MPDTH03050WA* Specification

1

DC-DC Converter Specification(DRAFT)

MPDTH03050WA*

1 . Application

This specification applies to DC-DC Converter for telecommunication/data-communication equipment,

MPDTH03050WAS/WAH.

For any other application, please contact us before using this product.

2 . Customer Reference

Customer Spec. Number

Customer Part Number

3 . Murata Part Number

MPDTH03050WAS / MPDTH03050WAH

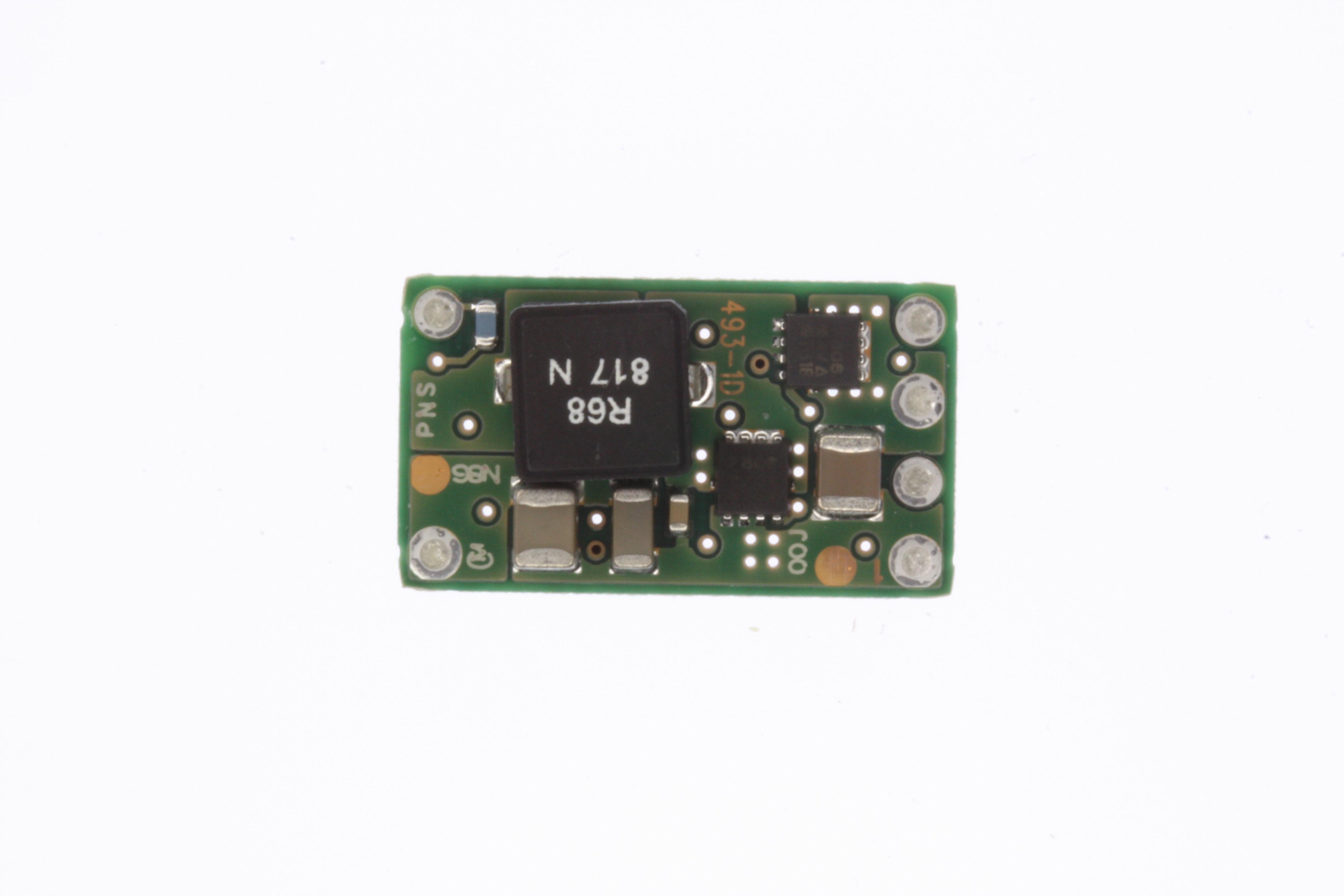

4 . Appearance, Dimensions

[WAS]

22.10

1.52

1.52

19.06

6

2

PPH

3.18

3

3.18

Solder Ball

φ1.02

6 Places

12.57

①②③

9.5 2

1

3.18

9.09

MAX.

5

4

SIDE VIEW

TOP VIEW

[WAH]

22.10

1.52

3.55

1.52

19.06

1

3

3.18

12.57

PNS

3.18

6

①②③

2

9.5 2

3.18

φ1.02

6 Places

Bottom side

Clearance

0.25MIN.

5

4

TOP VIEW

8.50

MAX.

Host Board

SIDE VIEW

[unit:mm]

Tolerance:0.25mm

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

2

Marking

(1) MFG ID

(2) Parts No.

PPH (designates “WAS” P/N series/ SMD packaging)

PNS (designates “WAH” P/N series/ TH packaging)

(3) Lot No.

①②③

①Production factory Mark

②Production Year

③Production Month(1,2,3,…9,O,N,D)

5 . Pin Number and Function

Pin No.

1

2

3

4

5

6

Symbol

GND

Track

Vin

Inhibit

VoAdjust

Vout

Function

GND

Tracking signal input

Input

Remote ON/OFF

Vout control

Output

6. Block Diagram

3

Vout

Vin

6

1

GND

4

Inhibit

5

Control Circuit

VoAdjust

2

Track

7.Ambient Condition

7 .1 Operating Temperature Range

7 .2 Storage Temperature Range

8. Absolute Rating

8 .1 Track Pin Input Voltage Range

-40 to +85oC

-40 to +125oC

-0.3V to (Vin + 0.3V)

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

3

9. Characteristics

9 .1 Electrical Characteristics (Ta=25oC)

Unless otherwise stated,

Ta=25oC,Vin=3.3V,Vo=2.5V,Cin=100µF,Co=0µF,Io=Iomax

Value

Item

Condition

Symbol

Unit

Min.

Typ.

Max.

0

-

6

A

2.95

(*1)

3.3

3.65

V

-

-

±2

(*2)

%Vo

o

o

-40 C≦Ta≦85 C

-

±0.5

-

%Vo

Output Current

Io

0.8V≦Vo≦2.5V

85oC, Natural Convection

Input Voltage Range

Vin

Over Io Range

Set-point Voltage

Vo tol

Temperature Variation

ΔRegtemp

Line Regulation

ΔRegline

Over Vin Range

-

±10

-

mV

Load Regulation

ΔRegload

Over Io Range

-

±12

-

mV

Total Output Variation

ΔRegtot

Include set-point, line, load

-40oC≦Ta≦85oC

-

-

±3

(*2)

%Vo

Rset=2.21kΩ Vo=2.5V

-

94

-

Rset=4.12kΩ Vo=2.0V

-

92

-

Rset=5.49kΩ Vo=1.8V

-

91

-

Rset=8.87kΩ Vo=1.5V

-

90

-

Rset=17.4kΩ Vo=1.2V

-

88

-

Rset=36.5kΩ Vo=1.0V

-

87

-

BW=20MHz, Co=10µF Ceramic

-

20 (*3)

-

mVpp

Reset, Followed by Auto-Recovery

-

12

-

A

Recovery

Time

-

70

-

µsec

Vo Deviation

-

100

-

mV

Pin to GND

-

-

-130

(*4)

µA

Cout≦Cout(max)

-

-

1

V/ms

Efficiency

η

Ripple Voltage

Vr

Short Circuit Protection

Io trip

ttr

Transient Response

ΔVtr

Io=4A

%

1A/µs load step,

50 to 100% Iomax,

Co=100µF

Track Input Current

IILtrack

Track Slew Rate Capability

dVtrack/dt

Rising UVLO Threshold

UVLOr

Vin = increasing

-

2.45

2.8

V

Falling UVLO Threshold

UVLOf

Vin = decreasing

2.2

2.4

-

V

Inhibit Control

VIH

Reference to GND

Inhibit Control

VIL

Reference to GND

Inhibit Control

IIL inhibit

Pin to GND

This pin should left open to

operate (*4)

-0.2

-

0.6

V

-

-130

-

µA

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

4

Value

Item

Condition

Symbol

Inhibit Control

Iin inh

Operating Frequency

Frq

External Input Capacitor

Cin

External Output Capacitor

MTBF

Typ.

Max.

Inhibit to GND, Track open

-

10

-

mA

Over Vin and Io ranges

-

600

-

kHz

100

(*5)

-

-

µF

non-ceramic (ESR≧4mΩ)

0

100

(*6)

3300

ceramic

0

-

300

Per Bellcore TR-332, 50% Stress,

o

Ta=40 C, Ground Benign

6

-

-

Cout

MTBF

Unit

Min.

µF

106Hrs

(*1) The minimum input voltage is equal to 2.95V or Vout+0.65V, whichever is greater.

(*2) The set-point voltage tolerance is affected by the tolerance and stability of Rset. The stated limit is

unconditionally met if Rset has a tolerance of +/- 1% with 100ppm/oC or better temperature-stability.

(*3) The peak-to-peak output ripple voltage is measured with an external 10µF ceramic capacitor.

(*4) This control pin has an internal pull-up. If it is left open-circuit the module will operate when input power is

applied.

(*5) The external input capacitor must have a ripple current rating at or above 300mA rms.

(*6) An external output capacitor is not required for basic operation. Adding 100µF of distributed capacitance at

the load however improves transient response.

9 .2 Safe Operating Area (SOA)

PTH03050W Safe Operating Area (Vout=2.5V)

90

80

Ta - °C

70

60

50

40

30

20

0

1

2

3

Iout - Amps

4

5

6

Nat conv

The above SOA represents the condition at which internal components are at or below the manufacturer’s

maximum operating temperatures. Derating limits apply to modules soldered directly to a 4 in.×4in. 4-layer

PCB with 1 oz. copper. For more reliable operation, appropriate derating is desirable.

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

5

10. Adjusting the Output Voltage

The output voltage may be adjusted from 0.8V to 2.5V by inserting resistance between

Vo Adjust-pin (pin 5) to GND-pin (pin 1). The resistance tolerance should be +/-1%, with 100ppm/oC (or better).

The following equation gives the required external-resistance value to adjust the output voltage to the required Vout.

Internal circuit

MPDTH03050W

Vout

Rset= 10kΩ

10kΩ

VoAdjust pin

2.49kΩ

0.8V

-2.49kΩ

Vout-0.8V

Error amp

Rset

<Rset calculation example>

Vout [V]

Calculated Rset[kΩ]

2.5

2.22

2.0

4.18

1.8

5.51

1.5

8.94

1.2

17.5

1.0

37.5

0.8

∞

Rset example

2kΩ+220Ω

3.9kΩ+270Ω

5.1kΩ+390Ω

8.2kΩ+750Ω

16kΩ+1.5kΩ

36kΩ+1.5kΩ

Open

11. Test Circuit

Utilizing the following test circuit, the initial values specified in section 9 should be met.

Track

Vin

+

2

3

MPDTH03050W

C1: 100µF

Inhibit

Vin

6

Vout

C2: 10µF

4

1

Open=ON

Short=OFF

C1 :

C2 :

RL

Vo Adjust

5

Rset

GND

100µF/25V (Aluminum Electrolytic Capacitor)

10µF/6.3V (Ceramic Capacitor)

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

6

Ripple Noise Measurement Circuit

Coaxial cable :1.5D-2V, L=1.5m

C2:10µF

Oscilloscope

Vout

BW :20MHz

DC-DC Converter

GND

Terminator

(Keisokugiken TRC-50F)

Equivalent circuit

R:50Ω

C:0.01µF

A

A:Output Ripple Voltage

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

7

12 . Packaging Information

12. 1 Tray Dimensions

DC-DC Converter devices are placed on the trays. (See Fig.1)

Fig.1

12. 2 Maximum Devices per Tray

56 pcs/tray

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

8

12. 3 Packaging Form

Trays with devices have lids placed on top and are packed in a corrugated box. (See Fig.2)

Tray lid

Tray

260

225

70

Marking ※

Corrugated Box

※ Marking on the box

MURATA Parts Number

Quantity

Inspection No.

Fig.2

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

9

13. Production factory

Komatsu Murata Mfg.Co.,Ltd.

Kanazu Murata Mfg.Co.,Ltd.

Wakura Murata Mfg.Co.,Ltd.

14 . ! Caution

1 . Inrush current protection is not a feature of this device.

2 . Correct polarity at the device’s input is critical. If connected incorrectly damage of the device may result.

We recommend that customers ensure that a diode/ fuse combination is utilized per the following diagram

to prevent a reverse polarity condition from occurring.

fuse

diode

+

+

IN

OUT

-

-

+

Load

※Please select a diode/ fuse combination after confirming the operation of your product.

3 . Limitation of Application

Please contact us before using this product for the applications listed below which require especially

high reliability for the prevention of defects, which might directly cause damage to the third party’s life,

body or property.

①Aircraft equipment

②Aerospace equipment

③Undersea equipment

④Power plant control equipment

⑤Medical equipment

⑥Transportation equipment (vehicles, trains, ships, etc.)

⑦Traffic signal equipment

⑧Disaster prevention /crime prevention equipment

⑨Any other application of similar complexity and/or reliability requirements to the applications listed above.

15 .Notice

15. 1 Soldering

15. 1. 1 Flux

Please solder this product with Rosin Flux which contains of 0.2%wt. or less chlorine.

Please do not use high activity acid flux or water soluble flux as they may reduce the reliability of this

device.

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

10

15 1. 2 PCB Land Pattern Recommendation

23.12

WAS

2.03

19.06

2.03

6

1

3

9.52

2

3.18

TOP VIEW

13.59

3.18

3.18

5

4

φ 2.16 Min. 6 Places

2.03

23.12

19.06

2.03

WAH

6

1

3

9.52

2

3.18

TOP VIEW

13.59

3.18

3.18

5

4

φ 1.40 Min. 6 Places

Plated through holes

15. 1. 3 Soldering Conditions Recommendation

This product is RoHS compatible. The following profile is recommended for the reflow of the

SMD product (WAS) using Pb-free solder paste (Sn-Ag-Cu).

Method

: Full convection reflow soldering

Reflow Soldering Profile

JEDEC IPC/JEDEC J-STD-020C

Table 5-2 Classification Reflow Profile

Pb-Free Assembly Large Body

Profile details

Soldering temperature

Soldering time

Heating time

Preheating time

Programming rate

Descending rate

Total soldering time

Times

:

:

:

:

:

:

:

:

245oC+0/-5oC

20 to 40 seconds, 240 to 245oC

60 to 150 seconds, over217oC

60 to 180 seconds,150 to 200oC

3oC/ sec. Max.,217 to 245oC

6oC/ sec. Max.

8 minutes Max., 25 to 245oC

1time

※ Elimination of any additional vibration applied to this device during reflow is

highly recommended.

Careful regulation of temperature is recommended to avoid the separation of mounted components

from this device during reflow.

15. 2 Cleaning

Please use no-clean type flux and do not wash this product.

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�MPDTH03050WA* Specification

11

15. 3 Storage

15. 3. 1 This product should be treated as MSL2 product when it is reflowed according to

recommended soldering conditions described in section 15.1.3. .

This product can be stored for up to 1 year at below 30oC 60%R.H., without requiring an additional baking

process.

If stored for over 1 year, baking of this device before soldering is recommended.

The recommended baking condition of individual devices is 125±5oC/24hour.

If devices are baked in the manufacturer’s tray or in manufacturer’s tape, 60±5oC/168hour is

recommended.

Please avoid dampness and heat or locations where temperatures may vary widely to avoid possible water

condensation on the device. Exposure to such environments may degrade the performance and/ or the

reliability of the device.

If the device must be stored for a longer time than 1 year it is recommend that solderability be tested

regularly to confirm material degradation has not occurred.

15. 3. 2 Murata recommends that this device not be stored under conditions such as:

a location where surfaces have an accumulation of dust, direct exposure to ocean air, or in an atmosphere

containing a corrosive gas (e.g., Cl2, NH3, SO2, NOX, etc.).

15. 4 Operational Environment and Operational Conditions

15. 4. 1 Operational Environment

This device is not water-, chemical- or corrosion-proof.

In order to prevent leakage of electricity and abnormal temperature rise of the device,

do not operate under the following environmental conditions:

(1) An atmosphere containing corrosive gas (Cl2, NH3, SO2, NOX, and so on)

(2) A high-dust environment

(3) Under the exposure of direct sunlight

(4) A location where the likelihood of exposure to water or water condensation exists.

(5) A location exposed to ocean air

(6) Any locations similar to the above

15. 4. 2 Operational Conditions

Please use this product within specified values (power supply, temperature, input, output and load condition,

and so on). If the device is exposed to conditions outside of the specified values reliability of the device may

be adversely affected.

15. 4. 3 Note prior to use

Exposure of this device to a high-level static charge, over-rated voltage, or reverse voltage may result in

diminished reliability and/ or failure. Murata recommends that the following conditions be avoided prior to

use of this device:

(1) Supply of power outside of rated value (see section 8), Supply of reverse power or inadequate

connection of a 0V (DC) line

(2) Electrostatic discharge from production line and/or operator

(3) Electrification of the device from electrostatic induction

In addition Murata recommends that excessive mechanical shock be avoided.

15. 5 Transportation

Murata recommends that when transporting this product, it be packed so as to avoid damage by mechanical

vibration or exposure to adverse conditions such as ocean air, high humidity. It is additionally recommended

that appropriate instructions and guidelines be communicated to carriers to prevent exposure to these same

conditions.

16. ! Note

1. Murata recommends that customers ensure that the evaluation and testing of these devices are completed

with this product actually assembled on their product.

2. All the items and parameters in this product specification have been prescribed on the premise that Murata’s

product is used for the purpose, under the condition and in the environment mutually agreed upon.

This document is subject to revision without prior or subsequent notice.

Please contact Murata for latest documentation

Note:

1. This datasheet is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’ s specifications are subject to change or our

products in it may be discontinued without advance notice. Please check with our sales representatives or product engineers before ordering.

2. This datasheet has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product

specifications or transact the approval sheet for product specifications before ordering.

2006.10.2

�