LDS8160

Dual-Output RGB / 6-Channel WLED Driver

with LED-SenseTM Temperature & Color Compensation

FEATURES

Six PowerLite

Linear LDO current drivers

with 25 mV drop-out in a common cathode

topology with up to 25 mA per channel

LED current programmable from 0 to 25 mA

in 200 linear steps

Three separately controlled driver banks (2

LED each) supports RGB LED applications.

Integrated digital temperature sensor with 100

0

bit ADC; 1 C resolution with 5 C accuracy

TM

LED-Sense * temperature compensation

algorithm continually monitors LED V-I

parameters and adjusts brightness per user

loaded PWM correction

Three integrated PWM generators support

RGB color correction and dimming with 12-bit

resolution and 256 user programmable

logarithmic steps (~ 0.17 dB per step)

2

I C serial programming interface; additional

address pin allows 4 unique slave addresses.

Power efficiency up to 98%; average

efficiency > 80% in Li-ion battery applications

Low current shutdown mode (< 1 µA); Low

current software “standby mode” (< 5 µA)

Soft start and current limiting

LED Short circuit detection and protection, LED

open detection

Thermal shutdown protection

Low EMI.

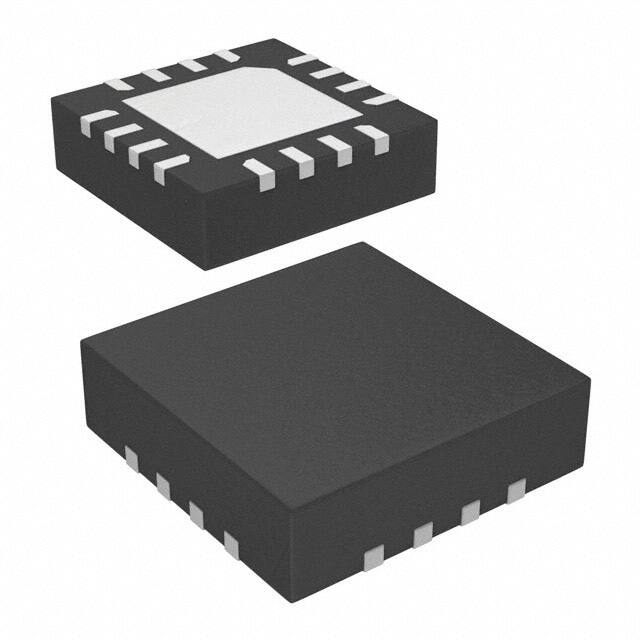

Available in 3 x 3 x 0.8 mm3 16-pin TQFN or ultra

small WCSP 3 x 4 ball grid (0.4mm pitch).

TM

Each channel contains a linear LDO current driver in

a common cathode (i.e., current source) topology.

The LDO drivers have a typical dropout voltage of

25mV at maximum rated current. This provides a low

power and low EMI solution in Li-ion battery

applications without voltage boosting and associated

external capacitors and components.

Three 12-bit PWM generators with “smooth”

logarithmic control support Temperature vs. LED

Luminosity adjustments as well, as RGB color

correction and dimming. The PWM generators are

2

programmable via an I C serial interface. User

programmed 8-bit codes are converted to 12-bit

resolution logarithmic steps of ~ 0.17 dB per step.

The PWM frequency is ~280 Hz to minimize noise.

TM

The LED-Sense temperature compensation engine

includes a multiplexed 10-bit ADC and digital

processing circuits. The algorithm continually

measures the V-I characteristics of the LEDs and an

on-chip temperature diode to determine LED junction

temperatures to within 5ºC accuracy.

APPLICATION

Keypad and Display Backlight

DESCRIPTION

Three user-programmable temperature correction

tables (LUTs) store PWM adjustment codes for every

5ºC increment from -35ºC to 120ºC. These codes

drive the PWM engine to adjust for luminosity

variations and/or high temperature current de-rating.

The three correction LUTs support independent

correction for 3-color RGB applications.

The LDS8160 is a dual-output RGB or 6-channel

white

LED

driver

with

three

temperature

compensation circuits for each bank of two LED

drivers. It supports both RGB LED and WLED

backlighting and keypad in portable applications.

The EN logic input functions as a chip enable. A logic

HIGH applied at EN allows the LDS8160 to respond

2

to I C communication. A serial address pin, SADD,

supports use in multi-target applications. The device

operates from 2.3V to 5.5V.

Three 8-bit DACs set the current level for each LED

bank (A, B, & C) from 0 to 25mA in 0.125mA steps.

The LDS8160 is available in a 0.4mm pitch 12-ball

WCSP or a 3 x 3 x 0.8 mm 16-lead TQFN packages.

Cellular Phones

Digital Still Cameras

PDAs and Smartphones

© 2009 IXYS Corp.

Characteristics subject to change without notice

1

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

TYPICAL APPLICATION CIRCUIT

© 2009 IXYS Corp.

Characteristics subject to change without notice

2

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

ABSOLUTE MAXIMUM RATINGS

Parameter

VIN, LEDx

EN, SDAT, SCLK voltage

Storage Temperature Range

Junction Temperature Range

Soldering Temperature

HBM

ESD Protection Level

MM

Rating

6

V IN + 0.7V

-65 to +160

-40 to +125

300

2

200

Unit

V

V

°C

°C

°C

kV

V

RECOMMENDED OPERATING CONDITIONS

Parameter

VIN

ILED per LED pin

Total Output Current ILOAD

Junction Temperature Range

EN pin Input Voltage @ LP Standby Mode

Rating

2.3 to 5.5

0 – 25

150

-40 to +125

1.8 ± 0.1

Unit

V

mA

mA

°C

V

Typical application circuit with external components is shown on page 1.

ELECTRICAL OPERATING CHARACTERISTICS

(Over recommended operating conditions unless specified otherwise) Vin = 3.6V, Cin = 1 µF, EN = High, TAMB = 25°C

Name

Conditions

Min

2

EN = 1.8 V

LP Standby (no I C clock)

2

EN = VIN

Standby (no I C clock)

Quiescent Current

6 Channels at 100% DC ILOAD = 120 mA

PWMs and Temp

ILOAD = 60 mA

Compensations Active

Shutdown Current

VEN = 0V

LED Current Accuracy

5mA ≤ILED ≤25 mA

LED Channel Matching

(ILED - ILEDAVG ) / I LEDAVG

Line Regulation

2.7 V ≤VIN ≤4.2 V

1

Load Regulation

0.2 V < Vdx < V IN -1.4 V

2

Dropout Voltage

5 mA ≤ILED ≤25 mA

10

PWM Frequency

# of PWM duty cycle steps

Log & Linear Mode

Minimum PWM On Time

PWM resolution

PWM Step Size

of

PWM Adjustment Steps

Log Mode

Linear Mode

Log Mode

Linear Mode

1-x Scale Mode

(~ 0.17 dB per step)

2-x Scale Mode

(~ 0.34 dB per step)

EN Pin

Logic Level

High

Low

1

40

Active mode, EN = VIN

LP Standby

Active Mode or Normal

Standby Mode

+7

-7

+7

-1

3

PWM

0

Steps/5 C

0

0

1

5

1.2

0.4

450

150

Units

µA

µA

mA

mA

µA

%

%

%/V

%/V

mV

Hz

µs

bits

bits

dB

1

5

Input Current Limit

Thermal Shutdown

© 2009 IXYS Corp.

Characteristics subject to change without notice

Max

-7

Temperature Measurement Resolution

Temperature Measurement Accuracy

Input current

Typ

5

125

0.6

0.4

0.5

±1.5

±1.5

2

0.8

25

285

256

13.7

12

8

0.17

ILED/256

C

C

µA

V

mA

°C

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Name

Thermal Hysteresis

Wake-up Delay Time (EN Raising Edge)

Shutdown Delay Time (EN Falling Edge)

LED Driver PWM Ramp-Up time

2

(from PWM write command via I C)

3

Output short circuit Threshold

Note:

Conditions

Min

Typ

20

0.5

10

Soft Ramp Disabled

Soft Ramping Enabled

(only wake-up)

ILED = 20 mA

Max

Units

ms

250

ms

0.14

V

1. Vdx = Vin – VF,

2. Vdx = Vin – VF, at which I ILED decreases by 10% from set value

3. Minimum LED forward voltage, which will be interpreted as “LED SHORT” condition

I 2C CHARACTERISTICS

Over recommended operating conditions unless otherwise specified for 2.7 VIN 5.5V, over full ambient temperature range -40 to +85ºC.

Symbol

fSCL

tHD:STA

tLOW

tHIGH

tSU:STA

tHD:DAT

tSU:DAT

tR

tF

tSU:STO

tBUF

tAA

tDH

Parameter

SCL Clock Frequency

Hold Time (repeated) START condition

LOW period of the SCL clock

HIGH period of the SCL clock

Set-up Time for a repeated START condition

Data In Hold Time

Data In Set-up Time

Rise Time of both SDAT and SCLK signals

Fall Time of both SDAT and SCLK signals

Set-up Time for STOP condition

Bus Free Time between a STOP and START condition

SCLK Low to SDAT Data Out and ACK Out

Data Out Hold Time

Min

0

0.6

1.3

0.6

0.6

0

100

Max

400

Unit

kHz

µs

µs

µs

µs

µs

ns

ns

ns

µs

µs

µs

ns

0.9

300

300

0.6

1.3

0.9

300

2

Figure 1: I C Bus Timing Diagram

READ OPERATION:

Option 1: Standard protocol sequential read:

S

Slave Address

R

A

Data 0

A

Data 1

From: Reg. m

Reg. m+1

where Reg. m is the last addressed in the write operation register

A

Data 2

Data n

A*

Reg. m+2

Reg. m+n,

P

Option 2: Random access:

S

Slave Address

R

A

Data m

A*

P

From reg. m, where Reg. m is the last addressed in the write operation register

© 2009 IXYS Corp.

Characteristics subject to change without notice

4

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Option 3: Random access with combined (extended) protocol:

S

Slave Address

W

A

Register Address m

A

Sr

Slave Address

R

A

Data m

A*

P

WRITE OPERATION:

Option 1: Standard protocol sequencial write:

S

Slave Address

W

A

Register Address m

A

Data 0

To: Reg. m

A

Data 1

Reg. m+1

A

Data 2

Reg. m+2

Data k

A*

P

Reg. m+k

At k = 4 data are send to register m and cycle repeats

Option 2: Combined (extended) protocol:

S

Slave Address

W

A

Register Address m

A

Sr

Slave Address

W

A

Data

A*

P

To: Reg. m

S: Start Condition

Sr Start Repeat Condition

R, W: Read bit (1), Write bit (0)

A: Acknowledge (SDAT high)

A*: Not Acknowledge (SDAT low)

P: Stop Condition

Slave Address: Device address 7 bits (MSB first).

Register Address: Device register address 8 bits

Data: Data to read or write 8 bits

- send by master

- send by slave

I2 C BUS PROTOCOL

Standard protocol

Combined protocol:

© 2009 IXYS Corp.

Characteristics subject to change without notice

5

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

WRITE INSTRUCTION SEQUENCE

Standard protocol:

Write Instruction Example - Setting 20mA Current in LEDB1 and LEDB2

REGISTER CONFIGURATION AND PROGRAMMING

ADDRESS

00h

01h

DESCRIPTION

Bank A Current setting

Bank B Current setting

BITS

8

8

02h

Bank C Current setting

8

03h

Channel Enable

6

04h

Global PWM Dimming

8

05h

Bank A PWM Duty Cycle

8

06h

Bank B PWM Duty Cycle

8

07h

Bank C PWM Duty Cycle

8

© 2009 IXYS Corp.

Characteristics subject to change without notice

NOTES

Reg00h – Reg02h data code = (ILED / 0.125 mA) (decimal)

converted into hex format

Bits 5:0 = 1 enables LEDs C2, C1, B2, B1, A2, A1 respectively

(See Table 1).

Both LEDs from one bank should be disabled to minimize

power consumption.

Log mode: (default)

Simultaneously decreases ILED in banks A – C by ~ – 0.17 dB

per step (256 steps).

Data Code 00h = 0 dB dimming, FEh = – 72 dB FFh = OFF

Example: 50% brightness reduction ( – 6dB) requires:

– 6dB / – 0.17dB = 35 (decimal) = 23h steps

Linear Mode:

Simultaneously decreases ILED in banks A – C by subtracting

Global Dimming Code (Reg04h data) from PWM Duty Cycle

Code (Reg05h – Reg07h data)

Data Code 00h = 0 dimming, If Global Dimming Code is equal

or exceeds PWM Duty Cycle Code, ILED = 0 mA.

Log Mode: (default):

~ – 0.17dB dimming per LSB for < 98% Dimming Level (i.e. >

2% Duty Cycle) from full scale;

Refer to 8 to 12 bit conversion curve (Figure 3 and Table

A4.1) for resolution in range 100% to 98% Dimming Level

(i.e. 0% to 2% Duty Cycle).

Data Code 00h = 0% Duty Cycle or 100% Dimming Level,

FFh = 100% Duty Cycle or 0% Dimming Level

Example: 50% brightness reduction ( – 6dB) requires: 255 –

(– 6 dB / – 0.17 dB) = 255 – 35 = 220 (decimal) = DCh steps

Linear Mode:

PWM Duty Cycle resolution ~ 0.39% per LSB

Code 00h = 0% Duty Cycle, FFh = 100% Duty Cycle

6

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

ADDRESS

`

DESCRIPTION

BITS

19h

Digital Test Mode

8

1Ch

LED shorted to GND

6

1Dh

LED Fault Detected

(LED shorted to V IN or

open)

6

1Eh

Configuration register

8

1Fh

Software reset, Standby

8

49h

Ta-Tj Temperature

Offset

8

4Ah

LED shutdown

Temperature

5

4Bh

2-x Table enable and

breakpoint (T-code)

6

50h – 5Fh

60h – 6Fh

70h – 7Fh

A0h

LUT-B

ΔPWM code1[7:4],

ΔPWM code0[3:0] –

ΔPWM code31[7:4],

ΔPWM code30[3:0]

LUT-G

ΔPWM code1[7:4],

ΔPWM code0[3:0] –

ΔPWM code31[7:4],

ΔPWM code30[3:0]

LUT-R

ΔPWM code1[7:4],

ΔPWM code0[3:0] –

ΔPWM code31[7:4],

ΔPWM code30[3:0]

Silicon diode dV F/dT [7:0]

© 2009 IXYS Corp.

Characteristics subject to change without notice

8

NOTES

See Table 2; Bit 5 = 1 sets user-initiated LED short/open

diagnostic

Bits from bit 5 to bit 0 represent LED status for LEDC2 –

LEDA1 respectively. Bit = 1 represents LED shorted to GND

When the corresponding bit in the “faults” detection register,

1Dh, is also High=1, and the associated LED driver current is

disabled.

Bits from bit 5 to bit 0 represent LED status for LEDC2 –

LEDA1 respectively. Bit = 1 represents that an LED Fault is

detected. If the corresponding bit in register 1Ch is also High

=1, than the LED is shorted to ground and current driver is

disabled. If the corresponding bit in register 1Ch is Low=0 than

the LED is either shorted to V IN or open

See Table 3

See Table 4

Two 4-bit compensation offsets between Ta and Tj:

Bit [7:4] = temperature offsets for LED temperature

Bit [3:0] = temperature offset for Silicon diode temperature

0

Each LSB = 5°C; temperature adjustment range from -40 C to

0

+35 C

Code 1000 in either nibble = -40ºC offset; Code 0111 in either

nibble = +35ºC offset. See Tables 5 and 6

Defines T-code, at which LED current shuts down per LED

vendor de-rating specification (see Table 7); Factory default

0

value = 11100 (bin) = 1Ch represents 105 C.

Bit 5 = 1 – enable 2-x scale LUT ΔPWM code correction (derating) starting at the breakpoint set by T-code (bits 4:0)

Bit 5 = 0 – 1-x scale (default) for entire temperature range

Bit [4:0] defines T-code, where temperature derating starts, or

where 2-x scaling begins (see Table 7)

1-x scale is ~ ± 0.17dB per step

2-x scale is ~ ± 0.34dB per step

2

Two LUT words per I C address.

Each word contains two 4-bit numbers representing of ΔPWM

codes.

See Table 8 and Appendix 1 for LUT programming.

Coding is different for Logarithmic and Linear Modes.

8

See above:

8

See above:

8

Silicon diode VF temperature coefficient :

Factory recommended value = -1.71 mV/°C = 001 10110

(bin) = 36h,

where bits from bit 7 to bit 5 represent integer part [1(decimal)

= 001 (bin)], and bits from bit 4 to bit 0 – fractional part [0.710 /

0.03125 = 22 (decimal) = 10110 (bin)]

7

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

ADDRESS

A2h

DESCRIPTION

LED-A dVF/dT [7:0]

BITS

8

A4h

LED-B dVF/dT [7:0]

8

A6h

LED-C dV F/dT [7:0]

8

C0h

Silicon diode η[7:0]

8

D0h

LED Tj offset [4:0]

5

D2h

Silicon diode Ta offset

[4:0]

5

D4h

Silicon diode Rs offset

[7:0]

8

D6h

LED-A Rs offset [7:0]

8

D8h

LED-B Rs offset [7:0]

8

DAh

LED-C Rs offset [7:0]

8

DCh

TMIN offset [7:0]

8

NOTES

User-loaded V F temperature coefficient for LEDs used at

Banks A, B, C respectively.

Negative tracking assumed with temperature;

Bits from bit 7 to bit 5 represent integer part and

bits from bit 4 to bit 0 - fractional part of the coefficient

0

Example: Temperature coefficient = -2.26 mV/ C;

Bit 7 – bit 5 = 2 (decimal) = 010 (bin), and

Bit 4 – bit 0 = INT{0.26 / 0.03125} = 8 (decimal) = 01000 (bin)

User loads 010 01000 (bin) = 48h = -2.25 (closest setting)

Silicon diode η(eta) or non-ideality factor:

Factory recommended loaded value = 1.0000 =

01000000(bin) = 40h

Bits from bit 7 to bit 6 represent integer part and

bits from bit 5 to bit 0 - fractional part (resolution = 0.015625

per LSB)

Example: η= 1.000;

Bit 7 – bit 6 = 1 (decimal) = 01 (bin), and

Bit 5 – bit 0 = INT{0.000 / 0.015625} = 0 (dec) = 000000 (bin)

User loads 01 000000 = 40h = 1.0000

LED Tj offset from Ta (user-loaded) – correction from ambient

temperature to LED junction temperature.

Factory default = 04h

Accounts for LED package thermal characteristics. See

Appendix 3 for details.

Silicon diode Tj offset from Ta – correction from ambient

temperature to Silicon diode junction temperature. Accounts

for LDS8160 package thermal characteristics. Factory default

= 02h

Silicon diode series resistance offset

Factory recommended loaded value = 04h (4 decimal) = ~ 68

Ω=Rs-si

-6

Formula (decimal) = 8192 x [(Rs-si x 8 x 10 A)/1.14 V]

Rs offset (user-loaded) for Banks A, B, and C LEDs for

specific LEDs used.

User loads per LED used. (1/slope of high current region of

LED I-V characteristic).

-4

Formula (decimal) = 8192 x [(Rs Ωx 8 x 10 A) / 1.14V]LEDs

Offset to establish minimum T-code = 0

0

This offset insures that -35C will equal T-code = 0. Factory

default supplied (237 decimal = EDh)

Table 1

Register

Address

03h

Bit 7

LED OT Flag

1 = OT

© 2009 IXYS Corp.

Characteristics subject to change without notice

Bit 6

N/A

Channel Enable Register

Bit 5

Bit 4

Bit 3

Enable

Enable

Enable

C2

C1

B2

8

Bit 2

Enable

B1

Bit 1

Enable

A2

Bit 0

Enable

A1

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Table 2

Register

Address

19h

Bit 7 Bit 6

Factory

Only

0*

Bit 5

Diagnostics

Request

0*

0*

Digital Test Modes Register

Bit 4

Bit 3

Bit 2

PWM Ramp

PWM Fast

Factory

Bypass = 1

Ramp = 1

Only

PWM Slow

0*

0*

Ramp = 0*

Bit 1

Post ADC

Filter On =1

Filter

Bypass=0*

Bit 0

Factory

Only

0*

Note: *) Value by default

Table 3

Register

Address

1Eh

Configuration Register

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Factory

dT adjust Soft Start

RGB mode

PWMs in

Silicon

PWM starts

LP standby

Only

disable PWM Ramp

with 3 LUTs

Linear

Diode

simultaneously

mode

(Leave set

= 1*

disabled

(3 PWM) =1* mode = 1

enable = 1

=1

=1

to 0)

=1

Normal

WLED mode

PWMs in

Silicon

PWMs

dt _adjust Soft Ramp

standby

with 1 LUT Logarithmic

Diode

shifted by

enabled

enabled

0*

mode

0

(1 PWM) = 0 mode = 0*

disable = 0*

120 = 0*

=0

= 0*

= 0*

Bit 7

Bit 6

Note: *) Value by default

Table 4

Register

Address

1Fh

Note:

Bit 7

Bit 6

Bit 5

Software

reset = 1

Standby

mode = 1

Temperature

request = 1

Normal

operation

= 0*

Normal

operation

= 0*

Normal

operation

= 0*

Control Register

Bit 4

Bit 3

Custom

Calibration

OSC trim

request = 1

=1

Factory

Normal

preset

operation

value =

= 0*

0*

Bit 2

Bit 1

Bit 0

Osc trim 2

**

Osc trim 1

**

Osc trim 0

**

*) Value by default

**) Trim code defined by customer

Bit 7 = 1 — Software reset: resets device, all registers reset/cleared.

Bit 6 = 1 — Standby (oscillator disabled, all registers retain programmed values.)

Table 5: Ta-Tj Temperature Gradient Offset

( set offset code to match reference De-rate point in LUT from LED Tj to Ta. Typically LED and Si are equal)

Register

Address

49h

Note:

Bit 7

LED

Offset 3

0*

Bit 6

LED

Offset 2

0*

Bit 5

LED

Offset 1

0*

Control Register

Bit 4

Bit 3

LED

Si Diode

Offset 0

Offset 3

0*

0*

Bit 2

Si Diode

Offset 2

0*

Bit 1

Si Diode

Offset 1

0*

Bit 0

Si Diode

Offset 0

0*

*) Value by default

© 2009 IXYS Corp.

Characteristics subject to change without notice

9

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Table 6: Offset Codes for Tj-Ta Temperature Gradient Offset (both LED and Si per Table 5).

Temperature

0

Offset C

(Ta-Tj)

-40

-35

-30

-25

Bit3 –

Bit 0

1000

1001

1010

1011

Temperature

0

Offset C

(Ta-Tj)

-20

-15

-10

-5

Temperature

0

Offset C

(Ta-Tj)

0

5

10

15

Bit3 –

Bit 0

1100

1101

1110

1111

Bit3 –

Bit 0

0000

0001

0010

0011

Temperature

0

Offset C

(Ta-Tj)

20

25

30

35

Bit3 –

Bit 0

0100

0101

0110

0111

Table 7: T-code values vs. Temperature (for registers 4Ah and 4Bh)

Temperature,

0

C

-35

-30

-25

-20

-15

-10

-5

0

Bit4 – Bit 0

00000

00001

00010

00011

00101

00101

00110

00111

Temperature,

0

C

5

10

15

20

25

30

35

40

Bit4 – Bit 0

01000

01001

01010

01011

01100

01101

01110

01111

Temperature,

0

C

45

50

55

60

65

70

75

80

Bit4 – Bit 0

10000

10001

10010

10011

10100

10101

10110

10111

Temperature,

0

C

85

90

95

100

105

110

115

120

Bit4 – Bit

0

11000

11001

11010

11011

11100

11101

11110

11111

Table 8: ΔPWM Code Allocation

Register

Address

50h, 60h, 70h

51h, 61h, 71h

52h, 62h, 72h

53h, 63h, 73h

54h, 64h, 74h

55h, 65h, 75h

56h, 66h, 76h

57h, 67h, 77h

Data bits

7– 4

3–0

ΔPWM code for

0

temperature, C

-30

-35

-20

-25

-10

-15

0

-5

10

5

20

15

30

25

40

35

Register

Address

58h, 68h, 78h

59h, 69h, 79h

5Ah, 6Ah, 7Ah

5Bh, 6Bh, 7Bh

5Ch, 6Ch, 7Ch

5Dh, 6Dh, 7Dh

5Eh, 6Eh, 7Eh

5Fh, 6Fh, 7Fh

Data bits

7 –4

3– 0

ΔPWM code for

0

temperature, C

50

45

60

55

70

65

80

75

90

85

100

95

110

105

120

115

Table 9: ΔPWM Codes vs. Number of Adjustment Steps

Number of

steps

Not Valid

-7

-6

-5

Binary

Code

1000

1001

1010

1011

Number of

steps

-4

-3

-2

-1

© 2009 IXYS Corp.

Characteristics subject to change without notice

Binary

Code

1100

1101

1110

1111

Number of

steps

0

1

2

3

10

Binary

Code

0000

0001

0010

0011

Number of

steps

4

5

6

7

Binary

Code

0100

0101

0110

0111

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

PROGRAMMING EXAMPLES

Operation

Set 18 mA current at Bank LEDA

Set 20 mA current at LEDA, 18 mA at LEDB, and 15 mA at LEDC

banks (assuming address at 00h and consecutive writes)

Turn LEDs A1, B1 and C1 on, all others off

Turn LEDs A2, B2, and C2 on, all others off

Turn all LEDs on

Decrease brightness at 50% (-6 dB) at all three channels

simultaneously (in logarithmic mode only)

Decrease brightness at 75% (-12 dB) at all three channels

simultaneously (in logarithmic mode only)

Restore full brightness at all three channels simultaneously

Set Bank B PWM duty Cycle at 50% (-6 dB) in logarithmic mode

Set Bank B PWM duty Cycle at 50% in linear mode

Short/open LED diagnostic request

Read out LED short to GND status

Read out LED short to VIN /open status

Set WLED Mode with 1 PWM generator in linear mode, soft start

disabled, and LP standby mode

Set Standby Mode

Resume normal operation from standby mode

Calibration request (conduct temperature calibration; wait >=16ms)

0

Set LEDs in shutdown mode at temperature above 85 C

0

Set 2-x scale de-rating at temperature equal or above 55 C

Software Reset (to default values) and/or clear of all registers

Note:

Register

Address

00h

90h

Command

(hex)

XX 00 90

00h

A0h 90h 78h

XX A0 90 78

03h

03h

03h

15h

24h

3Fh

XX 03 15

XX 03 24

XX 03 3F

04h

23h

XX 04 23

04h

47h

XX 04 47

04h

06h

06h

19h

1Ch

1Dh

00h

DCh

80h

20h

XX 04 00

XX 06 DC

XX 06 80

XX 19 20

XX 1C YY

XX 1D YY

1Eh

43h

XX 1E 43

1Fh

1Fh

1Fh

4Ah

4Bh

1Fh

40h

00h

10h

18h

32h

80h

XX 1F 40

XX 1F 00

XX 1F 10

XX 4A 18

XX 4B 32

XX 1F 80

Register Data

XX – The LDS8160 I2C customer-selected slave address followed by binary 0 for write command, i.e. if I 2C slave address is

001 0001 (see Table 10), XX = 0010 0010 (bin) = 22h

YY – The LDS8160 I2C customer-selected slave address followed by binary 1 for read command, i.e. if I 2C slave address is

001 0001 (see Table 10), YY = 0010 0011 (bin) = 23h

© 2009 IXYS Corp.

Characteristics subject to change without notice

11

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

PIN DESCRIPTION

Pin #

1

2

3

4

6

8

9

10

11

12

13

14

15

5, 7, 16

PAD

Name

SCLK

SDAT

SADD

GND

EN

LEDC2

LEDC1

LEDB2

LEDB1

LEDA2

LEDA1

V IN

TST

NC

PAD

Function

2

I C Serial clock input

2

I C Serial data input/output

2

I C Serial interface Addresses Programming

Ground Reference

Device enable (active high)

LEDC2 anode terminal

LEDC1 anode terminal

LEDB2 anode terminal

LEDB1 anode terminal

LEDA2 anode terminal

LEDA1 anode terminal

Power Source Input; connect to battery or supply

Test pin

Not connect (no internal connect to the device)

Connect to GND on the PCB

Top view: TQFN 16-lead 3 X 3 mm

PIN FUNCTION

2

VIN is the supply pin. A small 1μF ceramic bypass

capacitor is required between the VIN pin and ground

near the device. The operating input voltage range is

from 2.3 V to 5.5 V.

SADD is I C Serial interface Addresses Programming

2

pin that allows choice of one of four I C addresses

preprogrammed in device.

GND is the ground reference for internal circuitry.

The pin must be connected to the ground plane on

the PCB.

EN is the enable input for the device. Guaranteed

levels of logic high and logic low are set at 1.3 V and

0.4V respectively. When EN is initially taken high, the

device becomes enabled and can communicate

2

through I C interface after a 500 µsec wakeup

(initialization) period.

LEDA1 – LEDC2 provide the internal regulated

current sources for each of the LED anodes. These

pins enter high-impedance zero current state

whenever the device is in shutdown mode.

2

SDAT is the I C serial data line. This is a bidirectional

line allowing data to be written into and read from the

registers of the LDS8160

PAD is the exposed pad underneath the package.

For best thermal performance, the tab should be

soldered to the PCB and connected to the ground

plane

2

SCLK is the I C serial clock input.

TST is a test pin used by factory only. Leave it

floating (no external connection)

© 2009 IXYS Corp.

Characteristics subject to change without notice

12

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

BLOCK DIAGRAM

Figure 2: LDS8160 Functional Block Diagram

VIN

All Drivers 0 to 25 mA

Vin to

al l

Drivers

OverTemp

I2C Interface

Top Level Control

diagnostics

Shorted LED

Open LED

LED Calibration

Soft Start control

SCLK

PWMA

Calibrated

Reference

Currents

and

ADC bias

currents

Bandgap

Voltage

Reference

1.2V

SDAT

DA1

PWMA

1.2V

32

ADC

10 bit SAR

10

Digital Temperature

Sensor / Abritrator

DA2

Pre-Scale

8x, 1x, or 1/4x

PWMB

Si Iforce

LED Iforce

DB1

SADD

1 0 uA

2 uA 1 mA

0.2 mA

Blue LUT

PWMB

OTP

Green LUT

DB2

Si PNP

temp diode

Trim

PWMC

Red LUT

Temp

Compensation

Tables

Temp to PWM

adjust LUTs

OTP

Driver

GND

Vin to 1.8V LDO

for digital core

to PWMA

PWMB (green)

8 bit to 12 bit (log) PWM

Generator

to PWMB

PWMC (red)

8 bit to 12 bit (log) PWM

Generator

1.8V

Gnd

PWMA (blue)

8 bit to 12 bit (log) PWM

Generator

To top control

DC1

PWMC

to PWMC

DC2

to top control & dig processing

Vin

1.2V

POR

Start Up

Oscillator & Clock Generator

~ 1.2 MHz

Vin

EN

BASIC OPERATION

When EN is taken HIGH, a soft-start power-up

sequence begins and performs internal circuits reset

that requires less than 100 µs.

The LDS8160 may operate in follow modes:

a) Normal Operation Mode

b) Custom Operation Modes

c) Normal Standby Mode

d) Low Power (LP) Standby Mode

e) Programming Modes

f) Shutdown Mode

An initialization sequence then begins taking less

than 10 ms. This sequence determines the user2

selected I C slave address, loads factory

programmed settings, and conducts initial diagnostics

for open/shorted LEDs.

2

NORMAL OPERATION MODE

At this point, the I C interface is ready for

communication and the LDS8160 may be userprogrammed. Upon programming completion for all

required initial parameters and features’ settings, a

calibration command is given by setting bit 4 of the

At power-up, V IN should be in the range from 2.3 V to

5.5 V (max). If V IN is slow rising, EN pin should be

logic LOW at least until VIN reaches 2.3 V level.

© 2009 IXYS Corp.

Characteristics subject to change without notice

13

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Control Register (1Fh) HIGH. This starts the

TM

calibration sequence of the LDS8160 LED-Sense

temperature compensation circuits. The calibration

process takes approximately 16 ms.

02h) and data that represents the code for the

desired LED current. (See Table 10 for accessible

slave addresses.)

Code for LED current is determined as ILED/0.125 mA

in hex format, i.e. 20 mA current code = 20/0.125 =

160 (dec) = A0h.

The user can then additionally program the DC

current and PWM duty cycles for the LEDs. A PWM

ramp-up sequence occurs after the writing to the

PWM registers. This ramp-up delay in less than 250

ms in the default soft-start ramp mode, or can be 64

ms using the optional fast (4x) ramp mode (bit 3 of

Register 19h = HIGH). A further option is available to

bypass the soft-start PWM ramp mode entirely and

the initialization time will be reduced to just the

calibration sequence time of ~ 16ms. The initial softstart ramp mode can be bypassed by setting bit 4 of

register 19h HIGH.

The LDS8160 maximum current should not exceed

25 mA per LED (i.e. current code should not exceed

200 (dec) = C8h) to meet all electrical specifications.

To turn LEDs ON/OFF register 03h should be

addressed with data that represents the desired

combination of LEDs turned ON/OFF (see Table 1);

i.e. if LEDC1, LEDC2, LEDA1, LEDA2 should be ON,

and LEDB1, LEDB2 should be OFF, binary code that

should be written into register 03h is 110011 (bin) =

33h.

The calibration parameters for the temperature

measurement

engine

and

all

customer-set

parameters remain intact until the part is reset or

powered-down. Additionally, the user can re-calibrate

LDS8160 during times when LED currents are

brought to zero and the system is thermally stabilized

by programming the calibration command bit as

discussed.

The LDS8160 allows two ways for LED current

setting. One of them is using registers 00h – 02h

(static mode) and other one by using the PWM signal

to decrease average LED current value set by these

registers (dynamic mode).

For dynamic mode, the LDS8160 integrates 3 digital

PWM generators that operate at a frequency of ~ 285

Hz. In Logarithmic Mode, the PWM generators are

12-bit resolution and can be programmed with an 8bit code to provide 256 internally mapped 12-bit

logarithmic duty cycle steps to adjust the dimming

level. In Linear Mode, the PWM generates 256 linear

duty cycle steps to adjust the dimming levels from the

user programmed 8-bit code.

Factory preset values (upon completion of the powerup initialization but prior to user programming) are as

follow (see Table3):

a) All LEDs are disabled and ILEDA, B, C = 0;

b) RGB mode with three independent

Luminosity vs. Temperature correction tables

(LUTs) selected and three PWM generators;

The advantage of PWM dimming is stable LED color

temperature / wavelength that are determined by the

maximum LED current value set by registers 00h –

02h.

c) PWM dimming control in Logarithmic Mode

0

with PWM generators running by 120 phase

shift;

d) LED temperature compensation enabled with

LUTs

in

Logarithmic

Mode

Soft

start/shutdown enabled;

To use the dynamic PWM mode for LED current

setting, the maximum ILED value should be first set by

registers 00h – 02h as described above in static

mode and the desired PWM dimming should be set

by registers 05h – 07h. In Logarithmic Mode, set by

default, dimming resolution is approximately -0.17 dB

per step with 0dB dimming, or 100% duty cycle, at

th

the 256 step.

e) Internal Diode for temperature compensation

is enabled

f)

LEDs are used as sensors for temperature

compensation control.

Global PWM Dimming

LED Current Setting

The LDS8160 allows Global PWM Dimming control of

all three banks in the RGB Logarithmic mode, set by

default. It is convenient, because it allows the user to

simultaneously change LED brightness equally

across to all three channels independent of the

maximum static current setting (registers 00h, 01h

and 02h) in a particular channel.

Current setting registers 00h – 02h should be

2

programmed using I C interface and desired LEDs

should be enabled using register 03h before LEDs

turn on.

2

The standard I C interface procedure is used to

2

program ILED current (see section “I C INTERFACE”).

LDS8160 should be addressed with slave address

chosen followed by register address (00h, 01h, or

© 2009 IXYS Corp.

Characteristics subject to change without notice

14

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

For example, to decrease LED brightness by 50%

(-6dB) at all three LED banks, Global PWM Dimming

data code written in register 04h should be 6/0.17 =

35 (decimal) = 23h (see Figure 6: Global Dimming in

Logarithmic Mode in percent vs. register 04h data

(0% dimming = full LED brightness).

LUT corrections codes are added/subtracted to/from

the user-set duty cycle/dimming codes (dynamic

and/or global) for the channel to correct LED

brightness.

The LDS8160 integrates a 10-bit ADC and digital

processing to determine LED temperatures

approximately every 2.5 seconds. The proprietary

TM

LED-Sense algorithm allows direct measurement of

LED junction temperatures on the LEDA1, LEDB1,

and LEDC1 driver channels. Additionally an on-chip

silicon temperature sensing diode is also measured

to enhance temperature estimation accuracy.

The LDS8160 integrates temperature measurement

and compensation processing to maintain stable LED

brightness across varying ambient temperature and

de-rate power dissipated by LEDs, if the LED die

temperature exceeds a preset value.

Figure 3: Dynamic Mode Dimming in Logarithmic

Mode in dB vs. registers 05h – 07h data

(0dB dimming = full LED brightness)

Figure 5: Global Dimming in Logarithmic Mode in

dB vs. register 04h data

(0dB dimming = full LED brightness)

Figure 4: Dynamic Mode Dimming in Logarithmic

Mode in percent vs. registers 05h – 07h data

(0% dimming = full LED brightness)

Figure 6: Global Dimming in Logarithmic Mode in

percent vs. register 04h data

(0% dimming = full LED brightness)

Measured temperatures are encoded into 5-bit

0

T-codes representing 5 C temperature intervals from

0

-35 to +120 C. The measured T-code addresses

stored ΔPWM adjustment codes to adjust the

dimming level and therefore average current through

the LEDs. The user loads specific ΔPWM codes into

the LUTs to maintain constant average current and

therefore luminosity over temperature.

© 2009 IXYS Corp.

Characteristics subject to change without notice

In normal operation mode, the LDS8160 senses the

LED temperatures from all 3 available channels when

in the default RGB (3 channel) mode, or only from the

LEDA1 channel when used in the WLED (single

channel) mode.

15

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Temperature vs. PWM Duty Cycle Profiles

temperature with maximum

temperature of 85ºC.

The user must load the PWM correction look up

tables (LUTs) prior to operation. For the LDS8160 all

three tables, LUT-B, LUT-G and LUT-R require

loading (even if using same data for a WLED

application) with the user correction profiles prior to

operation. For RGB applications, LUT-B which drives

LEDA1 And LEDA2 respectively should be assigned

as the Blue color channel. LUT-G which drives

LEDB1 and LEDB2 should be assigned as the Green

color channel, and LUT-R which drives LEDC1 and

LEDC2 should be the RED channel.

ambient

operating

Figure 8: Luminosity vs. LED Forward Current

for Nichia NSSM038AT-E RGB LED

The correction tables are based upon LED vendor

characteristics for luminosity vs temperature and

current, LED current de-rating specifications, and

user system thermal design parameters. Figure 7

shows an actual Luminosity vs. Temperature curve of

the NSSM038AT-E RGB LED available from Nichia

Corp.

~ linear from

0 -30 mA

0

Figure 7: Luminosity vs. Temperature curve

(NSSM038AT-E RGB LED from Nichia)

Figure 9: Total power (combined R, G, and B

diodes) power de-rating curve

(NSSM038AT-E RGB LED from Nichia)

Figure 8 shows the typical LED characteristic of

decreasing illumination over temperature, but each

color changes differently. This results in white light

color shifts over temperature if not accounted for. It is

typical to see RED LED Luminosity vs Temperature

to change by ± 50% relative to the 25ºC level.

Figure 10 shows the final plot of typical LDS8160

PWM LUT correction profiles that could be

programmed by the user to adjust for this RGB LED.

This accumulated correction takes into account both

the Luminosity vs Temperature variations and the

adjustments to meet the higher temperature power

de-rating specification.

Figure 9 shows that luminosity is linearly dependent

with LED forward currents ≤30 mA. Therefore loss of

LED luminosity over temperature can be

compensated for by associated increases in LED

current.

Given the 5ºC increments of the temperature

adjustment intervals for the LDS8160, the currents

are slowly ramped to equalize loss of light output

before the de-rating profile begins. Once de-rating

begins, the PWM duty cycle is reduced, lowering LED

driver current, to insure meeting and regulating to the

desired maximum operating temperature.

Figure 9 gives the total RGB Power de-rating

specification for the same Nichia NSSM038AT-E

RGB LED. Total power is the combined power (VF x

IF) of each color LED. This curve specifies the

maximum RGB LED power that insures not

exceeding

the

maximum

specified

junction

© 2009 IXYS Corp.

Characteristics subject to change without notice

16

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Figure 10: Example LDS8160 Accumulated PWM

Correction Curves for Nichia NSMM038AT-E RGB

LED for ILED nominal (R, G, & B) = 15 mA @ 25ºC

The LDS8160 allows user to choose between one of

2

four preprogrammed I C addresses by connecting

SADD pin (#3) either to ground, SCLK, SDAT or VIN

pin (see Table 10). Consult factory about other

addresses available.

2

Table 10: LDS8160 I C Slave Addresses

SADD pin

connected to

Ground

SCLK

SDAT

VIN

2

I C Address

Binary code

001 0001

001 0101

101 0001

101 0101

Hex

11h

15h

51h

55h

2

For further details on the I C protocol, please refer to

2

the I C-Bus Specification, document number 9398393-40011, from Philips Semiconductors.

Appendix 1 describes how to generate PWM LUT

correction profiles. Additionally software tools and

support is available from the factory to assist

customers to generate LUT tables for specific LEDs

and applications. Please consult the factory or a

sales representative.

Recommended User Register Initialization

Table 11 is provided as a recommended user I2C

register initialization and calibration sequence for the

the LDS8160 for an RGB LED application. RED

values in the table mean these registers are

user/system dependent. Any values shown are for

example only.

Global Dimming Limitations

The final PWM dimming code value is the algebraic

sum of three codes: Dynamic Dimming code, Global

Dimming Code, and the Temperature Compensation

Code. If this sum is equal to or below zero, the LED

in that particular channel is disabled. It means that

the Global Dimming dynamic range is limited by

Dynamic Dimming and the Temperature Correction

Table used.

Unused LED Channels

For applications with less than six white or two RGB

2

LEDs, unused LED banks can be disabled via the I C

interface by addressing register 03h with data that

represent desired combination of LEDs turned

ON/OFF (see Table 1).

As an example:

If the user set PWM Dynamic Dimming in a particular

channel is set to -20 dB (registers 05h – 07h data =

TM

code 143 (dec)) and the LED-Sense Temperature

vs. PWM Correction requires 7 steps correction

dimming (data code 7 (dec)), the resultant allowable

additional Global Dimming range = 143 – 7 = 136

(dec) steps or ~ - 23.1 dB.

The LDS8160 unused LED outputs can be left open.

LED short/open protection

The LDS8160 runs a LED short/open diagnostic

routine upon the power up sequence. It detects both

LED pins shorted to ground and LED pins that are

open or shorted to VIN (fault conditions).

2

I C Interface

The results for short to GND detection are stored in

Diagnostics Register 1Ch. Bits from bit 5 to bit 0

indicate a short status as bit = 1 for LEDC2 - LEDA1

respectively, if the corresponding bit in the LED

Faults detection Diagnostics register, 1Dh, is also

High=1. A short to GND is detected if the measured

LED pin voltage is less than ~ 0.14 V independent of

the programmed LED current. Every channel

detected as shorted, is disabled

2

The LDS8160 uses a 2-wire serial I C-bus interface.

2

The SDAT and SCLK lines comply with the I C

electrical specification and should be terminated with

pull-up resistors to the logic voltage supply. When the

bus is not used, both lines are high. The device

supports a maximum bus speed of 400kbit/s. The

serial bit sequence is shown at REGISTER

CONFIGURATION AND PROGRAMMING section

for read and write operations into the registers. Read

and write instructions are initiated by the master

controller/CPU and acknowledged by the slave LED

driver.

© 2009 IXYS Corp.

Characteristics subject to change without notice

17

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Table 11: Recommended Register Load Sequence for LDS8160

Registers’ Load

Sequence #

1

2

3

4

5

6

Register

(hex)

1Eh

00h

01h

02h

03h

04h

7

05h

E7h

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22-47

48-64

65-80

81

06h

07h

49h

4Ah

4Bh

A0h

A2h

A4h

A6h

C0h

D4h

D6h

D8h

DAh

50h – 5Fh

60h – 7Fh

70h – 7Fh

1Fh

FBh

FAh

00h

1Ch

1Fh

36h

User Loads Per LED Used

User Loads Per LED Used

User Loads Per LED Used

40h

04h

User Loads Per LED Used

User Loads Per LED Used

User Loads Per LED Used

User Loads Per LED Used

User Loads Per LED Used

User Loads Per LED Used

10h

Value (hex)

Comments

8Ah

A0h

A0h

A0h

3Fh

00h

Initialize Configuration Register

Bank A ILED DC current @ 20 mA

Bank B ILED DC current @ 20 mA

Bank C ILED DC current @ 20 mA

Assume dual RGB use – enable all drivers

Global PWM Dimming 00h is full ON = 100% DC

Duty Cycle code for Blue channel PWM. Use set E7h=64% DC.

User uses to establish desired White Balance

Same as reg 05h, but for Green PWM. FBh=95% DC.

Same as reg 05h, but for Red PWM. FAh=90% DC

Ta-Tj 0ffset

Set LED Shutdown temperature 1Ch = 105C = Tj

Set optional 2x PWM adjust step start point; 1x scale below this point

Load Si Diode K factor for

- 1.71mV/C

User loads LED K factor @ 1mA I F

for BLED

User loads LED K factor @ 1mA IF. for GLED

User loads LED K factor @ 1mA IF

for RLED.

Load Si Diode

factor = 1.0

Load Si Diode Rs = 68 ohms

User loads LED Rs for BLED

User loads LED Rs for GLED

User loads LED Rs for RLED

LUT-B correction Table

LUT-G correction Table

LUT-R correction Table

User issues temp calibration command

Test results for open or short to VIN LED pins are

stored in the LED Faults Diagnostics Register 1Dh,

Bits from bit 5 to bit 0 represent LEDC2 - LEDA1

respectively with bit = 1 indicates a fault condition at

this particular LED pin. If the corresponding bit in

register 1Ch is also High = 1, than the LED is

shorted to GND as prior discussed. However when

the bit in 1Dh is High = 1 and the corresponding bit

in 1Ch is Low = 0, than the fault is either a short to

Vin or open.

Besides the power-up diagnostic sequence, the user

can re-initiate a diagnostic command at any time by

setting bit 5 of the Digital Test Modes Register, 19h, to

HIGH.

The LDS8160 restores LED current to programmed

value at channels with detected shorts to GND after

the fault condition is removed.

Over-Temperature Protection

If the die temperature exceeds +150°C the driver will

enter shutdown mode. The LDS8160 requires restart

after die temperature falls below 130°C.

An open LED pin fault causes no harm in the

LDS8160 or LED as the high side driver has no

current path from V IN or GND. Therefore, the fault

detection status indicates only in the 1Dh diagnostic

register, and no further action is required.

LED Selection

If the power source is a Li-ion battery, LEDs with VF =

1.9 V - 3.3 V are recommended to achieve highest

efficiency performance and extended operation on a

single battery charge.

In the case of and LED directly shorted to VIN, the

full VIN voltage will be connected to the LED and

current can flow independent of the LDS8160 LED

driver circuit directly to GND. The LDS8160 will

detect the fault and indicate the status in Register

1Dh, however further action needs taken at the

system level to shutdown VIN power to prevent

possible damage to the LED. The combined series

resistance of the LED (typically ~ 10Ω or more) and

additional board series resistance will result in

current limiting but not sufficient to prevent damage

to low power LEDs.

© 2009 IXYS Corp.

Characteristics subject to change without notice

External Components

The driver requires one external 1 µF ceramic capacitors (CIN ) X5R or X7R type.

CUSTOM OPERATION MODES

The LDS8160 allows the option to choose custom

operating modes overwriting content of Configuration

Register 1Eh (see Table 2).

18

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Bit 0 of this register allows switching between

standard and low power standby modes (see

detailed description at “STANDBY MODE” section).

two or three different brightness levels are required for

LED banks A, B, and C using dynamic dimming, RGB

Mode is recommended even with WLED.

Bit 1 allows bypass soft start / ramp down if fast

raising/falling LED current required.

Figure 11: Global Dimming in Linear Mode in

percent vs. register 04h data

(0% dimming = full LED brightness)

Bit 2 allows disable LED temperature compensation

if desired.

Bit 3 changes PWM generators start condition.

At normal operation mode, set by default, PWM

pulse rising edge of each PWM generator is shifted

0

by 120 in respect to two others. It allows for a

decrease in input current noise especially at high

LED currents. However, it may be important for

better color mix in RGB mode to start all three PWM

pulses simultaneously. To do so, set register 1Eh

bit 3 = 1.

Bits 4, 5 are for factory use only.

The LDS8160 also provides the option for using an

external remote temperature-sensing device such

as a 2N3904. This option is available on channel

LEDA1 In this case, channel LEDA1 should be

disabled via register 03h and it cannot operate as a

LED current source.

STANDBY MODES

The LDS8160 has two standby modes, which

2

customers may set by I C interface addressing register

1Fh with bit 6 = 1 (see Table 4).

2

In both standby modes, I C interface remains active

and all registers store information.

A further option is available to monitor temperatures

and make adjustments only from sensing the onchip silicon diode temperature. This option is

enabled by setting bit 4 = 1 in register 1Eh. In this

mode, temperature correction is via LUTA only.

In Normal Standby Mode the LED drivers and internal

clock are off; however, some internal circuits remain

active resulting in a standby current from the VIN power

source of 125 µA typical. In this mode, the EN pin

should be logic HIGH with signal level from 1.3 to VIN

voltage.

Bit 6 allows to change the PWM generators

operation mode from linear to logarithmic.

In Linear Mode, Dynamic Dimming resolution is ~

0.39% per LSB. Code 00h represents 100%

Dimming, while code FFh = 0%

In Low Power (LP) Standby Mode most of the device is

disabled and results in very low standby current from

VIN power source (5 µA typical). In LP Mode, the EN

pin should be connected to a 1.8V voltage source

capable to provide up to ~100 µA maximum dynamic

2

current to LDS8160 digital core in case of any I C

interface activity.. If this voltage source is unavailable,

Normal Standby Mode should be used.

To set LP Standby Mode, bit 0 in register 1Eh should

be set to 1 (see Table 2) before addressing to register

1Fh.

Linear Dimming Mode recommended for WLED

Mode operation only because it creates nonproportional Global Dimming in RGB Mode.

In Linear Dimming Mode, Dynamic Dimming

resolution is ~0.39% per LSB. Code 00h represents

100% Dimming, while Code FFh = 0% (See Figure

11).

Bit 7 allows switch between RGB and WLED

modes.

SHUTDOWN MODE

To set LDS8160 in shutdown mode, EN pin should be

logic low more than 10 ms. The LDS8160 shutdown

current is less than 1 µA. The LDS8160 wakes up from

shutdown mode with factory-preset data. To preserve

customer-programmed data, use either Normal or LP

standby modes.

In RBG Mode, set by default, the LDS8160 uses

three independent PWM generators for LED current

dynamic dimming and three LUTs for independent

luminosity vs temperature correction. In WLED

Mode, the LDS8160 uses a single PWM generator

to dim all six LEDs and one LUT for luminosity vs

temperature correction. It is convenient if all six

WLED should have identical brightness. However, if

© 2009 IXYS Corp.

Characteristics subject to change without notice

19

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

PROGRAMMING MODES

After initialization and user programming the user

2

should conduct an I C calibration sequence command

by writing Bit 4 = 1 in the Control register 1Fh. This

conducts a real time calibration of the initial starting

temperature and the actual LED parameters. Upon

completion, Bit 4 will be internally reset to 0, and the

LDS8160 is ready for use.

The LDS8160 is factory preprogrammed with

specific defaults for the Nichia NSSM038AT_E

RGB LEDs; however, application specific LEDs and

other user system conditions may require user

programming of the temperature compensation

LUTs and other LED specific parameters.

© 2009 IXYS Corp.

Characteristics subject to change without notice

20

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

TYPICAL CHARACTERISTICS

(Over recommended operating conditions unless specified otherwise) Vin = 3.6V, Cin = 1 µF, EN = High, TAMB = 25°C

Figure 13

Shutdown Delay En = H to L

Volts

Volts

Figure 12

Soft Start POR Delay En = L to H

Time (µs)

Time (µs)

Figure 15

PWM Dimming Response (TR / T F)

Volts

Volts

Figure 14

LED Driver @ 50% PWM Duty Cycle

Time (µs)

Time (ms)

Figure 16

PWM Minimum Pulse

Volts

IDriver (mA)

Figure 17

Output Driver Current vs. VDrop-Out Voltage

Time (µs)

Vdrop-out (Volts)

© 2009 IXYS Corp.

Characteristics subject to change without notice

21

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

PACKAGE DRAWING AND DIMENSIONS

16-PIN TQFN (HV3), 3mm x 3mm, 0.5mm PITCH

SYMBOL

A

A1

A2

b

D

D1

E

E1

e

L

m

n

MIN

0.70

0.00

0.178

0.20

2.95

1.65

2.95

1.65

0.325

NOM

0.75

0.02

0.203

0.25

3.00

1.70

3.00

1.70

0.50 typ

0.375

0.150 typ

0.225 typ

MAX

0.80

0.05

0.228

0.30

3.05

1.75

3.05

1.75

0.425

Note:

1. All dimensions are in millimeters

2. Complies with JEDEC Standard MO-220

© 2009 IXYS Corp.

Characteristics subject to change without notice

22

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

ORDERING INFORMATION

Part Number

LDS8160 002-T2

Notes:

1.

2.

Package

Package Marking

(1)

TQFN-16 3 x 3mm

8160

Matte-Tin Plated Finish (RoHS-compliant)

Quantity per reel is 2000

EXAMPLE OF ORDERING INFORMATION

Prefix

LDS

Device #

Suffix

8160

002

Product Number

Optional

Company ID

Package

T2

Tape & Reel

T: Tape & Reel

2: 2000/Reel

002: 3x3 TQFN

Notes:

1) All packages are RoHS-compliant (Lead-free, Halogen-free).

2) The standard lead finish is Matte-Tin.

3) The device used in the above example is a LDS8160A 002–T2 (3x3 TQFN, Tape & Reel).

4) For additional package and temperature options, please contact your nearest IXYS Corp. Sales office.

© 2009 IXYS Corp.

Characteristics subject to change without notice

23

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Appendix 1

CREATING LUT CORRECTION TABLES FOR LDS8160

LED luminosity (or brightness) is proportional to

forward current through the device and is

dependent on temperature. To maintain a constant

level of luminosity, the forward current should be

adjusted vs. temperature. However, changing the

static forward current also shifts the chromaticity of

the LED, where each white or color LED has a

different dependency with temperature.

The LDS8160 uses Dynamic Dimming control to

change average LED current while maintaining the

peak current thereby causing no color shift. The

TM

LED-Sense

temperature and color correction

algorithm implements this current compensation

feature by adjustment of the PWM duty cycles vs.

the LEDs temperature. The LEDs’ and an internal

chip diode’s I-V characteristics are routinely

measured, digitized, and mapped to ΔPWM code

adjustments stored in three integrated Luminosity

vs. Temperature (LUT) lookup tables. Each LUT is

assigned to one LED bank with two LED current

drivers each. By default, banks A, B, and C are

assigned to Blue, Green, and Red LEDs

respectively. Additionally, the same LUTs can be

used to insure current or power de-rating curve vs.

temperature.

Figure A1.2: Total power (combined R, G, and B

diodes) de-rating curve

(NSSM038AT-E RGB LED from Nichia

Assuming that compensation should maintain Relative

Luminosity = 1 in full range of temperatures, the

Compensation curve should be an inversion of the

Luminosity vs. Temperature curve shown at Figure 1

(see Figure A1-3).

Figure A1.1 shows an actual Luminosity vs.

Temperature curve of the NSSM038AT-E RGB LED

available from Nichia Corp.

Figure A1.3: Relative Luminosity Compensation Curve

(inverse Luminosity vs. Temperature curve)

NSSM038AT-E RGB LED from Nichia

This characteristic must be fitted to the chosen nominal

0

current at 25 C. Than the maximum current operating

point is established and it must comply with the

specified temperature de-rating curves for the LEDs.

Figure A1.1: Luminosity vs. Temperature curve

(NSSM038AT-E RGB LED from Nichia)

Figure A1.5 represents LED Current vs. Temperature

curve created for NSSM038AT-E RGB LED with 15ma

0

chosen as the nominal current at 25 C, and a

maximum power for the RGB LED of ~ 133mW as

depicted in Figure A1.4 showing the user-selected de-

Figure A1.2 shows the total power (combined R, G,

and B diodes) specification and de-rating for this

RGB LED.

© 2009 IXYS Corp.

Characteristics subject to change without notice

24

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

0

rating curve. The user operating point must comply

within the specification in Figure 2.

compensation temperature range is from -35 to 120 C.

Example:

0

If ΔPWM codes for the Red LED at 35 C are 0001 (1

0

step) and at 40 C 0010 (2 steps), register 77h should

be loaded with code 0010 0001 (bin) = 21h.

The LDS8160 has three integrated PWM generators

that allow programming of 256 logarithmic steps with

12-bit resolution in the LOG mode. Each PWM step is

~ 0.17 dB from 300uA to 25mA in the 1-x scale mode

and therefore ~ 0.34 dB in the 2-x scale mode.

1-x scale is typically used in the temperature

correction/compensation part of curve (as shown in

Figure 5) A 2-x scale mode is also available to support

the higher de-rating slope requirements

Figure A1.4: User Chosen Power and De-rating Curve

0

0

starting at 55 C and shutdown at 85 C

The LOG mode is required for RGB correction.

Linear mode operation and linear mode LUT correction

codes are an option in WLED applications. If Linear

WLED mode is chosen, all PWM related data for

Dynamic Dimming and Temperature Compensation

are entered as linear step codes, where each ΔPWM

step is 1/256 of full brightness (100% Duty Cycle)

The maximum current of ~ 18mA for the Red LED is

0

limited by power dissipation at 50 C and decreases

at higher temperatures in respect to the de-rating

specification of Figure A1.2.

In WLED applications where Linear PWM option mode

is chosen, only one PWM generator is active (i.e. the A

or Blue channel). In Linear mode the PWM is 8-bit

linear resolution where each bit represents is 1/256 of

100% duty cycle.

Example: RGB LUT Table Generation

0

Assume that the desired nominal forward current at 25 C

is 15 mA at all three LEDs and the forward voltages for

the R, G, B LEDs are ~ 2.1 V, 3.2 V, and 3.2 V,

respectively (per NSSM038AT-E datasheet).

0

If selected de-rating starts at 50 C, LED current values at

this temperature would be (per the Luminosity

Compensation Curve at Figure 3):

Figure A1.5: LED Current Correction Curves with

0

0

de-rating start at 55 C and shutdown at 85 C

The LED Current vs. Temperature curves are then

mapped to LDS8160 ΔPWM duty cycle codes that

are loaded into each of the three LUTs as 32 4-bit

words. Each word can represent from +7 to -7

0

ΔPWM steps for every 5 C temperature increment.

The ΔPWM codes are loaded into registers 50h –

7Fh as 4-bit two’s complement values (see Table 7

of main LDS8160 datasheet for code allocation).

~ 1.2x the nominal value at 250C, i.e. 15 x 1.2 = 18 mA for

Red LED;

~ 1.04X the nominal value at 250 C, i.e. 15 x 1.04 = 15.6

mA for Green LED;

~ 1x the nominal value for Blue LED to maintain constant

luminosity over temperature.

Users must also determine the typical forward voltage vs.

Temperature coefficients, or “k” factors, of the LEDs used

@ 1mA of forward current.

For the Nichia NSSM038AT-E these have been

determined as;

To maintain correlation to typical LED vendor data,

0

the tables establish 25 C as the zero-reference

point. Therefore, “0” is the required PWM code

0

value for 25ºC. For temperatures above 25 C, the

ΔPWM codes is the delta step change from the 5ºC

temperature point lower than the current step, while

0

for temperatures below 25 C the PWM code is the

delta step change from the 5ºC temperature higher

then the current step (i.e. closer to 25ºC). The

© 2009 IXYS Corp.

Characteristics subject to change without notice

0

- 2.0 mV/ C for RED LED,

0

- 1.5 mV/ C for Green LED, and

0

- 1.3 mV/ C for Blue LED.

Therefore, at 50 0C, forward voltages are

VF = 2.1V + [-2.0 mV/0 C x (500 C - 250 C)] = 2.05V for Red

25

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

ΔR @ 55ºC = 20Log [(18 mA – 1.69 mA) / 18 ma] =

-0.856 dB,

where 18 mA is the current for the 50ºC point and 1.69

0

mA is the de-rating current for each 5 C.

LED

0

0

0

VF = 3.2V + [-1.5 mV/ C x (50 C - 25 C)] = 3.163V for

Green LED, and

0

0

0

VF = 3.2V + [-1.3 mV/ C x (50 C - 25 C)] = 3.168V for

Blue LED.

Dividing this value by 0.34 dB/step (in 2-x scale used for

de-rating) and rounding result to the nearest integer value

give us follow ΔPWM code

The total RGB LED power at a 500 C with the applied

inverse curves to equalize the luminosity vs.

temperature would be

ΔPWM = INT (-0.846 dB / 0.34 dB/step) = -3 = 1101 (bin)

(see Table 8 of LDS8160 datasheet).

(2.05V x 18mA) + (3.16 V x 15.6 mA) + ( 3.17 V x

15mA) =~ 133.mW

The ΔPWM value would then be

The total RGB LED power for NSSM038AT-E must be

less than ~ 133 mW up to the de-rating point at 500C

(see Figure 2) complies with our result.

ΔPWM @ 60ºC = INT {20Log [(16.31mA – 1.69 mA) /

16.31 mA] / 0.34} = -3 =. 1101 (bin)

ΔPWM @ 65ºC = INT {20Log [(14.62 mA – 1.69 ma) /

14.62 mA) = -3 =. 1101 (bin)

Also from the curve in Figure 2, the total power must

0

de-rate to ~ 45mW at 85 C and diodes must be turned

off at higher temperatures.

ΔPWM @ 70ºC = INT {20Log [(12.93 mA – 1.69 ma) /

12.93 mA) = -4 =. 1100 (bin)

0

At 85 C, the R, G, B forward voltages will be reduced

to ~ 1.98 V, 3.11 V, and 3.12 V respectively.

ΔPWM @ 75ºC = INT {20Log [(11.24 mA – 1.69 ma) /

11.24 mA) = -4 =. 1100 (bin)

The de-rating is achieved by decreasing LED currents

in constant steps (i.e. linear rate) from 500 C to 850 C to

meet the final 45 mW power dissipation.

ΔPWM @ 80ºC = INT {20Log [(9.55 mA – 1.69 ma) / 9.55

mA) = -5 =. 1011 (bin)

To maintain the luminosity equalization during the derating, the 500C current ratios between Red, Green,

and Blue LED currents (i.e. 1.2:1.04:1) should be

preserved.

ΔPWM @ 85ºC = INT {20Log [(7.86 mA – 1.69 ma) / 8.1

mA) = -6 =. 1010 (bin)

At temperatures higher than 85ºC, the LED current should

be zero mA due to the shutdown temperature defined as

above 850C. Therefore, LUT ΔPWM entries for shutdown

regions are not used and may be zero.

With nominal forward current, I = 15mA, and

0

maintaining the 50 C current ratios, the B-LED current

at the end of de-rating (before shutdown) is calculated

as follows;

To set LED current in shutdown at temperature above

85 0C, write 850C T-code (11000 (bin)) with leading 1, i.e.

111000 (bin) = 38h, into register 4Ah (see Table 7 of

LDS8160 datasheet).

0

The total power dissipated by RGB LEDs at 85 C is

P85C = (1.2 x I x VR_85C ) + (1.04 x I x VG_85C ) + (1 x I x

VB_85C) = (1.2 x I x 1.98V) + (1.04 x I x 3.11 V) + (1 x I

x 3.12 V) = 45 mW ,

where I is the Blue LED current at 850C.

To maintain constant ratio between channels during the

de-rating, the Green and Blue channels can de- rated by

the same dB steps in Logarithmic mode as the Red

channel. This will maintain the same luminosity balance

as at the starting point of the de-rating.

Solving for I gives us I = ~ 45 mW / 8.73 V = 5.16mA

for Blue, 5.37 mA for Green, and 6.19 mA for Red

LED.

Users can adjust luminosity balance in the de-rating

section too to further optimize balance. This requires

more customized table entries (i.e. ratios continue to

match Luminosity vs. Temperature curve even for

temperatures where de-rating is being applied). The

decided approach is user/application dependent.

0

IR must de-rate from 18 mA to ~ 6.19 mA from 50 C to

850 C (seven 50 C steps).

For linear de-rate, each step is 18mA - 6.19mA / 7 = ~

1.69mA/step. Using the 2-x ΔPW M code scale, this is

met with the codes shown in the R-LUT table (See

0

0

Table 8 of LDS8160 datasheet) from 55 C to 85 C.

Table A1.1 shows the completed table used as LDS8160

default for Nichia NSSM038AT-E RGB LED with the

assumptions overviewed in this example.

In LOG mode the ΔPWM table entries for the de-rating

are found by first taking the current of the prior step

minus the de-rating current per step, then dividing the

result by the prior step current, and finally converting

to a number of dB step.

To aide users in building and loading their specific

correction tables IXYS can provide a software

development tool to map LED vendor information and

user defined operating points to final calculated LUT data

values. Please consult factory to obtain a copy.

The following example clarifies:

Using prior data for RED LED, we will find required

de-rating ΔR in dB at 55ºC

© 2009 IXYS Corp.

Characteristics subject to change without notice

26

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Figure A1.6 shows the effective curve formed by the

accumulated ΔPWM codes.

codes. The option for Linear Mode will adjust the code

entries and calculations accordingly.

The curves in the accumulated ΔPWM codes

should have same slope characteristics as the

curves in Figure A1.5.

Using the LDS8160 temperature compensation

capability to de-rate LEDs automatically, allows the

LED to be operated at maximum luminosity levels

(higher currents) and can reduce the total number of

LEDs required and/or reduce the total LED system

level power over systems that do not employ LED

temperature compensation. Figure A1.7 depicts this.

For WLED applications the Luminosity vs.

Temperature characteristics are similar to Blue

LEDs with the added effects of the yellow phosphor

coatings applied. In general, Luminosity of WLEDs

remains flat with temperature changed, but still

requires high temperature de-rating.

Figure A1.7: Allowable LED Forward Current vs.

Temperature

(WLED NSSW020BT-P1 from Nichia)

Figure A1.6: Accumulated ΔPWM Correction Codes

Typically, a single ΔPWM LUT correction table can

be used for all WLEDs. ΔPWM codes for the

correction table are calculated similarly to RGB

0

with de-rating start at 55 C

0

and shutdown at 85 C

© 2009 IXYS Corp.

Characteristics subject to change without notice

27

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Table A1.1: RGB ΔPWM LUT tables for this Nichia NSSM038AT-E device with 15mA nominal current at

0

25 C

Temperature

-35

-30

-25

-20

-15

-10

-5

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

86

90

95

100

105

110

115

120

Red T-code

-1

-2

-1

-1

-2

-1

-2

-2

-1

-1

-2

-2

0

2

2

2

2

2

-3

-3

-3

-4

-4

-5

-6

0

0

0

0

0

0

0

0

Green T-code

-1

0

-1

0

-1

0

-1

0

0

-1

0

0

0

0

0

1

0

1

-3

-3

-3

-4

-4

-5

-6

0

0

0

0

0

0

0

0

Note:

Blue T-code

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-3

-3

-3

-4

-4

-5

-6

0

0

0

0

0

0

0

0

Scale

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

1-x

2-x*

2-x

2-x

2-x

2-x

2-x

2-x

Shutdown**

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

Shutdown

0

*) Register 4Bh should be loaded with bit 5 = 1 and bits from Bit 4 to Bit 0 with T-code at 55 C (10011 (bin)), i.e.

register 4Bh should be addressed with data 11 0011 (bin) = 33h (see Table 7 of LDS8160 datasheet).

0

**) Register 4Ah should be loaded with bits from Bit 4 to Bit 0 with T-code at 85 C (11000 (bin)), i.e. register 4Bh should

be addressed with data 11000 (bin) = 18h (see Table 7 of LDS8160 datasheet).

© 2009 IXYS Corp.

Characteristics subject to change without notice

28

Doc. No. 8160_DS, Rev. N1.0

�LDS8160

Appendix 2

ADJUSTMENTS FOR RGB WHITE BALANCE