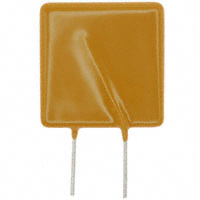

PolySwitch Resettable Devices – Line-Voltage-Rated Devices

PolySwitch Resettable Devices Line-Voltage-Rated Devices

PolySwitch LVR devices help protect electric motors and transformers used in commercial and home appliances from damage caused by mechanical overloads, overheating, stall, lost neutral and other potentially harmful conditions. The LVR line-voltage product line of polymeric positive temperature coefficient (PPTC) devices includes components that are rated for line voltages of 120VAC and 240VAC, for up to 2A of operating current at 20°C. They help protect against damage caused by both overcurrent surges and overtemperature faults, offer low resistance, and are compatibly sized with fuse solutions. Unlike traditional fuses, PolySwitch devices do not require replacement after a fault event. After power has been removed and the overcurrent condition eliminated, the circuit is restored to normal operating condition. Compared to bimetal breakers, they offer greater flexibility, longer lifespan, and lower electromagnetic interference (EMI). The PolySwitch LVR devices’ resettable functionality and latching attributes make them a reliable, cost-effective circuit protection solution for both intermittent- and continuous-operation motor applications. Their low resistance, fast time-to-trip, and low profile help circuit designers provide a safe and dependable product, comply with regulatory agency requirements, and reduce warranty repair costs. LVR/LVRL series are suitable for line-voltage applications up to a continuous operating voltage of 240VAC/120VAC. RoHS versions of all products are available.

Benefits

• Many product choices give engineers more design flexibility • Compatible with high-volume electronics assembly • Assist in meeting regulatory requirements • Higher voltage ratings allow use in new applications

Features

• RoHS compliant • Broadest range of radial-leaded resettable devices available in the industry • Current ratings from 50mA to 2A • Line voltage rating of 120VAC and 240VAC • Agency recognition : UL, CSA, TÜV • Fast time-to-trip • Low resistance

10

Applications

• Electromagnetic loads • Game machines • Industrial controls • Lighting ballast • Loudspeakers • Medical equipment • Motors, fans and blowers • POS equipment • Satellite video receivers • Security and fire alarm systems • Test and measurement equipment • Transformers • USB hubs, ports and peripherals

139

�Table L1 Product Series - Current Rating, Voltage Rating / Typical Resistance for LVR Devices

Voltage Rating Hold Current (A) 0.050 0.080 0.120 0.160 0.250 0.330 0.400 0.550 0.750 1.000 1.250 1.350 2.000 25.00Ω 9.800Ω 4.800Ω 3.400Ω 1.700Ω 1.000Ω 0.800Ω 0.590Ω 0.400Ω 0.276Ω 0.209Ω — 0.110Ω — — — — — — — — 0.325Ω 0.224Ω 0.148Ω 0.138Ω 0.097Ω LVR 240VAC / 120VAC LVRL 120VAC

Table L2 Thermal Derating for LVR Devices [Hold Current (A) at Ambient Temperature (°C)]

Maximum Ambient Temperature Part Number LVR/LVRL LVR005N LVR008N LVR012 LVR016 LVR025 LVR033 LVR040 LVR055 LVR075 LVR100 LVR125 LVR200 LVRL075 LVRL100 LVRL125 LVRL135 LVRL200 0.08 0.12 0.18 0.24 0.38 0.50 0.61 0.80 1.23 1.65 2.06 3.30 1.08 1.40 1.80 2.00 3.05 0.06 0.10 0.15 0.20 0.32 0.42 0.51 0.68 0.98 1.30 1.63 2.60 0.93 1.19 1.53 1.65 2.55 0.05 0.08 0.12 0.16 0.25 0.33 0.40 0.55 0.75 1.00 1.25 2.00 0.75 1.00 1.25 1.35 2.00 0.05 0.08 0.12 0.16 0.25 0.33 0.40 0.54 0.74 0.94 1.20 1.97 0.74 0.94 1.20 1.29 1.97 0.04 0.07 0.10 0.13 0.21 0.27 0.33 0.46 0.60 0.80 1.00 1.60 0.64 0.82 1.04 1.12 1.72 0.04 0.06 0.09 0.11 0.18 0.23 0.28 0.40 0.56 0.75 0.94 1.50 0.57 0.73 0.94 1.01 1.55 0.03 0.05 0.07 0.10 0.15 0.20 0.24 0.35 0.49 0.65 0.81 1.30 0.51 0.65 0.83 0.90 1.39 0.03 0.04 0.06 0.08 0.13 0.17 0.20 0.29 0.45 0.60 0.75 1.20 0.44 0.57 0.73 0.78 1.22 0.02 0.03 0.04 0.05 0.09 0.11 0.14 0.22 0.41 0.55 0.69 1.10 0.35 0.45 0.60 0.65 0.98 -20°C 0°C 20°C 25°C 40°C 50°C 60°C 70°C 85°C

10

Figure L1 Thermal Derating Curve for LVR Devices

A= B= C= LVR075-LVR200 LVRL075-LVRL200 LVR005N-LVR055

Figure L1

180 170 160

A B C

% of rated hold and trip current

150 140 130 120 110 100 90 80 70 60 50 40 30 -30

A C B

-20 -10 0 10 20 30 40 50 60 70 80 90

Ambient Temperature (˚C)

140

RoHS Compliant, ELV Compliant

�PolySwitch Resettable Devices – Line-Voltage-Rated Devices

Table L3 Electrical Characteristics for LVR Devices*

Part Number LVR/LVRL LVR005NK LVR005NS LVR008NK LVR008NS LVR012K LVR012S LVR016K LVR016S LVR025K LVR025S LVR033K LVR033S LVR040K LVR040S LVR055K LVR055S LVR075S LVR100S LVR125S LVR200S LVRL075S LVRL100S LVRL125S LVRL135S LVRL200S 0.05 0.05 0.08 0.08 0.12 0.12 0.16 0.16 0.25 0.25 0.33 0.33 0.40 0.40 0.55 0.55 0.75 1.00 1.25 2.00 0.75 1.00 1.25 1.35 2.00 0.12 0.12 0.19 0.19 0.30 0.30 0.37 0.37 0.56 0.56 0.74 0.74 0.90 0.90 1.25 1.25 1.50 2.00 2.50 4.00 1.52 2.00 2.50 2.70 4.20 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 120 240 240 240 240 120 120 120 120 120 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 135 265 265 265 265 135 135 135 135 135 1.0 20.0 1.0 20.0 1.2 20.0 1.2 20.0 1.2 20.0 1.2 20.0 2.0 20.0 2.0 20.0 3.5 20.0 3.5 20.0 4.5 20.0 4.5 20.0 5.5 20.0 5.5 20.0 7.0 20.0 7.0 20.0 7.5 10.0 12.5 20.0 7.5 10.0 12.5 13.5 20.0 0.9 0.9 0.9 0.9 1.0 1.0 1.4 1.4 1.5 1.5 1.7 1.7 2.0 2.0 3.4 3.4 2.6 2.9 3.3 4.5 1.8 2.2 2.0 2.8 3.9 0.25 0.25 0.40 0.40 0.60 0.60 0.80 0.80 1.25 1.25 1.65 1.65 2.00 2.00 2.75 2.75 3.75 5.00 6.25 10.00 3.75 5.00 6.25 6.75 10.00 10.0 10.0 10.0 10.0 15.0 15.0 15.0 15.0 18.5 18.5 21.0 21.0 24.0 24.0 26.0 26.0 18.0 21.0 23.0 28.0 14.0 13.6 18.0 20.0 36.0 18.500 18.500 7.400 7.400 3.000 3.000 2.500 2.500 1.300 1.300 0.770 0.770 0.600 0.600 0.450 0.450 0.316 0.218 0.165 0.089 0.250 0.179 0.117 0.109 0.075 31.000 31.000 12.000 12.000 6.500 6.500 4.100 4.100 2.100 2.100 1.240 1.240 0.970 0.970 0.730 0.730 0.483 0.334 0.253 0.131 0.400 0.269 0.179 0.167 0.117 65.000 65.000 26.000 26.000 12.000 12.000 7.800 7.800 3.800 3.800 2.600 2.600 1.900 1.900 1.450 1.450 0.839 0.580 0.440 0.221 0.690 0.470 0.320 0.300 0.205 [0.51mm(24)] [0.51mm(24)] [0.51mm(24)] [0.51mm(24)] [0.51mm(24)] [0.51mm(24)] [0.51mm(24)] [0.51mm(24)] [0.64mm(22)] [0.64mm(22)] [0.64mm(22)] [0.64mm(22)] [0.64mm(22)] [0.64mm(22)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] [0.81mm(20)] IH (A) IT (A) VMAX† Operating Interrupt (VAC) (VAC) IMAX† Interrupt (A) PD Typ (W) Max. Time-to-trip (A) (s) RMIN (Ω) RMAX (Ω) R1MAX (Ω) Lead Size [mm (AWG)]

10

Notes: : Hold current: maximum current device will pass without interruption in 20°C still air. IH : Trip current: minimum current that will switch the device from low resistance to high resistance in 20°C still air. IT VMAX Operating: Maximum continuous voltage device can withstand without damage at rated current. VMAX Interrupt : Under specified conditions this is the highest voltage that can be applied to the device at the maximum interrupt current. IMAX Interrupt : Maximum fault current device can withstand without damage at rated voltage. : Power dissipated from device when in the tripped state in 20°C still air. PD : Minimum resistance of device as supplied at 20°C unless otherwise specified. RMIN : Maximum resistance of device as supplied at 20°C unless otherwise specified. RMAX : Maximum resistance of device when measured one hour post trip at 20°C unless otherwise specified. R1MAX * Electrical characteristics determined at 20°C. † See Application Limitations on next page.

RoHS Compliant, ELV Compliant

141

�Warning : Application Limitations for the LVR Product Line

1) Users should independently evaluate the suitability of and test each product selected for their own application. 2) This product should not be used in an application where the maximum interrupt voltage or maximum interrupt current can be exceeded in a fault condition. Operation beyond the maximum ratings or improper use may result in device damage and possible electrical arcing and flame. 3) A PPTC device is not a fuse - it is a nonlinear thermistor that limits current. Under a fault condition all PPTC devices go into a high resistance state but do not open circuit, so hazardous voltage may be present at PPTC locations. 4) The devices are intended for protection against damage caused by occasional overcurrent or overtemperature fault conditions and should not be used when repeated fault conditions or prolonged trip events are anticipated. 5) In most applications power must be removed and the fault condition cleared in order to reset a PPTC device; however under certain unusual conditions, a PPTC device may automatically reset. PPTC devices should not be used in an application where an automatic reset could create a safety hazard, such as garbage disposals and blenders. Appropriate qualification testing should be performed. 6) It is the responsibility of the user to determine the need for back up or failsafe protection to prevent damage that may occur in the event of abnormal function or failure of the PPTC device. 7) Operation in circuits with a large inductance can generate a circuit voltage (Ldi/dt) above the rated voltage of a PPTC device.This product should not be used in an application where the maximum interrupt voltage or maximum interrupt current can be exceeded by inductive spikes. 8) Devices are not recommended for reflow soldering. 9) Device performance can be impacted negatively if devices are handled in a manner inconsistent with recommended electronic, thermal, or mechanical procedures for electronic components. 10) PPTC devices are not recommended for installation in applications where the device is constrained such that its PTC properties are inhibited, for example in rigid potting materials or in rigid housings, which lack adequate clearance to accommodate device expansion. 11) Contamination of the PPTC material with certain silicone-based oils or some aggressive solvents can adversely impact the performance of the devices.

Figure L2-L5 Dimension Figures for LVR Devices

Figure L2

A E

Figure L3

A E

B

B

D C C to C LL C C to C LL

D

10

Figure L4

A E

Figure L5

A E

B

B

D

D C C to C LL

C C to C LL

142

RoHS Compliant, ELV Compliant

�PolySwitch Resettable Devices – Line-Voltage-Rated Devices

Table L4 Dimensions for LVR Devices in Millimeters (Inches)

A Part Number LVR/LVRL LVR005NK LVR005NS LVR008NK LVR008NS LVR012K LVR012S LVR016K LVR016S LVR025K LVR025S LVR033K LVR033S LVR040K LVR040S LVR055K LVR055S LVR075S LVR100S LVR125S LVR200S LVRL075S LVRL100S LVRL125S LVRL135S LVRL200S — — — — — — — — — — — — — — — — — — — — — — — — — 6.9 (0.27) 6.9 (0.27) 7.2 (0.28) 7.2 (0.28) 8.3 (0.33) 8.3 (0.33) 9.9 (0.39) 9.9 (0.39) 9.6 (0.38) 9.6 (0.38) 11.4 (0.45) 11.4 (0.45) 11.5 (0.46) 11.5 (0.46) 14.0 (0.55) 14.0 (0.55) 11.5 (0.45) 18.7 (0.74) 21.2 (0.84) 24.9 (0.98) 10.9 (0.43) 11.5 (0.45) 14.0 (0.55) 16.3 (0.64) 23.5 (0.93) — — — — — — — — — — — — — — — — — — — — — — — — — 12.1 (0.48) 9.9 (0.39) 12.4 (0.49) 10.2 (0.40) 12.9 (0.51) 10.7 (0.43) 13.8 (0.54) 12.5 (0.50) 18.8 (0.74) 17.4 (0.69) 19.0 (0.75) 16.5 (0.65) 20.9 (0.82) 19.5 (0.77) 22.4 (0.88) 21.7 (0.85) 23.4 (0.92) 24.4 (0.96) 27.4 (1.08) 33.8 (1.33) 17.0 (0.67) 20.1 (0.79) 21.7 (0.85) 21.7 (0.85) 31.8 (1.25) 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.1 8.9 8.9 8.9 4.3 4.3 4.3 4.3 9.4 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 5.8 6.1 11.4 11.4 11.4 5.8 5.8 5.8 5.8 10.9 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 5.1 (0.20) 5.1 (0.20) 5.1 (0.20) 5.1 (0.20) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) 7.6 (0.30) — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — 4.6 (0.18) 4.6 (0.18) 4.6 (0.18) 4.6 (0.18) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 4.1 (0.16) 4.1 (0.16) 4.8 (0.19) 5.1 (0.20) 5.3 (0.21) 6.1 (0.24) 4.1 (0.16) 4.1 (0.16) 4.1 (0.16) 4.1 (0.16) 4.1 (0.16) L5 L5 L5 L5 L5 L5 L4 L4 L5 L5 L3 L5 L3 L5 L3 L5 L3 L4 L2 L4 L2 L4 L2 L4 L2 (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.16) (0.24) (0.35) (0.45) (0.35) (0.45) (0.35) (0.45) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.17) (0.23) (0.37) (0.43) Min. Max. Min. B Max. Min. C Max. Min. D Max. Min. E Max. Figure

10

RoHS Compliant, ELV Compliant

143

�Figure L6 Typical Time-to-trip curves at 20°C for LVR Devices

Figure L6

K L M N O P Q = = = = = = = LVRL100 LVR100 LVRL125 LVR125 LVRL135 LVRL200 LVR200

1000

LVR/LVRL A = LVR005N B = LVR008N C = LVR012 D = LVR016 E = LVR025 F = LVR033 G = LVR040 H = LVR055 I = LVRL075 J = LVR075

L

100

E B A C D

J FG H I

MN

Q O P

Time-to-trip (s)

K

10

N H

1

G A B C D E F

J I

L MO K

Q P

0.1 0.1 1 10 100

Fault Current (A)

Table L5 Physical Characteristics and Environmental Specifications for LVR Devices

LVR/LVRL Physical Characteristics

Lead material LVR005N-016 : Tin-plated copper, (24AWG), ø0.51mm (0.020in.) LVR025-040 : Tin-plated copper, (22AWG), ø0.64mm (0.025in.) LVR055-200 : Tin-plated copper, (20AWG), ø0.81mm (0.032in.) LVRL : Tin-plated copper, (20AWG), ø0.81mm (0.032in.) Solderability per ANSI/J-STD-002 Category 3 Per IEC-STD 68-2-20, Test Tb, Method 1A, Condition B, can withstand 10 seconds at 260°C ±5°C LVR005N-055 : Cured, flame-retardant epoxy polymer, meets UL 94V-0 LVR075-200 : Cured, flame-retardant modified silicone, meets UL 94V-0 LVRL : Cured, flame-retardant epoxy polymer, meets UL 94V-0

Soldering characteristics Solder heat withstand Insulating material

Note: Devices are not designed to be placed through a reflow process.

Environmental Specifications

Test Passive aging Humidity aging Thermal shock Solvent resistance Conditions 70°C, 1000 hours 85°C, 1000 hours 85°C, 85%RH, 1000 hours 85°C, -40°C (10 times) MIL-STD-202, Method 215F Resistance Change ±10% ±10% ±20% ±15% No change

10

Agency Recognitions for LVR Devices

UL CSA TÜV File # E74889 File # CA78165 Certificate number available on request (per IEC 60730-1).

144

RoHS Compliant, ELV Compliant

�PolySwitch Resettable Devices – Line-Voltage-Rated Devices

Table L6 Packaging and Marking Information for LVR Devices

Bag Quantity 500 — 500 — 500 — 500 — 500 — 500 — 500 — 500 — 500 — 500 — 500 — 500 — 500 — 500 — 500 500 — 500 250 250 250 500 500 500 500 250 Tape & Reel Quantity — 1,500 — 1,500 — 1,500 — 1,500 — 2,000 — 2,000 — 2,000 — 2,000 — 2,000 — 2,000 — 2,000 — 2,000 — 2,000 — 2,000 — — 1,000 — — — — — — — — — Ammo Pack Quantity — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — Standard Package Quantity 10,000 7,500 10,000 7,500 10,000 7,500 10,000 7,500 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000 5,000 10,000 5,000 5,000 5,000 10,000 10,000 10,000 10,000 5,000

Part Number LVR/LVRL LVR005NK LVR005NK-2 LVR005NS LVR005NS-2 LVR008NK LVR008NK-2 LVR008NS LVR008NS-2 LVR012K LVR012K-2 LVR012S LVR012S-2 LVR016K LVR016K-2 LVR016S LVR016S-2 LVR025K LVR025K-2 LVR025S LVR025S-2 LVR033K LVR033K-2 LVR033S LVR033S-2 LVR040K LVR040K-2 LVR040S LVR040S-2 LVR055K LVR055S LVR055S-2 LVR075S LVR100S LVR125S LVR200S LVRL075S LVRL100S LVRL125S LVRL135S LVRL200S

Part Marking L005 L005 L005 L005 L008 L008 L008 L008 L012 L012 L012 L012 L016 L016 L016 L016 L025 L025 L025 L025 L033 L033 L033 L033 L040 L040 L040 L040 L055 L055 L055 L075 L100 L125 L200 L075 L100 L125 L135 L200

Agency Recognition UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV UL,CSA, TÜV

10

RoHS Compliant, ELV Compliant

145

�Table L7 Tape and Reel Specifications for LVR Devices

LVR devices are available in tape and reel packaging per EIA468-B/IEC60286-2 standards. See Figures L7 and L8 for details.

Description Carrier tape width Hold-down tape width Top distance between tape edges Sprocket hole position Sprocket hole diameter Abscissa to plane (straight lead) (LVR005N to LVR016) Abscissa to plane (kinked lead) (LVR005N to LVR016) Abscissa to top (LVR005N to LVR016) Abscissa to top* (LVR025 to LVR055) Overall width with lead protrusion (LVR005N to LVR016) Overall width with lead protrusion (LVR025 to LVR055) Overall width without lead protrusion (LVR005N to LVR016) Overall width without lead protrusion (LVR025 to LVR055) Lead protrusion Protrusion of cut-out Protrusion beyond hold-down tape Sprocket hole pitch Device pitch (LVR005N to LVR040) Device pitch (LVR055) Pitch tolerance Tape thickness Overall tape and lead thickness (LVR005N to LVR040) Overall tape and lead thickness (LVR055) Splice sprocket hole alignment Body lateral deviation Body tape plane deviation Ordinate to adjacent component lead Lead spacing* Reel width (LVR005N to LVR040) Reel width* (LVR055) Reel diameter Space between flanges* (LVR005N to LVR040) Space between flanges* (LVR055) Arbor hold diameter Core diameter* Box Consecutive missing places EIA Mark W W4 W6 W5 D0 H H0 H1 H1 C1 C1 C2 C2 L1 L I2 P0 — — — t t1 t1 — h p P1 F w2 w2 a w1 w1 c n — — — Dimension (mm) 18 11 3 9 4 18.5 16.0 32.2 45.0 43.2 56.0 42.5 56.0 1.0 11.0 Not specified 12.7 12.7 25.4 20 consecutive 0.9 1.5 2.3 0 0 0 3.81 5.08 56.0 63.5 370.0 48.0 55.0 26.0 91.0 64/372/362 None 0.1% Tolerance -0.5/+1.0 Minimum Maximum -0.5/+0.75 ± 0.2 ± 2.5 ± 0.5 Maximum Maximum Maximum Maximum Maximum Maximum Maximum Maximum — ± 0.3 ± 0.3 ± 0.6 ±1 Maximum Maximum Maximum ± 0.3 ± 1.0 ± 1.3 ± 0.7 +0.75/-0.5 Maximum Maximum Maximum Maximum Maximum ± 12.0 Maximum Maximum — Maximum

10

Empty places per reel

*Differs from EIA specification.

146

RoHS Compliant, ELV Compliant

�PolySwitch Resettable Devices – Line-Voltage-Rated Devices

Figure L7 EIA Referenced Taped Component Dimensions for LVR Devices

h h p p

Reference plane H1 P1 F L A B W4 H0 W5 W I2 L1 P0 D0 Direction of unreeling H H1 C2 C1

Cross section A-B t

Figure L8 EIA Referenced Reel Dimensions for LVR Devices

Reel Upper side n Type a Direction of unreeling Lower side

c

w1 w2

Cross section Optional shape: Circular or polygonal

Part Numbering System for LVR Devices

LVR 075 S 2

Packaging Blank = Packaged in bags -1 = 25.4mm (1.0 inch) minimum lead length -2 = Tape and reel -X.X = Special lead cut length (inch) Modifier K = Standard kinked lead S = Straight lead Hold Current Indicator Product Series LVR = 240V rated LVRL = 120V rated

10

RoHS Compliant, ELV Compliant

147

�10

148

�