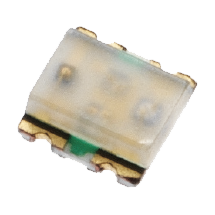

物料型号:

- LTST-C19GD2WT-G

器件简介:

- 符合ROHS标准,是绿色产品。

- 非常薄的全彩SMD芯片LED,厚度为0.40mm。

- 封装在8mm胶带上,7英寸直径的卷轴包装。

- 符合EIA STD封装标准,与自动放置设备兼容,适合红外和蒸汽相回流焊接工艺。

引脚分配:

- 引脚1:蓝色LED(InGaN)

- 引脚2:红色LED(AlInGaP)

- 引脚3:绿色LED(InGaN)

参数特性:

- 最大功耗:蓝色80mW,红色75mW,绿色80mW。

- 最大正向电流:蓝色100mA,红色80mA,绿色100mA。

- 正向电流额定值:蓝色20mA,红色30mA,绿色20mA。

- 反向电压:5V。

- 工作温度范围:-20°C至+80°C。

- 存储温度范围:-30°C至+100°C。

- 红外焊接条件:260°C持续5秒。

功能详解:

- 提供了建议的红外回流焊接曲线,包括普通过程和无铅过程。

- 电气/光学特性在25°C环境下测试,包括光强、视场角度、峰值发射波长、主波长、光谱线半宽、正向电压和反向电流。

应用信息:

- 这些LED适用于普通电子设备(如办公设备、通信设备和家用电器)。在需要极高可靠性的应用中,如航空、交通、医疗等,建议提前咨询光宝科技的销售部门。

封装信息:

- 提供了封装尺寸、胶带和卷轴的尺寸信息,以及建议的焊盘尺寸。

注意事项:

- 清洁时不要使用未指定的化学液体,以免损害封装。

- 存储环境不应超过30°C或70%相对湿度。

- 推荐使用酒精基清洁溶剂,如异丙醇。

- 焊接条件包括回流焊接、波峰焊接和烙铁焊接的建议参数。

- 为防止静电放电(ESD)损坏,建议使用导电腕带或防静电手套,并确保所有设备、设备和机器接地。

可靠性测试:

- 包括寿命测试、高温高湿存储、高温存储、低温存储、环境测试、热冲击、焊接抗性和可焊性测试。