Convergent Reflective Photoelectric Sensor

Amplifier Built-in

Timer

CX-400

PHOTOELECTRIC SENSORS

EX-40 SERIES

Conforming to

EMC Directive

Compact size (W10�H30�D18 mm W0.394�H1.181�D0.709 in)

Stable convergent distance sensing

)

10 mm

0.394 in

30 mm

1.181 in

50

1.969

30

1.181

0

Distance to convergent point

(

It can be installed in a limited space.

18 mm

0.709 in

100

3.937

Aluminum-evaporated mirror

Stainless steel plate

Aluminum plate

Glass epoxy printed circuit board

(Green masked surface)

White non-glossy paper

White ceramic circuit board

Cardboard

Black rubber sheet

Black substrate

Background

The sensor does not detect even a specular

object 100 mm 3.937 in, or more, away

from the sensing surface. (with EX-43)

However, the specular background

should be a plane surface, directly

facing the sensor. A spherical or

curved background may be detected.

EX-43: Correlation between material

and sensing range

Sensing range L (mm) (in)

Due to convergent distance sensing, the color

or material of the object has almost no effect.

Further, the background also has very little

effect, enabling stable sensing.

Variable OFF-delay timer (EX-43T only )

Waterproof

The spot-beam type EX-43T is incorporated with an OFF-delay timer.

The variable OFF-delay timer is useful

for detecting a printed circuit board

regardless of small holes, cutouts or

electronic parts on it.

Due to its IP67 construction, there is no

problem even if water splashes on the

sensor, as on a food processing line.

Various applications

Non-corrosive stainless

steel mounting bracket

(optional)

RX-LS200

RX

EX-40

EQ-30

EQ-20

Amplifier Built-in

EX-10

EX-20

EX-30

Reliable object

detection in limited

area

Diffused beam type

Sensing area

In the limited sensing area, the sensor

is not affected by small perforations or

unevenness. It is suitable for presence

detection.

Spot-beam type

Sensing point

Time chart

Light

Sensing

condition

Output operation

(Light-ON)

266

Dark

ON

T

OFF

Timer period: T�0.1 to 1 sec. approx.

Note: However, take care that if it is exposed to

water splashes during operation, it may

detect a water drop itself.

• Visible red spot beam allows easy targetting.

• It is suitable for positioning because of

its 0.05 mm 0.002 in repeatability.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�APPLICATIONS

Sensing parts in feeder

Positioning trays

EX-30

CX-400

Determining PCB position

PHOTOELECTRIC SENSORS

EX-40

Diffused beam type

Type

Appearance

Sensing range (Note 1)

Model No.

Output

Sensitivity

adjuster

Timer

function

Emitting

element

EX-20

ORDER GUIDE

NPN

open-collector

transistor

Incorporated

EX-43

With timer

Red LED

20 to 35 mm 0.787 to 1.378 in

(Convergent point: 30 mm 1.181 in)

EX-43T

Incorporated

NOTE: Mounting bracket is not supplied with the sensor. Please select from the range of optional sensor mounting

brackets (two types).

EQ-30

EX-44

10 to 70 mm 0.394 to 2.756 in

(Convergent point: 40 mm 1.575 in)

Amplifier Built-in

EQ-20

Long sensing range

Spot-beam type

Infrared LED

EX-10

EX-42

5 to 38 mm 0.197 to 1.496 in

(Convergent point: 20 mm 0.787 in)

Note: 1) The sensor does not detect even a specular background if it is separated by the distance specified below.

EX-42 ... 150 mm 5.906 in or more, EX-44 ... 300 mm 11.811 in or more, EX-43 and EX-43T ... 100 mm 3.937 in or more

These are typical values. However, the specular background should be a plane surface, directly facing the sensor.

A spherical or curved background may be detected.

)

EX-40

(

5 m 16.404 ft cable length type

5 m 16.404 ft cable length type (standard:2 m 6.562 ft) is also available.

• Table of Model Nos.

5 m 16.404 ft cable length type

RX

Standard

EX-42

EX-42-C5

EX-44

EX-44-C5

EX-43

EX-43-C5

EX-43T

EX-43T-C5

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

RX-LS200

Long sensing range

With timer

Spot-beam type

Diffused beam type

Type

267

�PHOTOELECTRIC SENSORS

CX-400

EX-40

OPTIONS

Sensor mounting bracket

Designation

Sensor mounting

bracket

Model No.

Description

MS-EX40-1

Rear mounting bracket

MS-EX40-2

Bottom mounting bracket

MS-AJ1

Horizontal mounting type

MS-AJ2

Vertical mounting type

MS-AJ1-A

Horizontal mounting type

MS-AJ2-A

Vertical mounting type

• MS-EX40-1

EX-30

Basic assembly

Universal

sensor mounting

stand (Note)

Two M3 (length 16 mm

0.630 in) screws with

washers are attached.

Two M3 (length 16 mm

0.630 in) screws with

washers are attached.

Universal sensor mounting stand

Lateral arm

assembly

Note: Refer to p.332l for details of the universal sensor mounting stand.

• MS-AJ1

• MS-AJ2

Swivel:

360� rotation

45�

45�

Elevation

angle: �45�

EX-20

• MS-EX40-2

Height

adjustment:

150 mm

5.906 in

approx.

Mounting

hole for

M6 screw

Swivel:

360� rotation

45�

45�

Elevation

angle: �45�

EX-10

• MS-AJ1-A

EQ-20

Amplifier Built-in

With the lateral

arm, the sensor

can sense from

above a production line.

Mounting

hole for

M6 screw

• MS-AJ2-A

Swivel:

360� rotation

Height

adjustment:

150 mm

5.906 in

approx.

With the lateral

arm, the sensor

can sense from

above a production line.

Mounting

hole for

M6 screw

45�

45�

Angle

adjustment: �45�

Swivel:

360� rotation

Height

adjustment:

150 mm

5.906 in

approx.

Mounting

hole for

M6 screw

360�

rotation

45�

45� Angle

adjustment: �45�

RX-LS200

RX

EX-40

EQ-30

360�

rotation

Height

adjustment:

150 mm

5.906 in

approx.

268

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�SPECIFICATIONS

Diffused beam type

Spot-beam type

Long sensing range

EX-42

With timer

EX-44

EX-43

EX-43T

Sensing range

5 to 38 mm 0.197 to 1.496 in (Conv. point: 10 to 70 mm 0.394 to 2.756 in (Conv. point:

20 mm 0.787 in) with white non-glossy 40 mm 1.575 in) with white non-glossy

paper (50 50 mm 1.969 1.969 in)

paper (50 50 mm 1.969 1.969 in)

Min. sensing object

"0.2 mm "0.008 in copper wire

"0.2 mm "0.008 in copper wire

"0.03 mm "0.001 in gold wire (Setting distance: 30 mm 1.181 in)

(Setting distance: 20 mm 0.787 in) (Setting distance: 40 mm 1.575 in)

Hysteresis

20 to 35 mm 0.787 to 1.378 in (Conv. point: 30 mm 1.181 in)

with white non-glossy paper (50 50 mm 1.969 1.969 in)

15 % or less of operation distance

10 % or less of operation distance

Repeatability

0.1 mm 0.004 in or less

0.2 mm 0.008 in or less

0.05 mm 0.002 in or less (Setting distance: 30 mm 1.181 in)

(perpendicular to sensing axis) (Setting distance: 20 mm 0.787 in) (Setting distance: 40 mm 1.575 in)

12 to 24 V DC�10 % Ripple P-P 10 % or less

Current consumption

Utilization category

DC-12 or DC-13

Output operation

Light-ON

Short-circuit protection

0.5 ms or less

Red LED (lights up when the output is ON)

Green LED (lights up under stable light received condition or stable dark condition)

Sensitivity adjuster

Continuously variable adjuster

Variable OFF-delay timer

(0.1 to 1 sec. approx.) (Note)

Timer function

Pollution degree

3 (Industrial environment)

Ambient temperature

Ambient humidity

Ambient illuminance

EMC

Voltage withstandability

IP67 (IEC)

�25 to�55 �C �13 to�131 �F (No dew condensation or icing allowed), Storage: �30 to�70 �C �22 to�158 �F

35 to 85 % RH, Storage: 35 to 85 % RH

Sunlight: 10,000 #x at the light-receiving face, Incandescent light: 3,000 #x at the light-receiving face

EN 50081-2, EN 50082-2, EN 60947-5-2

1,000 V AC for one min. between all supply terminals connected together and enclosure

Insulation resistance

20 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure

Vibration resistance

10 to 500 Hz frequency, 3 mm 0.118 in amplitude (20 G max.) in X, Y and Z directions for two hours each

Shock resistance

Emitting element

Material

Cable

Cable extension

Weight

Accessory

EQ-30

Environmental resistance

Protection

EX-40

Stability indicator

EX-10

Incorporated

Response time

Operation indicator

EX-20

NPN open-collector transistor

• Maximum sink current: 100 mA

• Applied voltage: 30 V DC or less (between output and 0 V)

• Residual voltage: 1.5 V or less (at 100 mA sink current)

0.4 V or less (at 16 mA sink current)

500 m/s2 acceleration (50 G approx.) in X, Y and Z directions for three times each

Infrared LED (modulated)

Red LED (modulated)

Polyalylate

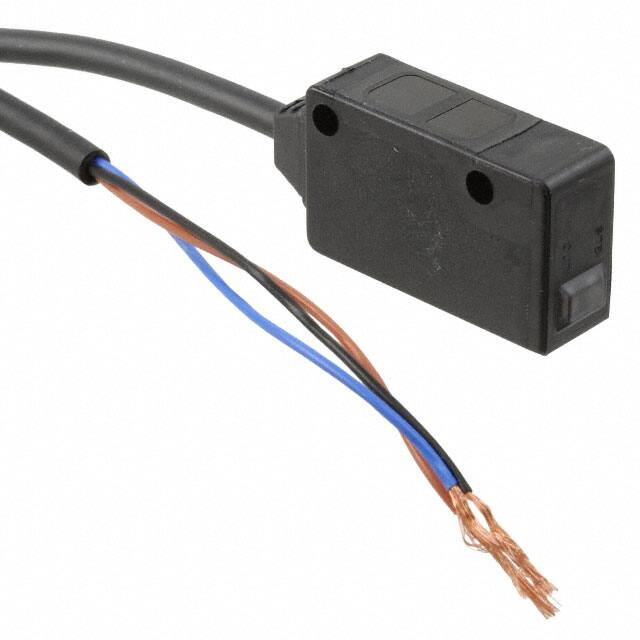

0.2 mm2 3-core cabtyre cable, 2 m 6.562 ft long

RX

Output

35 mA or less

Extension up to total 100 m 328.084 ft is possible with 0.3 mm2, or more, cable.

45 g approx.

Adjusting screwdriver: 1pc.

RX-LS200

Supply voltage

CX-400

Model No.

Amplifier Built-in

EQ-20

Item

EX-30

Type

PHOTOELECTRIC SENSORS

EX-40

Note: The timer is always effective.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

269

�PHOTOELECTRIC SENSORS

EX-40

I/O CIRCUIT AND WIRING DIAGRAMS

I/O circuit diagram

Wiring diagram

Color code

(Brown)�V

CX-400

Sensor circuit

D

Load

�

�

(Black) Output

Tr

100 mA max.

ZD

Brown

12 to 24 V DC

�10 %

Load

Black

(Blue) 0V

� 12 to 24 V DC

� �10%

Blue

EX-30

Internal circuit

Users’ circuit

EX-42

Sensor

0

20

40

60

0.787

1.575

2.362

White non-glossy paper

side length a (mm in)

The sensing region is represented by oblique lines in the left

figure. However, the sensitivity

should be set with enough margin because of slight variation in

products.

N2

Dark

N4

N6

Lightness

N8

Light

N1 N2 N3 N4 N5 N6 N7 N8 N9

270

(

100

3.937

50

1.969

20

0.787

0

Lightness shown on the left

may differ slightly from the

actual object condition.

)

Distance to convergent point

20

0.787

Distance to convergent point

Sensing region

80

3.150

Correlation between material (50�50 mm 1.969�1.969 in) and sensing range

Correlation between lightness and sensing range

40

1.575

(

L

For plotting the left graph, a sensor having a

sensitivity such that it can just detect a 50

50 mm 1.969 1.969 in white non-glossy

paper at a distance of 38 mm 1.496 in has

been used.

Black substrate

0

4

2

0

2

4

0.157

0.079

0.079

0.157

Center

(Down) Left

Right (Up)

Operating point ?(mm in)

20

0.787

Black rubber sheet

Sensor

a a mm a a in

White non-glossy paper

Stainless steel plate

Glass epoxy printed circuit board

(Green masked surface)

White non-glossy paper

White ceramic circuit

board

Cardboard

# L

40

1.575

Aluminum-evaporated

mirror

Aluminum plate

20

0.787

As the sensing object size becomes smaller than

the standard size (white non-glossy paper

50 50 mm 1.969 1.969 in), the sensing range

shortens, as shown in the left graph.

Sensing range L (mm in)

50 50 mm 1.969 1.969 in

White non-glossy paper

Sensing range L (mm in)

40

1.575

0

RX-LS200

Correlation between sensing object size and sensing range

Distance to convergent point

Setting distance L (mm in)

Sensing field

Sensing range L (mm in)

EQ-20

Amplifier Built-in

EQ-30

EX-40

RX

SENSING CHARACTERISTICS (TYPICAL)

(

EX-10

EX-20

Symbols ... D : Reverse supply polarity protection diode

ZD: Surge absorption zener diode

Tr : NPN output transistor

The bars in the graph indicate the

sensing range for the respective

material. However, there is a

slight variation in the sensing

range depending on the product.

Further, if there is a reflective

object (conveyor, etc.) in the

background of the sensing object,

since it affects the sensing,

separate it by more than twice the

sensing range shown in the left

graph.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�SENSING CHARACTERISTICS (TYPICAL)

EX-44

Correlation between sensing object size and sensing range

N1 N2 N3 N4 N5 N6 N7 N8 N9

(

0

Lightness shown on the left

may differ slightly from the

actual object condition.

)

(

)

EX-43

EX-43T

# L

Sensor

0

Distance to convergent point

Black substrate

Black rubber sheet

White ceramic circuit

board

Cardboard

Aluminum-evaporated

mirror

Stainless steel plate

Aluminum plate

Glass epoxy printed circuit board

(Green masked surface)

White non-glossy paper

Sensing range L (mm in)

0

N2

The bars in the graph indicate the

sensing range for the respective

material. However, there is a

slight variation in the sensing

range depending on the product.

Further, if there is a reflective

object (conveyor, etc.) in the

background of the sensing object,

since it affects the sensing,

separate it by more than twice the

sensing range shown in the left

graph, or adjust the sensitivity

adjuster.

The graph is drawn for the

maximum sensitivity setting.

However, EX-43T does not

incorporate the sensitivity

adjuster.

(

N4

N6

Lightness

N8

Light

N1 N2 N3 N4 N5 N6 N7 N8 N9

(

(

Lightness shown on the left

may differ slightly from the

actual object condition.

(

30

1.181

20

0.787

Dark

Correlation between material (50�50mm 1.969�1.969 in) and sensing range

50

1.969

Sensing region

0

4

2

2

4

0

0.157

0.079

0.079

0.157

Center

(Down) Left

Right (Up)

Operating point ?(mm in)

100

3.937

30

1.181

The sensing region is represented by oblique lines in the left figure. However, the sensitivity

should be set with enough margin because of slight variation in

products.

The graph is drawn for the

maximum sensitivity setting.

However, EX-43T does not

incorporate the sensitivity

adjuster.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

)

EX-10

RX-LS200

20

0.787

40

1.575

Distance to convergent point

50 50 mm

1.969 1.969 in

White non-glossy

paper

30

1.181

Sensing range L (mm in)

40

1.575

Distance to convergent point

Setting distance L (mm in)

Correlation between lightness and sensing range

(

Sensing field

EQ-30

Light

40

1.575

EX-40

N8

100

3.937

The bars in the graph indicate the

sensing range for the respective

material. However, there is a

slight variation in the sensing

range depending on the product.

Further, if there is a reflective

object (conveyor, etc.) in the

background of the sensing object,

since it affects the sensing,

separate it by more than twice the

sensing range shown in the left

graph, or adjust the sensitivity

adjuster.

The graph is drawn for the

maximum sensitivity setting.

RX

N4

N6

Lightness

Distance to convergent point

N2

Dark

)

200

7.874

EX-20

Correlation between material (50�50 mm 1.969�1.969 in) and sensing range

Amplifier Built-in

EQ-20

Sensing range L (mm in)

(

0

0

CX-400

80

3.150

The sensing region is represented by oblique lines in the left figure. However, the sensitivity

should be set with enough margin because of slight variation in

products.

The graph is drawn for the

maximum sensitivity setting.

Sensing region

50

1.969

40

1.575

EX-30

20

40

60

0.787

1.575

2.362

White non-glossy paper

side length a (mm in)

Distance to convergent point

0

Correlation between lightness and sensing range

100

3.937

)

Sensor

Black substrate

4

2

2

4

0.157

0.079

0.079

0.157

Center

(Down) Left

Right (Up)

Operating point ?(mm in)

(

L

For plotting the left graph, the sensitivity has been

set such that a 50 50 mm 1.969 1.969 in

white non-glossy paper is just detectable at a

distance of 70 mm 2.756 in.

Black rubber sheet

Sensor

0

0

a a mm a a in

White non-glossy paper

50

1.969

Stainless steel plate

Glass epoxy printed circuit board

(Green masked surface)

White non-glossy paper

White ceramic circuit

board

Cardboard

# L

Distance to convergent point

50 50 mm 1.969 1.969 in

White non-glossy paper

Aluminum-evaporated

mirror

Aluminum plate

50

1.969

40

1.575

As the sensing object size becomes smaller than

the standard size (white non-glossy paper 50

50 mm 1.969 1.969 in), the sensing range shortens, as shown in the left graph.

100

3.937

Sensing range L (mm in)

Setting distance L (mm in)

100

3.937

Sensing range L (mm in)

Sensing field

PHOTOELECTRIC SENSORS

EX-40

271

�PHOTOELECTRIC SENSORS

CX-400

EX-40

PRECAUTIONS FOR PROPER USE

This product is not a safety sensor. Its use is not

intended or designed to protect life and prevent body

injury or property damage from dangerous parts of

machinery. It is a normal object detection sensor.

Mounting

• With the optional sensor mounting bracket, the tightening

torque should be 0.5 N

m or less.

Refer to p.1135l for general precautions.

Timer function (Only for EX-43T)

• The variable OFF-delay timer prolongs the output for a

certain period (0.1 to 1 sec. approx.).

• It is useful when the connected device has a slow response

time or when small objects are sensed and the signal width

is small.

• (The timer is always effective.)

EX-30

Adjusters

Timer adjuster

time becomes longer

( OFF-delay

)

if it is turned clockwise.

EX-20

Sensor mounting bracket

MS-EX40-1

(Optional)

Operation indicator (Red)

Stability indicator (Green)

up when the output

( Lights

)

is ON.

up under stable light received

( Lights

condition or stable dark condition. )

M3 (length 16 mm 0.630 in) screw with washers

Others

• Do not use during the initial transient time (50 ms) after

the power supply is switched on.

EQ-20

Amplifier Built-in

EX-10

Time chart

Light

Sensing

condition

Output

operation

Dark

ON

T

T

T

OFF

RX-LS200

RX

EX-40

EQ-30

Timer period: T�0.1 to 1 sec. approx.

272

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�DIMENSIONS (Unit: mm in)

EX-42 EX-44

EX-43 EX-43T

The CAD data in the dimensions can be downloaded from the SUNX website: http://www.sunx.co.jp/

Sensor

CX-400

Stability indicator

(Green)

Sensitivity adjuster (Note)

Operation indicator

(Red)

18

0.709

1

3

0.039

0.118

10

0.394

8

0.315

Center of

sensing

Beamemitting

part

EX-30

Beamreceiving

part

30

1.181 19

0.748

12.5

0.492

PHOTOELECTRIC SENSORS

EX-40

6 0.236

"3.7 "0.146 cable,

2 m 6.562 ft long

EX-20

2-"3.2 "0.126 mounting holes

Note: EX-42 does not incorporate it.

In EX-43T, it is the timer adjuster.

EX-10

Sensor mounting bracket (Optional)

Assembly dimensions

1

t 1.2

t 0.047

8.5

0.335

18

0.709

(27.2)

(1.071)

8

0.315

3.5

0.138

6

0.236

8

8.5

0.335 0.315

R19 R0.748

Center of

30 sensing

1.181

t 1.5

t 0.059

24 0.945

19 0.748

3.2

0.126

2-M3 0.5 0.020

25 0.984

14

0.551

10°

18

19

0.709 0.748

t 1.2

t 0.047

35

1.378

10°

Material: Stainless steel (SUS304)

5 0.197

MS-EX40-2

13

0.512

10

0.394

R19 R0.748

35 19

1.378 0.748

6

0.236

2

25 0.984

14 0.551

10°

EQ-30

3.5

3.2 0.138

0.126

6

0.236

6

0.236

3.4 0.134

8 0.315

10°

14

0.551

Two M3 (length 16 mm 0.630 in) screws

with washers are attached.

EX-40

3.4

0.134

18

0.709

0.5

0.020

14

0.551

8

0.315

Amplifier Built-in

EQ-20

MS-EX40-1

Sensor mounting bracket (Optional)

Assembly dimensions

1

15

0.591

25 19

0.984 0.748

19

0.748

7.9

0.311

8

0.315

2

0.079

2

24 0.945

19 0.748

3.2

0.126

3.2

0.126

3.5

0.138

0.5

0.020

R25 R0.984

R19 R0.748

20 37

0.787 1.457

20

0.787

1.5

0.059

7°

45

1.772

5 6.5

7

0.197 0.256 0.276

18.9

0.744

(12.9)

(0.508) 10

0.394

4 0.157

21.5

0.846

30

1.181

18

0.709

45

1.772

3.5

0.138

7°

18.9

0.744

5 6.5

0.197 0.256 7 0.276

RX-LS200

t 1.5

t 0.059

RX

15

0.591

12

0.472

37

1.457

20

0.787

19

0.748

t 1.5

t 0.059

Material: Stainless steel (SUS304)

5 0.197

2-M3 0.5 0.020

Two M3 (length 16 mm 0.630 in) screws

with washers are attached.

Center of sensing

7°

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

273

�DIMENSIONS (Unit: mm in)

MS-AJ1

17.8 0.701

12

2-"3.2 "0.126

0.472 mounting holes

t2

2-3.2 0.126 4.2 0.165

t 0.079 oblong holes

1 0.039

Cable guide

(POM)

MS-AJ2

28 20

1.102 0.787

4

0.157

33 25 20

1.299 0.984 0.787

Attachment

(Nylon 6)

EX-30

The CAD data in the dimensions can be downloaded from the SUNX website: http://www.sunx.co.jp/

Universal sensor mounting stand (Optional)

11.8

0.465

20 0.787

6 0.236

CX-400

PHOTOELECTRIC SENSORS

EX-40

20

1

0.787 0.039

Sensor mounting bracket

[Stainless steel (SUS304)]

(147)

(5.787)(Note)

Cable guide

(POM)

28 20

1.102 0.787

4

0.157

20

25

33

1.299 0.984 0.787

45�

4.2 0.165

M4 hexagonsocket-head

bolt

"10 "0.394 pipe

[Stainless steel (SUS304)]

(218)

(8.583)

17.8 0.701

12

2-"3.2 "0.126

0.472 mounting holes

t2

2-3.2 0.126 4.2 0.165

t 0.079 oblong holes

1 0.039

11.8

0.465

20 0.787

6 0.236

45�

3.2

0.126

Universal sensor mounting stand (Optional)

Attachment

(Nylon 6)

20

1

0.787 0.039

Sensor mounting bracket

[Stainless steel (SUS304)]

(147)

(5.787)(Note)

45�

3.2

0.126

45�

4.2 0.165

M4 hexagonsocket-head

bolt

"10 "0.394 pipe

[Stainless steel (SUS304)]

(210)

(8.268)

EX-20

2-"6.6 "0.260

mounting holes

8

0.315

(44.5)

(1.752) 28

1.102

18

0.709

20

0.787

45

1.772

EX-10

10

0.394

2-"6.6 "0.260 mounting holes

MS-AJ1

MS-AJ2

20

0.787

31

1.220

8

15

0.591 0.315

Base

(PA)

24.5

0.965

Two M3 (length 14 mm 0.551 in) screws with

washers, two M3 (length 16 mm 0.630 in) screws

with washers, two M3 (length 18 mm 0.709 in)

screws with washers, one auxiliary mounting plate

for EQ-20 series and one auxiliary mounting plate

for EX-40 series are attached.

Note: The dimensions in the brackets indicate the adjustable range of the

movable part.

Universal sensor mounting stand (Optional)

Assembly dimensions (Mounting part only)

11.8

0.465

20

0.787

6

0.236

2-M3 (length

16 mm 0.630 in)

screws with

washers

24.4

0.961 17

0.669

20

28

t2

1.102 0.787

t 0.079

27

Center of

1.063

sensing

45�

15.5

0.610 33 19

1.299 0.748

45�

3

0.118

4.2

0.165

Auxiliary mounting

plate for EX-40 series

RX-LS200

RX

EX-40

Two M3 (length 14 mm 0.551 in) screws with

washers, two M3 (length 16 mm 0.630 in) screws

with washers, two M3 (length 18 mm 0.709 in)

screws with washers, one auxiliary mounting plate

for EQ-20 series and one auxiliary mounting plate

for EX-40 series are attached.

Note: The dimensions in the brackets indicate the adjustable range of the

movable part.

EQ-30

EQ-20

Amplifier Built-in

32

1.260

32

1.260

46

1.811

Base

(PA)

25.5

1.004

10

0.394

(36.5)

(1.437) 20

0.787

274

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

�DIMENSIONS (Unit: mm in)

MS-AJ1-A

Cable guide

(POM)

(33)

(1.299)

(16.5)

(0.650)

33

1.299

EX-30

Sensor mounting bracket

[Stainless steel (SUS304)]

(Note 2)

Arm joint

2-"3.2 "0.126

(147)

mounting holes (Nylon 6)

(5.787)

"10 "0.394 pipe

(Note 1)

[Stainless steel (SUS304)]

2-3.2 0.126 4.2 0.165

oblong holes

(218)

(8.583)

18

0.709

8

0.315

20

0.787

45

1.772

EX-20

(44.5)

(1.752)

28

1.102

CX-400

210

8.268

(134)(5.276)(Note 1)

4.2 "10 "0.394 pipe

0.165 [Stainless steel (SUS304)]

12

0.472

(203.5)

(8.012)

Base

(PA)

25.5

1.004

32

10

1.260

0.394

2-"6.6 "0.260 mounting holes

Two M3 (length 14 mm 0.551 in) screws with

washers, two M3 (length 16 mm 0.630 in) screws

with washers, two M3 (length 18 mm 0.709 in)

screws with washers, one auxiliary mounting plate

for EQ-20 series and one auxiliary mounting plate

for EX-40 series are attached.

EX-10

6 0.236

Universal sensor mounting stand (Optional)

Amplifier Built-in

EQ-20

28.45

1.120

16.5

0.650

The CAD data in the dimensions can be downloaded from the SUNX website: http://www.sunx.co.jp/

Notes: 1) The dimensions in the brackets indicate the adjustable range of the movable part.

Notes: 2) Refer to MS-AJ1/AJ2 for the assembly dimensions with the sensor mounting bracket or sensor.

Cable guide

(POM)

(147)

(5.787)

(Note 1)

(210)

(8.268)

32

1.260

46

1.811

20

0.787

(16.5)

(0.650)

33

1.299

"10 "0.394 pipe

[Stainless steel (SUS304)]

10

0.394

(36.5)

(1.437)

20

0.787

15

8

0.591 0.315

(33)

(1.299)

Sensor mounting bracket

[Stainless steel (SUS304)]

(Note 2)

Arm joint

2-"3.2 "0.126

mounting holes (Nylon 6)

2-3.2 0.126 4.2 0.165

oblong holes

Base

(PA)

31

1.220

210

8.268

(134)(5.276)(Note 1)

4.2 "10 "0.394 pipe

0.165 [Stainless steel (SUS304)]

EQ-30

6 0.236

12

0.472

EX-40

28.45

1.120

2-"6.6 "0.260

mounting holes

(208.5)

(8.209)

24.5

0.965

RX

16.5

0.650

Universal sensor mounting stand (Optional)

Two M3 (length 14 mm 0.551 in) screws with

washers, two M3 (length 16 mm 0.630 in) screws

with washers, two M3 (length 18 mm 0.709 in)

screws with washers, one auxiliary mounting plate

for EQ-20 series and one auxiliary mounting plate

for EX-40 series are attached.

RX-LS200

MS-AJ2-A

PHOTOELECTRIC SENSORS

EX-40

Notes: 1) The dimensions in the brackets indicate the adjustable range of the movable part.

Notes: 2) Refer to MS-AJ1/AJ2 for the assembly dimensions with the sensor mounting bracket or sensor.

Ramco Innovations - 1207 Maple Street, West Des Moines IA USA 50265 - 800-280-6933 - www.ramcoinnovations.com

275

�