PRODUCT SPECIFICATION

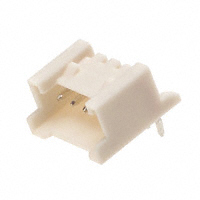

TITLE : 2.0 PITCH W/B CONN. (P-LOCK)

1.0 적용범위 (SCOPE)

이 사양서는 2.0 mm pitch connector(Positive Lock) LEAD FREE series에 대하여 규정한다.

This Product Specification covers the 2.0 mm pitch connector(Positive Lock) LEAD FREE series.

2.0 제품사양 (PRODUCT DESCRIPTION)

2.1 제품명 및 제품번호 (PRODUCT NAME AND SERIES NUMBERS)

제품명 (PRODUCT NAME)

제품번호 (PART NUMBER)

HOUSING

35507-**0*

35362-**0*, -**5*, -**6*, -**7*, -**8*

WAFER ASSY – ST

104065-1670, 104065-1676

WAFER ASSY – RA

35363-**6*

TERMINAL

50212-8000

2.2 SAFETY AGENCY APPROVALS

UL / CSA 인증 (UL/CSA APPROVALS)

3.0 RATINGS

항 목 (ITEM))

최대허용전압 [RATED VOLTAGE (MAX.)]

최대허용전류 및 사용 전선

[RATED CURRENT(MAX.) AND

APPLICABLE WIRES

사용온도범위 (AMBIENT TEMP. RANGE)

저장온도범위(Non-operating Temperature)

규 격 (STANDARD)

125V

AWG #24

2.0 A

[AC(rms)/DC]

AWG #26

1.5 A

AWG #28

1.0 A

AWG #30

0.5 A

☞ -40℃ ~ 105℃

☞ -20℃ ~ 60℃

REVISION: ECR/ECN INFORMATION: TITLE:

B2

EC No: KOR2013-0018

DATE: 2012/ 08/ 16

DOCUMENT NUMBER:

PS-35507-003

SHEET No.

2.0 W/B CONN. (Positive Lock)

(2-20P, 6Kinds of color version)

CREATED / REVISED BY:

HJEONG/SKCHO

CHECKED BY:

SHCHU

1 of 6

APPROVED BY:

YSOOKIM

TEMPLATE FILENAME: PRODUCT_SPEC[SIZE_A4](V.1).DOC

�PRODUCT SPECIFICATION

4.0 성 능 (PERFORMANCE)

4.1 전기적 성능 (ELECTRICAL REQUIREMENTS)

ITEM

DESCRIPTION

접촉저항

4.1.1

Contact

Resistance

압착상태의

접촉저항

4.1.2

Insulation

Resistance

내전압

4.1.4

Dielectric

Withstanding

Voltage

온도상승

4.1.5

REQUIREMENT

결합된 Connector를 개방전압 20mV이하,

단락전류 10mA에서 측정

20 mΩ MAX.

Mate connectors measure by dry circuit,

20mV Max. 10mA

Wire를 사용하여 터미널을 압착한

상태에서 개방전압 20mV이하, 단락전류

10mA에서 측정한다.

5 mΩ MAX.

Contact

Crimp the applicable connectors at the

Resistance of

Wire Termination speed rated of 25±3mm per minute

절연저항

4.1.3

TEST CONDITION

Temperature

Rise

결합된 Connector를 인접 Terminal사이

및 Terminal과 GND간에 DC500V를

인가하여 측정한다.

1000 MΩ MIN.

Mate connectors: apply a voltage of 500

VDC between adjacent terminals and

between terminals to ground.

결합된 Connector를 인접 Terminal사이

및 Terminal과 GND간에 AC500V를 1분간

인가한다.

No breakdown

Mate connectors: apply 500VAC for 1

minute between adjacent terminals and

between terminals to ground.

결합된 커넥터의 최대허용전류를

통전하고 커넥터의 온도 상승 분을

측정한다.

30℃ MAXIMUM

Mate connectors: measure the

temperature rise at the rated current

4.2 기계적 성능 (MECHANICAL REQUIREMENTS)

ITEM

DESCRIPTION

TEST CONDITION

REQUIREMENT

Connector를 25 ± 3 mm/분의 속도로

삽,발거를 실시한다

4.2.1

커넥터삽입력 및

발거력

Connector Mate

and

Unmate Forces

Mate and unmate connector at a rate of

25 ± 3 mm per minute.

제 6항 참조

(REFER TO PARAGRAPH 6)

REVISION: ECR/ECN INFORMATION: TITLE:

B2

EC No: KOR2013-0018

DATE: 2012/ 08/ 16

DOCUMENT NUMBER:

PS-35507-003

SHEET No.

2.0 W/B CONN. (Positive Lock)

(2-20P, 6Kinds of color version)

CREATED / REVISED BY:

HJEONG/SKCHO

CHECKED BY:

SHCHU

2 of 6

APPROVED BY:

YSOOKIM

TEMPLATE FILENAME: PRODUCT_SPEC[SIZE_A4](V.1).DOC

�PRODUCT SPECIFICATION

4.2 MECHANICAL REQUIREMENTS (continued)

전선 압착강도

4.2.2

Crimping Pullout

Forces

단자 삽입력

4.2.3

Terminal

Insertion Force

(into Housing)

단자 유지력

4.2.4

Terminal

Retention Force

(in Housing)

PIN 유지력

4.2.5

Pin Retention

Force

Connector 결합력

압착된 터미널을 매분 25±3mm의 속도로

WIRE를 축방향으로 당긴다.

Fix the crimped terminal, apply axial

pullout force on the wire at a rate of 25 ±

3 mm per minute.

AWG#24

3.0Kgf/MIN

AWG#26

2.0Kgf/MIN.

AWG#28

1.0Kgf/MIN.

AWG#30

0.5Kgf/MIN.

하우징에 압착된 단자를 25 ± 6 mm/분의

속도로 삽입한다.

1.0 kgf MAXIMUM

Apply an axial insertion force on the

terminal at a rate of 25 ± 3 mm per

minute

하우징과 단자를 조립한 상태에서 매분

25±3mm의 속도로 축 방향으로 당긴다.

1.5 kgf MINIMUM

Apply axial pullout force on the terminal in

the housing at a rate of 25 ± 3 mm per

minute.

하우징과 터미널을 조립한 상태에서 매분

25±3mm의 속도로 축 방향으로 당긴다.

1.0 kgf MINIMUM

Apply an axial push force on the pin at a

rate of 25 ± 3 mm per minute

단자간 결합이 제외된 결합된 커넥터를

매분 25±3mm의 속도로 축방향으로

당긴다.

2~3ckts

2 kgf

MINIMUM

Mated connector (Only mold part), apply

axial pullout force at the spped rate of

25±3mm per minute

4~20ckts

3 kgf

MINIMUM

커넥터를 최대 10회/1분의 속도로

삽,발거를 30회 실시한다.

접촉저항

4.2.6

Locking Strength

내구성

4.2.7

40 mΩ MAX.

Durability

Mate connectors up to 30 cycles at a

maximum rate of 10 cycles per minute.

Contact

Resistance

REVISION: ECR/ECN INFORMATION: TITLE:

B2

EC No: KOR2013-0018

DATE: 2012/ 08/ 16

DOCUMENT NUMBER:

PS-35507-003

SHEET No.

2.0 W/B CONN. (Positive Lock)

(2-20P, 6Kinds of color version)

CREATED / REVISED BY:

HJEONG/SKCHO

CHECKED BY:

SHCHU

3 of 6

APPROVED BY:

YSOOKIM

TEMPLATE FILENAME: PRODUCT_SPEC[SIZE_A4](V.1).DOC

�PRODUCT SPECIFICATION

4.2 MECHANICAL REQUIREMENTS (continued)

ITEM

DESCRIPTION

내진동성

TEST CONDITION

REQUIREMENT

외관

이상 없을 것

접촉저항

40 mΩ MAX.

순간단락

1㎲ MAX.

Appearance

No Damage

Contact

Resistance

40 mΩ MAX.

Discontinuity

1㎲ MAX.

외관

이상 없을 것

접촉저항

40 mΩ MAX.

순간단락

1㎲ MAX.

Appearance

No Damage

Contact

Resistance

40 mΩ MAX.

Discontinuity

1㎲ MAX.

커넥터를 결합하여 아래 진동상태를

가한다.

진 폭 : 1.5mm P-P

진동수 : 10-55-10 Hz/분

진동시간 : X.Y.Z축 각 2시간

4.2.8

VIBRATION

Mate connectors and subject to the

following vibration conditions:

Amplitude : 1.5mm P-P

Sweep Time : 10-55-10 Hz in 1 minute

Duration : 2 Hours in each X.Y.Z axes

커넥터를 결합하여 반정현파 50G

(490㎨)의 충격을 ±X,±Y,±Z축 방향에 3회

가한다.(총 18회)

내충격성

4.2.9

SHOCK

Mate connectors and shock at 50 g's with

½ sine wave (11 milliseconds) shocks in

the ±X,±Y,±Z axes (18 shocks total).

4.3 환경적 특성(ENVIRONMENTAL

REQUIREMENTS)

특성

ITEM

DESCRIPTION

내열성

TEST CONDITION

REQUIREMENT

커넥터를 결합하여 주위온도 105 ±

2°C에서 96시간 방치 후 꺼내어 측정한다.

외관

No Damage.

접촉저항변화

40mΩ MAX

Appearance

No Damage

Contact

Resistance

40mΩ MAX

외관

No Damage.

접촉저항변화

40mΩ MAX

Appearance

No Damage

Contact

Resistance

40mΩ MAX

4.3.1

Heat Resistance

내한성

Mate connectors; expose to:

96 hours at 105 ± 2°C

주위온도 -40 ± 3°C에서 96시간 방치 후

꺼내어 측정한다.

4.3.2

Cold Resistance Mate connectors:

Duration: 96 hours;

Temperature: -40 ± 3°C

REVISION: ECR/ECN INFORMATION: TITLE:

B2

EC No: KOR2013-0018

DATE: 2012/ 08/ 16

DOCUMENT NUMBER:

PS-35507-003

SHEET No.

2.0 W/B CONN. (Positive Lock)

(2-20P, 6Kinds of color version)

CREATED / REVISED BY:

HJEONG/SKCHO

CHECKED BY:

SHCHU

4 of 6

APPROVED BY:

YSOOKIM

TEMPLATE FILENAME: PRODUCT_SPEC[SIZE_A4](V.1).DOC

�PRODUCT SPECIFICATION

4.3 ENVIRONMENTAL REQUIREMENTS (continued)

ITEM

DESCRIPTION

열충격

4.3.3

Thermal

Shock

내습성

4.3.4

Humidity

(Steady State)

TEST CONDITION

REQUIREMENT

커넥터를 결합하고, 아래의 방법으로

5Cycle 적용

온 도 °C

시 간 (분)

-40 +0/-3

30

+25 ±10

5 MAXIMUM

+105 +3/-0

30

+25 ±10

5 MAXIMUM

Mate connectors; expose to 5 cycles of:

Temperature °C

Duration (Minutes)

-40 +0/-3

30

+25 ±10

5 MAXIMUM

+105 +3/-0

30

+25 ±10

5 MAXIMUM

외관

이상없을것

접촉저항

40mΩ MAX

Appearance

No Damage

Contact

Resistance

40mΩ MAX

외관

이상없을것

접촉저항

40mΩ MAX

내전압

4.1.4항 만족

절연저항

100MΩ MAX

Appearance

No Damage

Contact

Resistance

40mΩ MAX

Dielectric

Strength

Must meet

4.1.4

Insulation

Resistance

100MΩ MAX

외관

이상없을것

접촉저항

40mΩ MAX

Appearance

No Damage

Contact

Resistance

40mΩ MAX

외관

이상없을것

접촉저항

40mΩ MAX

Appearance

No Damage

Contact

Resistance

40mΩ MAX

커넥터를 결합하여 상대습도 90-95% ,

온도 60 ± 2°C 상태에서 96 시간

방치한다.

측정 전 수분을 제거하고 대기 에서 1시간

건조한다

Mate connectors: expose to a

temperature of 60 ± 2°C with a relative

humidity of 90-95% for 96 hours.

Note: Remove surface moisture and air

dry for 1 hour prior to measurements.

염수분무

4.3.5

Salt Spray

아황산가스

4.3.6

Corrosive

Atmosphere:

Sulfur Dioxide

Gas

(SO2)

결합된 커넥터를 35 ± 2°C에서 5± 1%

중량비의 염수를 48시간 분무하고 시험후

상온에서 물로 씻은후 실온에서

건조시킨다.

48hours exposure to a salt spray from 5±

1% solution at 35 ± 2°C

결합된 커넥터를 40 ± 2°C의 온도에서

50 ± 2 ppm의 아황산가스에 24시간

방치한다.

Mate connectors:

Duration: 24 hours exposure;

Atmosphere: 50 parts per million (ppm)

SO2 gas;

Temperature: 40 ± 2°C

REVISION: ECR/ECN INFORMATION: TITLE:

B2

EC No: KOR2013-0018

DATE: 2012/ 08/ 16

DOCUMENT NUMBER:

PS-35507-003

SHEET No.

2.0 W/B CONN. (Positive Lock)

(2-20P, 6Kinds of color version)

CREATED / REVISED BY:

HJEONG/SKCHO

CHECKED BY:

SHCHU

5 of 6

APPROVED BY:

YSOOKIM

TEMPLATE FILENAME: PRODUCT_SPEC[SIZE_A4](V.1).DOC

�PRODUCT SPECIFICATION

4.3 ENVIRONMENTAL REQUIREMENTS (continued)

ITEM

DESCRIPTION

납땜성

4.3.7

Solder ability

4.3.8

TEST CONDITION

REQUIREMENT

남땝시간 : 3 ± 0.5 sec

납땜온도 : 245 ± 5 °C

침적면적 95%이상

Soldering time : 3 ± 0.5 sec

Solder temperature : 245 ± 5 °C

Solder coverage: 95% MIN.

(Must be no voids, pin holes)

납땜내열성

남땝시간 : 5 ± 0.5 sec

납땜온도 : 260 ± 5 °C

Solder

Resistance

Dip connector terminal tails in solder:

Solder Duration: 5 ± 0.5 seconds;

Solder Temperature: 260 ± 5°C

이상없을것

Visual:

No Damage to insulator

material

5.0 외관,

외관 형상,

형상 칫수 및 재질 (PRODUCT SHAPE, DIMENSION & MATERIAL)

→ 도면참조 (Refer to the drawing)

6.0 삽입력 및 발거력 (INSERTION / WITHDRAWAL FORCE)

극수

(Ckt size)

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

삽입력[최대] INSERTION[MAX.]

1회

6회

30회

(INITIAL)

(6th)

(30th)

3.6

3.4

3.4

4.4

4.1

4.1

5.2

4.8

4.8

6.0

5.5

5.5

6.6

6.0

6.0

7.2

6.5

6.5

7.8

7.0

7.0

8.4

7.5

7.5

9.0

8.0

8.0

9.6

8.5

8.5

10.2

9.0

9.0

10.8

9.5

9.5

11.4

10.0

10.0

12.0

10.5

10.5

12.6

11.0

11.0

13.2

11.5

11.5

13.8

12.0

12.0

14.4

12.5

12.5

15.0

13.0

13.0

발거력[최소] WITHDRAWAL[MIN.]

1회

6회

30회

(INITIAL)

(6th)

(30th)

0.1

0.07

0.07

0.1

0.07

0.07

0.1

0.07

0.07

0.25

0.15

0.15

0.25

0.15

0.15

0.25

0.15

0.15

0.25

0.15

0.15

0.45

0.30

0.30

0.45

0.30

0.30

0.45

0.30

0.30

0.45

0.30

0.30

0.65

0.45

0.45

0.65

0.45

0.45

0.65

0.45

0.45

0.65

0.45

0.45

0.85

0.60

0.60

0.85

0.60

0.60

0.85

0.60

0.60

0.85

0.60

0.60

REVISION: ECR/ECN INFORMATION: TITLE:

B2

EC No: KOR2013-0018

DATE: 2012/ 08/ 16

DOCUMENT NUMBER:

PS-35507-003

SHEET No.

2.0 W/B CONN. (Positive Lock)

(2-20P, 6Kinds of color version)

CREATED / REVISED BY:

HJEONG/SKCHO

CHECKED BY:

SHCHU

6 of 6

APPROVED BY:

YSOOKIM

TEMPLATE FILENAME: PRODUCT_SPEC[SIZE_A4](V.1).DOC

�

很抱歉,暂时无法提供与“35363-0460”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 300+2.88324

- 1500+2.74302

- 3100+2.60280

- 6400+2.33989

- 15000+1.56869