LDS8161/41

6-Channel / 4-Channel High-Side Linear WLED Driver

with LED Temperature Compensation Using LED-SenseTM , I 2C, and Digital PWM

FEATURES

TM

Six (8161) / or Four (8141) Power-Lite Linear LDO

current regulators with 50 mV dropout in a highside driver topology.

High temperature LED current de-rating using the

TM

LED-Sense temperature compensation

algorithm, which directly monitors an LED PN

junction. No external temperature sensor is

required.

2

I C compatible serial programming interface

2

LED current programmable via I C from 0 to

~32 mA in 256 linear steps. Three (8161) or two

(8141) separately controlled driver banks with 2

LED drivers each

Integrated PWM generator for LED dimming with

12-bit resolution and 256 I2 C-programmable

logarithmic duty cycle steps from 0% to 100%

(~0.17 dB per step)

Total combined dimming range of > 16,384:1

Power efficiency up to 98%; average efficiency

> 80% in Li-ion battery applications

Low current shutdown mode ( < 1 µA );

Soft start and current limiting

LED Short circuit detection and protection, LED

open detection

Thermal shutdown protection

Low EMI.

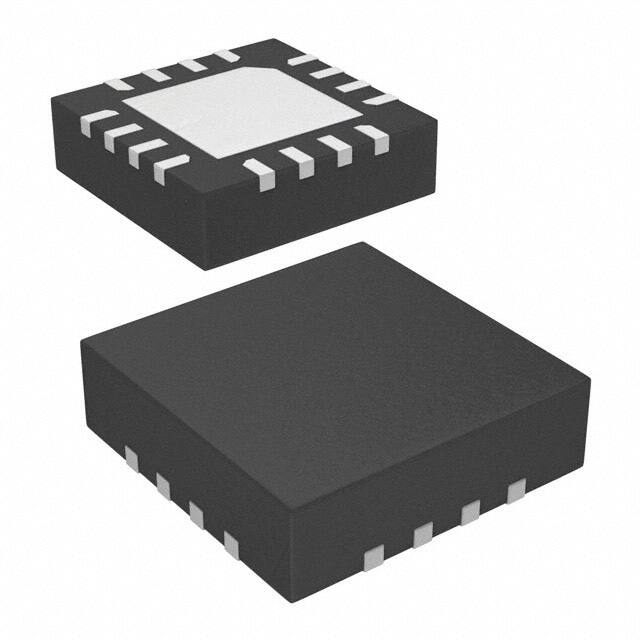

Available in 3 mm x 3 mm x 0.8 mm 16-pin TQFN

package

APPLICATIONS

Keypad and Display Backlight

Cellular Phone

PDAs and Smartphones

DESCRIPTION

The LDS8161 is a 6-channel and the LDS8141 is a 4channel linear LED driver for WLED applications. It

includes ultra low dropout LDO current regulators at a

maximum 31.875 mA per channel in a common

cathode high side driver topology.

The LDS8161/LDS8141 has an average efficiency of

> 80% in Li-ion battery applications. It includes three

(LDS8161) or two (LDS8141) 8-bit current setting

DACs (one per bank) allowing LED currents to be

2

programmed via an I C-compatible serial interface

from 0 to 31.875 mA in 256 steps of 125A per step.

The LDO drivers have a low dropout voltage of

50 mV typically at maximum rated current. This

provides a low power/low EMI solution in Li-ion

battery applications without voltage boosting and

associated external capacitors and components.

High temperature current de-rating insures LED

reliability and provides automatic adjustment of LED

current to achieve maximum specified LED

brightness across the ambient temperature range.

TM

The

proprietary

LED-Sense

temperature

compensation algorithm directly monitors the junction

temperature of an LED and applies current de-rating

per a user loadable LUT (look up table) in 5ºC steps.

No external temperature sensing device is needed.

An integrated 12-bit PWM generator with “smooth”

logarithmic control supports LED dimming and high

temperature current de-rating. The PWM duty cycle is

2

programmable via the I C serial interface from 0% to

100%. User programmed 8-bit codes are converted

to 12-bit resolution logarithmic steps of ~ 0.17 dB per

step. The PWM frequency is ~280 Hz to minimize

noise generation.

The EN logic input functions as a chip enable. A logic

HIGH applied at the EN pin allows the

2

LDS8161/LDS8141

to

respond

to

IC

communications. An external serial interface address

pin is available for use in multi-target applications.

The device operates from 2.5V to 5.5V.

The LDS8160 is available in a 3 x 3 x 0.8 mm

16-lead TQFN package.

3

�LDS8161/41

TYPICAL APPLICATION CIRCUITS

ABSOLUTE MAXIMUM RATINGS

Parameter

V IN, LEDx

EN, SDAT, SCLK, SADD voltage

Storage Temperature Range

Junction Temperature Range

Soldering Temperature

HBM

ESD Protection Level

MM

© 2009 IXYS Corp.

Characteristics subject to change without notice

Rating

6

V IN + 0.7V

-65 to +160

-40 to +125

300

2

200

2

Unit

V

V

°C

°C

°C

kV

V

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

RECOMMENDED OPERATING CONDITIONS

Parameter

VIN

ILED per LED pin

Total Output Current ILOAD

Junction Temperature Range

Rating

2.5 to 5.5

0 – 31.875

191.25

-40 to +125

Unit

V

mA

mA

°C

Typical application circuit with external components is shown on page 1.

ELECTRICAL OPERATING CHARACTERISTICS

(Over recommended operating conditions unless specified otherwise) VIN = 3.6V, CIN = 1 µF, EN = High, TAMB = 25°C

Name

LEDx Channel Current DAC Range

# of LEDx Current steps (linear steps)

LEDx Current DAC Resolution/step

EN = VIN

6/4 Channels at 100%

Quiescent Current

DC PWMs and Temp

De-Rating Active

Shutdown Current

LED Current Accuracy

LED Channel Matching

Line Regulation

1

Load Regulation

2

Dropout Voltage

PWM Frequency

# of PWM duty cycle steps

Conditions

Min

0

2

Standby (no I C clock)

ILOAD = 120 mA/ 80 mA

ILOAD = 60 mA / 40 mA

VEN = 0V

5 mA ≤ILED ≤30 mA

(ILED - ILEDAVG ) / I LEDAVG

2.7 V ≤VIN ≤4.2 V

0.2 V < Vdx < 1.2 V

1 mA ≤ILED ≤30 mA

Log Mode steps

Minimum PWM On Time

PWM resolution

PWM Step Size

of

PWM Steps for current de-rating

Log Mode

Log Mode

1-x Scale Mode

2-x Scale Mode

De-rating Temperature Adjust Steps

Programmable De-rating Start

Temperature (Tj) Range (typical)

Programmable LED Shutdown

Temperature(Tj) Range (typical)

Input current

EN Pin

Logic Level

High

Low

Input Current Limit

Thermal Shutdown

Thermal Hysteresis

Wake-up/Shutdown Delay Time from EN

Raising/Falling Edge

3

Output short circuit Threshold

Note:

Active mode, EN = VIN

Normal Standby

Active Mode or Normal

Standby Mode

Soft ramp disabled

Soft ramp enabled

ILED = 20 mA

Typ

Max

31.875

256

0.125

125

0.6/0.45

0.45/0.35 0.35

0.5

1

±1.5

±1.5

2

1

50

75

285

256

13.7

12

0.17

-7

0

-14

0

5

Units

mA

steps

mA

µA

mA

mA

µA

%

%

%/V

%/V

mV

Hz

µs

bits

dB

PWM

0

Steps/5 C

0

C

30

55

80

0

80

105

120

0

-1

1

5

1.2

0.4

450

150

20

10

250

0.14

C

C

µA

V

mA

°C

ms

ms

V

1. Vdx = Vin – V F,

2. Vdx = Vin – V F, at which IILED decreases by 10% from set value

3. Minimum LED forward voltage, which will be interpreted as “LED SHORT” condition

© 2009 IXYS Corp.

Characteristics subject to change without notice

3

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

I 2C CHARACTERISTICS

Over recommended operating conditions unless otherwise specified for 2.7 VIN 5.5V, over full ambient temperature range -40 to +85ºC.

Symbol

fSCL

tHD:STA

tLOW

tHIGH

tSU:STA

tHD:DAT

tSU:DAT

tR

tF

tSU:STO

tBUF

tAA

tDH

Parameter

SCL Clock Frequency

Hold Time (repeated) START condition

LOW period of the SCL clock

HIGH period of the SCL clock

Set-up Time for a repeated START condition

Data In Hold Time

Data In Set-up Time

Rise Time of both SDAT and SCLK signals

Fall Time of both SDAT and SCLK signals

Set-up Time for STOP condition

Bus Free Time between a STOP and START condition

SCLK Low to SDAT Data Out and ACK Out

Data Out Hold Time

Min

0

0.6

1.3

0.6

0.6

0

100

Max

400

Unit

kHz

µs

µs

µs

µs

ns

ns

ns

ns

µs

µs

µs

ns

0.9

300

300

0.6

1.3

0.9

300

2

Figure 1: I C Bus Timing Diagram

READ OPERATION:

Option 1: Standard protocol sequential read:

S

Slave Address

R

A

Data 0

A

Data 1

A

From: Reg. m

Reg. m+1

where Reg. m is the last addressed in the write operation register

Data 2

Data n

A*

Reg. m+2

Reg. m+n,

P

Option 2: Random access:

S

Slave Address

R

A

Data m

A*

P

From reg. m, where Reg. m is the last addressed in the write operation register

Option 3: Random access with combined (extended) protocol:

S

Slave Address

W

A

Register Address m

A

Sr

Slave Address

R

A

Data m

A*

P

WRITE OPERATION:

Option 1: Standard protocol sequencial write:

S

Slave Address

W

A

Register Address m

A

Data 0

To: Reg. m

© 2009 IXYS Corp.

Characteristics subject to change without notice

4

A

Data 1

Reg. m+1

A

Data 2

Reg. m+2

Data k

A*

P

Reg. m+k

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

Option 2: Combined (extended) protocol:

S

Slave Address

W

A

Register Address m

A

Sr

Slave Address

W

A

Data

A*

P

To: Reg. m

S: Start Condition

Sr Start Repeat Condition

R, W: Read bit (1), Write bit (0)

A: Acknowledge (SDAT high)

A*: Not Acknowledge (SDAT low)

P: Stop Condition

Slave Address: Device address 7 bits (MSB first).

Register Address: Device register address 8 bits

Data: Data to read or write 8 bits

- send by master

- send by slave

I2 C BUS PROTOCOL

Standard protocol

Combined protocol:

WRITE INSTRUCTION SEQUENCE

Standard protocol:

Write Instruction Example - Setting 20mA Current in LEDB1 and LEDB2

© 2009 IXYS Corp.

Characteristics subject to change without notice

5

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

LDS8161 / 41 REGISTERS DEFINITION AND PROGRAMMING

Note: Unlisted register addresses are for factory use only; For proper operation write only to registers defined.

ADDRESS

00h

01h

02h

DESCRIPTION

Bank A Current setting

Bank B Current setting

Bank C Current setting

(8161 only; Not for 8141)

BITS

8

8

8

Channel Enable

(No Bits 5, 4 for C2 and

C1 respectively for 8141)

6

Bank A, B, C PWM Duty

Cycle

8

19h

LED Diagnostics Test

8

1Ch

LED Faults Status

( shorted to GND)

5

1Dh

LED Faults Status

(shorted to VIN/open)

5

1Eh

1Fh

Configuration register

Software reset, Standby

8

8

49h

Ta-Tj Temperature Offset

8

4Ah

LED Shutdown

Temperature

5

4Bh

2-x Table enable and

breakpoint (T-code)

6

56h – 5Dh

Temp De-rating LUT

25C to 100C

(one 5C step every

nibble)

ΔPWM code1[7:4],

ΔPWM code0[3:0] –

ΔPWM code13[7:4],

ΔPWM code12[3:0]

8

03h

05h

© 2009 IXYS Corp.

Characteristics subject to change without notice

NOTES

Reg00h – Reg02h data code = (ILED / 0.125 mA) (decimal)

converted into hex format

Bits 5:0 = 1 enables LEDs C2, C1, B2, B1, A2, A1

respectively (See

Table 1). Both LEDs from one bank should be disabled to

minimize power consumption.

Log Mode:

~ – 0.17dB dimming per LSB for currents > 300 µA; Refer to

8 to 12 bit conversion curve (Figure 3 and Table 10) for

resolution in range 0 – 300 µA

Data Code 00h = 0% Duty Cycle, FFh = 100% Duty Cycle

Example: 50% brightness reduction ( – 6dB) requires: 255 –

(– 6 dB / – 0.17 dB) = 255 – 35 = 220 (decimal) = DCh steps

See Table 2; Bit 5 = 1 sets user-initiated LED short/open

diagnostic

Bits from bit 5 to bit 0 represent LED status for LEDC2 –

LEDA1 respectively. Bit = 1 represents LED shorted to GND

Bits from bit 5 to bit 0 represent LED status for LEDC2 –

LEDA1 respectively. Bit = 1 represents LED shorted to

VIN /open

See Table 3

See Table 4

Since junction temperature is measured, the values loaded

here allow an offset to account for Tj – Ta gradient.

This allows de-rate tables to be referenced to Ta levels.

Two 4 bit offsets value for the LED and the Si Diode;

Bit [7:4] = Tj-Ta offset for the LEDs

Bit [3:0] = Tj-Ta offset for the Si diode.

Typically should set both offsets to be equal.

See Table 5 & 6

Defines T-code, at which LED current shuts down per LED

vendor de-rating specification (see Table 5); Factory default

0

value = 11100 (bin) = 1Ch represents 105 C Tj

Bit 5 = 1 – enable 2-x scale LUT ΔPWM code correction (derating) starting at the breakpoint set by T-code (bits 4:0)

Bit 5 = 0 – 1-x scale (default) for entire temperature range

Bit [4:0] defines T-code, where temperature de-rating starts,

or where 2-x scaling begins (see Table 5)

2

Two LUT words per I C address.

Each word contains two 4-bit numbers repres enting of ΔPWM

codes. See

Table 6 and Appendix 1 for LUT programming.

Factory default setting is Logarithmic Mode table for WLED

LED (Nichia NSSW020BT WLED).

Default table could be used for WLED de-rating.

De-Rating starts at 55ºC junction.

6

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

A0h

Silicon diode dV F/dT [7:0]

8

A2h

LED dV F/dT [7:0]

8

Silicon diode η[7:0]

8

D4h

Silicon diode R s offset

[7:0]

8

D6h

LED Rs offset [7:0]

8

C0h

Silicon diode VF temperature coefficient (K factor) :

Factory recommended loaded value is 36h = -1.71 mV/°C =

001 10110 (bin),

where bits from bit 7 to bit 5 represent integer part

[1(decimal) = 001 (bin)], and bits from bit 4 to bit 0 – fractional

part [0.710 / 0.03125 = 22 (decimal) = 10110 (bin)]

User-loaded VF temperature coefficient @ 1mA for LEDs

used at Banks A, B, C respectively.

Negative tracking is assumed with temperature;

Bits from bit 7 to bit 5 represent integer part and

bits from bit 4 to bit 0 - fractional part of the coefficient

0

Example: Temperature coefficient = -2.26 mV/ C;

Bit 7 – bit 6 = 2 (decimal) = 010 (bin), and

Bit 4 – bit 0 = INT{0.26 / 0.03125} = 8 (decimal) = 01000 (bin)

User loads 010 01000 (bin) = 48h = -2.25 (closest setting)

Silicon diode η(eta, or non-ideality factor):

Factory recommended loaded value is default is 1.00 =

01000000(bin) = 40h

Bits from bit 7 to bit 5 represent integer part and

bits from bit 4 to bit 0 - fractional part (resolution = 0.015625

per LSB)

Example: η= 1.00;

Bit 7 – bit 6 = 1 (decimal) = 01 (bin), and

Bit 5 – bit 0 = INT{0.00 / 0.015625} = 0 (dec) = 000000 (bin)

User loads 01 000000 = 40h = 1.00

Silicon diode series resistance offset

Factory recommended loaded value = 04h = ~ 68 ohms

-6

Formula (decimal) = 8192 x [(68 ohms x 8 x 10 A)/1.14 V]

LED Rs offset (user-loaded) for Banks A, B, and C LEDs

Typically LED Rs = 5 – 30 Ω

User loads per LED used. (1/slope of high current region of

LED I-V characteristic).

-4

Formula (decimal) = 8192 x [(Rs Ωx 8 x 10 A) / 1.14V]

Table 1

Register

Address

03h

(8161)

(8141)

Bit 7

LED

OT

Flag

Same

Channel Enable Register

Bit 4

Bit 3

Bit 2

Bit 6

Bit 5

N/A

Enable C2

Enable C1

Enable B2

N/A

N/A

N/A

Same

Bit 1

Bit 0

Enable B1

Enable A2

Enable A1

Same

Same

Same

Table 2

Register

Address

19h

Bit 7

Factory

Only

0*

Bit 6

Factory

Only

0*

Bit 5

Diagnostics

Request

0*

Digital Test Modes Register

Bit 4

Bit 3

Bit 2

Slow Ramp Fast PWM

Factory

Bypass = 1

adjust =1

Only

0*

Normal = 0*

0*

Bit 1

Post ADC Filter

Enable =1

Filter Off=0*

Bit 0

Factory

Only

0*

Note: *) Value by default

© 2009 IXYS Corp.

Characteristics subject to change without notice

7

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

Table 3

Register

Address

1Eh

Bit 7

Factory Set

1*

Factory trimmed;

User should write 0

Configuration Register

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Factory Factory Factory Factory

dT adjust

Only

Only

Only

Only

disabled = 1*

dT adjust

0*

0*

0*

0*

enabled = 0

Bit 1

Soft Start

disabled = 1

Soft Start

enabled = 0*

Bit 0

Factory

Only

0*

Note: *) Value by default

Table 4

Register

Address

1Fh

Note:

Bit 7

Software

reset = 1

Bit 6

Standby

mode = 1

Bit 5

Temperature

request = 1

Control Register

Bit 4

Calibration

request = 1

Normal operation = 0*

Bit 3

Custom OSC

trim = 1

Factory

preset = 0*

Bit 2

Bit 1

Bit 0

Osc

trim 2

**

Osc

trim 1

**

Osc

trim 0

**

*) Value by default

**) Trim code defined by customer

Bit 7 = 1 — Software reset: resets device, all registers reset/cleared.

Bit 6 = 1 — Standby (oscillator disabled, all registers retain programmed values.)

Table 5: Ta-Tj Temperature Gradient Offset

( Set offset code to match reference De-rate point in LUT from LED Tj to Ta. Typically LED and Si are equal)

Register

Address

49h

Note:

Bit 7

LED

Offset 3

0*

Bit 6

LED

Offset 2

0*

Bit 5

LED

Offset 1

0*

Control Register

Bit 4

Bit 3

LED

Si Diode

Offset 0

Offset 3

0*

0*

Bit 2

Si Diode

Offset 2

0*

Bit 1

Si Diode

Offset 1

0*

Bit 0

Si Diode

Offset 0

0*

*) Value by default

Table 6: Offset Codes for Tj-Ta Temperature Gradient Offset (both LED and Si per Table 5).

Temperature

0

Offset C

(Ta-Tj)

-40

-35

-30

-25

Bit3– Bit

0

1000

1001

1010

1011

Temperature

0

Offset C

(Ta-Tj)

-20

-15

-10

-5

Bit3– Bit

0

1100

1101

1110

1111

Temperature

0

Offset C

(Ta-Tj)

0

5

10

15

0000

0001

0010

0011

Temperature

0

Offset C

(Ta-Tj)

20

25

30

35

Bit4 –

Bit 0

10110

10111

11000

11001

11010

Temperature

0

C

100

105

110

115

120

Bit3–

Bit 0

Bit3–

Bit 0

0100

0101

0110

0111

Table 7: T-code values vs. Temperature (for registers 4Ah & 4Bh)

Temperature

0

C

25

30

35

40

45

Bit4 –

Bit 0

01100

01101

01110

01111

10000

Temperature

0

C

50

55

60

65

70

© 2009 IXYS Corp.

Characteristics subject to change without notice

Bit4 –

Bit 0

10001

10010

10011

10100

10101

Temperature

0

C

75

80

85

90

95

8

Bit4 –

Bit 0

11011

11100

11101

11110

11111

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

Table 8: LDS8161 / 41 Temperature De-rating LUT Register Allocation

(data stored is PWM code per each temperature point)

Data bits

Register

Address

Data bits

7 –4

3– 0

ΔPWM code for

0

temperature, C

Register

Address

7–4

3–0

ΔPWM code for

0

temperature, C

56h

30

25

5Ah

70

65

57h

58h

59h

40

50

60

35

45

55

5Bh

5Ch

5Dh

80

90

100

75

85

95

Table 9: Valid ΔPWM Codes vs. Number of Adjustment Steps for LDS8161/ 41 De-rating

Number of

steps

Not Used

-7

-6

-5

Binary

Code

1000

1001

1010

1011

Number of

steps

-4

-3

-2

-1

Binary

Code

1100

1101

1110

1111

Number of

steps

0

Not Used

Not Used

Not Used

Binary

Code

0000

0001

0010

0011

Number of

steps

Not Used

Not Used

Not Used

Not Used

Binary

Code

0100

0101

0110

0111

PROGRAMMING EXAMPLES

Operation

Set 20 mA current at Bank LEDA

Set 30 mA at LEDA, 30 mA at LEDB, & 20 mA at LEDC banks

Turn LEDs A1, B1 and C1 on, all others off

Turn LEDs A2, B2, and C2 on, all others off

Turn all LEDs on

Set Bank A,B,C PWM duty Cycle at 50% (-6 dB)

Disable Temperature De-rating (DT_Adjust_disable)

Re-Enable Temperature De-rating

Short/open LED diagnostic request

Read out LED short to GND status

Read out LED short to VIN /open status

Set Standby Mode

Resume normal operation from standby mode

Calibration request (conduct temperature calibration)

0

Set LEDs in shutdown mode at junction temperature above 100 C

Set Ta-Tj offset for LED and Si Diode to -20ºC

Software Reset (to default values) and/or clear of all registers

Note:

Register

Address

00h

00h

03h

03h

03h

05h

1Eh

1Eh

19h

1Ch

1Dh

1Fh

1Fh

1Fh

4Ah

49h

1Fh

Register Data

A0h

F0h F0h A0h

15h

24h

3Fh

DCh

04h

00h

20h

40h

00h

10h

1Bh

CCh

80h

Command

(hex)

XX 00 A0

XX F0 F0 A0

XX 03 15

XX 03 24

XX 03 3F

XX 05 DC

XX 1E 04

XX 1E 00

XX 19 20

XX 1C YY

XX 1D YY

XX 1F 40

XX 1F 00

XX 1F 10

XX 4A 1B

XX 49 CC

XX 1F 80

XX – The LDS8160 I2C customer-selected slave address followed by binary 1 for write command, i.e. if I2C slave address is

001 0001 (see Table 8), XX = 0010 0011 (bin) = 23h

YY – The LDS8160 I2C customer-selected slave address followed by binary 0 for read command, i.e. if I2C slave address is

001 0001 (see Table 8), YY = 0010 0010 (bin) = 22h

© 2009 IXYS Corp.

Characteristics subject to change without notice

9

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

PIN DESCRIPTION

Function

2

I C Serial clock input

2

I C Serial data input/output

2

I C Serial interface Address Programming

Ground Reference

Device enable (active high)

LEDC2 anode terminal -8161 (NC for 8141)

LEDC1 anode terminal -8161 (NC for 8141)

LEDB2 anode terminal

LEDB1 anode terminal

LEDA2 anode terminal

LEDA1 anode terminal

Power Source Input; connect to battery or supply

Test pin

Pin

Name

SCLK

SDAT

SADD

GND

EN

LEDC2

LEDC1

LEDB2

LEDB1

LEDA2

LEDA1

V IN

TST

Not connect (no internal connect to the device)

Connect to GND on the PCB

NC

PAD

Pin #

8161

8141

1

1

2

2

3

3

4

4

6

6

8

9

10

10

11

11

12

12

13

13

14

14

15

15

5, 7, 8,

5, 7, 16

9, 16

PAD

PAD

PIN FUNCTION

VIN is the supply pin. A small 1μF ceramic bypass

capacitor is required between the VIN pin and ground

near the device. The operating input voltage range is

from 2.5 V to 5.5 V.

GND is the ground reference for internal circuitry.

The pin must be connected to the ground plane on

the PCB.

LEDA1 – LEDC2 provide the internal regulated

current source for each of the LED anodes. These

pins enter high-impedance zero current state

whenever the device is in shutdown mode. LEDC1

and LEDC2 are no connects (NC) for the LDS8141.

EN is the enable input for the entire device.

Guaranteed levels of logic high and logic low are set

at 1.3 V and 0.4V respectively. When EN is initially

taken high, the device becomes enabled and may

2

communicate through I C interface

PAD is the exposed pad underneath the package.

For best thermal performance, the tab should be

soldered to the PCB and connected to the ground

plane

2

SDAT is the I C serial data line. This is a bidirectional

line allowing data to be written into and read from the

four registers in the driver..

TST is a test pin used by factory only. Leave it

floating (no external connection)

2

SCLK is the I C serial clock input.

2

SADD is I C Serial interface Addresses tie to either

GND or VIN pin to allow choice of two salve

addresses

© 2009 IXYS Corp.

Characteristics subject to change without notice

10

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

BLOCK DIAGRAM

VIN

All Drivers 0 to 31.875 mA

OverTemp

I2C Interface

Top Level Control

diagnostics

Shorted LED

Open LED

LED Calibration

Soft Start control

SCL

Vin to

al l

Drivers

PWM

Calibrated

Reference

Currents

and

ADC bias

currents

Bandgap

Voltage

Reference

1.2V

SDA

LEDA1

PWM

1.2V

32

ADC

10 bit SAR

10

Digital Temperature

Sensor / Abritrator

LEDA2

Pre-Scale

8x, 1x, or 1/4x

PWM

Si Iforce

LED Iforce

LEDB1

SAD

1 0 uA

2 uA 1 mA

0.2 mA

Temp

De-Rating

LUT

PWM

PWM

OTP

LEDB2

Si PNP

temp diode

Temp

Trim

PWM

Temp

De-Rating

Table

Temp to PWM

adjust LUTs

PWM

8 bit to 12 bit (log) PWM

Generator

LEDC1

(8161)

to PWM

PWM

OTP

Driver

1.8V

Gnd

GND

To top control

LEDC2

(8161)

to top control & dig processing

Vin

Vin to 1.8V LDO

for digital core

1.2V

POR

Start Up

Vin

Oscillator & Clock Generator

~ 1.2 MHz

EN

Figure 2: LDS8161/41 Functional Block Diagram

An initialization sequence then begins, taking less

than 10 ms. This sequence determines the user2

selected I C slave address, loads factory

programmed settings, and conducts diagnostics for

open/shorted LEDs.

BASIC OPERATION

The LDS8161 / 41 may operate in following modes:

a) Normal Operation Mode

b) Normal Standby Mode

c) Programming Modes

d) Shutdown Mode

2

At this point, the I C interface is ready for

communication and the LDS8161/41 may be userprogrammed. Upon programming completion for all

required initial parameters and features’ settings, a

calibration command is given by setting bit 4 of the

Control Register (1Fh) HIGH. This starts the

calibration sequence of the LDS8161/41 LEDTM

Sense temperature de-rating circuits and occurs

simultaneous with a gradual ramp-up of LED PWM

and current levels to the user programmed values.

This initialization is completed in less than 250 ms in

NORMAL OPERATION MODE

At power-up, V IN should be in the range from 2.5 V to

5.5 V (max). If V IN is slow rising, EN pin should be

logic LOW at least until VIN reaches a 2.5 V level.

When EN is taken HIGH, a soft-start power-up

sequence begins and performs an internal circuits

reset that requires less than 100 µs.

© 2009 IXYS Corp.

Characteristics subject to change without notice

11

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

the default soft-start ramp mode, or s less than 10 ms

with the soft-start ramp mode disabled by setting bit 1

of the Configuration Register (1Eh) HIGH.

e) Soft start-up PWM ramp feature enabled;

If the factory default loaded de-rating curve is used

as shown in Figure 7, then following Table 10

identifies the necessary registers and initialization

required after the power-up or reset state to operate

the LDS8161/41.

The calibration parameters for the temperature derating and all customer-set parameters remain intact

until the part is reset or powered-down. Additionally,

the user can re-calibrate LDS8161/41 during times

when LED currents are brought to zero and thermally

stabilized by programming the calibration command

bit as discussed.

Factory preset values (upon completion of the powerup initialization) are as follow (see Table 3):

a) All LEDs are disabled and ILEDA, B, C = 0;

b) WLED mode (i.e. 1 De-rating LUT) selected

and 1 PWM generator drives all 3 banks

(8160) or 2 banks (8141).

c) PWM dimming control is enabled Logarithmic

Mode with reset duty cycle = 0%.

TM

Figure 3: LDS8161/41 Default De-rate Curve

d) LED-Sense

temperature de-rating is

disabled with the LUT in Logarithmic Mode

for a Nichia NSSW020BT WLED;

Table 10: Recommended Register Load Sequence for LDS8161/41

(Using the Factory Default De-Rating LUT)

Reg Load

Sequence #

Reg

(hex)

Value (hex)

1

2

3

4

5

1Eh

49h

4Ah

4Bh

A0h

00h

CCh

18h

20h

36h

6

A2h

User Loads Per LED Used

7

8

C0h

D4h

40h

04h

9

D6h

User Loads Per LED Used

10

11

12

13

1Fh

00h

01h

02h

14

03h

15

05h

10h

User Loads Ex: F0h = 30mA

Uer Loads Ex: F0h = 30mA

User Loads Ex: F0h = 30mA

User Loads Ex: 3Fh = all

channels

User Loads Ex: FEh = 91% DC

© 2009 IXYS Corp.

Characteristics subject to change without notice

Comments

12

Initialize Configuration Register

Ta-Tj 0ffset = -20ºC

Set LED Shutdown Temp = 85ºC (Ta referenced)

Set 2x de-rate mode starting at 55C

Load Si Diode K factor for - 1.71mV/C

User loads LED K factor @ 1mA IF

29h = -1.3mV/C for Nichia NSSW020BT

Load Si Diode

ηfactor = 1.0

Load Si Diode Rs = 68 ohms

User loads LED Rs

61h = 17 ohms for Nichia NSSW020BT

User issues temp calibration command

User sets Current for Bank A.

User sets Current for Bank A.

User sets Current for Bank B.

User enabled LED channels

User sets PWM duty cycle for all channels

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

To turn LEDs ON/OFF register 03h should be

addressed with data that represents the desired

combination of LEDs turned ON/OFF (see Table 1);

i.e. if LEDC1, LEDC2, LEDA1, LEDA2 should be ON,

and LEDB1, LEDB2 should be OFF, binary code that

should be written into register 03h is 110011 (bin) =

33h.

The de-rate table stored in the correction LUT is

referenced to the LED Tj. Register 49h can be used

to apply the Ta-Tj temperature offset between the

ambient and LED junction temperature. This can

effect a +/- shift of the de-rating curve in the

Temperature axis to reference the de-rating profile to

ambient, and/or set the start of de-rating to the

desired ambient temperature level to accommodate

different LEDs and current/power levels. The default

table will de-rate the current ~ - 9.2 dB (0.348x) from

its user set low temperature maximum level over

35ºC (from the start of the de-rate temperature). For

example, if the LED current is set to 30mA prior to

de-rating, and de-rating begins at 55ºC, at 85ºC the

current is de-rated to 0.348 x 30mA = 10.4mA.

The LDS8161/41 allows two ways for LED current

setting and dimming; analog (static) dimming using

the 8 bit current DACs, and dynamic dimming via the

integrated 12-bit digital PWM. Combining both

methods allows for total dimming capability of >

16,384:1

Analog dimming using the current setting DACs

discussed via registers 00h – 02h is referred to as the

static mode. Digital dimming using the internal PWM

generator changes the duty cycle per the value set in

register 05h and therefore adjusts the average LED

current. This is referred to as dynamic mode.

Register 4Ah sets the LEDs shutdown junction

temperature per the T-codes provided in Table 7.

When this temperature is exceeded, all of the LED

current driver channels are disabled to insure no

damage to the LEDS. Additionally, an LED OT (over

temperature) status flag is set HIGH in Bit 7 of the

enable channel register 03h. If the flag is set the user

can re-enable the channels by re-writing to the

channel enable bits in register 03h, however the OT

flag will still remain HIGH, until the device is power

sequenced, reset, or placed in the shutdown mode.

For dynamic mode, the LDS8161/41 integrates a

digital PWM generator that operates at a frequency of

~ 285 Hz. It operates in Logarithmic Mode. The PWM

generator has 12-bit resolution and can be

programmed with an 8-bit code to provide 256

internally mapped 12-bit logarithmic duty cycle steps

to adjust the dimming level

The advantage of PWM dimming is stable LED color

temperature / wavelength that is determined by the

maximum static mode LED current value set by

registers 00h – 02h. The integrated PWM generator

reduces the system requirement to provide a

continuous pulsed waveform.

If a Ta-Tj offset is used other than 00h (i.e. 0ºC) in

register, 49h, than the shutdown junction temperature

loaded in 4Ah should also include this offset. This

insures the LED shutdown is also properly referenced

to ambient level, Ta.

To use the dynamic PWM mode for LED current

setting, the maximum ILED value should first be set by

current DAC registers 00h – 02h as described above

for static mode, and desired dimming / duty cycle can

be set by register 05h. The logarithmic operating

mode provides a dimming resolution of approximately

-0.17 dB per step with 0dB dimming (i.e. 100% duty

th

cycle) at the 256 step (i.e. FFh), and 0% duty cycle

(~ -80 dB dimming) at 00h.

LED Current Setting

Current setting registers 00h – 02h should be

2

programmed using I C interface and desired LEDs

should be enabled using register 03h before LEDs

turn on.

2

The standard I C interface procedure is used to

2

program ILED current (see chapter “I C INTERFACE”).

LDS8161/41 should be addressed with slave address

chosen (see Table 11 for accessible slave

addresses) followed by register address (00h, 01h, or

02h) and data that represents the code for the

desired LED current.

LED-Sense

High Temperature Current De-rating

TM

The LDS8161/41 integrates the IXYS LED-Sense

temperature measurement and high temperature

current de-rating algorithm to insure LED reliability

and operating lifetimes.

Code for LED current is determined as ILED/0.125 mA

in hex format, i.e. 20 mA current code = 20/0.125 =

160 (dec) = A0h.

LED current is de-rated via reductions in PWM duty

cycle to meet LED vendor power dissipation vs. LED

junction temperature specifications.

The maximum current setting is 31.875 mA. Since

the LDS8161/41 is a low drop-out LDO based linear

LED driver, when using maximum current levels,

users should

select LEDs with V F < 3.3V to

maximize operation with Li-ion batteries.

© 2009 IXYS Corp.

Characteristics subject to change without notice

TM

User programmable de-rating adjustments are stored

in a correction LUT comprised of eight 8-bit registers

from 56h to 5Dh. Each register stores a 4-bit

13

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

adjustment code for two 5ºC temperature steps in its

lower (bits 3:0) and higher (bits 7:4) nibble. User

loadable de-rating codes in the 1x scale mode

represent 0 to -7 PWM de-rating steps. In the 2 x

scale mode the de-rating codes represent 0 to -14

PWM steps.

adjust the PWM duty cycle. Therefore this reduces

the av erage current through the LEDs as defined by

the LUT table.

The user loads specific ΔPWM de-rating codes into

the LUT (56h – 5Dh) for every 5ºC temperature step

from 25ºC to 100ºC to meet desired current and

power vs. LED junction temperature.

LUT de-rating correction codes are subtracted from

the user-set duty cycle/dimming code (dynamic

mode) loaded in register 05h to maintain reliable LED

current levels.

The LDS8161/41 includes a 10-bit ADC and digital

processing engine to determine LED temperatures

approximately every 2.5 seconds. The proprietary

TM

LED-Sense algorithm allows direct measurement of

LED junction temperatures on the LEDA1 driver

channel, without the need for an external temperature

sensor. Additionally an on-chip silicon temperature

sensing diode is also measured to enhance

temperature estimation accuracy.

Figure 4: Dynamic Mode Dimming in Logarithmic

Mode in dB vs. register 05h data

(0dB dimming = full LED brightness)

Additionally, the ADC and processing circuits are

time-multiplexed to provide an LED opens and shorts

diagnostic feature.

A Factory loaded de-rating curve is valid upon reset,

and provide the de-rating profile shown at Figure 3.

2

I C Interface

2

The LDS8160 uses a 2-wire serial I C-bus interface.

2

The SDAT and SCLK lines comply with the I C

electrical specification and should be terminated with

pull-up resistors to the logic voltage supply. When the

bus is not used, both lines are high. The device

supports a maximum bus speed of 400kbit/s. The

serial bit sequence is shown at REGISTER

DEFINITION AND PROGRAMMING section for read

and write operations into the registers. Read and

write instructions are initiated by the master

controller/CPU and acknowledged by the slave LED

driver.

Figure 5: Dynamic Mode Dimming in Logarithmic

Mode in percent vs. register 05h data

(0% dimming = full LED brightness)

The LDS8161/41 allows user to choose between two

2

I C addresses by connecting SADD pin (#3) either to

ground, or VIN pin (see Table ).

Additionally, the LED drivers are disabled (i.e. 0 DC

current) if the measured LED junction temperature

exceeds a preset value that is loaded in register 4Ah.

The default is set for 1Ch = 105ºC Tj.

2

Table 11: LDS8161/41 I C Slave Addresses

SADD pin

connected to

Ground

V IN

TM

The LED-Sense engine periodically measures the

LED junction temperature on channel LEDA1 and

encodes the value into 5-bit T-codes representing

0

0

5 C temperature intervals from -35 to +120 C.

Hex

11h

55h

2

For further details on the I C protocol, please refer to

2

the I C-Bus Specification, document number 9398393-40011, from Philips Semiconductors.

The measured T-code value addresses the stored

ΔPWM de-rating codes stored in the LUT registers to

© 2009 IXYS Corp.

Characteristics subject to change without notice

2

I C Address

Binary code

001 0001

101 0101

14

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

Unused LED Channels

level to shutdown VIN power to prevent possible

damage to the LED. The combined series resistance

of the LED (typically ~ 10Ω or more) and additional

board series resistance will result in current limiting

but not sufficient to insure no damage to low power

LEDs.

For applications with less than six (8161) or four

(8141) LEDs, the unused LED channels can be

2

disabled via the I C interface by addressing register

03h with data that represents the desired

combination of LEDs turned ON/OFF (see Table 1).

Besides the power-up diagnostic sequence, the user

can re-initiate a diagnostic command at any time by

setting bit 5 of the Digital Test Modes Register, 19h,

to HIGH.

The LDS8161/41 unused LED outputs can be left

open.

Parallel-Connected LED Channels for Higher

Current LEDs

The LDS8161/41 restores LED current to

programmed value at channels with detected shorts

to GND after the fault condition is removed.

In higher power LED applications requiring more than

31.875 mA DC current, LED driver channels can be

connected in parallel.

Over-Temperature Protection

For example, ½ watt, 150 mA LEDs can be driven

with the LDS8161 by paralleling all 6 channels with

25 mA per channel. Likewise, the LDS8141 can drive

up to 127.5 mA by connecting all 4 channels in

parallel at the maximum 31.875 mA per channel.

If the die temperature exceeds +150°C, the driver will

enter shutdown mode. The LDS8161/41 requires

restart after die temperature falls below 130°C.

LED Selection

LED short/open protection

If the power source is a Li-ion battery, LEDs with V F =

1.9 V - 3.3 V are recommended to achieve highest

efficiency performance and extended operation on a

single battery charge.

The LDS8161/41 runs a LED short/open diagnostic

routine upon the power up sequence. It detects both

LED pins shorted to ground and LED pins that are

open or shorted to V IN (fault conditions).

The results for short to GND detection are stored in

Diagnostics Register 1Ch. Bits from bit 5 to bit 0

indicate a short status as bit = 1 for LEDC2 - LEDA1

respectively. A short to GND is detected, if the

measured LED pin voltage is less than ~ 0.14 V

independent of the programmed LED current. Every

channel, detected as shorted, is disabled

External Components

The driver requires one external 1 µF ceramic capacitors (C IN) X5R or X7R type.

CONFIGURATION MODES

The LDS8161/41 allows the option to choose special

operating modes overwriting content of Configuration

Register 1Eh (see Table 2).

Test results for open or short to VIN LED pins are

stored in Diagnostics Register 1Dh, Bits from bit 5 to

bit 0 represent LEDC2 - LEDA1 respectively with bit

= 1 indicates fault condition at this particular LED pin.

Bit 1 allows bypass soft start / ramp down if fast

raising/falling LED current required.

Bit 2 allows disable LED temperature compensation if

desired.

An open LED pin fault causes no harm in the

LDS8161/41 or the LED as the high side driver has

no current path from V IN or GND. Therefore, the fault

detection status indicates only in the 1Dh diagnostic

register, and no further action is required.

The LDS8161/41 also provides the option for using

an external remote temperature-sensing diode device

such as a 2N3904. To use this option the diode

anode should be connected to channel LEDA1. The

cathode connected to GND. In this case, channel

LEDA1 should be disabled via register 03h and it

cannot operate as an LED current source.

In the case of an LED directly shorted to VIN , the full

V IN voltage will be connected to the LED and current

can flow independent of the LDS8161/41 LED driver

circuit directly to GND. The LDS8161/41 will detect

the fault and indicate the status in Register 1Dh,

however further action needs taken at the system

© 2009 IXYS Corp.

Characteristics subject to change without notice

Bits 0, 3, 4, 5, 6, and 7 of the Configuration Register

1Eh are for factory use only and should be set to 0 or

the user should use the power-on-reset values.

15

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

The LDS8161/41 wakes up from shutdown mode with

factory-preset default data. To preserve customerprogrammed data, use Normal standby mode.

STANDBY MODES

The LDS8161/41 has a “soft” standby or sleep mode,

2

which the customer may set by I C interface

addressing register 1Fh with bit 6 = 1 (see Table 4).

PROGRAMMING MODES

The LDS8161/41 is factory preprogrammed with a

default temperature de-rating LUT that works with the

Nichia NSSW020BT WLEDs or equivalent. However,

specific LEDs and other user system conditions may

require user programming of the temperature

compensation LUTs and other LED specific

parameters.

2

In the Standby Mode, the I C interface remains active

and all registers retain their programmed information.

In Standby Mode the LED drivers and internal clock

are powered off; however, internal regulators and

reference circuits remain active to insure power to the

digital sections to hold register values and maintain

2

I C interface communications. This results in standby

current ~ 125 µA typical. For this mode, the EN pin

should be logic HIGH with signal level from 1.3 to VIN

voltage.

After initialization and user programming the user

2

should conduct an I C calibration sequence

command by writing Bit 4 = 1 in the Control register

1Fh. This conducts a real time calibration of the initial

starting temperature and actual LED parameters.

Upon completion, Bit 4 will be internally reset to 0,

and the LDS8161/41 is ready for use.

SHUTDOWN MODE

To set LDS8161/41 into the shutdown mode, the EN

pin should be logic low more than 10 ms. The

LDS8161/41 shutdown current is less than 1 µA.

© 2009 IXYS Corp.

Characteristics subject to change without notice

16

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

PACKAGE DRAWING AND DIMENSIONS

16-PIN TQFN (HV3), 3mm x 3mm, 0.5mm PITCH

SYMBOL

A

A1

A2

b

D

D1

E

E1

e

L

m

n

MIN

0.70

0.00

0.178

0.20

2.95

1.65

2.95

1.65

0.325

NOM

0.75

0.02

0.203

0.25

3.00

1.70

3.00

1.70

0.50 typ

0.375

0.150 typ

0.225 typ

MAX

0.80

0.05

0.228

0.30

3.05

1.75

3.05

1.75

0.425

Note:

1. All dimensions are in millimeters

2. Complies with JEDEC Standard MO-220

© 2009 IXYS Corp.

Characteristics subject to change without notice

17

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

ORDERING INFORMATION

Part Number

LDS8161 002-T2

LDS8141 002-T2

Notes:

1.

2.

Package

Package Marking

TQFN-16 3 x 3mm

(1)

8161

TQFN-16 3 x 3mm

(1)

8141

Matte-Tin Plated Finish (RoHS-compliant)

Quantity per reel is 2000

EXAMPLE OF ORDERING INFORMATION

Prefix

LDS

Device #

Suffix

8161 or 8141

002

Product Number

Optional

Company ID

Package

T2

Tape & Reel

T: Tape & Reel

2: 2000/Reel

002: 3x3 TQFN

Notes:

1) All packages are RoHS-compliant (Lead-free, Halogen-free).

2) The standard lead finish is Matte-Tin.

3) The device used in the above example is a LDS8161A 002–T2 (3x3 TQFN, Tape & Reel).

4) For additional package and temperature options, please contact your nearest IXYS Corp. Sales office.

© 2009 IXYS Corp.

Characteristics subject to change without notice

18

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

Appendix 1

# of steps

Hex code

Dimming,

dB

Dimming,

%

# of steps

Hex code

Dimming,

dB

Dimming,

%

# of steps

Hex code

Dimming,

dB

Dimming,

%

Table 5 Dynamic Mode Dimming in Logarithmic Mode vs. register 05h data

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

15

16

17

18

19

1A

1B

1C

1D

1E

1F

-72.3

-66.3

-62.8

-60.3

-58.3

-56.7

-55.4

-54.3

-53.2

-52.3

-51.5

-50.7

-50

-49.4

-48.8

-48.2

-47.7

-47.2

-46.7

-46.3

-45.9

-45.5

-45.1

-44.7

-44.4

-44

-43.7

-43.4

-43.1

-42.8

-42.5

100

99.98

99.95

99.93

99.90

99.88

99.85

99.83

99.80

99.78

99.76

99.73

99.71

99.68

99.66

99.63

99.61

99.58

99.56

99.54

99.51

99.49

99.46

99.44

99.41

99.39

99.37

99.34

99.32

99.29

99.27

99.24

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

20

21

22

23

24

25

26

27

28

29

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

36

37

38

39

3A

3B

3C

3D

3E

3F

-41.9

-41.4

-40.9

-40.5

-40.1

-39.6

-39.2

-38.9

-38.5

-38.2

-37.8

-37.5

-37.2

-36.9

-36.6

-36.3

-36.1

-35.8

-35.5

-35.3

-35

-34.8

-34.6

-34.4

-34.1

-33.9

-33.7

-33.5

-33.3

-33.1

-32.9

-32.8

99.19

99.15

99.10

99.05

99.00

98.95

98.90

98.85

98.80

98.75

98.71

98.66

98.61

98.56

98.51

98.46

98.41

98.36

98.32

98.27

98.22

98.17

98.12

98.07

98.02

97.97

97.92

97.88

97.83

97.78

97.73

97.68

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

40

41

42

43

44

45

46

47

48

49

4A

4B

4C

4D

4E

4F

50

51

52

53

54

55

56

57

58

59

5A

5B

5C

5D

5E

5F

-32.6

-32.4

-32.2

-32.1

-31.9

-31.7

-31.6

-31.4

-31.3

-31.1

-30.9

-30.8

-30.7

-30.5

-30.4

-30.2

-30.1

-30

-29.8

-29.7

-29.6

-29.5

-29.3

-29.2

-29.1

-29

-28.8

-28.7

-28.6

-28.5

-28.4

-28.3

97.63

97.58

97.53

97.49

97.44

97.39

97.34

97.29

97.24

97.19

97.14

97.09

97.05

97.00

96.95

96.90

96.85

96.80

96.75

96.70

96.66

96.61

96.56

96.51

96.46

96.41

96.36

96.31

96.26

96.22

96.17

96.12

Continued

© 2009 IXYS Corp.

Characteristics subject to change without notice

19

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

Table 10 Dynamic Mode Dimming in Logarithmic Mode vs. register 05h data

# of steps

Hex code

Dimming,

dB

Dimming,

%

# of steps

Hex code

Dimming,

dB

Dimming,

%

# of steps

Hex code

Dimming,

dB

Dimming,

%

Continue

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

60

61

62

63

64

65

66

67

68

69

6A

6B

6C

6D

6E

6F

70

71

72

73

74

75

76

77

78

79

7A

7B

7C

7D

7E

7F

-28.1

-27.9

-27.7

-27.5

-27.3

-27.1

-26.9

-26.7

-26.5

-26.3

-26.2

-26

-25.8

-25.7

-25.5

-25.3

-25.2

-25

-24.9

-24.7

-24.6

-24.5

-24.3

-24.2

-24

-23.9

-23.8

-23.7

-23.5

-23.4

-23.3

-23.2

96.02

95.92

95.83

95.73

95.63

95.53

95.43

95.34

95.24

95.14

95.04

94.95

94.85

94.75

94.65

94.56

94.46

94.36

94.26

94.17

94.07

93.97

93.87

93.77

93.68

93.58

93.48

93.38

93.29

93.19

93.09

92.99

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

80

81

82

83

84

85

86

87

88

89

8A

8B

8C

8D

8E

8F

90

91

92

93

94

95

96

97

98

99

9A

9B

9C

9D

9E

9F

-22.9

-22.7

-22.5

-22.2

-22

-21.8

-21.6

-21.4

-21.2

-21

-20.8

-20.6

-20.5

-20.3

-20.1

-20

-19.8

-19.6

-19.5

-19.3

-19.2

-19

-18.9

-18.7

-18.6

-18.4

-18.3

-18.1

-18

-17.9

-17.7

-17.6

92.80

92.60

92.41

92.21

92.02

91.82

91.63

91.43

91.24

91.04

90.84

90.65

90.45

90.26

90.06

89.87

89.67

89.48

89.28

89.09

88.89

88.70

88.50

88.31

88.11

87.92

87.72

87.52

87.33

87.13

86.94

86.74

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

AA

AB

AC

AD

AE

AF

B0

B1

B2

B3

B4

B5

B6

B7

B8

B9

BA

BB

BC

BD

BE

BF

-17.4

-17.1

-16.9

-16.6

-16.4

-16.2

-16

-15.8

-15.6

-15.4

-15.2

-15

-14.8

-14.6

-14.4

-14.3

-14.1

-13.9

-13.8

-13.6

-13.4

-13.3

-13.1

-13

-12.8

-12.7

-12.5

-12.4

-12.3

-12.1

-12

-11.8

86.35

85.96

85.57

85.18

84.79

84.40

84.01

83.62

83.23

82.84

82.45

82.06

81.67

81.27

80.88

80.49

80.10

79.71

79.32

78.93

78.54

78.15

77.76

77.37

76.98

76.59

76.20

75.81

75.42

75.02

74.63

74.24

Continued

© 2009 IXYS Corp.

Characteristics subject to change without notice

20

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

Table 10 Dynamic Mode Dimming in Logarithmic Mode vs. register 05h data

# of steps

Hex code

Dimming,

dB

Dimming,

%

# of steps

Hex code

Dimming,

dB

Dimming,

%

Continue

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

C0

C1

C2

C3

C4

C5

C6

C7

C8

C9

CA

CB

CC

CD

CE

CF

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

DA

DB

DC

DD

DE

DF

-11.6

-11.3

-11.1

-10.9

-10.6

-10.4

-10.2

-10

-9.8

-9.5

-9.3

-9.2

-9

-8.8

-8.6

-8.4

-8.2

-8.1

-7.9

-7.7

-7.6

-7.4

-7.3

-7.1

-6.9

-6.8

-6.7

-6.5

-6.4

-6.2

-6.1

-6

73.46

72.68

71.90

71.12

70.34

69.56

68.77

67.99

67.21

66.43

65.65

64.87

64.09

63.31

62.52

61.74

60.96

60.18

59.40

58.62

57.84

57.06

56.27

55.49

54.71

53.93

53.15

52.37

51.59

50.81

50.02

49.24

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

E0

E1

E2

E3

E4

E5

E6

E7

E8

E9

EA

EB

EC

ED

EE

EF

F0

F1

F2

F3

F4

F5

F6

F7

F8

F9

FA

FB

FC

FD

FE

FF

-5.7

-5.4

-5.2

-4.9

-4.7

-4.5

-4.3

-4

-3.8

-3.6

-3.4

-3.2

-3

-2.8

-2.7

-2.5

-2.3

-2.1

-2

-1.8

-1.6

-1.5

-1.3

-1.2

-1

-0.8

-0.7

-0.6

-0.4

-0.3

-0.1

0

47.68

46.12

44.56

42.99

41.43

39.87

38.31

36.74

35.18

33.62

32.06

30.49

28.93

27.37

25.81

24.24

22.68

21.12

19.56

17.99

16.43

14.87

13.31

11.74

10.18

8.62

7.06

5.49

3.93

2.37

0.81

0.00

© 2009 IXYS Corp.

Characteristics subject to change without notice

21

Doc. No. 8141/61_DS, Rev. N1.0

�LDS8161/41

Warranty and Use

IXYS CORP. MAKES NO WARRANTY, REPRESENTATION OR GUARANTEE, EXPRESS OR IMPLIED, REGARDING THE SUITABILITY OF ITS PRODUCTS FOR ANY

PARTICULAR PURPOSE, NOR THAT THE USE OF ITS PRODUCTS WILL NOT INFRINGE ITS INTELLECTUAL PROPERTY RIGHTS OR THE RIGHTS OF THIRD

PARTIES WITH RESPECT TO ANY PARTICULAR USE OR APPLICATION AND SPECIFICALLY DISCLAIMS ANY AND ALL LIABILITY ARISING OUT OF ANY SUCH

USE OR APPLICATION, INCLUDING BUT NOT LIMITED TO, CONSEQUENTIAL OR INCIDENTAL DAMAGES.

IXYS Corp. products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications intended

to support or sustain life, or for any other application in which the failure of the IXYS Corp. product could create a situation where personal injury or death may occur.

IXYS Corp. reserves the right to make changes to or discontinue any product or service described herein without notice. Products with data sheets labeled "Advance

Information" or "Preliminary" and other products described herein may not be in production or offered for sale.

IXYS Corp. advises customers to obtain the current version of the relevant product information before placing orders. Circuit diagrams illustrate typical semiconductor

applications and may not be complete.

IXYS Corp.

1590 Buckeye Dr.,

Milpitas, CA 95035-7418

Phone: 408.457.9000

Fax:

408.496.0222

http://www.ixys.com

© 2009 IXYS Corp.

Characteristics subject to change without notice

Document No: 8141/61_DS

Revision:

N1.0

Issue date:

10/20/2009

22

Doc. No. 8141/61_DS, Rev. N1.0

�