LT1461 Micropower Precision Low Dropout Series Voltage Reference Family

FEATURES

s s s s s s s s s s s

DESCRIPTIO

Trimmed to High Accuracy: 0.04% Max Low Drift: 3ppm/°C Max Low Supply Current: 50µA Max Temperature Coefficient Guaranteed to 125°C High Output Current: 50mA Min Low Dropout Voltage: 300mV Max Excellent Thermal Regulation Power Shutdown Thermal Limiting Operating Temperature Range: – 40°C to 125°C Voltage Options: 2.5V, 3V, 3.3V, 4.096V and 5V

APPLICATIO S

s s s s

A/D and D/A Converters Precision Regulators Handheld Instruments Power Supplies

The LT ®1461 is a family of low dropout micropower bandgap references that combine very high accuracy and low drift with low supply current and high output drive. These series references use advanced curvature compensation techniques to obtain low temperature coefficient and trimmed precision thin-film resistors to achieve high output accuracy. The LT1461 family draws only 35µA of supply current, making them ideal for low power and portable applications, however their high 50mA output drive makes them suitable for higher power requirements, such as precision regulators. In low power applications, a dropout voltage of less than 300mV ensures maximum battery life while maintaining full reference performance. Line regulation is nearly immeasurable, while the exceedingly good load and thermal regulation will not add significantly to system error budgets. The shutdown feature can be used to switch full load currents and can be used for system power down. Thermal shutdown protects the part from overload conditions. The LT1461 is available in 2.5V, 3V, 3.3V 4.096V and 5V options.

, LTC and LT are registered trademarks of Linear Technology Corporation.

TYPICAL APPLICATIO

Basic Connection

(VOUT + 0.3V) ≤ VIN ≤ 20V LT1461 CIN 1µF CL 2µF

1461 TA01

LT1461-2.5 Load Regulation, PDISS = 200mW

VOUT

IOUT

0mA

20mA

VOUT LOAD REG 1mV/DIV

U

10ms/DIV

1461 TA02

U

U

1

�LT1461

ABSOLUTE AXI U RATI GS

Input Voltage ........................................................... 20V Output Short-Circuit Duration ......................... Indefinite Operating Temperature Range (Note 2) ........................................... – 40°C to 125°C Storage Temperature Range (Note 3) ... – 65°C to 150°C

PACKAGE/ORDER I FOR ATIO

ORDER PART NUMBER

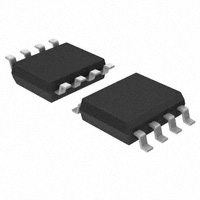

TOP VIEW DNC* 1 VIN 2 SHDN 3 GND 4 8 7 6 5 DNC* DNC* VOUT DNC*

S8 PACKAGE 8-LEAD PLASTIC SO *DNC: DO NOT CONNECT TJMAX = 150°C, θJA = 190°C/ W (Note 3)

LT1461ACS8-2.5 LT1461BCS8-2.5 LT1461CCS8-2.5 LT1461AIS8-2.5 LT1461BIS8-2.5 LT1461CIS8-2.5 LT1461DHS8-2.5 LT1461ACS8-3 LT1461BCS8-3 LT1461CCS8-3 LT1461AIS8-3 LT1461BIS8-3 LT1461CIS8-3 LT1461DHS8-3

LT1461ACS8-3.3 LT1461BCS8-3.3 LT1461CCS8-3.3 LT1461AIS8-3.3 LT1461BIS8-3.3 LT1461CIS8-3.3 LT1461DHS8-3.3 LT1461ACS8-4 LT1461BCS8-4 LT1461CCS8-4 LT1461AIS8-4 LT1461BIS8-4 LT1461CIS8-4 LT1461DHS8-4

Consult factory for Military grade parts.

AVAILABLE OPTIO S

INITIAL ACCURACY 0.04% Max 0.04% Max 0.06% Max 0.06% Max 0.08% Max 0.08% Max 0.15% Max TEMPERATURE COEFFICIENT 3ppm/°C Max 3ppm/°C Max 7ppm/°C Max 7ppm/°C Max 12ppm/°C Max 12ppm/°C Max 20ppm/°C Max TEMPERATURE RANGE 0°C to 70°C – 40°C to 85°C 0°C to 70°C – 40°C to 85°C 0°C to 70°C – 40°C to 85°C –40°C to 125°C OUTPUT VOLTAGE 2.5V LT1461ACS8-2.5 LT1461AIS8-2.5 LT1461BCS8-2.5 LT1461BIS8-2.5 LT1461CCS8-2.5 LT1461CIS8-2.5 LT1461DHS8-2.5 3.0V LT1461ACS8-3 LT1461AIS8-3 LT1461BCS8-3 LT1461BIS8-3 LT1461CCS8-3 LT1461CIS8-3 LT1461DHS8-3 3.3V LT1461ACS8-3.3 LT1461AIS8-3.3 LT1461BCS8-3.3 LT1461BIS8-3.3 LT1461CCS8-3.3 LT1461CIS8-3.3 LT1461DHS8-3.3 4.096V LT1461ACS8-4 LT1461AIS8-4 LT1461BCS8-4 LT1461BIS8-4 LT1461CCS8-4 LT1461CIS8-4 LT1461DHS8-4 5.0V LT1461ACS8-5 LT1461AIS8-5 LT1461BCS8-5 LT1461BIS8-5 LT1461CCS8-5 LT1461CIS8-5 LT1461DHS8-5

2

U

U

W

WW

U

U

W

(Note 1)

Specified Temperature Range Commercial ............................................ 0°C to 70°C Industrial ........................................... – 40°C to 85°C High ................................................. – 40°C to 125°C Lead Temperature (Soldering, 10 sec).................. 300°C

S8 PART MARKING LT1461ACS8-5 LT1461BCS8-5 LT1461CCS8-5 LT1461AIS8-5 LT1461BIS8-5 LT1461CIS8-5 LT1461DHS8-5 461A25 461B25 461C25 61AI25 61BI25 61CI25 61DH25 1461A3 1461B3 1461C3 461AI3 461BI3 461CI3 461DH3 461A33 461B33 461C33 61AI33 61BI33 61CI33 61DH33 1461A4 1461B4 1461C4 461AI4 461BI4 461CI4 461DH4 1461A5 1461B5 1461C5 461AI5 461BI5 461CI5 461DH5

�LT1461

ELECTRICAL CHARACTERISTICS

PARAMETER Output Voltage (Note 4)

The q denotes specifications which apply over the specified temperature range, otherwise specifications are at TA = 25°C. VIN – VOUT = 0.5V, Pin 3 = 2.4V, CL = 2µF, unless otherwise specified.

CONDITIONS LT1461ACS8/LT1461AIS8 LT1461BCS8/LT1461BIS8 LT1461CCS8/LT1461CIS8 LT1461DHS8 LT1461ACS8/LT1461AIS8 LT1461BCS8/LT1461BIS8 LT1461CCS8/LT1461CIS8 LT1461DHS8 (VOUT + 0.5V) ≤ VIN ≤ 20V

q q q q q

MIN – 0.04 – 0.06 – 0.08 – 0.15

TYP

MAX 0.04 0.06 0.08 0.15

UNITS % % % % ppm/°C ppm/°C ppm/°C ppm/°C ppm/V ppm/V ppm/V ppm/mA ppm/mA ppm/mA V V V V mA V µA V µA µA µA µA µA ppmP-P ppmRMS ppm/√kHr ppm ppm ppm

Output Voltage Temperature Coefficient (Note 5)

1 3 5 7 2

3 7 12 20 8 12 50 30 40 50

Line Regulation

LT1461DHS8 Load Regulation Sourcing (Note 6) VIN = VOUT + 2.5V 0 ≤ IOUT ≤ 50mA

q

15 12

q

LT1461DHS8, 0 ≤ IOUT ≤ 10mA Dropout Voltage VIN – VOUT, VOUT Error = 0.1% IOUT = 0mA IOUT = 1mA IOUT = 10mA IOUT = 50mA, I and C Grades Only Short VOUT to GND Logic High Input Voltage Logic High Input Current, Pin 3 = 2.4V Logic Low Input Voltage Logic Low Input Current, Pin 3 = 0.8V Supply Current Shutdown Current Output Voltage Noise (Note 7) Long-Term Drift of Output Voltage, SO-8 Package (Note 8) Thermal Hysteresis (Note 9) No Load

q

q q q

0.06 0.13 0.20 1.50 100 2.4 2 0.5 35

0.3 0.4 2.0

Output Current Shutdown Pin

q q q q q

15 0.8 4 50 70 35 55

RL = 1k

q

25 8 9.6 60 40 75 120

0.1Hz ≤ f ≤ 10Hz 10Hz ≤ f ≤ 1kHz See Applications Information ∆T = 0°C to 70°C ∆T = – 40°C to 85°C ∆T = – 40°C to 125°C

Note 1: Absolute Maximum Ratings are those values beyond which the life of a device may be impaired. Note 2: The LT1461 is guaranteed functional over the operating temperature range of – 40°C to 125°C. Note 3: If the part is stored outside of the specified temperature range, or the junction temperature exceeds the specified temperature range, the output may shift due to hysteresis. Note 4: ESD (Electrostatic Discharge) sensitive device. Extensive use of ESD protection devices are used internal to the LT1461, however, high electrostatic discharge can damage or degrade the device. Use proper ESD handling precautions. Note 5: Temperature coefficient is calculated from the minimum and maximum output voltage measured at TMIN, Room and TMAX as follows: TC = (VOMAX – VOMIN)/(TMAX – TMIN)

Incremental slope is also measured at 25°C. Note 6: Load regulation is measured on a pulse basis from no load to the specified load current. Output changes due to die temperature change must be taken into account separately. Note 7: Peak-to-peak noise is measured with a single pole highpass filter at 0.1Hz and a 2-pole lowpass filter at 10Hz. The unit is enclosed in a stillair environment to eliminate thermocouple effects on the leads. The test time is 10 seconds. RMS noise is measured with a single pole highpass filter at 10Hz and a 2-pole lowpass filter at 1kHz. The resulting output is full-wave rectified and then integrated for a fixed period, making the final reading an average as opposed to RMS. A correction factor of 1.1 is used to convert from average to RMS and a second correction of 0.88 is used to correct for the nonideal bandpass of the filters.

3

�LT1461

ELECTRICAL CHARACTERISTICS

Note 8: Long-term drift typically has a logarithmic characteristic and therefore, changes after 1000 hours tend to be much smaller than before that time. Total drift in the second thousand hours is normally less than one third that of the first thousand hours with a continuing trend toward reduced drift with time. Long-term drift will also be affected by differential stresses between the IC and the board material created during board assembly. See the Applications Information section. Note 9: Hysteresis in output voltage is created by package stress that depends on whether the IC was previously at a higher or lower temperature. Output voltage is always measured at 25°C, but the IC is cycled hot or cold before successive measurements. Hysteresis is roughly proportional to the square of the temperature change. Hysteresis is not normally a problem for operational temperature excursions where the instrument might be stored at high or low temperature. See Applications Information section.

TYPICAL PERFOR A CE CHARACTERISTICS

2.5V Reference Voltage vs Temperature

2.5020 2.5015 REFERENCE VOLTAGE (V) 2.5010 2.5005 2.5000 2.4995 2.4990 2.4985 2.4980 – 60 – 40 – 20 0 20 40 60 80 100 120 TEMPERATURE (°C)

1461 G01

Characteristic curves are similar for most LT1461s. Curves from the LT1461-2.5 and the LT1461-5 represent the extremes of the voltage options. Characteristic curves for other output voltages fall between these curves and can be estimated based on their output. 2.5V Load Regulation

1600

OUTPUT VOLTAGE CHANGE (ppm)

TEMPCO –60°C TO 120°C 3 TYPICAL PARTS

1200 125°C 25°C 800

LINE REGULATION (ppm/V)

2.5V Minimum Input/Output Voltage Differential vs Load Current

10

1000

RIPPLE REJECTION RATIO (dB)

INPUT/OUTPUT VOLTAGE (V)

SUPPLY CURRENT (µA)

1 125°C 25°C – 55°C 0.1 0.1 1 10 OUTPUT CURRENT (mA) 100

1461 G04

4

UW

2.5V Line Regulation vs Temperature

0 –1 –2 –3 –4 –5 –6 –7 SUPPLY ∆ = 15V 5V – 20V 0 20 40 60 80 TEMPERATURE (°C) 100 120

1461 G03

VIN = 7.5V

400 – 55°C 0 0.1

1 10 OUTPUT CURRENT (mA)

100

1461 G02

–8 –40 – 20

2.5V Supply Current vs Input Voltage

100 90 80 70 60 50 40 30 20 10 10 0 5 10 15 20 INPUT VOLTAGE (V) 25

1461 G05

2.5V Ripple Rejection Ratio vs Frequency

100 125°C – 55°C 25°C

0 0.01

0.1

1 10 FREQUENCY (kHz)

100

1000

1641 G06

�LT1461

Characteristic curves are similar for most LT1461s. Curves from the LT1461-2.5 and the LT1461-5 represent the extremes of the voltage options. Characteristic curves for other output voltages fall between these curves and can be estimated based on their output. 2.5V Output Impedance vs Frequency

1000 COUT = 2µF

TYPICAL PERFOR A CE CHARACTERISTICS

OUTPUT IMPEDANCE (Ω)

VOLTAGE (V)

10

2 VOUT 1 0 CIN = 1µF CL = 2µF RL = ∞ TIME (100µs/DIV)

1461 G08

VOLTAGE (V)

100

COUT = 1µF

1 0.01

0.1 1 FREQUENCY (kHz)

2.5V Transient Response to 10mA Load Step

IOUT 0mA 10mA/DIV 5V 4V

VOUT 50mV/DIV

VOUT 50mV/DIV

CL = 2µF

1461 G10

CIN = 0.1µF

1461 G11

OUTPUT NOISE (10µV/DIV)

UW

10

1461 G07

2.5V Turn-On Time

20 10 0 VIN 20 10 0

2.5V Turn-On Time

VIN

2 VOUT 1 0 TIME (100µs/DIV)

1461 G09

CIN = 1µF CL = 2µF RL = 50Ω

2.5V Line Transient Response

2.5V Output Noise 0.1Hz ≤ f ≤ 10Hz

VIN

TIME (2SEC/DIV)

1461 G12

5

�LT1461

Characteristic curves are similar for most LT1461s. Curves from the LT1461-2.5 and the LT1461-5 represent the extremes of the voltage options. Characteristic curves for other output voltages fall between these curves and can be estimated based on their output. 5V Reference Voltage vs Temperature

5.0040 TEMPCO –60°C TO 120°C 5.0030 3 TYPICAL PARTS 5.0020

REFERENCE VOLTAGE (V)

LOAD REGULATION (ppm)

TYPICAL PERFOR A CE CHARACTERISTICS

5.0010 5.0000 4.9990 4.9980 4.9970 4.9960 4.9950 4.9940 4.9930 –60 –40 –20 0 20 40 60 80 100 120 TEMPERATURE (°C)

1461 G13

–55°C

LINE REGULATION (ppm/V)

5V Minimum Input/Output Voltage Differential vs Load Current

10

RIPPLE REJECTION RATIO (dB)

INPUT/OUTPUT VOLTAGE (V)

SUPPLY CURRENT (µA)

1 25°C 125°C –55°C

0.1

0.01 0.1 1 10 OUTPUT CURRENT (mA) 100

1461 G16

5V Output Impedance vs Frequency

1000

OUTPUT IMPEDANCE (Ω)

100

COUT = 2µF

2V/DIV

0 4 2 0

2V/DIV

10

1 0.01

0.1 1 FREQUENCY (kHz)

6

UW

COUT = 1µF

1461 G19

5V Load Regulation

2000 VIN = 10V 125°C 25°C 1600 0 –1 –2 –3 –4 –5 –6 –7 100

1461 G14

5V Line Regulation vs Temperature

1200

800

25°C –55°C 125°C

400

0 0.1

1 10 OUTPUT CURRENT (mA)

SUPPLY ∆ = 14V 6V TO 20V –8 –40 –20 0 20 40 60 80 TEMPERATURE (°C)

100 120

1461 G15

5V Supply Current vs Input Voltage

10000

100 90

5V Ripple Rejection Ratio vs Frequency

1000

80 70 60 50 40 30 20 10

100

125°C –55°C 25°C

10

1 0 5 10 15 INPUT VOLTAGE (V) 20 25

1461 G17

0 0.01

0.1

1 10 FREQUENCY (kHz)

100

1000

1461 G18

5V Turn-On Time

6 4 2 VOUT VIN 6 4 2 0 4 2 CIN = 1µF COUT = 2µF IOUT = 0 200µs/DIV

1461 G20

5V Turn-On Time

VIN

VOUT

0 200µs/DIV

CIN = 1µF COUT = 2µF IOUT = 50mA

10

1461 G21

�LT1461

Characteristic curves are similar for most LT1461s. Curves from the LT1461-2.5 and the LT1461-5 represent the extremes of the voltage options. Characteristic curves for other output voltages fall between these curves and can be estimated based on their output. 5V Transient Response to 10mA Load Step

VIN 0mA 10mA VOUT 50mV/DIV 7V

OUTPUT NOISE (10µV/DIV)

TYPICAL PERFOR A CE CHARACTERISTICS

IOUT

VOUT 50mV/DIV

CL = 2µF

Supply Current vs Temperature

50 IS 140

CURRENT LIMIT (mA)

IS(SHDN) 30

SHDN PIN CURRENT (µA)

40

SUPPLY CURRENT (µA)

20

10

0 – 40 –20

0

20 40 60 80 TEMPERATURE (°C)

UW

1461 G25

5V Line Transient Response

5V Output Noise 0.1Hz ≤ f ≤ 10Hz

6V

1461 G22

CIN = 0.1µF

1461 G23

TIME (2SEC/DIV)

1461 G24

Current Limit vs Temperature

200 180 120 160 140 120 100 80 60 40 20 100 120 40 –50 0 –25 50 25 0 75 TEMPERATURE (°C) 100 125

SHDN Pin Current vs SHDN Input Voltage

125°C 25°C – 55°C

100

80

60

0

15 10 5 SHDN PIN INPUT VOLTAGE (V)

20

1461 G27

1461 G26

7

�LT1461

Characteristic curves are similar for most LT1461s. Curves from the LT1461-2.5 and the LT1461-5 represent the extremes of the voltage options. Characteristic curves for other output voltages fall between these curves and can be estimated based on their output. 0°C to 70°C Hysteresis

20 18 16 WORST-CASE HYSTERESIS ON 35 UNITS

TYPICAL PERFOR A CE CHARACTERISTICS

NUMBER OF UNITS

NUMBER OF UNITS

NUMBER OF UNITS

8

UW

14 12 10 8 6 4 2 0 –100

70°C TO 25°C

0°C TO 25°C

– 80

– 60

– 40

– 20 0 20 HYSTERESIS (ppm)

40

60

80

100

1461 G29

– 40°C to 85°C Hysteresis

20 18 16 14 12 10 8 6 4 2 0 –100 – 80 – 60 – 40 – 20 0 20 HYSTERESIS (ppm) 40 60 80 100

1461 G30

WORST-CASE HYSTERESIS ON 35 UNITS

85°C TO 25°C

– 40°C TO 25°C

– 40°C to 125°C Hysteresis

16 14 12 10 8 6 4 2 0 –200 –160 –120 –80 –40 0 40 HYSTERESIS (ppm) 80 120 160 200

1461 G31

WORST-CASE HYSTERESIS ON 35 UNITS 125°C TO 25°C

– 40°C TO 25°C

�LT1461

Characteristic curves are similar for most LT1461s. Curves from the LT1461-2.5 and the LT1461-5 represent the extremes of the voltage options. Characteristic curves for other output voltages fall between these curves and can be estimated based on their output. Long-Term Drift (Number of Data Points Reduced at 650 Hours)*

250 200 150

ppm

TYPICAL PERFOR A CE CHARACTERISTICS

100 50 0 –50 0 200 400 600 800 1000 HOURS 1200 1400 1600 1800 2000

1461 G15

APPLICATIO S I FOR ATIO

Examples shown in this Applications section use the LT1461-2.5. The response of other voltage options can be estimated by proper scaling. Bypass and Load Capacitors The LT1461 family requires a capacitor on the input and on the output for stability. The capacitor on the input is a supply bypass capacitor and if the bypass capacitors from other components are close (within 2 inches) they

IOUT 0mA 1mA/DIV 1mA IOUT 50mA/DIV VOUT 20mV/DIV VOUT 200mV/DIV

1461 F01

Figure 1. 1mA Load Step with CL = 1µF

U

W

UW

LT1461S8 3 TYPICAL PARTS SOLDERED ONTO PCB TA = 30°C

*SEE APPLICATIONS INFORMATION FOR DETAILED EXPLANATION OF LONG-TERM DRIFT

UU

should be sufficient. The output capacitor acts as frequency compensation for the reference and cannot be omitted. For light loads ≤ 1mA, a 1µF nonpolar output capacitor is usually adequate, but for higher loads (up to 75mA), the output capacitor should be 2µF or greater. Figures 1 and 2 show the transient response to a 1mA load step with a 1µF output capacitor and a 50mA load step with a 2µF output capacitor.

1461 F02

Figure 2. 50mA Load Step with CL = 2µF

9

�LT1461

APPLICATIO S I FOR ATIO

Precision Regulator

The LT1461 will deliver 50mA with VIN = VOUT + 2.5V and higher load current with higher VIN. Load regulation is typically 12ppm/mA, which means for a 50mA load step, the output will change by only 1.5mV. Thermal regulation, caused by die temperature gradients and created from load current or input voltage changes, is not measurable. This often overlooked parameter must be added to normal line and load regulation errors. The load regulation photo, on the first page of this data sheet, shows the output response to 200mW of instantaneous power dissipation and the reference shows no sign of thermal errors. The reference has thermal shutdown and will turn off if the junction temperature exceeds 150°C. Shutdown The shutdown (Pin 3 low) serves to shut off load current when the LT1461 is used as a regulator. The LT1461 operates normally with Pin 3 open or greater than or equal to 2.4V. In shutdown, the reference draws a maximum supply current of 35µA. Figure 3 shows the transient response of shutdown while the part is delivering 25mA. After shutdown, the reference powers up in about 200µs.

5V PIN 3

0V 2 VOUT 0V 4

1461 F03 1461 F04

Figure 3. Shutdown While Delivering 25mA, RL = 100Ω

10

U

PC Board Layout In 13- to 16-bit systems where initial accuracy and temperature coefficient calibrations have been done, the mechanical and thermal stress on a PC board (in a card cage for instance) can shift the output voltage and mask the true temperature coefficient of a reference. In addition, the mechanical stress of being soldered into a PC board can cause the output voltage to shift from its ideal value. Surface mount voltage references are the most susceptible to PC board stress because of the small amount of plastic used to hold the lead frame. A simple way to improve the stress-related shifts is to mount the reference near the short edge of the PC board, or in a corner. The board edge acts as a stress boundary, or a region where the flexure of the board is minimum. The package should always be mounted so that the leads absorb the stress and not the package. The package is generally aligned with the leads parallel to the long side of the PC board as shown in Figure 5a. A qualitative technique to evaluate the effect of stress on voltage references is to solder the part into a PC board and deform the board a fixed amount as shown in Figure 4. The flexure #1 represents no displacement, flexure #2 is concave movement, flexure #3 is relaxation to no displacement and finally, flexure #4 is a convex movement. This motion is repeated for a number of cycles and the

1 3

W

UU

Figure 4. Flexure Numbers

�LT1461

APPLICATIO S I FOR ATIO

relative output deviation is noted. The result shown in Figure 5a is for two LT1461S8-2.5s mounted vertically and Figure 5b is for two LT1461S8-2.5s mounted horizontally. The parts oriented in Figure 5a impart less stress into the package because stress is absorbed in the leads. Figures 5a and 5b show the deviation to be between 125µV and 250µV and implies a 50ppm and 100ppm change respectively. This corresponds to a 13- to 14-bit system and is not a problem for most 10- to 12-bit systems unless the system has a calibration. In this case, as with temperature hysteresis, this low level can be important and even more careful techniques are required.

2

OUTPUT DEVIATION (mV)

OUTPUT DEVIATION (mV)

1

0

LONG DIMENSION

–1 0 10 20 FLEXURE NUMBER 30 40

1461 F05a

Figure 5a. Two Typical LT1461S8-2.5s, Vertical Orientation Without Slots

2

OUTPUT DEVIATION (mV)

1

OUTPUT DEVIATION (mV)

0

LONG DIMENSION

–1 0 10 20 FLEXURE NUMBER 30 40

1461 F05b

Figure 5b. Two Typical LT1461S8-2.5s, Horizontal Orientation Without Slots

U

The most effective technique to improve PC board stress is to cut slots in the board around the reference to serve as a strain relief. These slots can be cut on three sides of the reference and the leads can exit on the fourth side. This “tongue” of PC board material can be oriented in the long direction of the board to further reduce stress transferred to the reference. The results of slotting the PC boards of Figures 5a and 5b are shown in Figures 6a and 6b. In this example the slots can improve the output shift from about 100ppm to nearly zero.

2 1 0 SLOT –1 0 10 20 FLEXURE NUMBER 30 40

1461 F06a

W

UU

Figure 6a. Same Two LT1461S8-2.5s in Figure 5a, but with Slots

2

1

0 SLOT –1 0 10 20 FLEXURE NUMBER 30 40

1461 F06b

Figure 6b. Same Two LT1461S8-2.5s in Figure 5b, but with Slots

11

�LT1461

APPLICATIO S I FOR ATIO

Long-Term Drift

Long-term drift cannot be extrapolated from accelerated high temperature testing. This erroneous technique gives drift numbers that are wildly optimistic. The only way long-term drift can be determined is to measure it over the time interval of interest. The erroneous technique uses the Arrhenius Equation to derive an acceleration factor from elevated temperature readings. The equation is:

EA 1 1 – = e K T 1 T 2

AF

where: EA = Activation Energy (Assume 0.7) K = Boltzmann’s Constant T2 = Test Condition in °Kelvin T1 = Use Condition Temperature in °Kelvin To show how absurd this technique is, compare the LT1461 data. Typical 1000 hour long-term drift at 30°C = 60ppm. The typical 1000 hour long-term drift at 130°C = 120ppm. From the Arrhenius Equation the acceleration factor is:

AF

1 0.7 1 – 0.0000863 303 403 =e

= 767

The erroneous projected long-term drift is: 120ppm/767 = 0.156ppm/1000 hr For a 2.5V reference, this corresponds to a 0.39µV shift after 1000 hours. This is pretty hard to determine (read impossible) if the peak-to-peak output noise is larger than this number. As a practical matter, one of the best laboratory references available is the Fluke 732A and its longterm drift is 1.5µV/mo. This performance is only available from the best subsurface zener references utilizing specialized heater techniques. The LT1461 long-term drift data was taken with parts that were soldered onto PC boards similar to a “real world” application. The boards were then placed into a constant temperature oven with TA = 30°C, their outputs were

12

U

scanned regularly and measured with an 8.5 digit DVM. As an additional accuracy check on the DVM, a Fluke 732A laboratory reference was also scanned. Figure 7 shows the long-term drift measurement system. The data taken is shown at the end of the Typical Performance Characteristics section of this data sheet. The long-term drift is the trend line that asymptotes to a value at 2000 hours. Note the slope in output shift between 0 hours and 1000 hours compared to the slope between 1000 hours and 2000 hours. Long-term drift is affected by differential stresses between the IC and the board material created during board assembly.

PCB3 PCB2 PCB1 SCANNER 8.5 DIGIT DVM COMPUTER

1461 F07

W

UU

FLUKE 732A LABORATORY REFERENCE

Figure 7. Long-Term Drift Measurement Setup

Hysteresis The hysteresis curves found in the Typical Performance Characteristics represent the worst-case data taken on 35 typical parts after multiple temperature cycles. As expected, the parts that are cycled over the wider – 40°C to 125°C temperature range have more hysteresis than those cycled over lower ranges. Note that the hysteresis coming from 125°C to 25°C has an influence on the – 40°C to 25°C hysteresis. The – 40°C to 25°C hysteresis is different depending on the part’s previous temperature. This is because not all of the high temperature stress is relieved during the 25°C measurement. The typical performance hysteresis curves are for parts mounted in a socket and represent the performance of the

�LT1461

APPLICATIO S I FOR ATIO

parts alone. What is more interesting are parts IR soldered onto a PC board. If the PC board is then temperature cycled several times from – 40°C to 85°C, the resulting hysteresis curve is shown in Figure 8. This graph shows the influence of the PC board stress on the reference. When the LT1461 is soldered onto a PC board, the output shifts due to thermal hysteresis. Figure 9 shows the effect of soldering 40 pieces onto a PC board using standard IR reflow techniques. The average output voltage shift is –110ppm. Remeasurement of these parts after 12 days shows the outputs typically shift back 45ppm toward their initial value. This second shift is due to the relaxation of stress incurred during soldering.

12 11 10 9 WORST-CASE HYSTERESIS ON 35 UNITS 85°C TO 25°C – 40°C TO 25°C

NUMBER OF UNITS

8 7 6 5 4 3 2 1 0 – 200 –160 –120 – 80 – 40 0 40 HYSTERESIS (ppm) 80 120 160 200

1461 F08

Figure 8. – 40°C to 85°C Hysteresis of 35 Parts Soldered Onto a PC Board

12 10 NUMBER OF UNITS 8 6 4 2 0 –300

Figure 9. Typical Distribution of Output Voltage Shift After Soldering Onto PC Board

U

The LT1461 is capable of dissipating high power, i.e., for the LT1461-2.5, 17.5V • 50mA = 875mW. The SO-8 package has a thermal resistance of 190°C/W and this dissipation causes a 166°C internal rise producing a junction temperature of TJ = 25°C + 166°C = 191°C. What will actually occur is the thermal shutdown will limit the junction temperature to around 150°C. This high temperature excursion will cause the output to shift due to thermal hysteresis. Under these conditions, a typical output shift is –135ppm, although this number can be higher. This high dissipation can cause the 25°C output accuracy to exceed its specified limit. For best accuracy and precision, the LT1461 junction temperature should not exceed 125°C.

200 0 100 –200 –100 OUTPUT VOLTAGE SHIFT (ppm) 300

1461 F09

W

UU

13

�LT1461

SI PLIFIED SCHE ATIC

2 VIN

100k SHDN 3

14

W

W

6 VOUT

4 GND

1461 SS

�LT1461

PACKAGE DESCRIPTIO U

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package 8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.189 – 0.197* (4.801 – 5.004) 8 7 6 5

0.228 – 0.244 (5.791 – 6.197)

0.150 – 0.157** (3.810 – 3.988)

1 0.010 – 0.020 × 45° (0.254 – 0.508) 0.008 – 0.010 (0.203 – 0.254) 0°– 8° TYP

2

3

4

0.053 – 0.069 (1.346 – 1.752)

0.004 – 0.010 (0.101 – 0.254)

0.014 – 0.019 (0.355 – 0.483) TYP *DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE **DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

0.016 – 0.050 (0.406 – 1.270)

0.050 (1.270) BSC

SO8 1298

Information furnished by Linear Technology Corporation is believed to be accurate and reliable. However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

15

�LT1461

TYPICAL APPLICATIO

VCC LT1461-2.5 VOUT 1µF GND INPUT 0.1µF

RELATED PARTS

PART NUMBER LT1019 LT1027 LT1236 LTC 1798 LT1460 LT1634 LT1790

®

DESCRIPTION Precision Reference Precision 5V Reference Precision Reference Micropower Low Dropout Reference Micropower Precision Series Reference Micropower Precision Shunt Voltage Reference Precision SOT-23 Series Reference

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408)432-1900 q FAX: (408) 434-0507 q www.linear-tech.com

U

Low Power 16-Bit A/D

VCC 35µA VCC FO LTC2400 VREF SCK SD0 CS VIN GND

1461 TA03

200µA

1µF

SPI INTERFACE

NOISE PERFORMANCE* VIN = 0V, VNOISE = 1.1ppmRMS = 2.25µVRMS = 16µVP-P VIN = VREF/2, VNOISE = 1.6ppmRMS = 4µVRMS = 24µVP-P VIN = VREF, VNOISE = 2.5ppmRMS = 6.25µVRMS = 36µVP-P *FOR 24-BIT PERFORMANCE USE LT1236 REFERENCE

COMMENTS Bandgap, 0.05%, 5ppm/°C Lowest TC, High Accuracy, Low Noise, Zener Based 5V and 10V Zener-Based 5ppm/°C, SO-8 Package 0.15% Max, 6.5µA Supply Current Bandgap, 130µA Supply Current 10ppm/°C, Available in SOT-23 Bandgap 0.05%, 10ppm/°C, 10µA Supply Current Bandgap 0.05% Max, 10ppm/°C Max

1461f LT/LCG 0800 4K • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 1999

�