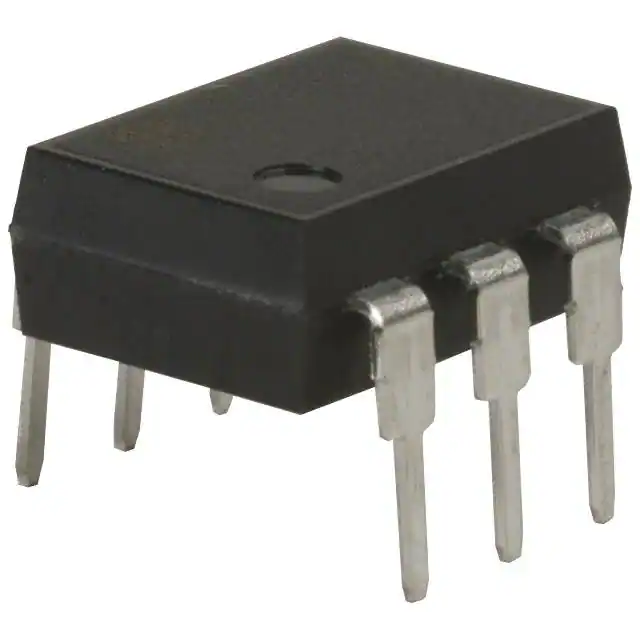

PhotoMOS

GE

1 Form B

Normally closed type with reinforced insulation

FEATURES

8.8

8.8

6.4

1 Form B output type

60V type couples high capacity (0.55A) with low onresistance (Typ. 1Ω)

Low on-resistance

Controls low-level analog signals

High sensitivity and low on-resistance

Low-level off-state leakage current

Reinforced insulation: 5,000 V

6.4

3.6

3.9

(Height includes standoff)

1

6

2

5

3

4

TYPICAL APPLICATIONS

Power supply

Measuring equipment

Security equipment

Telephone equipment

Sensing equipment

(Unit: mm)

Note: Please contact our sales representative for automotive applications of PhotoMOS.

TYPES

Output rating*1

Category

I/O isolation

voltage

AC/DC

5,000 Vrms

dual use (Reinforced)

Load

voltage

Load

current

Part No.

Through hole

terminal

Packing quantity

Surface mount terminal

Tape and reel

Tape and reel

packing style X*2 packing style Z*2

Tube packing style

60 V

550 mA

AQV412EH

AQV412EHA

AQV412EHAX

AQV412EHAZ

350 V

130 mA

AQV410EH

AQV410EHA

AQV410EHAX

AQV410EHAZ

400 V

120 mA

AQV414EH

AQV414EHA

AQV414EHAX

AQV414EHAZ

Tube

Tape and reel

1-tube: 50 pcs.

1-reel: 1,000 pcs.

Outer carton: 500 pcs. Outer carton: 1,000 pcs.

Note: �The surface mount terminal shape indicator “A” and the packing style indicator “X” or “Z” are not marked on the device.

(Ex. the label for product number AQV412EHAX is AQV412EH.)

*1.Indicate the peak AC and DC values.

*2.Tape and reel packing style X: picked from the 1/2/3-pin side, tape and reel packing style Z: picked from the 4/5/6-pin side.

2019.12

industrial.panasonic.com/ac/e/

ー1ー

Panasonic Corporation 2019

ASCTB127E 201912

�PhotoMOS GE 1 Form B

RATING

Absolute maximum ratings (Ambient temperature: 25°C)

Output

Input

Item

Type of

connection

Symbol

AQV412EH (A)

AQV410EH (A)

LED forward current

IF

50 mA

LED reverse voltage

VR

5V

Peak forward current

IFP

Power dissipation

Pin

Load voltage (peak AC)

VL

Continuous load current

Ipeak

Power dissipation

Pout

Remarks

f = 100 Hz,

Duty Ratio = 0.1%

1A

-

75 mW

IL

Peak load current

AQV414EH (A)

60 V

350 V

400 V

A

0.55 A

0.13 A

0.12 A

B

0.65 A

0.15 A

0.13 A

C

0.8 A

0.17 A

0.15 A

1.5 A

0.4 A

0.3 A

A connection:

Peak AC, DC

B, C connection: DC

A connection:

100 ms (1 shot),

VL = DC

500 mW

550 mW

Total power dissipation

PT

I/O isolation voltage

Viso

Ambient temperature (Operating)

Topr

–40 to +85°C

Ambient temperature (Storage)

Tstg

–40 to +100°C

-

5,000 Vrms

(Avoid icing and

condensation)

Electrical characteristics (Ambient temperature: 25°C)

Item

Input

LED operate

(OFF) current

LED reverse (ON)

current

LED dropout

voltage

Typical

Maximum

Minimum

Typical

Typical

Maximum

Typical

Output

Maximum

On resistance

Typical

Maximum

Typical

Maximum

Transfer characteristics

Off state leakage

current

Maximum

Typical

Operate (OFF)

time*

Maximum

Reverse (ON)

time*

Maximum

I/O capacitance

Initial I/O isolation

resistance

Typical

Typical

Maximum

Minimum

Symbol

Type of

connection

IFoff

-

IFon

-

VF

-

Ron

A

Ron

B

Ron

C

ILeak

-

Toff

-

Ton

-

Ciso

-

Riso

-

AQV412EH (A)

AQV410EH (A)

AQV414EH (A)

1.9 mA

IL = Max.

3 mA

0.4 mA

IL = Max.

1.8 mA

1.25 V (1.14 V at IF = 5 mA)

IF = 50 mA

1.5 V

1Ω

18 Ω

25.2 Ω

2.5 Ω

35 Ω

50 Ω

0.55 Ω

13 Ω

19 Ω

1.3 Ω

17.5 Ω

25 Ω

0.3 Ω

6.5 Ω

10 Ω

0.7 Ω

8.8 Ω

12.5 Ω

1.5 ms

8 ms

IF = 0 mA

IL = Max.

Within 1 s

IF = 0 mA

IL = Max.

Within 1 s

IF = 0 mA

IL = Max.

Within 1 s

IF = 5 mA

VL = Max.

10 μA

3 ms

Condition

1.3 ms

3 ms

0.3 ms

1.5 ms

0.8 pF

IF = 0 mA→5 mA

IL = Max.

IF = 5 mA→0 mA

IL = Max.

1.5 pF

f = 1 MHz

VB = 0 V

1,000 MΩ

500 V DC

*Operate/Reverse time

Input

Output

10%

90%

Toff

Ton

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー2ー

Panasonic Corporation 2019

ASCTB127E 201912

�PhotoMOS GE 1 Form B

Recommended operating conditions (Ambient temperature: 25°C)

Please use under recommended operating conditions to obtain expected characteristics.

Item

Symbol

Min.

Max.

Unit

LED current

IF

5

30

mA

Load voltage (Peak AC)

VL

-

48

V

Continuous load current

(A connection)

IL

-

0.55

A

Load voltage (Peak AC)

VL

-

280

V

Continuous load current

(A connection)

IL

-

0.13

A

Load voltage (Peak AC)

VL

-

320

V

Continuous load current

(A connection)

IL

-

0.12

A

AQV412EH (A)

AQV410EH (A)

AQV414EH (A)

REFERENCE DATA

1-1.�Load current vs. ambient temperature

characteristics

Allowable ambient temperature: –40 to +85°C

Type of connection: A

50

700

600

AQV414E(H)

Load current (mA)

Load current (mA)

120

100

80

60

AQV412EH

40

500

400

300

AQV414E(H)

20

AQV410EH

10

100

20

0

-40

-20

0

20

40

60

0

-40

80 85 100

0

-20

20

40

3.�Operate (OFF) time vs. ambient

temperature characteristics

4.�Reverse (ON) time vs. ambient

temperature characteristics

LED current: 5 mA; Load voltage: Max. (DC);

Continuous load current: Max. (DC)

LED current: 5 mA; Load voltage: Max. (DC);

Continuous load current: Max. (DC)

5

AQV410EH

AQV414EH

AQV410EH

AQV414EH

AQV412EH

0.2

1

-40

-20

0

20

40

60

Ambient temperature (°C)

80 85

0

60

80 85

4

3

2

1

-40

-20

0

20

40

60

Ambient temperature (°C)

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

40

5

0.6

0.4

20

Sample: All types;

Load voltage: Max. (DC);

Continuous load current: Max. (DC)

LED operate (OFF) current (mA)

Reverse (ON) time (ms)

3

0

-20

5.�LED operate (OFF) current vs. ambient

temperature characteristics

AQV412EH

2

AQV412EH

-40

Ambient temperature (°C)

0.8

4

0

80 85 100

60

Ambient temperature (°C)

Ambient temperature (°C)

Operate (OFF) time (ms)

30

200

40

0

Measured portion: between terminals 4 and 6;

LED current: 0 mA; Load voltage: Max. (DC);

Continuous load current: Max. (DC)

Allowable ambient temperature: –40 to +85°C

Type of connection: A

AQV410EH

2.�On resistance vs. ambient temperature

characteristics

On resistance (Ω)

140

1-2.�Load current vs. ambient temperature

characteristics

ー3ー

80 85

0

-40

0

-20

20

40

60

80 85

Ambient temperature (°C)

Panasonic Corporation 2019

ASCTB127E 201912

�PhotoMOS GE 1 Form B

6.�LED reverse (ON) current vs. ambient

temperature characteristics

7.�LED dropout voltage vs. ambient

temperature characteristics

Sample: All types;

LED current: 5 to 50 mA

Sample: All types;

Load voltage: Max. (DC);

Continuous load current: Max. (DC)

Measured portion: between terminals 4 and 6;

Ambient temperature: 25°C

140

120

100

80

60

40

20

-3.0 -2.5-2.0 -1.5-1.0-0.5

Current (mA)

1.5

1.4

4

LED dropout voltage (V)

3

2

1

1.3

1.2

1.1

1.0

-40

0

-20

20

40

60

0

80 85

-40

0

-20

8-2.�Current vs. voltage characteristics of

output at MOS portion

80 85

Sample: All types;

Measured portion: between terminals 4 and 6;

LED current: 5 mA; Ambient temperature: 25°C

0.6

10.�Operate (OFF) time vs. LED forward

current characteristics

Measured portion: between terminals 4 and 6;

Load voltage: Max. (DC); Continuous load current:

Max. (DC); Ambient temperature: 25°C

10

10-3

0.4

0.2

AQV412EH

0

0

1.0

0.5

Voltage (V)

-0.2

Off state leakage current (A)

Current (A)

60

9.�Off state leakage current vs. load voltage

characteristics

Measured portion: between terminals 4 and 6;

Ambient temperature: 25°C

-0.5

40

AQV414EH

Ambient temperature (°C)

Ambient temperature (°C)

-1.0

20

AQV410EH

0.5 1.0 1.5 2.0 2.5 3.0

-20

Voltage (V)

-40

-60

-80

-100

-120

-140

50 mA

30 mA

20 mA

10 mA

5 mA

AQV412EH

10-6

Operate (OFF) time (ms)

LED reverse (ON) current (mA)

5

0

8-1.�Current vs. voltage characteristics of

output at MOS portion

AQV414EH

AQV410EH

10-9

8

AQV410EH

AQV414EH

6

4

AQV412EH

2

-0.4

10-12

-0.6

0

20

40

60

80

100

0

0

10

20

Load voltage (V)

11.�Reverse (ON) time vs. LED forward

current characteristics

Output capacitance (pF)

Reverse (ON) time (ms)

AQV410EH, AQV414EH

AQV412EH

0.2

400

300

AQV412EH

200

100

0.1

10

20

30

40

50

60

0

AQV410EH, AQV414EH

0

10

20

LED forward current (mA)

30

40

50

60

Applied voltage (V)

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

60

500

0.4

0

50

Measured portion: between terminals 4 and 6;

Frequency: 1 MHz;

Ambient temperature: 25°C

0.5

0

40

12.�Output capacitance vs. applied voltage

characteristics

Measured portion: between terminals 4 and 6;

Load voltage: Max. (DC); Continuous load current:

Max. (DC); Ambient temperature: 25°C

0.3

30

LED forward current (mA)

ー4ー

Panasonic Corporation 2019

ASCTB127E 201912

�PhotoMOS GE 1 Form B

DIMENSIONS

CAD

Surface mount terminal type

External dimensions

Max.10°

6-0.8 dia.

Tolerance: ±0.1

1

8.8 ±0.05

3.4

Recommended mounting pad

(TOP VIEW)

3.4

0.47

1.25

0.47

1.25

0.47

1.25

1.25

1.25

2.54 2.54

1.25

2.54 2.54

0.47

8.3

1.9

0.47

ー0

0.2 +0.2

3

3.4

3.9 ±0.2

8.8±0.05

0.47

2.54

6.4

7.6

6.4 ±0.05

7.62 ±0.05

5.08

Max.10°

Max.10°

6.4±0.05

PC board pattern

(BOTTOM VIEW)

2.54

7.62

Through hole terminal type

External dimensions

CAD

Unit: mm

CAD The CAD data of the products with a “CAD” mark can be downloaded from our Website.

Terminal thickness: t = 0.25

General tolerance: ±0.1

Terminal thickness: t = 0.25

General tolerance: ±0.1

1.5

2.542.54

Tolerance: ±0.1

SCHEMATIC AND WIRING DIAGRAMS

Output

configuration

Schematic

Load

type

AC/DC

Connection

A

Wiring diagram

E1

IF

1

6

2

5

3

4

6

VL (AC, DC)

IL

4

Load

VL (AC, DC)

IL

Load

E1

1

6

2

5

3

1 Form B

DC

B

4

E1

IF

IF

*

1

6

2

5

3

4

1

6

2

5

3

4

Load

+

IL

VL (DC)

6

+

IL VL (DC)

5

Load

5

IL

Load

VL (DC)

+

Load

4

IL

VL (DC)

+

Can be also connected as 2 Form B type. (However, the sum of the continuous load current

should not exceed the absolute maximum rating.)

DC

C

E1

IF

1

6

Load

2

5

IL

3

4

+

VL (DC)

6

+

5

IL

4

Load

VL (DC)

*Terminal 3 cannot be used, since it is in the internal circuit of the device.

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー5ー

Panasonic Corporation 2019

ASCTB127E 201912

�PhotoMOS GE 1 Form B

SAFETY STANDARDS

UL (Recognized)

Part No.

File No.

(Standard No.)

AQV410EH (A)

AQV414EH (A)

Contact rating

Contact rating

0.55A 60V AC (peak) A connection

0.55A 60V DC A connection

0.65A 60V DC B connection

0.8A 60V DC C connection

AQV412EH (A)

AC/DC dual use

CSA (Certified)

File No.

(Standard No.)

E191218

(UL1577)

0.13A 350V AC (peak) A connection

0.13A 350V DC A connection

0.15A 350V DC B connection

0.17A 350V DC C connection

Remarks

VDE approved

(Nr. 40012839)

(Certified by C-UL)

BSI approved

(EN62368-1)

No.VC649393

0.12A 400V AC (peak) A connection

0.12A 400V DC A connection

0.13A 400V DC B connection

0.15A 400V DC C connection

Note: For the latest information on compliance with safety standards, please refer to our website.

Please refer to "the latest product specifications"

when designing your product.

•Requests to customers:

https://industrial.panasonic.com/ac/e/salespolicies/

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー6ー

Panasonic Corporation 2019

ASCTB127E 201912

�PhotoMOS® Cautions for Use

SAFETY WARNINGS

� o not use the product under conditions that exceed the range

D

of its specifications. It may cause overheating, smoke, or fire.

�Do not touch the recharging unit while the power is on. There

is a danger of electrical shock. Be sure to turn off the power

when performing mounting, maintenance, or repair operations

on the device (including connecting parts such as the terminal

board and socket).

� heck the wiring diagrams in the catalog and be sure to

C

connect the terminals correctly. If the device is energized

with short circuit or any wrong connection, it may cause

unexpected malfunction, abnormal heat or fire.

PhotoMOS® Cautions for Use

Derating design

Derating is a significant factor for reliable design and product life.

Even if the conditions of use (temperature, current, voltage, etc.) of

the product are within the absolute maximum ratings, reliability may

be lowered remarkably when continuously used in high load

conditions (high temperature, high humidity, high current, high

voltage, etc.) Therefore, please derate sufficiently below the

absolute maximum ratings and evaluate the device in the actual

condition.

Moreover, regardless of the application, if malfunctioning can be

expected to pose high risk to human life or to property, or if products

are used in equipment otherwise requiring high operational safety, in

addition to designing double circuits, that is, incorporating features

such as a protection circuit or a redundant circuit, safety testing

should also be carried out.

� pplying stress that exceeds the absolute maximum

A

rating

If the voltage or current value for any of the terminals exceeds the

absolute maximum rating, internal elements will deteriorate because

of the overvoltage or overcurrent. In extreme cases, wiring may

melt, or silicon P/N junctions may be destroyed.

Therefore, the circuit should be designed in such a way that the load

never exceed the absolute maximum ratings, even momentarily.

5) �When packing printed circuit boards and equipment, avoid using

high-polymer materials such as foam styrene, plastic, and other

materials which carry an electrostatic charge.

6) �When storing or transporting PhotoMOS®, the environment should

not be conducive to generating static electricity (for instance, the

humidity should be between 45% and 60%), and PhotoMOS®

should be protected using conductive packing materials.

Unused terminals

The No. 3 terminal is used with the circuit inside the device.

Therefore, do not connect it to the external circuitry with either

connection method A, B or C. (1 Form A 6-pin type)

Short across terminals

Do not short circuit between terminals when device is energized,

since there is possibility of breaking of the internal IC.

Surge voltages at the input

If reverse surge voltages are present at the input terminals, connect

a diode in reverse parallel across the input terminals and keep the

reverse voltages below the reverse breakdown voltage.

Typical circuits are below shown.

1) 6-pin

Input voltage (for Voltage-sensitive type)

For rising and dropping ratio of input voltage(dv/dt), maintain Min.

100mV/ms.

Oscillation circuit and control circuit (for TSON)

The oscillation circuit and control circuit of product may be destroyed

by external noise, surge, static electricity and so on.

For noise effect to peripheral circuits when oscillation circuit

operates, please implement safety measures on the system before

use by verifying operation under the actual design.

1

6

2

5

3

4

2) Power type

� eterioration and destruction caused by discharge of

D

static electricity (for TSON/RF C×R3/RF C×R5/RF

C×R10)

This phenomenon is generally called static electricity destruction,

and occurs when static electricity generated by various factors is

discharged while the PhotoMOS® terminals are in contact, producing

internal destruction of the element.

To prevent problems from static electricity, the following precautions

and measures should be taken when using your device.

1) �Employees handling PhotoMOS® should wear anti-static clothing

and should be grounded through protective resistance of 500kΩ

to 1MΩ.

2) �A conductive metal sheet should be placed over the worktable.

Measuring instruments and jigs should be grounded.

3) �When using soldering irons, either use irons with low leakage

current, or ground the tip of the soldering iron. (Use of low-voltage

soldering irons is also recommended.)

4) �Devices and equipment used in assembly should also be

grounded.

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー7ー

3

1

4

2

Panasonic Corporation 2020

ASCTB65E 202002

�PhotoMOS® Cautions for Use

� ecommended LED forward current or recommended

R

input voltage

Output spike voltages

1) �If an inductive load generates spike voltages which exceed the

absolute maximum rating, the spike voltage shall be limited.

Representative circuit examples of AC/DC dual use type are

shown below. There are the same with DC only type.

(1) 6-pin

Design in accordance with the recommended operating conditions

for each product.

Since these conditions are affected by the operating environment,

ensure conformance with all relevant specifications.

� ED forward current vs. Ambient temperature

L

characteristics

Please keep the LED forward current to within the range given

below.

1

6

2

5

3

4

Clamp diode is

connected in parallel

with the load.

100

LED forward current (mA)

Load

80

60

1

6

2

5

3

4

Load

40

CR snubber is

connected in parallel

with the load.

20

0

-40

-20

0

20

40

60

(2) Power type

8085 100

Ambient temperature (°C)

Ripple in the input power supply

1

2

3

4

If ripple is present in the input power supply, observe the following:

1) �For LED forward current at Emin, please maintain the value

mentioned at “■Recommended LED forward current.”

Load

2) �Please make sure the LED forward current for Emax. is no higher

than 50 mA.

1

2

3

4

Load

3) �Please maintain the input voltage at least 4V for Emin. (GU, RF

and Power voltage-sensitive type).

4) �Please make sure the input voltage for Emax. is no higher than 6V

(GU and RF voltage-sensitive type).

1

2

3

CR snubber is

connected in parallel

with the load.

4

Load

5) �Please make sure the input voltage for Emax. is no higher than 30V

(Power voltage-sensitive type).

Clamp diode is

connected in parallel

with the load.

A varistor is

connected in parallel

with PhotoMOS®

(3) TSON

Emin.

Emax.

1

4

2

3

Clamp diode is

connected in parallel

with the load.

6) �Please maintain the input voltage at least 3V for Emin. (for TSON)

7) �Please make sure the input voltage for Emax. is no higher than 5.5V.

(for TSON)

1

4

2

3

8) �Please keep amplitude voltage of ripple within ±0.5V. (for TSON)

Load

CR snubber is

connected in parallel

with the load.

within ±0.5 V

Set voltage

2) �When Clamp diode or CR Snubber is used in the circuit, the spike

voltages from the load are limited. But the longer wire may

become the inductance and cause the spike voltage. Keep the

wire as short as possible.

within ±0.5 V

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

Load

ー8ー

Panasonic Corporation 2020

ASCTB65E 202002

�PhotoMOS® Cautions for Use

Input wiring pattern

Reverse voltages at the input (for TSON)

1) �With AQY* or AQW* series avoid installing the input (LED side)

wiring pattern to the bottom side of the package if you require the

specified I/O isolation voltage (Viso) after mounting the PC board.

Since part of the frame on the output side is exposed, it may

cause fluctuations in the I/O isolation voltage.

If reverse voltages are present at the input terminals, for example,

connect a schottky barrier diode in reverse parallel across the input

terminals and keep the reverse voltages below the reverse

breakdown voltage. Typical circuit is shown below.

1

4

2

3

Portion of output side frame

(Output terminal side)

Continual DC bias (AQV259 and AQV258)

If a continual DC bias will be applied between the input and output,

the breakdown voltage of the switching element MOSFET on the

output side may degrade. Therefore, be sure to test the product

under actual conditions. Example of circuits that will cause

degradation of breakdown voltage of MOSFET is given below.

E

IF

1

6

2

5

3

4

Input wiring

pattern

(Input terminal side)

May not allow the prescribed I/O withstand

voltage (Viso) to be achieved

* Excluding reinforced insulation products and SSOP, SON, and TSON packages

IL

Load

Cleaning solvents compatibility

Cleaning the solder flux should use the immersion washing with an

organic solvent. If you have to use ultrasonic cleaning, please adopt

the following conditions and check that there are no problems in the

actual usage.

• Frequency: 27 to 29kHz

• Ultrasonic output: No greater than 0.25W/cm2*

• Cleaning time: 30s or less

• Cleanser used: Asahiklin AK-225

• �Others: �Float PCB and the device in the cleaning solvent to

prevent from contacting the ultrasonic vibrator

2) �Exposed terminals are electrically connected to internal elements.

Be aware that contact with external circuits may cause

deterioration of insulation between input and output, leading to

destruction of internal elements.

3) �If installed in proximity to other device, take care to avoid short

circuits between device, which may occur if exposed frames of

adjacent device come too close.

* Applies to unit area ultrasonic output for ultrasonic baths

Notes for mounting

1) �When different kinds of packages are mounted on PC boad,

temperature rise at soldering lead is highly dependent on

package size. Therefore, please set the lower temperature

soldering condition than the conditions of item “■Soldering”, and

confirm the temperature condition of actual usage before

soldering.

2) �When soldering condition exceeds our recommendation, the

PhotoMOS® characteristics may be adversely affected. It may

occur package crack or bonding wire breaking because of

thermal expansion unconformity and resin strength reduction.

Please contact our sales office about the propriety of the

condition.

3) �Please confirm the heat stress by using actual board because it

may be changed by board condition or manufacturing process

condition.

4) �Solder creepage, wettability, or soldering strength will be affected

by the soldering condition or used soldering type. Please check

them under the actual production condition in detail.

5) �Please apply coating when the device returns to a room

temperature.

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー9ー

Panasonic Corporation 2020

ASCTB65E 202002

�PhotoMOS® Cautions for Use

Soldering

1) Example of surface-mount terminal recommended conditions

(1) IR (Infrared reflow) soldering method

In case of automatic soldering, following conditions should be

observed. (recommended condition reflow: Max. 2 times,

measurement point: soldering lead)

t3

T1 = 150 to 180°C

T2 = 230°C

T3 = 240 to 250°C*

t1 = 60 to 120 s

t2 = Within 30 s

t3 = Within 10 s

T3

T2

T1

*240 to 245°C for SON, VSSOP

and TSON package

t1

t2

Part of frame on input side

Adjacent mounting

2) Example of through hole terminal recommended conditions

(1) DWS soldering method

In case of automatic soldering, following conditions should be

observed. (recommended condition number of times: Max. 1

time, measurement point: soldering lead *1)

T1 = 120°C

T2 = Max. 260°C

t1 = within 60 s

t2+t3 = within 5 s

T1

t1

t2

For VSSOP type, as shown in the following figure, part of the input

and output frames are exposed on the sides of the package. Due to

this, please be keep in mind the cautions listed below.

1) �Take care to avoid short circuits between exposed terminals,

which may cause insulation deterioration between input and

output, leading to destruction of internal elements.

2) �Since the exposed terminals are connected electrically to the

internal element, please refer to the item “■Deterioration and

destruction caused by discharge of static electricity”, and

implement sufficient measures to control static electricity.

3) �When installing the devices in the vicinity, please keep in mind

that if the exposed frames of adjacent devices get too close, a

short between devices may occur.

Part of frame on output side

(2) Other soldering methods

Other soldering methods (VPS, hot-air, hot plate, laser

heating, pulse heater, etc.) affect the PhotoMOS®

characteristics differently, please evaluate the device under

the actual usage.

(3) Manual soldering method

Temperature: 350 to 400°C, within 3s, electrical power 30 to

60W

T2

� bout the exposed terminals on the sides of the

A

package (for VSSOP)

When several PhotoMOS® are mounted closely each other or

heat-generating components are mounted close to the PhotoMOS®,

the abnormal heating may occur. This abnormal heat may be

caused by the internal element when energized or thermal

interference between the devices. The degree of temperature rise

depends on the mounting layout of the devices and usage condition,

therefore please be sure to use PhotoMOS® with reduced load

current after testing under the worst condition of the actual usage.

Transportation and storage

t3

*1 Solder temperature: Max. 260°C

(2) �Other soldering method (recommended condition: 1 time)

Preheating: Max. 120°C, within 120s, measurement point:

soldering lead

Soldering: Max. 260°C, within 10s, measurement area:

soldering temperature

(3) Manual soldering method

Temperature: 350 to 400°C, within 3s, electrical power 30 to

60W

1) �Extreme vibration during transport may deform the lead or

damage the PhotoMOS® characteristics. Please handle the outer

and inner boxes with care.

2) �Inadequate storage condition may degrade soldering,

appearance, and characteristics. The following storage conditions

are recommended:

• Temperature: 0 to 45°C

• Humidity: Max. 70%RH

• Atmosphere: �No harmful gasses such as sulfurous acid gas,

minimal dust.

3) Storage before TSON, VSSOP, SON, SSOP, or SOP processing

In case the heat stress of soldering is applied to the PhotoMOS®

which absorbs moisture inside of its package, the evaporation of

the moisture increases the pressure inside the package and it

may cause the package blister or crack. This device is sensitive

to moisture and it is packed in the sealed moisture-proof package.

Please make sure the following condition after unsealing.

* Please use the device immediately after unsealing.

(Within 30 days at 0 to 30°C and Max. 70%RH)

* If the device will be kept for a long time after unsealing, please

store in the another moisture-proof package containing silica gel.

(Please use within 90 days.)

Water condensation

Water condensation occurs when the ambient temperature changes

suddenly from a high temperature to low temperature at high

humidity, or the device is suddenly transferred from a low ambient

temperature to a high temperature and humidity. Condensation

causes the failures such as insulation deterioration. Panasonic

Corporation does not guarantee the failures caused by water

condensation. The heat conduction by the equipment the

PhotoMOS® is mounted may accelerate the water condensation.

Please confirm that there is no condensation in the worst condition

of the actual usage. (Special attention should be paid when high

temperature heating parts are close to the PhotoMOS®.)

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー 10 ー

Panasonic Corporation 2020

ASCTB65E 202002

�PhotoMOS® Cautions for Use

Packing format

1) Tape and reel

Tape dimensions

Dimensions of tape reel

21±0.8

1.2

1.05±0.1dia.

4±0.1

5.5±0.1

Device mounted

on tape

±0.3

180±3dia.

12

±0.3

TSON

4-pin

2±0.5

60 ±3dia.

4±0.1

2.2±0.2

2.4±0.2

0.2 ±0.05

1.75±0.1

Direction of picking

Tractor feed holes 1.5 +0.5

-0 dia.

2±0.1

13±0.5 dia.

(1) When picked from 1/2-pin side: Part No. AQY2C1R*PX (Shown above)

(2) When picked from 3/4-pin side: Part No. AQY2C1R*PZ

13±1.5

*Quality of material: Polystyrene (PS)

1.2±0.5

4.0 ±0.1

2.4±0.2

VSSOP

4-pin

12.0

±0.3

2.5±0.2

0.4 ±0.05

1.75±0.1

Direction of picking

Tractor feed holes 1.5 +0.5

ー0 dia.

1±0.1dia.

3.3±0.3

8±0.1

2±0.1

5.5±0.1

Device mounted

on tape

(1) When picked from 1 and 4-pin side: Part No. AQY*TY (Shown above)

(2) When picked from 2 and 3-pin side: Part No. AQY*TW

±0.3

3.6±0.2

21±0.8

80 ±1dia.

12

Device mounted

on tape

4±0.1

1.5±0.1dia.

2±0.3

2±0.1

5.5±0.1

SON

4-pin

4±0.1

2.8±0.2

2±0.5

80 ±1 dia.

(1) When picked from 1 and 4-pin side: Part No. AQY*MY (Shown above)

(2) When picked from 2 and 3-pin side: Part No. AQY*MW

250 ±2dia.

0.3±0.05

1.75±0.1

Direction of picking

Tractor feed holes 1.5 +0.5

ー0 dia.

3.0 ±0.1

4.0±0.1

4.0±0.1

5.5±0.1

Device mounted

on tape

2.7±0.3

1.5+0.1

ー 0 dia.

12.0±0.3

5.1±0.2

0.3±0.05

SSOP

4-pin

1.75±0.1

Direction of picking

Tractor feed holes 1.50 +0.5

ー 0 dia.

*Quality of material: Paper

13 ±0.5dia.

14±1.5

2 ±0.5

Device mounted on tape

2.8±0.3

12±0.1

12

7.2±0.1

±0.3

1.55±0.05dia.

5.5±0.1

SOP

4-pin

Direction of picking

Tractor feed holes

4.7±0.1

0.3±0.05

1.75±0.1

(1) When picked from 1 and 4-pin side: Part No. AQY*VY, APV2111VY (Shown above)

(2) When picked from 2 and 3-pin side: Part No. AQY*VW, APV2111VW

1.55±0.1dia.

4±0.1

2±0.1

(1) When picked from 1/2-pin side: Part No. AQY*SX, APV**21SX (Shown above)

(2) When picked from 3/4-pin side: Part No. AQY*SZ, APV**21SZ

Note: “ * ” indicates characters of number or alphabet.

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー 11 ー

Panasonic Corporation 2020

ASCTB65E 202002

�PhotoMOS® Cautions for Use

Tape dimensions

1.75±0.1

12±0.1

1.55±0.1dia.

2±0.1

7.5±0.1

Device mounted

on tape

12±0.1

14±1.5

13 ±0.5dia.

±0.1

2

2±0.5

Device mounted

on tape

2.8±0.3

*Quality of material: Paper

13 ±0.5dia.

17.5±1.5

2±1

1.55±0.1dia.

4±0.1

2±0.1

12±0.1

16±0.3

1.75±0.1

7.5±0.1

7.5±0.1

1.55±0.05dia.

11.15±0.1

SOP

16-pin

Direction of picking

Tractor feed holes

80 ±1dia.

(1) When picked from 1/2/3/4-pin side: Part No. AQW*SX (Shown above)

(2) When picked from 5/6/7/8-pin side: Part No. AQW*SZ

0.3±0.05

2 ±0.5

21±0.8

80 ±1dia.

1.55±0.1dia.

4±0.1

2.8±0.3

16±0.3

1.55±0.05dia.

7.5±0.1

SOP

8-pin

Direction of picking

Tractor feed holes

10.15±0.1

0.3±0.05

*Quality of material: Paper

1.75±0.1

(1) When picked from 1/2/3-pin side: Part No. AQV*SX (Shown above)

(2) When picked from 4/5/6-pin side: Part No. AQV*SZ

250 ±2 dia.

2.8

80 ±1 dia.

Device mounted on tape

±0.3

2±0.5

250 ±2dia.

7.2±0.1

12

4

1.55±0.05dia.

21±0.8

80 ±1dia.

±0.3

SOP

6-pin

Direction of picking

Tractor feed holes

±0.1

6.9 ±0.1

5.5±0.1

0.3±0.05

Dimensions of tape reel

(1) When picked from 1/2/3/4/5/6/7/8-pin side: Part No. AQS*SX (Shown above)

(2) When picked from 9/10/11/12/13/14/15/16-pin side: Part No. AQS*SZ

21±0.8

80 ±1dia.

1.75±0.1

12±0.1

4.2±0.3

80 ±1dia.

Device mounted on tape

2±0.5

300 ±2 dia.

10.2±0.1

12±0.3

4

1.5+0.1

ー0 dia.

5.5±0.1

DIP 4-pin

Surface mount

terminal

Direction of picking

Tractor feed holes

±0.1

5.25±0.1

0.3±0.05

1.55±0.1dia.

2±0.1

(1) When picked from 1/2-pin side: Part No. AQY*HAX, AQY210HLAX (Shown above)

(2) When picked from 3/4-pin side: Part No. AQY*HAZ, AQY210HLAZ

*Quality of material: Paper

13.5±2.0

13±0.5dia.

2±0.5

21±0.8

80 ±1dia.

4.5±0.3

12±0.1

16

±0.3

80±1dia.

2±0.5

300±2dia.

Device mounted on tape

7.5±0.1

10.1±0.1

1.5+0.1

ー0 dia.

9.2±0.1

DIP 6-pin

Surface mount

terminal

Tractor feed holes

1.75±0.1

Direction of picking

0.3±0.05

1.6±0.1dia.

4±0.1

2±0.1

(1) When picked from 1/2/3-pin side: Part No. AQV*AX (Shown above)

(2) When picked from 4/5/6-pin side: Part No. AQV*AZ

*Quality of material: Paper

13 ±0.5dia.

17.5±2

2±0.5

Note: “ * ” indicates characters of number or alphabet.

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー 12 ー

Panasonic Corporation 2020

ASCTB65E 202002

�PhotoMOS® Cautions for Use

Tape dimensions

1.75±0.1

10.1±0.1

7.5±0.1

Device mounted on tape

21±0.8

80 ±1dia.

1.55±0.1dia.

2±0.1

12±0.1

4.5±0.3

16

DIP 8-pin

Surface mount

terminal

(Basic insulation

type)

4

1.5+0.1

ー0 dia.

±0.3

0.3

Direction of picking

Tractor feed holes

±0.1

10.2±0.1

±0.05

Dimensions of tape reel

10.2±0.1

Device mounted on tape

12±0.1

4.2±0.3

2±0.1

16±0.3

80±1dia.

1.75±0.1

4±0.1

10.3±0.1

DIP 8-pin

Surface mount

terminal

(Reinforced

insulation type

Direction of picking

1.5 +0.1

ー0 dia.

7.5±0.1

Tractor feed holes

0.3±0.05

300±2dia.

2±0.5

(1) When picked from 1/2/3/4-pin side: Part No. AQW*AX (Shown above)

(2) When picked from 5/6/7/8-pin side: Part No. AQW*AZ

13 ±0.5dia.

*Quality of material: Paper

17.5±2

2±0.5

1.55±0.1dia.

(1) When picked from 1/2/3/4-pin side: Part No. AQW*EHAX,

AQW210HLAX (Shown above)

(2) When picked from 5/6/7/8-pin side: Part No. AQW*EHAZ, AQW210HLAZ

21±0.8

100±1dia.

1.75

1.55±0.1 dia.

2.0±0.1

(1) When picked from 1/2-pin side: Part No. AQY*AX (Shown above)

(2) When picked from 3/4-pin side: Part No. AQY*AZ

12±0.1

4.5

16

80±1dia.

Device mounted on tape

±0.3

1.6±0.1dia.

4±0.1

1.7±0.8

2±0.5

±0.3

10.1±0.1

1.5+0.1

ー0 dia.

7.5±0.1

DIP 6-pin

Surface mount

terminal

(Photovoltaic

MOSFET driver)

Tractor feed holes

9.2±0.1

0.3±0.05

25.5±2

21±0.8

80 ±1dia.

1.75±0.1

Direction of picking

13 ±0.5dia.

*Quality of material: Paper

300±2dia.

16.0±0.1

4.5±0.3

100±1dia.

330±2 dia.

Device mounted

on tape

2±0.5

24.0 ±0.3

Power-DIP

4-pin

SMD

12.6±0.1

4.0±0.1

1.55+0.05

ー 0.05 dia.

9.7±0.1

11.5 ±0.1

0.3±0.05

±0.1

Direction of picking

Tractor feed holes

2±0.1

(1) When picked from 1/2/3-pin side: Part No. APV1122AX (Shown above)

(2) When picked from 4/6-pin side: Part No. APV1122AZ

13 ±0.5dia.

*Quality of material: Paper

17.5±2

2±0.5

Note: “ * ” indicates characters of number or alphabet.

2) Tube

Devices are packaged in a tube so that 1-pin is on the stopper B

side. Observe correct orientation when mounting them on PC

boards.

(PD type)

Stopper B

(SOP type)

Stopper A

Stopper B (green)

(DIP type)

Stopper B

Stopper A

Green

Stopper B

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

Stopper A (gray)

(Power type)

ー 13 ー

Gray

Stopper A

Panasonic Corporation 2020

ASCTB65E 202002

�PhotoMOS® Cautions for Use

Adjacent mounting (for Power type)

Current limit function (output current control)

1) �When devices are mounted close together with the heatgenerated devices, ambient temperature may rise abnormally.

Mounting layout and ventilation should be considered.

1) �Current limit function aims to increase resistance to surges when

the switch is turned on. Before using this function, connect the

varistor to the output as shown in the figure below.

1

2

2) �When many devices are mounted close together, load current

should be reduced. (Refer to the data of “Load current in adjacent

mounting vs. Ambient temperature characteristics.”)

4

3

Varistor

Surge: 10×160μs 1.6kV

* Set the varistor voltage to 150 V or less.

Recommended load voltage

As a guide in selecting PhotoMOS®, please refer to the following

table.

2) �The current limit function capability can be lost if used longer than

the specified time. Be sure to set the output loss to the Max. rate.

1) Power photoMOS® (1 Form A)

Short circuit protection circuit

The short circuit protection circuit is designed to protect circuits from

excess current. Therefore, surge current may be detected as current

overload in which case the output current will be cut and the off

state maintained. For this reason, please include the inrush current

in the load current and keep it below the maximum load current.

Also, in order to maintain stability of internal IC operation, maintain

an input current of at least 5 mA (Latch type), 10 mA (Non Latch

type).

Photovoltaic MOSFET driver cautions for use

When two external MOSFETs are connected with a common source

terminal, oscillation may occur when operation is restored.

Therefore, please insert a 100 to 1,000 Ω resistor between the gate

terminal of the first MOSFET and the gate terminal of the second

MOSFET.

A typical example of this is given in the circuit below.

1

DC

type

AC/

DC

type

Load current

Recommended

load voltage

AQZ102

60 V DC

4.0 A DC

5, 12, 24 V DC

AQZ105

100 V DC

2.6 A DC

48 V DC

AQZ107

200 V DC

1.3 A DC

100 V DC

AQZ104

400 V DC

0.7 A DC

200 V DC

AQZ202

Peak AC, DC 60 V

Peak AC, DC 3.0 A

AQZ205

Peak AC, DC 100 V Peak AC, DC 2.0 A

24 V AC

48 V DC

AQZ207

Peak AC, DC 200 V Peak AC, DC 1.0 A

48 V AC

100 V DC

AQZ204

Peak AC, DC 400 V Peak AC, DC 0.5 A

120 V AC

200 V DC

Absolute maximum rating

Load voltage

AC/

DC

type

4

12 V AC

5, 12, 24 V DC

2) Power photoMOS® (1 Form B)

6

2

3

Absolute maximum rating

Load voltage

Load current

Peak AC, DC 400 V Peak AC, DC 0.5 A

AQZ404

Recommended

load voltage

100 V AC

200 V DC

3) Power photoMOS® Voltage-sensitive type (1 Form A)

Input LED current (for Standard type)

Absolute maximum rating

For rising and dropping ratio of input LED current (di/dt), maintain

Min. 100 μA/s.

Input voltage (for Power voltage-sensitive type)

For rising and dropping ratio of input voltage (dv/dt), maintain Min.

100 mV/s.

Load voltage

Load current

Recommended

load voltage

AQZ102D

60 V DC

3.6 A DC

5, 12, 24 V DC

DC AQZ105D

type AQZ107D

100 V DC

2.3 A DC

48 V DC

200 V DC

1.1 A DC

100 V DC

AQZ104D

400 V DC

0.6 A DC

200 V DC

AQZ202D

Peak AC, DC 60 V

Peak AC, DC 2.7 A

12 V AC

5, 12, 24 V DC

24 V AC

AC/ AQZ205D Peak AC, DC 100 V Peak AC, DC 1.8 A 48 V DC

DC

type AQZ207D Peak AC, DC 200 V Peak AC, DC 0.9 A 48 V AC

100 V DC

AQZ204D Peak AC, DC 400 V Peak AC, DC 0.45 A

120 V AC

200 V DC

4) Power photoMOS® High Capacity type (1 Form A)

Absolute maximum rating

DC

type

Load voltage

Load current

Recommended

load voltage

AQZ192

60 V DC

10 A DC

5, 12, 24 V DC

AQZ197

200 V DC

5 A DC

100 V DC

AQZ202G

Peak AC, DC 60 V

12 V AC

Peak AC, DC 6 A

5, 12, 24 V DC

24 V AC

AC/ AQZ205G Peak AC, DC 100 V Peak AC, DC 4 A 48 V DC

DC

type AQZ207G Peak AC, DC 200 V Peak AC, DC 2 A 48 V AC

100 V DC

AQZ206G2 Peak AC, DC 600 V Peak AC, DC 1 A

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ー 14 ー

Panasonic Corporation 2020

120, 240 V AC

200, 400 V DC

ASCTB65E 202002

�Please contact ..........

Electromechanical Control Business Division

1006, Oaza Kadoma, Kadoma-shi, Osaka 571-8506, Japan

industral.panasonic.com/ac/e/

©Panasonic Corporation 2020

ASCTB127E 202002

Specifications are subject to change without notice.

�