545

FIBER

SENSORS

Compact Safety Light Curtain

SF4B-C SERIES

Related Information

LASER

SENSORS

Type 4

■■General terms and conditions.............. F-3

■■SF-C13.......................................... P.663~

■■General precautions...................... P.1595

■■Selection guide.............................. P.457~

■■Glossary of terms........................ P.1549~

■■Korea’s S-mark.............................. P.1602

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

Certified

AREA

SENSORS

Certified by

NRTL

SAFETY LIGHT

CURTAINS /

SAFETY COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

Conforming to

OSHA / ANSI

Certified

PARTICULAR

USE SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

LASER

MARKERS

PLC

HUMAN MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA COMPONENTS

Category 4 PLe SIL3

panasonic.net/id/pidsx/global

The control category differs depending on the configuration and wiring of the external circuit.

Compact, light weight design, and advanced functionality in one package

Compact profile design, maximize the machinery opening area

The SF4B-C series is designed to fit onto an aluminum frame, maximizing the machinery opening area.

It can even allow zero dead zone.

Side mounting

MACHINE VISION

SYSTEMS

UV CURING

SYSTEMS

Width

Just

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

SF2B

SF2C

Definition of

Sensing Heights

19.6

0.772

mm

in

Depth

27.4

1.079

mm

Embedded mounting (side)

■ The safety light curtain

fits onto frame perfectly,

even in embedded

installations.

■ The safety light curtain

protrudes neither into

the machinery opening

nor outside the frame.

■ The safety light curtain will

not be damaged due to

collision with workpiece.

* When using standard mounting

brackets MS-SF4BC-1 (optional)

in

■ The presence of safety light curtain does not

narrow the opening area.

■ The safety light curtain is thin, so its bulge

from frame can be minimized.

*W

� hen using standard mounting brackets MS-SF4BC-1

(optional)

Rear mounting

■ The safety light curtain

fits onto a 20 × 20 mm

0.787 × 0.787 in

aluminum frame

perfectly.

■ The safety light curtain

does not protrude

from the frame.

* When using standard mounting

brackets MS-SF4BC-1 (optional)

�Compact Safety Light Curtain Type 4

SF4B-C SERIES

Plastic × metal

Maximum protective height of 1,943.4 mm 76.512 in

The SF4B-C series features a proprietary double

structure of a “plastic body” with a “metal inner frame”

which lightens the weight while maintaining the durability.

Despite its compact, plastic body, the SF4B-C series

features a metal inner frame that increases toughness

and also keeps its enclosure not to curve.

Protective heights range from 263.4 mm to 1,943.4 mm

10.370 in to 76.512 in.

546

FIBER

SENSORS

LASER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

Metal inner frame

Plastic

seamless

enclosure

Protective

height

Max.

1,943.4 mm

76.512 in

* This is an only image

for seamless enclosure

partially cut.

PARTICULAR

USE SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

Protective

height

Min.

263.4 mm

10.370 in

LASER

MARKERS

PLC

HUMAN MACHINE

INTERFACES

45% lighter* for easy installation in high places and when mounting long models

ENERGY

MANAGEMENT

SOLUTIONS

Thanks to its plastic body, the SF4B-C series is 45 %

lighter* than previous models with aluminum enclosures.

This helps to reduce the overall weight of the equipment

during transport and when shipping it overseas.

FA COMPONENTS

MACHINE VISION

SYSTEMS

* Comparing SF4B-H80 with SF4B-H80CA-J05

UV CURING

SYSTEMS

Large multi-purpose indicator

SF4B-□CA-J05

The SF4B-C series is equipped with the large multi-purpose indicator at the center of the unit. The indicator shows

the presence of the safety light curtain, helping to prevent unintentional beam interruption. The indicator can be used

in a variety of applications such as a muting indicator and work indicator.

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

Exceptional visibility with

wide angle

The large multi-purpose indicator

shines brightly through the plastic

body to ensure exceptional visibility.

SF2B

SF2C

Definition of

Sensing Heights

�547

FIBER

SENSORS

LASER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

Compact Safety Light Curtain Type 4

SF4B-C SERIES

Handy-controller SFB-HC (optional) offers easy access to settings for a range of functionality

Muting control function for individual beams:

Limit the muting area

SF4B-□CA-J05

Fixed blanking function:

Choose active beam channels

The SFB-HC handy-controller (optional) allows to

perform muting control for certain beams. Since beam

channels can be specified, so there is no need to install

a guard to prevent intrusions. For example, according to

the height of a sensing object, when muting control from

the lowermost beam channel to the 10th beam channel

is activated, the safety light curtain will detect any beam

interruption at the 11th or higher beam channel as a

human entry and stop the machinery.

The SFB-HC handy-controller (optional) provides a fixed

blanking function that prevents control output (OSSD)

from turning off even if certain beam channels are

interrupted. This function is convenient for applications

where an obstacle always interrupts certain beam

channels.

Additionally, it is safe since control output (OSSD) is

forcibly turned off in the event the obstruction moves

outside the detection area.

During muting (line operating)

Line stopped

PARTICULAR

USE SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

PLC

HUMAN MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA COMPONENTS

MACHINE VISION

SYSTEMS

UV CURING

SYSTEMS

Floating blanking function:

Disable unspecified beams

Use output and indicators to achieve preventive maintenance when the incident light intensity gets unstable

The floating blanking function allows to disable up

to three unspecified beam channels. Control output

(OSSD) will not turn off as long as the number of

interrupted beam channels is less than the set number

of beam channels. This function is convenient when an

obstruction moves inside the detection area during setup

changes or when loading materials within the detection

area of safety light curtain.

By setting the auxiliary output switching function to

off or on when light reception becomes unstable, the

safety light curtain provides notification in the event of

a reduction in the incident light intensity due to beam

misalignment or dirt via auxiliary output (non-safety

output) in addition to the incident light intensity indicator.

Auxiliary output

Incident light intensity indicator

* �The min. sensing object will change when the floating blanking function

is used.

Incident light

intensity (Note 1)

LASER

MARKERS

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

130 %

100 %

Set to off for

unstable incident

light (Note 3)

Set to on for

unstable incident

light (Note 3)

ON

OFF

OFF

ON

Under stable light received

condition: Green

Incident light intensity:

130 % or greater

Under unstable light received

condition: Orange

Incident light intensity:

100 % to less than 130 %

When light is interrupted

(Note 2): Off

Notes: 1) An incident light intensity value of 100 % refers to the threshold value

at which control outputs (OSSD1, OSSD2) change from off to on.

2) Interruption of the light refers to the presence of an object interrupts

beam in the detection area.

3) This setting is not available when using muting control for

individual beams, fixed blanking, or floating blanking.

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

SF2B

SF2C

Definition of

Sensing Heights

Extensive array of other functions

PNP/NPN polarity support

Extraneous light check & avoid (ELCA) function

Since a single model number can be switched between

PNP and NPN input, fewer model numbers need to be

registered.

The ELCA function reduces interference without an

interference prevention line.

External device monitor function

Beam-axis alignment indicator

External devices (such as safety relays, etc.) can be

directly connected to the handy-controller without any

dedicated unit, simplifying installation, reducing costs,

and helping to avoid various problems.

Beam-axis alignment indicators are indicated in 4 blocks,

allowing to see at a glance where light is being received.

�Compact Safety Light Curtain Type 4

SF4B-C SERIES

PRODUCT CONFIGURATION

548

FIBER

SENSORS

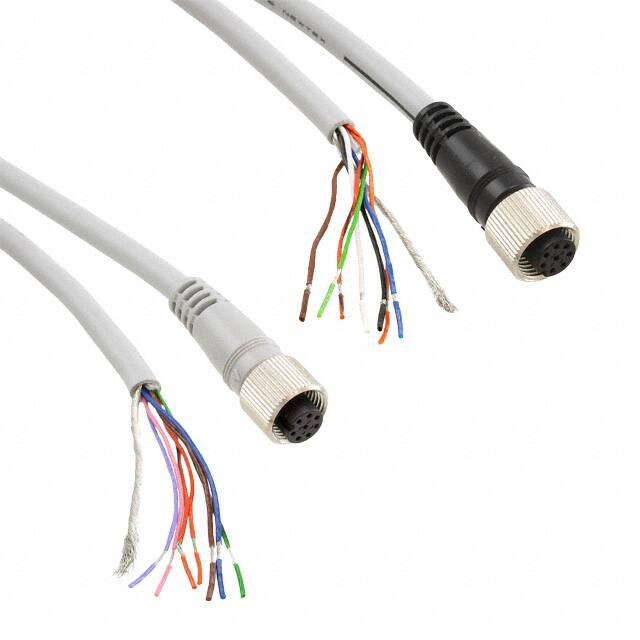

Pigtailed type (with muting function)

(with 0.5 m 1.640 ft connector attached cable)

LASER

SENSORS

Cable type

(with 5 m 16.404 ft cable)

PHOTOELECTRIC

SENSORS

3

3

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

1

2

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

5

INDUCTIVE

PROXIMITY

SENSORS

4

Cable 5 m 16.404 ft (discrete wire)

Connector attached cable 0.5 m 1.640 ft

SENSOR

OPTIONS

ORDER GUIDE

1

SIMPLE

WIRE-SAVING

UNITS

2 Safety light curtains

Hand protection type

Arm / Foot protection type

Min. sensing object ø45 mm ø1.772 in

(40 mm 1.575 in beam pitch)

Min. sensing object ø25 mm ø0.984 in

(20 mm 0.787 in beam pitch)

Type

Appearance

Beam

channel No.

Operating range

(Note 1)

21.7 mm

0.854 in

Protective height

Beam pitch

20 mm

0.787 in

0.3 to 7 m

0.984 to 22.966 ft

21.7 mm 0.854 in

21.7 mm

0.854 in

Beam pitch

Protective 40 mm

height 1.575 in

Beam

channel No.

0.3 to 7 m

0.984 to 22.966 ft

41.7 mm 1.642 in

Model No. (Note 2)

1 Pigtailed type

(with muting function)

WIRE-SAVING

SYSTEMS

2 Cable type

Number

of beam

channels

Protective height

SF4B-H12CA-J05

SF4B-H12C

12

263.4 mm 10.370 in

SF4B-H16CA-J05

SF4B-H16C

16

343.4 mm 13.520 in

SF4B-H20CA-J05

SF4B-H20C

20

423.4 mm 16.669 in

SF4B-H24CA-J05

SF4B-H24C

24

503.4 mm 19.819 in

SF4B-H28CA-J05

SF4B-H28C

28

583.4 mm 22.969 in

SF4B-H32CA-J05

SF4B-H32C

32

663.4 mm 26.118 in

SF4B-H36CA-J05

SF4B-H36C

36

743.4 mm 29.268 in

SF4B-H40CA-J05

SF4B-H40C

40

823.4 mm 32.417 in

SF4B-H48CA-J05

SF4B-H48C

48

983.4 mm 38.717 in

SF4B-H56CA-J05

SF4B-H56C

56

1,143.4 mm 45.016 in

SF4B-H64CA-J05

SF4B-H64C

64

1,303.4 mm 51.315 in

SF4B-H72CA-J05

SF4B-H72C

72

1,463.4 mm 57.614 in

SF4B-H80CA-J05

SF4B-H80C

80

1,623.4 mm 63.913 in

SF4B-H88CA-J05

SF4B-H88C

88

1,783.4 mm 70.212 in

SF4B-H96CA-J05

SF4B-H96C

96

1,943.4 mm 76.512 in

SF4B-A8CA-J05

SF4B-A8C

8

343.4 mm 13.520 in

SF4B-A12CA-J05

SF4B-A12C

12

503.4 mm 19.819 in

SF4B-A16CA-J05

SF4B-A16C

16

663.4 mm 26.118 in

SF4B-A20CA-J05

SF4B-A20C

20

823.4 mm 32.417 in

SF4B-A24CA-J05

SF4B-A24C

24

983.4 mm 38.717 in

SF4B-A28CA-J05

SF4B-A28C

28

1,143.4 mm 45.016 in

SF4B-A32CA-J05

SF4B-A32C

32

1,303.4 mm 51.315 in

SF4B-A36CA-J05

SF4B-A36C

36

1,463.4 mm 57.614 in

SF4B-A40CA-J05

SF4B-A40C

40

1,623.4 mm 63.913 in

SF4B-A44CA-J05

SF4B-A44C

44

1,783.4 mm 70.212 in

SF4B-A48CA-J05

SF4B-A48C

48

1,943.4 mm 76.512 in

Notes: 1) The operating range is the distance possible to set between the emitter and the receiver.

Receiver cannot be

placed in this range

Actual operating range of

the safety light curtain

0.3 m 0.984 ft

Setting range of

the receiver

Emitter Receiver

PARTICULAR

USE

SENSORS

7 m 22.966 ft

Receiver

2) The model No. with “E” shown on the label affixed to the product is the emitter, “D” shown on the label is the receiver.

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

LASER

MARKERS

PLC

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

SF2B

SF2C

Definition of

Sensing Heights

�549

FIBER

SENSORS

LASER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

Compact Safety Light Curtain Type 4

SF4B-C SERIES

ORDER GUIDE

3 Mounting brackets Mounting bracket is not supplied with the safety light curtain. Be sure to order it separately.

Designation

Model No.

Description

MS-SF4BC-1

Allows the safety light curtain to be mounted on the rear or side

of the target equipment. Designed for use with one M5 hexagonsocket head bolt.

(4 pcs. per set for the emitter and receiver)

MS-SF4BC-2

Allows the safety light curtain to be mounted on the rear of the

target equipment. Allows beam adjustment. Designed for use

with one M5 hexagon-socket head bolt. For space-saving

mounting, use one M5 hexagon head bolt.

(4 pcs. per set for the emitter and receiver)

MS-SF4BC-3

Allows the safety light curtain to be mounted on the side of the

target equipment. Allows beam adjustment. Designed for use

with one M5 hexagon-socket head bolt. For space-saving

mounting, use one M5 hexagon head bolt.

(4 pcs. per set for the emitter and receiver)

MS-SF4BC-4

Supports the middle of the safety light curtain when installing it

with utility mounting brackets. Allows the safety light curtain to be

mounted on the rear or side of the target equipment. Allows

beam adjustment. Designed for use with one M5 hexagon head

bolt.

(2 pcs. each per set for rear mounting and side mounting)

Intermediate supporting

bracket for standard

mounting bracket

(Note)

MS-SF4BC-5

Supports the middle of the safety light curtain when installing it

with standard mounting brackets. Allows the safety light curtain

to be mounted on the rear or side of the target equipment.

Designed for use with two M3 countersunk screws.

(2 pcs. each per set for rear mounting and side mounting)

Side mounting bracket

MS-SF4BC-6

Allows beam axis alignment and the safety light curtain to be

mounted on the device in confined spaces. Designed for use

with one M5 hexagon-socket head bolt.

(4 pcs. per set for the emitter and receiver)

MS-SF4BC-7

Supports the middle of the safety light curtain when installing it

with side mounting brackets. Allows beam axis alignment and

the safety light curtain to be mounted on the device in confined

spaces. Designed for use with one M5 hexagon-socket head

bolt.

(2 pcs. per set)

Standard mounting

bracket

Appearance

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

Rear utility mounting

bracket

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

Side utility mounting

bracket

Intermediate supporting

bracket for utility

mounting bracket

(Note)

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

LASER

MARKERS

PLC

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

SF2B

SF2C

Definition of

Sensing Heights

Intermediate supporting

bracket for use with side

mounting bracket

(Note)

Note: The numbers of sets required by SF4B-H□C(A-J05)(40 or more beam axes) and SF4B-A□C(A-J05) (20 or more beam axes) are as follows:

SF4B-H40C(A-J05), SF4B-H48C(A-J05), SF4B-H56C(A-J05), SF4B-A20C(A-J05), SF4B-A24C(A-J05), SF4B-A28C(A-J05): 1 set

SF4B-H64C(A-J05), SF4B-H72C(A-J05), SF4B-H80C(A-J05), SF4B-H88C(A-J05), SF4B-H96C(A-J05), SF4B-A32C(A-J05), SF4B-A36C(A-J05),

SF4B-A40C(A-J05), SF4B-A44C(A-J05), SF4B-A48C(A-J05): 2 sets

�Compact Safety Light Curtain Type 4

SF4B-C SERIES

550

ORDER GUIDE

FIBER

SENSORS

Standard mounting bracket and

intermediate supporting bracket for

standard mounting bracket

In case of side

mounting

In case of side

mounting

Rear utility mounting bracket and

intermediate supporting bracket for

utility mounting bracket

Space-saving

mounting (Note)

Standard

mounting

bracket

MS-SF4BC-1

Standard

mounting

Side utility mounting bracket and

intermediate supporting bracket for

utility mounting bracket

Space-saving

mounting (Note)

Standard

mounting

Side utility

mounting

bracket

MS-SF4BC-3

Rear utility

mounting

bracket

MS-SF4BC-2

LASER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

Intermediate

supporting

bracket for

utility mounting

bracket

MS-SF4BC-4

Intermediate

supporting

bracket for

utility

mounting

bracket

MS-SF4BC-4

Intermediate

supporting bracket

for standard

mounting bracket

MS-SF4BC-5

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

Rear utility

mounting

bracket

MS-SF4BC-2

Standard

mounting

bracket

MS-SF4BC-1

WIRE-SAVING

SYSTEMS

Side utility

mounting bracket

MS-SF4BC-3

• MS-SF4BC-1

• MS-SF4BC-2

• MS-SF4BC-3

• MS-SF4BC-5

• MS-SF4BC-4

• MS-SF4BC-4

Four brackets (two each R and L type) per set

Eight M3 (length: 5 mm 0.197 in) hexagon-socket

head bolts and four M5 flat washers are attached.

Two pcs. for rear mounting, two pcs. for side mounting

Four brackets (two each R and L type) per set

Eight M3 (length: 6 mm 0.236 in) hexagon-socket

head bolts and four M5 flat washers are attached.

Two brackets per set

M5 flat washers, two pcs. assembled M3 (length: 6 mm

0.236 in) hexagon-socket head bolts for rear mounting,

two pcs. attachments for side mounting

Note: �For space-saving mounting, use an M5

hexagon head bolt.

Side mounting bracket and

intermediate supporting bracket for

use with side mounting bracket

Space-saving

mounting

Standard

mounting

Side

mounting

bracket

MS-SF4BC-6

Four brackets (two each R and L type) per set

Eight M3 (length: 6 mm 0.236 in) hexagon-socket

head bolts and four M5 flat washers are attached.

Two brackets per set

M5 flat washers, two pcs. assembled M3 (length: 6 mm

0.236 in) hexagon-socket head bolts for rear mounting,

two pcs. attachments for side mounting

Note: �For space-saving mounting, use an M5

hexagon head bolt.

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

LASER

MARKERS

PLC

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Selection

Guide

Safety Light

Curtains

Intermediate

supporting

bracket for

use with side

mounting

bracket

MS-SF4BC-7

Safety

Control Units

Safety

Components

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

Side

mounting

bracket

MS-SF4BC-6

• MS-SF4BC-6

Four brackets (two each R and L type) per set

Eight M3 (length: 6 mm 0.236 in) hexagon-socket

head bolts and four M5 flat washers are attached.

• MS-SF4BC-7

Two brackets per set

Two pcs. M5 flat washers, two pcs. assembled

M3 (length: 6 mm 0.236 in) hexagon-socket

head bolts for side mounting

SF2B

SF2C

Definition of

Sensing Heights

�551

Compact Safety Light Curtain Type 4

ORDER GUIDE

FIBER

SENSORS

4

5 Mating cables

PHOTOELECTRIC

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

Mating cables

PRESSURE /

FLOW

SENSORS

4

With connectors on both ends

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

5

Net weight: 680 g approx. (1 cable)

Spare parts (Accessories for safety light curtain)

SF4B-TR25

MACHINE

VISION

SYSTEMS

Length: 3 m 9.843 ft

Net weight: 210 g approx. (1 cable)

Cable with connectors on both ends for pigtailed type

(with muting function)

Cable color: Gray for emitter,

Gray with black line for receiver

Connector color: Gray for emitter, Black for receiver

Min. bending radius: R6 mm R0.236 in

SFB-CCJ10D-MU Length: 10 m 32.808 ft

Test rod ø25

FA

COMPONENTS

Length: 3 m 9.843 ft

Net weight: 190 g approx. (1 cable)

SFB-CCJ3D-MU

STATIC

CONTROL

DEVICES

ENERGY

MANAGEMENT

SOLUTIONS

SFB-CCJ3E-MU

Net weight: 660 g approx. (1 cable)

Model No.

HUMAN

MACHINE

INTERFACES

SFB-CC10-MU

SFB-CCJ10E-MU Length: 10 m 32.808 ft

Designation

PLC

Description

Length: 3 m 9.843 ft

Cable with connector on one end for pigtailed type (with

Net weight: 430 g approx. (2 cables) muting function)

Two cables per set for emitter and receiver

Length: 7 m 22.966 ft

Cable color: Gray for emitter,

Net weight: 1,000 g approx. (2 cables)

Gray with black line for receiver

Connector color: Gray for emitter, Black for receiver

Length: 10 m 32.808 ft

Net weight: 1,300 g approx. (2 cables) Min. bending radius: R6 mm R0.236 in

SFB-CC7-MU

MEASUREMENT

SENSORS

LASER

MARKERS

Model No.

SFB-CC3-MU

For emitter

AREA

SENSORS

Appearance

With connector on

one end

Type

MICRO

PHOTOELECTRIC

SENSORS

For receiver

LASER

SENSORS

SF4B-C SERIES

Description

Min. sensing object for regular checking (ø25 mm ø0.984 in),

for hand protection type (min. sensing object ø25 mm ø0.984 in)

OPTIONS

Control units

Designation

Appearance

Slim type

control

�unit

Model No.

Description

SF-C13

Use a discrete wire cable to connect to the safety light curtain. Muting function

can be used. Compatible with up to Control Category 4.

When connecting pigtailed type (with muting function) SF4B-□CA-J05, be sure to

order a mating cable separately.

• Mating cable: SFB-CC□-MU

• Extension cable: SFB-CCJ□-MU

UV

CURING

SYSTEMS

Handy-controller

Selection

Guide

Designation

Appearance

Model No.

Pigtailed type (with muting function)

Safety Light

Curtains

Safety

Control Units

Safety

Components

SF4D

Handycontroller

SF2B

NC

TIO

N

SFB-HC

8core

NC

EL

EN

R

8core

FUNCTION

12-core → 8-core

* 2 adapter cables

included

SF4B-C

BSF4-AH80

Co

de

Mo

Pr nitor

ote

Co ct

py

FU

CA

TE

SF4B/

SF4B-G

SF4C

Fix

ed

Floa bla

ting nki

Aux blan ng

Lig iliary king

ht

con emoutput

trol iss

ion

8-core → 12-core

CANCEL

ENTER

Adapter cable (Accessory)

Handy-controller

Cable set for

cable type

connection

SFC-WNC1

Cable type

SF2C

Definition of

Sensing Heights

Adapter cable (Accessory) Extension cable

12-core → 8-core

+V 0V

Cable set

Synchronization Synchronization +

Control

circuit

Terminal block

Adapter cable (Accessory)

Not used

8-core

8-core

FUNCTION

CANCEL

ENTER

Handy-controller

�Compact Safety Light Curtain Type 4

SF4B-C SERIES

OPTIONS

FIBER

SENSORS

LASER

SENSORS

Metal protection case

Designation

Applicable beam channels

Hand protection

Arm / Foot

type

protection type

12

16

20

24

28

32

36

40

48

56

64

72

80

88

96

PHOTOELECTRIC

SENSORS

Metal protection case

(2 pcs. per set) (Note)

Appearance

MICRO

PHOTOELECTRIC

SENSORS

Model No.

MS-SF4BCH-12

MS-SF4BCH-16

MS-SF4BCH-20

MS-SF4BCH-24

MS-SF4BCH-28

MS-SF4BCH-32

MS-SF4BCH-36

MS-SF4BCH-40

MS-SF4BCH-48

MS-SF4BCH-56

MS-SF4BCH-64

MS-SF4BCH-72

MS-SF4BCH-80

MS-SF4BCH-88

MS-SF4BCH-96

8

12

16

20

24

28

32

36

40

44

48

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

Note: �In the case of using a metal protection case MS-SF4BCH-□ (optional), make sure to assemble it

with a standard mounting bracket MS-SF4BC-1 (optional).

STATIC

CONTROL

DEVICES

Others

Designation

552

Model No.

LASER

MARKERS

Description

PLC

Test rod ø45

SF4B-TR45

Min. sensing object for regular checking (ø45 mm ø1.772 in),

for arm / foot protection type (min. sensing object ø45 mm

ø1.772 in)

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

●Recommended safety relay

Panasonic Corporation

SF relay, slim type

SF relay, slim type

SFS3-L-DC24V (AG1S132)

SFS4-L-DC24V (AG1S142)

DIN terminal block

SFS4-SFD (AG1S847)[4-poles type]

SFS6-SFD (AG1S867)[6-poles type]

Note: Contact Panasonic Corporation for details on the recommended

products.

Item

Type

Model No.

Part No.

Contact arrangement

Rated nominal

switching capacity

Min. switching capacity

Coil rating

Rated power

consumption

Operation time

Release time

Ambient temperature

Applicable standards

With LED indicator

SFS3-L-DC24V

SFS4-L-DC24V

AG1S132

AG1S142

3a1b

4a2b

6 A / 250 V AC, 6 A / 30 V DC

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

1 mA / 5 V DC

15 mA / 24 V DC

20.8 mA / 24 V DC

360 mW

500 mW

20 ms or less

20 ms or less

–40 to +85 °C –40 to +185 °F

(Humidity: 5 to 85 % RH)

UL/c-UL, TÜV, Korea's S-mark

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

SF4D

SF4B/

SF4B-G

Safety control unit

SF4B-C

Creating safety circuits is easier than ever.

SF4C

SF-C21

BSF4-AH80

SF2B

SF2C

P.647~

Safety control unit

SF-C21

Definition of

Sensing Heights

�553

Compact Safety Light Curtain Type 4

SPECIFICATIONS

FIBER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

Safety light curtain individual specifications

SF4B-H□C(A-J05)

Model No.

LASER

SENSORS

Item

Type

SF4B-H12CA-J05

Pigtailed type

Cable type

SF4B-H12C

Number of beam channels

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

Protective height

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

Cable type

When large multi-purpose

indicator turns OFF

When large multi-purpose

indicator lights up

Pigtailed

type

INDUCTIVE

PROXIMITY

SENSORS

Current consumption

AREA

SENSORS

PRESSURE /

FLOW

SENSORS

PFHD

MTTFD

Net weight

(Total of emitter and receiver)

LASER

MARKERS

PLC

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

Pigtailed type

Cable type

Number of beam channels

Protective height

Cable type

When large multi-purpose

indicator turns OFF

When large multi-purpose

indicator lights up

PFHD

MTTFD

Net weight

(Total of emitter and receiver)

Pigtailed type

Cable type

Type

Model No.

MACHINE

VISION

SYSTEMS

Item

Pigtailed type

Cable type

Number of beam channels

Safety

Control Units

Safety

Components

Cable type

When large multi-purpose

indicator turns OFF

When large multi-purpose

indicator lights up

Pigtailed

type

Safety Light

Curtains

Current consumption

Protective height

Selection

Guide

PFHD

MTTFD

Net weight

SF4D

(Total of emitter and receiver)

SF4B/

SF4B-G

SF2C

Definition of

Sensing Heights

Pigtailed type

Cable type

16

343.4 mm

13.52 in

20

423.4 mm

16.669 in

24

503.4 mm

19.819 in

Emitter: 75 mA or less, Receiver: 85 mA or less

1.9 × 10−9

2.1 × 10−9

2.4 × 10−9

360 g approx.

700 g approx.

430 g approx.

770 g approx.

520 g approx.

860 g approx.

40

823.4 mm

32.417 in

Emitter: 80 mA or less

Receiver: 95 mA or less

2.6 × 10−9

2.8 × 10−9

100 years or more

590 g approx.

680 g approx.

930 g approx.

1,000 g approx.

32

663.4 mm

26.118 in

SF4B-H36CA-J05

SF4B-H36C

36

743.4 mm

29.268 in

Emitter: 75 mA or less

Receiver: 95 mA or less

Emitter: 85 mA or less

Receiver: 105 mA or less

3.0 × 10−9

3.3 × 10−9

750 g approx.

1,100 g approx.

840 g approx.

1,200 g approx.

Min. sensing object ø25 mm ø0.984 in (20 mm 0.787 in beam pitch)

SF4B-H48CA-J05 SF4B-H56CA-J05 SF4B-H64CA-J05 SF4B-H72CA-J05 SF4B-H80CA-J05

SF4B-H48C

SF4B-H56C

SF4B-H64C

SF4B-H72C

SF4B-H80C

SF4B-H88CA-J05

SF4B-H88C

48

983.4 mm

38.717 in

Emitter: 80 mA or less

Receiver: 100 mA or less

Emitter: 90 mA or less

Receiver: 110 mA or less

3.5 × 10−9

3.9 × 10−9

910 g approx.

1,300 g approx.

28

583.4 mm

22.969 in

Emitter: 70 mA or less

Receiver: 85 mA or less

Emitter: 65 mA or less, Receiver: 75 mA or less

1,100 g approx.

1,400 g approx.

Number of beam channels

Protective height

Cable type

When large multi-purpose

indicator turns OFF

When large multi-purpose

indicator lights up

PFHD

MTTFD

Net weight

Min. sensing object ø25 mm ø0.984 in

(20 mm 0.787 in beam pitch)

SF4B-H96CA-J05

SF4B-H96C

96

1,943.4 mm

76.512 in

Emitter: 105 mA or less

Receiver: 145 mA or less

Emitter: 115 mA or less

Receiver: 155 mA or less

6.6 × 10−9

100 years or more

1,900 g approx.

2,200 g approx.

Type

SF4B-A24CA-J05

Pigtailed type

Cable type

SF4B-A24C

Pigtailed

type

SF2B

Item

Current consumption

BSF4-AH80

Model No.

SF4B-C

SF4C

Min. sensing object ø25 mm ø0.984 in (20 mm 0.787 in beam pitch)

SF4B-H16CA-J05 SF4B-H20CA-J05 SF4B-H24CA-J05 SF4B-H28CA-J05 SF4B-H32CA-J05

SF4B-H16C

SF4B-H20C

SF4B-H24C

SF4B-H28C

SF4B-H32C

56

1,143.4 mm

45.016 in

64

1,303.4 mm

51.315 in

Emitter: 85 mA or less

Receiver: 120 mA or less

72

1,463.4 mm

57.614 in

80

1,623.4 mm

63.913 in

Emitter: 95 mA or less

Receiver: 130 mA or less

Emitter: 95 mA or less

Emitter: 105 mA or less

Receiver: 130 mA or less

Receiver: 140 mA or less

4.4 × 10−9

4.8 × 10−9

5.3 × 10−9

5.7 × 10−9

100 years or more

1,300 g approx. 1,400 g approx. 1,600 g approx. 1,700 g approx.

1,600 g approx. 1,700 g approx. 2,000 g approx. 2,000 g approx.

88

1,783.4 mm

70.212 in

Emitter: 100 mA or less

Receiver: 140 mA or less

Emitter: 110 mA or less

Receiver: 155 mA or less

6.2 × 10−9

1,800 g approx.

2,100 g approx.

SF4B-A□C(A-J05)

FA

COMPONENTS

UV

CURING

SYSTEMS

12

263.4 mm

10.37 in

Type

SF4B-H40CA-J05

Pigtailed type

Cable type

SF4B-H40C

Pigtailed

type

STATIC

CONTROL

DEVICES

Item

Current consumption

MEASUREMENT

SENSORS

Model No.

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

SF4B-C SERIES

(Total of emitter and receiver)

Pigtailed type

Cable type

24

983.4 mm

38.717 in

Min. sensing object ø45 mm ø1.772 in

(40 mm 1.575 in beam pitch)

SF4B-A8CA-J05 SF4B-A12CA-J05 SF4B-A16CA-J05 SF4B-A20CA-J05

SF4B-A8C

SF4B-A12C

SF4B-A16C

SF4B-A20C

8

343.4 mm

13.52 in

12

503.4 mm

19.819 in

Emitter: 60 mA or less

Receiver: 70 mA or less

16

663.4 mm

26.118 in

20

823.4 mm

32.417 in

Emitter: 65 mA or less

Receiver: 75 mA or less

Emitter: 70 mA or less

Emitter: 75 mA or less

Receiver: 80 mA or less

Receiver: 85 mA or less

1.7 × 10−9

1.9 × 10−9

2.2 × 10−9

2.4 × 10−9

100 years or more

430 g approx.

590 g approx.

750 g approx.

910 g approx.

770 g approx.

930 g approx.

1,100 g approx. 1,300 g approx.

Min. sensing object ø45 mm ø1.772 in (40 mm 1.575 in beam pitch)

SF4B-A28CA-J05 SF4B-A32CA-J05 SF4B-A36CA-J05 SF4B-A40CA-J05 SF4B-A44CA-J05

SF4B-A28C

SF4B-A32C

SF4B-A36C

SF4B-A40C

SF4B-A44C

28

1,143.4 mm

45.016 in

32

1,303.4 mm

51.315 in

36

1,463.4 mm

57.614 in

40

1,623.4 mm

63.913 in

44

1,783.4 mm

70.212 in

SF4B-A48CA-J05

SF4B-A48C

48

1,943.4 mm

76.512 in

Emitter: 70 mA or less

Receiver: 85 mA or less

Emitter: 75 mA or less

Receiver: 95 mA or less

Emitter: 80 mA or less

Receiver: 100 mA or less

Emitter: 80 mA or less

Receiver: 95 mA or less

2.7 × 10−9

2.9 × 10−9

Emitter: 85 mA or less

Receiver: 105 mA or less

3.2 × 10−9

3.4 × 10−9

3.7 × 10−9

100 years or more

1,400 g approx. 1,600 g approx. 1,700 g approx.

1,700 g approx. 2,000 g approx. 2,000 g approx.

Emitter: 90 mA or less

Receiver: 110 mA or less

3.9 × 10−9

4.2 × 10−9

1,100 g approx.

1,400 g approx.

1,300 g approx.

1,600 g approx.

1,800 g approx.

2,100 g approx.

Note: �Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 °C +68 °F.

PFHD: Probability of dangerous failure per hour, MTTFD: Mean time to dangerous failure (in years)

1,900 g approx.

2,200 g approx.

�Compact Safety Light Curtain Type 4

SF4B-C SERIES

554

SPECIFICATIONS

Safety light curtain common specifications

Pigtailed type (with muting function)

Cable type

Min.

sensing

object

Min.

sensing

object

Min.

sensing

object

Min. sensing object

Type

ø25 mm ø0.984 in

ø45 mm ø1.772 in

ø25 mm ø0.984 in

ø45 mm ø1.772 in

(20 mm 0.787 in beam pitch) (40 mm 1.575 in beam pitch) (20 mm 0.787 in beam pitch) (40 mm 1.575 in beam pitch)

Model No.

SF4B-H□CA-J05

SF4B-A□CA-J05

SF4B-H□C

SF4B-A□C

Applicable standards

Item

International standard

Japan

Europe (EU) (Note 2)

North America (Note 3)

South Korea (S-Mark)

CE marking directive compliance

Operating range (Note 4)

Beam pitch

Min. sensing object (Note 5)

Effective aperture angle

Supply voltage

Control outputs

(OSSD 1, OSSD 2)

Operation mode

Protection circuit

Response time

Auxiliary output

(Non-safety output)

IEC 61496-1/2 (Type 4), ISO 13849-1 (Category 4, PLe), IEC 61508-1 to 7 (SIL3)

JIS B 9704-1/2 (Type 4), JIS B 9705-1 (Category 4), JIS C 0508 (SIL3)

EN 61496-1 (Type 4), EN ISO 13849-1 (Category 4, PLe), EN 61508-1 to 7 (SIL3),

EN 55011, EN 50178, EN 61000-6-2

ANSI/UL 61496-1/2 (Type 4), ANSI/UL 508, CAN/CSA 61496-1/2 (Type 4), CAN/CSA C22.2 No.14,

OSHA 1910.212, OSHA 1910.217(C), ANSI B11.1 to B11.19, ANSI/RIA 15.06

S1-G-35-2005, S2-W-11-2003

Machine Directive, EMC Directive, RoHS Directive

0.3 to 7 m 0.984 to 22.966 ft

20 mm 0.787 in

40 mm 1.575 in

20 mm 0.787 in

40 mm 1.575 in

ø25 mm ø0.984 in opaque object ø45 mm ø1.772 in opaque object ø25 mm ø0.984 in opaque object ø45 mm ø1.772 in opaque object

±2.5° or less [for an operating range exceeding 3 m 9.843 ft (conforming to IEC 61496-2 / ANSI/UL 61496-2)]

24 V DC ±10 % Ripple P-P 10 % or less

PNP open-collector transistor / NPN open-collector transistor (switching method)

• Maximum sink current: 200 mA

• Maximum source current: 200 mA

• Applied voltage: Same as supply voltage (between the control output • Applied voltage: Same as supply voltage (between the control output

and +V)

and 0 V)

• Residual voltage: 2.5 V or less

• Residual voltage: 2.5 V or less

(source current 200 mA, when using 20 m 65.617 ft length cable)

(sink current 200 mA, when using 20 m 65.617 ft length cable)

• Leakage current: 0.1 mA or less (Including power supply OFF condition) • Leakage current: 0.1 mA or less (Including power supply OFF condition)

• Maximum load capacity: 0.22 μF (No load to maximum output current) • Maximum load capacity: 0.22 μF (No load to maximum output current)

• Load wiring resistance: 3 Ω or less

• Load wiring resistance: 3 Ω or less

ON when all beam channels are received, OFF when one or more beam channels are interrupted (OFF also in case of any malfunction in the safety light curtain or the synchronization signal) (Note 6, 7)

Incorporated

OFF response: 14 ms or less, ON response: 80 to 90 ms

PNP open-collector transistor / NPN open-collector transistor (switching method)

• Maximum source current: 60 mA

• Maximum sink current: 60 mA

• Applied voltage: Same as supply voltage (between the auxiliary

• Applied voltage: Same as supply voltage (between the auxiliary

output and +V)

output and 0 V)

• Residual voltage: 2.5 V or less

• Residual voltage: 2.5 V or less

(source current 60 mA, when using 20 m 65.617 ft length cable)

(sink current 60 mA, when using 20 m 65.617 ft length cable)

OFF when control outputs are ON, ON when control outputs are OFF [Factory setting, operating mode can be changed using the SFB-HC (optional) handy-controller.]

Incorporated

NPN open-collector transistor

• Maximum sink current: 100 mA

• Applied voltage: Same as supply voltage (between the

Muting auxiliary output

muting auxiliary output and 0 V)

• Residual voltage: 2.5 V or less (sink current 100 mA, when

using 20 m 65.617 ft length cable)

Operation mode

When muting auxiliary output: ON

Protection circuit

Incorporated

ELCA function

Incorporated (reducing mutual interference automatically)

Emission halt function

Incorporated

Interlock function

Incorporated [Manual reset / Auto reset (Note 8)]

External device monitoring function

Incorporated

Override function

Incorporated

Muting function

Incorporated

Large multi-purpose indicator function

Incorporated

Muting setting changing, override setting changing, fixed

Fixed blanking, floating blanking, light emitting amount control,

blanking, floating blanking, light emitting amount control,

Optional functions (Note 9)

auxiliary output switching, protecting, interlock setting

auxiliary output switching, protecting, interlock setting

changing, external relay monitor setting changing

changing, external relay monitor setting changing

Pollution degree

3

Operating altitude

2,000 m 6,561.68 ft or less (Note 10)

Degree of protection

IP65 (IEC)

Ambient temperature

–10 to +55 °C +14 to +131 °F (No dew condensation or icing allowed), Storage: –25 to +60 °C –3 to +140 °F

Ambient humidity

30 to 85 % RH, Storage: 30 to 85 % RH

Ambient illuminance

Incandescent light: 3,500 ℓx or less at the light-receiving face

Dielectric strength voltage /

1,000 V AC for one min. between all supply terminals connected together and enclosure / 20 MΩ or more, with 500 V DC

Insulation resistance

megger between all supply terminals connected together and enclosure

10 to 55 Hz frequency, 0.75 mm 0.030 in amplitude in X, Y and Z directions for two hours each / 300 m/s2 acceleration

Vibration resistance /

(30 G approx.) in X, Y and Z directions for three times each

Shock resistance

Environmental resistance

Operation mode

Protection circuit

Notes: 1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 °C +68 °F.

2) Regarding EU Machinery Directive, a Notified Body, TÜV SÜD, has certified with the type examination certificate.

3)

�The product has been safety-certified in accordance with UL, ANSI, CSA, and other standards by TÜV SÜD America, a nationally recognized

safety laboratory (NRTL) that has been approved by the Occupational Safety and Health Administration (OSHA) as defined by 29 CFR 1910.7

4) The operating range is the possible setting distance between the emitter and the receiver.

5) In case the blanking function is valid, the operation mode is changed.

6) During muting, control output will not turn off even if the beams are interrupted.

7) When the blanking function is enabled, the operating mode will change.

8) The manual reset and automatic reset are possible to be switched depending on the wiring status.

9) In case of using optional function, the handy-controller SFB-HC (optional) is required.

10) Do not use or store in an environment pressurized to atmospheric pressure or higher at an altitude of 0 m.

FIBER

SENSORS

LASER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

LASER

MARKERS

PLC

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

SF2B

SF2C

Definition of

Sensing Heights

�555

FIBER

SENSORS

LASER

SENSORS

Compact Safety Light Curtain Type 4

SPECIFICATIONS

Safety light curtain common specifications

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

Item

Emitting element

Material

Pigtailed type (with muting function)

Cable type

Min.

sensing

object

Min.

sensing

object

Min. sensing object

Min.

sensing

object

Type

ø45 mm ø1.772 in

ø25 mm ø0.984 in

ø45 mm ø1.772 in

ø25 mm ø0.984 in

(20 mm 0.787 in beam pitch) (40 mm 1.575 in beam pitch) (20 mm 0.787 in beam pitch) (40 mm 1.575 in beam pitch)

Model No.

SF4B-H□CA-J05

SF4B-A□CA-J05

SF4B-H□C

SF4B-A□C

Infrared LED (Peak emission wavelength: 850 nm 0.033 mil)

Enclosure: Polycarbonate

0.15 mm2 (power line: 0.2 mm2) 12-core heat-resistant PVC

0.15 mm2 (power line: 0.2 mm2) 8-core heat-resistant PVC

cable with connector, 0.5 m 1.640 ft long

cable, 5 m 16.404 ft long

Extension up to total 50 m 164.042 ft is possible for both

Extension up to total 50 m 164.042 ft is possible for 0.2 mm2

or more, cable (Note)

emitter and receiver optional mating cables

Cable

Cable extension

SF4B-TR25 (Test rod): 1 pc.

Accessories

Handy-controller

Model No.

Item

Supply voltage

Current consumption

Communication method

Digital display

Function indicator

Functions

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

SF4B-TR25 (Test rod): 1 pc.

Note: �When the synchronization + wire (orange) and synchronization - wire (orange / black) is extended with a cable other than exclusive cable, use a 0.2 mm2 or

more shielded twisted pair cable.

LASER

MARKERS

PLC

SF4B-C SERIES

Ambient temperature

Ambient humidity

Voltage withstandability

Insulation resistance

Cable

Weight

Accessory

SFB-HC

24 V DC ±10 % Ripple P-P10 % or less (common to safety light curtain power supply)

65 mA or less

RS-485 two-way communications (Specific procedure)

4-digit red LED display × 2 (Selected beam channels, setting contents etc. are displayed.)

Green LED × 9 (set function is displayed.)

Fixed blanking (Factory setting: Disabled) / Floating blanking (Factory setting: Disabled)

/ Auxiliary output changing (Factory setting: Negative Logic of OSSD) / Light emitting amount control (Factory

setting: Disabled)

/ Muting setting changing [Factory setting: All beam channels enabled, A = B, Setting of the muting lamp diagnosis

function enabled (Ver. 2 or later), Muting sensor output operation setting N.O. / N.C.

(Ver. 2.1 or later)]

/ Interlock setting changing (Factory setting: start / restart)

/ External device monitoring setting change (Factory setting: Enabled, 300 ms)

/ Override setting changing 60 sec. (Ver. 2.1 or later) / Setting detail monitoring /

/ Protecting (Factory setting: Disabled) (Factory password setting: 0000) / Initialization / Copy

–10 to +55 °C +14 to +131 °F (No dew condensation or icing allowed), Storage: –25 to +70 °C –13 to +158 °F

30 to 85 % RH, Storage: 30 to 85 % RH

1,000 V AC for one min. between all supply terminals connected together and enclosure

20 MΩ , or more, with 500 V DC megger between all supply terminals connected together and enclosure

8-core shielded cable, 0.5 m 1.640 ft long, with a connector at the end (2 cables)

Net weight: 200 g approx.

Adapter cable: 2 cables

Note: Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +20 °C +68 °F.

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

SF2B

SF2C

Definition of

Sensing Heights

�Compact Safety Light Curtain Type 4

SF4B-C SERIES

SPECIFICATIONS

FIBER

SENSORS

LASER

SENSORS

Control unit

Connectable safety light curtains

Applicable standards

CE marking directive compliance

Control category

Supply voltage

Current consumption

Fuse (rating)

Safety output

Utilization category

Rated operation voltage (Ue) /

Rated operation current (le)

Contact material / contacts

Contact resistance

Contact protection fuse rating�

Mechanical lifetime

Electrical lifetime

Pick-up delay (Auto reset/Manual reset)

Response time

Auxiliary output

Rated operation voltage/current�

Contact protection fuse rating

Semiconductor auxiliary output

(AUX)

Indicators

Output operation

Excess voltage category

Power supply (Ui)

Safety output [OUT]

Interlock (INTER_LOCK)

Fault (FAULT)

External relay monitor function

Trailing edge function

Polarity selection function

(Note 4)

Pollution degree

Protection

Ambient temperature

Ambient humidity

Vibration resistance

Connection terminal

Enclosure material

Weight

PHOTOELECTRIC

SENSORS

SF-C13

Safety light curtains manufactured by Panasonic Industrial Devices SUNX

EN 61496-1 (Type 4), EN 55011, EN ISO 13849-1 (Category 4, PLe), IEC 61496-1 (Type 4),

ISO 13849-1 (Category 4, PLe), JIS B 9704-1 (Type 4), JIS B 9705-1 (Category 4),

ANSI/UL 61496-1 (Type 4), UL 1998 (Class 2)

Machinery Directive, Low Voltage Directive, EMC Directive, RoHS Directive

ISO 13849-1 (EN ISO 13849-1, JIS B 9705-1) compliance up to Category 4, PLe standards�

24 V DC ±10 % Ripple P-P 10 % or less

100 mA or less (without safety light curtain)

Built-in electronic fuse, Triggering current: 0.5 A or more, Reset after power down�

NO contact × 3 (13-14, 23-24, 33-34)

AC-15, DC-13 (IEC 60947-5-1)

30 V DC / 4 A, 230 V AC / 4 A, resistive load (For inductive load, during contact protection)

Min. applicable load: 10 mA (at 24 V DC) (Note 2)

AgSnO, self cleaning, positively driven

100 mΩ or less (initial value)

4 A (slow blow)

10,000,000 times or more (open/close frequency of 180 times/min) (Note 3)

100,000 times or more (open/close frequency of 20 times/min, 230 V AC, 3 A, using resistance load) (Note 3)

80 ms or less / 90 ms or less�

10 ms or less

Safety relay contact (NC contact) × 1 (41-42) (Related to safety output)�

24 V DC / 2 A, Min. applicable load: 10 mA (at 24 V DC)�

2 A (slow blow)

PNP open‑collector transistor

• Maximum source current: 60 mA

• Applied voltage: Same as supply voltage (between the semiconductor auxiliary output and +V)

• Residual voltage: 2.3 V or less (at source current 60 mA)

• Leakage current: 2 mA or less

ON when the safety light curtain is interrupted

II

Green LED (lights up when the power is ON)

Green LED (lights up when enabling contacts are closed)

Yellow LED (lights up when enabling contacts are opened)

Yellow LED (blinks when fault occurs)

Incorporated

Incorporated

Incorporated (Cable connection allows selection of plus/minus ground)

Minus ground: Correspond to PNP output safety light curtain

Plus ground: Correspond to NPN output safety light curtain

2

Enclosure: IP40, Terminal: IP20�

–10 to +55 °C +14 to +131 °F (No dew condensation or icing allowed), Storage: –25 to +70 °C –13 to +158 °F�

30 to 85 % RH, Storage: 30 to 95 % RH

Resistance/malfunction 10 to 55 Hz frequency, 0.35 mm 0.014 in amplitude in X, Y, and Z directions for twenty times each

Spring-cage terminal

ABS

Net weight: 200 g approx.

Notes: 1) Where measurement conditions have not been specified precisely, the conditions used were an

ambient temperature of +20 °C +68 °F.

2) If several SF-C13 units are being used in line together, leave a space of 5 mm 0.197 in or more

between each unit.

If the units are touching each other, reduce the rated operating current for safety output in accordance

with the ambient operating temperature as shown in the graphs at right.

3) Relay switching lifetime will vary depending on factors such as the type of load, the switching

frequency, and ambient conditions.

4) Please switch the sliding switch to the PNP side for minus ground and to the NPN side for plus

ground.

Dilating when SF-C13 units

are mounted close together

Rated operation

current (A)

Model No.

Item

Environmental

resistance

556

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

LASER

MARKERS

PLC

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

UV

CURING

SYSTEMS

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Safety

Components

6

SF4D

5

SF4B/

SF4B-G

4

SF4B-C

3

SF4C

2

BSF4-AH80

1

0

32

SF2B

35 40 45 50 55

95 104 113 122 131

Ambient

temperature (°C °F)

SF2C

Definition of

Sensing Heights

�557

Compact Safety Light Curtain Type 4

・

I/O CIRCUIT AND WIRING DIAGRAMS

FIBER

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SF4B-□CA-J05

Pigtailed type (with muting function)

I/O circuit diagrams

Terminal No. of pigtailed type

Emitter

470 Ω

PRESSURE /

FLOW

SENSORS

0.22 μF

470 Ω

(Pink) Emission halt input /

*S1

Reset input

INDUCTIVE

PROXIMITY

SENSORS

0.22 μF

470 Ω

(Pale purple) Interlock setting input

Load

(Yellow-green / Black) Auxiliary output

*S1

Sensor circuit

–

(Yellow-green / Black) Auxiliary output

24 V DC

±10 %

(Gray / Black) Large multi-purpose *S1

indicator input (Emitter side)

(Gray / Black) Large multi-purpose

indicator input (Emitter side)

(Gray) NC

470 Ω

(Pale purple) Interlock setting input

(Gray) NC

0.22 μF

470 Ω

(Pink) Emission halt input /

*S1

Reset input

(Shield) Output polarity setting wire

0.22 μF

470 Ω

(Yellow) Override input

(Blue) 0 V

(Orange) Synchronization+

(Orange) Synchronization+

HUMAN

MACHINE

INTERFACES

Users’ circuit

0.047 μF

1 kΩ

0.047 μF

1 kΩ

0.22 μF

470 Ω

(Orange / Black) Synchronization-

(Orange / Black) Synchronization-

(Orange) Synchronization+

(Orange) Synchronization+

(Brown) +V

(Brown) +V

(Sky-blue / White) Muting input A

(Shield) Output polarity setting wire

(Sky-blue / Black) Muting input B

K1

*S1

(Yellow-green) External device monitor input

Sensor circuit

(Black) Control output 1 (OSSD 1)

*S1

*S1

(Gray / Black) Large multi-purpose

indicator input (Receiver side)

(White) Control output 2 (OSSD 2)

(Gray / Black) Large multi-purpose

indicator input (Receiver side)

Selection

Guide

(White) Control output 2 (OSSD 2)

K1

Safety Light

Curtains

Safety

Control Units

(Shield) Output polarity setting wire

Safety

Components

SF4B-C

SF4C

BSF4-AH80

SF2B

SF2C

Definition of

Sensing Heights

*S1

(Black) Control output 1 (OSSD 1)

(Gray) NC

SF4B/

SF4B-G

K2

K1 K2

(Gray) NC

K2

Internal circuit

K1, K2: External device

(Forced guided relay or magnetic contactor)

Users’ circuit

470 Ω

0.047 μF

1 kΩ

(Sky-blue / White) Muting input A

0.047 μF

1 kΩ

(Sky-blue / Black) Muting input B

*S1

Switch S1

Internal circuit

K1 K2

(Yellow-green) External device monitor input

0.22 μF

(Blue) 0 V

SF4D

24 V DC

±10 %

Receiver

PLC

FA

COMPONENTS

–

(Orange / Black) SynchronizationInternal circuit

Users’ circuit

Receiver

ENERGY

MANAGEMENT

SOLUTIONS

+

*S1

(Blue) 0 V

(Orange / Black) SynchronizationInternal circuit

*S1

*S1

0.22 μF

Load

STATIC

CONTROL

DEVICES

Load

Load

+

MEASUREMENT

SENSORS

UV

CURING

SYSTEMS

(Red) Muting auxiliary output

*S1

(Red) Muting auxiliary output

WIRE-SAVING

SYSTEMS

MACHINE

VISION

SYSTEMS

(Shield) Output polarity setting wire

(Yellow) Override input

SIMPLE

WIRE-SAVING

UNITS

LASER

MARKERS

Lead wire color of mating cable

(Brown) +V

(Brown) +V

0.22 μF

SENSOR

OPTIONS

Terminal No. of pigtailed type

Emitter

Lead wire color of mating cable

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PARTICULAR

USE

SENSORS

Sensor circuit

PHOTOELECTRIC

SENSORS

Sensor circuit

LASER

SENSORS

SF4B-C SERIES

*S1

*S1

(Blue) 0 V

K1, K2: External device

(Forced guided relay or magnetic contactor)

Users’ circuit

*S1

Switch S1

• Emission halt input / Reset input

For manual reset

Vs to Vs – 2.5 V (sink current 5 mA or less): Emission halt (Note)

Open: Emission

For automatic reset

Vs to Vs – 2.5 V (sink current 5 mA or less): Emission (Note)

Open: Emission halt

• Emission halt input / Reset input

For manual reset

0 to +1.5 V (source current 5 mA or less): Emission halt

Open: Emission

For automatic reset

0 to +1.5 V (source current 5 mA or less): Emission

Open: Emission halt

• Interlock setting input, Override input, Muting input A / B, External

device monitor input

Vs to Vs – 2.5 V (sink current 5 mA or less): Valid (Note)

Open: Invalid

• Interlock setting input, Override input, Muting input A / B, External

device monitor input

0 to +1.5 V (source current: 5 mA or less): Valid, Open: Invalid

• Large multi-purpose indicator input

0 to +1.5 V (source current 5 mA or less): Lights up, Open: Turns OFF

Note: Vs is the applying supply voltage.

• Large multi-purpose indicator input

0 to +1.5 V (source current 5 mA or less): Lights up, Open: Turns OFF

�Compact Safety Light Curtain Type 4

・

SF4B-C SERIES

I/O CIRCUIT AND WIRING DIAGRAMS

・

SF4B-□CA-J05

Pigtailed type (with muting function)

Connection examples

Lead wire color of mating cable

The diagram at left shows the configuration when using PNP

output, interlock function “disabled (automatic reset)”

and external device monitoring function “enabled”.

(Gray) NC

(Gray / Black) Large multi-purpose indicator input (Emitter side)

(Pale purple) Interlock setting input

(Brown) +V

(Pink) Emission halt input / Reset input

Emitter

Receiver

(Red) Muting auxiliary output

*S1

Load

In case of setting the interlock function to “enabled (manual reset)”

*S1

(Yellow) Override input

+

(Yellow-green / Black) Auxiliary output

–

(Shield) Output polarity setting wire

Load

24 V DC

±20 %

• When the interlock function is set to “Enable (manual

reset),” the override function cannot be used.

Emitter

(Blue) 0 V

(Orange) Synchronization+

*S1

(Orange / Black) Synchronization-

+24 V DC

(Pink) Emission halt input / Reset input

(Orange) Synchronization+

K1 K2

(Yellow-green) External device monitor input

(Brown) +V

*S1

*S1

(Sky-blue / White) Muting input A

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

In case of setting the external device monitoring function to “disabled”

K1

(Yellow-green / Black) Auxiliary output

(Gray) NC

K1, K2: External device (Forced guided relay or magnetic contactor)

Receiver

Switch S1

• Emission halt input / Reset input

For automatic reset Vs to Vs – 2.5 V (sink current 5 mA or less): Emission (Note)

Open: Emission halt

For manual reset Vs to Vs – 2.5 V (sink current 5 mA or less): Emission halt (Note)

Open: Emission

• Muting input A / B, Override input

Vs to Vs – 2.5 V (sink current 5 mA or less): Valid (Note), Open: Invalid

(Yellow-green) External device monitor input

Emitter

PARTICULAR

USE

SENSORS

(Gray) NC

(Gray / Black) Large multi-purpose indicator input (Emitter side)

(Pale purple) Interlock setting input

(Brown) +V

(Yellow-green / Black) Auxiliary output

Load

(Shield) Output polarity setting wire

(Red) Muting auxiliary output

Load

(Yellow) Override input

(Pink) Emission halt input / Reset input

*S1

(Blue) 0 V

(Orange) Synchronization+

(Orange / Black) Synchronization(Orange / Black) Synchronization(Orange) Synchronization+

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

K1

(White) Control output 2 (OSSD 2)

K2

(Shield) Output polarity setting wire

(Sky-blue / White) Muting input A

(Sky-blue / Black) Muting input B

*S1

WIRE-SAVING

SYSTEMS

LASER

MARKERS

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

Lead wire color of mating cable

Receiver

INDUCTIVE

PROXIMITY

SENSORS

HUMAN

MACHINE

INTERFACES

The diagram at left shows the configuration when using NPN

output, interlock function “disabled (automatic reset)”

and external device monitoring function “enabled”.

In case of setting the interlock function to “enabled (manual reset)”

+

*S1

–

24 V DC

±20 %

• When the interlock function is set to “Enable (manual

reset),” the override function cannot be used.

UV

CURING

SYSTEMS

Selection

Guide

Safety Light

Curtains

Safety

Control Units

Emitter

(Pale purple) Interlock setting input

Safety

Components

(Pink) Emission halt input / Reset input

*S1

SF4D

SF4B/

SF4B-G

K1 K2

0V

SF4B-C

SF4C

In case of setting the external device monitoring function to “disabled”

SF2C

Definition of

Sensing Heights

(Yellow-green / Black) Auxiliary output

K1, K2: External device (Forced guided relay or magnetic contactor)

Switch S1

• Emission halt input / Reset input

For automatic reset 0 to +1.5 V (source current 5 mA or less): Emission, Open: Emission halt

For manual reset 0 to +1.5 V (source current 5 mA or less): Emission halt, Open: Emission

• Muting input A / B, Override input

0 to + 1.5 V (source current 5 mA or less): Valid, Open: Invalid

BSF4-AH80

SF2B

Emitter

*S1

(Blue) 0 V

(Gray / Black) Large multi-purpose indicator input (Receiver side)

(Gray) NC

*S1

PRESSURE /

FLOW

SENSORS

PLC

Note: Vs is the applying supply voltage.

Gray cable

(with black line)

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

STATIC

CONTROL

DEVICES

K2

(Gray / Black) Large multi-purpose indicator input (Receiver side)

Gray

cable

AREA

SENSORS

MEASUREMENT

SENSORS

Emitter

(Blue) 0 V

*S1

MICRO

PHOTOELECTRIC

SENSORS

SIMPLE

WIRE-SAVING

UNITS

(Pale purple) Interlock setting input

(Sky-blue / Black) Muting input B

(Black) Control output 1 (OSSD 1)

LASER

SENSORS

SENSOR

OPTIONS

(Orange / Black) SynchronizationGray cable

(with black line)

FIBER

SENSORS

PHOTOELECTRIC

SENSORS

Muting control components: Interlock function “disabled (automatic reset)”, external device monitoring function “enabled”

Gray

cable

558

Receiver

(Yellow-green) External device monitor input

�559

Compact Safety Light Curtain Type 4

・

I/O CIRCUIT AND WIRING DIAGRAMS

FIBER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

SF4B-□C

Cable type

I/O circuit diagrams

Emitter

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

0.22 μF

470 Ω

0.22 μF

470 Ω

Sensor circuit

PRESSURE /

FLOW

SENSORS

Emitter

Lead wire color

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

Lead wire color

(Brown) +V

(Brown) +V

(Pale purple) Interlock setting input

(Shield) Output polarity setting wire

Load

(Pink) Emission halt input / Reset input *S1

*S1

+

(Yellow-green / Black) Auxiliary output

–

24 V DC

±10 %

Load

(Shield) Output polarity setting wire

Sensor circuit

LASER

SENSORS

SF4B-C SERIES

(Yellow-green / Black) Auxiliary output

–

0.22 μF

470 Ω

0.22 μF

470 Ω

(Pink) Emission halt input / Reset input

(Blue) 0 V

(Orange) Synchronization+

(Orange) Synchronization+

SIMPLE

WIRE-SAVING

UNITS

(Orange / Black) Synchronization-

(Orange / Black) Synchronization-

Receiver

0.22 μF

(Brown) +V

(Shield) Output polarity setting wire

K1 K2

K1

Sensor circuit

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

Safety

Components

SF4D

SF4B/

SF4B-G

SF4B-C

SF4C

BSF4-AH80

SF2B

SF2C

Definition of

Sensing Heights

K2

(White) Control output 2 (OSSD 2)

K2

(Yellow-green) External device monitor input K1 K2

(Blue) 0 V

Internal circuit

0.22 μF

K1, K2: External device

(Forced guided relay or magnetic contactor)

Users’ circuit

*S1

Switch S1

Safety

Control Units

(Black) Control output 1 (OSSD 1)

K1

MACHINE

VISION

SYSTEMS

Selection

Guide

(Orange / Black) Synchronization(Orange) Synchronization+

(Black) Control output 1 (OSSD 1)

FA

COMPONENTS

Safety Light

Curtains

Users’ circuit

(Brown) +V

470 Ω

*S1

(Blue) 0 V

(Orange) Synchronization+

ENERGY

MANAGEMENT

SOLUTIONS

UV

CURING

SYSTEMS

Receiver

(Yellow-green) External device monitor input

LASER

MARKERS

HUMAN

MACHINE

INTERFACES

Internal circuit

(Orange / Black) Synchronization-

STATIC

CONTROL

DEVICES

PLC

Users’ circuit

Sensor circuit

MEASUREMENT

SENSORS

Internal circuit

24 V DC

±10 %

*S1

(Pale purple) Interlock setting input

SENSOR

OPTIONS

WIRE-SAVING

SYSTEMS

+

470 Ω

Internal circuit

(Blue) 0 V

K1, K2: External device

(Forced guided relay or magnetic contactor)

Users’ circuit

*S1

Switch S1

• Emission halt input / Reset input

For manual reset

Vs to Vs – 2.5 V (sink current 5 mA or less): Emission halt (Note)

Open: Emission

For automatic reset

Vs to Vs – 2.5 V (sink current 5 mA or less): Emission (Note)

Open: Emission halt

• Emission halt input / Reset input

For manual reset

0 to +1.5 V (source current 5 mA or less): Emission halt

Open: Emission

For automatic reset

0 to +1.5 V (source current 5 mA or less): Emission

Open: Emission halt

• Interlock setting input

Vs to Vs – 2.5 V (sink current 5 mA or less): Valid (Note)

Open: Invalid

• Interlock setting input

0 to +1.5 V (source current 5 mA or less): Valid, Open: Invalid

Note: Vs is the applying supply voltage.

�Compact Safety Light Curtain Type 4

・

SF4B-C SERIES

I/O CIRCUIT AND WIRING DIAGRAMS

FIBER

SENSORS

SF4B-□C

Cable type

Connection examples

MICRO

PHOTOELECTRIC

SENSORS

The diagram at left shows the configuration when using PNP

output, interlock function “enabled (manual reset)” and external

device monitoring function “enabled”.

Emitter

Receiver

Lead wire color

(Brown) +V

*S1

(Pale purple) Interlock setting input

(Pink) Emission halt input / Reset input

(Yellow-green / Black) Auxiliary output

(Shield) Output polarity setting wire

+

–

Load

24 V DC

±10 %

In case of setting the interlock function to “disabled (automatic reset)”

Emitter

+24 V DC

(Blue) 0 V

*S1

(Orange) Synchronization+

(Pale purple) Interlock setting input

(Yellow-green) External device monitor input K1 K2

Open

(Brown) +V

(Black) Control output 1 (OSSD 1)

K1

(White) Control output 2 (OSSD 2)

In case of setting the external device monitoring function to “disabled”

K2

(Shield) Output polarity setting wire

(Blue) 0 V

Emitter

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

K1, K2: External device

(Forced guided relay or magnetic contactor)

STATIC

CONTROL

DEVICES

*S1

(Yellow-green / Black) Auxiliary output

Switch S1

• Emission halt input / Reset input

For manual reset

Vs to Vs – 2.5 V (sink current 5 mA or less): Emission halt (Note)

Open: Emission

For automatic reset

Vs to Vs – 2.5 V (sink current 5 mA or less): Emission (Note)

Open: Emission halt

• Interlock setting input

Vs to Vs – 2.5 V (sink current 5 mA or less): Valid (Note)

Open: Invalid

Receiver