LTC3400/LTC3400B

600mA, 1.2MHz Micropower

Synchronous Boost Converter

in ThinSOT

U

FEATURES

■

■

■

■

■

■

■

■

■

■

■

■

DESCRIPTIO

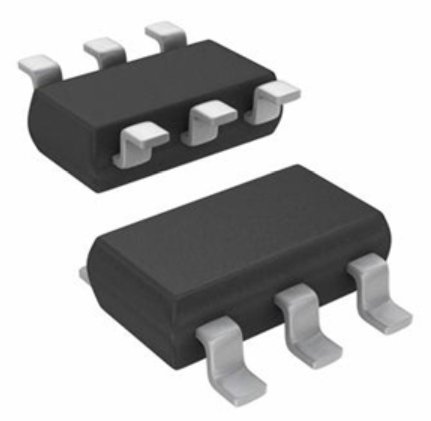

The LTC®3400/LTC3400B are synchronous, fixed frequency, step-up DC/DC converters delivering high efficiency in a 6-lead ThinSOT™ package. Capable of supplying

3.3V at 100mA from a single AA cell input, the devices

contain an internal NMOS switch and PMOS synchronous

rectifier.

Up to 92% Efficiency

Generates 3.3V at 100mA from a Single AA Cell

Low Start-Up Voltage: 0.85V

1.2MHz Fixed Frequency Switching

Internal Synchronous Rectifier

2.5V to 5V Output Range

Automatic Burst Mode® Operation (LTC3400)

Continuous Switching at Light Loads (LTC3400B)

Logic Controlled Shutdown (< 1µA)

Antiringing Control Minimizes EMI

Tiny External Components

Low Profile (1mm) SOT-23 Package

A switching frequency of 1.2MHz minimizes solution

footprint by allowing the use of tiny, low profile inductors

and ceramic capacitors. The current mode PWM design is

internally compensated, reducing external parts count.

The LTC3400 features automatic shifting to power saving

Burst Mode operation at light loads, while the LTC3400B

features continuous switching at light loads. Antiringing

control circuitry reduces EMI concerns by damping the

inductor in discontinuous mode, and the devices feature

low shutdown current of under 1µA.

U

APPLICATIO S

■

■

■

■

■

■

Pagers

MP3 Players

Digital Cameras

LCD Bias Supplies

Handheld Instruments

Wireless Handsets

GPS Receivers

Both devices are available in the low profile (1mm)

SOT-23 package.

, LTC, LT and Burst Mode are registered trademarks of Linear Technology Corporation.

ThinSOT is a trademark of Linear Technology Corporation.

U

■

TYPICAL APPLICATIO

Efficiency

L1

4.7µH

SINGLE

AA CELL

C1

4.7µF

VIN = 2.4V

1

6

90

SW

VOUT

VIN

5

LTC3400

OFF ON

4

FB

SHDN

GND

2

C1, C2: TAIYO-YUDEN X5R EMK316BJ475ML

L1: COILCRAFT DO160C-472

3

R1

1.02M

1%

R2

604k

1%

VOUT

3.3V

100mA

C2

4.7µF

3400 F01

EFFICIENCY (%)

+

100

VIN = 1.5V

80

70

60

50

FIGURE 1 CIRCUIT

WITH OPTIONAL SCHOTTKY DIODE

(SEE APPLICATIONS INFORMATION)

40

0.1

Figure 1. Single Cell to 3.3V Synchronous Boost Converter

1

10

100

LOAD CURRENT (mA)

1000

3400 F01a

3400fa

1

�LTC3400/LTC3400B

W W

W

AXI U

U

ABSOLUTE

RATI GS

U

U

W

PACKAGE/ORDER I FOR ATIO

(Note 1)

VIN Voltage ................................................. – 0.3V to 6V

SW Voltage ................................................. – 0.3V to 6V

SHDN, FB Voltage ....................................... – 0.3V to 6V

VOUT ........................................................... – 0.3V to 6V

Operating Temperature Range (Note 2) .. – 30°C to 85°C

Storage Temperature Range ................... – 65°C to 125°

Lead Temperature (Soldering, 10 sec).................. 300°C

ORDER PART

NUMBER

TOP VIEW

SW 1

GND 2

FB 3

6 VIN

LTC3400ES6

LTC3400BES6

5 VOUT

4 SHDN

S6 PART MARKING

S6 PACKAGE

6-LEAD PLASTIC SOT-23

LTWK

LTUN

TJMAX = 125°C, θJC = 102°C/W

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VIN = 1.2V, VOUT = 3.3V, unless otherwise specified.

PARAMETER

CONDITIONS

Minimum Start-Up Voltage

ILOAD = 1mA

Minimum Operating Voltage

SHDN = VIN (Note 4)

MIN

Output Voltage Adjust Range

TYP

MAX

0.85

1

0.5

0.65

V

5

V

1.268

V

2.5

Feedback Voltage

●

1.192

1.23

UNITS

V

Feedback Input Current

VFB = 1.25V (Note 3)

1

Quiescent Current (Burst Mode Operation)

VFB = 1.4V (Note 5), LTC3400 Only

19

30

µA

Quiescent Current (Shutdown)

VSHDN = 0V, Not Including Switch Leakage

0.01

1

µA

Quiescent Current (Active)

Measured On VOUT

300

500

µA

NMOS Switch Leakage

VSW = 5V

0.1

5

µA

PMOS Switch Leakage

VSW = 0V

0.1

5

µA

NMOS Switch On Resistance

VOUT = 3.3V

VOUT = 5V

0.35

0.20

Ω

Ω

PMOS Switch On Resistance

VOUT = 3.3V

VOUT = 5V

0.45

0.30

Ω

Ω

850

mA

NMOS Current Limit

600

nA

Burst Mode Operation Current Threshold

LTC3400 Only (Note 3)

3

mA

Current Limit Delay to Output

(Note 3)

40

ns

Max Duty Cycle

VFB = 1.15V

●

80

87

●

0.95

0.85

1.2

1.2

Switching Frequency

SHDN Input High

MHz

MHz

0.35

V

1

µA

1

V

SHDN Input Low

SHDN Input Current

%

1.5

1.5

VSHDN = 5.5V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3400E/LTC3400BE are guaranteed to meet performance

specifications from 0°C to 70°C. Specifications over the – 30°C to 85°C

operating temperature range are assured by design, characterization and

correlation with statistical process controls.

0.01

Note 3: Specification is guaranteed by design and not 100% tested in

production.

Note 4: Minimum VIN operation after start-up is only limited by the

battery’s ability to provide the necessary power as it enters a deeply

discharged state.

Note 5: Burst Mode operation IQ is measured at VOUT. Multiply this value

by VOUT/VIN to get the equivalent input (battery) current.

3400fa

2

�LTC3400/LTC3400B

U W

TYPICAL PERFOR A CE CHARACTERISTICS

Output Load Burst Mode Threshold

vs VIN

Minimum Start-Up Voltage

vs Load Current

VOUT vs Temperature

3.36

L = 4.7µH

TA = 25°C

1.4

FIGURE 1 CIRCUIT

IO = 10mA

1.3

START-UP VOLTAGE (V)

VOUT = 3.3V

VOUT = 5V

3.32

VOUT (V)

OUTPUT CURRENT (mA)

3.34

20

3.30

10

3.28

0.9

1.5

2.1

2.7

VIN (V)

3.3

3.9

3.24

–60

4.5

1.1

1.0

0.8

–30

0

30

60

TEMPERATURE (°C)

90

120

0.1

1

10

IOUT (mA) CURRENT SOURCE LOAD

3400 G02

3400 G01

100

3400 G03

Normalized Oscillator Frequency

vs Temperature

No Load Battery Current vs VBATT

1000

1.2

0.9

3.26

0

TA = 25°C

SW Pin Antiringing Operation

1.01

VOUT = 3.3V

TA = 25°C

NORMALIZED FREQUENCY

BATTERY CURRENT (µA)

1.00

100

0.99

VSW

1V/DIV

0.98

0.97

0V

0.96

10

0.9

1.2

1.5 1.8 2.1 2.4

BATTERY VOLTAGE (V)

2.7

0.95

–50 –30

3.0

30

50

–10 10

TEMPERATURE (°C)

3400 G04

Fixed Frequency and Burst Mode

Operation

VSW

1V/DIV

3400 G07

3400 G06

VOUT Transient Response

VOUT(AC)

100mV/DIV

VOUT(AC)

100mV/DIV

60mA

100mA

IOUT

40mA

IOUT

0V

100ns/DIV

90

100ns/DIV

3400 G05

SW Pin Fixed Frequency,

Continuous Inductor Current

Operation

VIN = 1.3V

VOUT = 3.3V

IOUT = 50mA

L = 6.8µH

COUT = 4.7µF

70

VIN = 1.3V

VOUT = 3.3V

IOUT = 10mA

L = 6.8µH

COUT = 4.7µF

10µA

10ms/DIV

VIN = 1.3V

VOUT = 3.3V

IOUT = 60mA TO 10µA

L = 6.8µH

COUT = 4.7µF

3400 G08

100µs/DIV

VIN = 1.3V

VOUT = 3.3V

IOUT = 40mA TO 100mA

L = 6.8µH

COUT = 4.7µF

3400 G09

3400fa

3

�LTC3400/LTC3400B

U

U

U

PI FU CTIO S

SHDN = Low: Shutdown, quiescent current < 1µA.

100Ω connected between SW and VIN.

SW (Pin 1): Switch Pin. Connect inductor between SW

and VIN. Optional Schottky diode is connected between

SW and VOUT. Keep these PCB trace lengths as short and

wide as possible to reduce EMI and voltage overshoot. If

the inductor current falls to zero, or SHDN is low, an

internal 100Ω antiringing switch is connected from SW to

VIN to minimize EMI.

Typically, SHDN should be connected to VIN through a 1M

pull-up resistor.

VOUT (Pin 5): Output Voltage Sense Input and Drain of the

Internal Synchronous Rectifier MOSFET. Bias is derived

from VOUT. PCB trace length from VOUT to the output filter

capacitor(s) should be as short and wide as possible. VOUT

is held at VIN – 0.6V in shutdown due to the body diode of

the internal PMOS.

GND (Pin 2): Signal and Power Ground. Provide a short

direct PCB path between GND and the (–) side of the output

capacitor(s).

FB (Pin 3): Feedback Input to the gm Error Amplifier.

Connect resistor divider tap to this pin. The output voltage

can be adjusted from 2.5V to 5V by:

VIN (Pin 6): Battery Input Voltage. The device gets its

start-up bias from VIN. Once VOUT exceeds VIN, bias

comes from VOUT. Thus, once started, operation is completely independent from VIN. Operation is only limited by

the output power level and the battery’s internal series

resistance.

VOUT = 1.23V • [1 + (R1/R2)]

SHDN (Pin 4): Logic Controlled Shutdown Input.

SHDN = High: Normal free running operation, 1.2MHz

typical operating frequency.

W

BLOCK DIAGRA

L1

4.7µH

SINGLE

CELL

INPUT

CIN

1µF

6 VIN

1 SW

OPTIONAL

SCHOTTKY

+

+

VOUT

GOOD

–

START-UP

OSC

A

2.3V

A/B

MUX

5

SYNC

DRIVE

CONTROL

PWM

CONTROL

RAMP

GEN

1.2MHz

3.3V

OUTPUT

VOUT

0.45Ω

B

Σ

SLOPE

COMP

0.35Ω

CURRENT

SENSE

R1

1.02M

1%

(EXTERNAL)

CFF

(OPTIONAL)

PWM

COMPARATOR

–

–

+

FB

–

SLEEP

Burst Mode

OPERATION

CONTROL

CC

150pF

SHDN

4

SHUTDOWN

CONTROL

SHUTDOWN

+

RC

80k

gm

ERROR

AMP

CP2

2.5pF

COUT

4.7µF

3

1.23V

REF

R2

604k

1%

(EXTERNAL)

2 GND

3400 BD

3400fa

4

�LTC3400/LTC3400B

U

OPERATIO

The LTC3400/LTC3400B are 1.2MHz, synchronous boost

converters housed in a 6-lead ThinSOT package. Able to

operate from an input voltage below 1V, the devices

feature fixed frequency, current mode PWM control for

exceptional line and load regulation. With its low RDS(ON)

and gate charge internal MOSFET switches, the devices

maintain high efficiency over a wide range of load current.

Detailed descriptions of the three distinct operating modes

follow. Operation can be best understood by referring to

the Block Diagram.

Low Voltage Start-Up

The LTC3400/LTC3400B will start up at a typical VIN voltage of 0.85V or higher. The low voltage start-up circuitry

controls the internal NMOS switch up to a maximum peak

inductor current of 850mA (typ), with an approximate

1.5µs off-time during start-up, allowing the devices to

start up into an output load. Once VOUT exceeds 2.3V, the

start-up circuitry is disabled and normal fixed frequency

PWM operation is initiated. In this mode, the LTC3400/

LTC3400B operate independent of VIN, allowing extended

operating time as the battery can droop to several tenths

of a volt without affecting output voltage regulation. The

limiting factor for the application becomes the ability of the

battery to supply sufficient energy to the output.

Low Noise Fixed Frequency Operation

Oscillator: The frequency of operation is internally set to

1.2MHz.

Error Amp: The error amplifier is an internally compensated

transconductance type (current output) with a transconductance (gm) = 33 microsiemens. The internal 1.23V reference

voltage is compared to the voltage at the FB pin to generate

an error signal at the output of the error amplifier. A voltage divider from VOUT to ground programs the output

voltage via FB from 2.5V to 5V using the equation:

VOUT = 1.23V • [1 + (R1/R2)]

Current Sensing: A signal representing NMOS switch

current is summed with the slope compensator. The

summed signal is compared to the error amplifier output

to provide a peak current control command for the PWM.

Peak switch current is limited to approximately 850mA

independent of input or output voltage. The current signal

is blanked for 40ns to enhance noise rejection.

Zero Current Comparator: The zero current comparator

monitors the inductor current to the output and shuts off

the synchronous rectifier once this current reduces to approximately 20mA. This prevents the inductor current from

reversing in polarity improving efficiency at light loads.

Antiringing Control: The antiringing control circuitry prevents high frequency ringing of the SW pin as the inductor

current goes to zero by damping the resonant circuit

formed by L and CSW (capacitance on SW pin).

Burst Mode Operation

Portable devices frequently spend extended time in low

power or standby mode, only switching to high power

drain when specific functions are enabled. In order to

improve battery life in these types of products, high power

converter efficiency needs to be maintained over a wide

output power range. In addition to its high efficiency at

moderate and heavy loads, the LTC3400 includes automatic Burst Mode operation that improves efficiency of

the power converter at light loads. Burst mode operation

is initiated if the output load current falls below an

internally programmed threshold (see Typical Performance graph, Output Load Burst Mode Threshold vs V IN).

Once initiated, the Burst Mode operation circuitry shuts

down most of the device, only keeping alive the circuitry

required to monitor the output voltage. This is referred to

as the sleep state. In sleep, the LTC3400 draws only 19µA

from the output capacitor, greatly enhancing efficiency.

When the output voltage has drooped approximately 1%

from nominal, the LTC3400 wakes up and commences

normal PWM operation. The output capacitor recharges

and causes the LTC3400 to reenter sleep if the output load

remains less than the sleep threshold. The frequency of

this intermittent PWM or burst operation is proportional to

load current; that is, as the load current drops further

below the burst threshold, the LTC3400 turns on less

frequently. When the load current increases above the

3400fa

5

�LTC3400/LTC3400B

U

OPERATIO

burst threshold, the LTC3400 will resume continuous

PWM operation seamlessly. Referring to the Block Diagram, an optional capacitor (CFF) between VOUT and FB in

some circumstances can reduce the peak-to-peak VOUT

ripple and input quiescent current during Burst Mode

operation. Typical values for CFF range from 15pF to

220pF. The LTC3400B does not use Burst Mode operation

and features continous operation at light loads, eliminating low frequency output voltage ripple at the expense of

light load efficiency.

U

W

U U

APPLICATIO S I FOR ATIO

PCB LAYOUT GUIDELINES

The high speed operation of the LTC3400/LTC3400B

demands careful attention to board layout. You will not get

advertised performance with careless layout. Figure 2

shows the recommended component placement. A large

ground pin copper area will help to lower the chip temperature. A multilayer board with a separate ground plane is

ideal, but not absolutely necessary.

of inductance will allow greater output current capability

by reducing the inductor ripple current. Increasing the

inductance above 10µH will increase size while providing

little improvement in output current capability.

The approximate output current capability of the LTC3400/

LTC3400B versus inductance value is given in the equation below and illustrated graphically in Figure 3.

VIN =1.2V

180

VIN

1

SW

2

GND VOUT 5

3

OUTPUT CURRENT (mA)

(OPTIONAL)

VIN 6

FB SHDN 4

SHDN

VOUT = 3V

VOUT = 3.3V

160

VOUT = 3.6V

140

120

VOUT = 5V

110

80

60

VOUT

3

5

7

9 11 13 15 17 19 21 23

INDUCTANCE (µH)

3400 F02

3400 F03

RECOMMENDED COMPONENT PLACEMENT. TRACES

CARRYING HIGH CURRENT ARE DIRECT. TRACE AREA AT

FB PIN IS SMALL. LEAD LENGTH TO BATTERY IS SHORT

Figure 2. Recommended Component Placement

for Single Layer Board

COMPONENT SELECTION

Inductor Selection

The LTC3400/LTC3400B can utilize small surface mount

and chip inductors due to their fast 1.2MHz switching

frequency. A minimum inductance value of 3.3µH is

necessary for 3.6V and lower voltage applications and

4.7µH for output voltages greater than 3.6V. Larger values

Figure 3. Maximum Output Current vs

Inductance Based On 90% Efficiency

V •D

IOUT(MAX) = η • IP – IN • (1 – D)

f • L • 2

where:

η = estimated efficiency

IP = peak current limit value (0.6A)

VIN = input (battery) voltage

D = steady-state duty ratio = (VOUT – VIN)/VOUT

f = switching frequency (1.2MHz typical)

L = inductance value

3400fa

6

�LTC3400/LTC3400B

U

W

U U

APPLICATIO S I FOR ATIO

The inductor current ripple is typically set for 20% to 40%

of the maximum inductor current (IP). High frequency

ferrite core inductor materials reduce frequency dependent power losses compared to cheaper powdered iron

types, improving efficiency. The inductor should have low

ESR (series resistance of the windings) to reduce the I2R

power losses, and must be able to handle the peak

inductor current without saturating. Molded chokes and

some chip inductors usually do not have enough core to

support the peak inductor currents of 850mA seen on the

LTC3400/LTC3400B. To minimize radiated noise, use a

toroid, pot core or shielded bobbin inductor. See Table 1

for some suggested components and suppliers.

Table 1. Recommended Inductors

PART

L

(µH)

MAX

DCR

mΩ

HEIGHT

(mm)

2.0

2.0

1.8

1.8

3.5

3.5

0.8

0.8

Sumida

(847) 956-0666

www.sumida.com

VENDOR

extremely low ESR and are available in small footprints. A

2.2µF to 10µF output capacitor is sufficient for most

applications. Larger values up to 22µF may be used to

obtain extremely low output voltage ripple and improve

transient response. An additional phase lead capacitor

may be required with output capacitors larger than 10µF

to maintain acceptable phase margin. X5R and X7R

dielectric materials are preferred for their ability to maintain capacitance over wide voltage and temperature ranges.

Low ESR input capacitors reduce input switching noise

and reduce the peak current drawn from the battery. It

follows that ceramic capacitors are also a good choice for

input decoupling and should be located as close as possible to the device. A 4.7µF input capacitor is sufficient for

virtually any application. Larger values may be used without limitations. Table 2 shows a list of several ceramic

capacitor manufacturers. Consult the manufacturers directly for detailed information on their entire selection of

ceramic parts.

CDRH5D18-4R1

CDRH5D18-100

CDRH3D16-4R7

CDRH3D16-6R8

CR43-4R7

CR43-100

CMD4D06-4R7MC

CMD4D06-3R3MC

4.1

10

4.7

4.7

10

4.7

3.3

57

124

105

170

109

182

216

174

DS1608-472

DS1608-103

DO1608C-472

4.7

10

4.7

60

75

90

2.9

2.9

2.9

Coilcraft

(847) 639-6400

www.coilcraft.com

D52LC-4R7M

D52LC-100M

4.7

10

84

137

2.0

2.0

Toko

(408) 432-8282

www.tokoam.com

Output Diode

LQH3C4R7M24

4.7

195

2.2

Murata

www.murata.com

Table 2. Capacitor Vendor Information

Output and Input Capacitor Selection

Low ESR (equivalent series resistance) capacitors should

be used to minimize the output voltage ripple. Multilayer

ceramic capacitors are an excellent choice as they have

SUPPLIER

PHONE

WEBSITE

AVX

(803) 448-9411

www.avxcorp.com

Murata

(714) 852-2001

www.murata.com

Taiyo Yuden

(408) 573-4150

www.t-yuden.com

Use a Schottky diode such as an MBR0520L, PMEG2010EA,

1N5817 or equivalent if the converter output voltage is 4.5V

or greater. The Schottky diode carries the output current for

the time it takes for the synchronous rectifier to turn on. Do

not use ordinary rectifier diodes, since the slow recovery

times will compromise efficiency. A Schottky diode is

optional for output voltages below 4.5V, but will increase

converter efficiency by 2% to 3%.

3400fa

7

�LTC3400/LTC3400B

U

TYPICAL APPLICATIO S

Single Cell to 3.3V Synchronous Boost Converter

with Load Disconnect in Shutdown

L1

4.7µH

+

SINGLE

AA CELL

C1

4.7µF

D1

1

6

SW

VIN

VOUT

5

R3

510k

LTC3400

OFF ON

4

FB

SHDN

3

C2

4.7µF

GND

2

D1: CENTRAL SEMI CMDSH2-3

L1: COILCRAFT DS1608-472

M1

Si2305DS

R3

510k

VOUT

3.3V

R1

100mA

1.02M

1%

R2

604k

1%

Q1

2N3904

3400 TA01a

3400fa

8

�LTC3400/LTC3400B

U

TYPICAL APPLICATIO S

Single Lithium Cell to 5V, 250mA

OPTIONAL

SNUBBER

2Ω

1nF

L1

4.7µH

+

LITHIUM

CELL

D1

1

C1

4.7µF

6

SW

VIN

VOUT

5

LTC3400

4

OFF ON

FB

SHDN

3

C2

4.7µF

GND

2

D1: PHILIPS PMEG2010EA

L1: SUMIDA CMD4D06-4R7

C1, C2: TAIYO YUDEN JMK212BJ475MG

R1

1.02M

1%

C3

100pF

R2

332k

1%

3400 TA02a

3.6V to 5V Efficiency

100

EFFICIENCY (%)

90

LTC3400

CO = 4.7µF

L = 4.7µH

80

70

60

50

0.1

1

10

100

LOAD CURRENT (mA)

1000

3400 TA02b

3400fa

9

�LTC3400/LTC3400B

U

TYPICAL APPLICATIO S

Single Cell AA Cell to ±3V Synchronous Boost Converter

C3

1µF

L1

4.7µH

+

SINGLE

AA CELL

C1

4.7µF

1

6

SW

VIN

VOUT

5

LTC3400

OFF ON

4

FB

SHDN

GND

2

3

R1

1.02M

1%

R2

750k

1%

D1

D2

VOUT1

3V

C2

90mA

4.7µF

C4

10µF

3400 TA03a

VOUT2

–3V

10mA

D1, D2: ZETEX FMND7000 DUAL DIODE

L1: COILCRAFT DS1608-472

3400fa

10

�LTC3400/LTC3400B

U

PACKAGE DESCRIPTIO

S6 Package

6-Lead Plastic TSOT-23

(Reference LTC DWG # 05-08-1636)

0.62

MAX

2.90 BSC

(NOTE 4)

0.95

REF

1.22 REF

3.85 MAX 2.62 REF

1.4 MIN

2.80 BSC

1.50 – 1.75

(NOTE 4)

PIN ONE ID

RECOMMENDED SOLDER PAD LAYOUT

PER IPC CALCULATOR

0.30 – 0.45

6 PLCS (NOTE 3)

0.95 BSC

0.80 – 0.90

0.20 BSC

0.01 – 0.10

1.00 MAX

DATUM ‘A’

0.30 – 0.50 REF

0.09 – 0.20

(NOTE 3)

1.90 BSC

S6 TSOT-23 0302

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

4. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. JEDEC PACKAGE REFERENCE IS MO-193

3400fa

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

11

�LTC3400/LTC3400B

U

TYPICAL APPLICATIO

Single AA Cell to 2.5V Synchronous Boost Converter

L1

3.3µH

+

SINGLE

AA CELL

C1

4.7µF

D1

1

6

SW

VIN

VOUT

LTC3400

OFF ON

4

FB

SHDN

3

GND

D1: PHILIPS PMEG2010EA

L1: SUMIDA CMD4D06-3R3MC

VOUT

2.5V

130mA

5

2

R1

1.02M

1%

R2

1.02M

1%

C2

4.7µF

3400 TA04a

RELATED PARTS

PART NUMBER

DESCRIPTION

COMMENTS

LT1308A/LT1308B

High Current, Micropower, Single Cell 600kHz DC/DC Converter

5V at 1A with Single Li-Ion Cell, VOUT to 34V

LT1613

1.4MHz, Single Cell DC/DC Converter in ThinSOT

VIN as Low as 1.1V, 3V at 30mA from Single Cell

LT1615

Micropower Step-Up DC/DC Converter in ThinSOT

IQ = 20µA, 1µA Shutdown Current, VIN as Low as 1V

LT 1618

1.4MHz Step-Up DC/DC Converter with Current Limit

1.5A Switch, 1.6V to 18V Input Range,

Input or Output Current Limiting

LT1619

High Efficiency Boost DC/DC Controller

1A Gate Drive, 1.1V to 20V Input, Separate VCC for Gate Drive

LTC1872

ThinSOT Boost DC/DC Controller

50kHz, 2.5V to 9.8V Input

LT1930/LT1930A

1.2MHz/2.2MHz DC/DC Converters in ThinSOT

VIN = 2.6V to 16V, 5V at 450mA from 3.3V Input

LT1932

Constant Current Step-Up LED Driver

Drives Up to Eight White LEDs, ThinSOT Package

LT1946/LT1946A

1.2MHz/2.7MHz Boost DC/DC Converters

1.5A, 36V Internal Switch, 8-Pin MSOP Package

LT1949

600kHz, 1A Switch PWM DC/DC Converter

1A, 0.5Ω, 30V Internal Switch, VIN as Low as 1.5V,

Low-Battery Detect Active in Shutdown

LTC3401

1A, 3MHz Micropower Synchronous Boost Converter

1A Switch, Programmable Frequency, 10-Pin MSOP Package

LTC3402

2A, 3MHz Micropower Synchronous Boost Converter

2A Switch, Programmable Frequency, 10-Pin MSOP Package

LTC3423

1A, 3MHz Micropower Synchronous Boost Converter

1A Switch, Separate Bias Pin for Low Output Voltages

LTC3424

2A, 3MHz Micropower Synchronous Boost Converter

2A Switch, Separate Bias Pin for Low Output Voltages

LTC3425

5A, 8MHz, 4-Phase Micropower Synchronous Boost Converter

Up to 95% Efficiency, 5A Switch, VIN: 0.5V to 4.5V,

VOUT (min): 2.4V to 5.25V, IQ = 12µA, QFN

®

3400fa

12

Linear Technology Corporation

LT/TP 0903 1K REV A • PRINTED IN USA

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

LINEAR TECHNOLOGY CORPORATION 2001

�