PTC04

Programmer for Melexis PTC Devices

1. Features

2. Application Examples

Universal programming utility

Fast development

Fast plug-in for software applications

Atmega128 Core

Firmware updatable via RS232 and USB

FPGA updatable via RS232 and USB

3 High Current Programmable Supplies

1 High Speed Fast Programmable Supply

16 bit Level Settings

16 bit differential Measurements

4 analog comparators

Vector Generator

I2C to Daughter Board

Mountable in 19” Rack

Experimental tool for Lab and Prototyping

Production Equipment for Serial

Programming

Programming tool for characterization

3. Ordering information

Product Code

PTC04

Description

Programmer Unit (Full Set: Including adapter, cables, software)

PTC04-DB-HALL01

Daughter Board 1st generation Linear Hall sensors products

PTC04-DB-HALL03

Daughter Board 2nd generation Linear Hall and current Sensors

PTC04-DB-HALL04

Daughter Board PSI5 interface products

PTC04-DB-HALL05

Daughter Board Current sensor products

PTC04-DB-90316

Daughter Board Triaxis sensor products

PTC04-DB-HALL06

Daughter Board 2nd and 3rd generation Triaxis and Linear sensor products

PTC04-DB-PRESSURE01

Daughter Board Pressure sensors products

PTC04-DB-SPI

Daughter Board SPI interface products

PTC04-DB-FastLoader

Daughter Board LIN interface products

PTC04-DB-922xx

Daughter Board Latch and Switch products

PTC04-DB-xxxxx

Other Daughter Boards for future products

PTC04-19-x (with x equal to 1 till 2)

19”Rack with build in x number of PTC04

4. Accessories

Product Code

Software Environment MPT (Windows)

Description

Including Calibration Software and update tools

DLL for Mini-Tester (Windows)

DLL’s for all supported products (Windows)

User Interface for most support products

(Windows)

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 1 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

5. Functional Diagram

Figure 5-1 PTC04 Functional Block Diagram

6. General Description

The PTC-04 programmer was designed for efficient, precise calibration of the Melexis families of programmable

ICs. The programmer is designed to be easily adapted to a standard PC and to an application module to allow

calibration of programmable sensor ICs within the operating environment. The PTC-04 programmer contains its

own programmable power supply and measurement circuitry. The programmer is similar to a standard EEPROM

programmer, but adds many special features such as 16 bit voltage and current measurement capability, and

configuration options that will accommodate users from the prototyping phase directly into production. An IBM

compatible PC is required (not included) to load software to the programmer and control the functions of the

programmer.

Communication is done through a standard RS-232 null modem cable to a COM port of the PC or via USB. The PC

requires no custom configuration, allowing the programmer to be used with any PC with a COM port speed of

115.2kbs or a standard USB 1.1 or USB 2.0 interface

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 2 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

7. Contents

1. Features .................................................................................................................................................... 1

2. Application Examples................................................................................................................................ 1

3. Ordering information................................................................................................................................ 1

4. Accessories ............................................................................................................................................... 1

5. Functional Diagram .................................................................................................................................. 2

6. General Description .................................................................................................................................. 2

7. Contents ................................................................................................................................................... 3

8. Glossary of Terms ..................................................................................................................................... 5

9. Absolute Maximum Ratings ...................................................................................................................... 5

10. PTC04 Electrical Specifications ............................................................................................................... 5

10.1. System Power Supply ..................................................................................................................... 5

10.2. Programmable High Current Power Supply 1-3 ............................................................................ 6

10.3. Programmable Fast Power Supply................................................................................................. 6

11. Measurement System ............................................................................................................................ 7

12. Function Timings .................................................................................................................................... 7

13. Unique Features ..................................................................................................................................... 8

13.1. Mini-Tester ..................................................................................................................................... 8

13.2. Analogue Vector Generator ........................................................................................................... 8

13.3. Acquisition memory ....................................................................................................................... 8

13.4. Port E Atmega128 .......................................................................................................................... 8

14. Main Board Description .......................................................................................................................... 9

14.1. Board Layout .................................................................................................................................. 9

14.2. Power Supplies ............................................................................................................................... 9

14.3. Power Supply System Check ........................................................................................................ 10

14.4. Supply Connector ......................................................................................................................... 10

14.5. LED Indicators .............................................................................................................................. 10

14.6. USB Connector ............................................................................................................................. 10

14.7. RS 232 Connector ........................................................................................................................ 10

14.8. Reset button ................................................................................................................................ 11

14.9. Daughter board Connectors ........................................................................................................ 11

14.9.1. Digital DB Connector (40 Pins)............................................................................................... 12

14.9.2. Analog DB Connector (48 Pins) .............................................................................................. 13

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 3 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

15. Daughter board concept ...................................................................................................................... 13

15.1. Background .................................................................................................................................. 13

15.2. Requirements ............................................................................................................................... 13

16. RS 232 Communication with host ........................................................................................................ 14

16.1. Connector..................................................................................................................................... 14

16.2. Cable............................................................................................................................................. 14

16.3. Settings ......................................................................................................................................... 14

17. USB Communication with host ............................................................................................................. 15

17.1. Connectors ................................................................................................................................... 15

17.2. Cable............................................................................................................................................. 15

17.3. Settings ......................................................................................................................................... 15

18. Measurement system ........................................................................................................................... 16

18.1. Channels ....................................................................................................................................... 16

18.2. Conversion time ........................................................................................................................... 16

18.3. Accuracy ....................................................................................................................................... 16

19. Application Information........................................................................................................................ 17

20. FAQ ....................................................................................................................................................... 17

21. Mechanical Outlines ............................................................................................................................. 18

22. ESD Precautions.................................................................................................................................... 20

23. Contact ................................................................................................................................................. 20

24. Disclaimer ............................................................................................................................................. 21

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 4 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

8. Glossary of Terms

PTC04

The programmer (including the applicable DB)

DB

Daughter board

PTC

PPS

MPT

PSF

DLL

Program Through Connector

Programmable Power Supply

Melexis Programmable Toolbox

Product specific function library (DLL)

Dynamic-link library

9. Absolute Maximum Ratings

Parameter

Supply Voltage (External input)

VS EXT

Reverse Voltage Protection

Value

48.2

Units

V

Yes

Supply Current

IS Fused

1

A

PPS 1,2,3 Output voltage

VPPS

34

V

PPS 1,2,3 Output Current (peak value)

IPPS

500

mA

PPS 4 Output Current (peak value)

IPPS

50

mA

Operating Temperature Range

TA

35

°C

Storage Temperature Range

TS

0°C – 55

°C

Table 1: Absolute maximum ratings

Exceeding the absolute maximum ratings may cause permanent damage. Exposure to absolute maximum rated conditions

for extended periods may affect device reliability.

10. PTC04 Electrical Specifications

10.1. System Power Supply

DC Operating Parameters TA = 25-35oC, V ext = 48V (unless otherwise specified)

Parameter

DC System Power Supply

Symbol

Vext_in

System Current Consumption

IExt_in

Test Conditions

Min

23

Typ

48

0.1

Daughter Board Analog Power Supply *

500

5

500

Daughter Board Digital Power Supply

Max

48.2

Units

V

1.2

A

36

V

mA

V

mA

Table 2: General electrical parameters

*Depends on DC System Power Supply

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 5 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

10.2. Programmable High Current Power Supply 1-3

DC Operating Parameters TA = 25-35oC, V ext = 48V (unless otherwise specified)

Parameter

Output voltage range *

Symbol

VPPS 1-3

Test Conditions

Unloaded

Min

0.62

Output resolution

Typ

Max

34.00

Units

V

0.52

mV

Output Current (peak value)

IPPS 1-3

-500

500

mA

Current Limit range

I limPPS 1-3

-500

500

mA

Unloaded

10

20

uS

I out = 10mA

0.035

34

V

I out = 100mA

0.2

32.5

V

I out = 500mA

1.15

26

V

I out = -10mA

1.14

34

V

I out = -100mA

2.3

30

V

I out = -500mA

9.46

30

V

Voltage Source Accuracy

PPS1-3, I out = 10mA

-1

-1.05

+1

+1.05

%

mV

Voltage Source Slew Rate

PPS1-3, C load = 100nF

PPS1-3, C load = 1uF

Between 20 & 80%

2.5

0.5

Settling time

Voltage Source Swing

PPS1-PPS3

Vout

V/uS

Table 3: Programmable High Current Power Supply 1-3

*Depends on the DC System Power Supply

10.3. Programmable Fast Power Supply

DC Operating Parameters TA = 25-35oC, V ext = 48V (unless otherwise specified)

Parameter

Output voltage range

Symbol

VPPS 4

Test Conditions

When Fast DAC = 255

Min

0.37

Output resolution

Output Current (peak value)

Typ

Max

13

0.2

IPPS 4

-20

Units

V

mV

20

Fast DAC resolution

Divider between Pos and Neg voltage

Settling time

This is taken by changing the Fast DAC only

0.5

5

uS

I out = 10mA

I out = 50mA

1

0.5

13

10

V

Voltage Source Accuracy

PPS4, I out = 10mA

-1

-0.8

+1

+0.8

%

mV

Voltage Source Slew Rate

Using 8 bit Fast DAC

PPS4, C load = 100nF

PPS4, C load = 1uF

Between 20 & 80%

0.25

0.08

Voltage Source Swing PPS4

Vout

8

mA

bits

V/uS

Table 4: Programmable Fast Power Supply

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 6 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

11. Measurement System

DC Operating Parameters TA = 25-35oC, V ext = 48V (unless otherwise specified)

Parameter

ADC Channels

Symbol

Test Conditions

Min

Typ

16

Max

Units

Pin Potential

-0.5

35.5

V

Voltage range (full mode)

-37.5

37.5

V

Resolution (full Mode)

1.15

mV

Accuracy (full Mode)

-0.1

-1.15

+0.1

+1.15

%

mV

Voltage range (fine mode)

-7.8

7.8

V

Resolution (fine Mode)

0.24

Accuracy (fine Mode)

Current Meter Range

PPS1-3

PPS4

Resolution (full Mode)

PPS1-3

PPS4

Current Meter Accuracy

PPS1-3

PPS4

mV

-0.1

-0.25

+0.1

0.25

%

mV

-500

-50

500

50

mA

77

52

uA

-2

-0.312

-2

-0.5

+2

0.312

+2

0.5

%

mA

%

mA

Table 5: Programmable Fast Power Supply

12. Function Timings

DC Operating Parameters TA = 25-35oC, V ext = 48V (unless otherwise specified)

Parameter

Voltage Source Program Rate

Symbol

Test Conditions

PPS1-4, Using PC Software and RS232

interface

Using vector functions

Min

Typ

20

Max

10

Units

mS

uS

Voltage Source Noise

PPS1-4, Peak-to-peak

2

Current Measurement Sample Time

Firmware Only

PC software and RS232

0.5

20

5

mV

mS

Table 6: Function Timings

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 7 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

13. Unique Features

13.1. Mini-Tester

Due to the architecture of the Hardware in combination with the Software, the PTC04 can be used as a mixed mode tester

(With limited performance).

There are library routines (DLL) available in order to interface with any software language. (C++, Visual Basic, Lab view, Excel

(VBA)…)

13.2. Analogue Vector Generator

A vector space of 512Kbyte allows you to store a huge amount of actions. These actions consist of setting a level on a

channel, waiting a time x, setting the Fast DAC and making samples on an analogue input (measurement) or a digital

comparator. For details, refer to the PSF of the PTC04 chapter Pattern functions.

13.3. Acquisition memory

An advance library on the Analogue vector generators, allows use of the vector area in combination with Measurement and

setting levels. Through this method one may use the PTC04 as a slow Data acquisition card.

13.4. Port E Atmega128

The port E of the Atmega128 core is connected fully to the Daughter board.

With this port, items like critical timing generation measurements can be performed. Also, all types of UARTS can be

configured. Other capabilities are possible with the PTC04.

For more details, refer to the Atmega128 datasheet.

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 8 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

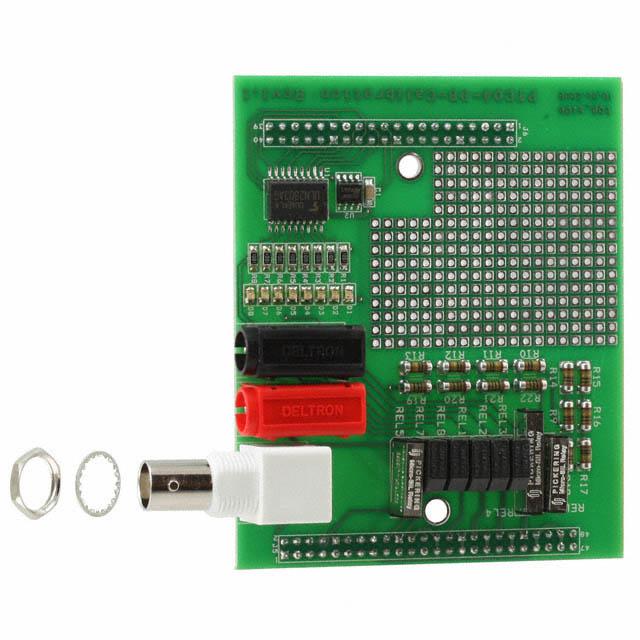

14. Main Board Description

14.1. Board Layout

Figure 14-1

As shown in Figure14-1, The Main board can be divided in 4 major areas.

The Supplies where all required voltage and current levels are created

The digital Core that processes all requests from the host computer

A Driver Area where the Programmable Power supplies are located

A Measurement area where the ADC and the input MUX are located

Beside these four areas, there are the input connector on the main board and the two connectors to the daughter board.

14.2. Power Supplies

The Power Supply input connector is a single input to supply the whole PTC. The Input supply requires a minimum of 24 volts

and can tolerate a maximum of 48 volts. It is not recommended to use a higher voltage than needed for the application.

There’s an internal fuse (on the main board) of 1 A in order to avoid damage when improperly used. The connected supply

should provide a minimum current of 1.5 A with peak capacity to source 10A.

The external Supply is the source to create all the internal requirements. Internal voltages are created on the main board by

using the input voltage from the external supply.

+35V for drivers

+5V Digital

+5V Analog

+3.3 V Digital

Revision 008 - 13 January 2021

3901290014501

(for the drivers or Programmable Power Supplies)

(Digital core as interface between PTC and Host application)

(measurement circuit with MUX and ADC)

(Supply for the FPGA and USB)

Datasheet

Programmer for Melexis PTC Devices

Page 9 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

14.3. Power Supply System Check

When something goes wrong it’s useful to check the status of all the above mentioned supplies.

The main board has the capability to measure all internal supplies. The only requirement is that the +5V Digital supply is

available. This is indicated by the red led on the rear panel of the programmer.

All the other supply could be checked by the Measurement system itself. Channels 8 till 11 are reserved for this. The channel

8 is connected to the driver supply and is very useful to check the voltages of the connected external supply. This can be

useful to check when applications are launched where extra high voltage is needed. Refer to the chapter “Measurement

system” for more details about measuring these channels. There are DLL functions available that will do these checks for

you.

A typical diagnostic check will start with checking if the external supply is available. Then it will check if the red led is lit. If

these steps are ok, the diagnostics via software can be executed.

14.4. Supply Connector

This connector provides the PTC with power. Either the power connector on the front or on the back side of the PTC04 can

be used.

Any power source that generates a voltage between 24 and 48 V DC with a minimum current of 1.5 A is allowed.

+24-48V DC

0V

Figure 14-2

14.5. LED Indicators

Two Led indicators will help the user to check the status of the PTC

The red led shows that the core inside has power

The green led will show a busy status. If the Programmer is executing a job, the led will be on.

Figure 14-3

14.6. USB Connector

One of the communication possibilities with the host PC is the USB link.

See chapter “USB communication with host” for more details

14.7. RS 232 Connector

One of the communication possibilities with the host PC is the serial Communication.

See chapter “RS communication with host” for more details

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 10 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

14.8. Reset button

This button is connected to all reset lines in the main board as well as on the daughterboard. This button allows the user to

reset the whole programmer after crashing software and when connected also to the application device under test.

14.9. Daughter board Connectors

The main board has two connectors to the interface with the application. The PTC allows the addition of a full PCB in

between the main board and the interface. This daughter board can be mounted on the two connectors. In some

exceptional cases, a daughter board contains only a few wires from the Analog connector to the application connector.

The connectors are described below.

Digital DB Connector

A0

A2

A4

A6

D0

D2

D4

D6

Rd

SCL

F8

FA

FC

FE

PE0

PE2

PE4

PE6

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

A1

A3

A5

A7

D1

D3

D5

D7

Wr

Reset

SDA

F9

FB

FD

FF

PE1

PE3

PE5

PE7

+5V_Digital_Supply

40 Pin Header

DGND

Analog DB Connector

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

47

SHTD_PPS1

SHTD_PPS2

SHTD_PPS3

SHTD_PPS4

ISENSE_PPS1

ISENSE_PPS2

ISENSE_PPS3

ISENSE_PPS4

ANA.COMP0

ANA.COMP2

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

48 pin Header

AGND

Meas_Line_P1

Meas_Line_P2

Meas_Line_P3

Meas_Line_P4

Meas_Line_N1

Meas_Line_N2

Meas_Line_N3

Meas_Line_N4

+36V_SUPPLY

+2.5V_REF_SUPPLY

VOUT_PPS1

VOUT_PPS2

VOUT_PPS3

VOUT_PPS4

ANA.COMP1

ANA.COMP3

AGND

Figure 14-4: Daughter Board Connectors

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 11 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

14.9.1. Digital DB Connector (40 Pins)

Mainly, the digital connector is meant to expand the programmer for extra needs. Address lines A0-A7 together with the

Map Select Lines F8-FF allows the user direct access to an area of 2 K. Example would be adding a simple addressed I/O

register by using the selection lines. If more complexity is needed, a full FPGA can be mounted on the DB board.

Pins

1–8

Names

A0 – A7

Description

Address lines

9 – 16

D0 – D7

Data Lines active during Rd or Wr signals

17

Rd

Read : A negative pulse will indicate a sampling of the data on the Data Bus

18

Wr

Write : A Negative pulse will indicate when data is available on the Data Bus

20

Reset

This signal goes low by powering the PTC or by pressing the reset button.

This line can be pulled low by application.

Check firmware documentation for resetting by software.

21-22

SCL / SDA

I2c Bus

23-30

F8,F9,…,FF

CS lines when the address areas are accessed

31-38

Port E

Note: These pins are limited to 5 Volt input\output.

The full Port E of the Atmega core is mounted to these pins. This allows us to use

advanced features like PWM, UARTS, Time Measurements, etc.

By using firmware that supports these functions, really nice application specific

requirements can be fulfilled.

39

DGND

Digital Ground

40

+5V Digital

5 Volt Digital Supply. Maximum current to get out of this supply : ….mA

Table 7: Digital daughter board connector

Note: All the pins are limited to 5 Volt input\output. However, there are protections, please take precautions in order to avoid

damage to the main board.

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 12 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

14.9.2. Analog DB Connector (48 Pins)

Mainly, the analog connector provides all the analog signals and measure possibilities.

Pins

28,32,36

Names

PPS 1-3

Description

Output of the Programmable Supplies

40

PPS 4

Output of the Fast DAC Programmable Power Supply

27,31,35,39

Isense_PP1-4

Outputs (Driver outputs before Rsens) for current evaluations.

These outputs could be used to connect to the analog comparators in order to

create fast digital signals based on current.

2,4,6,8

ExtMeas1-4Pos

There are 4 differential inputs for making measurements

10,12,14,16

ExtMeas1_4Neg

The negative inputs of ExtMeas1-4Pos

17,19,21,23

Shtd_PPS1-4

Outputs that show the status of the Drivers.

Signals are meant to connect LED’s for the front panel

43,44,47,48

AnaComp0-3

See *Note.

Input (limited to 5V)

Fast Level comparators in order to remove time consuming measurement

18

+35V_Supply

Supply to extend the daughter board with some extra drivers

20

NC

Not Connected

24

+2.5V Ref

Output of internal reference

All other

AGND

Analog Ground

Table 8: Analog daughter board connector

Note: All the pins are limited to 35 Volt input\output! However, there are protections, please take precautions in order to

avoid damage of the main board.

* Note: Some pins are protected and limited to 5 Volt! However, there are protections, please take precautions in order to

avoid damage of the main board.

15. Daughter board concept

15.1. Background

The future of our products is not known and building a universal programmer will not be possible to survive more than a few

years. For this reason, a flexibility is built in by having a Daughter board (abbreviation: DB) as interface between PTC04 and

the application connector. On this way, special needs can be fulfilled. The simplest DB is just wires form the DB connectors to

the application connector. The idea is to support with one single DB as many as possible products.

15.2. Requirements

See specific daughter board documentation.

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 13 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

16. RS 232 Communication with host

This page describes all items concerning the hardware of the RS232C communication link.

Information about the protocol is explained in the software documentation.

16.1. Connector

DB9-Male

2

Description

RxD

3

TxD

5

GND

Table 9: RS232 connection

(At the Computer and at the PTC04)

9 PIN D-SUB MALE at the Computer.

16.2. Cable

The cable between PTC and Host PC is a standard null-modem cable for RS232C Cable Description:

DB9-FEM

2

DB9 FEM

3

Description

RxD / TxD

3

2

TxD / RxD

5

5

GND

Table 10: RS232 cable

16.3. Settings

The microprocessor core has a fixed setting to communicate with the host.

Used settings are as follows:

Parameter

Baud rate

Value

115, 2 kBps

Bits

8

Parity

No

Flow Control

None

Stop bits

1

Table 11: RS232 settings

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 14 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

17. USB Communication with host

Universal Serial Bus (USB) is used (V1.0)

Developed by Compaq, Hewlett-Packard, Intel, Lucent, Microsoft, NEC and Phillips.

17.1. Connectors

Pin

1

Name

VBUS

Description

+5 VDC

2

D-

Data -

3

D+

Data+

4

GND

Ground

Table 12: USB connection

17.2. Cable

Default:

USB A (at the Connector) to plug into a PC

USB B (at the Connector) to plug into the PTC04

Series "A" plugs are used towards the host system and series "B" plugs are used towards the USB device.

17.3. Settings

Two drivers have to be installed and are available in one executable on the Software CD.

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 15 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

18. Measurement system

The measurement system on the main board contains mainly a high accurate 16 bit ADC and two 16 to 1 channels MUX.

Basically, the ADC always measures differential between inputs.

For the internal voltage channels, the negative input is the internal analog ground.

For the current measurements that use a sense resistor (PPS1-4) are clearly measuring over the sense resistor.

There are also 4 full differential lines going to the daughter board allowing the user to make high quality measurements by

selecting the reference by the application itself. This way of working easily supports the use of force and sense lines.

18.1. Channels

Nr.

0

Pos Input

Vout PPS1

Neg Input

Internal AGND

Description

Output Voltage PPS1

1

V driver PPS1

Vout PPS1

Output Current PPS1

2

Vout PPS2

Internal AGND

Output Voltage PPS2

3

V driver PPS2

Vout PPS2

Output Current PPS2

4

Vout PPS3

Internal AGND

Output Voltage PPS3

5

V driver PPS3

Vout PPS3

Output Current PPS3

6

Vout PPS4

Internal AGND

Output Voltage PPS4

7

V driver PPS4

Vout PPS4

Output Current PPS4

8

Supply Driver: +35/2

Internal AGND

Driver Supply divide by 2

9

Supply Analog : +5 V

Internal AGND

Analog 5V Supply

10

Supply Digital : +5 V

Internal AGND

Digital 5V Supply

11

Reference : +2.5V

Internal AGND

Reference Voltage for DAC\ADC

12

DB_Ana_conn Pin 2

DB_Ana_conn Pin 10

Daughterboard Meas. Channel 1

13

DB_Ana_conn Pin 4

DB_Ana_conn Pin 12

Daughterboard Meas. Channel 2

14

DB_Ana_conn Pin 6

DB_Ana_conn Pin 14

Daughterboard Meas. Channel 3

15

DB_Ana_conn Pin 8

DB_Ana_conn Pin 16

Daughterboard Meas. Channel 4

Table 13: ADC measurement channels

18.2. Conversion time

In general the conversion time depends on the loaded firmware version. Theoretically, a full conversion to a floating real

value takes about 4ms if the filter is put at 100 samples.

18.3. Accuracy

To preserve the accuracy of the PTC04, Melexis recommends checking the tolerance of the PTC04 once a year.

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 16 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

19. Application Information

When using the PTC04 in combination with external equipment or other PTC04’s, it is very important to have a good solid

earth/ground connection on the different appliances. A bad earth/ground connection on appliances and the PTC04 can

cause damage to the PTC04. The measuring unit and the digital channels of the PTC04 are sensitive to level shifts.

The metal case of the PTC04 has to be connected to the earth connection of the power grid via the frame connection or via

the earth connection on the back panel of the PTC04.

Earth Connection

When using the PTC04 for End Of Line calibration of a Melexis product, it is mandatory to use qualified reference equipment

for the End Of Line verification of the programmed/calibrated product.

20. FAQ

Please refer to the document FAQ_PTC04.pdf

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 17 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

21. Mechanical Outlines

Figure 21-1: Mechanical Outlines

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 18 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

Figure 21-2: Mechanical 3D View

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 19 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

22. ESD Precautions

Electronic semiconductor products are sensitive to Electro Static Discharge (ESD).

Always observe Electro Static Discharge control procedures whenever handling semiconductor products.

23. Contact

For the latest version of this document, go to our website at www.melexis.com.

For additional information, please contact our Direct Sales team and get help for your specific needs:

Europe, Africa

Telephone: +32 13 67 04 95

Email : sales_europe@melexis.com

Americas

Telephone: +1 603 223 2362

Address: Melexis NV, Rozendaalstraat 12, 8900 Ieper

Email : sales_usa@melexis.com

Asia

Email : sales_asia@melexis.com

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 20 of 21

Original Datasheet

�PTC04

Programmer for Melexis PTC Devices

24. Disclaimer

The content of this document is believed to be correct and accurate. However, the content of this document is furnished "as is" for informational use only

and no representation, nor warranty is provided by Melexis about its accuracy, nor about the results of its implementation. Melexis assumes no responsibility

or liability for any errors or inaccuracies that may appear in this document. Customer will follow the practices contained in this document under its sole

responsibility. This documentation is in fact provided without warranty, term, or condition of any kind, either implied or expressed, including but not

limited to warranties of merchantability, satisfactory quality, non-infringement, and fitness for purpose. Melexis, its employees and agents and its affiliates'

and their employees and agents will not be responsible for any loss, however arising, from the use of, or reliance on this document. Notwithstanding the

foregoing, contractual obligations expressly undertaken in writing by Melexis prevail over this disclaimer.

This document is subject to change without notice, and should not be construed as a commitment by Melexis. Therefore, before placing orders or prior to

designing the product into a system, users or any third party should obtain the latest version of the relevant information.

Users or any third party must determine the suitability of the product described in this document for its application, including the level of reliability required

and determine whether it is fit for a particular purpose.

This document as well as the product here described may be subject to export control regulations. Be aware that export might require a prior authorization

from competent authorities. The product is not designed, authorized or warranted to be suitable in applications requiring extended temperature range

and/or unusual environmental requirements. High reliability applications, such as medical life-support or life-sustaining equipment or avionics application

are specifically excluded by Melexis. The product may not be used for the following applications subject to export control regulations: the development,

production, processing, operation, maintenance, storage, recognition or proliferation of:

1. chemical, biological or nuclear weapons, or for the development, production, maintenance or storage of missiles for such weapons;

2. civil firearms, including spare parts or ammunition for such arms;

3. defense related products, or other material for military use or for law enforcement;

4. any applications that, alone or in combination with other goods, substances or organisms could cause serious harm to persons or goods and that can be

used as a means of violence in an armed conflict or any similar violent situation.

No license nor any other right or interest is granted to any of Melexis' or third party's intellectual property rights.

If this document is marked “restricted” or with similar words, or if in any case the content of this document is to be reasonably understood as being

confidential, the recipient of this document shall not communicate, nor disclose to any third party, any part of the document without Melexis’ express

written consent. The recipient shall take all necessary measures to apply and preserve the confidential character of the document. In particular, the recipient

shall (i) hold document in confidence with at least the same degree of care by which it maintains the confidentiality of its own proprietary and confidential

information, but no less than reasonable care; (ii) restrict the disclosure of the document solely to its employees for the purpose for which this document was

received, on a strictly need to know basis and providing that such persons to whom the document is disclosed are bound by confidentiality terms

substantially similar to those in this disclaimer; (iii) use the document only in connection with the purpose for which this document was received, and

reproduce document only to the extent necessary for such purposes; (iv) not use the document for commercial purposes or to the detriment of Melexis or its

customers. The confidentiality obligations set forth in this disclaimer will have indefinite duration and in any case they will be effective for no less than 10

years from the receipt of this document.

This disclaimer will be governed by and construed in accordance with Belgian law and any disputes relating to this disclaimer will be subject to the exclusive

jurisdiction of the courts of Brussels, Belgium.

The invalidity or ineffectiveness of any of the provisions of this disclaimer does not affect the validity or effectiveness of the other provisions.

The previous versions of this document are repealed.

Melexis © - No part of this document may be reproduced without the prior written consent of Melexis. (2021)

IATF 16949 and ISO 14001 Certified

Revision 008 - 13 January 2021

3901290014501

Datasheet

Programmer for Melexis PTC Devices

Page 21 of 21

Original Datasheet

�