLDER (2) Soldering Temperature

PD

(3) Package Power Dissipation

2.5

W

28-Lead DIP

10.0

C/W

Die

0.5

C/W

300

C

PJC

Package Thermal Resistance (Junction to Case)

VHBM

Electrostatic Discharge Protection Voltage (Human Body Model)

TJ

Junction Temperature

2000

V

(1) Stresses in excess of those listed above may result in immediate permanent damage to the device. These are stress ratings only and

operation at these levels is not implied. Frequent or extended exposure to absolute maximum conditions may affect device reliability.

(2) Maximum soldering temperature can be maintained for no more than 5 seconds.

(3) IDDSB power + IDDOP power + Output driver power due to external loading must not exceed this specification.

2

www.hightempsolutions.com

�HT6256

RECOMMENDED OPERATING CONDITIONS (1)

Symbol

Parameter

Limits

Unit

Min

Typ

Max

VDD

Positive Supply Voltage Referenced to VSS

4.5

5.0

5.5

V

TC

Case Temperature

-55

25

225

C

VIO

Voltage on Any Input or Output Pin Referenced to VSS

-0.3

VDD + 0.3

V

(1) Specifications listed in datasheet apply when operated under the Recommended Operating Conditions unless otherwise specified.

POWER PIN ELECTRICAL CHARACTERISTICS

Symbol

Parameter

IDDSB

IDDOPW

(1)(2)

IDDOPR

(1)(2)

IDDOPD

(1)(2)

IDR

Conditions

Static

Supply Current

VIH = VDD,

VIL = VSS,

DQ = High-Z

Dynamic

Supply Current

Selected, Write

Dynamic

Supply Current

Selected, Read

VIH = VDD,

VIL = VSS,

DQ = High-Z

VIH = VDD,

VIL = VSS,

DQ = High-Z

Dynamic

Supply Current

Deselected

VIH = VDD,

VIL = VSS,

DQ = High-Z

Data Retention

Supply Current

VDD = 2.5V

Typ(3)

Max

Unit

0.2

2.0

mA

1MHz

3.4

4

mA

1MHz

2.8

4

mA

20MHz

0.2

2.0

mA

500

uA

(1) All inputs switching. DC average current.

(2) All dynamic operating mode current measurements (IDDOPx) exclude standby mode current (IDDSB). The total power is the

sum of the power from the standby current (IDDSB), dynamic current (IDDOPx) and output driver current driving the output load

(3) Typical operating conditions: VDD=5.0V, TA=25ºC

SIGNAL PIN ELECTRICAL CHARACTERISTICS (1)(2)

Symbol

Parameter

Conditions

IIN

Input Leakage Current

VSS ≤ VIN ≤ VDD

IOZ

Output Leakage Current

DQ = High-Z

VIL

Low-Level Input Voltage

CMOS

VIH

High-Level Input Voltage

CMOS

VOL

Low-Level Output Voltage

CMOS

IOL = 6mA

VOH

High-Level Output Voltage

CMOS

IOH = -3mA

Min

Max

Unit

-5

5

uA

-10

10

uA

0.3 x VDD

V

0.7 x VDD

V

0.4

4.2

V

V

(1) Voltages referenced to VSS.

PIN CAPACITANCE (1)

Symbol

Parameter

Max

Unit

CIN

Input Capacitance

7

pF

Data I/O Capacitance

9

pF

CDQ

(1)

Maximum capacitance is verified as part of initial qualification only.

www.hightempsolutions.com

3

�HT6256

READ CYCLE TIMING CHARACTERISTICS (1)(2)

Symbol

Parameter

Limits

TAVAVR

Read Cycle Time

TAVQV

Address Valid to Output Valid Access Time

TAXQX

Address Change to Output Invalid Time

TSLQV

Chip Select to Output Valid Access Time

TSLQX

Chip Select to Output Low-Z Time

TSHQZ

Chip Select to Output High-Z Time

TGLQV

Output Enable to Output Valid Access Time

TGLQX

Output Enable to Output Low-Z Time

TGHQZ

Output Enable to Output High-Z Time

Min

Unit

Max

50

ns

50

3

ns

ns

50

5

ns

ns

20

ns

20

ns

0

ns

15

ns

(1) The timing specifications are referenced to the Timing Input / Output References diagrams and the

Timing Reference Load Circuit diagrams.

(2) NWE = High

READ CYCLE TIMING WAVEFORMS

TAVAVR

A

TAVQV

TSLQV

TAXQX

NCS

TSHQZ

TSLQX

Q

HIGH-Z

DATA VALID

TGLQX

TGLQV

TGHQZ

NOE

4

www.hightempsolutions.com

�HT6256

WRITE CYCLE TIMING CHARACTERISTICS (1)(2)(3)

Symbol

Parameter

Limits

TAVAVW

Write Cycle Time

50

ns

TWLWH

Start of Write to End of Write Pulse Width

45

ns

TSLWH

Chip Select to End of Write Time

45

ns

TDVWH

Data Input Valid to End of Write Time

35

ns

TAVWH

Address Valid to End of Write Time

45

ns

TWHDX

Data Input Hold after End of Write Time

0

ns

TAVWL

Address Valid Setup to Start of Write Time

0

ns

TWHAX

Address Valid Hold after End of Write Time

0

ns

TWLQZ

Start of Write to Output High-Z Time

TWHQX

End of Write to Output Low-Z Time

5

ns

End of Write to Start of Write Pulse Width

5

ns

Min

TWHWL

(4)

Unit

Max

15

ns

(1) The timing specifications are referenced to the Timing Input / Output References diagrams and the

Timing Reference Load Circuit diagrams. IBIS models should be used to evaluate timing under application load and conditions.

(2) For an NWE controlled write, NCS must be Low and CE must be High when NWE is Low.

(3) Can use NOE = High to hold Q in a High-Z state when NWE = High, NCS = Low and CE = High.

(4) Guaranteed but not tested.

WRITE CYCLE TIMING WAVEFORMS

TAVAVW

A

TAVWH

TWHAX

TAVWL

TWLWH

TWHWL

NWE

TWHQX

TWLQZ

Q

HIGH-Z

TDVWH

D

HIGH-Z

TWHDX

DATA VALID

TSLQX

TSLWH

TSHQZ

NCS

www.hightempsolutions.com

5

�HT6256

Typical Operating Current vs. Frequency

@ 225C

Typical Cycle Times vs. Temperature

TIMING REFERENCE LOAD CIRCUIT (CMOS)

VDD/2

50ohm

DUT

Output

Zo = 50ohm

30pF (1)

Notes

(1) Set to 5pF for T*QZ (Low-Z to High-Z) timing parameters.

6

www.hightempsolutions.com

�HT6256

FUNCTIONAL DESCRIPTION

SRAM Operation

SRAM operation is asynchronous. Operating modes

are defined in the Truth Table. Read operations can

be controlled by Address (A) or Chip Select (NCS).

Write operations can be controlled by Write Enable

(NWE) or Chip Select (NCS).

Read Operation

A read operation occurs when Chip Select (NCS) is

low and Write Enable (NWE) is high. The output

drivers are controlled independently by the Output

Enable (NOE) signal.

To control a read cycle with NCS where TSLQV is the

access time, all addresses must be valid TAVQV

minus TSLQV prior to the enabling NCS transition.

Address transitions can occur later; however, the valid

Data Output (Q) access time will then be defined by

TAVQV instead of TSLQV. NCS can disable the read

at any time; however, Data Output drivers will enter a

High-Z state TSHQZ later.

To control a read cycle with Address where TAVQV is

the access time, NCS must transition to active TSLQV

minus TAVQV prior to the last Address transition. The

NCS active transition can occur later; however, the

valid Data Output (Q) access time will then be defined

by TSLQV instead of TAVQV. To perform consecutive

read cycles, NCS is held continuously low/high, and

the toggling of any Address will start a new read cycle.

Any amount of toggling or skew between Address

transitions is permissible; however, Data Output will

not become valid until TAVQV following the last

occurring Address transition. The minimum Address

activated read cycle time is TAVAVR which is the time

between the last Address transition of the previous

cycle and the first Address transition of the next cycle.

The valid Data Output from a previous cycle will

remain valid until TAXQX following the first Address

transition of the next cycle.

Write Operation

A write operation occurs when Write Enable (NWE)

and Chip Select (NCS) are low. The write mode can

be controlled via two different control signals: NWE or

NCS can start the write mode and end the write mode,

but the write operation itself is defined by the overlap

of NWE low, and NCS low. Both modes of control are

similar, except the NCS mode deselects the SRAM

when NCS is high between writes.

www.hightempsolutions.com

To write Data (D) into the SRAM, NWE and NCS must

be held low for at least TWLWH and TSLSH

respectively. Any amount of skew between these

signal transitions can be tolerated, and any one of

these control signals can start or end the write

operation as long as there is sufficient overlap in these

signals to ensure a valid write time (e.g., TSLWH and

TWLSH).

Address inputs must be valid at least TAVWL/TAVSL

before the start of write and TAVWH/TAVSH before

the end of write and must remain valid during the write

operation. Hold times for address inputs with respect

to the end of write must be a minimum of

TWHAX/TSHAX.

A Data Input (D) valid to the end of write time of

TDVWH/TDVSH must be provided during the write

operation. Hold times for Data Input with respect to the

end of write must be at least TWHDX/TSHDX. To

avoid Data Input driver contention with the SRAM

output driver, the Data Input (D) must not be applied

until TWLQZ/TGHQZ/TSHQZ after the output drive

(Q) is put into a High-Z condition by NWE/NOE/NCS.

Consecutive write cycles are performed by toggling at

least one of the start of write control signals for

TWHWL/TSHSL. If only one of these signals is used,

the other two must be in their write enable states. The

minimum write cycle time is TAVAVW/TAVAVS.

Signal Integrity

As a general design practice, one should have good

signal integrity which means input signals that are free

of noise, glitches and ringing with rising and falling

edges of ≤10ns. More specifically, an input is

considered to have good signal integrity when the

input voltage monotonically traverses the region

between VIL and VIH in ≤10ns. This is especially

important in a selected and enabled state. When the

device is selected and enabled, the last transitioning

input for the desired operation must have good signal

integrity to maintain valid operation. The transitioning

inputs that bring the device into and out of a selected

and enabled state must also have good signal integrity

to maintain valid operation. When the device is

deselected and/or disabled, inputs can have poor

signal integrity and even float as long as the inputs that

are defining the deselected and/or disabled state stay

within valid VIL and VIH voltage levels. However,

floating inputs for an extended period of time is not

recommended.

7

�HT6256

PACKAGING

The standard package is a hermetic 28-lead DIP constructed of multilayer ceramic (AI2O3) and features internal

power and ground planes. Ceramic chip capacitors can be mounted on the package by the user to maximize

supply noise decoupling and increase board packing density. These capacitors connect to the internal package

power and ground planes. This design minimized resistance and inductance of the bond wire and package. For

other packaging options or external control of Chip Enable (CE), call Honeywell.

28-LEAD DIP PACKAGE

C

D

Z

All dimensions in inches

Y

Right

Reading

on Lid

Ceramic

Body

A

1

E

Optional

Capacitors

X

Q

L

b2

b

(width)

eA

A

b

b2

C

D

E

e

eA

L

Q

X

Y

Z

0.175 (max)

0.018 ± 0.002

0.050 (typ)

0.009 to 0.012

1.400 ± 0.014

0.595 ± 0.010

0.100 ±0.005

0.600 ±0.010

0.125 to 0.175

0.050 ±0.010

0.130 ref

0.050 ref

0.075 ref

e

(pitch)

PACKAGE LEVEL SCREENING

The HT6256 package screening includes assembly screening (die-bond and wire-bond adhesion testing, pre-cap

visual inspection, and hermetic seal leak checking). Post-assembly electrical screening includes initial electrical

test, dynamic burn-in at 250C, and final electrical testing at -55C, 25C, and 225C.

8

www.hightempsolutions.com

�HT6256

DIE DETAIL

Die Dimension (millimeters)

A

D

E

Min.

0.655

-----

Nom.

0.675

6.955

7.295

Max.

0.695

-----

Notes:

(1) Backside metalization is gold.

(2) Metalization on the pads is aluminum.

(3) The backside of the die is connected to VSS.

www.hightempsolutions.com

9

�HT6256

DIE PAD DIMENSIONS AND TERMINAL CONNECTIONS

Die Pad

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Terminal

Connection

VSS

NOE

A11

A9

A8

A13

VSS

NWE

VDD

A14

A12

A7

A6

A5

A4

A3

VSS

VSS

A2

A1

A0

D0

D1

D2

VSS

D3

D4

D5

D6

D7

NCS

A10

CE

VDD

VSS

Pad Dimensions (millimeters)

X

Y

0.139

0.080

0.129

0.100

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.233

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.100

0.129

0.080

0.129

0.080

0.129

0.100

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.233

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.119

0.129

0.100

0.129

0.216

0.139

0.080

ASSEMBLY INFORMATION FOR DIE

Die Bonding

Honeywell recommends using a Eutectic Gold/Silicon perform or high temperature conductive adhesive for die

bonding to a ceramic package.

Wire Bonding

Aluminum bond wires must be used to achieve high temperature reliability. Wirebond the power and ground

pads before the other signal pads.

10

www.hightempsolutions.com

�HT6256

DIE LEVEL SCREENING

The HT6256 die are specified to operate over the entire temperature range. To meet this objective, three levels of

screening are in place.

1. Wafer Level – Each die is 100% electrical tested at room temperature.

2. Sample Package Test – A sample of die from each wafer are assembled into packages and screened

over the temperature range of -55C to +225C to verify performance.

3. The sample packaged parts also receive 44 hours of burn-in at 250C.

RELIABILITY

Honeywell understands the stringent reliability requirements for extreme environment systems and has extensive

experience in reliability testing on programs of this nature. Reliability attributes of the HTMOS™ process were

characterized by testing test structures from which specific failure mechanisms were evaluated. These specific

mechanisms included, but were not limited to, hot carriers, electromigration, and time dependent dielectric

breakdown. This data was then used to make changes to the design models and process to ensure reliable -55

to +225ºC specified products.

ORDER INFORMATION

H

T

Process

T = Hi Temp SOI

x

6256

Part Type

6256 = SRAM

Source

Package

H = Honeywell

D = 28-lead DIP

Z = Die

Honeywell reserves the right to make changes to improve reliability, function or design. Honeywell does not assume any liability arising out of

the application or use of any product or circuit described herein; neither does it convey any license under its patent rights nor the rights of

others.

Honeywell International Inc.

12001 Highway 55

Plymouth, MN 55441

Tel: 800-323-8295

www.hightempsolutions.com

www.hightempsolutions.com

ADS-14253

November 2015

©2015 Honeywell International Inc.

11

�