Class X2

Metallized Impregnated Paper EMI Suppression Capacitors

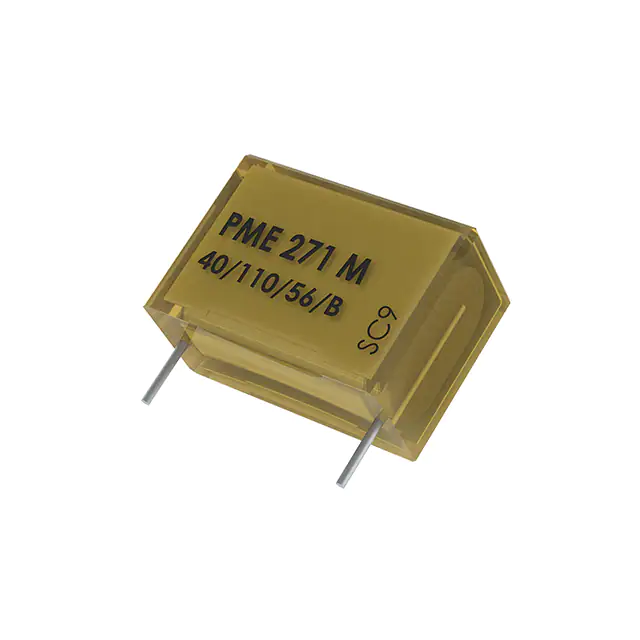

PME271M, Class X2, 275 VAC

Overview

Applications

The PME271M is constructed of multilayer metallized paper

encapsulated and impregnated in self-extinguishing material

meeting the requirements of UL 94 V–0.

Typical applications include worldwide use in

electromagnetic interference suppression in all X2 and

across-the-line applications.

Benefits

• Approvals: ENEC, UL, cUL

• Rated voltage: 275 VAC 50/60 Hz

• Capacitance range: 0.001 – 0.6 µF

• Lead spacing: 10.2 – 25.4 mm

• Capacitance tolerance: M = ±20% (for C ≤ 0.1 µF),

K = ±10% (for C > 0.1 µF)

• Climatic category: 40/110/56, IEC 60068–1

• Tape and reel in accordance with IEC 60286–2

• RoHS Compliant and lead-free terminations

• Operating temperature range of −40°C to +110°C

• 100% screening factory test at 2,150 VDC

Click image above for interactive 3D content

Open PDF in Adobe Reader for full functionality

Customer Part Number

PME271

M

(B)

610(0)

M

R30

Series

Rated Voltage (VAC)

Lead Spacing (mm)

Capacitance Code (pF)

Capacitance

Tolerance

Packaging

X2, Metallized Paper

M = 275

Blank = Standard

A = 10.2

B = 15.2

D = 22.5

The last three digits

represent significant

figures. The first digit

specifies the total

number of digits.

M = ±20%

(for C ≤ 0.1 µF)

K = ±10%

(for C > 0.1 µF)

See Ordering

Options Table

KEMET Internal Part Number

P

276

Q

E

104

M

275

A

Capacitor Class

Series

Lead Spacing

(mm)

Size Code

Capacitance

Code (pF)

Capacitance

Tolerance

Rated Voltage

(VAC)

Packaging

P = Paper

X2, Metallized

Paper

First two digits

represent

significant

figures. Third

digit specifies

number of

zeros.

M = ±20%

(for C ≤ 0.1 µF)

K = ±10%

(for C > 0.1 µF)

275 = 275

H = 10.2

Q = 15.2

C = 20.3

S = 22.5

E = 25.4

See Dimension

Table

See Ordering

Options Table

Built Into Tomorrow

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

1

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Benefits cont.

• The highest possible safety regarding active and passive

• High dV/dt capability

flammability

• The impregnated paper ensures excellent stability and

• Excellent self-healing properties ensure long life even when outstanding reliability properties, especially in applications

subjected to frequent over voltages

with continuous operation

• Good resistance to ionization due to impregnated dielectric

Ordering Options Table

Lead

Spacing

Nominal

(mm)

10.2

Type of Leads and Packaging

Standard Lead and Packaging Options

Bulk (Bag) – Short Leads

Bulk (Bag) – Maximum Length Leads

Lead Length

(mm)

KEMET

Legacy

Lead and

Lead and

Packaging Packaging

Code

Code

6 +0/−1

30 +5/−0

C

A

R06

R30

H0= 18.5 ±0.5

L

R19T0

Tape & Reel (Standard Reel)

H0= 18.5 ±0.5

P

R19T1

Ammo Pack

H0= 16.5 ±0.5

LAF3

R30XA

6 +0/−1

30 +5/−0

C

A

R06

R30

H0= 18.5 ±0.5

L

R19T0

H0= 18.5 ±0.5

P

R19T1

6 +0/−1

30 +5/−0

C

A

R06

R30

H0= 18.5 ±0.5

L

R19T0

Tape & Reel (Large Reel)

H0= 18.5 ±0.5

P

R19T1

Standard Lead and Packaging Options

Bulk (Bag) – Short Leads

Bulk (Bag) – Maximum Length Leads

Tape & Reel (Standard Reel)

6 +0/−1

30 +5/−0

H0= 18.5 ±0.5

C

A

L

R06

R30

R19T0

H0= 18.5 ±0.5

P

R19T1

6 +0/−1

30 +5/−0

C

A

R06

R30

Tape & Reel (Standard Reel)

Other Lead and Packaging Options

Native 10.2

formed to 7.5

15.2

Standard Lead and Packaging Options

Bulk (Bag) – Short Leads

Bulk (Bag) – Maximum Length Leads

Tape & Reel (Standard Reel)

Other Lead and Packaging Options

Tape & Reel (Standard Reel)

20.3

Standard Lead and Packaging Options

Bulk (Tray) – Short Leads

Bulk (Bag) – Maximum Length Leads

Tape & Reel (Standard Reel)

Other Lead and Packaging Options

22.5

Other Lead and Packaging Options

Tape & Reel (Large Reel)

25.4

Standard Lead and Packaging Options

Bulk (Tray) – Short Leads

Bulk (Bag) – Maximum Length Leads

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

2

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Dimensions – Millimeters

FRONT VIEW

SIDE VIEW

L

T

H

S

LL

F

Size Code

S

T

H

L

F

Nominal

Tolerance

Nominal

Tolerance

Nominal

Tolerance

Nominal

Tolerance

Nominal

Tolerance

HE

HH

HL

QE

QL

QP

QS

CE

CJ

CP

SJ

SP

SU

EG

10.2

10.2

10.2

15.2

15.2

15.2

15.2

20.3

20.3

20.3

22.5

22.5

22.5

25.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

±0.4

3.9

4.1

5.1

5.2

6.0

7.8

8.5

7.6

9.0

11.3

8.0

10.0

12.0

10.5

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

7.5

8.2

10.5

10.5

12.5

13.5

14.3

14.0

15.0

16.5

17.0

19.0

22.0

17.3

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

13.5

13.5

13.5

18.5

18.5

18.5

18.5

24.0

24.0

24.0

27.0

27.0

27.0

30.5

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

0.6

0.6

0.6

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

1.0

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

±0.05

EJ

EL

25.4

25.4

±0.4

±0.4

12.1

15.3

Maximum

Maximum

19.0

22.0

Maximum

Maximum

30.5

30.5

Maximum

Maximum

1.0

1.0

±0.05

±0.05

Note: See Ordering Options Table for lead length (LL) options.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

3

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Performance Characteristics

Rated Voltage

Capacitance Range

Capacitance Tolerance

Temperature Range

Climatic Category

Approvals

Dissipation Factor

Test Voltage Between Terminals

275 VAC 50/60 Hz

0.001 – 0.6 µF

±20%, ±10%, ±5% on request

−40°C to +110°C

40/110/56

ENEC, UL, cUL

Maximum Values at +23°C

1 kHz

1.3%

The 100% screening factory test is carried out at 2,150 VDC. The

voltage level is selected to meet the requirements in applicable

equipment standards. All electrical characteristics are checked

after the test. It is not permitted to repeat this test as there is a

risk to damage the capacitor. KEMET is not liable in such case

for any failures.

Minimum Values Between Terminals

Insulation Resistance

In DC Applications

C ≤ 0.33 µF

≥ 12,000 MΩ

C > 0.33 µF

≥ 4,000 MΩ • µF

Recommended voltage ≤ 630 VDC

Environmental Test Data

Test

IEC Publication

Procedure

Endurance

EN/IEC 60384–14

Vibration

IEC 60068–2–6 Test Fc

3 directions at 2 hours each 10 – 55 Hz at 0.75 mm or 98 m/s2

Bump

IEC 60068–2–29 Test Eb

1,000 bumps at 390 m/s2

Change of Temperature

IEC 60068–2–14 Test Na

Upper and lower rated temperature 5 cycles

Active Flammability

IEC 60384–14

VR + 20 surge pulses at 2.5 kV (pulse every 5 seconds)

Passive Flammability

IEC 60384–14

IEC 60384–1, IEC 60695–11–5 Needle-flame test

Damp Heat Steady State

IEC 60068–2–78 Test Cab

1.25 x VR VAC 50 Hz, once every hour increase to 1,000 VAC for 0.1

second, 1,000 hours at upper rated temperature

+40°C and 93% RH, 56 days

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

4

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Approvals

Mark

Specification

File Number

EN/IEC 60384–14

SE/0140–16D

UL 60384–14

CAN/CSA–E60384–14–09

E73869

Environmental Compliance

All KEMET EMI capacitors are RoHS Compliant.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

5

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Table 1 – Ratings & Part Number Reference

Maximum Dimensions in

mm

T

H

L

Lead

Spacing

(S)

0.001

0.0015

0.0022

0.0033

0.0047

0.0068

0.0068

0.010

0.015

0.022

0.033

0.047

0.068

0.1

0.1

0.15

0.22

0.1

0.15

0.22

0.27

0.33

0.27

0.33

0.47

0.6

3.9

3.9

3.9

4.1

5.1

5.1

5.2

5.2

5.2

6

6

6

7.8

8.5

7.6

9

11.3

8

8

10

12

12

10.5

12.1

15.3

15.3

7.5

7.5

7.5

8.2

10.5

10.5

10.5

10.5

10.5

12.5

12.5

12.5

13.5

14.3

14

15

16.5

17

17

19

22

22

17.3

19

22

22

13.5

13.5

13.5

13.5

13.5

13.5

18.5

18.5

18.5

18.5

18.5

18.5

18.5

18.5

24

24

24

27

27

27

27

27

30.5

30.5

30.5

30.5

10.2

10.2

10.2

10.2

10.2

10.2

15.2

15.2

15.2

15.2

15.2

15.2

15.2

15.2

20.3

20.3

20.3

22.5

22.5

22.5

22.5

22.5

25.4

25.4

25.4

25.4

53

44

37

30

24

21

19

16

13

10

8.4

7

5.6

4.3

4.1

3.4

2.7

3.9

3.3

2.6

2.3

2.1

2.4

2.1

1.8

1.6

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

600

600

600

600

600

600

400

400

400

400

400

400

P276HE102M275(1)

P276HE152M275(1)

P276HE222M275(1)

P276HH332M275(1)

P276HL472M275(1)

P276HL682M275(1)

P276QE682M275(1)

P276QE103M275(1)

P276QE153M275(1)

P276QL223M275(1)

P276QL333M275(1)

P276QL473M275(1)

P276QP683M275(1)

P276QS104M275(1)

P276CE104M275(1)

P276CJ154K275(1)

P276CP224K275(1)

P276SJ104M275(1)

P276SJ154K275(1)

P276SP224K275(1)

P276SU274K275(1)

P276SU334K275(1)

P276EG274K275(1)

P276EJ334K275(1)

P276EL474K275(1)

P276EL604K275(1)

PME271M410M(1)

PME271M415M(1)

PME271M422M(1)

PME271M433M(1)

PME271M447M(1)

PME271MA4680M(1)

PME271M468M(1)

PME271M510M(1)

PME271M515M(1)

PME271M522M(1)

PME271M533M(1)

PME271M547M(1)

PME271M568M(1)

PME271MB6100M(1)

PME271M610M(1)

PME271M615K(1)

PME271M622K(1)

PME271MD6100M(1)

PME271MD6150K(1)

PME271MD6220K(1)

PME271MD6270K(1)

PME271MD6330K(1)

PME271M627K(1)

PME271M633K(1)

PME271M647K(1)

PME271M660K(1)

Capacitance

Value (µF)

T (mm)

H (mm)

L (mm)

Lead Spacing

(S)

fo (MHz)

dV/dt

(V/µs)

KEMET

Part Number

Legacy

Part Number

Capacitance

Value (µF)

fo

(MHz)

dV/dt

(V/µs)

KEMET

Part Number

Legacy

Part Number

(1) Insert ordering code for lead type and packaging. See Ordering Options Table for available options.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

6

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Soldering Process

The implementation of the RoHS directive has resulted in the selection of SnAgCu (SAC) alloys or SnCu alloys as primary solder.

This has increased the liquidus temperature from that of 183ºC for SnPb eutectic alloy to 217 – 221°C for the new alloys. As a

result, the heat stress to the components, even in wave soldering, has increased considerably due to higher pre-heat and wave

temperatures. Polypropylene capacitors are especially sensitive to heat (the melting point of polypropylene is 160 – 170°C).

Wave soldering can be destructive, especially for mechanically small polypropylene capacitors (with lead spacing of 5 – 15

mm), and great care has to be taken during soldering. The recommended solder profiles from KEMET should be used. Please

consult KEMET with any questions. In general, the wave soldering curve from IEC Publication 61760–1 Edition 2 serves as a solid

guideline for successful soldering. Please see Figure 1.

Reflow soldering is not recommended for through-hole film capacitors. Exposing capacitors to a soldering profile in excess of the

above the recommended limits may result to degradation or permanent damage to the capacitors.

Do not place the polypropylene capacitor through an adhesive curing oven to cure resin for surface mount components. Insert

through-hole parts after the curing of surface mount parts. Consult KEMET to discuss the actual temperature profile in the oven,

if through-hole components must pass through the adhesive curing process. A maximum two soldering cycles is recommended.

Please allow time for the capacitor surface temperature to return to a normal temperature before the second soldering cycle.

Wave Soldering Recommendations

Manual Soldering Recommendations

Following is the recommendation for manual

soldering with a soldering iron.

300

2+3 seconds max

260°C

250

Second Wave

First Wave

Recommended Soldering Temperature

Temperature (°C)

200

400

Soldering Iron Bit Temperature (°C)

350

300

∆T<

150°C

Cooling

Preheating

150

ca. 2°C/second

ca. 3.5°C/second

typical

Tpreheat

100

Typical

250

200

50

150

0

100

0

40

80

120

160

200

240

Time (seconds)

50

0

0

1

2

3

4

5

6

7

8

Soldering Time (seconds)

The soldering iron tip temperature should

be set at 350°C (+10°C maximum) with the

soldering duration not to exceed more than 3

seconds.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

7

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Soldering Process cont.

Wave Soldering Recommendations cont.

1. The table indicates the maximum set-up temperature of the soldering process

Figure 1

Dielectric

Film Material

Maximum Preheat

Temperature

Maximum

Peak Soldering

Temperature

Capacitor Capacitor Capacitor Capacitor Capacitor

Pitch

Pitch

Pitch

Pitch

Pitch

≤ 10 mm = 15 mm > 15 mm ≤ 15 mm > 15 mm

Polyester

130°C

130°C

130°C

270°C

270°C

Polypropylene

100°C

110°C

130°C

260°C

270°C

Paper

130°C

130°C

140°C

270°C

270°C

Polyphenylene

Sulphide

150°C

150°C

160°C

270°C

270°C

2. The maximum temperature measured inside the capacitor:

Set the temperature so that inside the element the maximum temperature is below the limit:

Dielectric Film Material

Maximum temperature

measured inside the element

Polyester

160°C

Polypropylene

110°C

Paper

160°C

Polyphenylene Sulphide

160°C

Temperature monitored inside the capacitor.

Selective Soldering Recommendations

Selective dip soldering is a variation of reflow soldering. In this method, the printed circuit board with through-hole

components to be soldered is preheated and transported over the solder bath as in normal flow soldering without touching

the solder. When the board is over the bath, it is stopped and pre-designed solder pots are lifted from the bath with molten

solder only at the places of the selected components, and pressed against the lower surface of the board to solder the

components.

The temperature profile for selective soldering is similar to the double wave flow soldering outlined in this document,

however, instead of two baths, there is only one bath with a time from 3 to 10 seconds. In selective soldering, the risk of

overheating is greater than in double wave flow soldering, and great care must be taken so that the parts are not overheated.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

8

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Construction

Detailed Cross Section

Metallized Impregnated Paper

(First Layer)

Self-Extinguishing

Resin

Self-Extinguishing

Resin

Metallized Impregnated Paper

(Second Layer)

Margin

Margin

Metal Contact

Layer

Margin

Leads

Metal Contact

Layer

Winding Scheme

Metal

Spraying

Material

Metallization

Impregnated

Paper

Single Design — Multilayer Impregnated Paper Dielectric

1 Section

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

9

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Marking

FRONT

BACK

Series

IEC Climatic

Category

Voltage

Self

Healing

Approval

Mark

Approval

Mark

Manufacturing

Date Code

TOP

Capacitance

Safety Class

Manufacturing Date Code (IEC–60062)

Year

Code

Year

Code

Month

Code

Month

Code

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

A

B

C

D

E

F

H

J

K

L

2020

2021

2022

2023

2024

2025

2026

2027

2028

2029

M

N

P

R

S

T

U

V

W

X

January

February

March

April

May

June

1

2

3

4

5

6

July

August

September

October

November

December

7

8

9

O

N

D

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

10

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Packaging Quantities

Lead Spacing

(mm)

Thickness

(mm)

Height

(mm)

Length

(mm)

Bulk

Short Leads

Bulk

Long Leads

Standard Reel

360 mm

Large Reel

500 mm

Ammo

Formed

7.5

8.2

10.5

13.5

13.5

13.5

2,000

2,000

1,600

1,000

1,000

800

700

600

600

1,400

10.2

3.9

4.1

5.1

800

780

630

5.5

6.5

7.5

8.5

5.2

5.5

6

7.3

7.8

8.5

12.5

12.5

14.5

16

10.5

11

12.5

13

13.5

14.3

18

18

18

18

18.5

18.5

18.5

18.5

18.5

18.5

1,000

600

600

400

1,000

1,000

600

600

600

500

500

400

400

250

500

500

400

400

400

300

600

400

400

400

600

500

400

400

400

350

7.6

8.4

9

11.3

14

14

15

16.5

24

24

24

24

1,500

1,200

1,500

1,000

250

200

200

150

250

250

250

180

400

8

10

12

17

19

22

27

27

27

1,200

1,000

800

200

150

100

200

180

350

10.6

10.5

12.1

15.3

16.1

17.3

19

22

30.5

30.5

30.5

30.5

1,000

1,000

800

600

150

100

100

75

15.2

20.3

22.5

25.4

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

1,200

800

500

500

F3011_PME271M_X2_275 • 1/19/2021

11

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Lead Taping & Packaging (IEC 60286–2)

Lead Spacing 20.3 – 22.5 mm

Lead Spacing 10.2 – 15.2 mm

∆p

∆p

∆h

∆p

∆h

∆p

∆h

∆h

W

H1

W2

F

H0

H1

F

H0

W0 W1

W2

W0 W1

W

P1

D0

P0

P0

P1

D0

W

D0

t

t

Formed Leads from 10.2 – 7.5 mm

∆p

∆p

∆h

W2

H1

W0

∆h

W1

F = 7.5

H0

W

P0

P1

D0

Taping Specification

Standard IEC

60286–2

Dimensions in mm

Lead Spacing

+0.6/−0.1

F

Formed 7.5

10.2

15.2

20.3

22.5

F

±0.5

W

18.0

18.0

18.0

18.0

18.0

18 +1/−0.5

Minimum

W0

5.0

5.0

5.0

5.0

5.0

Position of Sprocket Hole

±0.5

W1

9.0

9.0

9.0

9.0

9.0

9 +0.75/−0.5

Distance Between Tapes

Maximum

W2

3.0

3.0

3.0

3.0

3.0

3.0

Sprocket Hole Diameter

±0.2

D0

4.0

4.0

4.0

4.0

4.0

4.0

Feed Hole Lead Spacing

±0.3

12.7

12.7

12.7

12.7

12.7

12.7

Distance Lead – Feed Hole

±0.7

P1

7.6

5.1

8.9

5.3

P1

Deviation Tape – Plane

Maximum

∆p

1.3

1.3

1.3

1.3

1.3

1.3

Lateral Deviation

Maximum

∆h

2.0

2.0

2.0

2.0

2.0

2.0

Total Thickness

±0.2

t

0.7

0.7

0.7

0.7

0.9 Maximum

0.9 Maximum

Nominal

H0(2)

18 +2/−0

18 +2/−0

18 +2/−0

18 +2/−0

18.5 ±0.5

18 +2/−0

Maximum

H1(3)

43

43

43

58

58

58 Maximum

Carrier Tape Width

Hold-Down Tape Width

Sprocket Hole/Cap Body

Sprocket Hole/Top of Cap Body

P0

(1)

(1) Maximum cumulative feed hole error, 1 mm per 20 parts

(2) 16.5 mm available on request

(4)

3.75

(3) Depending on case size

(4) 15 mm available on request

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

12

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

Lead Taping & Packaging (IEC 60286–2) cont.

Ammo Specifications

Series

R4x, R4x+R, R7x, RSB

F5A, F5B, F5D

F6xx, F8xx

PHExxx, PMExxx, PMRxxx

Dimensions (mm)

H

W

T

360

340

59

330

330

50

H

T

Reel Specifications

Series

R4x, R4x+R, R7x, RSB

F5A, F5B, F5D

F6xx, F8xx

PHExxx, PMExxx, PMRxxx

W

Dimensions (mm)

D

H

W

355

500

30

25

55 (Max)

360

500

30

46 (Max)

D

H

W

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

13

�Class X2

Metallized Impregnated Paper EMI Suppression Capacitors – PME271M, Class X2, 275 VAC

KEMET Electronics Corporation Sales Offices

For a complete list of our global sales offi ces, please visit www.kemet.com/sales.

Disclaimer

All product specifi cations, statements, information and data (collectively, the “Information”) in this datasheet are subject to change. The customer is responsible for

checking and verifying the extent to which the Information contained in this publication is applicable to an order at the time the order is placed. All Information given

herein is believed to be accurate and reliable, but it is presented without guarantee, warranty, or responsibility of any kind, expressed or implied.

Statements of suitability for certain applications are based on KEMET Electronics Corporation’s (“KEMET”) knowledge of typical operating conditions for such

applications, but are not intended to constitute – and KEMET specifi cally disclaims – any warranty concerning suitability for a specifi c customer application or use.

The Information is intended for use only by customers who have the requisite experience and capability to determine the correct products for their application. Any

technical advice inferred from this Information or otherwise provided by KEMET with reference to the use of KEMET’s products is given gratis, and KEMET assumes

no obligation or liability for the advice given or results obtained.

Although KEMET designs and manufactures its products to the most stringent quality and safety standards, given the current state of the art, isolated component

failures may still occur. Accordingly, customer applications which require a high degree of reliability or safety should employ suitable designs or other safeguards

(such as installation of protective circuitry or redundancies) in order to ensure that the failure of an electrical component does not result in a risk of personal injury

or property damage.

Although all product–related warnings, cautions and notes must be observed, the customer should not assume that all safety measures are indicted or that other

measures may not be required.

KEMET is a registered trademark of KEMET Electronics Corporation.

© KEMET Electronics Corporation • KEMET Tower • One East Broward Boulevard�

Fort Lauderdale, FL 33301 USA • 954-766-2800 • www.kemet.com

F3011_PME271M_X2_275 • 1/19/2021

14

�