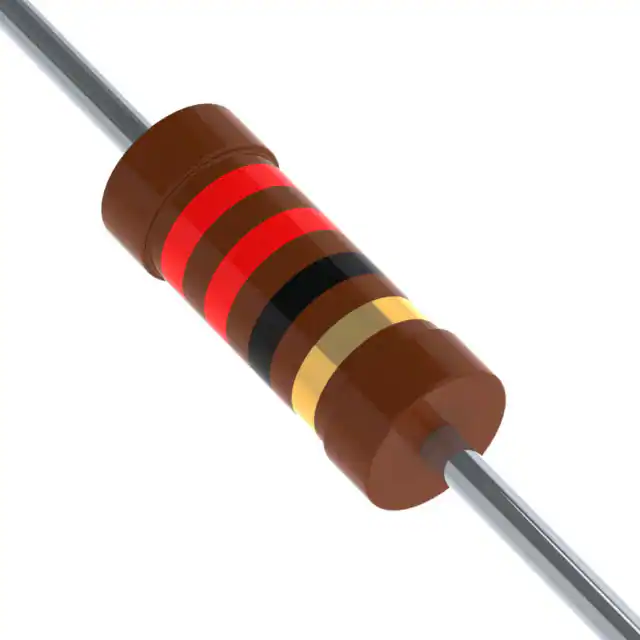

Carbon Composition Resistors

Key Features

Type CBT Series

Solid Carbon

Composition

Designed for

Pulse

Withstand

Low Cost, High

Performance

Two Sizes

Available

Supplied

Ammo Pack in

boxes of 2000

The CBT series of resistors is constructed utilising solid carbon composition,

which is the traditional medium for absorbing high energy pulses, in cases of

high inrush current. These resistors have evolved over many years to have

excellent pulse withstand capabilities, whilst remaining very stable. These

improved characteristics have been achieved by prudent selection of materials

of optimum physical properties and by advances in the manufacturing process.

Characteristics – Electrical

Power @ 70°C

Maximum Voltage

Tolerance

Selection Series

Resistance values

Ω

Limiting Element

Voltage

Maximum Overload

Voltage

Insulation Resistance

Operating Temperature

CBT25

0.25W (~0 @ 125°C)

250V

5%

10%

10% 20%

E24

E24

E12

E6

100K –

1 -91K

1 – 5M6

5M6

250v

CBT50

0.5W (~0 @ 125°C)

350V

5%

10%

10% 20%

E24

E24

E12 E6

1 – 91K 100K –

1 – 22M

22M

350v

500v

700v

1000M minimum

-55 ~ +125

Climatic Category

55/125/56

Lower Category Temperature

Upper Category Temperature

Damp Heat Steady State Duration

-55°C

+125°C

56 Days

Stability Class

10%

1773192 Rev D 03/2019

Limits For Change of Resistance

For Long Term Tests

For Short Term Tests

Dimensions in

millimetres unless

otherwise specified

Dimensions Shown for

reference purposes only.

Specifications subject to

change

±(10%+0.5Ω)

±(2%+0.1Ω)

For Email, phone or live chat,

go to: www.te.com/help

�Carbon Composition Resistors

Derating

At ambient temperatures in excess of 70°C the resistor shall be derated in

accordance with the following curve:

Rated Voltage

D.C. or A.C. rms voltage calculated from the square root of the product of the

rated resistance and the rated dissipation.

Where the calculated rated voltage is higher than the limiting element voltage,

the limiting element voltage must be applied.

Dimensions

1773192 Rev D 03/2019

CBT25

L

6.3±0.7

CBT50

9.5

Dimensions in

millimetres unless

otherwise specified

+0.8

-0.7

ØD

2.4±0.1

l

30±3

Ød

0.6±0.05

3.6±0.2

25±3

0.7

Dimensions Shown for

reference purposes only.

Specifications subject to

change

+0.07

-0.05

For Email, phone or live chat,

go to: www.te.com/help

�Carbon Composition Resistors

Performance Characteristics

Test Item

Condition of Test (JIS C 5201-1)

Visual Examination

Sub-clause 4.4.1

Checked by visual examination

Dimension

Sub-clause 4.4.2

Resistance

Sub-clause 4.5

Voltage Proof

Solderability

Overload

(mounted)

Terminal strength

Tensile

Bending

Torsion

1773192 Rev D 03/2019

Dimensions in

millimetres unless

otherwise specified

Sub-clause 4.7

Method: V-Block Method

Test Voltage: Alternating

voltage with a peak value of

1.42 times the insulation

voltage.

Duration 60s ±5s

Sub-clause 4.17

Without ageing

Method 1 (solder bath

method)

Bath Temperature: 235°C±5°C

Immersion time: 5s ±0.5s

Immersion depth: A point

within about 4mm from the

resistor body.

Sub-clause 4.13

The applied voltage shall be 2.5

times RCWV or 2 times limiting

element voltage, whichever is

lower.

Duration: 5s

Visual Examination

Resistance test

Sub-clause 4.16

Sub-clause 4.16.2

Force: 10N

Duration: 10s ±1s

Sub-clause 4.16.3

Method 1

Bending times: 2 times

Bending force: 5N

Sub-clause 4.16.4

Method A, Severity 2

(2 successive rotations of 180°)

Dimensions Shown for

reference purposes only.

Specifications subject to

change

Performance

Requirement

As per 4.4.1 Marking shall

be legible as checked

visually

As specified

As specified

Resistance value shall

correspond to the rated

resistance value taking

into account the

specified tolerance

No breakdown or

flashover

Good tinning as

evidenced by free flowing

of the solder with

wetting of the

terminations

No Visible Damage

Legible Marking

ΔR ±(2%+0.1Ω)

No visible damage

ΔR ±(2%+0.1Ω

For Email, phone or live chat,

go to: www.te.com/help

�Carbon Composition Resistors

Resistance to

soldering heat

Rapid Temperature

change

Vibration

Climatic sequence

Dry Heat

Damp Heat, cycle

(12 + 12h cycle

First Cycle

Cold

Low air pressure

Damp heat, cycle

(12 + 12h cycle)

Remaining cycle

D.C. load

Endurance @ 70°C

1773192 Rev D 03/2019

Dimensions in

millimetres unless

otherwise specified

Sub-clause 4.18

Method 1B

Solder Temperature:

CBT25: 300°C±10°C

CBT50: 350°C±10°C

Immersion time: 3.5s±0.5s

Immersion depth: A point within

4.0±0.8mm from the resistor body.

Sub-clause 4.19

Lower category temperature: 55°C

Upper category temperature:

125°C

Duration of exposure at each

temperature: 30 min.

Number of cycles: 5

Sub-Clause 4.22

Endurance by sweeping

Frequency range: 10Hz – 500Hz

Amplitude: 0.75mm or

acceleration 98m/s²

(whichever is less severe)

Total Duration: 6h

Sub-clause 4.23

Sub-clause 4.23.2

Test temperature: 125°C

Duration 16h

Sub-clause 4.23.3

Test Method: 2

Test temperature: 55°C

(Severity (2))

Sub-clause 4.23.4

Test temperature: -55°C

Duration: 2h

8kPa

Sub-clause 4.23.6

Test method: 2

Test temperature: 55°C

(Severity (2))

Number of cycles: 5

Sub-clause 4.23.7

The applied voltage shall be the

rated voltage or the limiting

element voltage, whichever is

smaller.

Duration: 1 min.

Sub-clause 4.25.1

Ambient temperature: 70°C±2°C

Duration: 1000h

Voltage applied 1.5h on and 0.5h

off

The applied voltage shall be the

rated voltage or the limiting

element voltage, whichever is

smaller

Examination at 48h, 500h and

1000h

Dimensions Shown for

reference purposes only.

Specifications subject to

change

No Visible Damage

Legible marking

ΔR ± %+ . Ω

No visible damage

ΔR ± %+ . Ω

No visible damage

ΔR ± %+ . Ω

No Visible Damage

Legible marking

ΔR ± %+ .5Ω

Insulation Resistance:

R

MΩ

No visible damage

ΔR ± %+ .5Ω

Insulation Resistance:

R GΩ

For Email, phone or live chat,

go to: www.te.com/help

�Carbon Composition Resistors

Variation of

Resistance with

Temperature

Damp Heat, Steady

State

Endurance at upper

category temperature

At -55°C

Resistance

Temp.

Range

Coefficient

R KΩ

+6.5-0(%)

R

KΩ

+10-0(%)

R

KΩ

+13-0(%)

R MΩ

+15-0(%)

R> MΩ

+20-0%

At +125°C

Resistance

Temp.

Range

Coefficient

R KΩ

+1-5(%)

R

KΩ

0-6(%)

R

KΩ

0-7.5(%)

R MΩ

0-10(%)

R> MΩ

0-15(%)

Sub-clause 4.8

-55°C / +20°C

+20°C / +125°C

Sub-clause 4.24

Ambient Temperature: 40°C±2°C

Relative Hu idity: 9 ⁺²/₋ %

a) 1st group: without

voltage applied

b) 2nd group: DC voltage

applied continuously in

accordance with subclause 4.24.2.1b

c) 3rd group: DC voltage –

20v±2v shall be applied

continuously.

Sub-clause 4.25.3

Ambient temperature: 125°C±2°C

Duration: 1000h

Examination at 48h, 500h and

1000h

Visual examination

Resistance

At 1000h only: Insulation

Resistance

No Visible Damage

Legible marking

ΔR ±

%+ .5Ω

Insulation resistance

MΩ

No Visible Damage

ΔR ± %+ .5Ω

I sulatio Resista ce

GΩ

Packaging

Taping in accordance with JIS C 0806-1:1999

W

CBT25

CBT50

1773192 Rev D 03/2019

52.4

+1.6

-1.4

Dimensions in

millimetres unless

otherwise specified

P

L -L

Z

S

T

t

5.08±0.38

1.0 max

1.0 max

3.2 min

6.0±0.5

0.5 max

Dimensions Shown for

reference purposes only.

Specifications subject to

change

For Email, phone or live chat,

go to: www.te.com/help

�Carbon Composition Resistors

Packaging

Notes:

The direction of the color codes should be unified.

No component shall be missed.

Wire leads shall be free from kinks and bends.

Pitch tolerance is 2mm for 20 pitches (100±2mm).

The edge waving on tape shall not be more than ±1.0mm through a length of

300mm.

The reinforcement of the tape cutting should be reinforced by a new tape

(30mm min) in 3mm limits and ensuring 1 pitch dimension as shown below.

Tape in Box (Ammo Pack)

Code

CBT25

CBT50

No Code

Qty per Box

2000

2000

a

60±5

65±5

b

75±5

75±5

C

275±5

455±5

How To Order

1773192 Rev D 03/2019

CBT

Common Part

25

Size

J

Tolerance

CBT – Carbon

Composition

Resistor

25 – 0.25W

50 – 0.5W

J – 5%

K – 10%

M – 20%

Dimensions in

millimetres unless

otherwise specified

Dimensions Shown for

reference purposes only.

Specifications subject to

change

10K

Resistance Value

1Ω - 1R0

100Ω - 100R

1000Ω KΩ - 1K0

100000Ω (100KΩ - 100K

1000000Ω (1MΩ - 1M0

For Email, phone or live chat,

go to: www.te.com/help

�

很抱歉,暂时无法提供与“CBT50J22R”相匹配的价格&库存,您可以联系我们找货

免费人工找货