®

IS43/46QR16256A

Long-term Support

World Class Quality

256Mbx16 4Gb DDR4 SDRAM

FEBRUARY 2018

FEATURES

Standard Voltage : VDD = VDDQ = 1.2V, VPP=2.5V

High speed data transfer rates with system frequency

up to 2400 Mbps

Data Integrity

Signal Integrity

- Internal VREFDQ Training

- Read Preamble Training

- Gear Down Mode

- Auto Self Refresh (ASR) by DRAM built-in TS

- Per DRAM Adressability

- Auto Refresh and Self Refresh Modes

- Configurable DS for system compatibility

DRAM access bandwidth

- Separated IO gating structures by Bank Groups

- Self Refresh Abort

- Fine Granularity Refresh

Signal Synchronization

- Write Leveling via MR settings

- Read Leveling via MPR

Reliability & Error Handling

- Command/Address Parity (Not Supported)

- Configurable On-Die Termination

- Data bus Inversion (DBI)

- ZQ Calibration for DS/ODT impedance accuracy via external

ZQ pad (240 ohm +/- 1%)

Power Saving and efficiency

- POD with VDDQ termination

- Command/Address Latency (CAL)

- Maximum Power Saving

- Low power Auto Self Refresh (LPASR)

- Data bus Write CRC

- MPR readout

- Boundary Scan

Speed Grade (CL-TRCD-TRP)

Operating Temperature

- Commercial ( Tc = 0 oC to + 95 oC)

- Industrial ( Tc = - 40 oC to + 95oC)

- 2133Mbps / 15-15-15 (-093P)

- Automotive A1 ( Tc = - 40 oC to + 95 oC)

- 2400Mbps / 16-16-16 (- 083R)

- Automotive A2 ( Tc = - 40 oC to + 105 oC)

PPROGRAMMABLE FUNCTIONS

Output Driver Impedance (34/48)

ADDRESS TABLE

Parameter

256M x16

Row Addressing

A0-A14

Column Addressing

A0-A9

Bank Addressing

BA0-BA1

Bank Groups

BG0

Page size

2KB

CAS Write Latency (9/0/11/12/14/16/18)

Additive Latency (0/CL-1/CL-2)

CS# to Command Address (3/4/5/6/8)

Burst Type (Sequential/Interleaved)

Write Recovery Time (10/12/14/16/18/20/24)

Read Preamble (1T/2T)

Write Preamble (1T/2T)

Burst Length (BL8/BC4/BC4 or 8 on the fly)

Options

tRFC

260ns

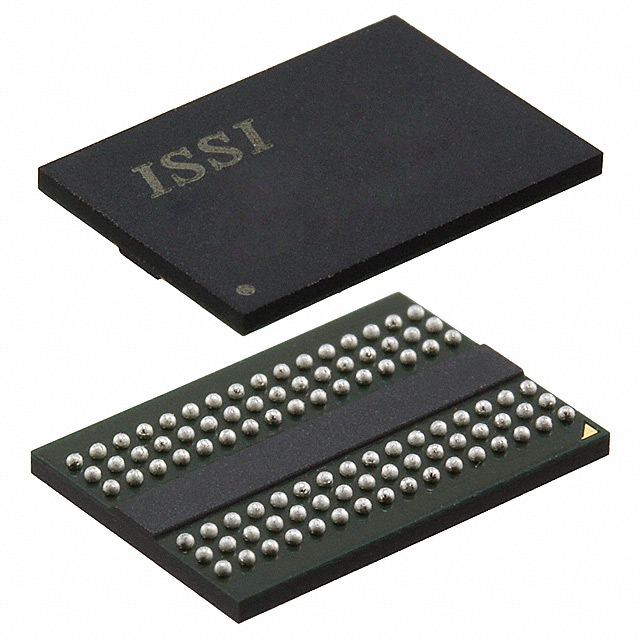

Configuration : 256Mx16

Package:

- 96-ball FBGA (9mm x 13mm, 0.8mm ball pitch)

Copyright © 2017 Integrated Silicon Solution, Inc. All rights reserved. ISSI reserves the right to make changes to this specification and its products at any time without notice. ISSI assumes no

liability arising out of the application or use of any information, products or services described herein. Customers are advised to obtain the latest version of this device specification before relying on

any published information and before placing orders for products.

Integrated Silicon Solution, Inc. does not recommend the use of any of its products in life support applications where the failure or malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly affect its safety or effectiveness. Products are not authorized for use in such applications unless Integrated Silicon

Solution, Inc. receives written assurance to its satisfaction, that:

a.) the risk of injury or damage has been minimized;

b.) the user assume all such risks; and

c.) potential liability of Integrated Silicon Solution, Inc is adequately protected under the circumstances

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

1

�® Long-term Support

World Class Quality

IS43/46QR16256A

1.2 DDR4 SDRAM package ball out 96-ball FBGA –x16 (Top View)

1

2

3

A

B

C

D

VDDQ

VPP

VDDQ

VDD

VSSQ

VSS

DQ12

VSSQ

DQ8

VDD

DQ10

DQ14

E

VSS

4

5

6

7

8

9

DQSU

DQSU

DQ11

DQ15

VSSQ

DQ9

DQ13

VSSQ

VDDQ

VDD

VSSQ

VDDQ

A

B

C

D

VSSQ

VSS

E

LDM/

LDBI

DQ1

F

VSSQ

UDM/

UDBI

VDDQ

G

H

J

K

VDDQ

VSSQ

VDD

VSS

DQ0

DQ4

VDDQ

CKE

DQSL

DQSL

DQ2

DQ6

ODT

L

VDD

WE/

A14

ACT

CS

CK

RAS/

A16

M

VREFCA

BG0

N

P

VSS

BA0

A6

A10/

AP

A4

A0

A12/

BC

A3

A1

CAS/

A15

BA1

A5

A8

A11

A2

PAR

A9

NC

A7

A13

R

T

RESET

VDD

VSS

VSSQ

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

VDD

DQ3

DQ7

CK

VDDQ

ZQ

F

VSS

DQ5

VDDQ

VDDQ

VSSQ

VDD

VSS

G

H

J

K

VDD

L

VSS

M

TEN

N

P

ALERT

VPP

VDD

R

T

2

�® Long-term Support

World Class Quality

IS43/46QR16256A

PINOUT DESCRIPTION

Symbol

Type

Function

Input

Clock: CK and CK are differential clock inputs. All address and control input signals

are sampled on the crossing of the positive edge of CK and negative edge of CK

CKE

Input

Clock Enable: CKE HIGH activates, and CKE Low deactivates, internal clock signals and

device input buffers and output drivers. Taking CKE Low provides Precharge PowerDown and Self-Refresh operation (all banks idle), or Active Power-Down (row Active in

any bank). CKE is synchronous for Self-Refresh exit. After VREFCA and Internal DQ Vref

have become stable during the power on and initialization sequence, they must be

maintained during all operations (including Self-Refresh). CKE must be maintained high

throughout read and write accesses. Input buffers, excluding CK, CK, ODT and CKE

are disabled during power-down. Input buffers, excluding CKE, are disabled during SelfRefresh.

CS

Input

Chip Select: All commands are masked when CS is registered HIGH. CS provides

for external Rank selection on systems with multiple Ranks. CS is considered part of

the command code.

ODT

Input

On Die Termination: ODT (registered HIGH) enables RTT_NOM termination resistance

internal to the DDR4 SDRAM. When enabled, ODT is applied to each DQ, DQSU,

DQSU, DQSL, DQSL, UDM and LDM signal. The ODT pin will be ignored if MR1 is

programmed to disable RTT_NOM.

ACT

Input

Activation Command Input : ACT_n defines the Activation command being entered along

with CS. The input into RAS/A16, CAS/A15 and WE/A14 will be considered as

Row Address A16, A15 and A14

CK, CK

RAS/A16.

CAS/A15

WE/A14

LDM, UDM

UDBI, LDBI

BG0

BA0 - BA1

A0 - A16

A10 / AP

Input

Input/Output

Command Inputs: RAS/A16, CAS/A15 and WE/A14 (along with CS) define the

command being entered. Those pins have multi function. For example, for activation

with ACT Low, those are Addressing like A16,A15 and A14 but for non-activation

command with ACT High, those are Command pins for Read, Write and other

command defined in command truth table

Input Data Mask and Data Bus Inversion: DM is an input mask signal for write data.

Input data is masked when DM is sampled LOW coincident with that input data during

a Write access. DM is sampled on both edges of DQS. DM is muxed with DBI function

by Mode Register A10,A11,A12 setting in MR5. DBI is an input/output

identifying whether to store/output the true or inverted data. If DBI is LOW, the data will

be stored/output after inversion inside the DDR4 SDRAM and not inverted if DBI is

HIGH. The DM and DBI functions must be configured in Mode Register Settings

Input

Bank Group Inputs: BG0 define to which bank group an Active, Read, Write or

Precharge command is being applied. BG0 also determines which mode register is to be

accessed during a MRS cycle. BG1 is not used for this component.

Input

Bank Address Inputs: BA0 - BA1 define to which bank an Active, Read, Write or

Precharge command is being applied. Bank address also determines which mode

register is to be accessed during a MRS cycle.

Input

Address Inputs: Provide the row address for ACTIVATE Commands and the column

address for Read/Write commands to select one location out of the memory array in the

respective bank. (A10/AP, A12/BC, RAS/A16, CAS/A15 and WE/A14 have

additional functions, see other rows.The address inputs also provide the op-code during

Mode Register Set commands. A15 and A16 are used on some higher densities.

Input

A12 / BC

Input

RESET

Input

Auto-precharge: A10 is sampled during Read/Write commands to determine whether

Autoprecharge should be performed to the accessed bank after the Read/Write

operation. (HIGH: Autoprecharge; LOW: no Autoprecharge).A10 is sampled during a

Precharge command to determine whether the Precharge applies to one bank (A10

LOW) or all banks (A10 HIGH). If only one bank is to be precharged, the bank is selected

by bank addresses.

Burst Chop: A12 / BC is sampled during Read and Write commands to determine if

burst chop (on-the-fly) will be performed. (HIGH, no burst chop; LOW: burst chopped).

See command truth table for details.

Active Low Asynchronous Reset: Reset is active when RESET is LOW, and inactive

when RESET is HIGH. RESET must be HIGH during normal operation. RESET is

a CMOS rail to rail signal with DC high and low at 80% and 20% of VDD,

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

3

�® Long-term Support

World Class Quality

IS43/46QR16256A

Symbol

Type

DQ0-DQ15

Input / Output

DQS, DQS,

DQSU, DQSU,

DQSL, DQSL

Input / Output

TDQS, TDQS

PAR

ALERT

TEN

Output

Input

Input/Output

Input

Function

Data Input/ Output: Bi-directional data bus. If CRC is enabled via Mode register then

CRC code is added at the end of Data Burst. Any DQ from DQ0~DQ3 may indicate the

internal Vref level during test via Mode Register Setting MR4 A4=High. During this mode,

RTT should be set Hi-Z.

Data Strobe: output with read data, input with write data. Edge-aligned with read data,

centered in write data. DQSL corresponds to the data on DQ0-DQ7;

DQSU corresponds to the data on DQ8-DQ15. The data strobe DQS, DQSL and

DQSU are paired with differential signals DQS, DQSL, and DQSU, respectively,

to provide differential pair signaling to the system during reads and writes. DDR4

SDRAM supports differential data strobe only and does not support single-ended.

Termination Data Strobe is not applicable. The TDQS function must be disabled

via mode register A11 = 0 in MR1.

The feature command and Address Parity is not supported. This should be treated as

NC or RFU.

Alert: It has multi functions such as CRC error flag, Command and Address Parity error

flag as Output signal. If there is error in CRC, then ALERT goes LOW for the period time

interval and goes back HIGH. If there is error in Command Address Parity Check, then

ALERT goes LOW for relatively long period until on going DRAM internal recovery

transaction to complete. During Connectivity Test mode, this pin works as input.

Using this signal or not is dependent on system. In case of not connected as Signal,

ALERT Pin must be bounded to VDD on board.

Connectivity Test Mode Enable: Required on X16 devices and optional input on x4/x8

with densities equal to or greater than 8Gb.HIGH in this pin will enable Connectivity Test

Mode operation along with other pins. It is a CMOS rail to rail signal with AC high and low

at 80% and 20% of VDD. Using this signal or not is dependent on System. This pin may

be DRAM internally pulled low through a weak pull-down resistor to VSS.

No Connect: No internal electrical connection is present.

NC

VDDQ

Supply

DQ Power Supply: 1.2 V +/- 0.06 V

VSSQ

Supply

DQ Ground

VDD

Supply

Power Supply: 1.2 V +/- 0.06 V

VSS

Supply

Ground

VPP

Supply

DRAM Activating Power Supply: 2.5V (2.375V min, 2.75V max)

VREFCA

Supply

Reference voltage for CA

ZQ

Supply

Reference Pin for ZQ calibration

NOTE Input only pins (BG0, BA0-BA1, A0-A17, ACT, RAS/A16, CAS/A15, WE/A14, CS, CKE, ODT, and RESET) do not supply

termination.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

4

�® Long-term Support

World Class Quality

IS43/46QR16256A

Simplified State Diagram

Power

applied

Power

On

RESET

SRX*

MRS

Reset

SRX*

MRS

ZQ

Calibra on

Self

Refresh

SRX

MRS

MRS

MRS

SRE

MRS

Test

Refreshing

REF

Idle

ZQCL, ZQCS

TEN=1

Any powered state

MRS, MPR,

Write Leveling,

VrefDQ training

PDA

mode

ZQCL

Connectivity TEN=0 RESET

Automa c Sequence

Command Sequence

CKE_L

Ini aliza on

Procedure

SRX* = SRX with NOP

IVREFDQ,

RTT, etc

MPSM

PDE

ACT

CKE_L

CKE_L

PDX

Ac ve

Power

Down

Precharge

Power

Down

Activa ng

PDX

PDE

Bank

Ac ve

WRITE

WRITE

READ

WRITE A

READ

READ A

READ

Wri ng

Reading

WRITE

WRITE A

READ A

READ A

WRITE A

Wri ng

Reading

PRE, PREA

PRE, PREA

PRE, PREA

Precharging

Abbr. Function

ACT

Ac ve

PRE

Precharge

PREA Precharge All

ZQCS ZQ Calibra on Short

Abbr.

Function

Read

RD, RDS4, RDS8

Read A RDA, RDAS4, RDAS8

Write

WR, WRS4, WRS8 with/without CRC

Write A WRA, WRAS4, WRAS8 with/without CRC

PDE

Enter Power-down

PDX

Exit Power-down

SRE

Self-Refresh entry

SRX

Self-Refresh exit

RESET Start RESET Procedure

TEN

Boundary Scan Mode Enable

MPR

Mul -Purpose Register

ZQCL ZQ Calibra on Long

REF

Refresh, Fine granularity Refresh

MRS Mode Register Set

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

Abbr. Function

5

�IS43/46QR16256A

® Long-term Support

World Class Quality

BASIC FUNCTIONALITY

The DDR4 SDRAM is a high-speed dynamic random-access memory internally organized with eight-banks

(2 bank groups each with 4 banks). The DDR4 SDRAM uses a 8n prefetch architecture to achieve

high-speed operation. The 8n prefetch architecture is combined with an interface designed to transfer two data

words per clock cycle at the I/O pins. A single read or write operation for the DDR4 SDRAM consists of a single

8n-bit wide, four clock data transfer at the internal DRAM core and eight corresponding n-bit wide, one-half

clock cycle data transfers at the I/O pins.

Read and write operation to the DDR4 SDRAM are burst oriented, start at a selected location, and continue for

a burst length of eight or a ‘chopped’ burst of four in a programmed sequence. Operation begins with the

registration of an ACTIVATE Command, which is then followed by a Read or Write command. The address bits

registered coincident with the ACTIVATE Command are used to select the bank and row to be activated

(BG0 select the bankgroup; BA0-BA1 select the bank; A0-A14 select the row; refer to Addressing section for

more details). The address bits registered coincident with the Read or Write command are used to select the

starting column location for the burst operation, determine if the auto precharge command is to be issued (via A10),

and select BC4 or BL8 mode ‘on the fly’ (via A12) if enabled in the mode register.

Prior to normal operation, the DDR4 SDRAM must be powered up and initialized in a predefined manner. The

following sections provide detailed information covering device reset and initialization, register definition,

command descriptions, and device operation.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

6

�® Long-term Support

World Class Quality

IS43/46QR16256A

RESET and Initialization Procedure

RESET and Initialization Procedure

For power-up and reset ini aliza on, in order to prevent DRAM from func oning improperly, default values for the

following MR se ngs are de ned:

Default MR se ngs for power-up and reset ini aliza on

MR funcƟŽns

MR bits

Value

Gear-down mode

MR3 A[3]

1/2 Rate

Per DRAM Addressability

MR3 A[4]

Disable

MR4 A[1]

Disable

CS to Command/Address Latency

Max Power Saving Mode

MR4 A[8:6]

Disable

CA Parity Latency Mode

MR5 A[2:0]

Disable

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

7

�IS43/46QR16256A

® Long-term Support

World Class Quality

Power-Up and Initialization Sequence

The following sequence (Step 1-15) is required for power-up and ini aliza on:

1) Apply power (RESET is recommended to be maintained below 0.2 × VDD; all other inputs may be unde ned). RESET

needs to be maintained for minimum 200 s with stable power. CKE is pulled LOW any me before RESET is being

deasserted (MIN me 10ns). The power voltage ramp me between 300mV to VDD, min must be no greater than

200ms, and, during the ramp, VDD must be greater than or equal to VDDQ and (VDD - VDDQ) < 0.3V. VPP must ramp

at the same me or earlier than VDD, and VPP must be equal to or higher than VDD at all mes.

During power-up, either of the following condi ons may exist and must be met:

Condi on A

– VDD and VDDQ are driven from a single-power converter output.

– The voltage levels on all balls other than VDD, VDDQ, VSS, and VSSQ must be less than or equal to VDDQ, and VDD on

one side and must be greater than or equal to VSSQ and VSS on the other side.

– VTT is limited to 0.76V MAX when the power ramp is complete.

– VREFCA tracks VDD/2.

Condi on B

– Apply VDD without any slope reversal before or at the same me as VDDQ.

– Apply VDDQ without any slope reversal before or at the same me as VTT and VREFCA.

– Apply VPP without any slope reversal before or at the same me as VDD.

– The voltage levels on all pins other than VPP, VDD, VDDQ, VSS, and VSSQ must be less than or equal to VDDQ and VDD

on one side and must be larger than or equal to VSSQ and VSS on the other side.

2) A er RESET is de-asserted, wait for another 500 s un l CKE becomes ac ve.

During this me, the DRAM will start internal state ini aliza on; this will be done independently of external clocks.

A reasonable a empt was made in the design to have the DRAM power up with the following default MR se ngs

(Refer to the table: default MR se ngs for power-up and reset ini aliza on).

3) Clocks (CK, CK) need to be started and stabilized for at least 10ns or 5 tCK Clocks (CK, CK) need to be started and

stabilized for at least 10ns or 5 tCK (whichever is larger) before CKE goes ac ve. Because CKE is a synchronous

signal, the corresponding setup me to clock (tIS) must be met. Also, a DESELECT command must be registered

(with tIS setup me to clock) at clock edge Td. A er the CKE is registered HIGH a er RESET, CKE needs to be

con nuously registered HIGH un l the ini aliza on sequence is nished, including expira on of tDLLK and tZQINIT.

4) The DDR4 SDRAM keeps its ODT in High-Z state as long as RESET is asserted. Further, the SDRAM keeps its ODT in

High-Z state a er RESET de-asser on un l CKE is registered HIGH. The ODT input signal may be in an unde ned

state un l tIS before CKE is registered HIGH. When CKE is registered HIGH, the ODT input signal may be sta cally

held at either LOW or HIGH. If RTT_NOM is to be enabled in MR1, the ODT input signal must be sta cally held LOW.

In all cases, the ODT input signal remains sta c un l the power-up ini aliza on sequence is nished, including the

expira on of tDLLK and tZQINIT.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

8

�® Long-term Support

World Class Quality

IS43/46QR16256A

5) A er CKE is registered HIGH, wait a minimum of RESET CKE EXIT me, tXPR, before issuing the rst MRS command

to load mode register (tXPR = MAX (tXS; 5 × tCK).

6) Issue MRS command to load MR3 with all applica on se ngs, wait tMRD.

7) Issue MRS command to load MR6 with all applica on se ngs, wait tMRD.

8) Issue MRS command to load MR5 with all applica on se ngs, wait tMRD.

9) Issue MRS command to load MR4 with all applica on se ngs, wait tMRD.

10) Issue MRS command to load MR2 with all applica on se ngs, wait tMRD.

11) Issue MRS command to load MR1 with all applica on se ngs, wait tMRD.

12) Issue MRS command to load MR0 with all applica on se ngs, wait tMOD.

13) Issue a ZQCL command to start ZQ calibra on.

14) Wait for tDLLK and tZQINIT to complete.

15) The DDR4 SDRAM will be ready for normal opera on.

RESET and Initialization Sequence at Power-On Ramping

Ta

Tb

Tc

Td

Te

Tf

Tg

Th

Ti

Tj

Tk

CK,

tCKSRX

VPP

VDD/VDDQ

200 us

500 us

tIS

10 ns

VALID

CKE

**

tXPR

tMRD

tMRD

tDLLK

tIS

CMD

1)

BA[2:0]

tZQinit

tMOD

tMRD

MRS

MRS

MRS

MRS

MRx

MRx

MRx

MRx

ZQCL

VALID

VALID

tIS

tIS

ODT

1)

Static LOW in case RTT_Nom is eanbled at time Tg, otherwise static HIGH or LOW

VALID

DRAM_RTT

TIME BREAK

DON’T CARE

NOTE 1 From the me point Td un l Tk, a DES command must be applied between MRS and ZQCL commands.

NOTE 2 MRS commands must be issued to all mode registers that have de ned se ngs.

NOTE 3 In general, there is no speci c sequence for se ng the MRS loca ons (except for dependent or co-related features, such as ENABLE DLL in

MR1 prior to RESET DLL in MR0, for example).

NOTE 4 TEN is not shown; however, it is assumed to be held LOW.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

9

�® Long-term Support

World Class Quality

IS43/46QR16256A

VDD Slew Rate

Symbol

Min

Max

Units

NOTE

VDD_sl

0.004

600

V/ms

1,2

200

ms

3

VDD_on

NOTE 1 Measurement made between 300mV and 80% VDD (minimum level).

NOTE 2 The DC bandwidth is limited to 20MHz

NOTE 3 Maximum me to ramp VDD from 300 mV to VDD minimum.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

10

�® Long-term Support

World Class Quality

IS43/46QR16256A

RESET Initialization with Stable Power Sequence

The following sequence is required for RESET at no power interrup on ini aliza on:

1. Assert RESET below 0.2 × VDD any me when reset is needed (all other inputs may be unde ned). RESET needs to

be maintained for minimum 100ns. CKE is pulled LOW before RESET is de-asserted (MIN me 10ns).

2. Follow Steps 2 to 7 in the Reset and Ini aliza on Sequence at Power-on Ramping procedure.

When the reset sequence is complete, the DDR4 SDRAM is ready for normal opera on.

RESET Procedure at Power Stable Condition

Ta

Tb

Tc

.

Td

.

Te

.

Tf

.

Tg

.

Th

.

Ti

.

Tj

.

Tk

.

.

CK,

tCKSRX

VPP

VDD/VDDQ

500 us

tPW_RESET

tIS

10 ns

VALID

CKE

tXPR

tMRD

tMRD

tMOD

tMRD

tZQin

tDLLK

tIS

CMD

1)

BA[2:0]

MRS

MRS

MRS

MRS

MRx

MRx

MRx

MRx

ZQCL

1)

VALID

VALID

tIS

ODT

Static LOW in case RTT_Nom is eanbled at time Tg, otherwise static HIGH or LOW

VALID

DRAM_RTT

TIME BREAK

DON’T CARE

NOTE 1 From the me point Td un l Tk, a DES command must be applied between MRS and ZQCL commands.

NOTE 2 MRS commands must be issued to all mode registers that have de ned se ngs.

NOTE 3 In general, there is no speci c sequence for se ng the MRS loca ons (except for dependent or co-related features, such as ENABLE DLL in

MR1 prior to RESET DLL in MR0,for example).

NOTE 4 TEN is not shown; however, it is assumed to be held LOW.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

11

�IS43/46QR16256A

® Long-term Support

World Class Quality

PROGRAMMING MODE REGISTERS

Mode Register Set (MRS)

MRS

Purpose

Range

DescripƟons

For applica on exibility, various func ons, features, and modes.

Seven Mode Registers. They are divided into various elds depending on func onality and modes.

1. As the default values of the Mode Registers (MRn) are not de ned, contents of Mode Registers

must be fully ini alized and/or re-ini alized, i.e., wri en, a er power up and/or reset for proper

opera on, as user de ned variables and they must be programmed.

2. MRS command and DLL Reset do not a ect array contents, which mean these commands can be

executed any me a er power-up without a ec ng the array contents.

3. When programming the mode registers, even if the user chooses to modify only a sub-set of the

MRS elds, all address elds within the accessed mode register must be redefined when the MRS

command is issued.

4. The contents of the Mode Registers can be altered by re-execu ng the MRS command during

normal opera on as long as the DRAM is in idle state, i.e., all banks are in the precharged state

with tRP sa s ed, all data bursts are completed and CKE is high prior to wri ng into the mode

register. If the RTT_NOM Feature is enabled in the Mode Register prior and/or a er an MRS

Command, the ODT Signal must con nuously be registered LOW ensuring RTT is in an o State

prior to the MRS command. The ODT Signal may be registered high a er tMOD has expired. If the

RTT_NOM feature is disabled in the Mode Register prior and a er an MRS command, the ODT

signal can be registered either LOW or HIGH before, during and a er the MRS command.

Regula ons

5. The mode register set command cycle me, tMRD is required to complete the write opera on to

the mode register and is the minimum me required between two MRS commands.

6. The most MRS command to Non-MRS command delay, tMOD, is required for the DRAM to update

the features, and is the minimum me required from an MRS command to a non-MRS command

excluding DES.

7. Some of the Mode Register se ngs a ect address/command/control input func onality. In these

cases, func on upda ng takes longer than tMOD so the next MRS command only can be allowed

when the func on upda ng by current MRS command completed. These MRS commands do not

apply tMRD ming to next MRS command. These MRS command input cases have unique a MR

se ng procedure, so refer to individual func on descrip on:

Gear-down mode

Per DRAM Addressability

Max Power Saving Mode

CS to Command/Address Latency

CA Parity Latency Mode

VrefDQ training Value

VrefDQ Training mode

VrefDQ training Range

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

12

�IS43/46QR16256A

® Long-term Support

World Class Quality

tMRD Timing

NOTE 1 This ming diagram depicts C/A Parity Mode "Disabled" case.

NOTE 2 tMRD applies to all MRS commands with the following excep ons:

Geardown Mode

C/A Parity Mode

CAL Mode

Per DRAM addressability Mode

VrefDQ training value, VreDQ training mode, and VrefDQ Training Range

tMOD Timing

The MRS command to nonMRS command delay, tMOD, is required for the DRAM to update features, except DLL RESET,

and is the minimum me required from an MRS command to a nonMRS command, excluding DES.

NOTE 1 This ming diagram depicts C/A Parity Mode "Disabled" case.

NOTE 2 tMOD applies to all MRS commands with the following excep ons:

DLL Enable

Geardown Mode

CA Parity Mode

Maximum Power Savings Mode

Per DRAM addressability Mode

VrefDQ training value, internal Vref monitor, VreDQ training mode, and VrefDQ Training Range

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

13

�® Long-term Support

World Class Quality

IS43/46QR16256A

MRS Overview

Detail op ons are described on the following pages.

MR0

MR1

MR2

A13

A12

RFU1

RFU1

A13

A12

A11

Qoī 2

TDQS

A12

A11

A13

RFU

1

RFU

1

A13

MR4

RFU

1

A13

MR5

RFU

1

A13

MR6

MR7

RFU

Write CRC

A12

A9

A10

A9

A11

A10

A10

A9

A8

Write CMD Latency

A11

A10

A9

tRPRE

training

SRF abort

A12

A11

A10

A9

WDBI

DM

RFU

A11

A10

A9

tCCD_L

A12

A11

A9

A5

A4

RFU1

A6

A2

BT

CL5

A3

A2

AL

A5

A4

LPASR

A7

A3

A3

A2

CWL

A5

A4

A3

A2

PDA

Geardown

MPR

OperaƟon

A6

A5

RFU

A8

1

A7

A7

A6

RTT_Park

A8

1

A8

A7

A6

VrefDQ

Training

VrefDQ

Range

A7

A6

RFU

1

A53

ODT IB for

PD

A5

A0

BL

A1

A0

DLL

A1

RFU

TS

CS to CMD/ADDR Latency Mode

A1

ODI

A6

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

A4

Fine Granularity Refresh Mode

A8

RFU

A10

A6

A7

1

A5

CL5

A7

A8

RFU

tRPRE

A6

Wlev

A9

A12

A12

A7

TM

A8

tWPRE

RDBI

A8

DLL

Rst

RTT_NOM

RTT_WR

MPR Read Format

1

A13

A10

WR & RTP3,4

RFU1

A13

MR3

A11

A0

1

A1

A0

MPR Page SelecƟon

A4

A3

A2

A1

A0

Internal Vref

TCRM

TCRR

MPS

RFU

A3

A2

A4

RFU

A4

1

CRC error

A3

A1

RFU

A2

1

A0

1

A1

A0

A1

A0

VrefDQ Training Value

A5

A4

A3

A2

1

14

�® Long-term Support

World Class Quality

IS43/46QR16256A

Mode Register 0 (MR0)

BG0 BA1 BA0

MR Select

BG0 BA1

BA0

MR Select

ņ

RAS / CAS / WE /

A16

ņ

A11

A15

A14

A9

A12

RFU1 RFU1

ņ

A10

A13

WR

RTP

A11

A10

A9

3,4

WR & RTP

A8

A7

DLL

Rst

TM

A6

A5

A4

A3

A2

BT

CL5

CAS Latency

A1

A0

CL5

A8

DLL Reset

A3

BT

0

Sequen a l

1

Interl ea ve

A1

A0

BL

0

0

0

MR0

0

0

0

10

5

0

NO

0

0

1

MR1

0

0

1

12

6

1

YES

0

1

0

MR2

0

1

0

14

7

0

1

1

MR3

0

1

1

16

8

A6

A5

A4

A2

1

0

0

MR4

1

0

0

18

9

0

0

0

0

9

0

0

8 (Fixed)

1

0

1

MR5

1

0

1

20

10

0

0

0

1

10

0

1

BC4 or 8 (on the y)

1

1

0

MR6

1

1

0

24

12

0

0

1

0

11

1

0

BC4 (Fixed)

1

1

1

DNU

2

1

1

1

RFU

RFU

0

0

1

1

12

1

1

RFU

0

1

0

0

13

0

1

0

1

14

0

1

1

0

15

0

1

1

1

16

1

0

0

0

18

1

0

0

1

20

1

0

1

0

22

1

0

1

1

24

1

1

0

0

RFU

1

1

0

1

17

1

1

1

0

19

1

1

1

1

21

BL

6

NOTE 1 Please refer to addressing table. If the address is available, it must be programmed to 0 during MRS

NOTE 2 Reserved for Register control word se ng. DRAM ignores MR command with BG0,BA[1:0]=111 and doesn’t respond.

NOTE 3 WR (write recovery for autoprecharge)min in clock cycles is calculated by dividing tWR(in ns) by tCK(in ns) and rounding up to the next

integer:WRmin[cycles] = Roundup(tWR[ns] / tCK[ns]). The WR value in the mode register must be programmed to be equal or larger than

WRmin. The programmed WR value is used with tRP to determine tDAL.

NOTE 4 The table shows the encodings for Write Recovery and internal Read command to Precharge command delay. For actual Write recovery

ming, please refer to AC ming table.

NOTE 5 The table only shows the encodings for a given Cas Latency. For actual supported Cas Latency, please refer to speedbin tables for each

frequency.

NOTE 6 When CL is equal to 24 or more than 24, AL does not support CL-1.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

15

�® Long-term Support

World Class Quality

IS43/46QR16256A

Burst Length, Type, and Order

Accesses within a given burst may be programmed to sequen al or interleaved order. The ordering of accesses within a

burst is determined by the burst length, burst type, and the star ng column address as shown in the following Burst

Type and Burst Order table. Burst length op ons include xed BC4, xed BL8, and on-the- y (OTF), which allows BC4 or

BL8 to be selected coincident with the registra on of a READ or WRITE command via A12/ BC.

Burst

Length

READ/

WRITE

StarƟng

Column

Address

Burst Type (Decimal)

SequenƟal

Interleaved

Notes

A2 A1 A0 B0 B1 B2 B3 B4 B5 B6 B7 B0 B1 B2 B3 B4 B5 B6 B7

READ

BC4

WRITE

BL8

READ

WRITE

0

0

0

0

1

2

3

T

T

T

T

0

1

2

3

T

T

T

T

1,3

0

0

1

1

2

3

0

T

T

T

T

1

0

3

2

T

T

T

T

1,2,3

0

1

0

2

3

0

1

T

T

T

T

2

3

0

1

T

T

T

T

1,2,3

0

1

1

3

0

1

2

T

T

T

T

3

2

1

0

T

T

T

T

1,2,3

1

0

0

4

5

6

7

T

T

T

T

4

5

6

7

T

T

T

T

1,2,3

1

0

1

5

6

7

4

T

T

T

T

5

4

7

6

T

T

T

T

1,2,3

1

1

0

6

7

4

5

T

T

T

T

6

7

4

5

T

T

T

T

1,2,3

1

1

1

7

4

5

6

T

T

T

T

7

6

5

4

T

T

T

T

1,2,3

0

V

V

0

1

2

3

X

X

X

X

0

1

2

3

X

X

X

X

1,2,4,5

1

V

V

4

5

6

7

X

X

X

X

4

5

6

7

X

X

X

X

1,2,4,5

0

0

0

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

2

0

0

1

1

2

3

0

5

6

7

4

1

0

3

2

5

4

7

6

2

0

1

0

2

3

0

1

6

7

4

5

2

3

0

1

6

7

4

5

2

0

1

1

3

0

1

2

7

4

5

6

3

2

1

0

7

6

5

4

2

1

0

0

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

2

1

0

1

5

6

7

4

1

2

3

0

5

4

7

6

1

0

3

2

2

1

1

0

6

7

4

5

2

3

0

1

6

7

4

5

2

3

0

1

2

1

1

1

7

4

5

6

3

0

1

2

7

6

5

4

3

2

1

0

2

V

V

V

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

2,4

NOTE 1 In the case of se ng burst l ength to BC4 ( xed) in MR0, the internal WRITE opera on starts two clock cycles earlier than for the

BL8 mode. This means that the star ng point for tWR and tWTR will be pulled in by two clocks. In the case of se ng burst

length to on-the- y in MR0, the internal WRITE opera on starts at the same point in me as a BL8 (even if BC4 was selected

during column me using A12/BC4). This means that if the on-the- y MR0 se ng is used, the star ng point for tWR and

tWTR will not be pulled in by two clocks as described in the BC4 ( xed) case.

NOTE 2 Bit number(B0…B7) is the value of CA[2:0] that causes this bit to be the rst READ during a burst.

NOTE 3 T = Output driver for data and strobes are in High-Z.

NOTE 4 V = Valid logic level (0 or 1), but respec ve bu er input ignores level on input pins.

NOTE 5 X = “Don’t Care.”

CAS Latency (CL)

The CAS latency se ng is de ned in the MR0 Register De ni on table. CAS latency is the delay, in clock cycles, between

the internal READ command and the availability of the rst bit of output data. DDR4 SDRAM does not support any

half-clock latencies. The overall read latency (RL) is de ned as addi ve latency (AL) + CAS latency (CL); RL = AL + CL.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

16

�IS43/46QR16256A

® Long-term Support

World Class Quality

Test Mode

The normal opera ng mode is selected by MR0[7] and all other bits set to the desired values shown in the MR0 Register

De ni on table. Programming MR0[7] to a 1 places the DDR4 SDRAM into a DRAM manufacturer de ned test mode

that is to be used only by the DRAM manufacturer; and should not be used by the end user. No opera ons or

func onality is speci ed if MR0[7] = 1.

Write Recovery/Read to Precharge

The programmed WR value MR0[11:9] is used for the auto precharge feature along with tRP to determine tDAL. WR

(write recovery for auto precharge) MIN in clock cycles is calculated by dividing tWR (in ns) by tCK (in ns) and rounding

up to the next integer:

WRmin[cycles] = roundup (tWR[ns]/tCK[ns])

The WR must be programmed to be equal to or larger than tWR(MIN). When both DM and Write CRC are enabled in

the DRAM mode register, the DRAM calculates CRC before sending the write data into the array; tWR values will change

when enabled. If there is a CRC error, the DRAM blocks the write opera on and discards the data.

RTP (internal READ command to PRECHARGE command delay for auto precharge) min in clock cycles is calculated by

dividing tRTP (in ns) by tCK (in ns) and rounding up to the next integer:

RTPmin[cycles] = roundup (tRTP[ns]/tCK[ns])

The RTP value in the mode register must be programmed to be equal or larger than RTPmin. The programmed RTP

value is used with tRP to determine the act ming to the same bank.

DLL Reset

The DLL reset bit is self-clearing, meaning that it returns back to the value of 0 a er the DLL reset func on has been

issued. A er the DLL is enabled, a subsequent DLL RESET should be applied. Any me that the DLL reset func on is used,

tDLLK must be met before any func ons that require the DLL can be used (for example, READ commands or ODT

synchronous opera ons).

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

17

�® Long-term Support

World Class Quality

IS43/46QR16256A

Mode Register 1 (MR1)

BG0 BA1 BA0

ņ

MR Select

ņ

A12

BG0

RAS / CAS /

A16

A15

WE/

A14

ņ

A13

RFU

Qoī (Data output disable)

1

A12

Qoī

A11

2

A10 A9

TDQS

A11

TDQS

A8

RTT_NOM

A7

Wlev

A7 Write Leveling

A6 A5 A4 A3

RFU

1

AL

A2 A1

ODI

DLL

ODI

Enabled (normal opera on)

0

Disabled

0

Disabled

0

0

RZQ/7(34 ohm)

1

Disabled (both ODI & RTT)

1

Enabled

1

Enabled

0

1

RZQ/5(48 ohm)

1

0

RFU

1

1

RFU

MR Select

A10

A9

A8

RTT_NOM

A4

A3

AL

A0

DLL

0

Disabled

1

Enabled

0

0

0

MR0

0

0

0

Disabled

0

0

Disabled

0

0

1

MR1

0

0

1

RZQ/4 (60 )

0

1

CL-1

0

1

0

MR2

0

1

0

RZQ/2 (120 )

1

0

CL-2

0

1

1

MR3

0

1

1

RZQ/6 (40 )

1

1

RFU

1

0

0

MR4

1

0

0

RZQ/1 (240 )

1

0

1

MR5

1

0

1

RZQ/5 (48 )

1

1

0

MR6

1

1

0

RZQ/3 (80 )

1

4

1

1

1

RZQ/7 (34 )

1

A1 A0

0

BA1 BA0

1

A2

DNU

5

3

NOTE 1 Please refer to addressing table. If the address is available, it must be programmed to 0 during MRS

NOTE 2 Outputs disabled - DQs, DQSs, DQSs.

NOTE 3 States reversed to “0 as Disable” with respect to DDR4.

NOTE 4 Reserved for Register control word se ng. DRAM ignores MR command with BG0,BA[1:0]=111 and doesn’t respond.

NOTE 5 Not allowed when 1/4 rate geardown mode is enabled.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

18

�IS43/46QR16256A

® Long-term Support

World Class Quality

DLL Enable/DLL Disable

The DLL must be enabled for normal opera on and is required during power-up ini aliza on and upon returning to

normal opera on a er having the DLL disabled. During normal opera on, (DLL-enabled) with MR1[0], the DLL is

automa cally disabled when entering the SELF REFRESH opera on and is automa cally re-enabled upon exit of the SELF

REFRESH opera on. Any me the DLL is enabled and subsequently reset, tDLLK clock cycles must occur before a READ

or SYNCHRONOUS ODT command can be issued to allow me for the internal clock to be synchronized with the

external clock. Failing to wait for synchroniza on to occur may result in a viola on of the tDQSCK, tAON, or tAOF

parameters.

During tDLLK, CKE must con nuously be registered HIGH. DDR4 SDRAM does not require DLL for any WRITE opera on,

except when RTT_WR is enabled and the DLL is required for proper ODT opera on.

The direct ODT feature is not supported during DLL-o mode. The ODT resistors must be disabled by con nuously

registering the ODT pin LOW and/or by programming the RTT_NOM bits MR1[9,6,2] = 000 via a MODE REGISTER SET

command during DLL-o mode.

The dynamic ODT feature is not supported in DLL-o mode; to disable dynamic ODT externally, use the MRS command

to set RTT_WR, MR2[10:9] = 00.

Output Driver Impedance Control

The output driver impedance of the DDR4 SDRAM device is selected by MR1[2,1].

ODT RTT_NOM Values

DDR4 SDRAM is capable of providing three di erent termina on values: RTT_Sta c, RTT_NOM, and RTT_WR. The

nominal termina on value, RTT_NOM, is programmed in MR1. A separate value (RTT_WR) may be programmed in MR2

to enable a unique RTT value when ODT is enabled during WRITEs. The RTT_WR value can be applied during WRITEs

even when RTT_NOM is disabled. A third RTT value, RTT_Sta c, is programed in MR5. RTT_Sta c provides a termina on

value when the ODT signal is LOW.

Additive Latency (AL)

The addi ve latency (AL) opera on is supported to make command and data bus e cient for sustainable bandwidths in

DDR4 SDRAM. In this opera on, the DDR4 SDRAM allows a READ or WRITE command (either with or without AUTO

PRECHARGE) to be issued immediately a er the ACTIVE command. The command is held for the me of AL before it is

issued inside the device. The read latency (RL) is controlled by the sum of the AL and CAS latency (CL) register se ngs.

Write latency (WL) is controlled by the sum of the AL and CAS write latency (CWL) register se ngs.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

19

�® Long-term Support

World Class Quality

IS43/46QR16256A

Write Leveling

For be er signal integrity, DDR4 memory modules use y-by topology for the commands,addresses, control signals, and

clocks. Fly-by topology has the bene t of reducing the number of stubs and their length, but it also causes ight- me

skew between clock and strobe at every DRAM on the DIMM. This makes it di cult for the controller to maintain tDQSS,

tDSS, and tDSH speci ca ons. Therefore, the DDR4 SDRAM supports a write-leveling feature, which allows the

controller to compensate for skew.

Output Disable

The DDR4 SDRAM outputs may be enabled/disabled by MR1[12]. When MR1[12] = 1 is enabled, all output pins (such as

DQ, DQS, and DQS) are disconnected from the device, which removes any loading of the output drivers. This feature

may be useful when measuring module power, for example.For normal opera on, set MR1[12] = 0.

Termination Data Strobe (TDQS)

Termina on data strobe (TDQS) is a feature of x8 DDR4 SDRAM and provides addi onal termina on resistance outputs

that may be useful in some system con gura ons. Because the TDQS func on is available only in x8 DDR4 SDRAM, it

must be disabled for x4 and x16 con gura ons. TDQS is not supported in x4 or x16 con gura ons. When enabled via

the mode register, the same termina on resistance func on that is applied to the TDQS and TDQS pins is applied to the

DQS and DQS pins.

The TDQS, DBI, and data mask func ons share the same pin. When the TDQS func on is enabled via the mode register,

the data mask and DBI func ons are not supported. When the TDQS func on is disabled, the data mask and DBI

func ons can be enabled separately.

TDQS

Disabled

Enabled

Data Mask (DM)

WRITE DBI

READ DBI

Enabled

Disabled

Enabled or disabled

Disabled

Enabled

Enabled or disabled

Disabled

Disabled

Enabled or disabled

Disabled

Disabled

Disabled

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

20

�® Long-term Support

World Class Quality

IS43/46QR16256A

Mode Register 2 (MR2)

BG0

BA1

BA0

ņ

ņ

MR Select

BG0

BA1

BA0

MR Select

0

0

0

MR0

0

0

1

MR1

0

1

0

0

1

1

RAS / CAS /

A16

A15

ņ

WE /

A14

A13

RFU

1

A12

A11

Write

CRC

A10

A9

RTT_WR

A8

A7

RFU

1

A6

LPASR

A11

A10

A9

RTT_WR

0

0

0

Disabled(WRITE does

not a ect RTT value)

MR2

0

0

1

RZQ/2 (120 )

MR3

0

1

0

RZQ/1 (240 )

1

0

0

MR4

0

1

1

Hi-Z

1

0

1

MR5

A12

Write CRC

1

0

0

RZQ/3 (80 )

1

1

0

MR6

0

Disabled

1

0

1

RFU

1

1

1

DNU2

1

Enabled

1

1

0

RFU

1

1

1

RFU

A7

A6

0

0

Manual Mode- Normal Operaing Temperature Range(TC: 0°C–85°C)

0

1

Manual Mode- Reduced Operaing Temperature Range(TC: 0°C–45°C)

1

0

Manual Mode- Extended Operaing Temperature Range(TC: 0°C–95°C)

1

1

ASR mode - Automa cally switching among all modes

A5

A4

A3

A2

CWL

A1

RFU

A0

1

Low-power auto self refresh (LPASR)

Speed Grade in MT/s

A5

A4

A3

CWL

1 tCK tWPRE

2 tCK tWPRE

1st Set 2nd Set 1st Set 2nd Set

0

0

0

9

1600

-

-

-

0

0

1

10

1866

-

-

-

0

1

0

11

2133

1600

-

-

0

1

1

12

2400

1866

-

-

1

0

0

14

2666

2133

2400

-

1

0

1

16

3200

2400

2666

2400

1

1

0

18

-

2666

3200

2666

1

1

1

RFU

-

-

-

-

NOTE 1 Please refer to addressing table. If the address is available, it must be programmed to 0 during MRS

NOTE 2 Reserved for Register control word se ng. DRAM ignores MR command with BG0, BA[1:0]=111 and doesn’t respond.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

21

�IS43/46QR16256A

® Long-term Support

World Class Quality

CAS Write Latency (CWL)

CAS write latency (CWL) is de ned by MR2[5:3] as shown in the MR2 Register De ni on table. CWL is the delay, in clock

cycles, between the internal WRITE command and the availability of the rst bit of input data. DDR4 SDRAM does not

support any half-clock latencies. The overall write latency (WL) is de ned as addi ve latency (AL) + CAS write latency

(CWL); WL = AL + CWL.

Low-Power Auto Self Refresh (LPASR)

Low-power auto self refresh (LPASR) is supported in DDR4 SDRAM. Applica ons requiring SELF REFRESH opera on over

di erent temperature ranges can use this feature to op mize the IDD6 current for a given temperature range as

speci ed in the MR2 Register De ni on table.

Dynamic ODT (RTT_WR)

In certain applica ons and to further enhance signal integrity on the data bus, it is desirable to change the termina on

strength of the DDR4 SDRAM without issuing an MRS command. Con gure the Dynamic ODT se ngs in MR2[11:9]. In

write-leveling mode, only RTT_NOM is available.

Write Cyclic Redundancy Check (CRC) Data Bus

The Write cyclic redundancy check (CRC) data bus feature during Writes has been added to DDR4 SDRAM. When

enabled via the mode register, the data transfer size goes from the normal 8-bit (BL8) frame to a larger 10-bit UI frame,

and the extra 2UIs are used for the CRC informa on.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

22

�® Long-term Support

World Class Quality

IS43/46QR16256A

Mode Register 3 (MR3)

BG0

BA1

ņ

BA0

RAS / CAS /

A16

ņ

MR Select

A15

WE /

A14

ņ

A13

RFU

1

A12

A11

MPR Read

Format

A10

A9

Write CMD

Latency

A12

A11

MPR Read

Format

A5

0

0

Seri a l

0

Disabled

0

1

Pa ra l l el

1

Enabled

1

0

Staggered

1

1

RFU

Temperature

sensor readout

A8

A7

A6

Per DRAM

Addressability

0

1

0

Page 0

0

1

Page 1

Enabled

1

0

Page 2

1

1

Page 3

4nCK

1600

0

5nCK

1866/2133/2400

1

1/4 ra te

1

0

RFU

RFU

1

1

RFU

RFU

A2

MPR OperaƟon

0

Normal Opera on

1

Data ow from MPR

0

0

0

0

0

0

Fine Granularity Refresh

d

Norma l (Fi xed 1x)

0

0

1

MR1

0

0

1

Fi xed 2x

0

1

0

MR2

0

1

0

Fi xed 4x

0

1

1

MR3

0

1

1

RFU

1

0

0

MR4

1

0

0

RFU

1

0

1

MR5

1

0

1

On-the- y 1x/2x

1

1

0

MR6

1

1

0

On-the- y 1x/4x

1

1

1

DNU2

1

1

1

RFU

BA1

A0

MPR Page

SelecƟon

0

MR0

BG0

A1

Disabled(Normal

Opera on)

0

A3

A2

MPR Page

SelecƟon

1

Speed Bin

A3

Geard MPR

PDA

own Operat

A0

0

Write CMD Latency

A4

A1

0

A9

TS

A4

Geardown

d

1/2 ra te

A10

A5

Fine Granularity

Refresh Mode

BA0

MR Select

A8

A7

A6

NOTE 1 Please refer to addressing table. If the address is available, it must be programmed to 0 during MRS

NOTE 2 Reserved for Register control word se ng. DRAM ignores MR command with BG0,BA[1:0]=111 and doesn’t respond.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

23

�IS43/46QR16256A

® Long-term Support

World Class Quality

WRITE CMD latency when CRC/DM enabled

The Write Command Latency (WCL) must be set when both Write CRC and DM are enabled for Write CRC persistent

mode. This provides the extra me required when comple ng a Write burst when Write CRC and DM are enabled.

Fine Granularity Refresh Mode

This mode had been added to DDR4 to help combat the performance penalty due to refresh lockout at high densi es.

Shortening tRFC and increasing cycle me allows more accesses to the chip and can produce higher bandwidth.

Temp Sensor Status

This mode directs the DRAM to update the temperature sensor status at MPR Page 2, MPR0 [4,3]. The temperature

sensor se ng should be updated within 32ms; at the me of MPR Read of the Temperature Sensor Status bits, the

temperature sensor status should be no older than 32ms.

Per-DRAM Addressability

The MRS command mask allows programmability of a given device that may be in the same rank (devices sharing the

same command and address signals). As an example, this feature can be used to program di erent ODT or VREF values

on DRAM devices within a given rank.

Gear-down Mode

The DDR4 SDRAM defaults in half-rate (1N) clock mode and u lizes a low frequency MRS command followed by a sync

pulse to align the proper clock edge for opera ng the control lines CS, CKE, and ODT when in quarter-rate (2N) mode.

For opera on in half-rate mode, no MRS command or sync pulse is required.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

24

�® Long-term Support

World Class Quality

IS43/46QR16256A

Mode Register 4 (MR4)

BG0

BA1

MR Select

BA0

ņ

RAS /

A16

CAS / WE/

A15

A14

ņ

ņ

RFU

A12

tWPRE

0

1nCK toggl e

2nCK toggl e

1

A13

1

A12

A11

A10

A9

tRPRE SRF

tWPRE tRPRE

training abort

A8

A7

A6

A5

CS to CMD/ADDR

RFU

Latency Mode

A4

1

A3

Internal

TCRM

Vref

A2

A1

A0

TCRR

MPS

RFU1

A10

READ

preamble

A4

Internal VREF

monitor

A1

3

0

Di s a bl ed

0

Di s a bl ed

0

Maximum power

savings mode

Norma l

4

1

Ena bl ed

1

Ena bl ed

1

Ena bl ed

A11

tRPRE

A9

Self refresh

abort mode

A3

Temperature controlled

refresh mode

A2

Temperature controlled

refresh range

0

1nCK toggl e 3

0

Di s a bl ed

0

Di s a bl ed

0

Norma l tempera ture mode

1

2nCK toggl e

1

Ena bl ed

1

Ena bl ed

1

Extended tempera ture

d

BG0

BA1

BA0

MR Select

A8

A7

A6

CAL

0

0

0

MR0

0

0

0

Di s a bl ed

0

0

1

MR1

0

0

1

3

0

1

0

MR2

0

1

0

4

0

1

1

MR3

0

1

1

5

1

0

0

MR4

1

0

0

6

1

0

1

MR5

1

0

1

8

1

1

0

MR6

1

1

0

RFU

1

1

1

DNU2

1

1

1

RFU

NOTE 1 Please refer to addressing table. If the address is available, it must be programmed to 0 during MRS

NOTE 2 Reserved for Register control word se ng .DRAM ignores MR command with BG0,BA[1:0]=111 and doesn’t respond.

NOTE 3 Not allowed when 1/4 rate Gear-down mode is enabled.

NOTE 4 When opera ng in 2tCK Write Preamble Mode, CWL must be programmed to a value at least 1 clock greater than the lowest CWL se ng

supported in the applicable tCK range.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

25

�IS43/46QR16256A

® Long-term Support

World Class Quality

WRITE Preamble

DDR4 SDRAM introduces a programmable WRITE preamble tWPRE that can either be set to 1tCK or 2 tCK via the MR3

register. Note the 1tCK se ng is similar to DDR3; however, the 2tCK se ng is di erent. When opera ng in 2tCK Write

Preamble Mode, CWL must be programmed to a value at least 1 clock greater than the lowest CWL se ng supported in

the applicable tCK range. Check the table of CWL Selec on for details.

READ Preamble

DDR4 SDRAM introduces a programmable READ preamble tRPRE that can be set to either 1tCK or 2tCK via the MR3

register. Note that both the 1tCK and 2tCK DDR4 preamble se ngs are di erent from what DDR3 SDRAM de ned. Both

of these READ preamble se ngs may require the memory controller to train (or READ-level) its data strobe receivers

using the READ preamble training.

READ Preamble Training

DDR4 supports programmable READ preamble se ngs (1tCK or 2tCK). This mode can be used by the memory controller

to train or READ level its data strobe receivers.

Temperature-Controlled Refresh (MR4[3] = 1 & MR2[6:7]=11)

When temperature-controlled refresh mode is enabled, the DDR4 SDRAM may adjust the internal refresh period to be

longer than tREFI of the normal temperature range by skipping external refresh commands with the proper gear ra o.

For example, the DRAM temperature sensor detected less than 45° C. Normal temperature mode covers the range of 0°

C to 85° C, while the extended temperature range covers 0° C to 95° C.

Command Address Latency (CAL)

DDR4 supports the command address latency (CAL) func on as a power savings feature. This feature can be enabled or

disabled via the MRS se ng. CAL is de ned as the delay in clock cycles (tCAL) between a CS registered LOW and its

corresponding registered command and address. The value of CAL (in clocks) must be programmed into the mode

register and is based on the roundup (in clocks) of [tCK(ns)/tCAL(ns)].

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

26

�IS43/46QR16256A

® Long-term Support

World Class Quality

Internal Vref Monitor

DDR4 generates its own internal VrefDQ. This mode is allowed to be enabled during VrefDQ training and when enabled,

Vref_ me-short and Vref_ me-long need to be increased by 10ns if DQ0, or DQ1, or DQ2, or DQ3 have 0pF loading;

and add an addi onal 15ns per pF of added loading.

Maximum Power Savings Mode

This mode provides the lowest power mode where data reten on is not required. When DDR4 SDRAM is in the

maximum power saving mode, it does not need to guarantee data reten on or respond to any external command

(except maximum power saving mode exit command and during the asser on of RESET signal LOW).

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

27

�® Long-term Support

World Class Quality

IS43/46QR16256A

Mode Register 5 (MR5)

BG0

BA1

ņ

BA0

ņ

MR Select

RAS /

CAS/

WE /

A16

A15

A14

ņ

A13

RTT_PARK

ODT IB

for PD

0

Di s a bl ed

0

Di s a bl ed

0

ODT Input Buīer

for Power Down

Ena bl ed

1

Ena bl ed

1

Ena bl ed

1

Di s a bl ed

MR0

0

1

Ena bl ed

1

0

MR2

0

1

1

MR3

1

0

0

MR4

1

0

1

MR5

1

1

0

MR6

1

1

1

0

A53

A6

A5

MR1

0

RFU1

A7

WRITE DBI

1

0

0

A8

A11

0

0

DM

A9

READ DBI

Data mask

(DM)

Di s a bl ed

BA0

A10

A12

A10

BA1

A11

RFU1 RDBI WDBI

MR Select

BG0

A12

DNU

2

A4

A3

RFU1

CRC

error

A2

A1

RFU1

0

CRC Error

Status

Cl ea r

1

Error

A3

A0

Parked ODT Value

(RTT_PARK)

A8

A7

A6

0

0

0

Di s a bl ed

0

0

1

RZQ/4 (60 )

0

1

0

RZQ/2 (120 )

0

1

1

RZQ/6 (40 )

1

0

0

RZQ/1 (240 )

1

0

1

RZQ/5 (48 )

1

1

0

RZQ/3 (80 )

1

1

1

RZQ/7 (34 )

NOTE 1 Please refer to addressing table. If the address is available, it must be programmed to 0 during MRS

NOTE 2 Reserved for Register control word se ng. DRAM ignores MR command with BG0,BA[1:0]=111 and doesn’t respond.

NOTE 3 When RTT_NOM Disable is set in MR1, A5 of MR5 will be ignored.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

28

�IS43/46QR16256A

® Long-term Support

World Class Quality

Data Bus Inversion (DBI)

The data bus inversion (DBI) func on has been added to DDR4 SDRAM and is supported for x8 and x16 con gura ons

only (x4 is not supported). The DBI func on shares a common pin with the DM and TDQS func ons. The DBI func on

applies to both READ and WRITE opera ons and cannot be enabled at the same me the DM func on is enabled. Refer

to the TDQS Func on Matrix table for valid con gura ons for all three func ons (TDQS/DM/DBI).

Data Mask (DM)

The data mask (DM) func on, also described as a par al write, has been added to DDR4 SDRAM and is supported for x8

and x16 con gura ons only (x4 is not supported). The DM func on shares a common pin with the DBI and TDQS

func ons. The DM func on applies only to WRITE opera ons and cannot be enabled at the same me the DBI func on

is enabled. Refer to the TDQS Func on Matrix table for valid con gura ons for all three func ons (TDQS/DM/DBI).

CA Parity Persistent Error Mode

Normal CA Parity Mode (CA Parity Persistent Mode disabled) no longer performs CA parity checking while the parity

error status bit remains set at 1. However, with CA Parity Persistent Mode enabled, CA parity checking con nues to be

performed when the parity error status bit is set to a 1.

ODT Input Buffer for Power Down

Determines whether the ODT input bu er is on or o during Power Down. If the ODT input bu er is con gured to be on

(enabled during power down), the ODT input signal must be at a valid logic level. If the input bu er is con gured to be

o (disabled during power down), the ODT input signal may be oa ng and the DRAM does not provide R TT_NOM

termina on. The DRAM may, however, provide R _Park termina on depending on the MR se ngs. This is primarily for

addi onal power savings.

CA Parity Error Status

DRAM will set the error status bit to 1 upon detec ng a parity error. The parity error status bit remains set at 1 un l the

DRAM Controller clears it explicitly using an MRS command.

CRC Error Status

DRAM will set the error status bit to 1 upon detec ng a CRC error. The CRC error status bit remains set at 1 un l the

DRAM controller clears it explicitly using an MRS command.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

29

�® Long-term Support

World Class Quality

IS43/46QR16256A

Mode Register 6 (MR6)

BG0

BA1

ņ

BA0

ņ

MR Select

RAS/

CAS/

WE /

A16

A15

A14

ņ

A13

RFU

A12

1

A11

A10

3

A9

A8

RFU

tCCD_L

1

A7

A6

VrefDQ

Training

VrefDQ

Range

A5

A4 A3 A2 A1 A0

VrefDQ Training Value

BG0

BA1

BA0

MR Select

A12

A11

A10

tCCD_L.m

in(nCK)

Remark

A7

VrefDQ Training

Enable

A6

VrefDQ

Range

0

0

0

MR0

0

0

0

4

2400Mbps

0

Di s a bl ed

0

Ra nge 1

0

0

1

MR1

0

0

1

5

TBD

1

Ena bl ed

1

Ra nge 2

0

1

0

MR2

0

1

0

6

TBD

0

1

1

MR3

0

1

1

7

TBD

1

0

0

MR4

1

0

0

8

TBD

1

0

1

MR5

1

0

1

RFU

1

1

0

MR6

1

1

0

RFU

1

1

1

DNU2

1

1

1

RFU

MR6

Range 1

Range 2

MR6

Range 1

Range 2

MR6

Range 1

Range 2

[5:0]

(MR6[6]=0) (MR6[6]=1) [5:0]

(MR6[6]=0) (MR6[6]=1) [5:0] (MR6[6]=0) (MR6[6]=1)

00 0000

60.00%

45.00% 00 1101

68.45%

53.45% 01 1010

76.90%

61.90%

MR6

[5:0]

10 0111

Range 1

Range 2

(MR6[6]=0) (MR6[6]=1)

85.35%

70.35%

00 0001

60.65%

45.65%

00 1110

69.10%

54.10%

01 1011

77.55%

62.55%

10 1000

86.00%

71.00%

00 0010

61.30%

46.30%

00 1111

69.75%

54.75%

01 1100

78.20%

63.20%

10 1001

86.65%

71.65%

00 0011

61.95%

46.95%

01 0000

70.40%

55.40%

01 1101

78.85%

63.85%

10 1010

87.30%

72.30%

00 0100

00 0101

62.60%

63.25%

47.60%

48.25%

01 0001

01 0010

71.05%

71.70%

56.05%

56.70%

01 1110

01 1111

79.50%

80.15%

64.50%

65.15%

10 1011

10 1100

87.95%

88.60%

72.95%

73.60%

00 0110

63.90%

48.90%

01 0011

72.35%

57.35%

10 0000

80.80%

65.80%

10 1101

89.25%

74.25%

00 0111

64.55%

49.55%

01 0100

73.00%

58.00%

10 0001

81.45%

66.45%

10 1110

89.90%

74.90%

00 1000

65.20%

50.20%

01 0101

73.65%

58.65%

10 0010

82.10%

67.10%

10 1111

90.55%

75.55%

00 1001

65.85%

50.85%

01 0110

74.30%

59.30%

10 0011

82.75%

67.75%

11 0000

91.20%

76.20%

00 1010

00 1011

66.50%

67.15%

51.50%

52.15%

01 0111

01 1000

74.95%

75.60%

59.95%

60.60%

10 0100

10 0101

83.40%

84.05%

68.40%

69.05%

91.85%

92.50%

76.85%

77.50%

00 1100

67.80%

52.80%

01 1001

76.25%

61.25%

10 0110

84.70%

69.70%

11 0001

11 0010

11 0011 to

111111

Reserved

Reserved

NOTE 1 Please refer to addressing table. If the address is available, it must be programmed to 0 during MRS

NOTE 2 Reserved for Register control word se ng. DRAM ignores MR command with BG0,BA[1:0]=111 and doesn’t respond.

NOTE 3 tCCD_L should be programmed according to the value de ned in AC parameter table per opera ng frequency.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

30

�IS43/46QR16256A

® Long-term Support

World Class Quality

tCCD_L Programming

The DRAM Controller must program the correct tCCD_L value. tCCD_L will be programmed according to the value

de ned in the AC parameter table per opera ng frequency.

VREFDQ Training Enable

VREFDQ Training is where the DRAM internally generates it’s own VREFDQ used by the DQ input receivers. The DRAM

controller must use a MRS protocol (adjust up, adjust down, etc.) for se ng and calibra ng the internal VREFDQ level.

The procedure is a series of Writes and Reads in conduc on with VREFDQ adjustments to op mize and verify the data

eye. Enabling VREFDQ Training should be used whenever MR6[6:0] register values are being wri en to.

VREFDQ Training Range

DDR4 de nes two VREFDQ training ranges - Range 1 and Range 2. Range 1 supports VREFDQ between 60% and 92% of

VDDQ while Range 2 supports VREFDQ between 45% and 77% of VDDQ. Range 1 is targeted for module based designs

and Range 2 is added targe ng point-to point designs.

VREFDQ Training Value

Fi y se ngs provided 0.65% of granularity steps sizes for both Range 1 and Range 2 of VREFDQ.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

31

�® Long-term Support

World Class Quality

IS43/46QR16256A

Mode Register 7 (MR7)

DRAM MR7 Ignore

The DDR4 SDRAM shall ignore any access to MR7 for all DDR4 SDRAM.Any bit se ng within MR7 may not take any

e ect in the DDR4 SDRAM.

BG0

BA1

ņ

BA0

ņ

MR Select

BG0

BA1

BA0

MR Select

0

0

0

MR0

0

0

1

MR1

0

1

0

MR2

0

1

1

MR3

1

0

0

MR4

1

0

1

MR5

1

1

0

MR6

1

1

1

DNU

RAS /

CAS /

WE /

A16

A15

A14

A13 A12 A11 A10

ņ

A9

A8

A7

RFU

A6

A5

A4 A3 A2 A1 A0

1

2

NOTE 1 Please refer to addressing table. If the address is available, it must be programmed to 0 during MRS

NOTE 2 Reserved for Register control word se ng. DRAM ignores MR command with BG0,BA1;BA0=111 and doesn’t respond.

Integrated Silicon Solution, Inc. — www.issi.com

Rev. A

05/05/2017

32

�® Long-term Support

World Class Quality

IS43/46QR16256A

Truth Table

Command Truth Table

Note 1,2,3 and 4 apply to the entire Command truth table.

Note 5 applies to all Read/Write commands.

[BG = Bank group address;BA = Bank address; RA =Row address; CA = Column address; BC = Burst chop; X = Don’t Care; V = H or L]

CKE

Symbol Function

Prev. Pres.

MRS

REF

SRE

MODE REGISTER SET

Self refresh entry

H

H

H

H

H

L

SRX

Self refresh exit

L

H

Single-bank PRECHARGE

Device DESELECTED

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

PDE

Power-down entry

H

L

PDX

Power-down exit

L

H

ZQCL

ZQCS

ZQ CALIBRATION LONG

H

H

H

H

PRE

PREA

RFU

ACT

WR

WRS4

WRS8

WRA

WRAS4

WRAS8

RD

RDS4

RDS8

RDA

RDAS4

RDAS8

NOP

DES

REFRESH

PRECHARGE all banks

Reserved for future use

Bank ACTIVATE

Fixed BL8 or BC4

WRITE

BC4OTF

BL8OTF

WRITE

with auto

precharge

Fixed BL8 or BC4

BC4OTF

BL8OTF

Fixed BL8 or BC4

READ

BC4OTF

BL8OTF

READ

with auto

precharge

Fixed BL8 or BC4

BC4OTF

BL8OTF

NO OPERATION

ZQ CALIBRATION SHORT

CS ACT