MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

1. Features and Benefits

2. Application Examples

Analog Signal Processing

Quad Switched Hall Plate

Chopper Stabilized Amplifier

Linear Analog Ratiometric Output Voltage

Programmable Output Quiescent Voltage (VOQ)

-100%VDD…200%VDD Range

Programmable Magnetic Sensitivity

Programmable Low Pass Filter

Programmable Clamping Voltage

Programmable Temperature Compensation

Melexis ID Number

Programmable Customer ID Number

Lead-free package

Linear Position Sensing

Rotary Position Sensing

Current Sensing

Magnetic Field Measurement

Ordering Information

Product Code

MLX90251

MLX90251

MLX90251

MLX90251

MLX90251

MLX90251

MLX90251

MLX90251

Temperature Code

E

E

E

E

L

L

L

L

Legend:

Temperature Code:

Package Code

VA

VA

VA

VA

VA

VA

VA

VA

Option Code

FAA-000

FAA-100

FAA-200

FAA-300

FAA-000

FAA-100

FAA-200

FAA-300

Package Code:

Option Code:

Packing Form:

L for Temperature Range -40°C to 150°C

E for Temperature Range -40°C to 85°C

VA for Plastic Single in Line thickness 1.1-1.2mm

See section 12.4

BU for Bulk

Ordering example:

MLX90251LVA-FAA-000-BU

REVISION 016 – 25 JUN 2021

3901090251

Packing Form Code

BU

BU

BU

BU

BU

BU

BU

BU

Page 1 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

3. Functional Diagram

Supply

4. General Description

1

Filter

OPA

OPA

OPA

4

3

DAC

DAC

DAC

DAC

DAC

DAC

2

Shift Register

E E P R O M

Figure 1-1 Functional Diagram

VDD

Test

VSS (Ground)

VOUT

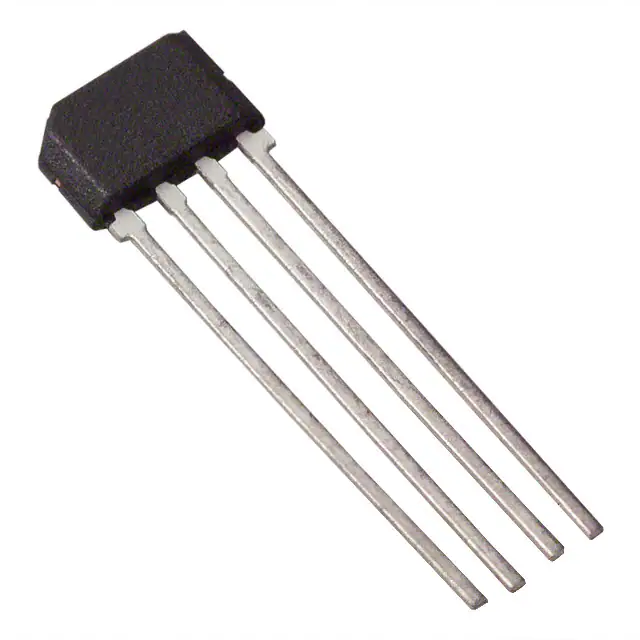

Pin Out

VA package

1

2

3

4

Program

decoder

The MLX90251 is a CMOS Programmable, Ratiometric

Linear Hall Effect sensor IC. The linear output voltage is

proportional to the magnetic flux density. The

ratiometric output voltage is proportional to the

supply voltage. The MLX90251 possesses active error

correction circuitry, which virtually eliminates the

offset errors normally associated with analog Hall

Effect devices. All the parameters of the MLX90251

transfer characteristic are fully programmable. The

VOQ (VOUT @ B = 0 Gauss), the Sensitivity, the slope

polarity, the Output Clamping levels, the thermal

Sensitivity drift, the internal bias point and a low-pass

filter are all programmable in end-user applications.

The MLX90251 has a very stable thermal

compensation for both the Sensitivity and the VOQ over

a broad temperature range. For traceability purpose

the MLX90251 will carry a unique ID number

programmed by Melexis and 24 bits of EEPROM

memory are allocated for a user programmed serial

number.

Table 1: Pin out

REVISION 016 – 25 JUN 2021

3901090251

Page 2 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

Table of Contents

1. Features and Benefits ................................................................................................................... 1

2. Application Examples .................................................................................................................... 1

3. Functional Diagram....................................................................................................................... 2

4. General Description ...................................................................................................................... 2

5. Glossary of Terms ......................................................................................................................... 4

6. Maximum Ratings ......................................................................................................................... 4

7. Detailed Block Diagram ................................................................................................................. 5

7.1. Detailed Description .................................................................................................................... 5

8. General Electrical Specifications ................................................................................................... 6

9. Programming Range ..................................................................................................................... 7

10. Timing Specifications .................................................................................................................. 7

11. Accuracy ..................................................................................................................................... 7

12. Programmable Features ............................................................................................................. 8

12.1. Output Quiescent Voltage (VOQ)................................................................................................ 9

12.2. Thermal VOQ Drift (DRIFT) .......................................................................................................... 9

12.3. Sensitivity, Rough Gain and Fine Gain ..................................................................................... 10

12.4. Sensitivity Range Selection ...................................................................................................... 11

12.5. Sensitivity Polarity (INVERT) .................................................................................................... 13

12.6. Clamping Levels (CLAMPLOW, CLAMPHIGH) .......................................................................... 13

12.7. Filter (FILTER) .......................................................................................................................... 14

12.8. Sensitivity Temperature Compensation (TC, TCW, TC2) .......................................................... 15

12.9. Diagnostic Output Level (FAULTLEV) ....................................................................................... 15

12.10. The EEPROM, Parity, and Melexis CRC .................................................................................. 15

12.11. Output Amplifier Configuration (MODE) ............................................................................... 16

12.12. Memory Lock (MEMLOCK) .................................................................................................... 16

12.13. IC traceability ........................................................................................................................ 16

13. Performance Graphs ................................................................................................................. 17

14. Applications Information........................................................................................................... 18

14.1. Application Circuits – VA-package ........................................................................................... 18

14.2. Programming the Sensor......................................................................................................... 18

14.3. Calibration Procedure ............................................................................................................. 19

15. Standard information regarding manufacturability of Melexis products with different soldering

processes ....................................................................................................................................... 20

16. ESD Precautions........................................................................................................................ 20

17. Package Information ................................................................................................................. 21

17.1. VA Package Outline and Hall Plate Position ............................................................................ 21

18. Contact ..................................................................................................................................... 22

19. Disclaimer................................................................................................................................. 22

REVISION 016 – 25 JUN 2021

3901090251

Page 3 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

5. Glossary of Terms

Term

Explanation

mT (milli-Tesla)

Unit of measurement for magnetic flux density. 1mT is equal to 10 Gauss.

VOQ (Output Quiescent Voltage)

Output voltage at zero magnetic field, VOUT for B = 0 mT.

Sensitivity

Change in output voltage versus change in magnetic field (Δ VOUT / Δ B)

TempCo (Sensitivity

Temperature Compensation)

PTC (Programming Through the

Connector)

Change in Sensitivity over temperature.

Listed in units of ppm / °C (where 100ppm / °C. = 0.01% / °C)

MSB

Most Significant Bit.

LSB

Least Significant Bit.

Melexis in-circuit programming protocol.

6. Maximum Ratings

Parameter

Units

Maximum Supply Voltage, VDD_MAX

(over Voltage)

30 V

Maximum Supply Current, IDD_MAX

(Over Voltage)

50 mA

Reverse Voltage, VDD_REV

- 15 V

Reverse Supply Current, IDD_REV

- 85 mA

Positive Output Voltage, VOUT_MAX

24 V

Positive Output Current, IOUT_POS_FAULT

40 mA

Reverse Output Voltage, VOUT_REV

- 0.7 V

Reverse Output Current, IOUT_REV_FAULT

-50 mA

Operating Ambient Temperature

Range, TA

-40°C to 150°C

Storage Temperature Range, TS

-55°C to 165°C

Magnetic Flux Density

Infinite

Table 2: Absolute Maximum Ratings

Note: Exceeding the absolute maximum ratings may cause permanent damage. Exposure to absolute-maximum-rated

conditions for extended periods may affect device reliability.

REVISION 016 – 25 JUN 2021

3901090251

Page 4 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

EEPROM

Current

Source

Hall

Plate

Chopper

Stabilized

Amplifier

InvertSlope

RG:

4 Bits

Sample & Hold

Filter

Offset Stage

Clamp

Stage

Output

Amplifier

Output

Analog Signal Processing

7. Detailed Block Diagram

TCW: 3 Bits

TC: 5 Bits

TC^2: 6 Bits

Lock Out:

MemLock

MLXLock

AGND:

10 Bits

CLAMP

Hi: 10 Bits

Lo: 10 Bits

FG:

10 Bits

FILTER:

4 Bits

OFFSET: 10 Bits

DRIFT: 4 Bits

MODE:

2 Bits

Fault

Level

Figure 5-1 Detailed Block Diagram

7.1. Detailed Description

Integrated on the MLX90251 is a temperature-compensated quad switched Hall plate, chopper

stabilized amplifiers, adjustable output filter, output driver, voltage protection circuitry and a

programmable EEPROM with security and redundancy. Programming the EEPROM allows each device to

be calibrated in the application.

In normal operation data stored in the EEPROM feeds a register, RAM that updates internal DACs and

switches that effect the operation of the device. In programming mode the RAM can be directly

accessed to allow faster calibration of the parameters. Communication to the device is done using

Melexis' PTC serial interface.

REVISION 016 – 25 JUN 2021

3901090251

Page 5 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

8. General Electrical Specifications

DC operating parameters at VDD = 5V (unless otherwise specified) and for TA as specified by the

temperature range (E or L).

Parameter

Symbol

Nominal Supply Voltage

VDDNOM

Operating Supply Voltage

VDD

Nominal Supply Current

IDDNOM

Supply Current

Min

Typical

Max

Units

-

5

-

V

4.5

-

5.5

V

VDD = VDDNOM

4.0

7.0

8.0

mA

IDD

VDD = 4.5 … 5.5 V

3.0

-

9.0

mA

VOUTPD

Pull Down Load ≥ 10 kΩ

no clamping

2

96

%VDD

VOUTPU

Pull Up Load ≥ 10 kΩ

no clamping

5

97

%VDD

IOUT

VDD = VDDNOM

-1.25

1.25

mA

-12

4

-4

12

mA

mA

0.5

%VDD

1

Output Voltage Swing

Output Current

Output Short-Circuit

Current

Test Conditions

IOUTSC+

IOUTSC-

VDD = VDDNOM

Output shorted to supplypermanent

Output shorted to groundpermanent

VOUT1

Broken supply,

Pull-down load > 10 kΩ

0

VOUT2

Broken ground,

Pull-down load > 10 kΩ

94

96

100

%VDD

VOUT3

Broken supply,

Pull-up load > 10 kΩ

0

3

5

%VDD

VOUT4

Broken ground,

Pull-up load > 10 kΩ

99.5

100

%VDD

Power on Reset

VDD_POR

Voltage on VDD

1.5

3.8

V

Over Voltage Detection

VDD_OVD

Voltage on VDD

6.5

8.5

V

Diagnostic Output Voltage

Table 3: Electrical Specifications

The ratiometric output voltage is proportional to the supply voltage. When using the supply voltage as a reference for

an A/D converter, fluctuations of ±10% in supply voltage are compensated.

1

REVISION 016 – 25 JUN 2021

3901090251

Page 6 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

9. Programming Range

TA programming 20°C to 30°C.

Parameter

Symbol

Test Conditions

Min

Output Quiescent Voltage

VOQ

AGND = Default

AGND = 0…1023

Sensitivity

S

Output Clamping Voltage

Low

ClampLo

Output Clamping Voltage

High

ClampHi

Temperature Compensation TempCo

Max

Units

-10

-100

110

200

%VDD

%VDD

2.6

210

mV/mT

0

100

%VDD

0

100

%VDD

0

2300

ppm / °C

1st order

Typical

Table 4: Programming Range Specifications

10. Timing Specifications

DC operating parameters at VDD = 5V (unless otherwise specified) and for TA as specified by the

temperature range (E or L).

Parameter

Symbol

Test Conditions

Power On Delay

TPO

FILTER = 0, RG = 0

FILTER = 0, RG = 15

FILTER = 15, RG = 0

FILTER = 15, RG = 15

Step Response Time

RG = 0 to 3, FILTER = 0

RG = 4 to 7, FILTER = 0

RG = 8 to 11, FILTER = 0

RG = 12 to 15, FILTER = 0

Min

Typical

Max

Units

0.4

0.6

1.1

5

0.8

1.2

2.2

10

ms

ms

ms

ms

32

64

132

264

μs

μs

μs

μs

24

48

100

200

Table 5: Timing Specifications

11. Accuracy

DC operating parameters at VDD = 5V (unless otherwise specified) and for TA as specified by the

temperature range (E or L).

Parameter

Symbol††

Test Conditions

Min

Thermal Voq Drift

Δ VOQ

VOQ = 2.5V , 25°C / 150°C

VOQ = 2.5V2, 25°C / -40°C

T

Life Time Drift of the L T

Δ Δ VOQ

Thermal Voq Drift

Life Time Voq Drift

ΔLΔVOQ

Life Time Sensitivity Drift

ΔLΔS

2

2

Typical

Max

Units

- 0.2

- 0.4

+ 0.2

+ 0.4

%VDD

%VDD

- 0.2

+ 0.2

%VDD

- 0.3

-1

+ 0.3

+1

%VDD

%

For other test conditions, please contact the Melexis Sales representative of your area.

REVISION 016 – 25 JUN 2021

3901090251

Page 7 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

Parameter

Symbol††

Sensitivity

Coefficient 3

Test Conditions

Temperature TCs

Thermal Drift of Sensitivity

Temperature Compensation

Thermal

Drift

Output

Clamping Levels

Life Time Drift Output

Clamping Levels 4

Linearity error

ΔTTC

ΔTVOUTCLAMP

0 to 500 ppm / °C

500 to 1200 ppm / °C

1200 to 2300 ppm / °C

VA-package

GO-package

ΔLVOUTCLAMP

Min

Max

Units

ppm / °C

ppm / °C

ppm / °C

ppm / °C

- 0.4

± 100

± 150

± 200

150

250

+ 0.4

- 0.2

+ 0.2

%VDD

Le

Typical

0.2

%VDD

%

Table 6: Accuracy Specifications

12. Programmable Features

The MLX90251 has many programmable features for adjusting the output characteristic. The features

are utilized by writing data into the redundant non-volatile EEPROM. Below is a quick list and

description of all the programmable parameters. Many of the parameters are set by Melexis and they

are not used by the end customer. Later sections of the data sheet give details on how the parameters

are used.

Parameter

Symbol

Description

Number of Bits

Default

AGND

Coarse adjustment of VOQ.

10

Trimmed

Analog Clock Choice

CKANACH

Adjustment for amplifier clock generator.

2

Preset

Clamping High

CLAMPHIGH Adjustment of upper output clamping

voltage.

10

512

Clamping Low

CLAMPLOW Adjustment of lower output clamping

voltage.

10

512

Customer ID††

CUSTID

Open bits for customer’s ID

programming.

24

Preset

Offset Drift†

DRIFT

VOQ temperature drift compensation.

4

Trimmed

EEPROM Fault Level

FAULTLEV

Output state for EEPROM parity error.

1

0

Fine Gain

FG

Fine adjustment for Sensitivity.

10

0

Filter

FILTER

Adjustment for low pass output filter.

4

0

Invert Slope

INVERT

Sensitivity polarity selection.

1

0

Memory Lock

MEM_LOCK Used to lock the entire EEPROM.

1

0

Melexis ID

MLX_ID

Melexis IC identification number.

MLX_LOCK

Used to lock Melexis area of the EEPROM.

1

0

MODE

Adjustment for output stage amplifier.

2

1

OFFSET

Fine adjustment of VOQ.

10

0

OSCADJ

Chip oscillator frequency adjustment.

4

Preset

Internal Bias Point

†

†

Melexis Lock

†

Output Driver

†

Offset DAC

Oscillator Adjust

3

4

†

Preset

Valid for Rough Gain within the specified option code.

∆L = Life Time Drift (based on HTOL data [1000 hours @ 150°C]).

∆T = Thermal Drift.

REVISION 016 – 25 JUN 2021

3901090251

Page 8 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

Parameter

Symbol

Description

Number of Bits

Default

EEPROM Parity

PARITY

Ensures the integrity of the EEPROM data.

3

Calculated

Rough Gain

RG

Rough adjustment for Sensitivity.

4

0

Slow

SLOW

Amplifier speed adjustment.

1

Preset

Temperature

Compensation Window

TCW

Range adjustment for Sensitivity

Temperature Compensation.

3

0

Temperature

Compensation

TC

Fine adjustment of Sensitivity

Temperature Compensation.

5

0

Linearization adjustment of the Sensitivity

Temperature Compensation.

6

0

†

2nd Order Temperature TC2

Compensations

Table 7: Programmable Parameters

†

Melexis parameter adjusted at final test.

Not included in redundant area of the EEPROM.

††

12.1. Output Quiescent Voltage (VOQ)

Two parameters, AGND and OFFSET, are used for adjustment of the VOQ. The AGND is a 10 bit

parameter for coarse adjustment of VOQ. It has a resolution of approximately 0.014V and a range from 100%VDD to 200%VDD. The OFFSET is a 10 bit parameter with a resolution of approximately -0.005V.

The OFFSET parameter is used for fine adjustment of the VOQ, while the AGND parameter is used to set

the range. The large adjustable range allows the MLX90251 to be used in an unipolar magnetic system

without limiting the output voltage span. The formula below shows how the AGND and OFFSET

parameters combine to set the VOQ.

14.25V

5.0V

∗ AGND + −

∗ OFFSET

VOQ = −0.75V +

1023

1023

VDD =5.00V

This formula approximates the typical VOQ of the MLX90251. The actual VOQ formula varies slightly from

chip to chip. Melexis calibrates the AGND setting during final test so that the VOQ is approximately

50%VDD with OFFSET set to 512. This gives the VOQ a range of 0%VDD to 100%VDD without adjusting the

AGND value. The OFFSET parameter is often used to set the offset in the application's output transfer

characteristic.

12.2. Thermal VOQ Drift (DRIFT)

The Thermal VOQ Drift is tuned using 4 bits. This parameter, DRIFT, is calibrated for each unit by Melexis

during final test. The value is set to achieve a VOQ accuracy below 10mV over a temperature span of

25°C to 150°C. This parameter is not used by the end customer.

REVISION 016 – 25 JUN 2021

3901090251

Page 9 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

12.3. Sensitivity, Rough Gain and Fine Gain

The Sensitivity of the MLX90251 is controlled through parameters linked to dedicated internal

amplification stages. The parameter Rough Gain (RG), or pre-amplifier, has 4 bits for adjustment of two

stages. The two MSB affect the Differential Input Differential Output (DIDO) stage. The two LSB effect

the Differential to Single output (DTS) stage. The gain of both the DIDO and DTS are multiplied to get

the total RG. The table below shows the theoretical small signal amplifier gain vs. the parameter RG.

The pre-amplifier is chopper stabilized and the refresh frequency is adapted automatically to the RG

setting to match the chopper gain-bandwidth product.

Rough Gain (MSB LSB)

DIDO

DTS

Gain

00 (00 00)

01 (00 01)

02 (00 10)

03 (00 11)

04 (01 00)

05 (01 01)

06 (01 10)

07 (01 11)

08 (10 00)

09 (10 01)

10 (10 10)

11 (10 11)

12 (11 00)

13 (11 01)

14 (11 10)

15 (11 11)

16

16

16

16

39

39

39

39

82

82

82

82

205

205

205

205

1.0

1.5

2.33

4.0

1.0

1.5

2.33

4.0

1.0

1.5

2.33

4.0

1.0

1.5

2.33

4.0

16

24

37

64

39

59

91

156

82

123

191

328

205

308

477

820

Table 8: MLX90251 Rough Gain Small Signal Amplifier Gain

The MLX90251 also has an additional stage, Fine Gain, for fine tuning the Sensitivity. The stage

(parameter FG) follows the RG and provides a 10 bit adjustment. The small signal gain of the FG is

within 1.0 and 2.5. The RG and FG parameters are adjusted in the application to calibrate the device's

sensitivity (gain) and output slope transfer characteristic. The function for the fine gain is given in the

following equation:

Fine Gain =

1

1 − 0.6 *

FG

1023

Note. The one bit parameter INVERT is used to fix the “sign” of the sensitivity. A value of 0 makes the Sensitivity

positive and the output voltage increases in response to an increasing South magnetic field. A value of 1 makes the

Sensitivity negative and the output voltage decreases in response to an increasing South magnetic field. Refer to

section 12.5, Sensitivity Polarity, for more information on INVERT.

REVISION 016 – 25 JUN 2021

3901090251

Page 10 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

12.4. Sensitivity Range Selection

Each unit is characterized over temperature during final test to optimize its performance and accuracy.

To achieve the best possible Sensitivity Temperature Compensation, TempCo, each unit is optimized for

use within a specific Sensitivity range. This is represented in the ordering information by the option

code. There are four available ranges, option codes 0, 1, 2 and 3. The option code corresponds with

the two MSB of the RG parameter. Each device is tested to meet the TempCo specification in the

Sensitivity range determined by the RG parameter (RG = 0...3, RG = 4…7, RG = 8…11 or RG = 12…15),

regardless of the FG parameter.

Option Code

Rough Gain

xxx-000

xxx-100

xxx-200

xxx-300

0-3 (00 xx)

4-7 (01 xx)

8-11 (10 xx)

12-15 (11 xx)

Sensitivity Range

(mV/mT)

2.6 < S < 15

10 < S < 35

18 < S < 90

50 < S < 210

Typical Magnetic Field Range

(mT, BMAX - BMIN)

333 < B < 800

156 < B < 333

62 < B < 156

6 < B < 62

Table 9: Optimized Sensitivity Range (Rough Gain = RG)

The next figures show the typical Sensitivity versus the FG and RG parameters. The gray areas are

representative of the chip to chip dispersion (i.e.: for the same RG and FG parameters, the Sensitivity

can vary from chip to chip). There is a large overlap between the different ranges for use of one range

for applications with large magnetic and/or mechanical dispersions. The Sensitivity graphs and tables

can be used to select the right device type for the application. If one is unsure of the applications

magnetic design and the desired Sensitivity range Melexis recommends option code 2.

REVISION 016 – 25 JUN 2021

3901090251

Page 11 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

Figures 10.4-1…10.4-4 Sensitivity versus RG and FG, The first (bold) digit in Table 9 is the sensitivity range.

REVISION 016 – 25 JUN 2021

3901090251

Page 12 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

12.5. Sensitivity Polarity (INVERT)

The slope transfer characteristic defines the Sensitivity. The INVERT parameter changes the

Sensitivity's polarity, or the slope's direction. This allows the device to accommodate the application

requirements and the magnet's polarity. The slope is inverted in the first stage of the IC, at the Hall

plate. With INVERT set to 0, the output voltage increases when an increasing South magnetic field is

applied and decreases in the presence of an increasing North magnetic field. An INVERT value of 1

causes the output voltage to increase in the presence of a North magnetic field and decrease in the

presence of a South magnetic field. The magnetic field polarity is referenced to the field component

perpendicular to the top-face of the MLX90251.

12.6. Clamping Levels (CLAMPLOW, CLAMPHIGH)

Two independent values, called the clamping levels, can limit the output voltage range or swing. The

CLAMPLOW parameter adjusts the minimum output voltage level, ClampLo. The CLAMPHIGH sets the

maximum output voltage level, ClampHi. Both parameters have 10 bits of adjustment with a resolution

of approximately 0.005V. The formulas below give a close approximation of the output clamp voltage.

The actual clamping level formulas vary slightly from chip to chip. If CLAMPLOW exceeds CLAMPHIGH

the output voltage is fixed at the high clamp voltage level. The CLAMPHIGH and CLAMPLOW have an

initial value of 512, set by Melexis. This results in a fixed output voltage of approximately 50% VDD.

ClampLo =

5.10V

∗ CLAMPLOW

1023

V DD = 5.00V

ClampHi =

5.10V

∗ CLAMPHIGH

1023

V DD = 5.00V

At the point the output voltage switches between the linear operating region and the clamping region

the output can deviate slightly. This is represented by the grey areas in the figure below. The limits for

deviation in the Y axis are listed in Table 10. The deviation in the X axis is calculated from the

application's transfer function. The Clamp Comparator Offset does not affect the output linearity or

clamp voltage accuracy. During calibration it is recommended to set the clamp voltage outside of the

transition region (0V to 5V).

VOUT

CLAMP HIGH

Linear Operating

Region

CLAMP LOW

Transition Point

FIELD

Figure 10.6 Output Voltage Clamping Deviation

REVISION 016 – 25 JUN 2021

3901090251

Page 13 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

DC operating parameters at VDD = 5V (unless otherwise specified) and for TA as specified by the

temperature range (E or L).

Parameter

Symbol

Clamp Comparator Offset

CLAMPOFF

Test Conditions

Min

Typical

- 0.7

Max

Units

+ 0.7

%VDD

Table 10: Clamp Comparator Offset Specification

12.7. Filter (FILTER)

The MLX90251 includes two programmable low-pass filters located within the chopper amplifier stages.

The two low-pass filters are controlled through a 4 bit parameter, FILTER. The FILTER value 0

corresponds to minimum filtering, maximum speed (impulse response time), and maximum output

noise. The value 15 provides the maximum filtering, minimum speed, and minimum output noise. It is

important to note the noise is also linked to the gain settings. The FILTER parameter needs to be

adjusted to achieve optimal performance. The next table shows typical values the cut-off frequency at

-3 dB versus FILTER and RG parameters. FILTER values from 8 to 11 are not used. For most applications

FILTER values 7 or 15 are recommended.

Cut-off frequency at -3 dB (Hz) – Typical

Filter

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

MLX90251-000

Rough Gain 0…3

22900

19500

12300

10400

7450

5850

5700

5050

2200

1000

920

800

MLX90251-100

Rough Gain 4…7

14300

11450

10000

6750

3900

2900

2700

2550

840

480

380

330

MLX90251-200

Rough Gain 8…11

7000

5550

3000

2100

1500

1125

1350

1380

Not used

Not used

Not used

Not used

565

470

290

250

MLX90251-300

Rough Gain 12…15

3850

2950

2300

1100

850

860

715

650

250

190

155

135

Table 11: Cut-off Frequency versus FILTER and RG Parameters

REVISION 016 – 25 JUN 2021

3901090251

Page 14 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

12.8. Sensitivity Temperature Compensation (TC, TCW, TC2)

The change in the device's Sensitivity versus temperature is defined as the Sensitivity Temperature

Compensation, TempCo. In an application the slope output transfer characteristic is often affected by

temperature. Fluctuations in temperature can cause variations in the air gap, mechanical alignment

and magnetic field. The Sensitivity Temperature Compensation feature compensates for these effects.

Three parameters, TC, TCW, TC2 are used for adjustment of the TempCo. The TCW is used to adjust the

TempCo range, TC is for fine adjustment of the TempCo value, and TC2 effects the TempCo linear

response. To simplify use of these parameters Melexis stores a look up table within the EEPROM of

each device. The look up table is optimized for each device by characterizing the unit over temperature

at final test.

The value of TempCo is often determined by the magnet. In the application the TempCo is adjusted to

compensate for the temperature coefficient of the magnet. To adjust the value the look up table is

read from the device. The parameters are then calculated to match the desired value. The Melexis PTC

hardware and software tools contain built in functions for programming the TempCo.

TempCo Range (ppm / °C)

Accuracy (ppm / °C)

0 to 500

500 to 1200

1200 to 2000

± 100

± 150

± 200

Table 12: TempCo Accuracy

Note: The budget error of the whole system, the compensation mismatch (system Vs. IC) tolerance should be taken into

consideration during the design. Table 11 is valid for Rough Gain within the specified option code. See section 12.4 for

information on selecting the option code.

12.9. Diagnostic Output Level (FAULTLEV)

The MLX90251 EEPROM memory content is secured through a parity check. This self-diagnostic feature

brings the output to a defined range in case of a parity error. The parameter, FAULTLEV, is used to

define the parity error diagnostic state. With the FAULTLEV set to 0 a parity error event will result in an

output diagnostic voltage low. With the FAULTLEV set to 1 a parity error event will result in an output

diagnostic voltage high. To get rid of the output load influence the output diagnostic voltage level can

be fixed to either Ground (to be used with pull-down load) or VDD (to be used with pull-up load).

Melexis PTC software and hardware tools have built in functions for calculating and programming the

parity.

Note: The MLX90251 EEPROM is also redundant. Each parameter bit is written in three separate cells and a “majority

voting” is applied to determine its status. A parity error is detected only if two out of the three cells unexpectedly

change state. The bits available for the customer ID are not redundant.

12.10. The EEPROM, Parity, and Melexis CRC

The memory cells of the EEPROM are arranged in a table of four columns and one hundred twenty

eight rows. This configuration gives redundancy to the parameters stored in the EEPROM. Each

REVISION 016 – 25 JUN 2021

3901090251

Page 15 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

parameter bit is written in three separate cells in an individual row. A majority voting applied to the

three cells determines the logic status of the bit.

A parameter bit only toggles state in error if two out of three memory cells, within a row, unexpectedly

change. If this happens the feature, PARITY, forces the output voltage to the FAULTLEV diagnostic

level. This ensures the device does not operate with a critical memory fault.

The remaining memory cells are used for data storage. The status of these cells does not effect the

device operation. For example the Customer ID, CUSTID, is stored in this area. Melexis stores the

device ID information, TempCo look-up table and CRC bits in the extra cells. The CRC bits ensure the

integrity of the Melexis data.

Note: To avoid parity and CRC errors, the entire contents of the EEPROM must be read before programming. Melexis

PTC software and hardware tools have built in functions for reading the EEPROM and handling parity.

12.11. Output Amplifier Configuration (MODE)

The output buffer can be configured to accommodate capacitive loads and improve the saturation

voltage (output swing). The two bit parameter, MODE, sets the current capacity of the output

amplifier. Melexis sets this parameter to 1 at final test. This parameter is not used by the end

customer.

12.12. Memory Lock (MEMLOCK)

The Memory Lock feature prevents the device from entering programming mode and from any changes

to the EEPROM. The entire EEPROM is locked by setting the MEMLOCK parameter to 1. This should be

the last parameter set in the application.

12.13. IC traceability

A unique ID number is programmed into the EEPROM of every IC. The ID number gives Melexis

additional traceability to better service its customers. The ID number is composed of the lot number,

wafer number, and wafer coordinates (X and Y). Memory is also available for the customer to add a

serial number of the product or any other data.

REVISION 016 – 25 JUN 2021

3901090251

Page 16 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

13. Performance Graphs

Typical I DD VS VDD

Typical I DD VS VDDNOM

60

8.5

8

Over Voltage

40

V DDNOM

7.5

Under Voltage

20

6.5

DD

(mA)

0

-20

I

I

DD

(mA)

7

6

-40

5.5

150°C

-40°C

25°C

-60

-80

-10

0

10

20

150°C

-40°C

25°C

5

30

4.5

4

VDD (Volts)

4.5

5

5.5

VDD (Volts)

Figure 11-1…11-2 IDD Versus VDD

REVISION 016 – 25 JUN 2021

3901090251

Page 17 / 22

6

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

14. Applications Information

14.1. Application Circuits – VA-package

Pin 2, TEST, is not used in applications. For EMC protection it is recommended to connect pin 2 to pin 3,

Ground, as close as possible to the device pins. The values for capacitors, C1 and C2, can be adjusted to

satisfy ESD and EMC requirements according to the environment. Ceramic capacitors are recommended

for use in the application. However for stable operation, the global output capacitor (C2 + C3) should

not be higher than 150nF. If higher capacitors (due to special ESD or EMC requirements) or special

circuit configurations are requested, please contact Melexis.

The MLX90251 can operate with a high impedance load and C2, a load resistor is not required.

VDD

VDD

MLX90251

1

2

3

MLX90251

A/D

µC

4

1

2

3

R

10k

4

VOUT

C1

100nF

VOUT

C3

C2

100nF

A/D

µC

4.7nF

GND

R

10k

C1

C2

C3

100nF

100nF GND

4.7nF

Pull-Down Load

Pull-Up Load

Figures 12.1-1…12.1-2 Application Circuits

A voltage of 9V is required on VDD for programming. All additional components connected to VDD must

be able to withstand the voltage. The MLX90251 is designed for operation with a stable 5V supply. If

fast voltage transients occur additional filtering may be required.

14.2. Programming the Sensor

To program the MLX90251 connection to VDD, GND, and VOUT is required. The device is placed into

program mode by increasing the supply voltage to the VDD program level. In program mode data is

clocked into the device through the output pin using the Melexis tri-level PTC protocol. The clock and

data are integrated into one serial data stream, eliminating the need for a dedicated clock signal. The

data is clocked at the leading edge of each bit.

5.0V

VOUT

Program Wave Form

2.5V

0V

9.0V

VDD Program

Device

Decoded

Clock

5.0V

Device

Decoded

Data

Figure 12.2-1 VDD Programming Level

REVISION 016 – 25 JUN 2021

3901090251

X

1

X

0

X

Figure 12.2-2 Tri-Level PTC

Page 18 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

Note: External capacitors and resistors will affect the rise and fall times for the programming

waveforms. Program pulse timings may require adjustment for the application. The device cannot be

programmed if MEMLOCK equals 1.

The EEPROM contents can be read from the device. This procedure, known as a read back, is done by

sending a read command and then measuring the supply current. To successfully read the EEPROM it

must be possible to measure the supply current to the device. The Melexis PTC hardware and software

tools contain built in functions for reading the EEPROM.

The MLX90251 can be programmed by using the PTC-04 programmer and the dedicated software tools.

The timing and voltage levels are controlled through the programming hardware and software. Further

details can be found in the MLX90251 software documentation.

14.3. Calibration Procedure

The programmable features of the device allow for calibration within the application. This section gives

general information for a two point calibration procedure. The two point calibration is the most

common however, it is possible to adapt other procedures.

1.) The first step in the calibration procedure is to initialize the device. This is done by establishing

communication and reading the contents of the EEPROM.

2.) The second step is to set the TempCo and FILTER settings.

3.) Step three is the evaluation of position one. During this step the output voltage is measured with

initial values for RG, FG and OFFSET.

4.) Step four is the evaluation of position two. During this step, the output voltage is measured with

the same values from step 3. From the measurements it is possible to calculate the slope and offset

error. Next the output slope transfer characteristic versus FG and RG is interpolated. With this

information the initial settings are adjusted and the output voltage is measured again.

5.) Step five is the final check and adjustment. At this stage small corrections are made to the OFFSET

and FG parameters. Next, the output clamping parameters, CLAMPHIGH and CLAMPLOW, are

determined.

6.) The sixth step is the program phase. Now that all the parameters are determined and the

application requirements are satisfied, the settings are programmed into the EEPROM.

7.) The final step, seven, is the lock and verify step. Here the customer can perform any number of

additional measurements and verify the EEPROM contents. After this is completed the MEMLOCK is set

and the EEPROM is locked, preventing any further programming.

Note: EEPROM verification is done by reading the contents of the EEPROM and comparing it to the data

written. It is possible to read the EEPROM contents regardless of the status of MEMLOCK.

The Melexis PTC software tools contain built in functions and procedures for calibrating the MLX90251.

Please refer to the software documentation for more information on how to use the calibration tools.

The output of the MLX90251 is ratiometric. To avoid calibration errors from fluctuations in the supply

voltage, the output voltage should be measured as a percentage of the supply voltage.

REVISION 016 – 25 JUN 2021

3901090251

Page 19 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

15. Standard information regarding manufacturability of Melexis

products with different soldering processes

Our products are classified and qualified regarding soldering technology, solder ability and moisture

sensitivity level according to standards in place in Semiconductor industry.

For further details about test method references and for compliance verification of selected soldering

method for product integration, Melexis recommends reviewing on our web site the General

Guidelines soldering recommendation. For all soldering technologies deviating from the one mentioned

in above document (regarding peak temperature, temperature gradient, temperature profile etc),

additional classification and qualification tests have to be agreed upon with Melexis.

For package technology embedding trim and form post-delivery capability, Melexis recommends to

consult the dedicated trim & form recommendation application note: lead trimming and forming

recommendations

Melexis is contributing to global environmental conservation by promoting lead free solutions. For

more information on qualifications of RoHS compliant products (RoHS = European directive on the

Restriction Of the use of certain Hazardous Substances) please visit the quality page on our

website: http://www.melexis.com/en/quality-environment

16. ESD Precautions

Electronic semiconductor products are sensitive to Electro Static Discharge (ESD).

Always observe Electro Static Discharge control procedures whenever handling semiconductor products.

REVISION 016 – 25 JUN 2021

3901090251

Page 20 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

17. Package Information

VA-package: the lead-free VA-package is released for MSL1/245°C.

17.1. VA Package Outline and Hall Plate Position

Hall Plate Position

REVISION 016 – 25 JUN 2021

3901090251

Marking Instructions

Page 21 / 22

�MLX90251

Programmable Linear Hall Effect Sensor

Datasheet

18. Contact

For the latest version of this document, go to our website at www.melexis.com.

For additional information, please contact our Direct Sales team and get help for your specific needs:

Europe, Africa

Telephone: +32 13 67 04 95

Email : sales_europe@melexis.com

Americas

Telephone: +1 603 223 2362

Email : sales_usa@melexis.com

Asia

Email : sales_asia@melexis.com

19. Disclaimer

The content of this document is believed to be correct and accurate. However, the content of this document is furnished "as is" for informational use only and no

representation, nor warranty is provided by Melexis about its accuracy, nor about the results of its implementation. Melexis assumes no responsibility or liability for any

errors or inaccuracies that may appear in this document. Customer will follow the practices contained in this document under its sole responsibility. This documentation is

in fact provided without warranty, term, or condition of any kind, either implied or expressed, including but not limited to warranties of merchantability, satisfactory

quality, non-infringement, and fitness for purpose. Melexis, its employees and agents and its affiliates' and their employees and agents will not be responsible for any loss,

however arising, from the use of, or reliance on this document. Notwithstanding the foregoing, contractual obligations expressly undertaken in writing by Melexis prevail

over this disclaimer.

This document is subject to change without notice, and should not be construed as a commitment by Melexis. Therefore, before placing orders or prior to designing the

product into a system, users or any third party should obtain the latest version of the relevant information.

Users or any third party must determine the suitability of the product described in this document for its application, including the level of reliability required and determine

whether it is fit for a particular purpose.

This document as well as the product here described may be subject to export control regulations. Be aware that export might require a prior authorization from

competent authorities. The product is not designed, authorized or warranted to be suitable in applications requiring extended temperature range and/or unusual

environmental requirements. High reliability applications, such as medical life-support or life-sustaining equipment or avionics application are specifically excluded by

Melexis. The product may not be used for the following applications subject to export control regulations: the development, production, processing, operation,

maintenance, storage, recognition or proliferation of:

1. chemical, biological or nuclear weapons, or for the development, production, maintenance or storage of missiles for such weapons;

2. civil firearms, including spare parts or ammunition for such arms;

3. defense related products, or other material for military use or for law enforcement;

4. any applications that, alone or in combination with other goods, substances or organisms could cause serious harm to persons or goods and that can be used as a

means of violence in an armed conflict or any similar violent situation.

No license nor any other right or interest is granted to any of Melexis' or third party's intellectual property rights.

If this document is marked “restricted” or with similar words, or if in any case the content of this document is to be reasonably understood as being confidential, the

recipient of this document shall not communicate, nor disclose to any third party, any part of the document without Melexis’ express written consent. The recipient shall

take all necessary measures to apply and preserve the confidential character of the document. In particular, the recipient shall (i) hold document in confidence with at least

the same degree of care by which it maintains the confidentiality of its own proprietary and confidential information, but no less than reasonable care; (ii) restrict the

disclosure of the document solely to its employees for the purpose for which this document was received, on a strictly need to know basis and providing that such persons

to whom the document is disclosed are bound by confidentiality terms substantially similar to those in this disclaimer; (iii) use the document only in connection with the

purpose for which this document was received, and reproduce document only to the extent necessary for such purposes; (iv) not use the document for commercial

purposes or to the detriment of Melexis or its customers. The confidentiality obligations set forth in this disclaimer will have indefinite duration and in any case they will be

effective for no less than 10 years from the receipt of this document.

This disclaimer will be governed by and construed in accordance with Belgian law and any disputes relating to this disclaimer will be subject to the exclusive jurisdiction of

the courts of Brussels, Belgium.

The invalidity or ineffectiveness of any of the provisions of this disclaimer does not affect the validity or effectiveness of the other provisions.

The previous versions of this document are repealed.

Melexis © - No part of this document may be reproduced without the prior written consent of Melexis. (2021)

IATF 16949 and ISO 14001 Certified

REVISION 016 – 25 JUN 2021

3901090251

Page 22 / 22

�