Instruction Sheet

408-9830

PRO-CRIMPER* III Hand Tool Assembly

58499-1 with Die Assembly 58483-1

08 AUG 07

Rev E

PROPER USE GUIDELINES

Cumulative Trauma Disorders can result from the prolonged use of manually powered hand tools. Hand tools are intended for occasional use and low volume

applications. A wide selection of powered application equipment for extended-use, production operations is available.

Stationary

Jaw

Back of Tool

(Wire Side)

Pivot Pin

Die Assembly

PRO-CRIMPER III Hand Tool

Moving Jaw

Frame 354940-1 (See Instruction

Sheet 408-9930)

Ratchet Adjustment

Wheel

Stationary Handle

The PRO-CRIMPER III Hand Tool is a Commercial" grade tool and is

designed primarily for field installation, repair, maintenance work, or

prototyping in industrial, commercial, or institutional applications. Product

crimped with this tool will meet the crimp height requirement for hand tools in

Moving Handle

the appropriate Application Specification (114-series), but may not comply

with other feature parameters of the specification. A variety of tools are offered

to satisfy your performance requirements. For additional information, contact

the Tooling Assistance Center at 1-800-722-1111.

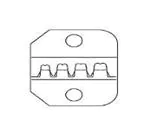

DIE ASSEMBLY

58483-1

PRODUCT

FLEXIBLE COAXIAL

FAMILY

CABLE SIZE (RG/U)

SMB Straight Cable

Plug Connectors

DIE ASSEMBLY

CRIMPING CHAMBER

MARKING

178, 196

.105 (A)

174, 179, 187, 188, 316

.128 (B)

174, 188, 316 (All Double Braid)

.151 (C)

Figure 1

1. INTRODUCTION

NOTE

Dimensions in this instruction sheet are in

millimeters [with inches in brackets]. Figures are

PRO–CRIMPER III Hand Tool Assembly 58499–1

consists of PRO–CRIMPER III Hand Tool Frame

354940–1 and Die Assembly 58483–1. The tool

assembly is used to crimp the ferrule of the

connectors listed in Figure 1. In this use, the die

assembly does not provide for crimping of the center

contact.

For additional information on the hand tool frame,

refer to 408–9930. Refer to the applicable connector

instruction sheet for assembly of the connector.

Read these instructions thoroughly before using the

tool assembly.

Reasons for reissue of this instruction sheet are

provided in Section 8, REVISION SUMMARY.

E

2007 Tyco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

i

not drawn to scale.

TOOLING ASSISTANCE CENTER 1-800-722-1111

This controlled document is subject to change.

PRODUCT INFORMATION 1-800-522-6752

For latest revision and Regional Customer Service,

TE logo and Tyco Electronics are trademarks.

*Trademark. Other products, logos, and company names used are the property of their respective owners.

visit our website at www.tycoelectronics.com

1 of 3

LOC B

�408-9830

PRO-CRIMPER III Hand Tool Assembly 58499-1 with Die Assembly 58483-1

2. DESCRIPTION

4. CRIMPING PROCEDURE

(Figure 1)

The tool frame features a stationary jaw and handle, a

moving jaw, a moving handle, and an adjustable

ratchet that ensures full crimping. The tool frame

holds the die assembly.

The die assembly consists of an indenter (stationary

die) and an anvil (moving die). When closed, the dies

form three crimping chambers. Each die is held in the

hand tool frame by a single screw.

(Ferrule Only)

Make sure that the center contact is properly crimped

and assembled onto the connector as described in

applicable connector instruction sheet. Then proceed

as follows:

1. Slide the ferrule over the cable braid until it is

positioned against the shoulder of the plug body.

2. Close the tool handles until the ratchet releases,

then allow the handles to open FULLY.

3. Place the ferrule in the appropriate crimping

chamber on the anvil die so that the shoulder of

the plug body is close to the edge of the die. Refer

to Figure 3.

3. INSTALLATION AND REMOVAL OF

DIE ASSEMBLY (Figure 2)

1. Close the tool handles until the ratchet releases,

then allow the handles to open fully.

2. Insert the dies into the tool jaws as shown in

Figure 2, and align the retaining holes in each die

with the associated hole in the tool.

NOTE

Refer to Figure 1 for the appropriate crimping

chamber.

i

Tool Frame

Jaws

Indenter

Shoulder of Plug

Body Close to

Edge of Die

Crimping

Chamber

(Ref)

Figure 3

4. While holding the assembly, close the tool

handles until the dies hold the ferrule in place.

Die Retaining

Anvil

Screws

6. Remove the ferrule from the dies.

Figure 2

3. Thread, but do not tighten, the die retaining

screws into the holes.

4. Carefully close the tool handles, making sure

that the dies align properly.

5. Tighten the die retaining screws with the

appropriate hex wrench.

6. To disassemble, close the tool handles until the

ratchet releases, remove the two die retaining

screws, and slide the dies out of the tool jaws.

2 of 3

5. Carefully close the tool handles until the ratchet

releases, then allow the handles to open FULLY.

7. Inspect the crimped ferrule according to

applicable connector instruction sheet. If

necessary, adjust the ratchet as described in

Section 5.

5. RATCHET ADJUSTMENT (Figure 4)

The tool ratchet mechanism features an adjustment

wheel with numbered settings. The adjustment wheel

controls the amount of handle pressure exerted on

the jaws during crimping. If the crimp is not

acceptable, adjust the ratchet as follows:

1. Remove the lockscrew from the ratchet

adjustment wheel.

Tyco Electronics Corporation

Rev

E

�408-9830

PRO-CRIMPER III Hand Tool Assembly 58499-1 with Die Assembly 58483-1

6.3. Measuring Die Opening

Screwdriver

Figure 5 provides dimensions for the die openings.

C

A

Ratchet

Adjustment

Wheel

B

Lockscrew

Figure 4

2. With a screwdriver, adjust the ratchet wheel

from the front of the tool.

3. Observe the ratchet adjustment wheel. If a

tighter crimp is required, rotate the adjustment

wheel counterclockwise to a higher–numbered

setting. If a looser crimp is required, rotate the

adjustment wheel clockwise to a lower–numbered

setting.

4. Re–assemble the lockscrew.

5. Make a sample crimp. If the crimp is acceptable,

the adjustment setting is correct. If the crimp is

unacceptable, continue to adjust the ratchet, and

again measure a sample crimp.

DIE OPENING DIMENSION +0.10 [+.004]

A

B

C

2.667 [.105]

3.251 [.128]

3.835 [.151]

Figure 5

7. REPLACEMENT

Customer–replaceable parts are shown in Figure 1.

Available separately, Repair Kit 679221–1 includes a

replacement nut and a variety of pins, rings, screws,

and springs. If the dies are damaged or worn

excessively, they must be replaced. Order the repair

kit and replaceable parts through your representative,

or call 1–800–526–5142, or send a facsimile of your

purchase order to 717–986–7605, or write to:

CUSTOMER SERVICE (038–035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105–3608

6. MAINTENANCE AND INSPECTION

6.1. Maintenance

Ensure that the tool frame and dies are clean by

wiping them with a clean, soft cloth. Remove any

debris with a clean, soft brush. Do not use objects

that could damage any components. When not in use,

keep tool handles closed to prevent objects from

becoming lodged in the dies, and store in a clean, dry

area.

8. REVISION SUMMARY

Revisions to this instruction sheet include:

S Updated document to corporate requirements

6.2. Visual Inspection

Inspection of the dies should be made on a regular

basis to ensure that they have not become worn or

damaged. Inspect the crimping sections for flattened,

chipped, worn, or broken areas. If damage or

abnormal wear is evident, the dies must be replaced.

Refer to Section 7, REPLACEMENT.

Rev

E

Tyco Electronics Corporation

3 of 3

�