LTC3101

Wide VIN, Multi-Output

DC/DC Converter and

PowerPath Controller

DESCRIPTION

FEATURES

n

n

n

n

n

n

n

n

n

n

n

n

The LTC®3101 is a complete power management solution

for low power portable devices. It provides three high

efficiency switching DC/DC converters which seamlessly

transition from battery to USB/wall adapter power when

available. A synchronous buck-boost regulator provides

complete flexibility, allowing operation from a single

Li-Ion/Polymer battery, 2 to 3 AA cells, a USB port or any

other power source operating from 1.8V to 5.5V.

Low Loss PowerPath™ Control: Seamless,

Automatic Transition from Battery to USB or

Wall Adapter Power

Wide VIN Range: 1.8V to 5.5V

Buck-Boost VOUT: 1.5V to 5.25V

Buck-Boost Generates 3.3V at 300mA for

VIN ≥ 1.8V, 3.3V at 800mA for VIN ≥ 3V

Dual 350mA Buck Regulators, VOUT: 0.6V to VIN

38μA Quiescent Current in Burst Mode® Operation

1.8V, 50mA Always-On LDO

Protected 100mA Hot Swap™ Output

Pushbutton On/Off Control

Current Limited 200mA MAX Output

Programmable Power-Up Sequencing

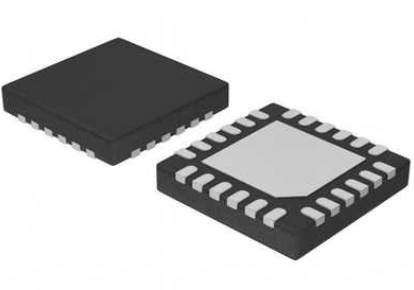

24-lead 4mm × 4mm × 0.75mm QFN Package

Two always-alive outputs, a 50mA LDO and a 200mA MAX

output that tracks the higher voltage input supply, provide

power for critical functions or additional external regulators. Flash memory cards can be directly powered from

the protected 100mA Hot Swap output. Pushbutton control

logic and a programmable-duration microprocessor reset

generator simplify interfacing to a microprocessor while

internal sequencing and independent enable pins provide

flexible power-up options. The LTC3101 is available in a low

profile (0.75mm) 24-lead 4mm × 4mm QFN package.

APPLICATIONS

n

n

n

Ultra-Portable Digital Video Cameras

Personal Handheld GPS Navigators

Portable Medical Instruments

L, LT, LTC, LTM, Burst Mode, Linear Technology and the Linear logo are registered trademarks

and Hot Swap and PowerPath are trademarks of Linear Technology Corporation. All other

trademarks are the property of their respective owners.

TYPICAL APPLICATION

10μF

CELLS

USB/WALL

ADAPTER

4.3V TO 5.5V

10μF

10μF

4.7μH

BAT1 BAT2 SW3A

USB1

USB2

CRS

SW3B OUT3

FB3

HSO

MAX

LDO

0.1μF

DIS ENA

ENA1

ENA2

ENA3

SW2

LTC3101

ON/OFF

96

Hot Swap OUTPUT: 3.3V AT 100mA

TRACKING OUTPUT: 200mA

1.8V AT 50mA

4.7μF

4.7μH

VOUT2

1.8V

10μF 350mA

221k

110k

SW1

10μF

221k

FB1

GND

BUCK-BOOST

IOUT = 150mA

94

92

BUCK2

IOUT = 150mA

90

BUCK1

IOUT = 150mA

88

86

4.7μH

PBSTAT

PWM

PWRON

RESET

Efficiency vs VBAT

221k

FB2

PWRKEY

μP

1M

VOUT3 = 3.3V

300mA FOR VIN ≥ 1.8V

800mA FOR VIN ≥ 3V

EFFICIENCY (%)

+

2 AA

147k

VOUT1

1.5V

350mA

84

1.5

2.5

3.5

VBAT (V)

4.5

5.5

3101 TA01b

3101 TA01a

3101fb

1

�LTC3101

ABSOLUTE MAXIMUM RATINGS

PIN CONFIGURATION

(Note 1)

ENA3

SW3B

ENA1

FB2

FB1

ENA2

TOP VIEW

24 23 22 21 20 19

PWM 1

18 HSO

SW1 2

17 OUT3

BAT1 3

16 USB2

25

GND

USB1 4

15 SW3A

SW2 5

14 BAT2

13 RESET

PBSTAT

CRS

9 10 11 12

MAX

8

LDO

7

FB3

PWRON 6

PWRKEY

VBAT1, VBAT2, VUSB1, VUSB2 ......................... –0.3V to 6V

VSW1, VSW2, VSW3A, VSW3B

DC............................................................ –0.3V to 6V

Pulsed (400mA), it

is recommended that a 22μF or larger output capacitor be

used. The capacitor should be placed as close to the IC as

possible and should have a short return path to ground.

ENA3 (Pin 19): Enable Pin for Buck-Boost Converter.

Forcing this pin above 1V will turn on the buck-boost

converter when the IC is enabled (via the pushbutton

interface). Forcing this pin below 0.3V will disable the

buck-boost converter.

SW3B (Pin 20): Buck-Boost Switch Pin. This pin should

be connected to one side of the buck-boost inductor.

ENA1 (Pin 21): Enable Pin for Buck Converter 1. Forcing

this pin above 1V will turn on the buck converter when the

IC is enabled (via the pushbutton interface). Forcing this

pin below 0.3V will disable buck converter 1.

FB2 (Pin 22): Feedback Voltage Input for Buck Converter 2.

The resistor divider connected to this pin sets the output

voltage for buck converter 2.

FB1 (Pin 23): Feedback Voltage Input for Buck Converter 1.

The resistor divider connected to this pin sets the output

voltage for buck converter 1.

ENA2 (Pin 24): Enable Pin for Buck Converter 2. Forcing

this pin above 1V will turn on the buck converter when the

IC is enabled (via the pushbutton interface). Forcing this

pin below 0.3V will disable buck converter 2.

GND (Exposed Pad Pin 25): Small-Signal and Power

Ground for the IC. The Exposed Pad must be soldered to

the PCB and electrically connected to ground through the

shortest and lowest impedance connection possible.

HSO (Pin 18): Hot Swap Output. An internal current-limited

switch connects the HSO output to the buck-boost output

voltage after the buck-boost output reaches regulation.

With the buck-boost operating in PWM mode, this output

is guaranteed to support a 100mA load and is short-circuit

protected.

3101fb

11

�LTC3101

BLOCK DIAGRAM

14

16

BAT2*

15

USB2*

20

SW3A

17

SW3B

OUT3

WELL

CONTROL

MAX

CONTROL

AND

CURRENT

LIMIT

D

HSO

18

A

11

MAX

B

A´

10

3

4

C

Hot Swap

CONTROL

ALWAYS-ON

LDO

CONTROL

LDO

BAT1*

FB3

BUCK-BOOST

CONTROL

USB1*

ENA3

4M

WELL

CONTROL

7

19

VCC

400k

2

SW1

1.27MHz

OSCILLATOR

BANDGAP

REFERENCE

OVERTEMPERATURE

SHUTDOWN AND

UNDERVOLTAGE

LOCKOUT

BUCK 1

CONTROL

23

21

24ms

DEGLITCH

FB1

ENA1

PBSTAT

8

9

PUSHBUTTON

CONTROL

LOGIC

PWM

PWRON

1

6

4M

4M

RESET

WELL

CONTROL

5

PWRKEY

1μA

SW2

1.20V

+

–

CRS

13

12

DISABLED

FB1 POWER BAD (IF ENABLED)

FB2 POWER BAD (IF ENABLED)

FB3 POWER BAD (IF ENABLED)

UNDERVOLTAGE FAULT

OVERTEMPERATURE FAULT

BUCK 2

CONTROL

4M

24

22

ENA2

FB2

GND

(EXPOSED PAD)

25

*BAT1 AND BAT2 MUST BE CONNECTED TOGETHER IN THE APPLICATION

USB1 AND USB2 MUST BE CONNECTED TOGETHER IN THE APPLICATION

3101 BD

3101fb

12

�LTC3101

OPERATION

INTRODUCTION

The LTC3101 provides a complete power management

solution for low power portable devices. It generates a

total of six output voltage rails and provides a seamless,

automatic transition between two input power sources.

The LTC3101 contains three high efficiency synchronous

DC/DC converters: a 5-switch buck-boost DC/DC converter and two synchronous 3-switch step-down DC/DC

converters. The buck-boost DC/DC converter is typically

utilized to provide a 3V or 3.3V rail that lies within the

input voltage range. The two step-down converters can

be configured to provide two lower voltage output rails,

such as a 1.8V rail for SDRAM and a 1.2V rail to supply

the system microprocessor.

The LTC3101 can operate from any power source over the

wide input voltage range of 1.8V to 5.5V. All three switching

DC/DC converters operate from a common 1.27MHz oscillator and a single pin can be used to place all three DC/DC

converters into Burst Mode operation to reduce the total

no-load quiescent current with all six output voltage rails

active to only 38μA (typical). In standby operation, with

only the LDO and MAX outputs active, the input current

is reduced to 15μA (typical).

The 5-switch buck-boost DC/DC converter generates a

user-programmable output voltage rail that can lie within

the voltage range of the input power sources. Utilizing

a proprietary switching algorithm, the buck-boost converter maintains high efficiency and low noise operation

with input voltages that are above, below, or even equal

to the required output rail. A protected Hot Swap output

powered by the buck-boost output voltage rail is enabled

once the buck-boost reaches regulation. This provides a

current-limited output that can be shorted without affecting

the primary buck-boost output. One use of the Hot Swap

output is to power external flash memory cards that need

to be hot-plugged without disrupting the primary buckboost output rail.

The synchronous buck converters are typically used to

provide two high efficiency lower voltage rails and support 100% duty cycle operation to extend battery life. The

output voltage of each buck converter is independently

user programmable and can be set as low as 0.6V.

An always-alive LDO provides a fixed 1.8V output at 50mA

which can be utilized to power critical functions such as a

real time clock. Reverse blocking allows the LDO to be used

to charge a supercapacitor for memory retention when both

power sources are removed. The MAX output generates

a secondary always-alive, current-limited output rail that

tracks the higher voltage input power source (battery or

USB) and is convenient for powering additional external

LDOs and circuitry that can function directly from a wide

input voltage range.

A pushbutton interface and internal supply sequencing

complete the LTC3101 as a total power supply solution

while requiring only a minimal number of supporting

external components. Integral to the pushbutton control

is an internal microprocessor reset generator with a reset

duration that can be easily programmed using a single

external capacitor allowing the interface to be customized

to each particular application.

The extensive functionality and flexibility of the LTC3101,

along with its small size and high efficiency, make it an

excellent power solution for a wide variety of low power

portable electronic products.

PUSHBUTTON INTERFACE

The LTC3101 includes a pushbutton interface that allows

a single momentary pushbutton to control the sequenced

power-up and power-down of all output rails in coordination with an external microprocessor. In addition, three

independent enable pins allow an unused DC/DC converter

to be independently disabled and also provide the means

to manually implement an alternate power-up sequence.

The LTC3101 can be enabled by either forcing PWRON

high or by forcing PWRKEY low. In either case, the DC/DC

converters (if enabled by their respective enable pin)

will power up in the internally fixed default sequence:

buck converter 1, buck converter 2, and finally the buckboost converter. In the typical application, the power-on

sequence is initiated when the PWRKEY is driven low by an

external momentary pushbutton. Once the microprocessor is powered up it must assert PWRON high before the

pushbutton is released, thereby forcing the LTC3101 to

3101fb

13

�LTC3101

OPERATION

remain enabled. Power-down is usually accomplished by

having the microprocessor monitor PBSTAT to detect an

additional push of the pushbutton. Once this is detected,

the microprocessor disables the LTC3101 by forcing

PWRON low (or simply releasing PWRON and allowing

it be pulled low by its internal pull-down resistor). In

this manner, a single external momentary pushbutton is

all that is required to provide sequenced power-up and

power-down control.

Figure 1 depicts the waveforms in the standard power-up

sequence. In this example, it is assumed that all three

DC/DC converter rails are used in the application and

therefore ENA1, ENA2 and ENA3 are driven high (or tied

to the MAX output). An external normally-open pushbutton

is connected between ground and the PWRKEY pin. When

the pushbutton is not pressed, PWRKEY is pulled high

via an internal 400k pull-up resistor. Until the power-up

sequence is initiated, the IC is in the standby state, and

only the LDO and MAX outputs are active.

The standard power-up sequence is initiated when

the pushbutton is pressed, forcing PWRKEY low for a

duration that is longer than the 24ms (typical) internal

debouncing duration. Once the PWRKEY is held low for

the debouncing duration, PBSTAT is driven low to indicate

the pushbutton status. In addition, buck converter 1 is

enabled and its output begins rising into regulation. Once

the feedback voltage of buck converter 1 reaches its power

good threshold, buck converter 2 is enabled. After buck

converter 2 reaches its power good threshold, the buckboost converter is enabled. Finally, once the buck-boost

output reaches its power good threshold, the Hot Swap

output is enabled and simultaneously the microprocessor

reset duration begins when a 1μA (nominal) current begins

charging the external CRS capacitor. The microprocessor

reset output, RESET, is driven low throughout this entire

power-up sequence until the CRS pin is charged to 1.2V

(typical). Once RESET goes high, the microprocessor in

the application initializes and must drive the PWRON input

of the LTC3101 high in order to keep the LTC3101 enabled.

If PWRON is not driven high by the time PWRKEY returns

high (i.e., the pushbutton is released) then the LTC3101

will be disabled and all outputs will be actively discharged

to ground.

PWRKEY

PBSTAT

24ms BLANKING

VOUT BUCK 1

VOUT BUCK 2

VOUT BUCK-BOOST

HSO

CRS

RESET

PWRON

3101 F01

Figure 1. Power-Up Sequence Waveforms

3101fb

14

�LTC3101

OPERATION

Independent Enables

Each of the buck converters and the buck-boost converter

have independent enable pins (ENA1, ENA2 and ENA3).

These provide an additional degree of flexibility by allowing any unused channels to be independently disabled

and skipped in the power-up sequence. For example, if

the additional low voltage rail generated by the second

buck converter is not required, it can be disabled by

simply forcing ENA2 to ground. The power-up sequence

will be unaffected except that second buck converter will

be skipped. As a result, buck converter 1 will power up

and the buck-boost will be enabled as soon as buck converter 1 reaches regulation. Any unused channels can be

disabled in this fashion and they will simply be skipped

in the power-up sequence.

Manual Power-Up Via The PWRON Pin

If the pushbutton interface is not required, the LTC3101

can be manually enabled by simply forcing the PWRON

pin high. When PWRON is forced high any channels that

are enabled via their independent enable pin will power

up in the standard sequence (buck converter 1, buck converter 2 and then the buck-boost converter). An arbitrary

power-up sequence can be forced manually, by forcing all

enables (ENA1, ENA2, ENA3) low while bringing PWRON

high. Then, after waiting 10μs for the logic to initialize,

the individual converters can be manually enabled via their

independent enable pins in any order required. For example,

a simultaneous power-up is initiated by bringing PWRON

high while holding ENA1, ENA2 and ENA3 low. Then after

a 10μs or longer delay, ENA1, ENA2 and ENA3 can be

brought high simultaneously causing the two buck rails

and the buck-boost rail to begin rising simultaneously.

Fault Conditions

On an overtemperature or input undervoltage fault condition, all DC/DC converters, the LDO, and the MAX output

are disabled and the CRS pin is driven low which results

in the microprocessor reset output, RESET, being driven

low as well. In the standard application, this will cause

the microprocessor to release the PWRON pin, thereby

disabling the LTC3101. Consequently, the LTC3101 will not

automatically re-enable even if the fault condition clears.

Instead, the LTC3101 will have to be restarted via repeating

the normal power-up sequence. Alternatively, if PWRON is

held high until the fault condition clears, then any enabled

converters will power up in the default sequence once the

fault clears and the microprocessor reset will clear after

its programmed delay.

If the power good comparator for any converter indicates a

fault condition (loss of regulation), the CRS pin and RESET

pins are driven low. In a typical application, this will place

the microprocessor in the reset condition which will release

the force on PWRON and therefore disable the LTC3101.

However, if PWRON is maintained high, all converters will

remain enabled through the fault condition. Once the fault

condition clears, the affected converter output will recover,

and CRS will begin charging. After the programmed reset

duration, RESET will be released.

LDO OUTPUT

The LDO output generates a regulated 1.8V (nominal)

output voltage rail that is guaranteed to support a 50mA

load. The LDO output remains active whenever a valid

supply is present on either the USB2 or BAT2 inputs and

is unaffected by the pushbutton interface. Its always-on

status allows the LDO to power critical functions such as

a real time clock which must remain powered under all

conditions.

The LDO output is reverse blocking in shutdown (i.e.,

when undervoltage lockout threshold is reached) allowing

its output to stay charged when both input supplies are

removed with reverse leakage guaranteed to be under 1μA.

This allows the LDO to be used to charge a supercapacitor for memory retention purposes or powering standby

functions during times when both power sources are

removed. The LDO is specifically designed to be stable

with a small 4.7μF capacitor, but to also maintain stable

operation with arbitrarily large capacitance supercapacitors

without requiring a series isolation resistor.

The LDO output is current-limit protected. On an

undervoltage or overtemperature fault, the LDO is disabled

until the fault condition clears.

3101fb

15

�LTC3101

OPERATION

MAX OUTPUT

The MAX output generates a protected output rail that tracks

the higher of the two input supplies, BAT2 or USB2. The

MAX output is current-limit protected and is guaranteed

to support a 200mA load.

The MAX output is an always-alive output, meaning it is

always enabled independent of the state of the pushbutton

interface. This allows the MAX output to power additional

LDOs or critical circuitry that must remain powered in

standby. In addition, the MAX output can be used to

efficiently power additional application circuits that can

operate directly from a wide input voltage range without

burdening one of the switching converters. The MAX output

is also a convenient supply for forcing logic inputs (such

as PWM, ENA1, ENA2 and ENA3) high since it is powered

whenever either input supply is present.

The MAX output is disabled in undervoltage lockout and

during overtemperature shutdown. Since the MAX output

serves as the input to the LDO, it is recommended that

it be bypassed with a 1μF or greater ceramic capacitor if

the LDO is to be used in the application.

Hot Swap (HSO) OUTPUT

The HSO output is generated by a protected power switch

from the output of the buck-boost converter. It provides

a current-limited output that can be shorted to ground

without disrupting the buck-boost output voltage. This

is primarily intended to be used as a supply rail for flash

memory cards which can be hot-plugged in the application. When a card is hot-plugged into the HSO output,

the supply bypass capacitors on the card are gradually

charged via the current-limited output without affecting

the buck-boost output rail. The HSO output is not enabled

until the buck-boost is enabled and the buck-boost power

good comparator indicates it is in regulation.

BUCK CONVERTER OPERATION

The LTC3101 contains two independent buck DC/DC

converters each capable of supplying a 350mA load. Each

has an adjustable output voltage that can be set as low as

0.6V. In addition, each buck converter supports low dropout operation to extend battery life. These converters can

be utilized in Burst Mode operation to improve light-load

efficiency and no-load standby current or in PWM mode

to ensure low noise operation. Each buck converter has

dual P-channel power switches and a single N-channel

synchronous rectifier. The dual P-channel power switches

allow the buck converters to operate directly from either

the battery or USB inputs (BAT1 or USB1). The buck

converters will automatically and seamlessly transition

to operate from the higher voltage supply. Both buck

converters feature short-circuit protection and frequency

foldback to prevent inductor current run-away during low

resistance output short conditions.

PWM Mode Operation

If the PWM pin is forced high, both buck converters will

operate in fixed frequency pulse width modulation mode

using current mode control. At the start of each oscillator

cycle, the active P-channel switch is turned on and remains

on until the inductor current with superimposed slope

compensation ramp exceeds the error amplifier output.

At this point, the synchronous rectifier is turned on and

remains on until the inductor current falls to zero or a new

switching cycle is initiated. As a result, the buck converter

operates with discontinuous inductor current at light loads

in order to improve efficiency. At extremely light loads, the

minimum on-time of the P-channel switch will be reached

and the buck converter will begin turning off for multiple

cycles in order to maintain regulation.

Burst Mode Operation

When the PWM pin is forced low, both buck converters

will automatically and independently transition between

Burst Mode operation at sufficiently light loads (below

approximately 10mA) and PWM mode at heavier loads.

Burst Mode entry is determined by the peak inductor current and therefore the load current at which Burst Mode

operation will be entered depends on the input voltage,

the output voltage and the inductor value. Typical curves

for Burst Mode entry threshold are provided in the Typical

Performance Characteristics section of this data sheet.

In dropout operation, the active P-channel switch will

remain on continuously and Burst Mode operation will

not be entered.

3101fb

16

�LTC3101

OPERATION

Low Dropout Operation

Internal Voltage Mode Soft-Start

As the input voltage decreases to a value approaching

the output regulation voltage, the duty cycle increases to

the maximum on-time of the P-channel switch. Further

reduction of the supply voltage will force the main switch

to remain on for more than one cycle and subharmonic

switching will occur to provide a higher effective duty cycle.

If the input voltage is decreased further, the buck converter

will enter 100% duty cycle operation and the P-channel

switch will remain on continuously. In this dropout state,

the output voltage is determined by the input voltage less

the resistive voltage drop across the P-channel switch and

series resistance of the inductor.

Each buck converter has an independent internal voltage

mode soft-start circuit with a nominal duration of 800μs.

The buck converters remain in regulation during soft-start

and will therefore respond to output load transients which

occur during this time. In addition, the output voltage risetime has minimal dependency on the size of the output

capacitor or load current during start-up.

Slope Compensation

Current mode control requires the use of slope compensation to prevent sub-harmonic oscillations in the inductor

current waveform at high duty cycle operation. This function

is performed internally on the LTC3101 through the addition

of a compensating ramp to the current sense signal. In

some current mode ICs, current limiting is performed by

clamping the error amplifier voltage to a fixed maximum.

This leads to a reduced output current capability at low

step-down ratios. In contrast, the LTC3101 performs current-limiting prior to addition of the slope compensation

ramp and therefore achieves a peak inductor current limit

that is independent of duty cycle.

Output Short-Circuit Operation

When the output is shorted to ground, the error amplifier

will saturate high and the P-channel switch will turn on

at the start of each cycle and remain on until the current

limit trips. During this minimum on-time of the P-channel

switch, the inductor current will increase rapidly but will

decrease very slowly during the remainder of the period

due to the very small reverse voltage produced by a hard

output short. To eliminate the possibility of inductor current

runaway in this situation, the switching frequency of the

buck converters is reduced by a factor of four when the

voltage on the respective feedback pin (FB1 or FB2) falls

below 0.3V. This provides additional time for the inductor

current to reset and thereby protects against a build-up

of current in the inductor.

Error Amplifier and Internal Compensation

The LTC3101 buck converters utilize internal transconductance error amplifiers. Compensation of the buck converter

feedback loops is performed internally to reduce the size

of the application circuit and simplify the design process.

The compensation network has been designed to allow use

of a wide range of output capacitors while simultaneously

ensuring a rapid response to load transients.

Power Good Comparator Operation

Each buck converter has an internal power good comparator that monitors the respective feedback pin voltage (FB1

or FB2). The power good comparator outputs are used at

power-up for sequencing purposes. During normal operation, the power good comparators are used to monitor

the output rails for a fault condition. If either buck power

good comparator indicates a fault condition, the CRS and

RESET pins are driven low. This can be used to reset a

microprocessor in the application circuit when either buck

converter output rail loses regulation.

The buck power good comparator will trip when the

respective feedback pin falls 8% (nominally) below the

regulation voltage. With a rising output voltage, the power

good comparator will typically clear when the respective

feedback voltage rises to within 5.5% of the regulation

voltage. In addition, there is a 60μs typical deglitching

delay in the power good comparators in order to prevent

false trips due to brief voltage transients occurring on

load steps.

3101fb

17

�LTC3101

OPERATION

BUCK-BOOST CONVERTER OPERATION

The buck-boost converter is a synchronous 5-switch

DC/DC converter with the capability to operate efficiently

with input voltages that are above, below or equal to

the output regulation voltage. A proprietary switching

algorithm provides a smooth transition between operational modes while maintaining high efficiency and low

noise performance. Referring to the Block Diagram, the

buck-boost converter has two P-channel input power

switches, A and A´. This provides the capability for the

buck-boost converter to operate directly from either input

power source, USB or battery. The buck-boost converter

automatically and seamlessly transitions to the higher

voltage input supply.

PWM Mode Operation

When the PWM pin is held high, the LTC3101 buck-boost

converter operates in a fixed frequency pulse width modulation mode using voltage mode control. A proprietary

switching algorithm allows the converter to transition

between buck, buck-boost, and boost modes without

discontinuity in inductor current or loop characteristics.

The switch topology for the buck-boost converter is shown

in Figure 2.

When the input voltage is significantly greater than the

output voltage, the buck-boost converter operates in

buck mode. Switch D turns on continuously and switch

C remains off. Switches A (or A´) and B are pulse width

modulated to produce the required duty cycle to support the

output regulation voltage. As the input voltage decreases,

switch A remains on for a larger portion of the switching

cycle. When the duty cycle reaches approximately 85%,

the switch pair AC begins turning on for a small fraction

of the switching period. As the input voltage decreases

further, the AC switch pair remains on for longer durations

and the duration of the BD phase decreases proportionally.

As the input voltage drops below the output voltage, the

AC phase will eventually increase to the point that there is

no longer any BD phase. At this point, switch A remains on

continuously while switch pair CD is pulse width modulated to obtain the desired output voltage. At this point,

the converter is operating solely in boost mode.

This switching algorithm provides a seamless transition

between operating modes and eliminates discontinuities

in average inductor current, inductor current ripple, and

loop transfer function throughout all three operational

modes. These advantages result in increased efficiency

and stability in comparison to the traditional 4-switch

buck-boost converter.

Error Amplifier and Internal Compensation

The buck-boost converter utilizes a voltage mode error

amplifier with an internal compensation network as shown

in Figure 3.

Notice that resistor R2 of the external resistor divider

network plays an integral role in determining the frequency

response of the compensation network. The ratio of R2 to

R1 is set to program the desired output voltage but this

still allows the value of R2 to be adjusted to optimize the

LTC3101

VOUT3

L

USB2 BAT2

A´

SW3A

SW3B

D

VOUT3

VOUT3

R2

+

–

0.599V

FB3

A

R1

B

C

GND (EXPOSED PAD)

LTC3101

3101 F02

Figure 2. Buck-Boost Switch Topology

Figure 3. Buck-Boost Error Amplifier and Compensation

3101fb

18

�LTC3101

OPERATION

transient response of the converter. Increasing the value

of R2 generally leads to greater stability at the expense of

reduced transient response speed. Increasing the value of

R2 can yield substantial transient response improvement

in cases where the phase margin has been reduced due to

use of a small value output capacitor or a large inductance

(particularly with large boost step-up ratios). Conversely,

decreasing the value of R2 increases the loop bandwidth

which can improve the speed of the converter’s transient

response. This can be useful in improving the transient

response if a large value output capacitor is utilized. In

this case, the increased bandwidth created by decreasing

R2 is used to counteract the reduced converter bandwidth

caused by the large output capacitor.

Current Limit Operation

The buck-boost converter has two current limit circuits.

The primary current limit is an average current limit circuit which injects an amount of current into the feedback

node which is proportional to the extent that the switch A

(or A´) current exceeds the current limit value. Due to the

high gain of the feedback loop, the injected current forces

the error amplifier output to decrease until the average

current through switch A decreases approximately to the

current limit value. The average current limit utilizes the

error amplifier in an active state and thereby provides a

smooth recovery with little overshoot once the current limit

fault condition is removed. Since the current limit is based

on the average current through switch A (or A´), the peak

inductor current in current limit will have a dependency

on the duty cycle (i.e., on the input and output voltages)

in the overcurrent condition.

The speed of the average current limit circuit is limited by

the dynamics of the error amplifier. On a hard output short,

it would be possible for the inductor current to increase substantially beyond current limit before the average current

limit circuit would react. For this reason, there is a second

current limit circuit which turns off switch A (and A´) if the

current ever exceeds approximately 165% of the average

current limit value. This provides additional protection in

the case of an instantaneous hard output short.

Reverse Current Limit

A reverse current comparator on switch D monitors the

current entering the OUT3 pin. When this current exceeds

400mA (typical) switch D will be turned off for the remainder of the switching cycle. This feature protects the

buck-boost converter from excessive reverse current if the

buck-boost output is held above the regulation voltage by

an external source.

Burst Mode Operation

With the PWM pin held low, the buck-boost converter

operates utilizing a variable frequency switching algorithm

designed to improve efficiency at light load and reduce

the standby current at zero load. In Burst Mode operation,

the inductor is charged with fixed peak amplitude current

pulses. These current pulses are repeated as often as

necessary to maintain the output regulation voltage. The

maximum output current, IMAX, which can be supplied in

Burst Mode operation is dependent upon the input and

output voltage as given by the following formula:

IMAX =

0.15 • VIN

A

VIN + VOUT

( )

If the buck-boost load exceeds the maximum Burst Mode

current capability, the output rail will lose regulation and the

power good comparator will indicate a fault condition.

In Burst Mode operation, the error amplifier is not used but

is instead placed in a low current standby mode to reduce

supply current and improve light load efficiency.

Internal Voltage Mode Soft-Start

The buck-boost converter has an internal voltage mode

soft-start circuit with a nominal duration of 800μs. The

converter remains in regulation during soft-start and will

therefore respond to output load transients that occur

during this time. In addition, the output voltage rise time

has minimal dependency on the size of the output capacitor or load. During soft-start, the buck-boost converter is

forced into PWM mode operation regardless of the state

of the PWM pin.

3101fb

19

�LTC3101

OPERATION

Power Good Comparator Operation

The buck-boost converter contains an internal power

good comparator that continuously monitors the voltage

of the feedback pin FB3. The output of this comparator

is used during power-up for sequencing purposes. In addition, during operation, if the power good comparator

indicates a fault condition, CRS and RESET will be driven

low. This feature can be used to reset a microprocessor

in the application circuit if the buck-boost output loses

regulation.

In Burst Mode operation (PWM = low), the buck-boost

power good comparator will indicate a fault when the

feedback voltage falls approximately 8.5% below the regulation voltage. There is approximately 2.5% hysteresis in

this threshold when the output voltage is returning good.

In addition, there is a 60μs typical deglitching delay in

order to prevent false trips due to short duration voltage

transients in response to load steps.

In PWM mode, operation of the power good comparator

is complicated by the fact that the feedback pin voltage

is driven to the reference voltage independent of the

output voltage through the action of the voltage mode

error amplifier. Since the soft-start is voltage mode, the

feedback voltage will track the output voltage correctly

during soft-start, and the power good comparator output

will correctly indicate the point at which the buck-boost

attains regulation at the end of soft-start. However, once

in regulation, the feedback voltage will no longer track the

output voltage and the power good comparator will not

immediately respond to a loss of regulation in the output.

For this reason, the power good comparator output is also

designed to indicate a fault condition if the buck-boost

converter enters current limit. The only means by which a

loss of regulation can occur is if the current limit has been

reached thereby preventing the buck-boost converter from

delivering the required output current. In such cases, the

occurrence of current limit will directly cause the power

good comparator to indicate a fault state. However, there

may be cases at the boundary of reaching current limit

when the buck-boost converter is continuously in current

limit, causing the power good comparator to indicate a

fault, but the output voltage may be slightly above the

actual power good threshold.

COMMON FUNCTIONS

Thermal Shutdown

If the die temperature exceeds 150°C all DC/DC converters

will be disabled. In addition, the LDO and MAX outputs are

disabled. All power devices are turned off and all switch

nodes will be high impedance. The soft-start circuits for all

converters are reset during thermal shutdown to provide

a smooth recovery once the overtemperature condition is

eliminated. All DC/DC converters (if enabled) and the LDO

and MAX outputs will restart when the die temperature

drops to approximately 140°C.

Undervoltage Lockout

If the supply voltage decreases below 1.65V (typical) then

all DC/DC converters will be disabled and all power devices

are turned off. In addition, the MAX and LDO outputs are

disabled. The LDO is forced into its reverse blocking state,

allowing the LDO output to remain powered with less

than 1μA reverse current being drawn by the LTC3101.

The soft-start circuits for all DC/DC converters are reset

during undervoltage lockout to provide a smooth restart

once the input voltage rises above the undervoltage

lockout threshold.

Active Output Discharge

All three DC/DC converter outputs are actively discharged

to ground when disabled through 1kΩ (typical) impedances. The buck converter outputs are discharged through

the inductor via a pull-down resistor on the respective

switch pin.

3101fb

20

�LTC3101

APPLICATIONS INFORMATION

The basic LTC3101 application circuit is shown as the

Typical Application on the front page of this data sheet.

The external component selection is dependent upon the

required performance of the IC in each particular application given considerations and tradeoffs such as PCB

area, output voltages, output currents, ripple voltages

and efficiency. This section of the data sheet provides

some basic guidelines and considerations to aid in the

selection of external components and the design of the

application circuit.

CRS Capacitor Selection

A capacitor from the CRS pin to ground is used to program the duration of the microprocessor reset signal on

the RESET pin. A low leakage ceramic capacitor should

be utilized to ensure reliable temperature independent

operation. At the start of the active-low reset pulse, a 1μA

(typical) current begins charging the CRS capacitor. The

RESET pulse ends when the voltage at the CRS pin reaches

1.20V (typical). Therefore, the required CRS capacitor value,

CRS, is given by the following equation where tRESET is the

desired reset duration in milliseconds:

CRS =

tRESET

μF

1200

( )

If the microprocessor reset function of the LTC3101 is

unused, the CRS pin can be left unconnected.

LDO Output Capacitance

The LDO has been specifically designed for stable operation with a wide range of output capacitors. For most applications, a low ESR ceramic capacitor of at least 4.7μF

should be utilized. Large valued supercapacitors can be

connected directly to the LDO output without requiring a

series isolation resistor for loop stability. However, if the

supercapacitor has significant ESR, it may be necessary

to place a small 4.7μF ceramic in parallel with the supercapacitor to maintain an adequate phase margin.

MAX Capacitor Selection

The MAX output serves as the input to the LDO. Therefore, even if the MAX output is unused directly in the

application, it is recommended that it be bypassed with

a 1μF or larger ceramic capacitor. There is no limit to the

maximum capacitance on this pin. However, the soft-start

duration is formed by the current-limited output charging the capacitance attached to the pin so larger output

capacitors will result in proportionally longer soft-start

durations.

Buck Inductor Selection

The choice of buck inductor value influences both the efficiency and the magnitude of the output voltage ripple.

Larger inductance values will reduce inductor current

ripple and will therefore lead to lower output voltage

ripple. For a fixed DC resistance, a larger value inductor

will yield higher efficiency by lowering the peak current to

be closer to the average output current. However, a larger

inductor within a given inductor family will generally have

a greater series resistance, thereby counteracting this

efficiency advantage.

Given a desired peak-to-peak current ripple, ΔIL, the

required inductance can be calculated via the following

expression, where f represents the switching frequency

in MHz:

L=

VOUT � VOUT �

�1–

� (μH)

f • �IL �

VIN �

A reasonable choice for ripple current is ΔIL = 140mA

which represents 40% of the maximum 350mA load

current. The DC current rating of the inductor should be

at least equal to the maximum load current plus half the

ripple current in order to prevent core saturation and loss

of efficiency during operation. To optimize efficiency the

inductor should have a low DC resistance (DCR).

In particularly space-restricted applications it may be

advantageous to use a much smaller value inductor at

the expense of larger ripple current. In such cases, the

converter will operate in discontinuous conduction for a

wider range of output loads and efficiency will be reduced.

In addition, there is a minimum inductor value required

to maintain stability of the current loop as determined by

the fixed internal slope compensation. Specifically, if the

3101fb

21

�LTC3101

APPLICATIONS INFORMATION

buck converter is going to be utilized at duty cycles over

40%, the inductance value must be at least equal to LMIN

as given by the following equation:

Table 2. Representative Buck Inductors

VALUE

(μH)

DCR

(Ω)

MAX DC

CURRENT (A)

SIZE (mm)

W×L×H

Coilcraft

LPS3015

EPL2014

EPL2010

LPS4018

4.7

4.7

4.7

4.7

0.20

0.23

0.43

0.125

1.2

0.88

0.65

1.9

3.0 × 3.0 × 1.5

2.0 × 2.0 × 1.4

2.0 × 2.0 × 1.0

4.0 × 4.0 × 1.8

Cooper-Bussmann

SD3118

SD3112

SD3110

SD10

4.7

4.7

4.7

4.7

0.162

0.246

0.285

0.154

1.31

0.80

0.68

1.08

3.1 × 3.1 × 1.8

3.1 × 3.1 × 1.2

3.1 × 3.1 × 1.0

5.2 × 5.2 × 1.0

Murata

LQH3NP

LQM31PN

LQH32CN

4.7

4.7

4.7

0.26

0.30

0.15

0.80

0.70

0.65

3.0 × 3.0 × 0.9

3.2 × 1.6 × 0.85

3.2 × 2.5 × 2.0

Panasonic

ELLVEG

ELL4G

ELL4LG

4.7

4.7

4.7

0.24

0.16

0.09

0.70

0.86

1.10

3.0 × 3.0 × 1.0

3.8 × 3.8 × 1.1

3.8 × 3.8 × 1.8

Sumida

CDRH2D09

CDRH3D16/LD

CDRH2D09B

4.7

4.7

4.7

0.167

0.081

0.218

0.42

0.62

0.70

3.2 × 3.2 × 1.0

3.2 × 3.2 × 1.8

3.0 × 2.8 × 1.0

Taiyo-Yuden

CBC2518

CBC3225T

NR3010T

4.7

4.7

4.7

0.2

0.1

0.19

0.68

1.01

0.75

2.5 × 1.8 × 1.8

3.2 × 2.5 × 2.5

3.0 × 3.0 × 1.0

TOKO

DE2812C

D310F

DB3015C

4.7

4.7

4.7

0.13

0.26

0.09

1.2

0.9

0.86

3.0 × 3.2 × 1.2

3.8 × 3.8 × 1.0

3.2 × 3.2 × 1.8

Buck Output Capacitor Selection

Wurth

744028004

744032004

744029003

4.7

4.7

4.7

0.265

0.280

0.170

0.90

0.49

0.80

2.8 × 2.8 × 1.1

3.2 × 2.5 × 2.0

2.8 × 2.8 × 1.35

A low ESR output capacitor should be utilized at the buck

converter output in order to minimize output voltage ripple.

Multilayer ceramic capacitors are an excellent choice as

they have low ESR and are available in small footprints. In

addition to controlling the ripple magnitude, the value of

the output capacitor also sets the loop crossover frequency

and therefore can impact loop stability. In general, there is

both a minimum and maximum capacitance value required

to ensure stability of the loop. If the output capacitance is

too small, the loop crossover frequency will increase to

the point where switching delay and the high frequency

parasitic poles of the error amplifier will degrade the phase

margin. In addition, the wider bandwidth produced by a

small output capacitor will make the loop more susceptible

to switching noise. Table 3 depicts the minimum recommended output capacitance for several typical output

voltages. At the other extreme, if the output capacitor is

too large, the crossover frequency can decrease too far

below the compensation zero and also lead to degraded

phase margin. In such cases, the phase margin and transient performance can be improved by simply increasing

the size of the feedforward capacitor in parallel with the

upper resistor divider resistor. (See Buck Output Voltage

Programming section for more details).

LMIN = 2.5 • VOUT (μH)

Table 1 depicts the minimum required inductance for

several common output voltages.

Table 1. Buck Minimum Inductance

OUTPUT VOLTAGE

MINIMUM INDUCTANCE

0.8V

2.0μH

1.2V

3.0μH

1.8V

4.7μH

2.0V

5.0μH

2.7V

6.8μH

A large variety of low ESR, high current power inductors

are available that are well suited to LTC3101 buck converter

applications. The tradeoff generally involves PCB area,

application height, required output current and efficiency.

Table 2 provides a representative sampling of small surface mount inductors that are well suited for use with

the LTC3101 buck converters. All inductor specifications

are listed at an inductor value of 4.7μH for comparison

purposes but other values within these inductor families

are generally well suited to this application as well. Within

each family (i.e., at a fixed inductor size), the DC resistance

generally increases and the maximum current generally

decreases with increased inductance.

PART NUMBER

3101fb

22

�LTC3101

APPLICATIONS INFORMATION

capacitance of the feedback pin produce a parasitic pole

that can reduce the loop phase margin if it becomes too

low in frequency. For these reasons, it is recommended

that the resistance of R1 in parallel with R2 be kept under

300k. A reasonable compromise between noise immunity and quiescent current is provided by choosing R2 =

221k. The required value for R1 can then be calculated

via Equation 1.

Table 3. Buck Minimum Recommended Output Capacitance

OUTPUT VOLTAGE

MINIMUM RECOMMENDED

OUTPUT CAPACITANCE

0.6V

22μF

0.8V

22μF

1.2V

10μF

1.8V

10μF

2.7V

4.7μF

3.3V

4.7μF

Buck Input Capacitor Selection

The BAT1 and USB1 pins provides current to the power

stages of both buck converters. It is recommended that a

low ESR ceramic capacitor with a value of at least 4.7μF

be used to bypass each of these pins. These capacitors

should be placed as close to the respective pin as possible and should have a short return path to the backpad

of the IC.

Buck Output Voltage Programming

The buck output voltages are programmed via external

resistor dividers connected to the respective feedback pin

(FB1 or FB2) as shown in Figure 4.

The resistor divider resistors control the output voltage

according to the following formula:

� R2 �

VOUT1,2 = 0.596 �1+ � ( V )

� R1 �

(1)

If the impedance of the resistor divider is too high it will

increase noise sensitivity due to coupling of stray noise

to the feedback pin. In addition, the parallel resistance

of the resistor divider resistors in series with the input

VOUT1,2 ≥ 0.600V

R2

CFF

FB1,2

LTC3101

R1

GND

3101 F04

To further increase the noise immunity of the feedback pin

and improve the transient response of the buck converter,

a small value feedforward capacitor, CFF , can be added in

parallel with the upper feedback divider resistor, R2. This

reduces the impedance of the feedback pin at high frequencies thereby increasing its immunity from picking up stray

noise. In addition, this adds a pole-zero pair to the loop

dynamics which generates a phase boost that can improve

the phase margin and increase the speed of the transient

response, resulting in smaller voltage deviation on load

transients. The zero frequency depends not only on the

value of the feedforward capacitor, but also on the upper

resistor divider resistor. Specifically, the zero frequency,

fZERO, is given by the following equation:

fZERO =

1

2 • π • R2 • CFF

Ideally, the phase boost generated by the pole-zero pair

should be centered at the loop crossover frequency. Table 4

provides the recommended feedback divider resistor values

and corresponding feedforward capacitors for several

commonly utilized output voltages.

Table 4. Buck Resistor Divider and Feedforward Capacitor

Values

VOUT

R1

R2

CFF

COUT

0.6V

–

0

–

22μF

0.8V

649k

221k

18pF

22μF

1.0V

324k

221k

18pF

22μF

1.2V

221k

221k

18pF

10μF

1.5V

147k

221k

18pF

10μF

1.8V

110k

221k

18pF

10μF

2.0V

86.6k

205k

18pF

10μF

2.7V

56.2k

200k

18pF

4.7μF

3.3V

48.7k

221k

18pF

4.7μF

Figure 4. Setting the Buck Output Voltages

3101fb

23

�LTC3101

APPLICATIONS INFORMATION

If a substantially larger output capacitor is utilized, the

bandwidth of the loop will be reduced. In such cases, the

feedforward capacitor can be increased in value in order

to lower the zero frequency and improve the transient

response.

Buck-Boost Output Voltage Programming

The buck-boost output voltage is set via an external resistor

divider connected to the FB3 pin as shown in Figure 5.

buck-boost inductor must have a saturation current rating that is greater than the worst-case average inductor

current plus half the ripple current. The peak-to-peak

inductor current ripple will be larger in buck and boost

mode then in the buck-boost region. The peak-to-peak

inductor current ripple for each mode can be calculated

from the following formulas, where f is the frequency in

MHz and L is the inductance in μH:

�IL(P-P)(BUCK) =

5.25 ≥ VOUT3 ≥ 1.5V

VOUT � VIN – VOUT �

�

�

f •L �

VIN

�

R2

�IL(P-P)(BOOST) =

FB3

LTC3101

VIN � VOUT – VIN �

�

�

f • L � VOUT �

R1

GND

3101 F05

Figure 5. Setting the Buck-Boost Output Voltage

The resistor divider values determine the buck-boost output

voltage according to the following formula:

� R2 �

VOUT3 = 0.599 �1+ � ( V )

� R1 �

(2)

The buck-boost converter utilizes voltage mode control

and in addition to setting the output voltage, the value of

R2 plays an integral role in the dynamics of the feedback

loop. In general, a larger value for R2 will increase stability

and reduce the speed of the transient response. A smaller

value of R2 will reduce stability but increase the speed of

the transient response. A good starting point is to choose

R2 = 1M and then calculate the required value of R1 to

set the desired output voltage according to Equation 2.

If a large output capacitor is used, the bandwidth of the

converter is reduced. In such cases R2 can be reduced

to improve the transient response. If a large inductor or

small output capacitor is utilized the loop will be less stable

and the phase margin can be improved by increasing the

value of R2.

Buck-Boost Inductor Selection

To achieve high efficiency, a low ESR inductor should

be utilized for the buck-boost converter. In addition, the

In addition to affecting output current ripple, the size of

the inductor can also impact the stability of the feedback

loop. In boost mode, the converter transfer function has

a right half plane zero at a frequency that is inversely

proportional to the value of the inductor. As a result, a

large inductor can move this zero to a frequency that is

low enough to degrade the phase margin of the feedback

loop. It is recommended that the inductor value be chosen

less than 10μH if the buck-boost converter is to be used

in the boost region.

In addition to affecting the efficiency of the buck-boost

converter, the inductor DC resistance can also impact the

maximum output capability of the buck-boost converter

at low input voltage. In buck mode, the buck-boost output

current is limited only by the inductor current reaching the

current limit value. However, in boost mode, especially at

large step-up ratios, the output current capability can also

be limited by the total resistive losses in the power stage.

These include switch resistances, inductor resistance,

and PCB trace resistance. Use of an inductor with high

DC resistance can degrade the output current capability

from that shown in the graph in the Typical Performance

Characteristics section of this data sheet.

Different inductor core materials and styles have an impact

on the size and price of an inductor at any given current

rating. Shielded construction is generally preferred as it

minimizes the chances of interference with other circuitry.

The choice of inductor style depends upon the price, sizing,

and EMI requirements of a particular application. Table 5

3101fb

24

�LTC3101

APPLICATIONS INFORMATION

provides a small sampling of inductors that are well suited

to many LTC3101 buck-boost converter applications. All

inductor specifications are listed at an inductance value

of 4.7μH for comparison purposes but other values within

these inductor families are generally well suited to this application. Within each family (i.e., at a fixed size), the DC

resistance generally increases and the maximum current

generally decreases with increased inductance.

Table 5. Representative Buck-Boost Surface Mount Inductors

VALUE

(μH)

DCR

(mΩ)

MAX DC

CURRENT (A)

SIZE (mm)

W×L×H

Coilcraft

LPS4018

LPS4012

ME3220

MSS5121

4.7

4.7

4.7

4.7

125

175

190

95

1.9

1.8

1.5

1.66

4.0 × 4.0 × 1.8

4.0 × 4.0 × 1.2

3.2 × 2.5 × 2.0

5.4 × 5.4 × 2.1

Cooper-Bussmann

SD12

SD14

4.7

4.5

118

94

1.29

1.74

5.2 × 5.2 × 1.2

5.2 × 5.2 × 1.4

Panasonic

ELL6PG

ELL5PS

4.7

4.7

58

61

1.5

1.5

6.0 × 6.0 × 2.0

5.0 × 5.0 × 1.85

Sumida

CDRH3D18

CDRH4D15/S

CDRH4D22/HP

4.7

4.7

4.7

86

103

66

1.35

1.4

2.2

4.0 × 4.0 × 2.0

4.7 × 4.7 × 1.7

5.0 × 5.0 × 2.4

Taiyo-Yuden

NR6020T

NP04SZB

4.7

4.7

58

75

2.0

1.8

6.0 × 6.0 × 2.0

5.0 × 5.0 × 2.0

TOKO

DE2815C

DP418C

DE4514C

4.7

4.7

4.7

100

50

100

1.3

1.50

1.9

3.0 × 2.8 × 1.5

4.2 × 4.2 × 1.8

4.7 × 4.9 × 1.4

Wurth

744042004

7447785004

7447745056

4.7

4.7

4.7

82

78

57

1.65

2.20

2.40

4.8 × 4.8 × 1.8

5.9 × 6.2 × 3.3

5.2 × 5.8 × 2.0

PART NUMBER

capacitance in μF, L is the inductance in μH, and ILOAD is

the output current in Amps.

ΔVP-P(BUCK) =

1

8 • L • COUT • f 2

ΔVP-P(BOOST) =

•

( VIN – VOUT ) VOUT

VIN

ILOAD ( VOUT – VIN )

COUT • VOUT • f

Given that the output current is discontinuous in boost

mode, the ripple in this mode will generally be much larger

than the magnitude of the ripple in buck mode. In addition to controlling the ripple magnitude, the value of the

output capacitor also affects the location of the resonant

frequency in the open-loop converter transfer function.

If the output capacitor is too small, the bandwidth of the

converter will extend high enough to degrade the phase

margin. To prevent this from happening, it is recommended

that a minimum value of 10μF be used for the buck-boost

output capacitor. If the required buck-boost load current

is greater than 400mA, it is recommended that the output

capacitor be increased to 22μF to improve output voltage

ripple and loop stability.

Buck-Boost Input Capacitor Selection

The supply current to the buck-boost converter is provided

by the USB2 and BAT2 pins. In addition, these pins provide

power to the internal circuitry of the LTC3101. It is recommended that a low ESR ceramic capacitor with a value of

at least 10μF be located as close to each of these pins as

possible. In addition, the return trace from each pin to the

ground plane should be made as short as possible.

Buck-Boost Output Capacitor Selection

Capacitor Vendor Information

A low ESR output capacitor should be utilized at the buckboost converter output in order to minimize output voltage ripple. Multilayer ceramic capacitors are an excellent

choice as they have low ESR and are available in small

footprints. The capacitor should be chosen large enough

to reduce the output voltage ripple to acceptable levels.

Neglecting the capacitor ESR and ESL, the peak-to-peak

output voltage ripple can be calculated by the following

formulas, where f is the frequency in MHz, COUT is the

Both the input bypass capacitors and DC/DC converter

output capacitors used with the LTC3101 must be low ESR

and designed to handle the large AC currents generated

by switching converters. This is important to maintain

proper functioning of the IC and to reduce output ripple.

Many modern low voltage ceramic capacitors experience

significant loss in capacitance from their rated value

with increased DC bias voltages. For example, it is not

uncommon for a small surface mount ceramic capacitor

3101fb

25

�LTC3101

APPLICATIONS INFORMATION

to lose 45% of its rated capacitance when operated near

its rated voltage. As a result, it is sometimes necessary to

use a larger value capacitance or a capacitor with a higher

voltage rating than required in order to actually realize

the intended capacitance at the full operating voltage. For

details, consult the capacitor vendor’s curve of capacitance

versus DC bias voltage.

The capacitors listed in Table 6 provide a sampling of small

surface mount ceramic capacitors that are well suited to

LTC3101 application circuits. All listed capacitors are either

X5R or X7R dielectric in order to ensure that capacitance

loss over temperature is minimized.

Table 6. Representative Bypass and Output Capacitors

VALUE

(μF)

VOLTAGE

(V)

SIZE (mm)

L × W × H (FOOTPRINT)

AVX

12106D475K

12104D106K

12106D106K

12106D226K

4.7

10

10

22

6.3

4

6.3

6.3

1.6 × 0.8 × 0.86 (0603)

1.6 × 0.8 × 1.02 (0603)

2.0 × 1.25 × 1.4 (0805)

2.0 × 1.25 × 1.4 (0805)

Kemet

C0603C475K9P

C0603C106K9P

C0805C476K9P

4.7

10

47

6.3

6.3

6.3

1.6 × 0.8 × 0.8 (0603)

1.6 × 0.8 × 0.8 (0603)

2.0 × 1.25 × 1.25 (0805)

Murata

GRM18

GRM21

GRM21

GRM21

4.7

4.7

10

22

6.3

10

10

6.3

1.6 × 0.8 × 0.8 (0603)

2.0 × 1.25 × 1.25 (0805)

2.0 × 1.25 × 1.25 (0805)

2.0 × 1.25 × 1.25 (0805)

Samsung

CL10A475KP5LNN

CL10A106KQ8NNN

CL21A226MQCLRN

CL21A476MQYNNN

4.7

10

22

47

10

6.3

6.3

6.3

1.6 × 0.8 × 0.55 (0603)

1.6 × 0.8 × 0.90 (0603)

2.0 × 1.25 × 0.95 (0805)

2.0 × 1.25 × 1.45 (0805)

Taiyo Yuden

JMK107BJ

LMK107BJ

JMK212BJ

JMK212BJ

10

4.7

22

47

6.3

10

6.3

6.3

1.6 × 0.8 × 0.8 (0603)

1.6 × 0.8 × 0.8 (0603)

2.0 × 1.25 × 0.85 (0805)

2.0 × 1.25 × 0.85 (0805)

TDK

C1608X5ROJ

C1608X5R0J

C1608X5R0J

C2012X5R0J

4.7

6.8

10

15

6.3

6.3

6.3

6.3

1.6 × 0.8 × 0.8 (0603)

1.6 × 0.8 × 0.8 (0603)

1.6 × 0.8 × 0.8 (0603)

2.0 × 1.25 × 0.85 (0805)

PART NUMBER

PCB Layout Considerations

The LTC3101 switches large currents at high frequencies.

Special attention should be paid to the PCB layout to ensure a stable, noise-free and efficient application circuit.

Figure 6 presents a representative PCB layout to outline

some of the primary considerations. A few key guidelines

are listed:

1. All circulating high current paths should be kept as

short as possible. This can be accomplished by keeping the routes to all components in Figure 6 as short

and as wide as possible. Capacitor ground connections

should via down to the ground plane in the shortest

route possible. The bypass capacitors on USB1, USB2,

BAT1 and BAT2 should be placed as close to the IC as

possible and should have the shortest possible paths

to ground.

2. The Exposed Pad is the small-signal and power ground

connection for the LTC3101. Multiple vias should connect the backpad directly to the ground plane. In addition maximization of the metallization connected to

the backpad will improve the thermal environment and

increase the power handling capabilities of the IC.

3. The components shown in bold and their connections

should all be placed over a complete ground plane to

minimize loop cross-sectional areas. This minimizes

EMI and reduces inductive drops.

4. Connections to all of the components shown in bold

should be made as wide as possible to reduce the series

resistance. This will improve efficiency and maximize the

output current capability of the buck-boost converter.

5. To prevent large circulating currents from disrupting

the output voltage sensing, the ground for each resistor

divider should be returned to the ground plane using

a via placed close to the IC and away from the power

connections.

6. Keep the connection from the resistor dividers to the

feedback pins FB1 and FB2 as short as possible and

away from the switch pin connections.

7. Crossover connections (such as the one shown from

SW3A to the inductor) should be made on inner copper

layers if available. If it is necessary to place these on

the ground plane, make the trace on the ground plane

as short as possible to minimize the disruption to the

ground plane.

3101fb

26

�VUSB

VBAT

VOUT2

INNER

COPPER

LAYER

INNER

COPPER

LAYER

(21)

ENA1

(10)

LDO

(22)

FB2

(9)

PBSTAT

(23)

FB1

(8)

PWRKEY

(24)

ENA2

(7)

FB3

(13)

RESET

(14)

BAT2

(15)

SW3A

(16)

USB2

(17)

OUT3

(18)

HSO

INNER

COPPER

LAYER

Figure 6. PCB Layout Recommendations

VIA TO GOUND PLANE

(AND TO INNER LAYER WHERE SHOWN)

UNINTERRUPTED GROUND PLANE SHOULD EXIST UNDER ALL COMPONENTS

SHOWN IN BOLD AND UNDER TRACES CONNECTING TO THOSE COMPONENTS

(6)

PWRON

(5)

SW2

(4)

USB1

(3)

BAT1

(2)

SW1

(1)

PWM

(20)

SW3B

(11)

MAX

KELVIN TO

VOUT1

FEEDBACK RESISTOR DIVIDERS SHOULD

VIA TO GROUND PLANE NEAR IC

(19)

ENA3

(12)

CRS

VOUT1

3101 F06

VOUT3

LTC3101

APPLICATIONS INFORMATION

3101fb

27

�LTC3101

TYPICAL APPLICATIONS

2 AA Cell/USB/Wall Adapter Power Supply with Six Output Rails and Pushbutton On/Off

C4

10μF

CELLS

USB POWER

4.3V TO 5.5V

WALL ADAPTER

4.0V TO 5.5V

C5

10μF

C3

10μF

L3

4.7μH

BAT1 BAT2 SW3A

USB1

USB2

LTC3101

ON/OFF

VOUT1

L2

4.7μH

R6

221k

PWRKEY

5V/DIV

100

VOUT1 2V/DIV

80

VOUT2 2V/DIV

70

EFFICIENCY (%)

3101 TA02b

C10

22pF

C1

10μF

VOUT2

1.8V

350mA

R5

110k

R4

221k

VOUT1

1.5V

350mA

FB1

R3

147k

GND

3101 TA02a

Buck Converter Efficiency

vs Load Current, VBAT = 3V

100

Burst Mode

OPERATION

90

5ms/DIV

C2

10μF

Buck-Boost Converter Efficiency

vs Load Current

Waveforms During Power-Up

CRS 100mV/DIV

C9

22pF

SW1

C1-C5: MURATA GRM31CR71A106KA01

L1, L2: TAIYO YUDEN NR3010T4R7M

L3: COILCRAFT LPS4018-472ML

HSO 5V/DIV

1.8V

50mA

C6

4.7μF

L1

4.7μH

R2

50k

VOUT3 5V/DIV

TRACKING OUTPUT

200mA

C7

4.7μF

LDO

FB2

PBSTAT

PWRON

RESET

PWM

Hot Swap OUTPUT

3.3V

100mA

C8

4.7μF

SW2

PWRKEY

μP

R7

221k

MAX

ENA3

ENA2

ENA1

CRS

R1

50k

R8

1M

SW3B OUT3

FB3

HSO

0.22μF

VOUT3 = 3.3V

300mA FOR VIN ≥ 1.8V

800mA FOR VIN ≥ 3V

Burst Mode

OPERATION

90

80

EFFICIENCY (%)

+

2 AA

PWM MODE

60

50

40

30

70

PWM MODE

60

50

40

30

20

20

VBAT = 2V

VBAT = 3V

10

0

1

100

10

LOAD CURRENT (mA)

1000

3101 TA02c

BUCK1 (1.5V)

BUCK2 (1.8V)

10

0

1

100

10

LOAD CURRENT (mA)

1000

3101 TA02d

3101fb

28

�LTC3101

TYPICAL APPLICATIONS

Manual Enable with Simultaneous Start-Up

+

2 AA

C3

10μF

CELLS

USB POWER

4.3V TO 5.5V

C2

10μF

C4

10μF

4.7μH

BAT1 BAT2 SW3A

USB1

USB2

R1

1M

VOUT3 = 3.3V

300mA FOR VIN ≥ 1.8V

800mA FOR VIN ≥ 3V

R2

221k

SW3B OUT3

FB3

HSO

Hot Swap OUTPUT

3.3V

100mA

C5

4.7μF

MAX

PWM

PWRON

TRACKING OUTPUT

200mA

C6

4.7μF

LDO

DISABLE ENABLE

C1

0.22μF

ENA1

ENA2

ENA3

LTC3101

4.7μH

SW2

R3

221k

CRS

1.8V

50mA

C7

4.7μF

C8

22pF

C9

10μF

C10

22pF

C11

10μF

VOUT2

1.8V

350mA

FB2

R4

110k

4.7μH

SW1

R5

221k

VOUT1

1.5V

350mA

FB1

GND

R6

147k

3101 TA03a

Power-Up Waveforms

RESET Timing During Power Up

ENABLE

5V/DIV

OUTPUT

VOLTAGES

1V/DIV

VOUT3

ENABLE

5V/DIV

CRS

2V/DIV

VOUT2

RESET 5V/DIV

VOUT1

VOUT1 2V/DIV

HSO

2V/DIV

VOUT2 5V/DIV

VOUT3 5V/DIV

200μs/DIV

3101 TA03b

50ms/DIV

3101 TA03c

3101fb

29

�LTC3101

TYPICAL APPLICATIONS

Li-Ion/USB-Powered Six Output Power Supply with Pushbutton Control

Li-Ion

1.8V TO 4.2V

+

C3

10μF

USB POWER

4.3V TO 5.5V

C2

10μF

C4

10μF

L3

4.7μH

BAT1 BAT2 SW3A

USB1

USB2

R3

1M

R4

221k

SW3B OUT3

FB3

HSO

CRS

TRACKING OUTPUT

200mA

C6

4.7μF

LDO

LTC3101

ON/OFF

Hot Swap OUTPUT

3.3V

100mA

C5

4.7μF

MAX

ENA3

ENA2

ENA1

C1

0.22μF

VOUT3 = 3.3V

300mA FOR VIN ≥ 1.8V

800mA FOR VIN ≥ 3V

L2

4.7μH

SW2

PWRKEY

R5

221k

VOUT2

1.8V

50mA

C7

4.7μF

C8

22pF

C9

10μF

C10

22pF

C11

22μF

VOUT2

1.2V

350mA

FB2

R1

50k

R2

50k

μP

PBSTAT

PWRON

RESET

PWM

SW1

R7

221k

R8

649k

L1, L2: WURTH 744031004

L3: TAIYO YUDEN NR4018T4R7M

3101 TA04a

Buck-Boost Efficiency

vs Load Current

Buck Converter 1 Efficiency

vs Load Current

Buck Converter 2 Efficiency

vs Load Current

100

100

Burst Mode

OPERATION

100

90

90

Burst Mode

OPERATION

80

80

EFFICIENCY (%)

70

PWM MODE

60

50

40

70

60

40

30

30

20

20

VBAT = 3.0V

VBAT = 4.2V

10

0

1

100

10

LOAD CURRENT (mA)

1000

3101 TA04b

PWM MODE

50

Burst Mode

OPERATION

80

EFFICIENCY (%)

90

VOUT1

0.8V

350mA

FB1

GND

EFFICIENCY (%)

R6

221k

L1

4.7μH

70

60

PWM MODE

50

40

30

20

VBAT = 3.0V

VBAT = 4.2V

10

0

1

100

10

LOAD CURRENT (mA)

1000

3101 TA02c

VBAT = 3.0V

VBAT = 4.2V

10

0

1

100

10

LOAD CURRENT (mA)

1000

3101 TA04d

3101fb

30

�LTC3101

TYPICAL APPLICATIONS

Sequenced Start-Up, Buck-Boost Followed by Buck Converters

+

2 AA

C3

10μF

CELLS

USB POWER

4.3V TO 5.5V

C2

10μF

C4

10μF

4.7μH

BAT1 BAT2 SW3A

USB1

USB2

LTC3101

R5

100k

R4

221k

C5

0.1μF

Hot Swap OUTPUT

3.3V

100mA

C6

4.7μF

MAX

PWM

ENA3

CRS

ON/OFF

R3

1M

SW3B OUT3

FB3

ENA2

ENA1

HSO

C1

0.033μF

VOUT3 = 3.3V

300mA FOR VIN ≥ 1.8V

800mA FOR VIN ≥ 3V

TRACKING OUTPUT

200mA

C7

4.7μF

LDO

4.7μH

SW2

PWRKEY

R6

221k

VOUT1

C9

22pF

C10

10μF

C11

22pF

C12

10μF

VOUT2

1.8V

350mA

FB2

R1

50k

μP

1.8V

50mA

C8

4.7μF

R7

110k

4.7μH

R2

50k

SW1

PBSTAT

PWRON

RESET

R8

221k

VOUT1

1.2V

350mA

FB1

R9

221k

GND

3101 TA05a

Power-Up Waveforms

PWRKEY 5V/DIV

PBSTAT 2V/DIV

VOUT2

OUTPUT

VOLTAGES

1V/DIV

VOUT3

VOUT1

CRS 2V/DIV

RESET 2V/DIV

10ms/DIV

3101 TA05b

3101fb

31

�LTC3101

PACKAGE DESCRIPTION

UF Package

24-Lead Plastic QFN (4mm × 4mm)

(Reference LTC DWG # 05-08-1697)

0.70 ±0.05

4.50 ± 0.05

2.45 ± 0.05

3.10 ± 0.05 (4 SIDES)

PACKAGE OUTLINE

0.25 ±0.05

0.50 BSC

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

4.00 ± 0.10

(4 SIDES)

BOTTOM VIEW—EXPOSED PAD

R = 0.115

TYP

0.75 ± 0.05

PIN 1 NOTCH

R = 0.20 TYP OR

0.35 × 45° CHAMFER

23 24

PIN 1

TOP MARK

(NOTE 6)

0.40 ± 0.10

1

2

2.45 ± 0.10

(4-SIDES)

(UF24) QFN 0105

0.200 REF

0.00 – 0.05

0.25 ± 0.05

0.50 BSC

NOTE:

1. DRAWING PROPOSED TO BE MADE A JEDEC PACKAGE OUTLINE MO-220 VARIATION (WGGD-X)—TO BE APPROVED

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE, IF PRESENT