MagAlpha MA800

8-Bit Contactless Angle Encoder with

Push Button Function

DESCRIPTION

FEATURES

The MA800 is an easy-to-use, magnetic, angle

encoder with a digital output designed to

replace analogic potentiometers or rotary

switches. The MA800 is designed for slow

operation such as human-machine interface,

manual controls, etc. where the rotating speed

remains below 200 rpm. The sensor detects the

absolute angular position of a permanent

magnet attached to a rotating shaft.

The magnet shapes and configurations are very

flexible. Typically, the MA800 is used with a

diametrically magnetized cylinder of 2 - 8mm in

diameter.

The MA800 features programmable magnetic

field strength thresholds, which allow for the

implementation of a push or pull button function.

These are output as two logic signals.

On-chip non-volatile memory provides storage

for the configuration parameters, including the

reference zero angle position and magnetic

field detection threshold settings.

8-Bit Resolution Absolute Angle Encoder

Contactless Sensing for Long Life with No

Wear

SPI and SSI Serial Interface

Programmable Magnetic Field Strength

Detection for Push/Pull Button Detection

3.3V, 12mA Supply

-40 to +125°C Operating Temperature

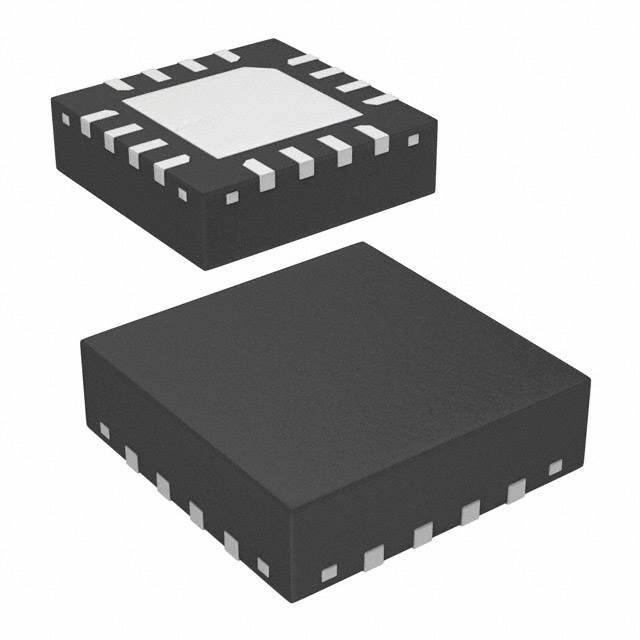

Available in a QFN-16 (3mmx3mm)

Package

APPLICATIONS

Rotary Knob Control Interfaces

Manual Controls

Encoders

Automotive

White Goods

All MPS parts are lead-free, halogen-free, and adhere to the RoHS directive. For

MPS green status, please visit the MPS website under Quality Assurance. “MPS”

and “The Future of Analog IC Technology” are registered trademarks of

Monolithic Power Systems, Inc.

TYPICAL APPLICATION

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

1

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

ORDERING INFORMATION

Part Number*

MA800GQ

Package

QFN-16 (3mmx3mm)

Top Marking

See Below

* For Tape & Reel, add suffix –Z (e.g. MA800GQ–Z)

TOP MARKING

AXV: Product code of MA800GQ

Y: Year code

LLL: Lot number

PACKAGE REFERENCE

TOP VIEW

N/C

GND

MISO

N/C

CS

8

7

6

5

9

4

MOSI

3

N/C

TEST

10

MGL

11

2

N/C

SCLK

12

1

SSD

17

PAD

13

14

15

VDD

N/C

SSCK

16

MGH

QFN-16 (3mmx3mm)

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

2

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

ABSOLUTE MAXIMUM RATINGS (1)

Thermal Resistance

Supply voltage ............................ -0.5V to +4.6V

Input pin voltage (VI) ................... -0.5V to +6.0V

Output pin voltage (VO) ............... -0.5V to +4.6V

(2)

Continuous power dissipation (TA = +25°C)

..................................................................2.0W

Junction temperature ............................... 125°C

Lead temperature .................................... 260°C

Storage temperature .................. -65°C to 150°C

QFN-16 (3mmx3mm) ............ 50 ....... 12 ... °C/W

MA800 Rev. 1.02

6/15/2018

(3)

θJA

θJC

NOTES:

1) Exceeding these ratings may damage the device.

2) The maximum allowable power dissipation is a function of the

maximum junction temperature TJ (MAX), the junction-toambient thermal resistance θJA, and the ambient temperature

TA. The maximum allowable continuous power dissipation at

any ambient temperature is calculated by PD (MAX) = (TJ

(MAX)-TA)/θJA.

3) Measured on JESD51-7, 4-layer PCB.

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

3

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

ELECTRICAL CHARACTERISTICS

Parameter

Symbol Condition

Recommended Operating Conditions

Min

Typ

Max

Units

Supply voltage

VDD

3.0

3.3

3.6

V

Supply current

IDD

10.2

11.7

13.8

mA

Operating temperature

Applied magnetic field

Top

B

-40

30

125

60

°C

mT

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

4

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

GENERAL CHARACTERISTICS

VDD = 3.3V, 45mT < B < 100mT, temp = -40°C to +125°C, unless otherwise noted.

Parameter

Resolution

Symbol Condition

3σ deviation of the noise

distribution

Effective resolution

Noise rms

Refresh rate

Data output length

Response Time

Power-up time

Latency

Min

Typ

8

0.005

850

8

Constant speed propagation

delay

Filter cutoff frequency

Accuracy

(4)

Fcutoff

At room temperature over the full

field range

Over the full temperature range

and field range

INL at 25°C

INL between -40°C to +125°C

(5)

Units

bit

0.01

980

(4)

(5)

Max

0.02

1100

8

deg

kHz

bit

20

ms

4

ms

90

Hz

0.7

deg

1.1

deg

Output Drift

Temperature induced drift at

(5)

room temperature

Temperature induced variation

Magnetic field induced

From 25°C to 85°C

From 25°C to 125°C

(5)

(5)

0.015

0.04

deg/°C

0.5

1.0

0.005

1.2

2.1

deg

deg

deg/mT

0.3

deg/V

(5)

Voltage supply induced

Magnetic Field Detection Thresholds

(5)

Accuracy

(5)

Hysteresis

(5)

Temperature drift

Digital I/O

VIH

VIL

Input high voltage

Input low voltage

Output low voltage

5

6

-600

MagHys

(5)

Output high voltage

(5)

VOL

VOL = 4mA

VOH

VOH = 4mA

RPU

RPD

Pull-up resistor

Pull-down resistor

(4)

Rising edge slew rate

(4)

Falling edge slew rate

TR

TF

CL = 50pF

CL = 50pF

mT

mT

ppm/°C

2.5

5.5

V

-0.3

0.8

V

0.4

V

2.4

V

46

66

97

kΩ

43

55

97

kΩ

0.7

0.7

V/ns

V/ns

NOTES:

4) Guaranteed by design.

5) Guaranteed by characteristic test.

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

5

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

TYPICAL CHARACTERISTICS

VDD = 3.3V, Temp = 25°C, unless otherwise noted.

Current Consumption at

VDD = 3.3V

Filter Transfer Function

Error Curves at 50mT

2

12

5

1.5

11

10.5

1

0

25癈

125癈

0.5

-3 dB

ERROR (deg)

FILTER TRANSFER FUNCTION (dB)

SUPPLY CURRENT (mA)

11.5

-5

-45癈

0

-0.5

-10

-1

-15

-1.5

10

-2

-50

0

50

100

150

-20

0

1

10

100

TEMPERATURE (癈 )

1000

10

50

100

150

200

250

300

350

4

ANGLE (deg)

f (Hz)

Non-Linearity (INL and

Harmonics)

1.5

NON-LINEARITY (deg)

INL

1

H1

0.5

H2

0

0

20

40

60

80

100

MAGNETIC FIELD (T)

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

6

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

PIN FUNCTIONS

Package

Pin #

Name

SSD

Description

Data out (SSI).

1

2, 3, 6,

9, 14

4

MOSI

5

CS

7

MISO

8

10

11

12

13

15

GND

TEST

MGL

SCLK

VDD

SSCK

Chip select (SPI). CS has an internal pull-up resistor.

Data out (SPI). MISO has an internal pull-down resistor that is enabled at a high

impedance state.

Supply ground.

Factory use only. Connect TEST to ground.

Digital output indicating field strength below MGLT level.

Clock (SPI). SCLK has an internal pull-down resistor.

3.3V supply.

Clock (SSI). SSCK has an internal pull-down resistor.

16

17

MGH

PAD

Digital output indicating field strength above MGHT level.

Exposed pad.

NC

MA800 Rev. 1.02

6/15/2018

No connection. Leave NC unconnected.

Data in (SPI). MOSI has an internal pull-down resistor.

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

7

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

BLOCK DIAGRAM

Figure 1: Functional Block Diagram

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

8

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

OPERATION

Sensor Front-End

The magnetic field is detected with integrated

Hall devices located in the center of the

package. The angle is measured using the

SpinaxisTM method, which digitizes the direction

of the field directly without complex arctangent

computations or feedback loop-based circuits

(interpolators).

The SpinaxisTM method is based on phase

detection and generates a sinusoidal signal with

a phase that represents the angle of the

magnetic field. The angle is then obtained by a

time-to-digital converter, which measures the

time between the zero crossing of the

sinusoidal signal and the edge of a constant

waveform (see Figure 2). The time-to-digital is

output from the front-end to the digital

conditioning block.

Sensor – Magnet Mounting

The sensitive volume of the MA800 is confined

in a region less than 100µm wide and has

multiple integrated Hall devices. This volume is

located both horizontally and vertically within

50µm of the center of the QFN package. The

sensor detects the angle of the magnetic field

projected in a plane parallel to the package’s

upper surface. This means that the only

relevant magnetic field is the in-plane

component (X and Y components) in the middle

point of the package.

By default, when looking at the top of the

package, the angle increases when the

magnetic field rotates clockwise. Figure 3

shows the zero angle of the unprogrammed

sensor, where the cross indicates the sensitive

point. Both the rotation direction and the zero

angle can be programmed.

Top: Sine Waveform

Bottom: Clock of the Time-to-Digital Converter

Figure 2: Phase Detection Method

The output of the front-end delivers a digital

number proportional to the angle of the

magnetic field at the rate of 1MHz in a

straightforward and open-loop manner.

Digital Filtering

The front-end signal is further treated to

achieve the final effective resolution. This

treatment does not add any latency in steady

conditions. The filter transfer function can be

calculated with Equation (1):

H(s)

1 2s

(1 s)2

(1)

Where τ is the filter time constant related to the

cutoff frequency by τ = 0.38/Fcutoff. See the

General Characteristics table on page 5 for the

value of Fcutoff.

MA800 Rev. 1.02

6/15/2018

Figure 3: Detection Point and Default Positive

Direction

This type of detection provides flexibility for the

design of an angular encoder. The sensor only

requires the magnetic vector to lie essentially

within the sensor plane with a field amplitude of

at least 30mT. Note that the MA800 can work

with fields smaller than 30mT, but the linearity

and resolution performance may deviate from

the specifications. The most straightforward

mounting method is to place the MA800 sensor

on the rotation axis of a permanent magnet (i.e.:

a diametrically magnetized cylinder) (see Figure

4). The recommended magnet is a Neodymium

alloy (N35) cylinder with dimensions Ø5x3mm

inserted into an aluminum shaft with a 1.5mm

air gap between the magnet and the sensor

(surface of package). For good linearity, the

sensor is positioned with a precision of 0.5mm.

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

9

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

In general, the MagAlpha works well with or

without the exposed pad connected to anything.

For optimum conditions (electrically, thermally,

and mechanically), it is recommended that the

exposed pad be connected to ground.

Figure 4: End-of-Shaft Mounting

Figure 5 shows an example of sensor and

magnet mounting in a contactless switch

assembly. A Neodymium alloy magnet is

inserted into an aluminum shaft. The air gap

between the magnet and the sensor is 1.0mm.

The sensor is positioned on the rotation axis

with a precision of 0.5mm.

Figure 5: Example of Potentiometer-Like

Assembly

Electrical Mounting and Power Supply

Decoupling

It is recommended to place a 1µF decoupling

capacitor close to the sensor with a low

impedance path to GND (see Figure 6).

Serial Interface

The sensor supports the SPI serial interface for

angle reading and register programming.

Alternatively, the SSI bus can be used for angle

reading (programming through SSI is not

supported).

SPI

SPI is a four-wire, synchronous, serial

communication interface. The MagAlpha

supports SPI Mode 3 and Mode 0 (see Table 1

and Table 2). The SPI Mode (0 or 3) is detected

automatically by the sensor and therefore does

not require any action from the user. The

maximum clock rate supported on SPI is

25MHz. There is no minimum clock rate. Note

that real-life data rates depend on the PCB

layout quality and signal trace length. See

Figure 7 and Table 3 for SPI timing.

All commands to the MagAlpha (whether for

writing or reading register content) must be

transferred through the SPI MOSI pin and must

be 16 bits long. See the SPI Communication

section on page 12 for details.

Table 1: SPI Specification

SCLK idle state

Data capture

Data transmission

CS idle state

Data order

Mode 0

Mode 3

Low

High

On SCLK rising edge

On SCLK falling edge

High

MSB first

Table 2: SPI Standard

CPOL

CPHA

Data order (DORD)

Mode 0

Mode 3

0

1

0

1

0 (MSB first)

Figure 6: Connection for Supply Decoupling

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

10

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

tcsL

CS

tsclk

tsclkL tsclkH

tcsH

tMISO

tMISO

tidleAngle

tidleReg

tnvm

SCLK

tMISO

MISO

hi-Z

MOSI

MSB

X

LSB

MSB

hi-Z

MSB

X

LSB

MSB

tMOSI

Figure 7: SPI Timing Diagram

tidleAngle

tidleAngle

tidleAngle

tidleReg

tidleReg

tidleAngle

tnvm

tidleReg

CS

MISO

Angle

Angle

Angle

Angle

Reg Value

Angle

Angle

Reg Value

Angle

MOSI

0

0

0

Read Reg Cmd

0

0

Write Reg Cmd

0

0

Figure 8: Minimum Idle Time

Table 3: SPI Timing

Parameter

(6)

Description

Min

Max

tidleAngle

Idle time between two subsequent angle transmissions

150

ns

tidleReg

Idle time before and after a register readout

750

ns

tnvm

Idle time between a write command and a register readout

(delay necessary for non-volatile memory update)

20

ms

tcsL

Time between CS falling edge and SCLK falling edge

80

ns

tsclk

SCLK period

40

ns

tsclkL

Low level of SCLK signal

20

ns

tsclkH

High level of SCLK signal

20

ns

tcsH

Time between SCLK rising edge and CS rising edge

25

ns

tMISO

SCLK setting edge to data output valid

tMOSI

Data input valid to SCLK reading edge

15

15

Unit

ns

ns

NOTE:

6) All values are guaranteed by design.

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

11

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

SPI Communication

The sensor supports three types of SPI

operation:

Read angle

Read configuration register

Write configuration register

Therefore, angle reading can be optimized

without any loss of information by reducing the

number of clock counts. In the case of a 12-bit

data output length, only 12 clock counts are

required to get the full sensor resolution.

MSB

Each operation has a specific frame structure

described below.

SPI Read Angle

Every 1µs, new data is transferred into the

output buffer. The master device triggers the

reading by pulling CS low. When a trigger event

is detected, the data remains in the output

buffer until the CS signal is de-asserted (see

Table 4).

LSB

MISO

Angle(15:4)

MOSI

0

If less resolution is needed, the angle can be

read by sending even fewer clock counts (since

the MSB is first).

In case of a fast reading, the MagAlpha

continues sending the same data until the data

is refreshed (see the refresh rate in the General

Characteristics table on page 5).

Table 4: Sensor Data Timing

Event

CS falling edge

CS rising edge

Action

Start reading and freeze

output buffer

Release of the output buffer

See Figure 9 for a diagram of a full SPI angle

reading. See Figure 10 for a diagram of a

partial SPI angle reading. A full angle reading

requires 16 clock pulses. The sensor MISO line

returns:

MSB

LSB

MISO

Angle(15:0)

MOSI

0

Figure 9: Diagram of a Full 16-Bit SPI Angle

Reading

The MagAlpha family has sensors with different

features and levels of resolution. Check the

data

output

length

in

the

General

Characteristics table on page 5 for the number

of useful bits delivered at the serial output. If the

data length is smaller than 16, the rest of the

bits sent are zeros.

For example, a data output length of 12 bits

means that the serial output delivers a 12-bit

angle value with four bits of zeros padded at the

end (MISO state remains zero). If the master

sends 16 clock counts, the MagAlpha replies

with:

MSB

MISO

MOSI

MA800 Rev. 1.02

6/15/2018

Figure 10: Diagram of a Partial 8-Bit SPI Angle

Reading

LSB

Angle(15:4)

0 0 0 0

0

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

12

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

SPI Read Register

A read register operation is constituted of two

16-bit frames. The first frame sends a read

request which contains the 3-bit read command

(010) followed by the 5-bit register address. The

last eight bits of the frame must all be set to

zero. The second frame returns the 8-bit

register value (MSB byte).

See Figure 11 for a complete transmission.

For example, to get the value of the magnetic

level high and low flags (MGH and MGL), read

register 27 (bit 6, bit 7) by sending the following

first frame:

MSB

The first 16-bit SPI frame (read request) is:

MSB

MISO

LSB

Angle(15:0)

command

reg. address

MOSI 0 1 0 A4 A3 A2 A1 A0

MOSI

Angle(15:0)

command

0 1 0

reg. address

1 1 0 1 1

0 0 0 0 0 0 0 0

reg. value

MISO MGH MGL X X X X X X

0 0 0 0 0 0 0 0

MSB

0 0 0 0 0 0 0 0

MSB

MOSI

reg. value

MISO V7 V6 V5 V4 V3 V2 V1 V0

0 0 0 0 0 0 0 0

In the second frame, the MagAlpha replies:

The second 16-bit SPI frame (response) is:

MOSI

LSB

MISO

LSB

0

See Figure 12 for a complete example.

LSB

0

Figure 11: 16-Bit Frames Read Register Operation

Figure 12: Example Read Magnetic Level Flags High and Low (MGH, MGH) on Register 27, Bit 6 to Bit 7

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

13

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

SPI Write Register

Table 7 shows the programmable 8-bit registers.

Data written to these registers are stored in the

on-chip non-volatile memory and reloaded

during power-on automatically. The factory

default register values are shown in Table 8.

A write register operation is constituted of two

16-bit frames. The first frame sends a write

request, which contains the 3-bit write

command (100) followed by the 5-bit register

address and the 8-bit value (MSB first). The

second frame returns the newly written register

value (acknowledge).

The on-chip memory is guaranteed to endure

1,000 write cycles at 25°C.

It is critical to wait 20ms between the first and

second frame. This is the time taken to write the

non-volatile memory. Failure to implement this

wait period results in the register’s previous

value being read. Note that this delay is only

required after a write request. A read register

request and read angle do not require this wait

time.

The second 16-bit SPI frame (response) is:

reg. value

MISO V7 V6 V5 V4 V3 V2 V1 V0

0 0 0 0 0 0 0 0

MSB

LSB

MOSI

0

The read-back register content can be used to

verify the register programming. See Figure 13

for a complete transmission overview.

For example, to set the value of the output

rotation direction (RD) to counterclockwise

(high), write register 9 by sending the following

first frame:

MSB

MISO

LSB

Angle(15:0)

command

MOSI 1 0 0

reg. address

0 1 0 0 1

reg. value

1 0 0 0 0 0 0 0

Send the second frame after 20ms of wait time

(see Figure 8). If the register is written correctly,

the reply is:

reg. value

MISO 1 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

The first 16-bit SPI frame (write request) is:

MSB

MISO

LSB

Angle(15:0)

command

reg. address

reg. value

MOSI 1 0 0 A4 A3 A2 A1 A0 V7 V6 V5 V4 V3 V2 V1 V0

MSB

MOSI

LSB

0

See Figure 14 for a complete example.

Figure 13: Overview of Two 16-Bit Frames Write Register Operation

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

14

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

Figure 14: Example Write Output Rotation Direction (RD) to Counterclockwise (High) on Register 9, Bit 7

SSI

SSI is a 2-wire synchronous serial interface for

data reading only. The sensor operates as a

slave to the external SSI master and supports

angle reading only. It is not possible to read or

write registers using SSI.

SSI Communication

Unlike SPI, the sensor SSI supports angle

reading operation only. It is not possible to read

or write registers using SSI. The SSI timing

communication is shown in Figure 15 and Table

5.

Figure 15: SSI Timing

Table 5: SSI Timing

Parameter

Description

Min

tssd

Max

Unit

15

ns

tssck

SSCK period

0.04

16

µs

tssckL

Low level of SSCK signal

0.02

8

µs

tssckH

High level of SSCK signal

0.02

8

µs

tm

Transfer timeout (monoflop time)

25

µs

tp

Dead time: SSCK high time for next data reading

40

µs

SSI Read Angle

The bit order of the transmitted data is MSB first

and LSB last. Every 1µs, new data is

transferred into the output buffer. The master

device triggers the reading by pulling SSCK

down. Just like with an SPI reading, a full

reading requires 16 clock counts, but if the data

length is less than 16, the 16-bit output word is

completed by zeros. Therefore, reading can

MA800 Rev. 1.02

6/15/2018

also be performed with fewer than 16 clock

counts (see Figure 16). When a trigger event is

detected, the data remains in the output buffer

until the clock rising edge for the LSB bit 0 and

the transfer time out time has passed. See

Table 6 for sensor data timing.

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

15

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

When a trigger event is detected, the data

remains in the output buffer until the clock rising

edge for the LSB bit 0 and the transfer time out

time has passed. See Table 6 for sensor data

timing.

Table 6: Sensor Data Timing

Trigger event

Release of the

output buffer

First SSCK falling

edge

SSCK rising

edge + time out

tm (Fig 15)

Figure 16: Full 16-Bit SSI Angle Reading

For consecutive angle readings, see the timing diagram in Figure 17.

Figure 17: Two Consecutive 16-Bit SSI Angle Reading with the Required Dead Time between the Frames

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

16

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

REGISTER MAP

Table 7: Register Map

Bit 7

MSB

No

Hex

Bin

Bit 6

Bit 5

Bit 4

0

0x0

00000

Z(7:0)

1

0x1

00001

Z(15:8)

6

0x6

00110

9

0x9

01001

RD

-

-

-

-

27

0x1B

11011

MGH

MGL

-

-

-

MGLT(2:0)

Bit 3

Bit 2

Bit 1

Bit 0 LSB

-

-

-

-

-

-

-

-

MGHT(2:0)

Table 8: Factory Default Values

No

Hex

Bin

Bit 7

MSB

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

LSB

0

0x0

00000

0

0

0

0

0

0

0

0

1

0x1

00001

0

0

0

0

0

0

0

0

6

0x6

00110

0

0

0

1

1

1

0

0

9

0x9

01001

0

0

0

0

0

0

0

0

Table 9: Programming Parameters

Parameters

Symbol

Number of Bits

Description

See Table

Zero setting

Magnetic field high

threshold

Magnetic field low

threshold

Z

16

Set the zero position

10

MGHT

3

Sets the field strength high threshold.

14

MGLT

3

Sets the field strength low threshold.

14

RD

1

Determines the sensor positive

direction

12

Rotation direction

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

17

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

REGISTER SETTINGS

Zero Setting

The zero position of the MagAlpha (a0) can be

programmed with 16 bits of resolution. The

angle streamed out by the MagAlpha (aout) is

given by Equation (2):

aout araw a0

(2)

Where araw is the raw angle provided by the

MagAlpha front-end.

The parameter Z(15:0), which is zero by default,

is the complementary angle of the zero setting.

It can be written in decimals using Equation (3):

a0 216 Z (15 : 0)

(3)

Table 10 shows the zero setting parameter.

0

1

2

…

65534

65535

Zero pos.

a0 16-bit (dec)

65536

65535

65534

…

2

1

Table 12: Rotation Direction Parameter

RD

Positive Direction

0

1

Clockwise (CW)

Counterclockwise (CCW)

Magnetic Field Thresholds

Push Button Detection

The MA800 has two threshold options (MGHT

or MGLT), which are complementary in

operation. The flag MGH becomes TRUE (logic

1) if the magnetic field increases above MGHT.

The flag MGL becomes TRUE (logic 1) if the

magnetic field falls below MGLT (see Figure 19).

Table 10: Zero Setting Parameter

Z(15:0)

Figure 18: Positive Rotation Direction of the

Magnetic Field

Zero pos.

a0 (deg)

360.000

359.995

359.989

…

0.011

0.005

Example

To set the zero position to 20 deg, the Z(15:0)

parameter must be equal to the complementary

angle shown in Equation (4):

Z (15 : 0) 216

20 deg 16

2 61895

360 deg

(4)

In binary, this is written as 1111 0001 1100

0111.

Table 11 shows the content of registers 0 and 1.

Table 11: Register Content

Reg Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0

1

1

0

0

0

1

1

1

1

1

1

1

1

0

0

0

1

Rotation Direction

By default, when looking at the top of the

package, the angle increases when the

magnetic field rotates clockwise (CW) (see

Figure 18 and Table 12).

MA800 Rev. 1.02

6/15/2018

Figure 19: MGH and MGL Signals as a Function

of the Field Strength

The MGL and MGH flags can be used for

detecting an approaching magnet (e.g.: when a

button is pressed). With the 5mmx3mm magnet

example, if the MGHT threshold is set to binary

110 (106 - 112mT), the MGH signal is set to

logic high when the sensor-magnet airgap is

smaller than 1.0mm (see Figure 20).

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

18

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

Table 14: MGLT and MGHT Binary to mT Relation

MGLT or

(8)

MGHT

000

001

010

011

100

101

110

111

Figure 20: Magnetic Field Produced by a

5mmx3mm N35 Magnet as a Function of the

Airgap with Threshold Set to 110mT

In this way, it is possible to implement a push or

pull action.

MagHys, the hysteresis on the signals MGH

and MGL, is indicated in the General

Characterisitcs table on page 5. The MGLT and

MGHT thresholds are coded on three bits and

stored in register 6 (see Table 13).

Field threshold in mT

From low to high

magnetic field

26

41

56

70

84

98

112

126

(7)

From high to low

magnetic field

20

35

50

64

78

92

106

120

NOTES:

7) Valid for VDD = 3.3V. If different, then the field threshold is

scaled by the factor VDD/3.3V.

8) MGLT can have a larger value than MGHT.

The alarm flags (MGL and MGH) can be read in

register 27 (bit 6 and bit 7), and their logic state

is also given at the digital output pins 11 and 16.

To read the MGL and MGH flags by SPI, send

the 8-bit command write to register 27:

command

0 1 0

reg. address

1 1 0 1 1

value

LSB

0 0 0 0 0 0 0 0

MSB

Table 13: Register 6

The MA800 answers with the register 27

content in the next transmission:

Reg Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

6

MGLT

MGHT

Reg Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

27 MGH MGL x

x

x

x

x

x

The 3-bit values of MGLT and MGHT

correspond to the magnetic field (see Table 14).

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

19

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

TYPICAL APPLICATION CIRCUITS

Figure 21: Typical Configurations using SPI Interface

Figure 22: Typical Configuration Using SSI Interface and Output Signals MGL, MGH

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

20

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

PACKAGE INFORMATION

QFN-16 (3mmx3mm)

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

21

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

APPENDIX A: DEFINITIONS

Resolution (3σ noise level)

Smallest angle increment distinguishable from the noise. The

resolution is measured by computing three times σ (the standard

deviation in degrees) taken over 1,000 data points at a constant

position. The resolution in bits is obtained with log2(360/6σ).

Refresh Rate

Rate at which new data points are stored in the output buffer.

Latency

Time elapsed between the instant when the data is ready to be read

and the instant at which the shaft passes that position. The lag in

degrees is lag lantency v , where v is the angular velocity in deg/s.

Power-Up Time

Time until the sensor delivers valid data starting at power-up.

Integral Non-Linearity (INL)

Maximum deviation between the average sensor output (at a fixed

position) and the true mechanical angle.

Figure A1: Integral Non-Linearity

Drift

MA800 Rev. 1.02

6/15/2018

Angle variation rate when one parameter is changed (e.g.:

temperature, VDD) and all the others, including the shaft angle, are

maintained constant.

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

22

�MA800 – 8-BIT, DIGITAL ANGLE SENSOR

APPENDIX B: SPI COMMUNICATION CHEATSHEET

Read Angle

Read Register

Write Register

NOTICE: The information in this document is subject to change without notice. Users should warrant and guarantee that third

party Intellectual Property rights are not infringed upon when integrating MPS products into any application. MPS will not

assume any legal responsibility for any said applications.

MA800 Rev. 1.02

6/15/2018

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2018 MPS. All Rights Reserved.

23

�