MLX90373 Triaxis® Position Processor

Datasheet

Features and Benefits

Description

The MLX90373 is a monolithic sensor sensitive to

the three components of the flux density applied

to the IC (i.e. B X, BY and BZ). This allows the

MLX90373 with the correct magnetic circuit to

decode the absolute position of any magnet

moving in its vicinity (e.g. rotary position from 0

to 360 Degrees or linear displacement, see Figure

2).

Hall Technology.

On-Chip Signal Processing for Robust Absolute

Position Sensing.

ISO26262 ASIL-C Safety

Element out of Context (SEooC).

Programmable Measurement Range.

Programmable Linear Transfer Characteristic

(Multi-points 4 or 8 points or Piece-WiseLinear 17 or 32 points).

2-wire PSI5 protocol (v1.3 and v2.1).

48 bit ID Number option.

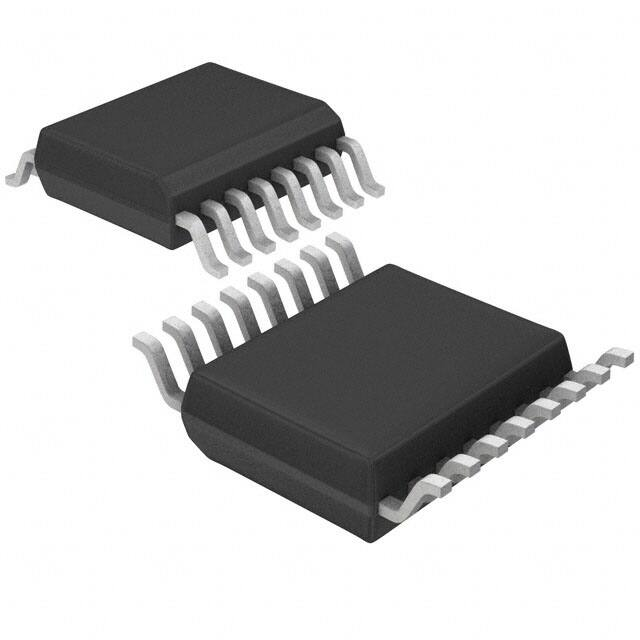

Dual Die (Full Redundant) - TSSOP-16 Package

(RoHS).

PCB-less DMP-4 Package (RoHS).

Robustness against Stray-Field.

TSSOP-16

DMP-4

Application Examples

Absolute Rotary Position Sensor.

Absolute Linear Position Sensor.

Pedal Position Sensor.

Throttle Position Sensor.

Ride Height Position Sensor.

Steering Wheel Position Sensor.

Fuel Level Sensor.

Non-Contacting Potentiometer.

The MLX90373 provides a 2-wires PSI5 (Peripheral

Sensor Interface 5) output protocol over the

supply line. The protocol is compatible with v1.3

and v2.1 PSI5 specifications.

�MLX90373 Triaxis® Position Processor

Datasheet

Ordering Information

Product

Temp

Package

Option Code

Packing Form

Definition

MLX90373

K

VS

ABA-100

RE/RX

Angular Position Stray-Field Immune

MLX90373

K

VS

ABA-103

RE/RX

Angular Position Stray-Field Immune

MLX90373

K

VS

ABA-108

RE/RX

Angular Position Stray-Field Immune

MLX90373

K

VS

ABA-300

RE/RX

Linear / Angular Position

MLX90373

K

VS

ABA-303

RE/RX

Linear / Angular Position

MLX90373

K

VS

ABA-308

RE/RX

Linear / Angular Position

MLX90373

K

GO

ABA-300

RE

Linear / Angular Position

Legend:

Temperature Code:

K: from -40°C to 125°C

Package Code:

GO : TSSOP-16 package (fully redundant dual die, see 18.1)

VS : DMP-4 package (dual mold PCB-less, see 18.2)

Option Code:

ABA: die Version

xxx-123:

1: Application – Magnetic configuration

1: Angular Rotary Stray-Field Immune

3: Legacy / Angular Rotary / Linear position

2: SW Configuration

0 : Default Configuration

3: Trim-and-Form for DMP-4 package

Packing Form:

0: Standard straight leads. See 18.2.1.1

3: Trim-and-Form STD2 2.54. See 18.2.1.2

8: Trim-and-Form STD4 2.54. See 18.2.1.3

RE : Tape & Reel

RX : Tape & Reel, similar to RE with parts face-down (DMP-4 package only)

Ordering Example:

“MLX90373KVS-ABA-100-RE”

For an Angular Rotary Stray-Field Immune application in DMP-4 package,

delivered in Reel, face-up.

Table 1: Ordering information legend

Revision 1.0

May 2019

Page 2 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Contents

Features and Benefits ................................................................................................................................ 1

Application Examples ................................................................................................................................. 1

Description................................................................................................................................................. 1

Ordering Information ................................................................................................................................. 2

1. Functional Diagram and Application Modes ........................................................................................... 5

2. Glossary of Terms................................................................................................................................... 6

3. Pin Definitions and Descriptions............................................................................................................. 7

3.1. Pin Definition for TSSOP-16 Package................................................................................................. 7

3.2. Pin Definition for DMP-4 Package ..................................................................................................... 7

4. Absolute Maximum Ratings.................................................................................................................... 8

5. Isolation Specification ............................................................................................................................ 8

6. General Electrical Specifications............................................................................................................. 8

7. Timing Specification ............................................................................................................................. 10

7.1. Definitions......................................................................................................................................... 10

7.2. General Timing ................................................................................................................................. 11

7.3. PSI5 Timing ...................................................................................................................................... 11

8. Magnetic Field Specifications ............................................................................................................... 12

8.1. Rotary Stray-Field Immune (-10x code) .......................................................................................... 12

8.2. Standard/Legacy Mode (-30x code) ................................................................................................ 13

9. Accuracy Specifications ........................................................................................................................ 14

9.1. Angular accuracy .............................................................................................................................. 14

9.2. Angular Velocity Accuracy ............................................................................................................... 17

9.3. Temperature Accuracy ..................................................................................................................... 17

10. Memory Specification ........................................................................................................................ 18

11. PSI5 Communication Interface ........................................................................................................... 18

11.1. PSI5 Communication Supported Standards .................................................................................. 18

11.2. Data Current Modulation .............................................................................................................. 18

11.3. Communication Mode ................................................................................................................... 20

11.4. Cycle Time....................................................................................................................................... 21

11.5. Data Frame in Run-Time ................................................................................................................ 22

11.6. Sensor Start-Up .............................................................................................................................. 24

11.7. Sensor Initialization ........................................................................................................................ 24

11.8. Error Reporting Mode .................................................................................................................... 26

Revision 1.0

May 2019

Page 3 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

12. End-User Programmable Items .......................................................................................................... 27

12.1. End-User Identification Items ........................................................................................................ 31

13. Description of End-User Programmable Items ................................................................................... 31

13.1. Output Transfer Characteristic ...................................................................................................... 31

13.2. Sensor Front-End............................................................................................................................ 37

13.3. Filter ................................................................................................................................................ 38

13.4. Programmable Diagnostics Settings.............................................................................................. 40

14. Functional Safety ............................................................................................................................... 41

14.1. Safety Manual................................................................................................................................. 41

14.2. Safety Mechanisms ........................................................................................................................ 41

15. Recommended Application Diagrams ................................................................................................ 44

15.1. Wiring in TSSOP-16 Package .......................................................................................................... 44

15.2. Wiring in DMP-4 Package .............................................................................................................. 45

16. Standard Information Regarding Manufacturability Of Melexis Products With Different

Soldering Processes............................................................................................................................. 46

17. ESD Precautions ................................................................................................................................. 46

18. Package Information .......................................................................................................................... 47

18.1. TSSOP-16 Package .......................................................................................................................... 47

18.2. DMP-4 Package .............................................................................................................................. 49

19. Contact .............................................................................................................................................. 55

20. Disclaimer .......................................................................................................................................... 55

Revision 1.0

May 2019

Page 4 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

1. Functional Diagram and Application Modes

Figure 1: MLX90373 Block Diagram

Angular Rotary Stray-Field

Immune

Legacy / Angular Rotary

Legacy / Linear Position

Figure 2: Application Modes

Revision 1.0

May 2019

Page 5 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

2. Glossary of Terms

Name

Description

ADC

Analog-to-Digital Converter

AWD

Absolute Watchdog

CPU

Central Processing Unit

CRC

Cyclic Redundancy Check

DMP

Dual Mould Package

DP

Discontinuity Point

DSP

Digital Signal Processing

ECC

Error Correcting Code

ECU

Electronic Control Unit

EMA

Exponential Moving Average

EMC

Electro-Magnetic Compatibility

EoL

End of Line

FIR

Finite Impulse Response

Gauss (G)

Alternative unit for the magnetic flux density (10G = 1mT)

HW

Hardware

IMC

Integrated Magnetic Concentrator

IWD

Intelligent Watchdog

LSB/MSB

Least Significant Bit / Most Significant Bit

NC

Not Connected

NVRAM

Non Volatile RAM

PSF

Product Specific Functions

PSI5

Peripheral Sensor Interface 5

PTC

Programming Through Connector

PWL

Piecewise Linear

RAM

Random Access Memory

ROM

Read-Only Memory

SEooC

Safety Element out of Context

TC

Temperature Coefficient (in ppm/°C)

Tesla (T)

SI derived unit for the magnetic flux density (Vs/m2)

Table 2: Glossary of Terms

Revision 1.0

May 2019

Page 6 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

3. Pin Definitions and Descriptions

3.1. Pin Definition for TSSOP-16 Package

Pin #

Name

Description

1

VDEC1

Decoupling pin die 1

2

VSS1

Ground die 1

3

VDD1

Supply die 1

4

IN1

External sensor input die 1

5

TEST2

Test pin die 2

6

IDATA2

Current sensing die 2

7

N.C.

Not connected

8

N.C.

Not connected

9

VDEC2

Decoupling pin die 2

10

VSS2

Ground die 2

11

VDD2

Supply die 2

12

IN2

External sensor input die 2

13

TEST1

Test pin die 1

14

N.C.

Not connected

15

IDATA1

Current sensing die 1

16

N.C.

Not connected

Table 3: TSSOP-16 Pin definition and description

Pins Input and Test are internally grounded in application. For optimal EMC behavior always connect the

unused pins to the ground of the PCB. Pins IDATA must be non-connected.

3.2. Pin Definition for DMP-4 Package

Pin #

Name

Description

1

VSS

Ground

2

VDD

Supply/PSI5-OUT

3

N.C.

Not connected

4

VSS

Ground

Table 4: DMP-4 Pin definition and description

Revision 1.0

May 2019

Page 7 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

4. Absolute Maximum Ratings

Parameter

Symbol

Supply Voltage

Reverse Voltage Protection

Min.

Max.

Unit

Condition

VDD

27

V

< 24h ; TJ < 175°C

VDD

37

V

< 60s ; TAMB ≤ 35°C

VDD-REV

-14

V

< 24h ; TJ < 175°C

VDD-REV

-20

V

< 1h

Internal Voltage

VDEC

Internal Voltage

VDEC-rev

3.6

-0.3

Positive Input pin Voltage

VInput

Reverse Input pin Voltage

VInput-rev

-3

TAMB

-40

Operating Temperature

V

V

6

V

V

125

°C

175

°C

See 18.2.5 and 18.1.5 for packages

thermal dissipation values

Refer to the qualification profile

Junction Temperature

TJ

Storage Temperature

TST

-55

170

°C

Sensed magnetic field

BMAX

-1

1

T

Table 5: Absolute maximum ratings

Exceeding the absolute maximum ratings may cause permanent damage. Exposure to absolute maximumrated conditions for extended periods may affect device reliability.

5. Isolation Specification

Only valid for the package code GO, i.e. TSSOP-16 package (dual die).

Parameter

Isolation Resistance

Symbol

Min.

Typ.

Max.

Unit

Condition

Risol

4

-

-

MΩ

Between dice, measured between

VSS1 and VSS2 with +/-20V bias

Table 6: Isolation Specification

6. General Electrical Specifications

General electrical specifications are valid for temperature range [-40; 125] °C and the supply voltage

range inside their defined operating range unless otherwise noted.

Revision 1.0

May 2019

Page 8 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Electrical Parameter

Symbol

Min

Typ

Max

Unit

Operating Supply Voltage

during PSI5 communication

VDD

6

12

18(1)

V

DMP-4 package

VDD

4.1

5

6(1)

V

TSSOP-16 and DMP-4 package

Quiescent Supply current(2)

IDDQ

10

11.5

13.5

mA

Rotary Stray-Field application

(option code -10x).

Quiescent Supply current(2)

IDDQ

9

10.5

12.5

mA

Legacy application

(option code -30x).

Start-up Level

VDDstart

3.6

Undervoltage detection

VDDUVH

3.8

4.0

Undervoltage detection

VDDUVL

3.70

VDDstartHyst

Start-up Hysteresis

PTC Entry Level (rising)

PTC Entry Level Hysteresis

Current settling error at

startup

Condition

V

Minimal supply start-up

voltage

4.1

V

High threshold

3.90

4.00

V

Low threshold

0.05

0.10

0.15

V

VPROV1

22

24

26

V

VPROV1Hyst

0.8

1.4

2.0

V

IERRSTART

-2

2

mA

Current consumption settling

error 5ms after power-up

µs

PSI5 std.

Microcut rejection

Tucut

Regulated Voltage

VDEC

3.2

3.3

3.4

V

Internal analog voltage

Regulated Voltage

Overvoltage detection

VDECOVH

3.65

3.75

3.85

V

High threshold

Regulated Voltage

Undervoltage detection

VDECUVL

2.70

2.85

2.92

V

Low threshold

VDECOVHyst

VDECUVHyst

100

150

200

mV

VDDD

1.80

1.85

1.95

V

Digital supply Overvoltage

detection

VDDDOVH

2.00

2.10

2.20

V

Digital Supply Undervoltage

detection

VDDDUVL

1.585

1.680

1.735

V

Digital Supply OV / UV

detection Hysteresis

VPORHyst

30

100

200

mV

Regulated voltage UV / OV

detection hysteresis

Digital supply

10

Power-on Reset low threshold

Table 7:General electrical specifications

1

The maximum PSI5 operating voltage, excluding Synchronization pulse, is limited by the die temperature and the thermal

dissipation performance of the considered package.

2

For the dual die version, the supply current is multiplied by 2.

Revision 1.0

May 2019

Page 9 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

7. Timing Specification

Timing conditions, including the variations of supply, temperature and aging, unless specified .

7.1. Definitions

7.1.1. Latency

Latency is the average delay between the movement of the detected object (magnet) and the response

of the sensor output. This value is representative of the time constant of the system for regulation

calculations.

Figure 3: Definition of latency

7.1.2. Step Response

Step response is defined as the delay between the movement of the detected object (magnet) and the

100% settling time of the sensor output with full angle accuracy with regards to filtering. Worst case is

happening when the movement of the magnet occurs just after a measurement sequence has begun.

Step response therefore consists of the sum of:

δmag,measSeq: the delay between magnetic change and start of next measurement sequence.

TmeasSeq: the measurement sequence length.

δmeasSeq,frameStart: the delay between end of measurement sequence and start of next frame.

Tframe: the frame length.

Worst case happens when δ mag,measSeq = TmeasSeq, which gives: 𝑇wcStep = 2TmeasSeq,frameStart + Tframe

Magnetic

stimuli (step)

Step Response

Data

acquisition

Data

acquisition

Data

acquisition

Data

acquisition

DSP

processing DaP

DSP

processing DaP

DSP

processing DaP

DSP

processing DaP

TS1

TS1

N-1 cycle

Output response to

the magnetic step

N cycle

TS1

TS1

N+1 cycle

N+2cycle

TS1

Figure 4: Step response and latency

Revision 1.0

May 2019

Page 10 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

7.2. General Timing

General electrical specifications are valid for temperature range [-40;125] °C and supply voltage range

[4.1;5.5] V unless otherwise noted.

Parameter

Symbol

Min.

Typ.

Max.

Unit

Condition

FCK

22.8

24

25.2

MHz

Including thermal and lifetime

drift

-5

5

% FCK

-2

2

% FCK

Main Clock Frequency

Relative tolerances, including

thermal and lifetime drift

Main Clock Frequency

Thermal Drift

ΔFCK,0

1MHz Clock Frequency

F1M

Intelligent Watchdog Timeout

TIWD

19

20

21

ms

FCK = 24MHz

Absolute Watchdog Timeout

TAWD

19

20

21

ms

F1M = 1MHz

Tcycle =500μs

Tcycle =300μs

1

Relative to clock frequency at

35°C. No ageing effects.

MHz

Analog Diagnostics

DCTANA

15.5

9.3

ms

Digital Diagnostics

DCTDIG

20

ms

5

ms

Stabilization of the quiescent

current after start-up power on

ms

when no diagnostic is enabled

ms

when all diagnostics are enabled

Current settling Time at startup(3)

TSET

Start-up time

TSU

4

5

20.5

Table 8: General Timing Specification

7.3. PSI5 Timing

Parameter

Symbol

Cycle time

Tcycle

Bit time

Sync Pulse Hold Time

Min.

Typ

Max

300

500

Tbit

5

TSHOLD

9

8.4

350

DSP calculation + Data

preparation

Latency Time

250

350

Tlatency

850

μs

μs

Synchronous mode only

μs

5 acquisitions at 4 MHz

9 acquisitions at 3 MHz

μs

2 phase spinning + DSP trimming down

Default configuration

μs

Default configuration, no filtering

μs

Rotary mode, default configuration, no

filtering

Velocity mode, default configuration, no

filtering

1480

Step Response Time

(4)

Condition

μs

150

Data acquisition

Unit

TwcStep

2125

Table 9: PSI5 Timing Specification

3

4

Due to duration of initialization phases in PSI5 protocol no PSI5 data frame will be transmitted before initialization phase II.

Main clock variations not included.

Revision 1.0

May 2019

Page 11 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

8. Magnetic Field Specifications

Magnetic field specifications are valid for temperature range [-40; 125] °C unless otherwise noted.

8.1. Rotary Stray-Field Immune (-10x code)

Parameter

Unit

Symbol

Min

Typ

Max

Number of magnetic poles

NP

4(5)

-

-

Magnetic Flux Density in XY plane

BX, BY(6)

25(7)

mT

√

(this is not the useful signal)

Magnetic Flux Density in Z

BZ

100

mT

(this is not the useful signal)

√(

Magnetic in-plane gradient

of in-plane field

component

Magnet Temperature

Coefficient

Condition

4.1

TCm

Field Strength Resolution(8)

10

)

(

)

this is the useful signal (see

Figure 5)

0

-2400

0.075

0.100

0.125

Field too Low Threshold(9)

BTH_LOW

0.8

1.2

(10)

Field too High Threshold(9)

BTH_HIGH

70

100(11)

102(11)

Magnetic field gradient norm

(12bits data)

Typ. value recommended

Table 10 Magnetic specification for rotary Stray-Field immune application

Nominal performances apply when the useful signal

is above the typical specified limit. Under

this value, limited performances apply. See 9.1 for accuracy specifications.

5

Due to 4 poles magnet usage, maximum angle measurement range is limited to 180°

The condition must be fulfilled for all combinations of B X and BY.

7

Above this limit, the IMC® starts to saturate, yielding to an increase of the linearity error.

8

Only valid with default MAGNET_SREL_T[1..7] configuration

9

See section 11 for the value set by default.

10

Higher values of Field too Low threshold are not recommended by Melexis and shall only been set in accordance with the

magnetic design and taking a sufficient safety margin to prevent false positive.

11

Due to the saturation effect of the IMC, the FieldTooHigh monitor detects only defects in the sensor

6

Revision 1.0

May 2019

Page 12 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Temperature (°C)

125

-40

Limited

Performances

Nominal

Performances

Typical magnet

characteristics

4.1 5.7

10

B XY mT

XY mm

Figure 5: Minimum useful signal definition for rotary Stray-Field immune application

8.2. Standard/Legacy Mode (-30x code)

Parameter

Number of magnetic poles

Magnetic Flux Density in X-Y

plane

Magnetic Flux Density in Z

Symbol

Min.

Typ.

Max.

NP

-

2

-

Unit

Condition

BX, BY (6)

70

mT

√

BZ

100

mT

in absolute value

√

Useful Magnetic Flux

Density Norm

BNorm

11(12)

20

(x-y mode)

√

(

) (x-z mode)

√

(

) (y-z mode)

mT

See section 13.2.1 for sensing

mode description.

(13)

IMC gain

GIMC

1.19

Magnet Temperature

Coefficient

TCm

-2400

Field Strength Resolution(8)

BNorm

0.075

0.100

0.125

Field too Low Threshold(9)

BTH_LOW

0.4

4.0

(10)

mT

Field too High Threshold(9)

BTH_HIGH

70

100(11)

100(11)

mT

0

Magnetic field gradient norm

expressed in 12bits words

Typ. Value recommended

Table 11: Magnetic specification for standard application

Nominal performances apply when the useful signal B Norm is above the typical specified limit. Under this

value, limited performances apply. See 9.1 for accuracy specifications.

12

Below 11 mT the performances are degraded due to a reduction of the signal-to-noise ratio, signal-to-offset ratio

IMC has better performance for concentrating in-plane (x-y) field components, resulting in a better overall magnetic

sensitivity. A correction factor, called IMC gain has to be applied to the z field component to account for this difference.

13

Revision 1.0

May 2019

Page 13 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

125

Temperature (°C)

Limited

Performances

Nominal

Performances

Typical magnet

characteristic

-40

11

15

20

Norm (mT)

Figure 6: Minimum useful signal definition for Standard/Legacy application

9. Accuracy Specifications

Accuracy specifications are valid for temperature range [-40; 125] °C and supply voltage range specified

in section 6 unless otherwise noted.

9.1. Angular accuracy

9.1.1. Definitions

9.1.1.1. Intrinsic Linearity Error

Id

M eal

ea Cu

r

su

re ve

d

Cu

rv

e

Output (%DC, Deg)

Figure 7 depicts the intrinsic linearity error in new parts. The Intrinsic Linearity Error refers to the IC itself

(offset, sensitivity mismatch, orthogonality) taking into account an ideal magnetic field. Once associated

to a practical magnetic construction and the associated mechanical and magnetic tolerances, the output

linearity error increases. However, it can be improved with the multi-point end-user calibration (see

13.1). As a consequence, this error is not critical in application because it is calibrated away .

Noise (pk-pk)

Intrinsic Linearity Error

(LE)

±3σ

Input (Deg.)

Figure 7: Sensor accuracy definition

Revision 1.0

May 2019

Page 14 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

9.1.1.2. Total Angle Drift

After calibration, the output angle of the sensor might still change due to temperature change, aging,

etc.. This is defined as the total drift

:

{ (

𝑇 )

(

𝑇

)}

where

is the input angle, 𝑇 is the temperature, 𝑇 is the room temperature, and is the elapsed

lifetime after calibration. represents the status at the start of the operating life. Note the total drift

is always defined with respect to angle at room temperature. In this datasheet, 𝑇 is typically

defined at 35°C, unless stated otherwise. The total drift is valid for all angles along the full mechanical

stroke.

9.1.1. Performances

Valid before EoL calibration and for all applications under nominal performances conditions described in

sections 8.1 & 6.

Revision 1.0

May 2019

Page 15 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Mode

Parameter

Symbol

XY - Intrinsic Linearity Error

LE_XY

Nominal performances

Min

Typ

-1

Limited performances

Max

Min

1

-1

Typ

1

0.4

Noise

Rotary StrayField Immune

(-10x code)

(14)

0.2

XY - Total Drift(16)

-0.85

Hysteresis

0.85

Output Stray Field Immunity

XY - Intrinsic Linearity Error

XZ - Intrinsic Linearity Error

YZ - Intrinsic Linearity Error

Standard/

Legacy

(-30x code)

-0.85

0.1

Max

-1

-2.5

-2.5

1.25

1.25

0.05

0.1

0.1

0.2

Deg.

0.85

Deg.

Relative to 35°C

Deg.

Deg.

-1

-2.5

-2.5

Noise(14)

0.05

XY - Total Drift

XZ - Total Drift

YZ - Total Drift

-0.45

-0.6

-0.6

1.25

1.25

0.2

0.14

0.1

0.1

0.45

0.6

0.6

-0.6

-0.8

-0.8

0.05

1

2.5

2.5

0.4

0.28

0.2

0.6

0.8

0.8

0.1

Hysteresis

Deg.

Filter = 0(15)

Filter = 1

Filter = 2

0.1

1

2.5

2.5

Condition

0.7

0.5

0.35

0.6

LE_XY

LE_XZ

LE_YZ

Unit

0.2

0.1

14

with 10mT/mm useful gradient

field and 4kA/m stray-field (17)

Deg.

Deg.

Filter = 0; 40mT

Filter = 0; 20mT

Filter = 0

Filter = 1

Filter = 2

Deg.

Relative to 35°C

Deg.

10mT

20mT

±3σ

See section 13.3 for details concerning Filter parameter

16

Verification done on aged devices after HTOL in uniform field gradient. The limit represents the peak to peak value of the me asured distribution of the largest angle drift, calculated as 6σ

of the output angle θout. An additional application-specific error arises from the non-ideal magnet and mechanical tolerance drift.

17

Tested in accordance with ISO 11452-8:2015 at 30°C, with stray-field strength of 4kA/m from any direction. This error scales linearly with both the useful field and the disturbing field.

15

Revision 1.0

May 2019

Page 16 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

9.2. Angular Velocity Accuracy

The MLX90373 device can calculate the velocity based on the angle measurement. The velocity algorithm

must be enabled (VELOCITY_ENABLE) (disabling is advised for "turbo" modes with no velocity

information, where computation speed is critical).

The velocity algorithm is selectable (VELOCITY_ALGORITHM, 0: simple, 1: tracking loop).

Parameter

Angular velocity range

Symbol

Min

Typ

Max

Unit

ASFS

-1000

-

+1000

Deg./s

Angular velocity error

26

145

Deg./s

Angular velocity noise (14)

For VELOCITY_FILTER_FIR=0

31

23

43

41

Deg./s

Condition

Only error calculation is

considered.

Max is considering abrupt

velocity change 0 to 1000

Deg./s

VELOCITY_ALGORITHM =0

VELOCITY_ALGORITHM =1

9.3. Temperature Accuracy

One can get the physical temperature of the die using following formula:

𝑇

[

]

𝑇

DIAG_TEMP_THR_LOW/HIGH are encoded on 8-bit unsigned values with the following relationship towards TLin

𝑇

𝑇

(

)

𝑇

Following table summarizes the characteristics of the linearized temperature sensor and the encoding of

the temperature monitor thresholds.

Parameter

Symbol

Min

Typ

Max

Unit

TLIN resolution

ResTLIN

-

0.125

-

°C/LSB

TLIN refresh rate

FS,TLIN

-

200

-

Hz

TLIN linearity error

TLinErr

-8

-

8

°C

from -40 to 125°C

-

8

-

LSB

Recommended value,

corresponds to -57°C

-

136

-

LSB

Recommended value,

corresponds to 199°C

DIAG_TEMP_THR_LOW

DIAG_TEMP_THR_HIGH

Temperature threshold resolution

ResTthr

2

Condition

°C/LSB

Table 12: Linearized Temperature Sensor characteristics (die temperature)

Revision 1.0

May 2019

Page 17 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

10. Memory Specification

Parameter

Symbol

Min.

Typ.

Max.

Unit

ROM

32

kB

RAM

1024

B

NVRAM

256

B

Condition

Table 13: Memory specification

11. PSI5 Communication Interface

11.1. PSI5 Communication Supported Standards

The MLX90373 uses PSI5 communication protocol. The information is transmitted by modulating the

current of the supply pin VDD according to PSI5 protocol specification. The sensor interface, electrical

parameters and data transmission fully complies with v2.1 of the PSI5 protocol specifications. The

backward compatibility to the operation modes described in v1.3 of PSI5 standard is also part of the

MLX90373 implementation. The configuration of the sensor interface follows the "Chassis and Safety PSI5

Substandard”.

The denomination of the PSI5 protocol is defined as follows:

A/P

PD

P/CRC

-

Tcycle

/

n

L/H

Communication mode

Payload

Error detection

Cycle time in µs

n° of Time Slots per cycle

Bit rate

Figure 8: Denomination of PSI5 operation modes

11.2. Data Current Modulation

11.2.1. PSI5 Current Modulation Method

The Data Frame is transmitted through a modulation of the current consumption. The Figure 9 shows the

current modulation and bit encoding (Manchester encoding). A low level (ISlow) represents the quiescent

current consumption of the sensor. A high level (IShigh) is generated by an increased Sink current of the

sensor (ISlow+ΔIS). The sink current (Δ IS) and the duration of the bit (TBIT) are selectable (see Table 14).

Revision 1.0

May 2019

Page 18 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

IS

Bit 0

0

IShigh

Bit 1

0

Bit 2

1

Bit 3

0

ΔIS

ISlow

TBIT

t

Figure 9: PSI5 current modulation

11.2.2. Current Modulation Specification

Electrical Parameter

Sink current

Symbol

Min

Typ

Max

Unit

ΔIS

21

26

30(18)

mA

Common power mode (see section12)

10

13

15

mA

Low power mode (see section 12)

4

mA

0.3

mA/s

Assuming a maximum temperature drift

rate of 20K/s

Quiescent current drift

DRIFTIS

Quiescent current

thermal drift rate

DRIFTRIS

-4

Condition

IS Current modulation

Falling time(19)

TF

0.33

1

μs

Time for IS to fall from 80% to 20% of ΔIs

See section 15.

IS Current modulation

Rising time(19)

TR

0.33

1

μs

Time for IS to rise from 20% to 80% of

ΔIs.

See section 15.

Mark/Space Ratio at

Sensor(21)

MSR

Bit time

TBIT

Slope rate

47

50

53

%

(tfall, 80 - trise,20) / TBit

(tfall, 20 - trise, 80) / TBit

7.6

8

8.4

μs

Low speed transmission (125 kbit/s)

5

5.3

5.6

μs

High-speed transmission (189 kbit/s)

(22)

fast

High-speed transmission (189 kbit/s)

slow

Low speed transmission (125 kbit/s)

Table 14: Data modulation specification table

For the power mode (PSI5_LOWCOMMON_MODE) and the speed transmission (PSI5_TRANSMITSPEED)

programming, see section 12.

18

19

The maximum value is found at 125deg.C

Small rise and fall times will lead to increased radiated emission. Sensors/Bus must meet the test conditions of PSI5 standard.

21

Single sensor configuration shall satisfy the requirement for sending current rise/fall time such that trise from 20 to 80%

of IS and tfall from 80 down to 20% of IS is reached within 1μs..

22

Minimum value of duty cycle has been found at 125deg.C

Revision 1.0

May 2019

Page 19 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

11.3. Communication Mode

The sensor can be programmed to communicate in 2 possible modes: asynchronous mode and

synchronous parallel bus mode (see Table 15). In asynchronous mode, the sensor transmits the Data

Frames periodically without external synchronization, while in synchronous mode; the communication is

synchronized by the ECU with a synchronization pulse.

Protocol Parameter

Communication modes

Option

Id

Option

A

2: Asynchronous Mode

P

3: Synchronous Parallel Bus Mode

NVRAM parameters

PROTOCOL

Table 15: Communication mode configuration synchronous/asynchronous

11.3.1. Asynchronous Communication

In asynchronous mode, the timing and repetition rate of the data transmission are controlled by the

sensor. The sensor starts transmitting the data to the ECU periodically (see section 11.4) once the power

supply is on.

The Figure 10 shows the periodic transmission from one PSI5 Sensor with period T cycle. The supply

voltage must enter the operation voltage specified in the section 6.

VDD

OV

TS1

TS2

TS3

TS4

TS1

Tcycle

Figure 10: Asynchronous data transmission for x4 Time Slots per cycle

11.3.2. Synchronous Communication in Parallel Bus

In synchronous operation, the sensor data transmission is synchronized by the ECU using voltage

modulation. Once the sync pulse received, each sensor starts the data transmission (see section

11.3.2.1).

VDD

TS1

TS2

TS3

TS4

Tcycle

Figure 11: Synchronous Parallel bus data transmission for x4 Time Slots per cycle

Revision 1.0

May 2019

Page 20 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

11.3.2.1. Synchronization Pulse

The sync pulse generated by the ECU is detected by the sensor as soon as the variation in voltage on VDD

is higher than the minimum sync pulse voltage. The sync pulse (reduced or standard, see Table 16) is

selectable (PSI5_TRIGGER_STD).

Electrical Parameter

Symbol

Sync Pulse Voltage

VSYNC

Sensor Trigger threshold

VTRIG

Tolerance of internal trigger

detection timing delay at

sensor

Sync Pulse Hold Time

Min

Max

Unit

Condition

2.5

V

For reduced sync pulse

3.5

V

For standard sync pulse

1.2

1.5

1.8

V

For reduced sync pulse

1.4

2.0

2.6

V

For standard sync pulse

3

μs

See definition of

parameter in PSI5 spec

9

μs

For reduced sync pulse

36

μs

For standard sync pulse

TTOLDETECT

TSHOLD

Typ

Table 16: Synchronization pulse parameters

VDD

VSYNC

TSHOLD

VDDDC

t

Figure 12: Sync pulse detection

VDDDC being the static value of the supply voltage before the synchronization pulse occurs.

11.4. Cycle Time

The periodicity of transmission (or Cycle Time) is programmable, see Figure 10. The maximum number of

Time Slots (time allocation of a Data Frame within a Cycle) is 4. Each Time Slot must be enabled

(PSI5_TSx_ENABLE) and a corresponding start time specified (PSI5_TSx_START TIME). The time separating

two consecutive Time Slots, TGAP, must be higher than T BIT.

Revision 1.0

May 2019

Page 21 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Protocol Parameter

PSI5 Cycle time selection

Symbol

Option

NVRAM parameters

0: 500 μs

Tcycle

PSI5_CYCLETIME

1: 300 μs

Table 17: Cycle time selection

11.5. Data Frame in Run-Time

11.5.1. Data Frame Content

The Data Frame consists in Start, Payload and Error Detection bits, see Table 18. The Payload consists in

Control (optional), Status (optional) and Data bits.

Data Frame content

Start bits

Bit Symbol

S0, S1

Control bits

F0-2

Payload (PD)

Status bit

E0

Data bits

A[0:N-1]

Error Detection bits

P

C0-2

Description

Frame start bits, always coded as "0"

Optional (only for High precision format).

Rolling counter, incremented once per Time Slot, during runtime and error transmission, with LSB transmission first.

Overflow leads to a reset, e.g. 0x7+0x1=0x0.

Optional (only for High precision format).

Error flag bit.

Data bits, transmitted LSB first. Recommended number of bits

for data, N∈{8, 10, 16, 20}.

Parity bit

CRC

Table 18: Description of data Content in run time

11.5.2. Data Frame Format

The Error Detection, the Payload size and the Format Precision are selectable, see Table 19.

Protocol Parameter

Error Detection

Option Id

P/CRC

Option

NVRAM parameters

0: CRC mode

1: Parity Bit mode

Payload (PD)

N/A

Selectable between 8 to 24 bits.

Data Frame Format

precision

N/A

0: PSI5 low precision

1: PSI5 high precision

PSI5_ERRORDETECTION

PSI5_PAYLOAD_SIZE

PSI5_FRAMEFORMAT_STD

Table 19: Parameterization of the format data

Revision 1.0

May 2019

Page 22 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

11.5.2.1. Data Frame Format Supported by the MLX90373

Payload

Start

S0

Data (N bits)

S1

CRC

A0 to AN-1

C2

C1

C0

Payload

Start

S0

S1

Data (N bits)

Parity

A0 to AN-1

P

Figure 13: Low Precision Data Frame Format

Payload

Start

S0

S1

Control

F0

F1

F2

Status

Data (N bits)

E0

A0 to AN-1

CRC

C2

C1

C0

Payload

Start

S0

S1

Control

F0

F1

F2

Statu s

Data (N bits)

Parity

E0

A0 to AN-1

P

Figure 14: High Precision Data Frame Format

11.5.2.2. Example of Data Frame

Start

S0

S1

Data (10 bits)

A0

A1

A2

A3

A4

A5

Parity

A6

A7

A8

A9

P

A10P-300/1L in Low Precision Format

Start

S0

S1

Control

F0

F1

Data (12 bits)

Status

F2

E0

A0

A1

A2

A3

A4

A5

A6

CRC

A7

A8

A9

A10 A11 C2

C1

C0

A16CRC-500/1L in High Precision Format

Figure 15: Example of Data Frame

11.5.3. Data

11.5.3.1. Data Selection

The data can be selected Time Slot by Time Slot (see Table 20).

NVRAM parameter

Number of bits

Description

PSI5_TSx_SENSORPARAM with x=1, 2, 3, 4 (Time Slot)

3

Time Slot data to be transmitted:

0x0: Angular data

0x1: Angular velocity

0x2: Temperature

0x3: Bfield

0x4: Ramprobe data

PSI5_x_NBITS with x= ANGULARDATA,

ANGULARVELOCITY, TEMPERATURE, BFIELD,

RAMPROBE

4

Data size: (MSB), [1 - 16] bits

Table 20: Selection of sensor data

Revision 1.0

May 2019

Page 23 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

11.5.3.2. Data Padding

Sensor Data padding is performed:

For High precision Frame Format, when PD > PSI5_x_NBITS + 4

For Low precision Frame Format, when PD > PSI5_x_NBITS

Where x=ANGULARDATA, ANGULARVELOCITY, TEMPERATURE, BFIELD, RAMPROBE.

When the padding applies, extra MSBs of A[0:N-1] are transmitted from bit number PSI5_x_NBITS to bit

number N-1 and set to 0.

11.6. Sensor Start-Up

Normal or full safe start-up after power-on reset is selectable (COLD_SAFE_STARTUP_EN).

11.7. Sensor Initialization

After startup, three initialization phases are present before entering run-time operation mode. The

initialization phases can be skipped or enabled and configured after reset or error recovery. The

parameters

associated

are

PSI5_COLD_INIT_PHASES

(normal

and

safe

boot)

and

PSI5_RECOVERY_INIT_PHASES (error recovery). Both are encoded as:

0x0: Phase II and III in succession

0x1: Skip phase II, go directly to phase III after phase I

0x2: Skip phase II and III, go directly to running mode after phase I

0x3: Reserved

11.7.1. Initialization Phase I

No sensor data is transmitted during this phase. The duration of this phase is configurable

(PSI5_INIT_I_DURATION) in step of 1ms.

Electrical Parameter

Symbol

Min

Typ

Max

Unit

Initialization Phase I duration

DURPHI

50

100

200

ms

Condition

Table 21: Description of data content of phase I

11.7.2. Initialization phase II

The content transferred during this phase includes mandatory fields (F1 -F5) and optional fields (F6-F9)

selectable (PSI5_INIT_II_EXTRA_FIELDS, MSbit enables F9). During this phase, the Status bit of the

Payload (E0) is set to 0.

The initialization phase II can be sent more than once (PSI5_INIT_II_REPETITIONCOUNT).

Revision 1.0

May 2019

Page 24 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Field

Name and NVRAM parameter

Parameter definition

Value

F1-F5: Mandatory

F1

(D1)

Protocol Description

PSI5_INIT_METAINFO

PSI5 Spec V1.x

PSI5 Spec V2.x, Data Range Initialization

PSI5 Spec V2.x, Serial Channel Initialization

0100

0110

0111

F2

(D2, D3)

Number of data nibbles

transmitted (in phase II)

PSI5_INIT_INITLENGTH

Examples:

F1- F5 = 9 Nibbles

F1- F9 = 32 Nibbles

F3

(D4, D5)

Sensor Manufacturer Code

PSI5_INIT_VENDORID

Information depending on the

corresponding sensor type

Sensor specific

information

F4

(D6, D7)

Definition of sensor type

PSI5_INIT_SENSORTYPE

Information depending on the

corresponding sensor type

Sensor specific

information

F5

(D8, D9)

Definition of specific sensor

parameters

PSI5_INIT_SENSORPARAMS

Information depending on the

corresponding sensor type

Sensor specific

information

Examples:

0000 1001

0010 0000

F6 - F9 recommended information for automotive applications

F6

(D10, D11)

Definition of sensor specific

parameters or additional

information

PSI5_INIT_SENSORCODE

To be specified by the sensor manufacturer

Sensor specific

definition

F7

(D12-D14)

Sensor Code (Sensor

application)

PSI5_INIT_SENSORAPPCODE

Usage e.g. for product revision information

Sensor specific

definition

F8

(D15-D18)

Sensor production Date

PSI5_INIT_PRODUCTIONDATE

Binary coded Julian date:

Year: 00-99 (7b)

Month: 01-12 (4b)

Day: 01-31 (5b)

Example

2006: 0000110

March: 0011

30: 11110

F9

(D19-D32)

Sensor Trace information

E.g. production lot/line/serial

number

Specified by the sensor manufacturer

MLX_ID[0-2] will be sent here

Sensor specific

definition

Table 22: Description of data content of phase II

11.7.3. Initialization Phase III

During this phase, the Status bit of the Payload (E0) is used as an error flag and the sensor sends one of

the status messages listed in the Table below.

Status message

Sent output value

"Sensor ready"

0x1E7

"Sensor defect"

0x1F4

Table 23: Description of data content of phase III

The number of messages is configurable (PSI5_INIT_III_COUNT).

Revision 1.0

May 2019

Page 25 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Electrical Parameter

Symbol

Min

Typ

Max

Unit

Initialization Phase III, number of messages

NBMSG

2

10

200

msgs

Condition

Table 24: Configuration of initialization III duration

11.8. Error Reporting Mode

When the MLX90373 detects an internal error, the error is reported through the PSI5 Data Frame using

the format depicted in section 11.8.1, transmitting the information described in section 11.8.2.

11.8.1. Error Reporting Data Format

The Data Frame content during error reporting depends on the Frame Format.

11.8.1.1. High Precision Frame Format

In case of High precision frame format then the format is defined by the following picture.

Start

0

0

Control

F0

F1

Status

F2

1

Error Register (6 bits)

Status Data (10 bits)

ER0 ER1 ER2 ER3 ER4 ER5

A0 to A9

CRC

C2

C1

C0

Figure 16: Error reporting in High precision Frame Format

11.8.1.2. Low Precision Frame Format

Status Data (10 bits)

Parity

A0 to A9

P

Figure 17: Error reporting in Low precision Frame Format

11.8.2. Error Register

The error register is computed as described in the table below depending on the error bits (See section

14.2 and safety manual for more information).

Bit number in the error register Calculation

Comment

0

GAINOOS || ROCLIP || HE_SYMMETRY

Aggregation

1

FIELDTOOLOW || FIELDTOOHIGH

Aggregation

2

ADCCLIP || ADCDROP

Aggregation

3

ADC_TEST

4

SUP_OV_VDDA || SUP_OV_V1V8

5

OVERTEMP

Aggregation

Table 25: Error register and diagnostics

Revision 1.0

May 2019

Page 26 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

11.8.3. Status Data

The status data (D0-D9) from Figure 17 is used to transmit 10 bits status data, LSB being transmitted first,

and the data value is specified in the table below.

Value(dec)

Value(Hex)

Signification

+500

0x1F4

Sensor Defect

+489

0x1E9

Sensor in service Mode

+487

0x1E7

Sensor Ready

+483

0x1E3

Reserved Sensor used

Table 26: Status data

12. End-User Programmable Items

Default values marked in the table below are subject to change.

Parameter

Description

Default

standard

#

bit

USER_ID[0..5]

User ID. Reference. Reserved for customers

traceability

see 12.1

8

MEMLOCK

Enable NVRAM write LOCK

0x0

2

SENSOR FRONT END

GAINMIN

Low threshold for virtual gain

0x01

8

GAINMAX

High threshold for virtual gain

0x3F

8

GAINSATURATION

Gain saturated on GAINMIN and GAINMAX

0x0

1

SENSING_MODE

Mapping fields for output angle

- Rotary Stray-Field robust

- Legacy mode

0x0

0x1

3

MAGNET_SREL_T[1..7]

Magnet relative sensitivity at temperature Tx. This

parameter is mainly used in linear Hall mode. It is

advised to keep defaults for other modes.

0xFF

8

DSP_NB_CONV(23)

Number of phase spinning within ADC sequence

0x0(23)

2

PROTOCOL

Selection of output protocol

0x2: PSI5 Asynchronous

0x3: PSI5 Synchronous

0x3

2

PSI5_PAYLOAD_SIZE

Payload size

0x14

5

PSI5_ERRORDETECTION

Select CRC (0) or Parity (1) as error detection

0x0

1

PSI5 OUTPUT PROTOCOL

23

Changing default value could impact the safety metrics. Default value shall be used.

Revision 1.0

May 2019

Page 27 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Default

standard

#

bit

Select 500us (0x0) or 300us (0x1) PSI5 cycle time

0x0

2

PSI5_TRANSMITSPEED

PSI5 transmission speed selection

0: Low speed transmission (125 kbit/s)

1: High-speed transmission (189 kbit/s )

0x1

1

PSI5_FRAMEFORMAT_STD

Select low (0) or high (1) precision PSI5 frame

format

0x1

1

PSI5_TRIGGER_STD

Trigger level selection

0: reduced sync pulse

1: standard sync pulse

0x1

1

PSI5_TS[1..4]_ENABLE

Enable timeslot

0x0, 0x1,

0x1, 0x0

1

PSI5_TS[1..4]_SENSORPARAM

Content of timeslot

0x0, 0x0,

0x1, 0x0

3

PSI5_TS[1..4]_STARTTIME

Start time of timeslot (TTOLDETECT excluded)

0x0, 0x175,

0x2AC, 0x0

11

PSI5_ANGULARDATA_NBITS

Number of bits to represent angular data by [1..16]

0xB

4

PSI5_ANGULARVELOCITY_NBITS

Number of bits to represent velocity data by [1..16]

0xB

4

PSI5_TEMPERATURE_NBITS

Number of bits to represent temperature data by

[1..16]

0x0

4

PSI5_BFIELD_NBITS

Number of bits to represent field strength data by

[1..16]

0x0

4

PSI5_RAMPROBE_NBITS

Number of bits to represent ramprobe data by

[1..16]

0xF

4

PSI5_ALTERNATE_A

Alternate measurement, phase A

0x0

3

PSI5_ALTERNATE_B

Alternate measurement, phase B

0x0

3

WARM_TRIGGER_LONG

Add delay to enter PTC mode (MT7V)

0x0

1

PSI5_SYNC_ERROR_REPORT

One (0) or three (1) error frames are sent for SYNC

error reporting

0x1

1

PSI5_SYNC_TO_MIN_CNT_REPORT

Number of SYNC errors to be detected before

reporting

0x0

3

PSI5_SYNC_MAX_TOL

Set timeout for receiving sync pulses

0xC

8

PSI5_SYNC_MIN_TOL

Set short condition for receiving sync pulses

0xC

8

PSI5_LOWCOMMON_MODE

Low (0, 13mA) or common (1, 26mA) current

modulation level

0x1

1

PSI5_REDUCEDCURRENT_MODE

Reduced current modulation level

0x0

1

0x1

2

Parameter

Description

PSI5_CYCLETIME

FILTERING

DSP_FILTER

Revision 1.0

Filter mode selection

May 2019

Page 28 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Default

standard

#

bit

Hysteresis threshold for EMA filter

0x0

8

DENOISING_FILTER_ALPHA_SEL

Select the alpha parameter of the IIR filter

0x0

2

PSI5_DPI_FILTER_ENABLE

Enable DPI filter in analog interface

0x0

1

VELOCITY_FILTER_FIR

Filter selection for velocity measurement

0x1

2

VELOCITY_DENOISING_FILTER_ALPH

A_SEL

Select the alpha parameter of the IIR filter of the

velocity measurement

0x0

2

VELOCITY_HYST

Hysteresis threshold for EMA filter of velocity

measurement

0x1

8

Parameter

Description

HYST

LINEAR TRANSFER CHARACTERISTIC

DSP_SEL_4PTS

Set for LNR selection

0x0

1

DSP_LNR_RESX2

Set for LNR selection

0x0

1

CW

Set rotation to clockwise

0x0

1

DP

Discontinuity point

0x0000

16

CLAMPLOW

Low clamping value of output signal

0x0010

16

CLAMPHIGH

High clamping value of output signal

0xFF80

16

USEROPTION_SCALING

Enables the output scaling

0 = [0..100%]

1 = [-50%..150%]

0x1

1

LNR_S0

Slope before point A in 4-Pts LNR

-

16

LNR_A_S, LNR_B_S, LNR_C_S,

LNR_D_S

Slopes after point A/B/C/D in 4-Pts LNR

-

16

LNR_A_X, LNR_B_X, LNR_C_X,

LNR_D_X

X coordinates of point A/B/C/D in 4-Pts LNR

-

16

LNR_A_Y, LNR_B_Y, LNR_C_Y,

LNR_D_Y

Y coordinates of point A/B/C/D in 4-Pts LNR

-

16

LNR_X[00..07]

X coordinates for the 8-Pts LNR

-

16

LNR_Y[00..07]

Y coordinates for the 8-Pts LNR

Y coordinates for the 17-Pts LNR

0x4009 -

16

GAIN_ANCHOR_MID

Re-scaling before the piece-wise linearization step

0x1

1

LNR_Y[08..16]

Y coordinates for the 17-Pts LNR

- 0xBFC8

16

LNR_S0_Q15

Slope for 32-Pts LNR

-

16

LNR_DELTA_Y[01..32]

Delta Y for 32-Pts LNR

-

8

LNR_DELTA_Y_EXPAND_LOG2

Adjust the span of LNR_DELTA_Y[01..32], for 32-Pts

LNR

0x0

2

WORK_RANGE_GAIN

Angle range in 17-Pts and 32-Pts LNR

0x10

8

Revision 1.0

May 2019

Page 29 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Parameter

Description

Default

standard

#

bit

VELOCITY

VELOCITY_ALGORITHM

Enable tracking loop algorithm for angular velocity

measurement

0x1

1

VELOCITY_ENABLE

Enable velocity measurement

0x1

1

0x0000

16

0x1(23)

1

RAMPROBE

RAMPROBE_PTR

RAM address to be probed

DIAGNOSTICS

DIAG_GLOBAL_EN(23)

Diagnostics global enable. DO NOT MODIFY!

DIAG_DEBOUNCE_STEPDOWN

Diagnostic debouncing step-down time

0x1

4

DIAG_DEBOUNCE_STEPUP

Diagnostic debouncing step-up time

0x2

4

DIAG_DEBOUNCE_THRESH

Diagnostic debouncing threshold

0x02

6

DIAG_TEMP_THR_LOW(23)

Temperature threshold for under-temperature

diagnostic

0x08

8

DIAG_TEMP_THR_HIGH(23)

Temperature threshold for over-temperature

diagnostic

0x88

8

DIAG_FIELDTOOLOWTHRES

Field limit under which a fault is reported

application

dependant

8

DIAG_FIELDTOOHIGHTHRES

Field limit over which a fault is reported

0xFF

8

OUT_DIAG_HIZ_TIME

Transient failure reporting time. When a transient

digital failure is detected, the output drivers are

disabled during N ms. The time-out is calculated as:

timeout = (OUT_DIAG_HIZ_TIME+1) * 4 * 1ms.

0x7

3

COLD_SAFE_STARTUP_EN

Normal (0) or full safe (1) start-up after power-on

reset

0x0

1

INITIALIZATION

PSI5_COLD_INIT_PHASES

Initialization phase configuration, after normal and

safe boot

0x0

2

PSI5_RECOVERY_INIT_PHASES

Initialization phase configuration, after error

recovery

0x2

2

PSI5_INIT_I_DURATION

Duration of initialization phase I

0x32

8

PSI5_INIT_II_EXTRA_FIELDS

Enable extra fields in initialization phase II

0x0

4

PSI5_INIT_II_REPETITIONCOUNT

Repetition count of initialization phase II

0x4

4

PSI5_INIT_METAINFO

Initialization phase II, protocol description

0x6

4

PSI5_INIT_INITLENGTH

Initialization phase II, number of nibbles

0x09

8

PSI5_INIT_VENDORID

Initialization phase II, vendor identification

0x06

8

PSI5_INIT_SENSORTYPE

Initialization phase II, sensor type

0x06

8

Revision 1.0

May 2019

Page 30 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

Default

standard

#

bit

Initialization phase II, sensor specific parameters

0x00

8

PSI5_INIT_SENSORCODE

Initialization phase II, sensor manufacturer

0x00

8

PSI5_INIT_SENSORAPPCODE

Initialization phase II, sensor application specific

code

0x000

12

PSI5_INIT_PRODUCTIONDATE

Initialization phase II, production data

0x0000

16

PSI5_INIT_III_COUNT

Message count for initialization phase III

0x2

8

Parameter

Description

PSI5_INIT_SENSORPARAMS

Table 27: End-user Programmable Items

12.1. End-User Identification Items

Parameter

Description

Default Standard

# bit

MLX_ID0

X-Y position on the wafer (8 bits each)

-

16

MLX_ID1

Wafer ID (5 bits); Lot ID [10..0] (11 bits)

-

16

MLX_ID2

Lot ID [16..11] (6 bits); Fab ID (4 bits); Test Database ID (6 bits)

-

16

CHIP_

VERSION

IMC shape version identifier

Order code 10x

Order code 30x

0

1

7

Status of MLX final test (0: Fail and 1: Pass)

1

1

Program '1' at last step of FT to indicate a bin 1

1

8

0

8

1

8

USER_ID3

2

8

USER_ID4

0

8

USER_ID5

0

8

TEST_STATUS

USER_ID0

USER_ID1

USER_ID2

Die version (1 = ABA)

Table 28: End-user identification items

13. Description of End-User Programmable Items

13.1. Output Transfer Characteristic

13.1.1. Selection

The transfer function (LNR) is selectable ( DSP_SEL4PTS and DSP_LNR_RESX2) as per the Table 29.

Revision 1.0

May 2019

Page 31 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

DSP_SEL4PTS

DSP_LNR_RESX2

LNR type

1

0

4Pts

1

1

8Pts

0

0

17Pts

0

1

32Pts

Table 29: Output Transfer Characteristic Selection

13.1.2. Programmable Items

Output Mode

LNR type

4pts

8pts

17pts

32pts

Value

Unit

0: 0 100

1: -50 150

%

USEROPTION_SCALING

●

●

●

CW

●

●

●

●

0: CCW

1: CW

LSB

DP

●

●

●

●

0 359.9999

Deg.

CLAMPLOW

●

●

●

●

0 100

%

CLAMPHIGH

●

●

●

●

0 100

%

LNR_x_X with x=A, B, C, D

●

0 359.9999

Deg.

LNR_x_Y with x=A, B, C, D

●

see USEROPTION_SCALING

%

LNR_S0

LNR_x_S with x=A, B, C, D

●

-17 … 0 … 17

%/Deg.

0 359.9999

Deg.

see USEROPTION_SCALING

%

LNR_Xx with x=0-7

●

LNR_Yx with x=0-7

●

LNR_Yx with x=8-16

●

●

LNR_DELTAYx with x=0132

●

0 100%

selectable

offset range

LNR_S0_Q15

●

0 … 0.555

% /Deg. (scales

with working

range)

LNR_DELTA_Y_EXPAND

_LOG2

●

-3.125 3.125

-6.256.25

-12.5 12.5

-25 25

%

GAIN_ANCHOR_MID

●

Always use “1”

●

-01x code: 11.29 180

-03x code: 22.59 360

WORK_RANGE_GAIN

●

Deg.

Table 30: Programmable items: Output transfer characteristic

Revision 1.0

May 2019

Page 32 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

13.1.3. Enable Scaling Parameter

The parameter USEROPTION_SCALING enables to double the scale of Y coordinates linearization

parameters, see the Table 31. This is valid for all Output Linear Characteristic except the 32 segments

one.

USEROPTION_SCALING

LNR_Y min value

LNR_Y max value

0

0%

100%

1

-50%

150%

Table 31: Y coordinates scaling

13.1.4. CLOCKWISE Parameter

The CLOCKWISE parameter defines the magnet rotation direction (CW).

CCW is the defined by 1-8-9-16 pin order direction for the TSSOP-16 package.

CW is defined by the reverse direction: 16-9-8-1 pin order direction for the TSSOP-16 package.

Refer to the drawing in the sensitive spot positioning (see 18.1.3 and 18.2.3)

13.1.5. Discontinuity Point or Zero Degree Point

The Discontinuity Point (DP) defines the 0 Deg. point on the circle. The DP places the origin at any

location of the trigonometric circle. The DP is used as reference for all the angular measurements.

360 Deg.

0 Deg.

Figure 18: The placement of the DP is programmable

Revision 1.0

May 2019

Page 33 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

13.1.6. CLAMPING Parameters

The clamping levels are two independent values to limit the output voltage range. The CLAMPLOW

parameter adjusts the minimum output voltage level. The CLAMPHIGH parameter sets the maximum

output voltage level. Both parameters have 16 bits of adjustment and are available for all LNR modes.

13.1.7. WORKING RANGE (PWL only)

The range for the angle can be selected using the WORK_RANGE_GAIN parameter, which applies a fixed

gain to the transfer characteristics. Using WORK_RANGE_GAIN parameter, the anchor point is kept at 180°

and the range is symmetrically set around this value. It creates a zoom-in of the angle around this point.

WORK_RANGE_GAIN is coded on 8 bits where the 4 MSB defines the integer part and the 4 LSB the

fractional parts (in power of twos). Therefore, the following equation applies to define the angle range

W:

with FA=180° for -10x code and FA=360° for -30x code.

Both minimal and maximal angles are then defined by:

where θmin corresponds to the angle yielding 0% output and θmax the angle giving a 100% output.

Following table gives the extreme values as example:

WORK_RANGE_GAIN

0x10

0xFF

code

Range (w)

θmin

θmax

Δx 17 pts

Δx 32 pts

-10x

180°

90°

270°

11.25°

5.63°

-30x

360°

0°

360°

22.50°

11.25°

-10x

11.29°

0°

360°

0.71°

0.35°

-30x

22.59°

168.7°

191.3°

1.41°

0.71°

Table 32: Working range defined with GAIN parameter and option code

Outside of the working range, the output will remain at clamping levels.

13.1.8. 4-Pts LNR Parameters

The LNR parameters, together with the clamping values, fully define the relation (the transfer function)

between the digital angle and the output signal.

The shape of the MLX90373 four points transfer function from the digital angle value to the digital o utput

is described in Figure 19. Seven segments can be programmed but the clamping levels are necessarily

flat.

Two, three, or even six calibration points are then available, reducing the overall non-linearity of the IC

by almost an order of magnitude each time. Three or six calibration point will be preferred by customers

Revision 1.0

May 2019

Page 34 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

looking for excellent non-linearity figures. Two-point calibrations will be preferred by customers looking

for a cheaper calibration set-up and shorter calibration time.

100%

CLAMPHIGH

Clamping High

D

LNR_D_Y

C

Slope LNR_C_S

LNR_C_Y

B

LNR_B_Y

A

Slope LNR_B_S

Slope

LNR_A_S

LNR_A_Y

Slope

LNR_S0

CLAMPLOW

0%

LNR_A_X

0 (Deg.)

Slope LNR_D_S

Clamping Low

LNR_B_X

LNR_C_X

LNR_D_X

360 (Deg.)

Figure 19: 4-Points Transfer function

13.1.9. 8-Pts LNR Parameters

The 8-Pts LNR parameters, together with the clamping values, fully define the relation (the transfer

function) between the digital angle and the output signal.

The shape of the MLX90373 eight points transfer function from the digital angle value to the output

voltage is described in Figure 20. Eight calibration points [LNR_X0...7, LNR_Y0...7] together with 2 fixed

points at the extremity of the range ([0°, 0%] ; [360°, 100%]) divides the transfer curve into 9 segments.

Each segment is defined by 2 points and the values in between is calculated by linear interpolation.

100%

CLAMPHIGH

Clamping High

LNR_Y7

7

...

5

4

3

2

LNR_Y1

LNR_Y0

6

1

0

Clamping Low

CLAMPLOW

0%

0 (Deg.)

LNR_X0 LNR_X1

...

LNR_X7

360 (Deg.)

Figure 20: 8-Points Transfer function

Revision 1.0

May 2019

Page 35 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

13.1.10. 17-Pts LNR Parameters (PWL)

The LNR parameters, together with the clamping values, fully define the relation (the transfer function)

between the digital angle and the output signal.

The shape of the MLX90373 seventeen points transfer function from the digital angle value to the output

voltage is described in Figure 21. In the 17-Pts mode, the output transfer characteristic is Piece-WiseLinear (PWL).

LNR_Y16

16

100

LNR_Y15

LNR_Y14

15

14

Output [%]

...

13

12

11

10

LNR_Y9

LNR_Y8

50

LNR_Y7

9

8

7

Δx = w/16, fixed delta angle, with

6

...

5

w=

4

LNR_Y3

LNR_Y2

LNR_Y1

DP(0,0)

LNR_Y0

16·360°

WORK_RANGE_GAIN

3

1

180-

2

w

2

180

Angle [°]

180+

w

2

0

Figure 21: 16-Segments calibration transfer function

All the Y-coordinates can be programmed from -50% up to +150% to allow clamping in the middle of one

segment (like on the figure), but the output value is limited to CLAMPLOW and CLAMPHIGH values.

Between two consecutive points, the output characteristic is interpolated.

13.1.11. 32-Pts LNR Parameters (PWL)

The LNR parameters, together with the clamping values, fully define the relation (the transfer function)

between the digital angle and the output signal.

The shape of the MLX90373 thirty-two points transfer function from the digital angle value to the output

voltage is described in Figure 22. In the 32-Pts mode, the output transfer characteristic is Piece-WiseLinear (PWL).

Revision 1.0

May 2019

Page 36 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

LNR_Delta_Y32

100

Output [%]

CLAMPHIGH

LNR_deltaY :

Programmable delta correction vs. Ideal slope (%)

The adjustable range can be selected from

[+/-3.125%, +/-6.25%, +/-12.5%, +/-25%]

Adjustable

range

Δx fixed delta angle (w/32)

Prog. Slope :

WORK_RANGE_GAIN

LNR_Delta_Y16

LNR_Delta_Y15

50

Anchor point

w=

CLAMPLOW

DP(0,0)

Δx

LNR_Delta_Y01

180-

16·360°

WORK_RANGE_GAIN

w

2

180

Angle [°]

180+

w

2

Figure 22: 32-Segments calibration transfer function

The points are spread evenly across the working range (see 13.1.7 for working range selection). The Ycoordinates can be offset from the ideal characteristic within an adjustable range defined by

LNR_DELTA_Y_EXPAND_LOG2. The available values are summarized in the table below. All

LNR_delta_Y## parameters are encoded in a fractional signed 8-bit value.

LNR_DELTA_Y_EXPAND_LOG2

Offset range %

Delta range [LSB12]

Resolution [LSB12]

0

±3.125

-128..127

1

1

±6.25

-256..254

2

2

±12.5

-512..508

4

3

±25

-1024..1016

8

13.2. Sensor Front-End

Parameter

Value

SENSING_MODE

[0 - 4]

GAINMIN

[0 - 63]

GAINMAX

[0 - 63]

GAINSATURATION

[0, 1]

Table 33: Programmable items: sensor front-end

Revision 1.0

May 2019

Page 37 of 55

�MLX90373 Triaxis® Position Processor

Datasheet

13.2.1. SENSING MODE

The SENSING_MODE parameter defines which sensing mode and fields are used to calculate the angle.

The different possibilities are described in the tables below.

This 2 bits value selects the first (B1) and second (B2) field components according the table below.

SENSING_MODE

B1

B2

Application

0

ΔX

ΔY

Angular Rotary Stray-Field Immune

1

X

Y

Legacy / XY Angular Rotary

2

Y

Z

Legacy / YZ Angular Rotary

3

X

Z

Legacy / XZ Angular Rotary

Table 34: Programmable items: sensing modes

13.2.2. GAINMIN and GAINMAX Parameters

GAINMIN and GAINMAX define the thresholds on the gain code outside which the fa ult “GAIN out of

Spec.” is set. If GAINSATURATION is set, then the virtual gain code is saturated at GAINMIN and

GAINMAX, and no Diagnostic fault is set since the saturations applies before the diagnostic check.

13.3. Filter

The MLX90373 includes 2 types of programmable filters:

Low Pass FIR Filter.

Exponential moving average Filter.

Filter

Low Pass

Angular

Angular

velocity

●

DSP_FILTER

●

[0 - 2]

VELOCITY_FILTER_FIR

●

Exponential

moving

average

Value

parameter

HYST

[0 - 255]

●

VELOCITY_HYST

[0 - 1]

●

VELOCITY_DENOISING_FILTER_ALPHA_SEL

●

DENOISING_FILTER_ALPHA_SEL

[0 - 3]

Table 35: Filtering configuration