EFMAF210 thru EFMAF280

Surface Mount Glass Passivated Super Fast Rectifiers

Reverse Voltage 50 to 600V Forward Current 2.0A

FEATURES

* Plastic package has Underwriters Laboratory

Flammability Classification 94V-0

* High temperature metallurgically

bonded construction

* For use in high frequency rectifier circuits

* Fast switching for high efficiency

* Cavity-free glass passivated junction

* Capable of meeting environmental standards

of MIL-S-19500

* 1.0 A operation at TC=75°C with no thermal runaway

* Typical IR less than 1.0µA

* High temperature soldering guaranteed:

260°C/10 seconds

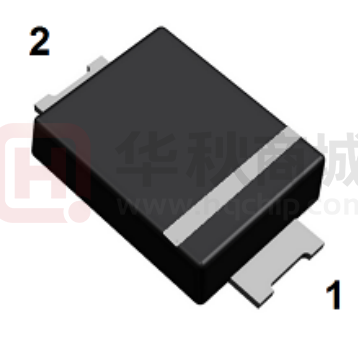

Mechanical Data

Case: JEDEC SMA-FL, molded plastic over glass die

Terminals: Plated leads, solderable per

MIL-STD-750, Method 2026

Polarity: Color band denotes cathode end

Mounting Position: Any

Weight: 28mg

Handling precautin:None

We declare that the material of product is

Haloggen free (green epoxy compound)

1.Electrical Characteristic

Maximum & Thermal Characteristics Ratings at 25°C ambient temperature unless otherwise specified.

Parameter Symbol

symbol

Making

EFMAF EFMAF EFMAF EFMAF EFMAF EFMAF EFMAF EFMAF

210

220

230

240

250

260

270

280

EF21

EF22

EF23

EF24

EF25

EF26

EF27

EF28

Unit

Maximum repetitive peak reverse voltage

VRRM

50

Maximum RMS voltage

VRMS

35

70

105

140

210

280

350

420

V

Maximum DC blocking voltage

VDC

50

100

150

200

300

400

500

600

V

Maximum average forward rectified current

lead length at Tc= 75°C

100

150

200

300

400

500

600

V

IF(AV)

2.0

A

Peak forward surge current 8.3ms single half sinewave superimposed on rated load (JEDEC Method)

IFSM

60

A

Typical thermal resistance (Note 2)

RθJA

RθJL

150

35

°C/W

TJ, TSTG

–50 to +150

°C

Operating junction and storage temperature range

Electrical Characteristics Ratings at 25°C ambient temperature unless otherwise specified.

Parameter Symbol

Maximum instantaneous forward voltage at 2.0A

symbol

VF

EFMAF EFMAF EFMAF EFMAF EFMAF EFMAF EFMAF EFMAF

210

220

230

240

250

260

270

280

1.7

0.95

1.25

Unit

V

IR

5.0

100

µA

Typical reverse recovery time (Note 1)

trr

35

ns

Typical junction capacitance at 4.0V, 1MHz

NOTES:

1. IF = 0.5A, IR = 1.0A, IRR = 0.25A

2. 8.0mm2 (.013mm thick) land areas

CJ

15.0

PF

Maximum DC reverse current TA = 25°C

at rated DC blocking voltage TJ = 125°C

Leshan Radio Company, LTD.

Rev.B Jul. 2017

1/3

�EFMAF210 thru EFMAF280

2.Ratings and Characteristic Curves ( TA = 25°C unless otherwise noted )

Fig. 2 – Maximum Non-repetitive Peak

Forward Surge Current

2.0

1

0.375" (9.5mm) Lead Length

0

Instantaneous Forward Current (A)

0

25

50 75 100 125

Case Temperature, °C

100

1.0

0.1

80

60

40

20

0

1

Tj=125℃

10

1.0

Tj=25℃

0.1

0

20

40

60

80

100

Percent of Rated Peak Reverse Voltage (%)

Fig 6. – Typical Junction Capacitance

20

100

10

1

0.1

1.0

10

t,Pulse duration,sec

Leshan Radio Company, LTD.

100

100

Fig 5. –typical transient thermal

impedance

0.01

10

Number of Cycles at 60Hz

0.01

0.8

1.0

1.2

1.4

1.6

Instantaneous Forward Voltage (V)

Junction Capacitance (pF)

1000

TJ = TJ max

8.3ms Single Half Sine-wave

(JEDEC Method)

Fig 4. – Typical Reverse Characteristics

TJ = 25°C

Pulse width = 300µs

1% Duty Cycle

10

50

150 175

Fig 3. – Typical Instantaneous Forward

Characteristics

0.01

0.6

Transient thermal impedance(°C/W)

Average Forward Rectified Current (A)

60 Hz

Resistive or

Inductive Load

Instantaneous Reverse Current (µA)

Average Forward Rectified Current (A)

Fig. 1 – Forward Current Derating Curve

100

TJ = 25°C

f = 1.0 MHz

Vsig = 50mVp-p

10

1.0

0.1

Rev.B Jul. 2017

1

10

Reverse Voltage (V)

2/3

�3.OUTLINE AND DIMENSIONS

SMA-FL

MIN

MAX

4.40

4.80

2.30

2.70

3.30

3.70

DIM

Typ.

A

4.60

B

2.60

C

3.50

D

0.55

E

0.90

1.20

1.05

F

0.11

0.21

0.17

G

1.30

1.50

1.40

I

0.90

K

0.80

L

0.20

All Dimensions in mm

GENERAL NOTES

1.Top package surface finish Ra0.4±0.2um

2.Bottom package surface finish Ra0.7±0.2um

4.SOLDERING FOOTPRINT

SMA-FL

DIM

(mm)

X

1.60

Y

1.80

B

3.70

Leshan Radio Company, LTD.

Rev.B Jul. 2017

3/3

�Title: Power Packages Product Packing Specification

功率产品包装规范

Document Number: APS-QA-QS-009

Proprietary Information

Revision C

Page 3 of 6

8.1.2 Label position and QA stamp position.(Empty area) 标签张贴位置及QA印章位置。(印章盖在标

签空白区

静电敏感器件标识

7英寸卷盘标签张贴及QA印章位置

13英寸卷盘标签张贴及QA印章位置

8.1.3 Ensure direction In the same reel. The same steel coil plate direction,With antistatic bubble to

package reel。Refer to the below picture.

同一箱内的卷盘方向一致,用防静电泡沫对卷盘进行包裹。

7英寸卷盘防静电泡沫包裹

13英寸卷盘防静电泡沫包裹

Do not copy without written permission from Advanced Power Semiconductor

�Title: Power Packages Product Packing Specification

功率产品包装规范

Document Number: APS-QA-QS-009

Proprietary Information

Revision C

Page 4 of 6

8.1.4 Put in the antistatic packing box after packaged reels. And QA stamp on the box label .

将包装好的卷盘放入防静电纸箱中,并在盒标签上盖章。

7 英寸卷盘内盒及标签

8.1.5 Product use printing inner box.

13 英寸卷盘内盒及标签

产品使用LRC印字内箱。

印字内盒

印字内盒

7英寸卷盘内箱印字(侧面)

13英寸卷盘内箱印字(正面)

8.1.6 Inner box packing quantity requirement.内盒包装数量要求。

Product

Description

QTY

SOD123-FL

1-10Reels

SOD323-HE

1-10Reels

SMA-FL

1-7Reels

SMB-FL

1-4Reels

8.1.7 With transparent tape sealing. 透明胶带封箱。

Do not copy without written permission from Advanced Power Semiconductor

�Title: Power Packages Product Packing Specification

功率产品包装规范

Document Number: APS-QA-QS-009

Proprietary Information

Revision C

Page 5 of 6

7英寸内箱封盒

13英寸内箱封盒

8.1.8 Outer box size and packing quantity requirement,外箱尺寸及包装数量要求。

Product

Description

卷盘尺寸

Height(H) Width(W) Length(L)

Max. Qty

Power

Device

7 英寸

410mm

400mm

445mm

12

Power

Device

13 英寸

410mm

400mm

445mm

5

统一方向

7 英寸卷盘产品装箱

13 英寸卷盘产品装箱

Do not copy without written permission from Advanced Power Semiconductor

�Title: Power Packages Marking & Taping

Specification

功率封装字模和编带规范

Proprietary Information

Document Number:APS-QA-QS-010

Revision C

Page 6 of 9

8.2 Standard Products Taping Specification

标准产品编带规范

8.2.1 Tape length of no component

空带长度说明

Taping leader length 引导部分:440mm±40mm ,Tape trailer 尾部:200mm±40mmt

160mm-240mm

400mm-480mm

TAPE LEADER

8.2.2 Component packaging orientation: The cathode lead is close to the carrier tape’s index hole.

产品放置方向:印阴极带引脚邻近载带索引孔

Do not copy without written permission from Advanced Power Semiconductor

�Title: Power Packages Marking & Taping

Specification

功率封装字模和编带规范

Proprietary Information

Document Number:APS-QA-QS-010

Revision C

Page 7 of 9

8.2.3 Tape enwind orientation

编带缠绕方向要求

Do not copy without written permission from Advanced Power Semiconductor

�

很抱歉,暂时无法提供与“EFMAF240”相匹配的价格&库存,您可以联系我们找货

免费人工找货