AYL1

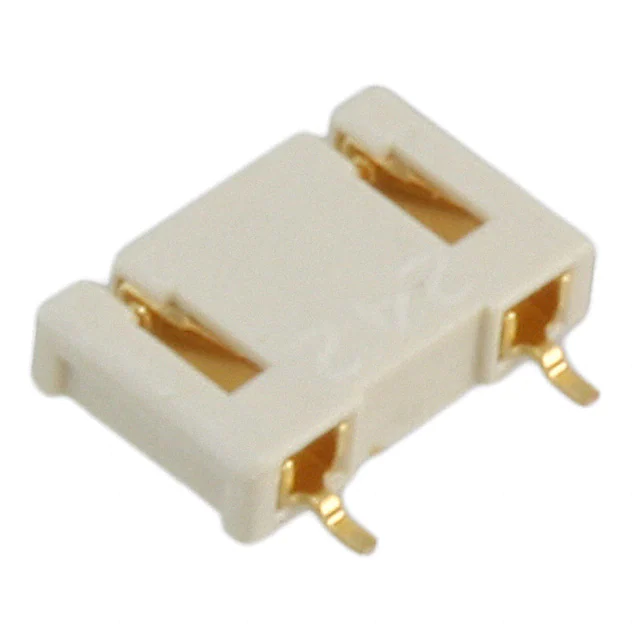

For LED

LED lighting connector

L1 Series

(Joint type)

FEATURES

New

1. Small and low profile design does

not obstruct the LED light

The connector is of a 2.4 mm pitch two

pins board joint type. The LED light is not

obstructed by the low profile (1.4 mm

mated height) L1 series connector.

Explanatory diagram of the connector

mounted on a circuit board

Joint plug

3. Safety covered by ensuring

insulation distance (Min. 1.6 mm)

4. Mating lock construction using

molded lock

5. Unmating configured with jig

APPLICATIONS

Straight LED tube lights, LED base

lights, etc.

Receptacle (common)

1.4mm

LED

RoHS compliant

4.4mm

LED mounted board

2. Floating design

The three-directional floating function

(X: ±0.3 mm, Y: ±0.5 mm, Z: ±0.3 mm)

accommodates thermal expansion of

circuit boards.

X-direction: ±0.3 mm

Y-direction: ±0.5 mm

Z-direction: ±0.3 mm

ORDERING INFORMATION

AYL 1

1

2

4

0

1: L1

Product type

1: Receptacle

2: Joint plug

Type of mating

1: Vertical

Number of pins (1 digit)

Terminal pitch

4: 2.4 mm

Function

0: Standard

ACCTB50E 201207-T

Panasonic Corporation

Automation Controls Business Unit

industrial.panasonic.com/ac/e/

�AYL1

PRODUCT TYPES

1. Receptacle

Mated height

Part No.

1.4mm

AYL111240

Mated height

Part No.

1.4mm

AYL121240

Packing

Inner carton (1-reel)

5,000 pieces

Outer carton

10,000 pieces

2. Joint plug

Packing

Inner carton (1-reel)

5,000 pieces

Outer carton

10,000 pieces

Notes: 1. Order unit:

For volume production: 1-inner carton (1-reel) units

Samples for mounting check: 50-connector units. Please contact our sales office.

2. Please contact us for connectors having a number of pins other than those listed above.

SPECIFICATIONS

1. Characteristics

Electrical

characteristics

Item

Rated current

Rated voltage

1.0A/pin contact

125V AC/DC

Breakdown voltage

1,250V AC for 1 min.

Insulation resistance

Min. 1,000MΩ (initial)

Contact resistance

Max. 90mΩ

Composite insertion force

(initial)

Composite removal force

(initial)

Specifications

Conditions

No short-circuiting or damage at a detection current of 1 mA

when the specified voltage is applied for one minute.

Using 500V DC megger (applied for 1 min.)

Based on the contact resistance measurement method

specified by JIS C 5402.

Two contacts of receptacle and a post of joint plug

Max. 25.2N

Insertion force of two receptacles and a joint plug

Min. 4.0N

Removal force of two receptacles and a joint plug

Y

Mechanical

characteristics

Floating distance

(Receptacle and joint plug

mated)

X direction: ±0.3 mm

Y direction: ±0.5 mm

Z direction: ±0.3 mm

X

Z

Ambient temperature

–40°C to +105°C

No freezing at low temperatures. No dew condensation.

Storage temperature

–40°C to +85°C (product only)

–40°C to +50°C (packing structure)

No freezing at low temperatures. No dew condensation.

Conformed to MIL-STD-202F, method 107G

Thermal shock resistance

(Receptacle and plug)

Order Temperature (°C)

1

–40 −30

2

3

105 +30

4

–40 −30

200 cycles,

insulation resistance min. 100MΩ,

contact resistance max. 90mΩ

Environmental

characteristics

Humidity resistance

(Receptacle and plug)

Saltwater spray resistance

(Receptacle and plug)

H2S resistance

(Receptacle and plug)

Durability

Soldering

temperature

resistance

Receptacle

Solder paste thickness

500 hours,

insulation resistance min. 100MΩ,

contact resistance max. 90mΩ

24 hours,

insulation resistance min. 100MΩ,

contact resistance max. 90mΩ

Time (minutes)

30

Max. 5

30

Max. 5

Bath temperature 85±2°C,

humidity 80 to 85% R.H.

Conformed to MIL-STD-1344F, method 1001

Bath temperature 35±2°C,

saltwater concentration 5±1%

Conformed to JEIDA-38-1984

Bath temperature 40±2°C, gas concentration 3±1 ppm,

humidity 75 to 80% R.H.

48 hours,

contact resistance max. 90mΩ

3 times,

contact resistance max. 90mΩ

Using removal tool

The initial specification must be satisfied electrically

and mechanically

Reflow soldering:

Max. peak temperature of 260°C, Max. 2 times

(PC board surface temperature near connector terminals)

Soldering iron: 300°C within 5 s

350°C within 3s

The initial specification must be satisfied electrically

and mechanically

Recommendation t = 0.12 mm screen

Note: The preceding show characteristics, when mated with receptacle and Joint plug.

Panasonic Corporation

Automation Controls Business Unit

industrial.panasonic.com/ac/e/

ACCTB50E 201207-T

�AYL1

2. Material and surface treatment

1. Receptacle

Part name

Molded portion

Material

LCP resin (UL94V-0)

Color

White

Contact

Copper alloy

—

Soldering terminal

Copper alloy

—

Material

LCP resin (UL94V-0)

Copper alloy

Color

White

—

Surface treatment

—

Contact portion: Pd-Ni+Au flash plating over Ni

Terminal portion: Au plating over Ni (except the terminal tips)

Terminal portion: Au plating over Ni

2. Joint plug

Part name

Molded portion

Post

Surface treatment

—

Terminal portion: Pd-Ni+Au flash plating over Ni

DIMENSIONS (Unit: mm)

Receptacle

Terminal coplanarity

0.08

0.20±0.03

2.42

X

X

(Contact and

soldering terminals)

3.78

Y

2.00

(Suction face)

2.40±0.05

3.02

Y

0.90±0.05

0.38

0.60

General tolerance: ±0.2

1.00

0.19

0.15

0.75

4.40

15.00

2.40±0.05

1.60 (Suction face)

Joint plug

1.38

13.62

1.35

1.15

3.22

3.00

3.08

9.60

General tolerance: ±0.2

ACCTB50E 201207-T

Panasonic Corporation

Automation Controls Business Unit

industrial.panasonic.com/ac/e/

�AYL1

Receptacle and Joint plug are mated

Joint plug

Receptacle

1.40±0.1

Receptacle

EMBOSSED TAPE DIMENSIONS (Unit: mm)

(1.75)

(17.4±1)

Top cover tape

Label

Top cover tape

Embossed carrier tape

Embossed carrier tape

to 18

0°

380 dia.

Note 1)

(4.0)

(16.0 +0.3

−0.1 )

(7.5)

• Specifications for the plastic reel

(In accordance with EIAJ ET-7200B.)

(8.0) (2.0)

1.

5

Embossed mounting-hole

165°

Leading direction after packaging

• Tape packed status

Receptacle

Taping reel

Receptacle

+0

0 .1

dia

.

(24.0 +0.3

−0.1 )

(11.50)

Top cover tape

(1.75)

(25.4±1)

Label

0°

to 18

5

165°

1.

+0

0 .1

Top cover tape

Embossed carrier tape

Embossed carrier tape

380 dia.

Note 1)

(4.0)

(8.0) (2.0)

Leading direction after packaging

Joint plug

Embossed mounting-hole

Joint plug

Taping reel

dia

.

• Connector orientation with respect to embossed tape feeding direction

Type

L1

Direction

of tape progress

Receptacle

Panasonic Corporation

Automation Controls Business Unit

Joint plug

industrial.panasonic.com/ac/e/

ACCTB50E 201207-T

�AYL1

NOTES ON USING CONNECTOR FOR LED LIGHTING

Recommended PC board pattern (mounting pad layout)

(TOP VIEW)

Unit: mm

0.05±0.03

2.32±0.03

0.05±0.03

Note 3) Between

ACCTB50E 201207-T

Panasonic Corporation

2.40±0.03

0.40±0.03

PC board: Max. 1.00

Note 1)

1.10±0.03

Note 2)

0.20±0.05

Note 2)

Note 2) 0.20±0.05

0.20±0.05

Note 2) 0.20±0.05

Note 1)

Pad area

Note 2)

It is necessary to do the resist processing on the copper foil.

Note 3) These dimensions are applied when the insulation distance from the edge of the PC board is 1.5 mm.

2) Reflow soldering

• Screen-printing is recommended for printing paste solder.

• To determine the relationship between the screen opening area

and the PC board foot pattern area, refer to the diagrams in the

recommended patterns for PC boards and metal masks.

Make sure to use the terminal tip as a reference position when

setting.

• Too much solder may cause solder creeping near the

contacting part or contact failure.

Terminal

� About receptacle

• PC board design

Design the recommended foot pattern in order to secure the

mechanical strength in the soldered areas of the terminal.

• Connector mounting

When mounting, if there is too much suction nozzle pressure,

the molded and metal parts might deform and break.

Please check beforehand.

In case of dry condition, please care the occurrence of static

electricity.

The product may be adhered to the embossed carrier tape or

the cover tape in dry condition.

Recommended humidity is between 40 to 60 % and please

remove static electricity by ionizer in manufacturing scene.

• Soldering

1) Manual soldering.

• Since this connector is the low profile type the amount of solder

supplied should be closely monitored.

Too much solder during manual soldering may cause solder

creeping near the contacting part or contact failure.

• Make sure that the soldering iron tip is heated within the

temperature and time limits indicated in the specifications.

• Flux from the solder wire may adhere to the contact surfaces

during soldering operations. After soldering, carefully check the

contact surfaces with a magnifying glass and clean off any flux

before use.

• Be aware that a load applied to the connector terminals while

soldering may displace the contact.

• Thoroughly clean the soldering iron tip.

Note 1) 1.10±0.03

11.92±0.05

0.40±0.03

Note 3) (Min. 1.84)

� Safety precautions

Observe the following safety precautions to prevent accidents

and injuries.

1) The use of the connector outside of the specified rated current

and breakdown voltage ranges may cause abnormal heating,

smoke, and fire.

Never use the connector beyond the specified ranges of the

product.

2) In order to avoid accidents, make sure you have thoroughly

reviewed the specifications before use.

Consult us if you plan to use the product in a way not covered by

the specifications.

3) We are consistently striving to improve quality and reliability.

However, the fact remains that electrical components and

devices generally fail at a given statistical probability.

Furthermore, their durability varies depending on where and

how they are used. Please be sure to verify electrical

components and devices under actual conditions before use.

Continuously using them in a state of degraded performance

may cause deterioration in insulation performance, thus

resulting in abnormal heat generation, smoke generation, or fire.

To avoid that, we ask you to implement safe designs that include

redundancy, fire prevention, and malfunction prevention. Also,

please conduct periodic maintenance so that no accidents

resulting in injury or death, fire, or harm to society will be caused

as a result of product failure or service life.

Paste

solder

PC board

foot pattern

• Consult us when using a screen-printing thickness other than

that recommended.

• Depending on the size of the connector being used, self

alignment may not be possible. Accordingly, carefully position

the terminal with the PC board pattern.

• The recommended reflow temperature profile is given in the

figure below

Upper limit (Soldering heat resistance)

Lower limit (Solder wettability)

Temperature

260°C

230°C

180°C

150°C

Peak temperature

Preheating

220°C

200°C

25 sec.

60 to 120 sec.

70 sec.

Time

• The temperature is measured on the surface of the PC board

near the connector terminal.

• Certain solder and flux types may cause serious solder

creeping.

Solder and flux characteristics should be taken into

consideration when setting the reflow soldering conditions.

• Do not apply adhesive to secure the connector, because it can

affect the spring action of the contact.

• When coating the PC board after soldering the connector to

prevent the deterioration of insulation, perform the coating in

such a way so that the coating does not get on the connector.

3) Reworking on a soldered portion

• Finish reworking in one operation.

• For reworking of the solder bridge, use a soldering iron with a

flat tip. Do not add flux, otherwise, the flux may creep to the

contact parts.

• Use a soldering iron whose tip temperature is within the

temperature range specified in the specifications.

Automation Controls Business Unit

industrial.panasonic.com/ac/e/

�AYL1

• Although this product has floating structure, it’s the

performance in the state of receptacles and a plug mated. We

can’t guarantee mating in the state where receptacles and a

plug are shifted from the center. When inserting a plug in

receptacles, please check the position of a mutual receptacle.

Position

sifts

Joint plug

Joint plug

Position

sifts

Receptacle

Position

sifts

• Do not drop or handle the connector carelessly. Otherwise, the

terminals may become deformed due to excessive force or

applied solderability may degrade.

• When cutting or bending the PC board after mounting the

connector, be careful that the soldered sections are subjected to

excessive forces.

� Insertion / Removal and mating retention of connectors

• Do not insert or remove the connector when it is not soldered.

Also, forcibly applied external pressure on the terminals can

weaken the adherence of the terminals to the molded part or

cause the terminals to lose their evenness.

• Excessive prying-force applied to one end may cause product

breakage and separation of the solder joints at the terminal.

Excessive force applied for insertion in a pivot action as shown

may also cause product breakage.

Always align the connector with the mating part and slide it in

parallel.

Mating

X

Z

Receptacle

X

Y

Receptacle

Joint plug

Joint plug

Z

Z

Y

Y

Receptacle

Receptacle

• Pushing the plug excessively when inserting it may deform and

break the product.

• This product has simple lock structure for mating. However,

connectors may be unmated because of impact by dropping and

so on. Please take countermeasures at the equipment side for

preventing removal of connectors. In order to prevent removal of

connectors, please fix the PC board by frame and so on not to

move more than floating distance, especially the neighborhood

of connectors.

Receptacle

Fix the PC board by frame and so on

Z

Y

PC board with mounted connectors

(Don’t move more than floating distance)

• When removing the connector, please use the recommended

removal tool.

After inserting the tip of removal jig under the plug, push down

the jig shown in below. (Removable from either the left or right

side) Since holding force of mating will decline when removing

the connector without using tool, please don’t use the remove

plug, and exchange to a new plug.

Removal tool

Z

Insert removal tool and push down

in the direction of the arrow.

Y

X

Z

Insertion point

of removal tool

Panasonic Corporation

Y

Automation Controls Business Unit

industrial.panasonic.com/ac/e/

ACCTB50E 201207-T

�