1057

FIBER

SENSORS

LASER

SENSORS

Compact Laser Displacement Sensor

HL-G1 SERIES

Related Information

■■General terms and conditions.............. F-7

■ Glossary of terms / General precautions...... P.1493 / P.1501

■■Sensor selection guide................ P.1055~

■■About laser beam........................ P.1499~

PHOTOELECTRIC

SENSORS

Conforming to

EMC Directive

MICRO

PHOTOELECTRIC

SENSORS

Conforming to

FDA regulations

AREA

SENSORS

LIGHT CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

This product is classified

as a Class 2 (specular

reflection type: Class 1)

Laser Product in IEC / JIS

standards and in FDA*

regulations. Do not look

at the laser beam directly

or through optical system

such as a lens.

PARTICULAR

USE SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

*�This product complies with 21 CFR 1040.10

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC ELECTRICITY

PREVENTION

DEVICES

LASER

MARKERS

PLC

HUMAN MACHINE

INTERFACES

ENERGY CONSUMPTION

VISUALIZATION

COMPONENTS

FA COMPONENTS

MACHINE VISION

SYSTEMS

UV CURING

SYSTEMS

Selection

Guide

Laser

Displacement

Magnetic

Displacement

Collimated

Beam

Digital Panel

Controller

Metal-sheet

Double-feed Detection

HL-G1

HL-C2

HL-C1

panasonic.net/id/pidsx/global

and 1040.11 Laser Notice No. 50, dated

June 24, 2007, issued by CDRH (Center for

Devices and Radiological Health) under the

FDA (Food and Drug Administration).

Introducing the new standard in CMOS laser displacement sensors

This single instrument delivers both high-precision measurement and computer-driven data analysis.

High resolution of 0.5 μm 0.02 mil

Thanks to high-precision measurement at a resolution of 0.5 μm 0.02 mil

and an LED digital display that provides exceptional ease of use, the HL-G1

series will see use in a variety of applications on production lines worldwide.

Diffuse reflection type

Specular reflection type

Measurement range: 30 ±4 mm

1.181 ±0.157 in

0.5 μm 0.020 mil

Resolution:

Linearity:

±0.1 % F.S.

0.1 × 0.1 mm

Beam diameter:

0.004 × 0.004 in

Measurement range: 26.3 ±2 mm

1.035 ±0.079 in

0.5 μm 0.020 mil

Resolution:

Linearity:

±0.2 % F.S.

0.1 × 0.1 mm

Beam diameter:

0.004 × 0.004 in

HL-G103□

HL-G103A□

Diffuse reflection type

Specular reflection type

Measurement range: 50 ±10mm

1.969 ±0.394 in

1.5 μm 0.059 mil

Resolution:

Linearity:

±0.1 % F.S.

0.5 × 1.0 mm

Beam diameter:

0.020 × 0.039 in

Measurement range: 47.3 ±5 mm

1.862 ±0.197 in

1.5 μm 0.059 mil

Resolution:

Linearity:

±0.2 % F.S.

0.1 × 0.1 mm

Beam diameter:

0.004 × 0.004 in

HL-G105□

HL-G105A□

Diffuse reflection type

Specular reflection type

Measurement range: 85 ±20 mm

3.346 ±0.787 in

2.5 μm 0.098 mil

Resolution:

Linearity:

±0.1 % F.S.

0.75 ×1.25 mm

Beam diameter:

0.030×0.049 in

Measurement range: 82.9 ±10 mm

3.264 ±0.394 in

2.5 μm 0.098 mil

Resolution:

Linearity:

±0.2 % F.S.

0.2 × 0.2 mm

Beam diameter:

0.008 × 0.008 in

HL-G108□

Diffuse reflection type

HL-G112□

Measurement range: 120 ±60 mm

4.724 ±2.362 in

8 μm 0.315 mil

Resolution:

Linearity:

±0.1 % F.S.

1.0 × 1.5 mm

Beam diameter:

0.039 × 0.059 in

Diffuse reflection type

HL-G125□

Measurement range: �250 ±150 mm

9.843 ±5.906 in

20 μm 0.787 mil

Resolution:

Linearity:

±0.3 % F.S.

1.75 × 3.5 mm

Beam diameter:

0.069 × 0.138 in

HL-G108A□

�Compact Laser Displacement Sensor

HL-G1 SERIES

APPLICATIONS

Controlling the height of a

dispenser nozzle

1058

FIBER

SENSORS

Positioning of wafer

Measuring the eccentricity of

a metal shaft

LASER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

LIGHT CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

Detection of circuit board warpage

Measurement of sheet thickness

Testing sheet slack

PARTICULAR

USE SENSORS

SENSOR

OPTIONS

HL-G1

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

Circuit board

STATIC ELECTRICITY

PREVENTION

DEVICES

LASER

MARKERS

BASIC PERFORMANCE

PLC

Easy input settings while looking at digital display

HUMAN MACHINE

INTERFACES

The built-in digital display makes it easy to perform

sensor setting while checking displacement values.

5-digit, 7-segment LED display

UP key

ENERGY CONSUMPTION

VISUALIZATION

COMPONENTS

FA COMPONENTS

MACHINE VISION

SYSTEMS

ENTER key

UV CURING

SYSTEMS

DOWN key

Selection

Guide

Laser

Displacement

Magnetic

Displacement

Collimated

Beam

Digital Panel

Controller

Metal-sheet

Double-feed Detection

HL-G1

Lightweight body that can be installed on movable parts

Its lightweight resin body weighs 70 g approx., which can

be installed on moving parts such as sliders and robot

arms. Cable with superior flexibility is fitted as standard.

HL-C2

HL-C1

�1059

FIBER

SENSORS

LASER

SENSORS

Compact Laser Displacement Sensor

Compact

Easy to embed in machines and production lines

Compact size despite the built-in controller and digital

read out.

Controller installation and mounting space is not required

because controller function is included in sensor unit.

PHOTOELECTRIC

SENSORS

AREA

SENSORS

LIGHT CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE SENSORS

:

pth

De

m

m

57

44

2.2

in

Height: 60 mm 2.362 in

MICRO

PHOTOELECTRIC

SENSORS

HL-G1 SERIES

Width: 20.4 mm 0.803 in

Amplifier separated type sensor

Flexible cable

HL-G1

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

IP67 protective enclosure protects from water and dust

WIRE-SAVING

SYSTEMS

Thanks to its IP67 protective enclosure, the HL-G1 can

be used in the presence of water and dust.

Mounting holes are lined with metal sleeves, allowing the

instrument to be tightened securely in place with up to

0.8 N·m of torque.

MEASUREMENT

SENSORS

STATIC ELECTRICITY

PREVENTION

DEVICES

LASER

MARKERS

PLC

HUMAN MACHINE

INTERFACES

ENERGY CONSUMPTION

VISUALIZATION

COMPONENTS

FA COMPONENTS

FUNCTIONS

MACHINE VISION

SYSTEMS

Timing input and multi input

Featuring 3 outputs and an analog 2 outputs

UV CURING

SYSTEMS

Inaddition to timing input select the desired input

according to your application:

With three outputs, the HL-G1 can be used to generate

HI / GO / LOW judgment output or alarm output. The

analog output can be used in both current and voltage

modes.

• Zero set on/off

• Reset

• Memory switching

Selection

Guide

Laser

Displacement

Magnetic

Displacement

Collimated

Beam

Digital Panel

Controller

Metal-sheet

Double-feed Detection

HL-G1

HL-C2

HL-C1

• Laser control

• Teaching

• Saving

Support for both NPN and PNP polarity GLOBAL SUPPORT

Memory switching function

A single model number accommodates both NPN and

PNP wiring polarity, reducing the number of model

numbers that must be registered for maintenance

purposes.

Up to four groups of sensor settings can be stored for

fast recall. Easy switching among setting groups allows

smooth setup changes.

HIGH FUNCTION TYPE

The integrated communications interface lets the sensor communicate with upstream

devices such as PLCs.

Sensors and other devices can be connected in a 1:1

manner using RS-422, or up to 16 HL-G1 series sensors

can be connected using RS-485, enabling them to return

measured values in response to messages from the PLC.

When using one of our PLCs*, you can use the PLC’s data

write/read instructions (F145 and F146) to easily configure

HL-G1 series settings and acquire measurement output.

*�Supported PLCs from Panasonic Industrial Devices SUNX:

FP0R, FPΣ, FP-X

PLC

High-function type

HL-G1□-S-J

�Compact Laser Displacement Sensor

HL-G1 SERIES

HIGH FUNCTION TYPE

1060

FIBER

SENSORS

Software tool for sensor configuration and evaluation (Free download available)

LASER

SENSORS

In addition to configuring up to 16 sensors at once,

this free tool makes it easy to gather data needed for

analysis, such as received light waveform monitoring

and data buffering. The interface language can be

selected at the time of installation.

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

●D

� ata buffering

Stores and displays measurement data, which can be

superimposed on previously recorded data for easy

comparison and analysis.

●R

� eceived light waveform display

Displays the amount of light received by cell from lightreceiving element.

●M

� easured value display

Displays measured values as well as the output state

for each terminal.

LIGHT CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC ELECTRICITY

PREVENTION

DEVICES

LASER

MARKERS

PLC

HUMAN MACHINE

INTERFACES

ENERGY CONSUMPTION

VISUALIZATION

COMPONENTS

HMI screen (Free download available)�

FA COMPONENTS

The GT02 / GT12 series HMI can be used in

combination with the HL-G1 to allow easy confirmation

of sensor status and configuration of sensor settings

from a remote location. Japanese, English, Chinese, and

Korean are supported. For more information about the

GT series, visit our website

or refer to our catalog.

Select from the following HMI

MACHINE VISION

SYSTEMS

operator panels:

Power supply: 24 V

Communication port: �RS422

(RS485)

● AIG02GQ14D

● AIG02MQ15D

● AIG12GQ14D / AIG12GQ15D

● AIG12MQ14D / AIG12MQ15D

Meas

mm

–7.8257

LSR

OUT1

OUT2

AL

OUT3

Hold

Timing

Zero set

Reset

UV CURING

SYSTEMS

Top

Meas

LSR

AL

–7. 8257

OUT1

OUT2

OUT3

mm

Hold

Timing

Zero set

Reset

Refer to the programable display GT series pages.

Top

Selection

Guide

Laser

Displacement

Magnetic

Displacement

Collimated

Beam

Digital Panel

Controller

Metal-sheet

Double-feed Detection

HL-G1

Multilingualization

GLOBAL SUPPORT

Software tool and HMI screen data support not only

Japanese and English, but also Chinese and Korean,

providing a new level of support for devices and

equipment in use worldwide.

Terms of use

Panasonic Industrial Devices SUNX offers no warranty for this software and is not liable for any loss or damage suffered as a result of

its use or operation, whether direct, indirect, incidental, consequential, or unforeseen.

HL-C2

HL-C1

�1061

When using the high function type sensor, please order the extension cable separately.

PHOTOELECTRIC

SENSORS

Type

MICRO

PHOTOELECTRIC

SENSORS

LIGHT

CURTAINS /

SAFETY

COMPONENTS

High function

type

PRESSURE /

FLOW

SENSORS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

Diffuse reflection type

SIMPLE

WIRE-SAVING

UNITS

STATIC

ELECTRICITY

PREVENTION

DEVICES

High function

type

Metal-sheet

Double-feed

Detection

Specular reflection type

HL-G103-A-C5

0.5 × 1 mm

0.020 × 0.039 in

HL-G105-A-C5

2.5 μm

0.098 mil

0.75 × 1.25 mm

0.030 × 0.059 in

HL-G108-A-C5

FDA / IEC: Class 2

HL-G108-S-J

Standard type

120 ±60 mm

4.724 ±2.362 in

8 μm

0.315 mil

1.0 × 1.5 mm

0.039 × 0.059 in

HL-G112-A-C5

HL-G112-S-J

High function type

250 ±150 mm

9.843 ±5.906 in

20 μm

0.787 mil

1.75 × 3.5 mm

0.069 × 0.138 in

HL-G125-A-C5

HL-G125-S-J

26.3 ±2 mm

1.035 ±0.079 in

High function

type

HL-G103A-RA-C5

0.5 μm

0.020 mil

0.1 × 0.1 mm

0.004 × 0.004 in

Standard type

47.3 ±5 mm

1.862 ±0.197 in

High function

type

HL-G103A-RS-J

HL-G105A-RA-C5

1.5 μm

0.059 mil

FDA / IEC: Class 1

HL-G105A-RS-J

Standard type

82.9 ±10 mm

3.264 ±0.394 in

Selection

Guide

Digital Panel

Controller

1.5 μm

0.059 mil

Standard type

FA

COMPONENTS

Laser

class

Model No.

HL-G105-S-J

85 ±20 mm

3.346 ±0.787 in

High function

type

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

Collimated

Beam

0.1 × 0.1 mm

0.004 × 0.004 in

Standard type

High function

type

HUMAN

MACHINE

INTERFACES

Magnetic

Displacement

0.5 μm

0.020 mil

50 ±10 mm

1.969 ±0.394 in

High function

type

Standard type

Laser

Displacement

30 ±4 mm

1.181 ±0.157 in

Beam

diameter

HL-G103-S-J

PLC

UV

CURING

SYSTEMS

Resolution

Standard type

LASER

MARKERS

MACHINE

VISION

SYSTEMS

Measurement

center distance and

measuring range

Standard type

INDUCTIVE

PROXIMITY

SENSORS

SENSOR

OPTIONS

Appearance

Standard type

AREA

SENSORS

PARTICULAR

USE

SENSORS

HL-G1 SERIES

ORDER GUIDE

FIBER

SENSORS

LASER

SENSORS

Compact Laser Displacement Sensor

High function

type

2.5 μm

0.098 mil

0.2 × 0.2 mm

0.008 × 0.008 in

HL-G108A-RA-C5

HL-G108A-RS-J

OPTIONS

When using the high function type sensor, please order the extension cable separately.

HL-G1

HL-C2

Type

Appearance

Model No.

Description

HL-C1

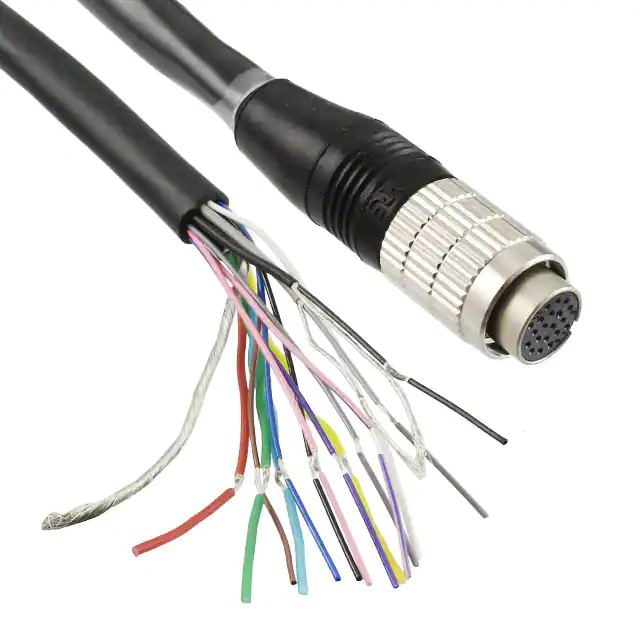

Extension cable

(for High

function type)

HL-G1CCJ2

Length: 2 m 6.562 ft, Weight: 130 g approx.

HL-G1CCJ5

Length: 5 m 16.404 ft, Weight: 320 g approx.

HL-G1CCJ10

Length: 10 m 32.808 ft, Weight: 630 g approx.

HL-G1CCJ20

Length: 20 m 65.617 ft, Weight: 1,300 g approx.

14-core cabtyre cable

with connector on

both ends

�Compact Laser Displacement Sensor

HL-G1 SERIES

1062

OPERATING ENVIRONMENT OF SOFTWARE TOOL

FIBER

SENSORS

LASER

SENSORS

Operating environment

PC environment

PC / AT compatible

OS

Windows® XP

OS

Windows® Vista

Windows® 7

CPU

32 bits / 64 bits

32 bits

Edition

Service Pack

Professional

SP2 or later

Business

32 bits / 64 bits

Professional

—

Intel Pentium 4 2 GHz or more, either equaling or surpassing

®

Graphics

Memory

XGA (1,024 × 768 256 colors) or more

1 GB or more

Hard disk

USB interface

Free space 100 MB or more

USB 2.0 full speed (USB 1.1 compatible)

Notes: 1) �This software accommodates below language. You can select the language when installing.

Japanese, English, Korean, Chinese

2) �Windows® 7 Professional, Vista Business, and XP Professional are trademarks or registered trademarks of Microsoft Corporation in the United States

and other countries.

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

INFORMATION OF INTERFACE CONVERTER

The communications interface converter of HL-G1 series is RS-422 or RS-485. Use the HMI operator panel GT02 or GT12 (through mode) or

the following interface converter when using the tool software HL-G1SMI and connecting to PC by USB.

LINEEYE CO., LTD.

Interface converter (USB to RS-422/485) SI-35USB

Website: http://www.lineeye.com

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

ELECTRICITY

PREVENTION

DEVICES

LASER

MARKERS

PLC

HUMAN

MACHINE

INTERFACES

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Selection

Guide

Laser

Displacement

Magnetic

Displacement

Collimated

Beam

Digital Panel

Controller

Metal-sheet

Double-feed

Detection

HL-G1

HL-C2

HL-C1

�1063

Compact Laser Displacement Sensor

SPECIFICATIONS

FIBER

SENSORS

LASER

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

Type

Item

Model No.

PHOTOELECTRIC

SENSORS

Measurement center

distance

30 mm

1.181 in

50 mm

1.969 in

85 mm

3.346 in

120 mm

4.724 in

250 mm

9.843 in

26.3 mm

1.035 in

47.3 mm

1.862 in

82.9 mm

3.264 in

Measuring range

±4 mm

±0.157 in

±10 mm

±0.394 in

±20 mm

±0.787 in

±60 mm

±2.362 in

±150 mm

±5.906 in

±2 mm

±0.079 in

±5 mm

±0.197 in

±10 mm

±0.394 in

Resolution

0.5 μm

0.020 mil

1.5 μm

0.059 mil

2.5 μm

0.098 mil

8 μm

0.315 mil

20 μm

0.787 mil

0.5 μm

0.020 mil

1.5 μm

0.059 mil

2.5 μm

0.098 mil

Linearity

±0.1 % F.S.

Temperature characteristics

Light source

SENSOR

OPTIONS

Receiving element

MEASUREMENT

SENSORS

STATIC

ELECTRICITY

PREVENTION

DEVICES

LASER

MARKERS

Supply voltage

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

Sampling rate

Analog

output

Digital Panel

Controller

Metal-sheet

Double-feed

Detection

Output polarity setting input

Timing input

Multi input

Communications interface

(high-function type only)

Laser emission

Alarm

Output

Protection

Ambient temperature

Ambient humidity

Ambient illuminance

Ambient altitude

Pollution degree

Insulation resistance

CMOS image sensor

100 mA max.

200 μs, 500 μs, 1 ms, 2 ms

• Maximum sink current : 50 mA

• Applied voltage : 3 to 24 V DC (between output and 0 V)

• Residual voltage : 2 V or less (at 50 mA of sink current)

• Maximum source current : 50 mA

• Residual voltage : 2.8 V or less (at 50 mA of source current)

Open when the output is ON.

Incorporated (automatic restoration)

NPN open collector output operates when 0 V is connected. PNP open collector output operates when 24 V DC is connected.

NPN output operates when 0 V is connected and NPN is set (depending on settings).

PNP output operates when external power + is connected and PNP is set (depending on settings).

Zero set, zero set off, reset, memory switching, teaching, saving, and laser control according to the input time.

In case NPN output is selected, function varies according to the time 0 V is connected NPN.

In case PNP output is selected, function varies according to the time external power + is connected.

RS-422 or RS-485 (selectable)

Baud rate: 9,600 / 19,200 / 38,400 / 115,200 / 230,400 / 460,800 / 921,600 bps

Data length 8 bits, stop bit length 1 bit, without parity check, BCC check, termination code: CR

Green LED (lights up during laser emission)

Orange LED (lights up when this product cannot measure because of insufficient or excessive light intensity)

Yellow LED × 3

Red LED 5.5 digit display

IP67 (IEC)

–10 to +45 °C +14 to +113 °F (No dew condensation), Storage: –20 to +60 °C –4 to +140 °F (No dew condensation)

35 to 85 % RH, Storage: 35 to 85 % RH

Incandescent light: 3,000 ℓ x or less at the light-receiving face (Note 3)

2,000 m 6,561 ft or less

2

20 MΩ, or more, with 250 V DC megger between all supply teminals connected together and enclosure

Voltage withstandability

1,000 V AC one min. between all supply terminals connected together and enclosure

Vibration resistance

10 to 55 Hz (period: 1 min.) frequency, 1.5 mm 0.059 in amplitude in X,Y and Z directions for two hours each

Shock resistance

Material

500 m/s2 acceleration (50 G approx.) in X,Y and Z directions for three times each

Enclosure: PBT, front cover: acrylic, cable: PVC

Standard type: 0.1 mm2 10-core cabtyre cable, 5 m 16.404 ft long, high function type: 14-core cabtyre cable with connector, 0.5 m 1.640 ft long

Cable

Cable extension

Weight

HL-C1

0.2 × 0.2 mm

0.008 × 0.008 in

24 V DC ±10 % including ripple 0.5 V (P-P)

Output range: 0 to 10.5 V (normal) / 11 V (at alarm), Output impedance: 100 Ω

Short circuit protection

HL-G1

HL-C2

0.1 × 0.1 mm

0.004 × 0.004 in

Output range: 3.2 to 20.8 mA (normal) / 21.6 mA (at alarm), Load impedance: 300 Ω max.

Output operation

Environmental resistance

Collimated

Beam

0.1 × 0.1 mm

0.5 ×1.0 mm

0.75 × 1.25 mm 1.0 × 1.5 mm

1.75 × 3.5 mm

0.004 × 0.004 in 0.020 × 0.039 in 0.030 × 0.049 in 0.039 × 0.059 in 0.069 × 0.138 in

Current

Output

(OUT 1, OUT 2, OUT 3)

Selection

Guide

Magnetic

Displacement

±0.08 % F.S./°C

Red semiconductor laser, Class 2 (Class 1 for specular reflection type) (IEC / JIS / FDA, Laser Notice No. 50)

Max. output: 1 mW (0.39mW for specular reflection type) Peak emission wavelength: 655 nm 0.026 mil

Voltage

Digital display

Laser

Displacement

±0.2 % F.S.

Judgment output or alarm output (setting selectable)

NPN transistor, open-collector / PNP transistor, open-collector (selectable)

Indicator

UV

CURING

SYSTEMS

±0.3 % F.S.

Current consumption

PLC

HUMAN

MACHINE

INTERFACES

Specular reflection type

Standard type HL-G103-A-C5 HL-G105-A-C5 HL-G108-A-C5 HL-G112-A-C5 HL-G125-A-C5 HL-G103A-RA-C5 HL-G105A-RA-C5 HL-G108A-RA-C5

Beam diameter (Note 2)

WIRE-SAVING

SYSTEMS

Diffuse reflection type

High function type HL-G103-S-J HL-G105-S-J HL-G108-S-J HL-G112-S-J HL-G125-S-J HL-G103A-RS-J HL-G105A-RS-J HL-G108A-RS-J

PARTICULAR

USE

SENSORS

SIMPLE

WIRE-SAVING

UNITS

HL-G1 SERIES

Extension up to total 20 m 65.617 ft is possible with optional cable (Cable for standard type cannot be extended).

Standard type

Net weight: 70 g approx. (not including cable), 320 g approx. (including cable), gross weight: 380 g approx.

High function type

Net weight: 70 g approx. (not including cable), 110 g approx. (including cable), gross weight: 160 g approx.

Accessory

Warning label: 1 set

Notes: 1) Where measurement conditions have not been specified precisely, the conditions used were as follows: supply voltage 24 V DC, ambient temperature

+20 °C +68 °F, sampling rate 500 μs, average number of samples: 1024, measurement center distance, object measured is made of white ceramic

(specular reflection type: an aluminum vapor deposition surface reflection mirror) and analog measurement values.

2) This beam diameter is the size at the measurement center distance. These values were defined by using 1/e2 (13.5 %) of the center light intensity.

The results may be affected if there is a slight leakage of light outside the normal spot diameter and if the periphery surrounding the sensing point has

a higher reflectivity than the sensing point itself.

3) The fluctuation by ambient illuminance is ±0.1 % F.S. or less.

�Compact Laser Displacement Sensor

HL-G1 SERIES

1064

I/O CIRCUIT AND WIRING DIAGRAMS

FIBER

SENSORS

LASER

SENSORS

I/O circuit diagrams

When selecting NPN output

Color code

MICRO

PHOTOELECTRIC

SENSORS

Color code

(Brown) + V

(Black)

Output 1: OUT 1

Load

50 mA max.

(Brown) + V

(Black)

Output 1: OUT 1

(White)

Output 2: OUT 2 Load

50 mA max.

(Gray)

Output 3: OUT 3

Load

50 mA max.

50 mA max.

(White)

Output 2: OUT 2

External

power

3 to 24 V DC

50 mA max.

(Gray)

Output 3: OUT 3

50 mA max.

Main unit power

24 V DC ±10 %

Including ripple

0.5 V (P-P)

(Pink/Purple) Output polarity setting input: NP

3.3 V

AREA

SENSORS

LIGHT

CURTAINS /

SAFETY

COMPONENTS

Load

PRESSURE /

FLOW

SENSORS

Load

INDUCTIVE

PROXIMITY

SENSORS

Load

(Pink/Purple)

Output polarity setting input: NP

Main circuit

Main circuit

PHOTOELECTRIC

SENSORS

When selecting PNP output

*1

External power

3 to 30 V DC

(Pink)

Timing input: TM

(Pink) Timing input: TM

Main unit power

24 V DC ±10 %

Including ripple

0.5 V (P-P)

(Purple) Multi input: MI

*1

(Blue) 0 V

Sensor head

internal circuit

Sensor head

internal circuit

*1

External connection example

MEASUREMENT

SENSORS

STATIC

ELECTRICITY

PREVENTION

DEVICES

PLC

HUMAN

MACHINE

INTERFACES

*1

Non-voltage contact

SIMPLE

WIRE-SAVING

UNITS

LASER

MARKERS

(Blue) 0 V

External connection example

SENSOR

OPTIONS

WIRE-SAVING

SYSTEMS

3.3 V

(Purple) Multi input: MI

PARTICULAR

USE

SENSORS

Non-voltage contact or PNP open-collector transistor output

IN

IN

0V

0V

or

IN

0V

High [+5 V to +30 V DC (source current 0.04 mA or less)] : Effective

Low (0 to 0.6 V DC or open) : Ineffective

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Analog output (common in NPN output type and PNP output type)

Color code

0 to 11 V

Main circuit

100 Ω

AGND

+V

22 Ω

AGND

Sensor head

internal circuit

Analog

input

(Black)

Analog voltage output device

: A (V)

(Shield)

Analog ground

: AGND

(Gray)

3.2 to 22 mA Analog current output

: A (I)

(Shield)

Analog ground

: AGND

External connection example

Notes: 1) �Analog output is not equipped with the short-circuit protection.

Do not short-circuit or apply voltage to them.

2) �Use shielded wires for analog outputs.

Selection

Guide

Laser

Displacement

Magnetic

Displacement

Collimated

Beam

Digital Panel

Controller

Metal-sheet

Double-feed

Detection

HL-G1

HL-C2

HL-C1

�1065

FIBER

SENSORS

LASER

SENSORS

Compact Laser Displacement Sensor

I/O CIRCUIT AND WIRING DIAGRAMS

Communication specifications (High function type)

PHOTOELECTRIC

SENSORS

Communication method

MICRO

PHOTOELECTRIC

SENSORS

Synchronization method

AREA

SENSORS

LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

HL-G1 SERIES

RS-422

RS-485

Full duplex

Half duplex

Asynchronous communication method

Transmission code

ASC ll

Baud rate

9,600/19,200/38,400/115,200/230,400/460,800/921,600 bps

Data length

8 bit

Stop bit length

1 bit

Parity check

None

BCC

Yes

Termination code

CR

The HL-G1 can be connected to upper devices of RS-422/485.

When upper device sends the request command, the HL-G1 series send the response command.

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

PLC etc.

Request

command

MEASUREMENT

SENSORS

STATIC

ELECTRICITY

PREVENTION

DEVICES

LASER

MARKERS

HL-G1 series

Upper device

Response

command

RS-422 1-to-1 connection

RS-485 1-to-N connection

PLC

HUMAN

MACHINE

INTERFACES

RS-422 host device

HL-G1

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Selection

Guide

Laser

Displacement

Magnetic

Displacement

Collimated

Beam

+SD -SD +RD -RD SG

• Connectable up to 16 units.

• Please set the prefix with no duplication.

HL-G1

Area:01

(Green) Transmission data:+SD

(Sky Blue) Transmission data:-SD

Terminator

ON

(Orange) Reception data:+RD

Terminator

OFF

(Yellow) Reception data:-RD

(Shield) Signal ground:SG (Note 2)

Notes: �1) �The transmission data cable and reception data cable are both

twisted-pair cables.

2) �The shield is connected to the 0-V side of the power supply line

inside the sensor.

3) �Be sure to connect the signal ground.

4) �The sensor is of non-isolated type. Make sure that the potential

difference between the sensor and RS-422 connecting device

does not exceed 4V. A difference in potential in excess may

cause the connecting device or the sensor to malfunction.

Terminator

OFF

HL-C1

(Green)

Transmission data:+SD

(Sky Blue)

Transmission data:-SD

(Orange)

Reception data:+RD

(Yellow)

Reception data:-RD

(Shield)

Signal ground:SG(Note 2)

HL-G1

Area:16

Metal-sheet

Double-feed

Detection

HL-C2

+SD -SD +RD -RD SG

(Green)

Transmission data:+SD

(Sky Blue)

Transmission data:-SD

(Orange)

(Note 7)

Reception data:+RD

(Yellow)

Reception data:-RD

(Shield)

Signal ground:SG(Note 2)

HL-G1

Area:02

Digital Panel

Controller

HL-G1

RS-485 host device

Terminator

ON(Note 5)

(Green)

Transmission data:+SD

(Sky Blue)

Transmission data:-SD

(Orange)

Reception data:+RD

(Yellow)

Reception data:-RD

(Shield)

Signal ground:SG(Note 2)

Notes: 1) �The transmission data cable and reception data cable are both

twisted-pair cables.

2) �The shield is connected to the 0-V side of the power supply line

inside the sensor.

3) �Be sure to connect the signal ground.

4) �The sensor is of non-isolated type. Make sure that the potential

difference between the sensor and RS-485 connecting device does

not exceed 4V. A difference in potential in excess may cause the

connecting device or the sensor to malfunction.

5) �The sensor has a built-in terminating resistor. Be sure to turn ON

the terminating resistor of the terminating sensor.

6) Perform transition wiring for the transmission path.

7) Connect the wires according to the specification of the equipment.

�Compact Laser Displacement Sensor

1066

HL-G1 SERIES

SENSING CHARACTERISTICS (TYPICAL)

FIBER

SENSORS

LASER

SENSORS

Correlation between measuring distance and error characteristics

Diffuse reflection type

− +

−

HL-G103□

Diffuse reflection type

Horizontal positioning

0

–0.2

0.2

–0.2

–2.0

0

2.0

–0.079 (Center) 0.079

Measuring distance L (mm in)

–0.4

–4.0

–0.157

4.0

0.157

0.4

0.2

–10.0

0

10.0

–0.394 (Center) 0.394

Measuring distance L (mm in)

–0.4

–20.0

–0.787

20.0

0.787

0

0.2

−75

0

−2.953 (Center)

75

2.953

150

5.906

Measuring distance L (mm in)

0.1°

0°

−0.1°

0.4

Sampling rate: 500 μs

Average number of

samples: 1024

0

−0.2

−0.4

−5.0

−0.197

10°

0°

−10°

0.2

2.5

0.098

Measuring distance L (mm in)

5.0

0.197

−0.4

−5.0

−0.197

10.0

0.394

0.2

75

2.953

150

5.906

0.4

0.2

0.5°

0°

−0.5°

Sampling rate: 500 μs

Average number of

samples: 1024

5.0

0.197

10°

0°

–10°

–0.4

–60.0

–2.362

0.1°

0°

−0.1°

0.4

0.2

1.0

0.039

2.0

0.079

HUMAN

MACHINE

INTERFACES

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

–30.0

0

30.0

–1.181 (Center) 1.181

Measuring distance L (mm in)

60.0

2.362

0.1°

0°

−0.1°

Sampling rate: 500 μs

Average number of

samples: 1024

UV

CURING

SYSTEMS

Magnetic

Displacement

Collimated

Beam

Digital Panel

Controller

Metal-sheet

Double-feed

Detection

−1.0

0

−0.039 (Center)

1.0

0.039

2.0

0.079

Measuring distance L (mm in)

HL-G1

Specular reflection type

Horizontal positioning

−0.2

0.4

0.2

0.05°

0°

−0.05°

Sampling rate: 500 μs

Average number of

samples: 1024

0

−0.2

5.0

0.197

Measuring distance L (mm in)

10.0

0.394

Selection

Guide

Laser

Displacement

0

−0.4

−2.0

−0.079

Sampling rate: 500 μs

Average number of

samples: 1024

−5.0

0

−0.197 (Center)

LASER

MARKERS

PLC

Sampling rate: 500 μs

Average number of

samples: 1024

−0.2

−1.0

0

−0.039 (Center)

STATIC

ELECTRICITY

PREVENTION

DEVICES

Horizontal positioning

0

−0.4

−10.0

−0.394

10.0

0.394

0

HL-G108A-R□

0.2

Measuring distance L (mm in)

0.2

Sampling rate: 500 μs

Average number of

samples: 1024

Vertical positioning

2.5

0.098

0.4

Measuring distance L (mm in)

0.4

–5.0

0

5.0

–0.197 (Center) 0.197

Measuring distance L (mm in)

MEASUREMENT

SENSORS

Specular reflection type

0

−0.4

−2.0

−0.079

0.05°

0°

−0.05°

−2.5

0

−0.098 (Center)

–0.4

–10.0

–0.394

HL-G103A-R□

−0.2

−75

0

−2.953 (Center)

WIRE-SAVING

SYSTEMS

–0.2

60.0

2.362

SENSOR

OPTIONS

–0.2

Horizontal positioning

–30.0

0

30.0

–1.181 (Center) 1.181

Measuring distance L (mm in)

PARTICULAR

USE

SENSORS

SIMPLE

WIRE-SAVING

UNITS

10° Sampling rate: 500 μs

0° Average number of

–10° samples: 1024

0

–0.4

–60.0

–2.362

Sampling rate: 500 μs

Average number of

samples: 1024

Diffuse reflection type

Vertical positioning

0

−0.2

−2.5

0

−0.098 (Center)

0.4

Sampling rate: 500 μs

Average number of

samples: 1024

Horizontal positioning

Error (% F.S.)

Error (% F.S.)

0.2

20.0

0.787

Specular reflection type

Vertical positioning

–5.0

0

5.0

–0.197 (Center) 0.197

Measuring distance L (mm in)

10°

0°

–10°

INDUCTIVE

PROXIMITY

SENSORS

0

HL-G112□

Measuring distance L (mm in)

HL-G105A-R□

0.4

–10.0

0

10.0

–0.394 (Center) 0.394

Measuring distance L (mm in)

0

−0.4

−150

−5.906

0.2

–0.2

−0.2

−0.2

−0.4

−150

−5.906

0.4

0.4

Vertical positioning

Horizontal positioning

Sampling rate: 500 μs

Average number of

samples: 1024

Error (% F.S.)

Error (% F.S.)

10°

0°

−10°

–0.4

–10.0

–0.394

Sampling rate: 500 μs

Average number of

samples: 1024

Diffuse reflection type

Vertical positioning

0.2

10°

0°

–10°

0

HL-G125□

0.4

4.0

0.157

–0.2

–0.2

Horizontal positioning

Sampling rate: 500 μs

Average number of

samples: 1024

0

Error (% F.S.)

0

–0.4

–20.0

–0.787

–2.0

0

2.0

–0.079 (Center) 0.079

Measuring distance L (mm in)

Horizontal positioning

Sampling rate: 500 μs

Average number of

samples: 1024

Error (% F.S.)

Error (% F.S.)

0.2

10°

0°

–10°

0.2

10°

0°

–10°

PRESSURE /

FLOW

SENSORS

Diffuse reflection type

–0.2

Diffuse reflection type

Vertical positioning

0.4

LIGHT

CURTAINS /

SAFETY

COMPONENTS

Measuring

L

object

Measuring object

Vertical positioning

Sampling rate: 500 μs

Average number of

samples: 1024

0

HL-G108□

0.4

10°

0°

–10°

Error (% F.S.)

–0.4

–4.0

–0.157

0.4

Sampling rate: 500 μs

Average number of

samples: 1024

AREA

SENSORS

L

HL-G105□

Error (% F.S.)

Error (% F.S.)

0.2

10°

0°

–10°

Error (% F.S.)

0.4

Measuring

object

L

MICRO

PHOTOELECTRIC

SENSORS

Sensor head

Sensor head

L

L

Measuring

Measuring

object object

Vertical positioning

+

Error (% F.S.)

L

L

Measuring

Measuring

object object

−

Sensor Sensor

head head

Sensor Sensor

head head

Error (% F.S.)

+

Aluminum vapor deposition

surface reflection mirror

Horizontal orientation

Sensor head

+ −+ –

Error (% F.S.)

+

Alminum vapor deposition

surface reflection mirror

Vertical orientation

Error (% F.S.)

+ −

White ceramic

Horizontal orientation

Error (% F.S.)

White ceramic

Vertical orientation

−

PHOTOELECTRIC

SENSORS

Specular reflection type

−0.4

−10.0

−0.394

−5.0

0

−0.197 (Center)

5.0

0.197

Measuring distance L (mm in)

10.0

0.394

HL-C2

HL-C1

�1067

Compact Laser Displacement Sensor

HL-G1 SERIES

PRECAUTIONS FOR PROPER USE

FIBER

SENSORS

LASER

SENSORS

Refer to p.1501 for general precautions and p.1499~ for information about laser beam.

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

LIGHT

CURTAINS /

SAFETY

COMPONENTS

• Do not operate products using methods other than the ones

described in the instruction manual included with each product.

Control or adjustment through procedures other than the ones

specified may cause hazardous laser radiation exposure.

• The following label is attached to the product. Handle the

product according to the instruction given on the warning label.

The Japanes, English, Chinese, Korean warning label is

packed with the sensor.

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

(�

SENSOR

OPTIONS

)

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

• This product is classified as a Class 2 (specular

reflection type: Class 1) Laser Product in IEC /

JIS standards and FDA* regulations. Do not

look at the laser beam directly or through

optical system such as a lens.

• Never use this product as a sensing device for

personnel protection.

• In case of using sensing devices for personnel protection,

use products which meet laws and standards, such

as OSHA, ANSI or IEC etc., for personnel protection

applicable in each region or country.

• This product has been developed / produced for

industrial use.

PHOTOELECTRIC

SENSORS

*�This product complies with 21 CFR 1040.10 and 1040.11 Laser Notice

No. 50, dated June 24, 2007, issued by CDRH (Center for Devices and

Radiological Health) under the FDA (Food and Drug Administration).

Beam diameter (Unit: mm in)

Diffuse reflection type

PLC

HUMAN

MACHINE

INTERFACES

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

Model No.

Measuring range

LASER

MARKERS

Measurement center distance

STATIC

ELECTRICITY

PREVENTION

DEVICES

b

a

d

c

UV

CURING

SYSTEMS

f

e

Selection

Guide

HL-G103-S-J

HL-G103-A-C5

HL-G105-S-J

HL-G105-A-C5

HL-G108-S-J

HL-G108-A-C5

HL-G112-S-J

HL-G112-A-C5

HL-G125-S-J

HL-G125-A-C5

a

0.15

0.006

b

0.15

0.006

Beam diameter

c

d

0.1

0.1

0.004

0.004

e

0.15

0.006

f

0.15

0.006

1.2

0.047

0.6

0.024

1.0

0.039

0.5

0.020

0.9

0.035

0.4

0.016

1.5

0.059

0.9

0.030

1.25

0.049

0.75

0.030

1.0

0.039

0.6

0.024

1.8

0.071

1.2

0.047

1.5

0.059

1.0

0.039

0.8

0.031

0.5

0.020

2.5

0.098

1.5

0.059

3.5

0.138

1.75

0.069

4.5

0.177

2.0

0.079

a

0.15

0.006

b

0.15

0.006

Beam diameter

c

d

0.1

0.1

0.004

0.004

e

0.15

0.006

f

0.15

0.006

0.15

0.006

0.15

0.006

0.1

0.004

0.1

0.004

0.15

0.006

0.15

0.006

0.2

0.008

0.2

0.008

0.2

0.008

0.2

0.008

0.2

0.008

0.2

0.008

Specular reflection type

Laser

Displacement

HL-G1

HL-C2

HL-C1

b

a

c

e

d

f

Model No.

HL-G103-RS-J

HL-G103-RA-C5

HL-G105-RS-J

HL-G105-RA-C5 b

a

HL-G108-RS-J

HL-G108-RA-C5

Measuring range

Metal-sheet

Double-feed

Detection

Measuring range

Digital Panel

Controller

Measurement center distance

Collimated

Beam

Measurement center distance

Magnetic

Displacement

c

e

d

f

�Compact Laser Displacement Sensor

PRECAUTIONS FOR PROPER USE

HL-G1 SERIES

1068

Refer to p.1501 for general precautions and p.1499~ for information about laser beam.

FIBER

SENSORS

LASER

SENSORS

Sensor head mounting direction

• To obtain the greatest precision, the sensor head should be oriented facing the direction of movement of the object’s

surface, as shown in the figure below.

Rotating object

Object with variations in material

or color

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

Object that has large differences in gaps, grooves and colors

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

ELECTRICITY

PREVENTION

DEVICES

LASER

MARKERS

PLC

DIMENSIONS (Unit: mm in)

The CAD data in the dimensions can be downloaded from our website.

HL-G1□-A-C5 HL-G1□-S-J

Model No.

HL-G103-A-C5

HL-G103-S-J

HL-G105-A-C5

HL-G105-S-J

HL-G108-A-C5

HL-G108-S-J

HL-G112-A-C5

HL-G112-S-J

HL-G125-A-C5

HL-G125-S-J

Sensor head

Measurement center

distance (ℓ)

θ

30 mm 1.181 in

30°

50 mm 1.969 in

21°

85 mm 3.346 in

15°

120 mm 4.724 in

11°

250 mm 9.843 in

6.2°

5.5 digit LED display (Red)

Alarm indicator (Orange)

Laser emission indicator (Green)

OUT 1 indicator (Yellow)

OUT 2 indicator (Yellow)

OUT 3 indicator (Yellow)

ENTER key

20.4

0.803

47.5

1.870

Measurement

center distance

Beamemitting axis

Beam-receiving axis

3.8

0.150

6.2°

HUMAN

MACHINE

INTERFACES

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

UP key

DOWN key

57 2.244

49.4 1.945

2-ø4.5 ø0.177

Selection

Guide

51.4

2.024

60

2.362

Laser

Displacement

Magnetic

Displacement

5

0.

Collimated

Beam

m

Digital Panel

Controller

0

64

1.

4.3 ø6.85 ø0.270

0.169

ft

43 93

6

1.

Equipped on HL-G1□-S-J only

ø12.5

ø0.492

Metal-sheet

Double-feed

Detection

HL-G1

HL-C2

HL-C1

�1069

Compact Laser Displacement Sensor

DIMENSIONS (Unit: mm in)

FIBER

SENSORS

LASER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

5.5 digit LED display (Red)

Alarm indicator (Orange)

Laser emission indicator (Green)

Measurement

center distance

26.3

1.035

17.5

0.689

Beamemitting axis

20.4

0.803

PRESSURE /

FLOW

SENSORS

66.6 2.622

34.41

1.355

47.5 1.8

Beamreceiving axis

70

ø6.85

ø0.270

0.5

m

ø12.5

ø0.492

4

1. 3

1.6 693

40

ft

PLC

2-ø 4.5 ø 0.177

66.8

2.630

57.4

2.260

15.05°

66.8

2.630

31.2

1.228

47.5

1.870

UV

CURING

SYSTEMS

ø12.5

ø0.492

OUT 1 indicator (Yellow)

OUT 2 indicator (Yellow)

OUT 3 indicator (Yellow)

62.3 2.453

42.24

1.663

Beam-emitting axis

Beamreceiving axis

ø6.85

ø0.270

0.5

4

m

1.6 1.693

3

40

ft

UP key

DOWN key

Measurement

center distance

82.9 3.264

10.75 0.423

20.4

0.803

ENERGY

CONSUMPTION

VISUALIZATION

COMPONENTS

10.39°

Sensor head

ENTER key

HUMAN

MACHINE

INTERFACES

69

2.717

59.5

2.343

32.8

1.291

Equipped on HL-G105A-RS-J only

HL-G108A-RA-C5 HL-G108A-RS-J

5.5 digit LED display (Red)

Alarm indicator (Orange)

Laser emission indicator (Green)

2-ø 4.5 ø 0.177

69

2.717

Equipped on HL-G103A-RS-J only

LASER

MARKERS

MACHINE

VISION

SYSTEMS

64.2 2.528

39.32

1.548

20.77°

72.3

2.846

33

1.299

15°

WIRE-SAVING

SYSTEMS

FA

COMPONENTS

UP key

DOWN key

47.5

1.870

62.4

2.457

SIMPLE

WIRE-SAVING

UNITS

STATIC

ELECTRICITY

PREVENTION

DEVICES

20.4

0.803

2-ø4.5 ø0.177

Measurement

center distance

47.3

1.862

13.4

0.528

Beam-emitting axis

Sensor head

OUT 1 indicator (Yellow)

OUT 2 indicator (Yellow)

OUT 3 indicator (Yellow)

ENTER key

UP key

DOWN key

72.3

2.846

Beamreceiving axis

HL-G105A-RA-C5 HL-G105A-RS-J

5.5 digit LED display (Red)

Alarm indicator (Orange)

Laser emission indicator (Green)

30°

SENSOR

OPTIONS

MEASUREMENT

SENSORS

Sensor head

OUT 1 indicator (Yellow)

OUT 2 indicator (Yellow)

OUT 3 indicator (Yellow)

ENTER key

LIGHT

CURTAINS /

SAFETY

COMPONENTS

PARTICULAR

USE

SENSORS

The CAD data in the dimensions can be downloaded from our website.

HL-G103A-RA-C5 HL-G103A-RS-J

AREA

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

HL-G1 SERIES

7.53°

ø6.85

ø0.270

0.

5

m

4

1. 1.6 3

64 93

0

ft

ø12.5

ø0.492

Equipped on HL-G108A-RS-J only

Selection

Guide

Laser

Displacement

Magnetic

Displacement

HL-G1CCJ□

Extension cable (Optional)

Collimated

Beam

Digital Panel

Controller

Metal-sheet

Double-feed

Detection

HL-G1

HL-C2

HL-C1

Model No.

L

HL-G1CCJ2

2,000 +2000

78.740 +7.8740

5,000 +5000

196.850 +19.6850

10,000 +1,0000

393.701 +39.3700

20,000 +2,0000

787.402 +78.7400

HL-G1CCJ5

HL-G1CCJ10

HL-G1CCJ20

L

ø6.85 ø0.270 cable

(

)

43

1.693

12.5

( øø0.492

)

14-core × 0.1 mm2

insulator diameter: ø0.7 mm ø0.028 in

(RS-422/485 communication cable:

ø1.0 mm ø0.039 in)

50

(1.969

)

�