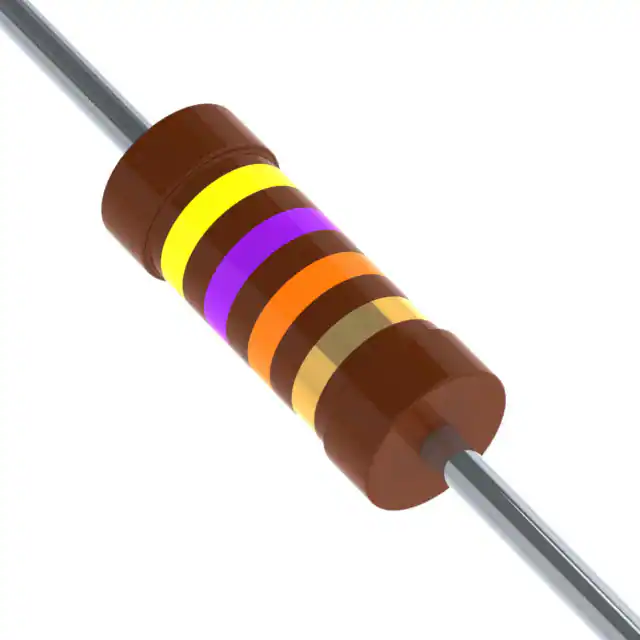

物料型号:CBT系列,包括CBT25(0.25W)和CBT50(0.5W)两种型号。

器件简介:该系列电阻器采用固体碳复合材质,具有优秀的抗脉冲能力和稳定性,适用于高脉冲吸收和高初始电流的情况。

引脚分配:文档中未明确提及引脚分配信息。

参数特性:

- 电气特性包括功率、最大电压、公差等级、电阻值范围、限制元件电压、最大过载电压、绝缘电阻和工作温度范围。

- 气候类别为55/125/56,表示在-55°C至+125°C的温度范围内,湿热稳态持续时间为56天。

- 稳定性等级为±(10%+0.5Ω)长期测试和±(2%+0.1Ω)短期测试。

功能详解:文档详细描述了电阻器的测试项目和性能要求,包括视觉检查、尺寸、电阻、耐电压、焊锡性、过载(安装)、端强度拉伸、弯曲、扭转、耐焊锡热、快速温度变化、振动、气候顺序测试等。

应用信息:文档未明确提供应用信息,但从其特性来看,适用于需要高脉冲承受能力的应用场景。

封装信息:提供了详细的尺寸信息,包括CBT25和CBT50的尺寸参数,以及包装方式,如胶带包装符合JIS C 0806-1:1999标准,以及箱装(弹药包装)的相关信息。

如何订购:提供了订购信息的示例,包括物料型号、尺寸、公差、电阻值等。