Flame-Proof Power Metal Oxide Film Resistors

Key Features

Type ROX Series

High Power

with Small

Size for Space

Saving

Excellent Long

Term Stability

Controlled

Temperature

Capability

The resistive element comprises a metal oxide film deposited on a ceramic

former. The element is protected by a flameproof coating which will withstand

overload conditions without flame or mechanical damage. They are

recommended for use in applications such as line protection etc

Characteristics – Electrical

Solvent

Resistant Coat

and Code

Normal Size

Small Size

Special Lead

Formations

Possible

Type

ROX025

ROX05

ROX1

ROX2

ROX3

ROX5

ROX7

ROX8

ROX9

ROX05S

ROX1S

ROX2S

ROX3S

ROX4S

ROX5SS

ROX5S

Rated

Power @

70°C

0.25W

0.5W

1W

2W

3W

5W

7W

8W

9W

0.5W

1W

2W

3W

4W

5W

5W

Max.

Working

Voltage

250V

250V

350V

350V

500V

750V

750V

750V

750V

250V

350V

350V

350V

500V

500V

500V

Max.

Overload

Voltage

400V

400V

600V

600V

800V

1000V

1000V

1000V

1000V

400V

600V

600V

600V

800V

800V

800V

Dielectric

Withstand

Voltage

250V

250V

350V

350V

500V

750V

750V

750V

750V

250V

350V

350V

350V

500V

500V

500V

Resistance

Range

Ω

0.3 ~ 50K

0.3 ~ 330K

0.1 ~ 470K

0.1 ~ 560K

5.0 ~ 100K

5.0 ~ 150K

20 ~ 150K

30 ~ 200K

50 ~ 200K

0.3 ~ 50K

0.1 ~ 270K

0.1 ~ 470K

0.3 ~ 560K

5.0 ~ 100K

5.0 ~ 100K

5.0 ~ 560K

Operating

Temp.

Range

-55 ~ 155°C

Complete

Flameproof

Construction

Resistors shall have a rated direct-current (DC) continuous working voltage or an

approximate sine-wave root-mean-square (RMS) alternating-current (AC) continuous

working voltage at commercial line frequency and waveform corresponding to the

power rating , as determined from the following formula :

RCWV = √P x R

Where : RCWV = Rated DC or RMS AC continuous working voltage at commercial-line

frequency and waveform (volt)

P = Power Rating (watt)

R = Nominal Resistance (ohm)

Rated Voltage = RCWV or Max. Working Voltage, whichever is smaller

1773271 Rev. G 01/2019

Dimensions in

millimetres unless

otherwise specified

Dimensions Shown for

reference purposes only.

Specifications subject to

change

For Email, phone or live chat,

go to: www.te.com/help

�Flame-Proof Power Metal Oxide Film Resistors

Environmental Characteristics

Characteristics

DC. Resistance

Specification

Must be within the specified

tolerance

Range Ω

Temperature

Coefficient

1773271 Rev. G 01/2019

. Ω~ Ω

. Ω~

K

101K ~ 1M

1.1M ~ 10M

TCR

(PPM/°C)

±200

±350

-700

-1500

Short time

overload

Resistance change rate is

Nor al Size : ± % + . 5Ω Max.

S all Size : ± % + . 5Ω Max.

with no evidence of mechanical

damage

Dielectric

Withstanding

Voltage

No evidence of flashover

mechanical damage, arcing or

insulation break down

Terminal Strength

No Evidence of mechanical

damage

Resistance to

soldering heat

Resistance change rate is:

± % + . 5Ω Max. with o

evidence of mechanical damage

Solderability

95 % coverage Min.

Dimensions in

millimetres unless

otherwise specified

Dimensions Shown for

reference purposes only.

Specifications subject to

change

Test Methods

( JIS C 5201-1 )

5.1 The limit of error of

measuring apparatus shall not

exceed allowable range or 5% of

resistance tolerance

5.2 Natural resistance change per

temp. degree centigrade.

R -R

R (t -t )

x 10⁶ (PPM/℃)

R : Resistance value at room

temperature (t )

R : Resistance value at room temp.

plus 100 ℃ (t )

5.5 Permanent resistance change

after the application of a

potential of 2.5 times RCWV or

the max. overload voltage

respectively specified in the

above list, whichever less for 5

seconds

5.7 Resistors shall be clamped in

the trough of a 90° metallic Vblock and shall be tested at AC

potential respectively specified in

the electrical characteristics table

for

60 + 10/ -0 seconds

6.1 Direct load:

Resistance to a 2.5 kgs direct load

for 10 secs. in the direction of the

longitudinal axis of the terminal

leads

Twist test:

Terminal leads shall be bent

through 90 ° at point of about

6mm from the body of the

resistor and shall be rotated

through 360° about the original

axis of the bent terminal in

alternating direction for a total of

3 rotations.

6.4 Permanent resistance change

when leads immersed to 3.2 mm

to 4.8 mm from the body in

350℃ ± 10 ℃ solder for 3 ± 0.5

seconds

6.5 The area covered with a new ,

smooth, clean , shiny and

continuous surface free from

concentrated pinholes.

Test temp. of solder: 245℃ ± 3℃

Dwell time in solder : 2 ~ 3

seconds

For Email, phone or live chat,

go to: www.te.com/help

�Flame-Proof Power Metal Oxide Film Resistors

Environmental Characteristics (continued)

Characteristics

Specification

Resistance to

Solvent

No deterioration of protective

coatings and marking

Temperature

cycling

Resistance change rate is:

± % + . 5Ω Max. with no

evidence of mechanical damage

Resistance Value

Less tha

KΩ

KΩ or ore

△R/R

±5%

± 10 %

Load life

Resistance Value

Less tha

KΩ

KΩ or ore

△R/R

±5%

± 10 %

Pulse overload

Resistance change rate is:

Nor al Size : ± % + . 5Ω Max.

S all Size : ± 5% + . 5Ω Max.

with no evidence of mechanical

damage

Load life in

humidity

Test Methods

( JIS C 5201-1 )

6.9 Specimens shall be immersed

in a bath of trichroethane

completely for 3 minutes with

ultrasonic

7.4 Resistance change after

continuous 5 cycles for duty

shown below:

Step

Step

Step

1

1

1

2

2

2

3

3

3

4

4

4

7.9 Resistance change after 1,000

hours operating at RCWV with

duty cycle of (1.5 hours "on", 0.5

hour "off") in a humidity test

chamber controlled at 40 ℃ ± 2

℃ and 90 to 95 % relative

humidity

7.10 Permanent resistance

change after 1,000 hours

operating at RCWV with duty

cycle of (1.5 hours "on", 0.5 hour

"off") at 70℃ ± 2℃ ambient

5.8 Resistance change after

10,000 cycles (1 second "on", 25

se o ds "off”) at 4 times RCWV

or the max. pulse overload

voltage

Derating:

In ambient temperatures greater than 70°C the load shall de-rate as shown in

the graph below:

1773271 Rev. G 01/2019

Dimensions in

millimetres unless

otherwise specified

Dimensions Shown for

reference purposes only.

Specifications subject to

change

For Email, phone or live chat,

go to: www.te.com/help

�Flame-Proof Power Metal Oxide Film Resistors

Construction:

No.

1

2

Name

Basic Body

Resistance Film

3

4

5

6

End Cap

Lead Wire

Joint

Coating

7

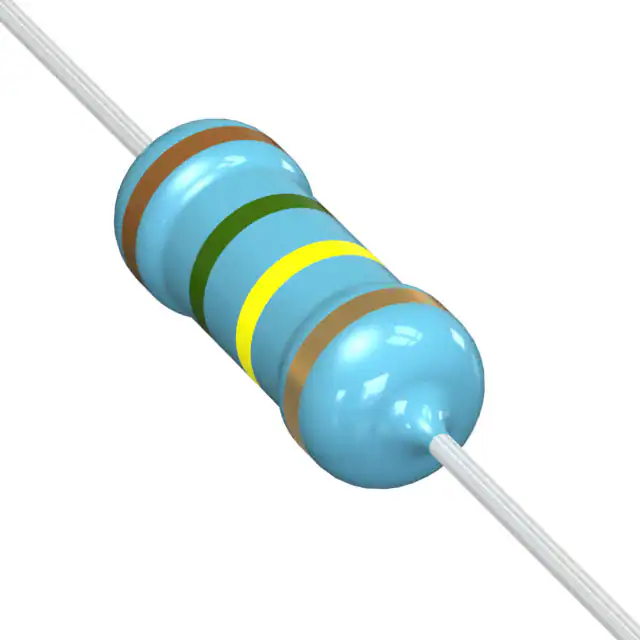

Color Code

Material

Rod Type Ceramics

. Ω ≤ R ≤ Ω : CNP fil

Ω≤R≤

kΩ : Metal oxide fil

R>

kΩ : Car o fil

Steel (Tin plated iron surface)

Annealed copper wire coated with tin

By welding

Normal size:

--Insulated & Non-Flame Paint (Color : Gray )

Small size:

--Insulated & Non-Flame Paint (Color : Sea-Blue )

Non-Flame epoxy resin

Dimensions:

Small Size

Normal Size

Type

ROX025

ROX05

ROX1

ROX2

ROX3

ROX5

ROX7

ROX8

ROX9

ROX05S

ROX1S

ROX2S

ROX3S

ROX4S

ROX5SS

ROX5S

D (max.)

2.5

3.5

5

5.5

6.5

8.5

8.5

8.5

8.5

2.5

3.5

5

5.5

6.5

6.5

8

Dimensions (MM)

L (max.)

d ±0.05

7.5

0.54

10

0.54

12

0.70

16

0.70

17.5

0.75

26

0.75

32

0.75

41

0.75

54

0.75

7.5

0.54

10

0.54

12

0.70

16

0.70

17.5

0.75

17.5

0.75

25

0.75

H ±3

28

28

25

28

28

38

38

38

38

28

28

25

28

28

28

38

NB. Pre-formed leads available on request.

1773271 Rev. G 01/2019

Dimensions in

millimetres unless

otherwise specified

Dimensions Shown for

reference purposes only.

Specifications subject to

change

For Email, phone or live chat,

go to: www.te.com/help

�Flame-Proof Power Metal Oxide Film Resistors

Painting method:

Welding point, terminal and lead wire, is permissible to be exposed without

the outer coated cover. The extent should be within 1/2 of the resistor body

diameter.

Marking:

For 1/4W, 1/2W, 1W, 2W, 3W, 4W, 5W and all of small size Resistors shall be

marked with color coding. colors shall be in accordance with JIS C 0802

For 7W, 8W, 9W marking shall be in text format:

Code description and regulation

1. Wattage rating.

2. Nominal resistance value.

3. Resistance Tolerance.

G: ± 2 %

J: ± 5 %

K: ± 10 %

1773271 Rev. G 01/2019

Dimensions in

millimetres unless

otherwise specified

Dimensions Shown for

reference purposes only.

Specifications subject to

change

For Email, phone or live chat,

go to: www.te.com/help

�Flame-Proof Power Metal Oxide Film Resistors

Packing Specification:

Small Size

Normal Size

Taping:

Type

ROX025

ROX05

ROX1

ROX2

ROX3

ROX05S

ROX1S

ROX2S

ROX3S

ROX4S

ROX5SS

Style

PT-52

PT-52

PT-52

PT-64

PT-64

PT-52

PT-52

PT-52

PT-64

PT-64

PT-64

O±1

52

52

52

64

64

52

52

52

64

64

64

P

5±0.3

5±0.3

5±0.3

10±0.5

10±0.5

5±0.3

5±0.3

5±0.3

10±0.5

10±0.5

10±0.5

L1-L2

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

T

6±1

6±1

6±1

6±1

6±1

6±1

6±1

6±1

6±1

6±1

6±1

Z

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

1 Max

R

0

0

0

0

0

0

0

0

0

0

0

t

4±1

4±1

4±1

5±1

5±1

4±1

4±1

4±1

5±1

5±1

5±1

S

0.5 max

0.5 max

0.5 max

0.5 max

0.5 max

0.5 max

0.5 max

0.5 max

0.5 max

0.5 max

0.5 max

Tape in box packing (Ammopack):

Type

ROX025

ROX05

ROX1

ROX2

ROX3

ROX05S

ROX1S

ROX2S

ROX3S

ROX4S

ROX5SS

C±5

250

260

262

262

256

250

260

262

262

256

256

A±5

75

85

86

92

92

75

85

86

92

92

92

B±5

96

70

80

108

80

96

70

80

108

80

80

Pack Quantity

5000

1000

1000

1000

500

5000

1000

1000

1000

500

500

NB Certain products can be supplied reeled on request.

1773271 Rev. G 01/2019

Dimensions in

millimetres unless

otherwise specified

Dimensions Shown for

reference purposes only.

Specifications subject to

change

For Email, phone or live chat,

go to: www.te.com/help

�Flame-Proof Power Metal Oxide Film Resistors

Plastic cases in box:

Type

C ±5

A ±5

B ±5

ROX5S

ROX5

36

36

20

20

8

8

Quantity

Plastic Case

Box

100

1000

100

1000

Bulk packaging (plastic bag in inner box):

Type

Qty/Bag

(Pcs)

Qty/Box

(Pcs)

Qty/Carton

Pcs

Box size

LxWxH (±5)

Carton size

LxWxH (±5)

ROX7

8

32

1600

150 x 75 x 33

ROX8

8

32

1600

150 x 75 x 33

ROX9

10

300

1800

200 x 171 x

113

432 x 308 x

215

432 x 308 x

215

520 x 215 x

250

Gross

wt

±2 Kgs

9.5

11.5

15

How To Order

ROX

Common

Part

ROX – Flame

proof power

metal oxide

film resistor

1773271 Rev. G 01/2019

1S

J

Power Rating

Tolerance

Normal size

025 - 1/4W

05 – 1/2W

1 – 1W

2 – 2W

3 – 3W

5 – 5W

7 – 7W

8 – 8W

9 – 9W

Dimensions in

millimetres unless

otherwise specified

100K

Resistance

Value

Special

Request

Small size

05S – 1/2W

1S – 1W

2S – 2W

3S – 3W

4S – 4W

5SS – 5W

5S – 5W

G – 2%

J – 5%

Dimensions Shown for

reference purposes only.

Specifications subject to

change

R33 -0.33Ω

1R0 - 1Ω

10R - 10Ω

100R - 100Ω

1K0 – 1KΩ

(1000Ω)

100K – 100KΩ

,

Ω

BL * – Preformed

Leads

TR Reeled

For Email, phone or live chat,

go to: www.te.com/help

�

很抱歉,暂时无法提供与“ROX3SJ150K”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格 香港价格

- 1+4.375821+0.54708

- 10+3.1665210+0.39589

- 25+2.5394325+0.31749

- 50+1.8862650+0.23583

- 100+1.33044100+0.16634

- 250+1.18526250+0.14819

- 500+1.01584500+0.12701