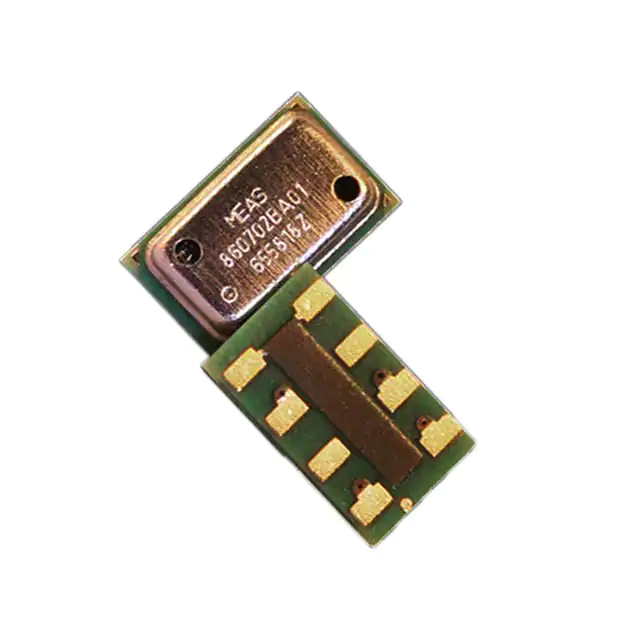

MS8607-02BA01

PHT Combination Sensor

SPECIFICATIONS

• Integrated pressure, humidity and temperature sensor

• QFN package 5 x 3 x 1 mm3

• Operating range: 10 to 2000 mbar, 0%RH to 100%RH,

-40 to 85 °C

• High-resolution module: 0.016 mbar, 0.04%RH, 0.01°C

• Supply voltage: 1.5 to 3.6 V

• Fully factory calibrated sensor

• I2C interface

The MS8607 is the novel digital combination sensor of MEAS

providing 3 environmental physical measurements all-in-one:

pressure, humidity and temperature (PHT). This product is

optimal for applications in which key requirements such as ultralow power consumption, high PHT accuracy and compactness

are critical. High pressure resolution combined with high PHT

linearity makes the MS8607 an ideal candidate for environmental

monitoring and altimeter in smart phones and tablet PC, as well

as PHT applications such as HVAC and weather stations. This

new sensor module generation is based on leading MEMS

technologies and latest benefits from Measurement Specialties

proven experience and know-how in high volume manufacturing

of sensor modules, which has been widely used for over a

decade.

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 1

�MS8607-02BA01

PHT Combination Sensor

FEATURES

FIELD OF APPLICATION

•

•

•

•

•

Smart phones and Tablet PCs

HVAC applications

Weather station

Printers

Home Appliance and humidifiers

TECHNICAL DATA

Sensor Performances (VDD = 3 V)

Characteristics

Pressure [mbar]

Min

Max. Operating Range

Typ

10

Relative Humidity [%RH]

Max

Min

2000

0

300…1100mbar

Absolute Accuracy @25°C

-2

Resolution (highest mode)

SENSOR SOLUTIONS ///MS8607-02BA01

Max

Min

100

-40

20…80%RH

2

0.016

Typ

Temperature [°C]

-3

06/2017

Max

+85

@ 25°C

3

0.04

Typ

-1

1

0.01

Page 2

�MS8607-02BA01

PHT Combination Sensor

PERFORMANCE SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

Parameter

Supply voltage

Symbol

VDD

Storage temperature

Overpressure

Maximum Soldering

Temperature

ESD rating

Latch up

Condition

Min.

-0.3

-20

TS

Pmax

Typ.

Max.

3.6

Unit

V

85

°C

bar

250

°C

2

100

kV

mA

Max.

3.6

+85

Unit

V

°C

nF

6

Tmax

40 sec max

-2

Human Body Model

JEDEC standard No 78

-100

ELECTRICAL CHARACTERISTICS

Parameter

Operating Supply voltage

Operating Temperature

VDD to GND Capacitor

Supply current P or T

(1 Pressure or temperature

conversion per sec.)

Symbol

VDD

T

General electrical characteristics

Condition

Min.

Typ.

1.5

3.0

-40

+25

220

470

IPT

OSR 8192

4096

2048

1024

512

256

IH

OSR 8192

4096

2048

1024

20.09

10.05

5.02

2.51

1.26

0.63

µA

6.22

Supply current H

(1 humidity conversion per

sec.)

Peak supply current

(during P or T conversion)

Peak supply current

(during humidity conversion)

Standby supply current

ADC Output Word

ADC Conversion time(3)

3.11

0.78

@ 25°C, V DD = 3V

1.25

mA

0.45

mA

0.03

Pressure and temperature

Condition

Min.

Typ.

Max.

24

OSR 8192

16.44

17.2

4096

8.22

8.61

2048

4.13

4.32

1024

2.08

2.17

512

1.06

1.10

256

0.54

0.56

Heater: power dissipation

and temperature increase

over humidity sensor

Low battery indicator

accuracy

µA

1.56

Min.

Relative humidity

Typ.

Max.

16

13.82

15.89

8.03

6.98

3.55

4.08

1.84

2.12

2 - 13

0.5 - 1.5

±50 (Typ.)

0.24

µA

Unit

bit

ms

mW

°C

mV

(3): Maximum values must be applied to determine waiting times in I2C communication

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 3

�MS8607-02BA01

PHT Combination Sensor

PERFORMANCE SPECIFICATIONS (CONTINUED)

PHT CHARACTERISTICS (VDD = 3.0 V, T = 25 °C UNLESS OTHERWISE NOTED )

Operating Range

Extended Range (4)

Absolute Accuracy

@25°C

Absolute Accuracy

Relative Accuracy

@25°C

OSR 8192

4096

2048

Resolution

RMS(7)

1024

512

256

Maximum error with

supply voltage

(Condition)

Long-term stability

Reflow soldering impact

Recovering time after

reflow (8)

Pressure [mbar]

Typ.

Max.

1200

2000

300…1100 mbar

-2

2

300…1100mbar, -20...85°C

-4

4

700…1000 mbar (5)

±0.1 (6)

0.016

0.021

0.028

0.039

0.062

0.11

Relative Humidity [%RH]

Min.

Typ.

Max.

0.04

0.7

0.002

0.003

0.004

0.006

0.009

0.012

±0.5

±0.25

±0.3

Min.

300

10

0

Min.

100

-40

3

-1

5

-2

20 …80%RH

-3

85

@25°C

5…95%RH

-5

Temperature [°C]

Typ.

Max.

1

-20...85°C

2

(VDD = 1.5 V … 3.6 V)

Response Time

±1 / year

-0.6

±0.5 / year

2

5 days

5 days

< 5ms

5 sec.

±0.3 / year

(at 63% of signal recovery,

From 33%RH to 75%RH,

At 3m/s air flow)

(Condition)

(4): Linear range of ADC

(5): Auto-zero at one pressure point

(6): Characterized value performed on qualification devices

(7): Characterization performed sequentially (P&T conversion followed by H conversion)

(8): Recovering time at least 66% of the reflow impact

DIGITAL INPUTS (SDA, SCL)

Parameter

Serial data clock

Input high voltage

Input low voltage

Symbol

SCL

VIH

VIL

Conditions

Symbol

VOH

VOL

CLOAD

Conditions

Isource = 1 mA

Isink = 1 mA

Min.

Typ.

Max.

400

100% VDD

20% VDD

Unit

kHz

V

V

Typ.

Max.

100% VDD

20% VDD

Unit

V

V

pF

80% VDD

0% VDD

DIGITAL OUTPUTS (SDA)

Parameter

Output high voltage

Output low voltage

Load Capacitance

SENSOR SOLUTIONS ///MS8607-02BA01

Min.

80% VDD

0% VDD

16

06/2017

Page 4

�MS8607-02BA01

PHT Combination Sensor

PERFORMANCE CHARACTERISTICS

PHT ACCURACY AND PHT ERROR VERSUS SUPPLY VOLTAGE (TYPICAL)

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 5

�MS8607-02BA01

PHT Combination Sensor

FUNCTIONAL DESCRIPTION

GENERAL

The MS8607 includes two sensors with distinctive MEMS technologies to measure pressure, humidity and

temperature. The first sensor is a piezo-resistive sensor providing pressure and temperature. The second sensor

is a capacitive type humidity sensor providing relative humidity. Each sensor is interfaced to a ∆Σ ADC integrated

circuit for the digital conversion. The MS8607 converts both analog output voltages to a 24-bit digital value for the

pressure and temperature measurements, and a 12-bit digital value for the relative humidity measurement.

SERIAL I2C INTERFACE

The external microcontroller clocks in the data through the input SCL (Serial CLock) and SDA (Serial DAta). Both

sensors respond on the same pin SDA which is bidirectional for the I2C bus interface. Two distinct I2C addresses

are used (one for pressure and temperature, the other for relative humidity, see Figure 2).

Module reference

MS860702BA01

Mode

I2C

Pins used

SDA, SCL

Figure 1: Communication Protocol and pins

Sensor type

Pressure and Temperature P&T

Relative Humidity RH

I2C address (binary value)

1110110

1000000

I2C address (hex. value)

0x76

0x40

Figure 2: I2C addresses

COMMANDS FOR PRESSURE AND TEMPERATURE

For pressure and temperature sensing, five commands are possible:

1. Reset

2. Read PROM P&T (112 bit of calibration words)

3. D1 conversion

4. D2 conversion

5. Read ADC (24 bit pressure / temperature)

Each command is represented over 1 byte (8 bits) as described in Figure 3. After ADC read commands, the

device will return 24 bit result and after the PROM read 16 bit results. The address of the PROM is embedded

inside of the read PROM P&T command using the a2, a1 and a0 bits.

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 6

�MS8607-02BA01

PHT Combination Sensor

Command byte

7

6

PROM CONV

Bit number

Bit name

Command

Reset

Convert D1 (OSR=256)

Convert D1 (OSR=512)

Convert D1 (OSR=1024)

Convert D1 (OSR=2048)

Convert D1 (OSR=4096)

Convert D1 (OSR=8192)

Convert D2 (OSR=256)

Convert D2 (OSR=512)

Convert D2 (OSR=1024)

Convert D2 (OSR=2048)

Convert D2 (OSR=4096)

Convert D2 (OSR=8192)

ADC Read

PROM Read P&T

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

1

1

1

1

1

1

1

1

1

1

1

1

0

0

hex value

5

-

4

Typ

3

Ad2/

Os2

2

Ad1/

Os1

1

Ad0/

Os0

0

Stop

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

0

0

1

1

1

1

1

1

0

0

1

0

0

0

0

1

1

0

0

0

0

1

1

0

Ad2

1

0

0

1

1

0

0

0

0

1

1

0

0

0

Ad1

1

0

1

0

1

0

1

0

1

0

1

0

1

0

Ad0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0x1E

0x40

0x42

0x44

0x46

0x48

0x4A

0x50

0x52

0x54

0x56

0x58

0x5A

0x00

0xA0 to 0xAE

Figure 3: Command structure for pressure and temperature sensing

COMMANDS FOR RELATIVE HUMIDITY

For relative humidity sensing, six commands are possible:

1. Reset

2. Write user register

3. Read user register

4. Measure RH (Hold master)

5. Measure RH (No Hold master)

6. PROM read RH

Each I2C communication message starts with the start condition and it is ended with the stop condition. The I2C

address for humidity sensing is 1000000. The address of the PROM is embedded inside of the PROM read

command using the a2, a1 and a0 bits. Figure 4 shows the commands with their respective code:

Bit number

Command :

1. Reset

2. Write user register

3. Read user register

4. Measure RH (Hold master)

5. Measure RH (No Hold master)

6. PROM read RH

8 bits Command

7

6

5

4

1

1

1

1

1

1

1

1

1

1

1

0

1

1

1

1

1

1

1

0

0

0

1

0

hex value

3

2

1

0

1

0

0

0

0

adr2

1

1

1

1

1

adr1

1

1

1

0

0

adr0

0

0

1

1

1

0

0xFE

0xE6

0xE7

0xE5

0xF5

0xA0 to 0xAE

Figure 4: command structure for relative humidity sensing

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 7

�MS8607-02BA01

PHT Combination Sensor

USER REGISTER

The user register is used to configure several operating modes of the humidity sensor (resolution measurements,

heater) and monitor the battery state. The possible configurations of the user register are described in the table

below.

User register Bit

Bit Configuration/Coding

Default value

bit 7, bit 0

Measurement resolution

‘00’

Bit 7

0

0

1

1

bit 6

bit 3,4,5

bit 2

bit 1

Bit 0

0

1

0

1

OSR

4096

2048

1024

256

Resolution

Highest

Lowest

Battery state:

‘0’ VDD>2.25V

‘1’ VDD>1]>>8);

for (n_bit = 8; n_bit > 0; n_bit--)

{

if (n_rem & (0x8000))

n_rem = (n_rem 12) & 0x000F);

// final 4-bit remainder is CRC code

return (n_rem ^ 0x00);

}

C CODE EXAMPLE FOR CRC-4 CALCULATION (RH MEMORY PROM)

unsigned char crc4_RH(unsigned int n_prom[])

{

int cnt;

unsigned int n_rem=0;

unsigned char n_bit;

// n_prom defined as 8x unsigned int (n_prom[8])

// simple counter

// crc remainder

n_prom[6]=((n_prom[6]) & 0xFFF0);

// CRC byte is replaced by 0

n_prom[7]=0;

// Subsidiary value, set to 0

for (cnt = 0; cnt < 16; cnt++)

// operation is performed on bytes

{

// choose LSB or MSB

if (cnt%2==1)

n_rem ^= (unsigned short) ((n_prom[cnt>>1]) & 0x00FF);

else

n_rem ^= (unsigned short) (n_prom[cnt>>1]>>8);

for (n_bit = 8; n_bit > 0; n_bit--)

{

if (n_rem & (0x8000))

n_rem = (n_rem 12) & 0x000F);

// final 4-bit remainder is CRC code

return (n_rem ^ 0x00);

}

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 18

�MS8607-02BA01

PHT Combination Sensor

PIN CONFIGURATION

Type

Function

1

Nam

e

VDD

P

Positive supply voltage

3

GND

G

Ground

7

SDA

IO

I2C data IO

8

SCL

SCL

NC

I

Serial data clock

Pin

2,4,5,6

DEVICE PACKAGE OUTLINE

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 19

�MS8607-02BA01

PHT Combination Sensor

RECOMMENDED PAD LAYOUT

Pad layout for bottom side of the MS8607-02BA01 soldered onto printed circuit board.

Reserved area:

Please do not route

tracks between pads

SHIPPING PACKAGE

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 20

�MS8607-02BA01

PHT Combination Sensor

MOUNTING AND ASSEMBLY CONSIDERATIONS

SOLDERING

Please refer to the application note AN808 available on our website for all soldering issues.

MOUNTING

The MS8607 can be placed with automatic Pick & Place equipment using vacuum nozzles. It will not be damaged

by the vacuum. Due to the low stress assembly the sensor does not show pressure hysteresis effects. It is

important to solder all contact pads.

CONNECTION TO PCB

The package outline of the module allows the use of a flexible PCB for interconnection. This can be important for

applications in watches and other special devices.

CLEANING

The MS8607 has been manufactured under cleanroom conditions. It is therefore recommended to assemble the

sensor under class 10’000 or better conditions. Should this not be possible, it is recommended to protect the

sensor opening during assembly from entering particles and dust. To avoid cleaning of the PCB, solder paste of

type “no-clean” shall be used. Cleaning might damage the sensor!

ESD PRECAUTIONS

The electrical contact pads are protected against ESD up to 2 kV HBM (human body model). It is therefore

essential to ground machines and personnel properly during assembly and handling of the device. The MS8607 is

shipped in antistatic transport boxes. Any test adapters or production transport boxes used during the assembly of

the sensor shall be of an equivalent antistatic material.

DECOUPLING CAPACITOR

Particular care must be taken when connecting the device to the power supply. A minimum 220nF ceramic

capacitor must be placed as close as possible to the MS8607 VDD pin. This capacitor will stabilize the power

supply during data conversion and thus, provide the highest possible accuracy.

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 21

�MS8607-02BA01

PHT Combination Sensor

ORDERING INFORMATION

Part Number / Art. Number

MS860702BA01-50

Product

Delivery Form

PHT Combination Sensor Module 5x3mm

Tape & Reel

NORTH AMERICA

EUROPE

ASIA

Measurement Specialties, Inc.,

a TE Connectivity company

Tel: 800-522-6752

Email: customercare.frmt@te.com

Measurement Specialties (Europe), Ltd.,

a TE Connectivity Company

Tel: 800-440-5100

Email: customercare.bevx@te.com

Measurement Specialties (China) Ltd.,

a TE Connectivity company

Tel: 0400-820-6015

Email: customercare.shzn@te.com

TE.com/sensorsolutions

Measurement Specialties, Inc., a TE Connectivity company.

Measurement Specialties, TE Connectivity, TE Connectivity (logo) and EVERY CONNECTION COUNTS are trademarks. All other logos, products and/or company names referred to

herein might be trademarks of their respective owners.

The information given herein, including drawings, illustrations and schematics which are intended for illustration purposes only, is believed to be reliable. However, TE Connectivity makes

no warranties as to its accuracy or completeness and disclaims any liability in connection with its use. TE Connectivity‘s obligations shall only be as set forth in TE Connectivity‘s Standard

Terms and Conditions of Sale for this product and in no case will TE Connectivity be liable for any incidental, indirect or consequential damages arising out of the sale, resale, use or

misuse of the product. Users of TE Connectivity products should make their own evaluation to determine the suitability of each such product for the specific application.

© 2015

TE Connectivity Ltd. family of companies

All Rights Reserved.

SENSOR SOLUTIONS ///MS8607-02BA01

06/2017

Page 22

�